Self sintering conductive ink based on liquid-state metal particles as well as preparation method and application thereof

A conductive ink, liquid metal technology, applied in applications, inks, household appliances, etc., can solve the problems of unsuitable fine pattern preparation and large-scale production, pattern structure influence, influence on electrical conductivity and other problems, to achieve easy installation and connection, Meet the requirements of complex circuits, the effect of less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

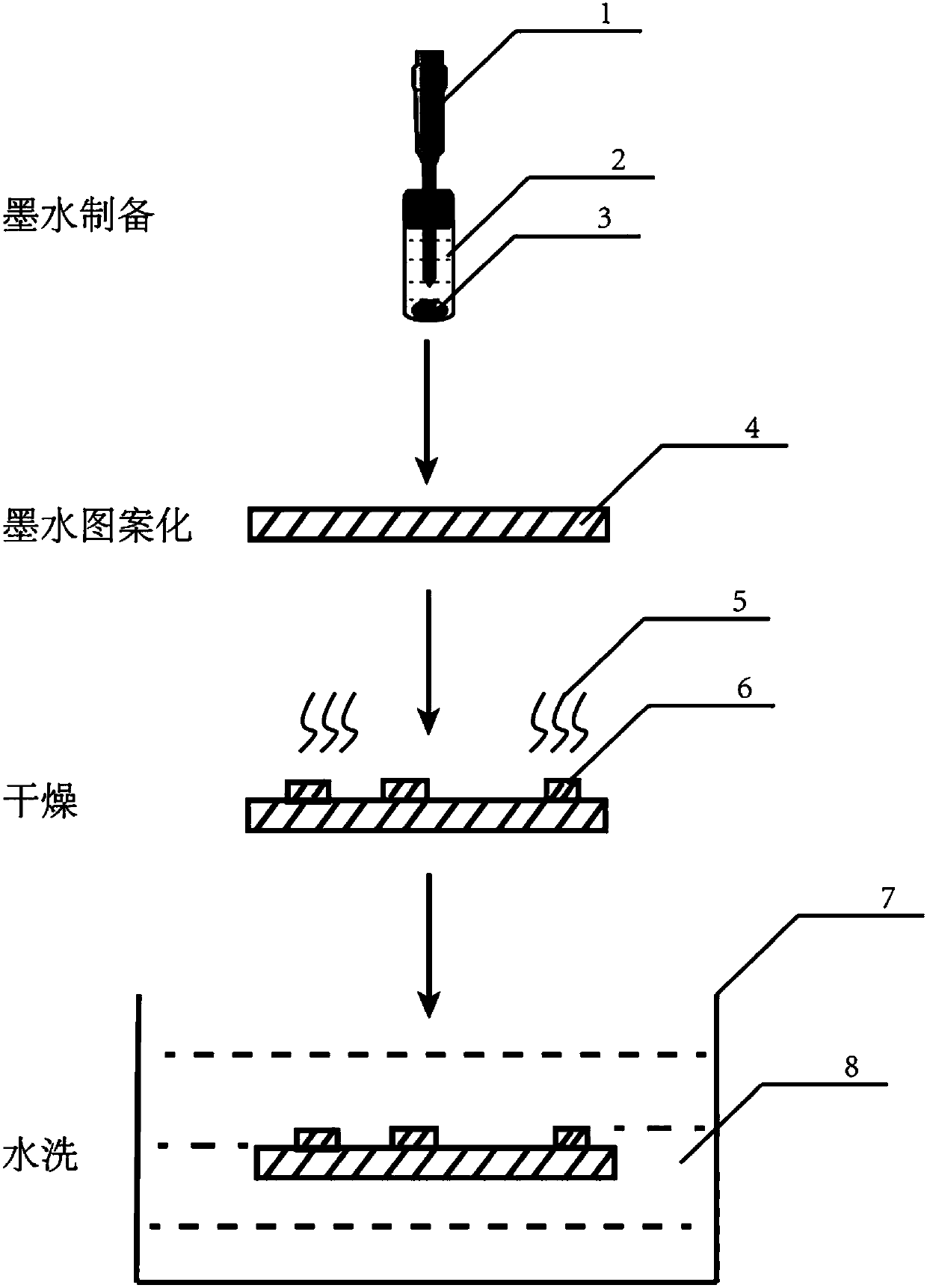

Method used

Image

Examples

Embodiment 1

[0075] This embodiment is used to illustrate the liquid metal conductive ink and the use of the ink to prepare flexible conductive circuits.

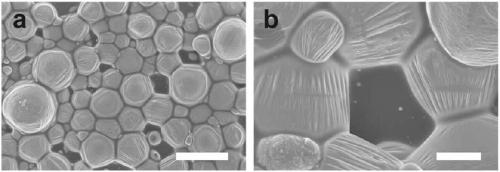

[0076] Add 1g of polyvinylpyrrolidone into 10mL of deionized water, stir for 6h to fully dissolve. After the polyvinylpyrrolidone was fully dissolved, 1 ml of the solution was placed in a plastic tube, and 2 g of liquid indium gallium eutectic alloy (Ga 75.5%wtIn 24.5%wt) was added at the same time. Use an ultrasonic cell disruptor to sonicate for 60 seconds at a 30% amplitude to obtain a gray liquid metal suspension. The metal is dispersed into numerous micro-nano-sized small particles with an average particle size of 4700nm. The core of the small particles is liquid metal, and the outside is covered by a thin oxide film. The inventor utilizes a manual screen printing station to cooperate with a screen printing screen to print ink onto a polyethylene terephthalate (PET) plastic film. At this time, the pattern formed by liquid metal pa...

