Preparation method of nano silica microspheres

A nano-silicon dioxide, silicon dioxide technology, applied in the directions of silicon dioxide, silicon oxide, nanotechnology, etc., can solve the problems of unstable preparation process, difficult to meet the market demand of industrial scale production, etc., and achieve a simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

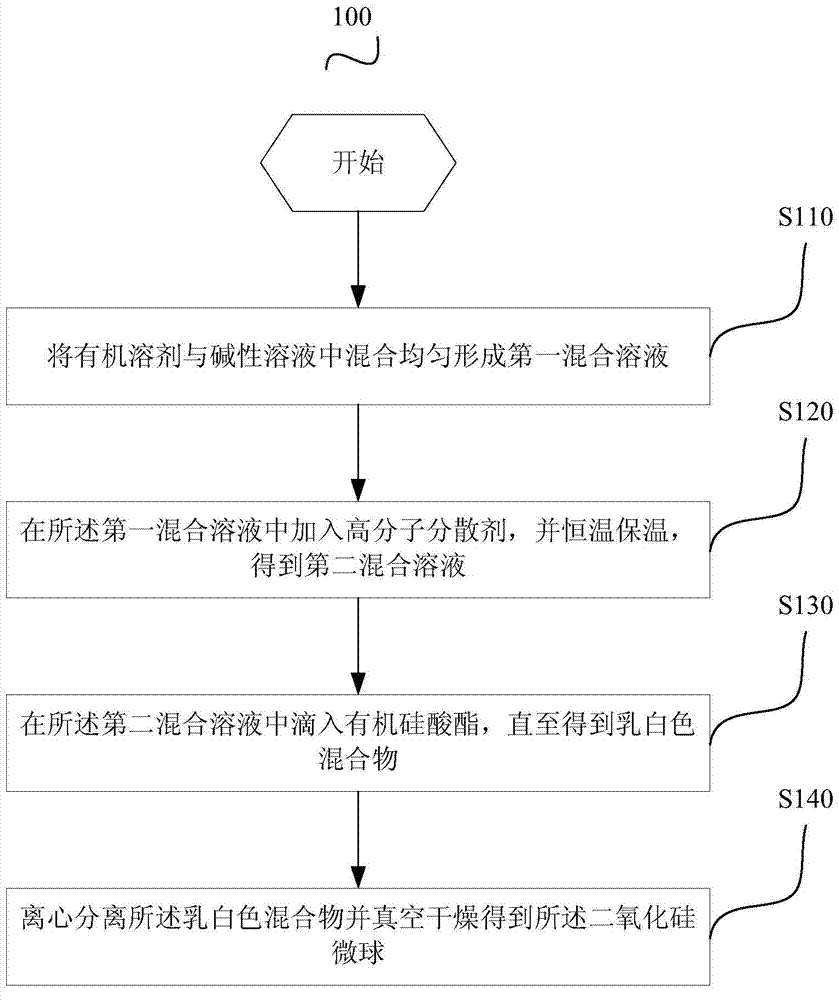

[0028] see figure 1 , figure 1 The flow chart of the steps of the method 100 for preparing nano-silica microspheres provided by the embodiment of the present invention includes:

[0029] Step S110: uniformly mixing the organic solvent and the alkaline solution to form a first mixed solution;

[0030] Preferably, the organic solvent is at least one of ethanol, methanol and propanol.

[0031] Preferably, the alkaline solution is an aqueous ammonia solution. It can be understood that the alkaline solution is an ammonia solution is only a preferred embodiment, and other alkaline solutions can also be used in practice.

[0032] Step S120: adding a polymer dispersant to the first mixed solution, and keeping it at a constant temperature to obtain a second mixed solution;

[0033] Preferably, the polymer dispersant is at least one of polyethylene glycol and ethylene glycol.

[0034] Preferably, the constant temperature is 20-60° C., and the holding time is 0.5-1 h.

