Patents

Literature

41results about How to "Fine fiber diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite nano fiber filtration material with photocatalysis/anti-bacterial functions and preparation method of filtration material

ActiveCN107497182AIncrease spinning speedSolve problems such as easy blockageDispersed particle separationElectro-spinningFiberSpinning

The invention relates to a composite nano fiber filtration material with photocatalysis / anti-bacterial functions and a preparation method of the filtration material. The filtration material comprises a supporting layer and a nano fiber filtration layer which adheres to the surface of the supporting layer, the nano fiber layer is uniformly filled with an photocatalyst and an antibacterial agent, and the preparation method comprises the following steps: 1, preparing a spinning liquid: dispersing a certain amount of the photocatalyst and the antibacterial agent into a solution uniformly to form a dispersion liquid, performing ultrasonic treatment, and adding a high polymer to form a stable and uniform electrostatic spinning solution; 2, performing electrostatic spinning: setting up electrostatic spinning parameters, and performing stretching on the spinning polymer solution at solid metal wire tips for wire production by utilizing an assembled needle head; and 3, performing slight dissolving treatment on the surface of the composite nano fiber filtration material by adopting solvent vapour recovery at a certain releasing speed to obtain the final composite nano fiber filtration material with the photocatalysis / the anti-bacterial functions. The composite nano fiber filtration material effectively solves a problem that the liquid outlet end of a current needle head / spray nozzle used for the electrostatic spinning is easy to block, can be directly used for decomposition of organic pollutants, inactivation of microorganism pathogenes and the like under visible light, and has excellent filtration performance at the same time.