Embodiment 2

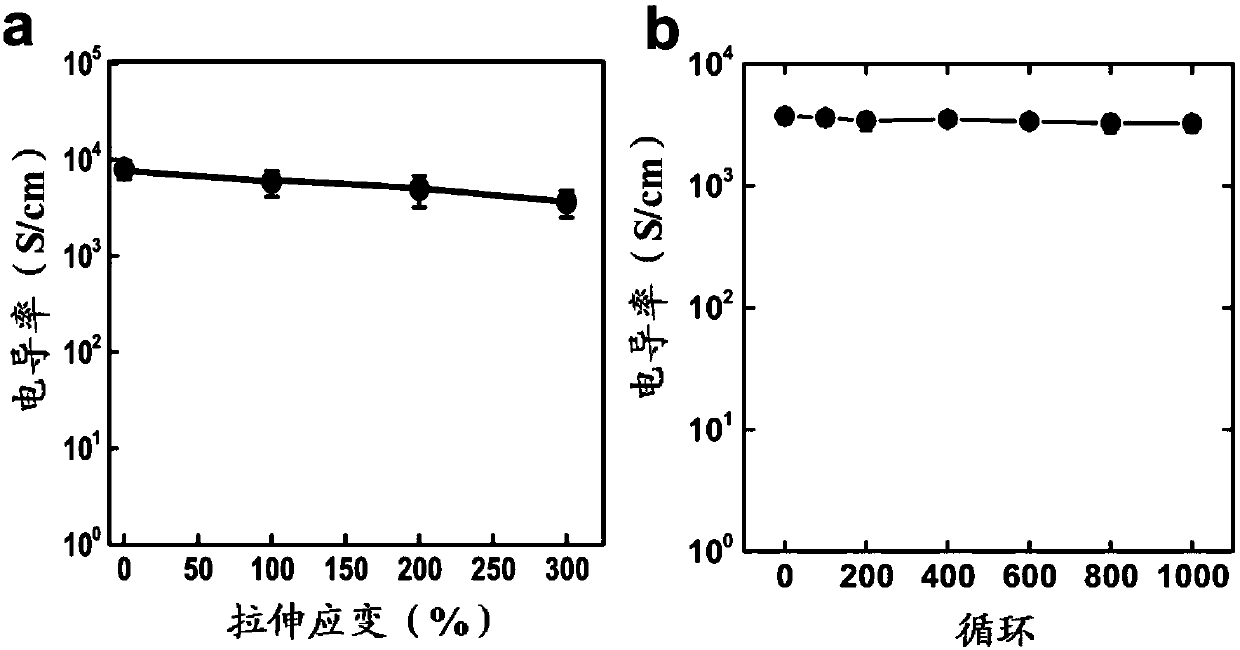

[0078] This example is used to illustrate the liquid metal conductive ink and the flexible and stretchable conductive circuit prepared using the ink.

[0079] Put 1g of polyvinylpyrrolidone, 5uL of fluorocarbon surfactant and 0.1g of chitin in 10mL of phosphate buffer, and stir for 6 hours to fully dissolve. After the polyvinylpyrrolidone is fully dissolved, take 1mL of the solution and place it in a plastic tube, and add 2g of liquid indium gallium tin alloy (In 22%wt Ga 68%wt Sn10%wt) at the same time. Use an ultrasonic cell disruptor to sonicate for 30 minutes at an amplitude of 30%, to obtain a gray liquid metal suspension. The metal is dispersed into small particles of micro-nano size, and the average particle size of the small particles is 800nm. Mix the components A and B of Ecoflex silica gel in equal quantities, stir well, apply on PET plastic film, and cure at room temperature for 6 hours to obtain Ecoflex silica gel film. The prepared conductive ink was added to a ...

Embodiment 3

[0081] This example is used to illustrate the liquid metal conductive ink and the flexible and stretchable conductive circuit prepared using the ink.

[0082] Put 0.5 g of polyvinyl alcohol and 0.01 g of N-(2-hydroxyethyl) dodecylamide into 10 mL of Tris-hydrochloric acid buffer solution, place in a water bath at 95 degrees Celsius and stir for 1 hour to fully dissolve. Take 1 mL of the solution and place it in a plastic tube, and the inventors added 2 g of gallium-zinc alloy (Ga 95%wt Zn 5%wt) into the solution. The conductive ink was prepared according to the method of Example 1. Since the gallium-zinc alloy melting point (37 degrees Celsius) was slightly higher than room temperature, it was heated in an oven at 80 degrees Celsius for 30 minutes before ultrasonication. Utilizing the prepared conductive ink, the inventors used screen printing technology to print conductive patterns on clean T-shirts. Due to the use of screen printing technology, this embodiment can obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com