In-situ preparation method of multi-grade carbon based iron nickel hydroxide and product thereof and application

A nickel hydroxide, in-situ preparation technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as expensive equipment, achieve low cost, The effect of controllable shape, simple equipment and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

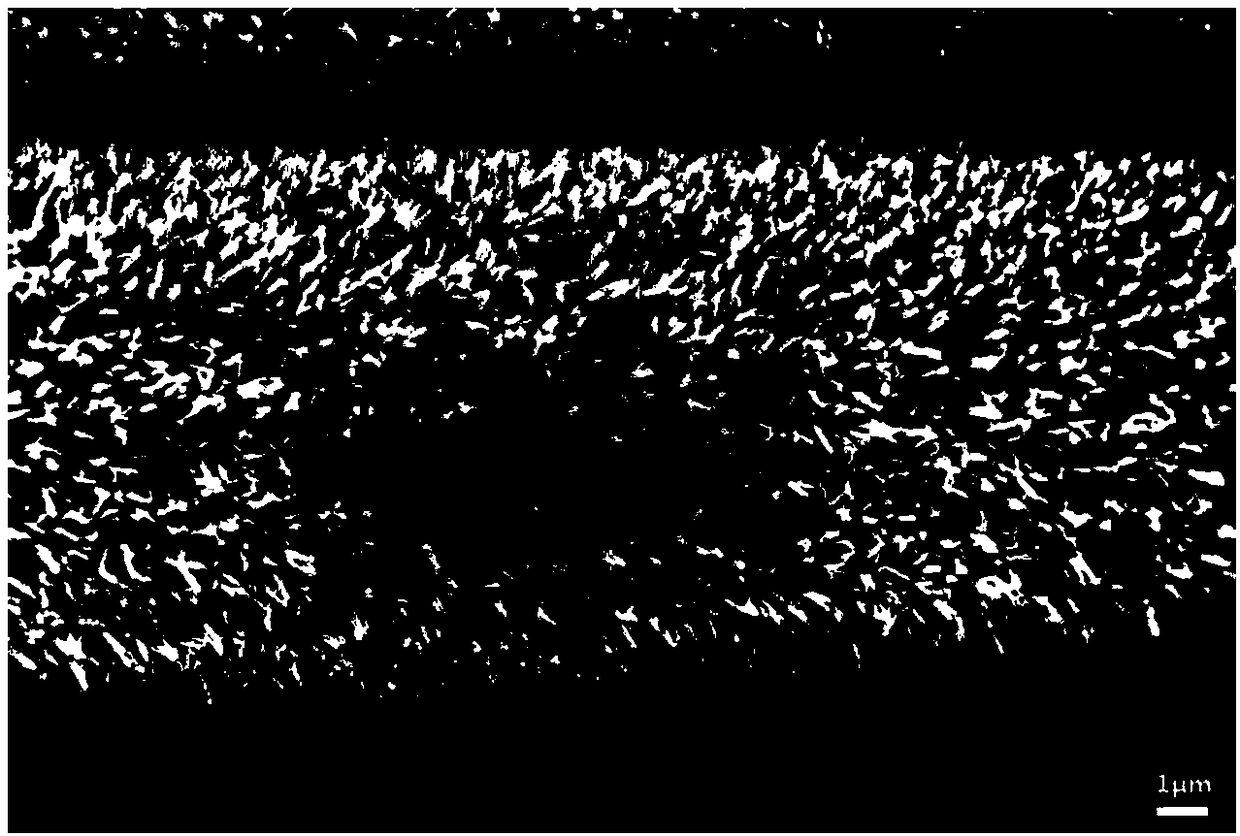

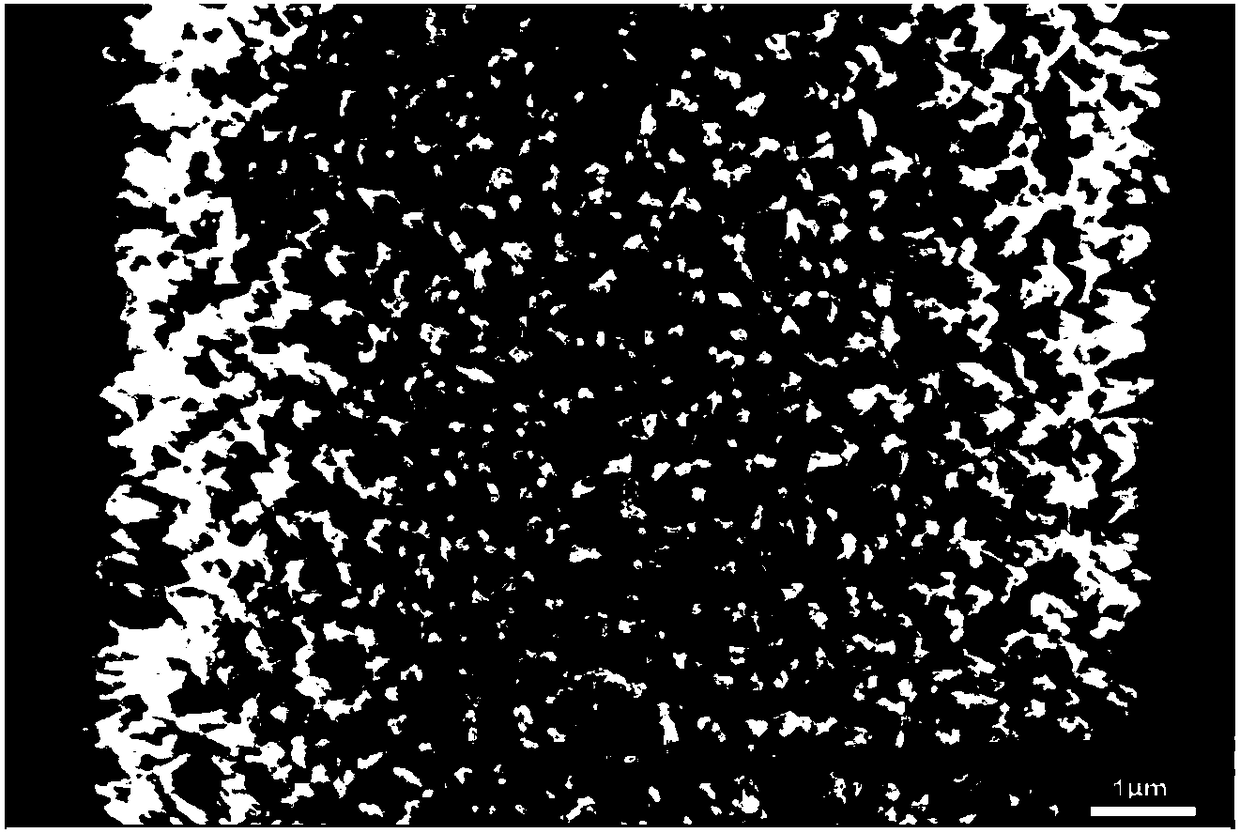

Image

Examples

Embodiment 1

[0031] A kind of in-situ preparation method of multi-level carbon-based iron-nickel hydroxide, comprising the steps of:

[0032] (1) Preparation of multilevel carbon-based acicular nanowire / needle arrays:

[0033] a. Put the cut carbon cloth in acetone, sonicate it for 15 minutes, and put it in alcohol for 15 minutes to remove impurities on the surface of the commercial carbon cloth, and rinse it with deionized water until the carbon cloth becomes super hydrophilic and obtains a hydrophilic water carbon cloth;

[0034] b. 6.5g disodium hydrogen phosphate (Na 2 HPO 4 ) and 5.8g sodium dihydrogen phosphate (NaH 2 PO 4 ) was dissolved in 200mL deionized water to obtain a phosphate buffer solution;

[0035] c. Add 1.4 mL of pyrrole to the phosphate buffer solution prepared in step b, and then ultrasonically treat the solution to fully disperse the pyrrole in the solution to obtain an electrodeposition electrolyte;

[0036] d. use the hydrophilic carbon cloth obtained in step...

Embodiment 2

[0041] A kind of in-situ preparation method of multi-level carbon-based iron-nickel hydroxide, comprising the steps of:

[0042] (1) Preparation of polypyrrole nanowires on carbon cloth:

[0043] a. Put the cut carbon cloth in acetone, sonicate it for 15 minutes, and put it in alcohol for 15 minutes to remove impurities on the surface of the commercial carbon cloth, and rinse it with deionized water until the carbon cloth becomes super hydrophilic and obtains a hydrophilic water carbon cloth;

[0044] b. 6.5g disodium hydrogen phosphate (Na 2 HPO 4 ) and 5.8g sodium dihydrogen phosphate (NaH 2 PO 4 ) was dissolved in 200mL deionized water to obtain a phosphate buffer solution;

[0045] c. Add 1.4 mL of pyrrole to the phosphate buffer solution in step b, and then ultrasonically treat the solution to fully disperse the pyrrole in the solution to obtain an electrodeposition electrolyte;

[0046]d. the hydrophilic carbon cloth processed with step a is used as a working elect...

Embodiment 3

[0051] A kind of in-situ preparation method of multi-level carbon-based iron-nickel hydroxide, comprising the steps of:

[0052] (1) Preparation of polypyrrole nanowires on carbon cloth:

[0053] a. Put the cut carbon cloth in acetone, sonicate it for 15 minutes, and put it in alcohol for 15 minutes to remove impurities on the surface of the commercial carbon cloth, and rinse it with deionized water until the carbon cloth becomes super hydrophilic and obtains a hydrophilic water carbon cloth;

[0054] b. 6.5g disodium hydrogen phosphate (Na 2 HPO 4 ) and 5.8g sodium dihydrogen phosphate (NaH 2 PO 4 ) was dissolved in 200mL deionized water to obtain a phosphate buffer solution;

[0055] c. Add 1.4 mL of pyrrole to the phosphate buffer solution in step b, and then ultrasonically treat the solution to fully disperse the pyrrole in the solution to obtain an electrodeposition electrolyte;

[0056] d. the hydrophilic carbon cloth processed with step a is used as a working elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com