Owner:DONGHUA UNIV

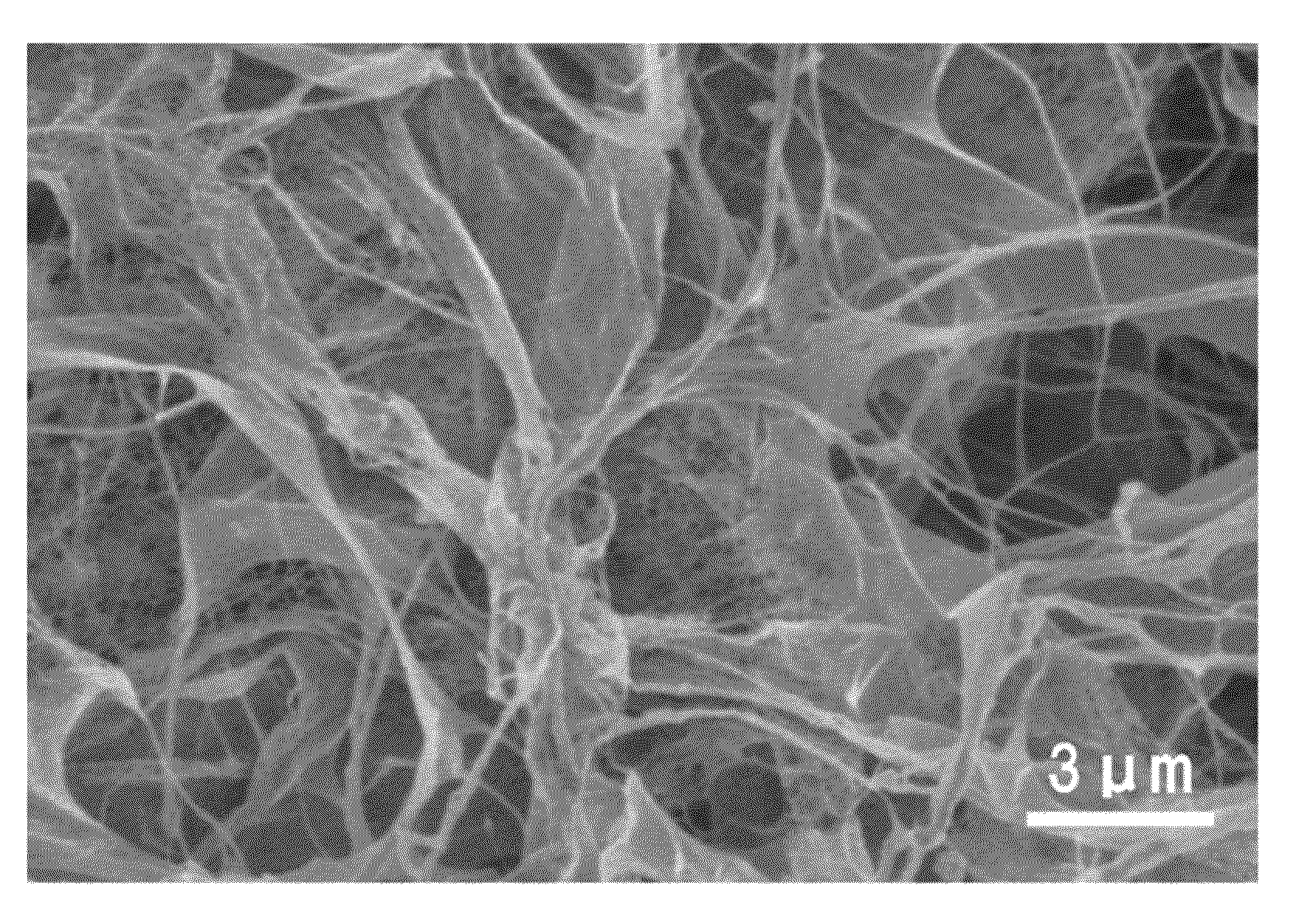

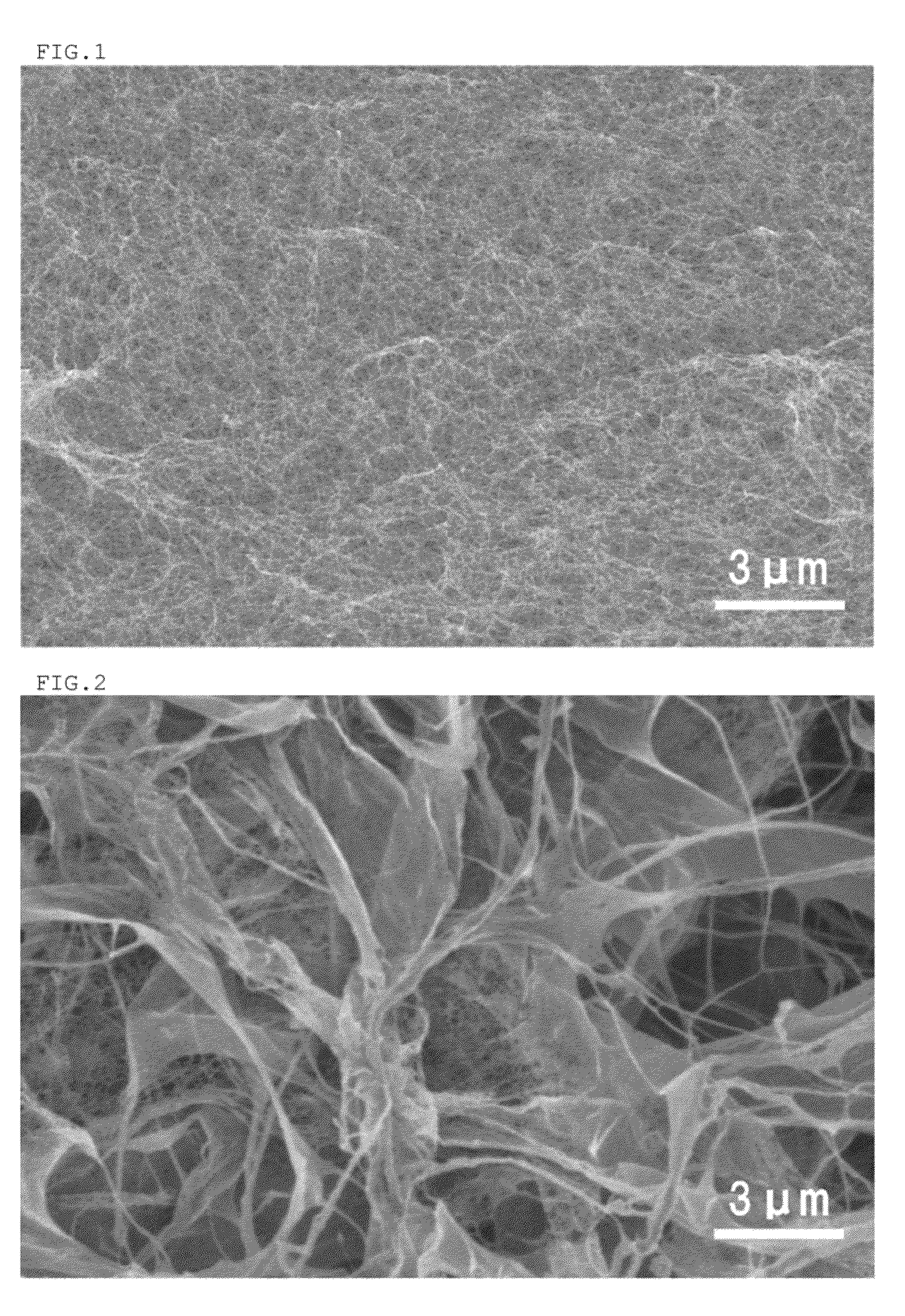

