Method for preparing carbon nanometer tube in large-scale

A technology for large-scale preparation of carbon nanotubes, applied in the field of large-scale preparation of soluble carbon nanotubes, can solve problems such as being unsuitable for large-scale preparation of soluble carbon nanotubes, and achieve simple and effective preparation, solvent saving, convenient and effective recovery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

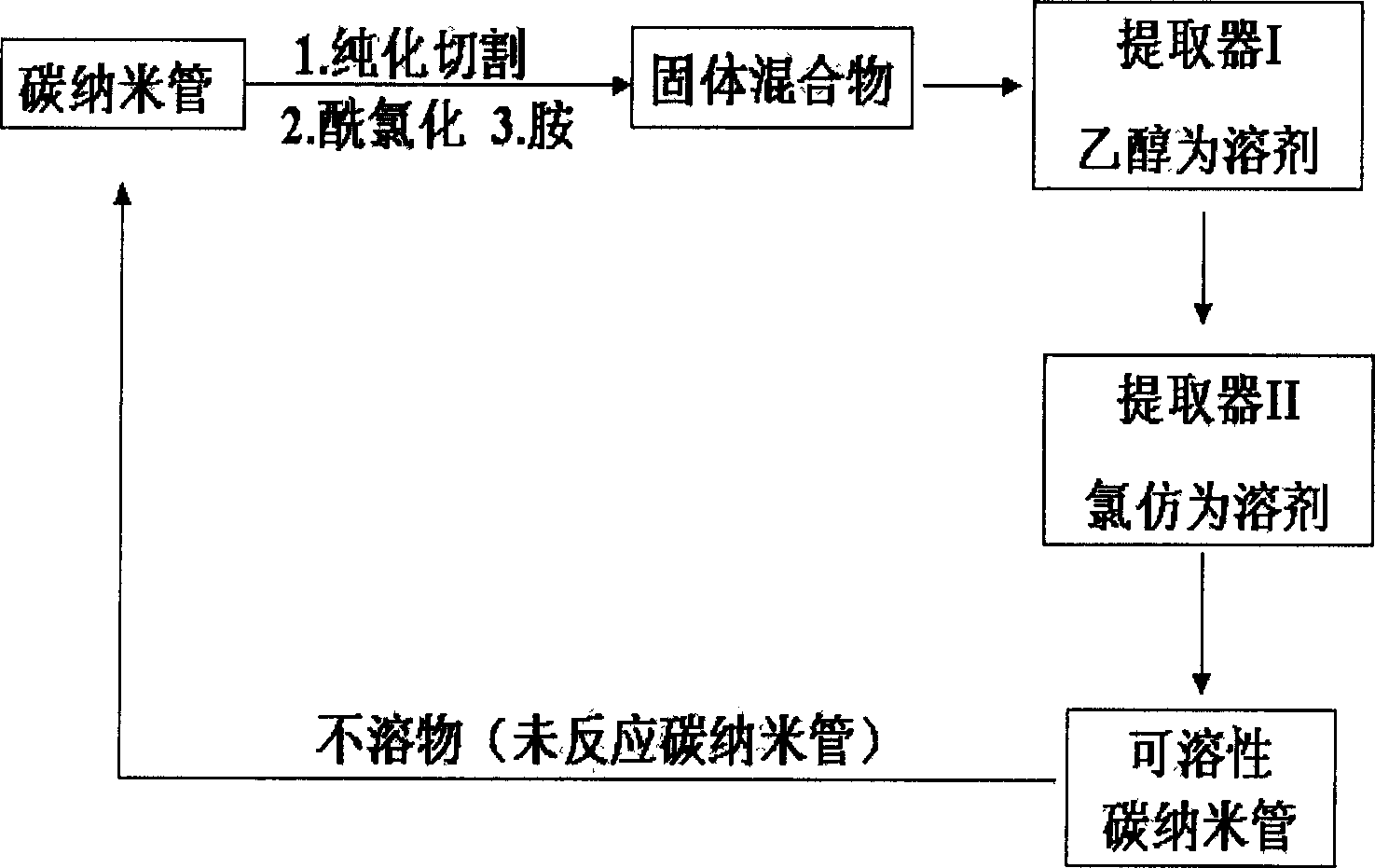

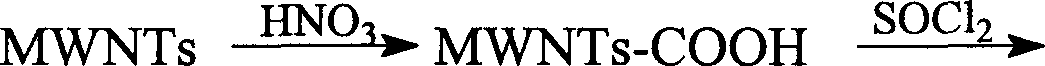

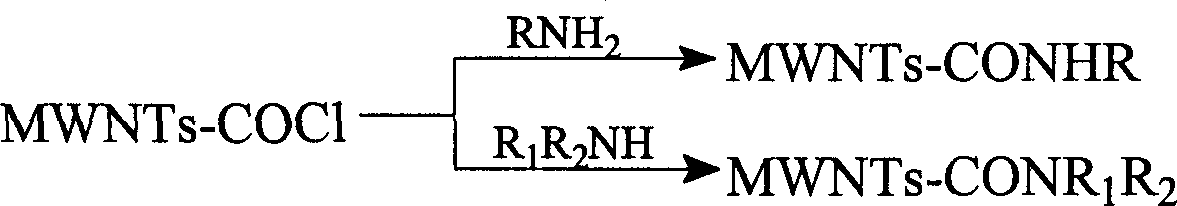

Method used

Image

Examples

Embodiment 1

[0026] 50 g of raw multi-walled carbon nanotubes were heated to reflux in 500 ml of 65% concentrated nitric acid for 24 hours, and after centrifugation, the precipitate was washed with deionized water until it was nearly neutral. The obtained purified multi-walled carbon nanotubes were dried in a vacuum oven at 50° C., and then heated to reflux in 500 ml of freshly steamed thionyl chloride for 24 hours. After the product was centrifuged, the solid was washed several times with anhydrous tetrahydrofuran, dried in a vacuum oven, mixed with 30 g of octadecylamine, heated to 80° C. and stirred for 96 hours under nitrogen protection. After the product is cooled, wrap it with filter paper and place it in a Soxhlet extractor to extract unreacted octadecylamine with 300ml ethanol, and then use 300ml chloroform to extract soluble carbon nanotubes after 24 hours. After 24 hours, the chloroform solution was evaporated to dryness with a rotary evaporator to obtain about 20 g of soluble ca...

Embodiment 2

[0029] 50 g of raw multi-walled carbon nanotubes were heated to reflux in 500 ml of 65% concentrated nitric acid for 24 hours, and after centrifugation, the precipitate was washed with deionized water until it was nearly neutral. The obtained purified multi-walled carbon nanotubes were dried in a vacuum oven at 50° C., and then heated to reflux in 500 ml of freshly steamed thionyl chloride for 24 hours. After the product was centrifuged, the solid was washed several times with anhydrous tetrahydrofuran, dried in a vacuum oven, mixed with 30 g of didecylamine, heated to 80° C. and stirred for 96 hours under nitrogen protection. After the product is cooled, wrap it with filter paper and place it in a Soxhlet extractor to extract unreacted didecylamine with 300ml ethanol, and then use 300ml chloroform to extract soluble carbon nanotubes after 24 hours. After 24 hours, the chloroform solution was evaporated to dryness with a rotary evaporator to obtain about 20 g of soluble carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com