[0035] Step...

Embodiment 1

[0045] Quantitatively take 1.5L of ammonia water and 16L of ethanol and add them into a 30L glass reactor, stir and mix evenly to form the first mixed solution; weigh 5g of polyethylene glycol, add it to the above-mentioned first mixture, keep it warm at 20°C for 1 hour, and stir to dissolve to form the first mixed solution. Two mixed solutions; add 1.8L tetramethoxysilane dropwise to the above second mixed solution for about 5 hours until the reaction mixture is milky white; after the reaction is completed, the above emulsion is centrifuged and vacuum-dried to obtain a particle size of 300 - 400nm silica nanospheres.

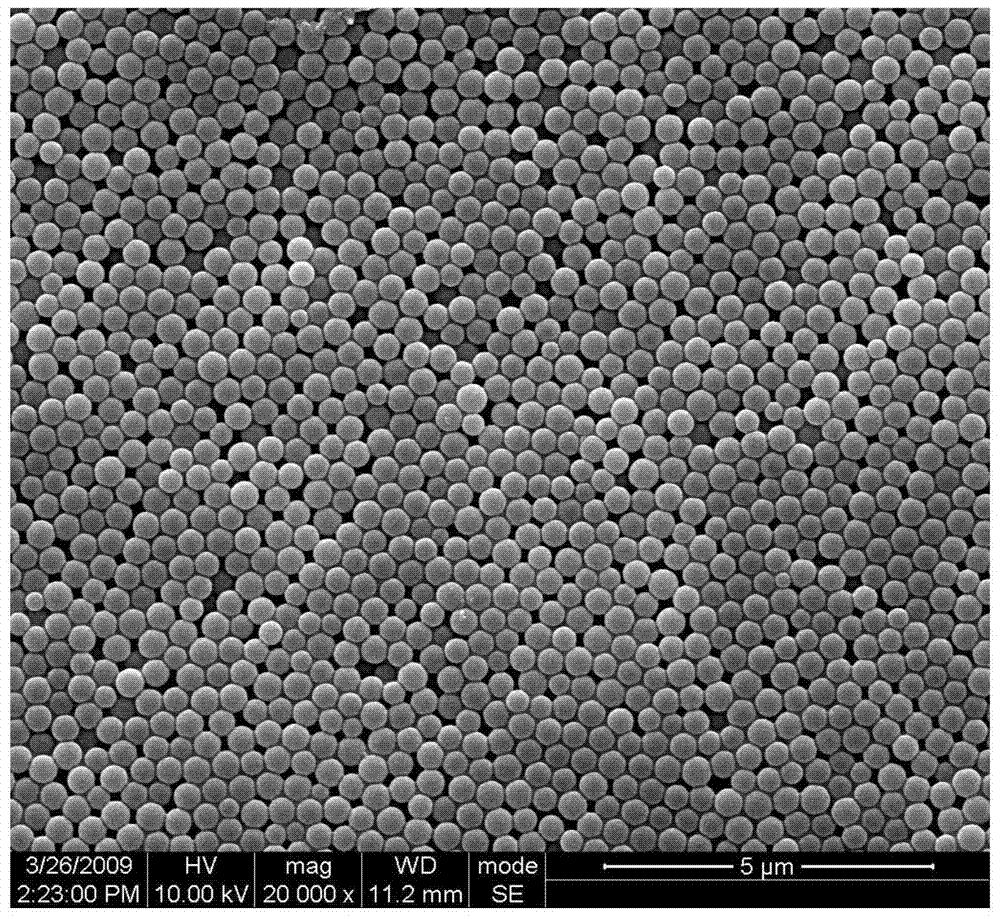

[0046] see figure 2 , for the nano-silica microspheres prepared in Example 1 of the present invention, from figure 2 It can be seen that the sphericity is good, the uniformity of the average particle size is good, the deviation is less than 10%, and the surface of the microspheres is smooth and free of defects.

