Preparation method of magnetic graphene aerogel

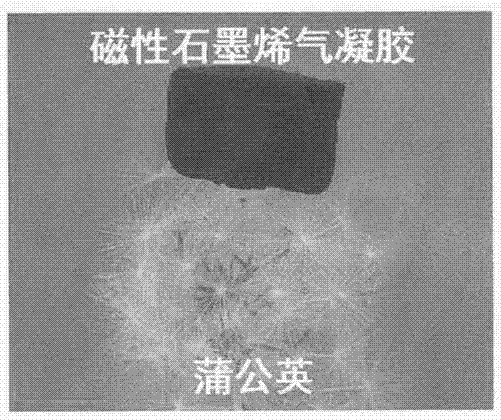

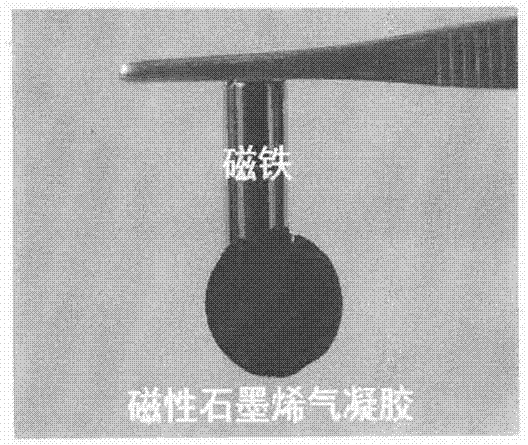

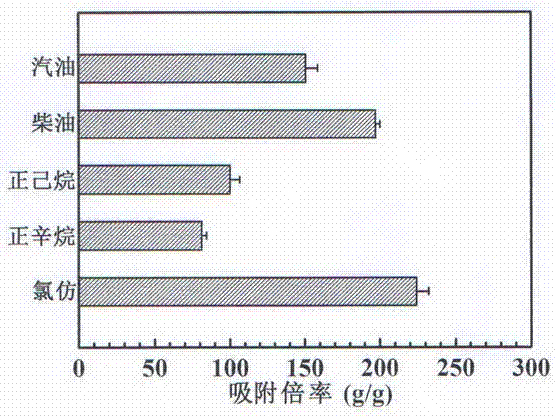

A technology of magnetic graphene and graphene hydrogel, which is applied in the preparation of magnetic graphene airgel and the field of magnetic aerogel preparation, can solve the problems of complex preparation of magnetic graphene foam materials in large quantities, and achieve mechanical properties Good, wide application prospect, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] a. Dissolve graphite oxide in deionized water, and ultrasonically disperse to form a uniform graphene oxide aqueous solution with a concentration of 1 mg / mL;

[0021] b. Add 0.5 mg / mL dopamine and 0.1 mg / mL ferric nitrate to the graphene oxide solution obtained in step a, stir evenly with a magnetic force, and keep it warm for 24 hours under hydrothermal conditions at a constant temperature of 100° C. to obtain graphene hydrogel glue;

[0022] c. Freeze-drying the graphene hydrogel obtained in step b for 1 day to obtain a freeze-dried sample;

[0023] d. Heat the freeze-dried sample obtained in step c to 800° C. at a temperature of 1° C. / min in an oxygen-free environment, heat it for 6 hours, and obtain the magnetic graphene airgel material after natural cooling.

Embodiment 2

[0025] a. Dissolve graphite oxide in deionized water, and ultrasonically disperse to form a uniform graphene oxide aqueous solution with a concentration of 2 mg / mL;

[0026] b. Add 0.75 mg / mL dopamine and 5 mg / mL ferric chloride to the graphene oxide solution obtained in step a, stir evenly with a magnetic force, and keep it warm for 18 hours under hydrothermal conditions at a constant temperature of 120° C. to obtain graphene hydrogel glue;

[0027] c. Freeze-drying the graphene hydrogel obtained in step b for 1 day to obtain a freeze-dried sample;

[0028] d. Heat the freeze-dried sample obtained in step c to 850° C. at a temperature of 3° C. / min in an oxygen-free environment, heat it for 4 hours, and then cool naturally to obtain a magnetic graphene airgel material.

Embodiment 3

[0030] a. Dissolve graphite oxide in deionized water, and ultrasonically disperse to form a uniform graphene oxide aqueous solution with a concentration of 4 mg / mL;

[0031] b. Add 1 mg / mL dopamine and 10 mg / mL ferric sulfate to the graphene oxide solution obtained in step a, stir evenly with magnetic force, and keep it warm for 12 hours under hydrothermal conditions at a constant temperature of 140° C. to obtain a graphene hydrogel;

[0032] c. Freeze-drying the graphene hydrogel obtained in step b for 1 day to obtain a freeze-dried sample;

[0033] d. Heat the freeze-dried sample obtained in step c to 900° C. at a temperature of 5° C. / min in an oxygen-free environment, heat it for 2 hours, and then cool naturally to obtain a magnetic graphene airgel material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com