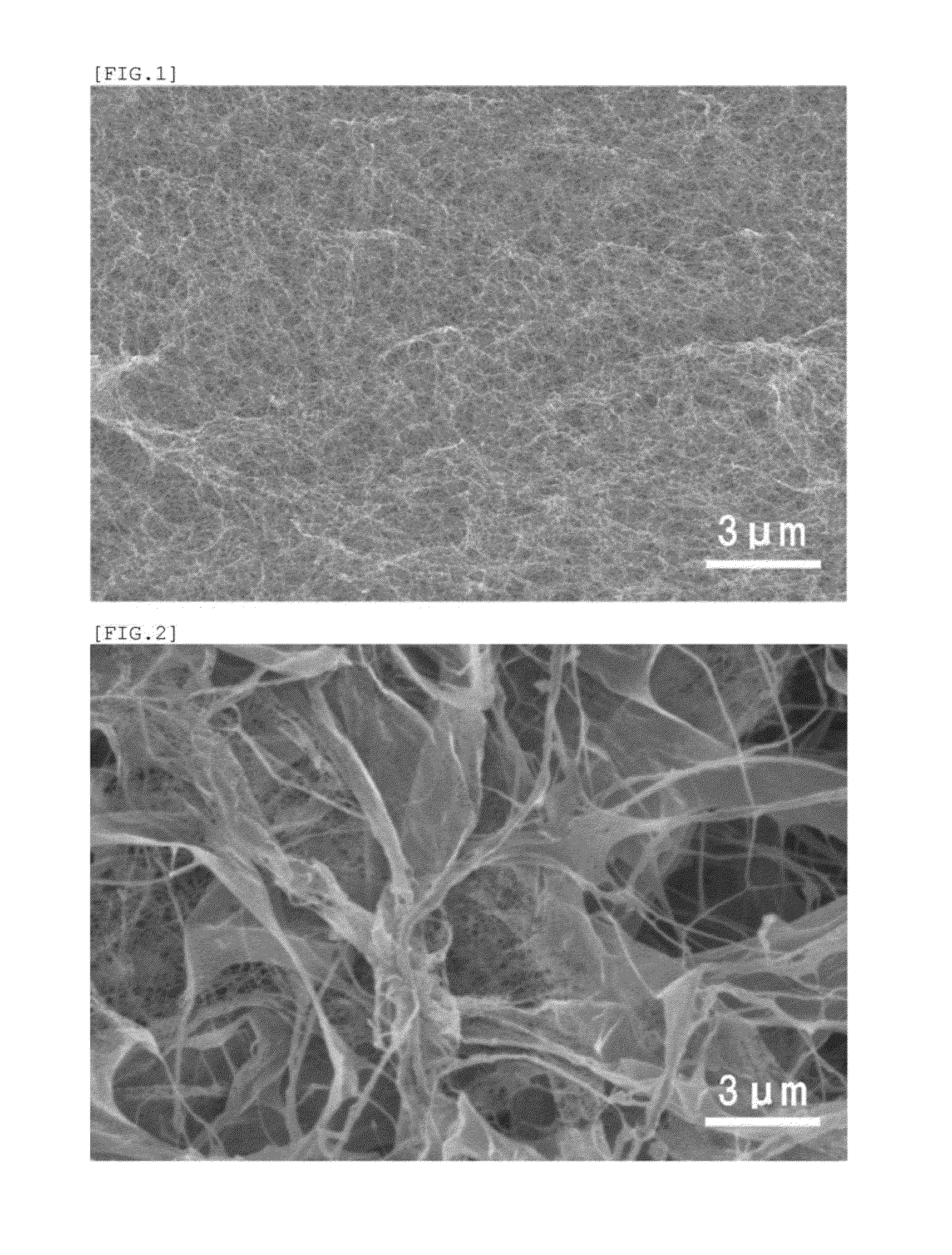

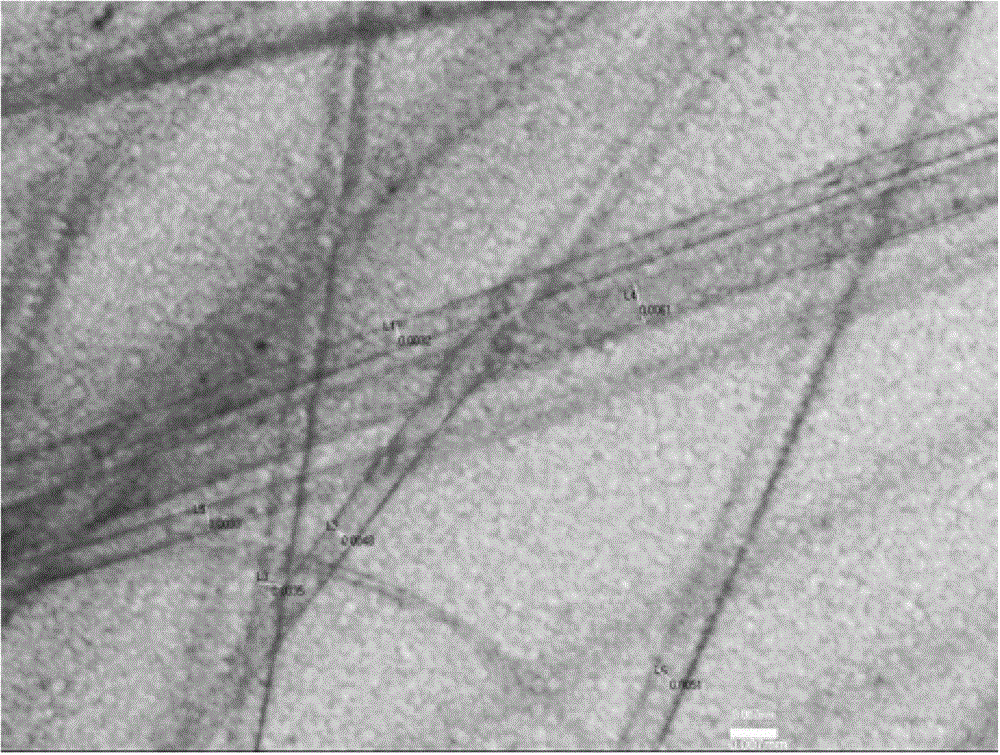