Embodiment 2

[0048] In a three-necked flask (250mL) equipped with a stirrer, a syringe, and a thermometer, first add 112mL of a mixed solution of absolute ethanol and ammonia water, stir and mix evenly to form the first mixed solution; then add ethylene glycol dispersant, and keep the temperature at 45°C React in a water bath for 6 hours to obtain a second mixed solution; drop tetraethoxysilane into the second mixed solution until a milky white mixture is obtained; centrifuge and vacuum dry to obtain SiO2 with a particle size of about 500nm. powder.

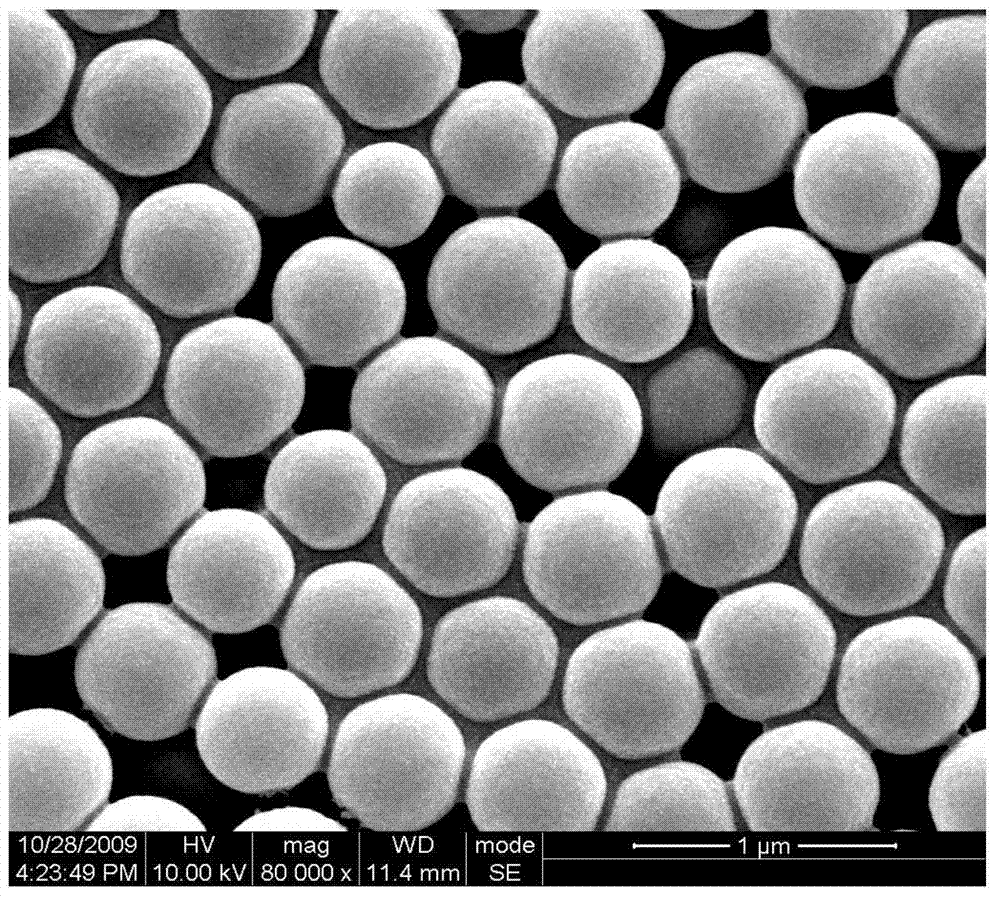

[0049] see image 3 , for the nano-silica microspheres prepared in Example 2 of the present invention, from figure 2 It can be seen that the sphericity is good, the surface of the microspheres is smooth and free of defects.

[0050] see Figure 4 , which is the surface morphology and particle size distribution diagram of the nano-microspheres prepared by the above method in the present invention, from Figure 4 It can be seen from the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com