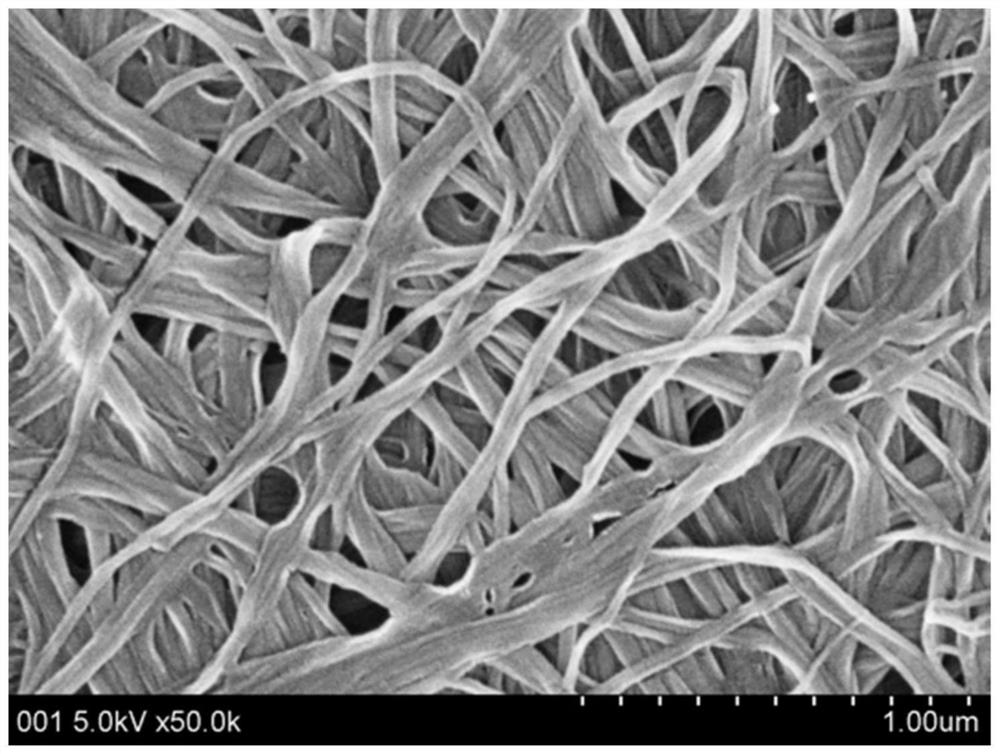

Porous cellulose body and method for producing same

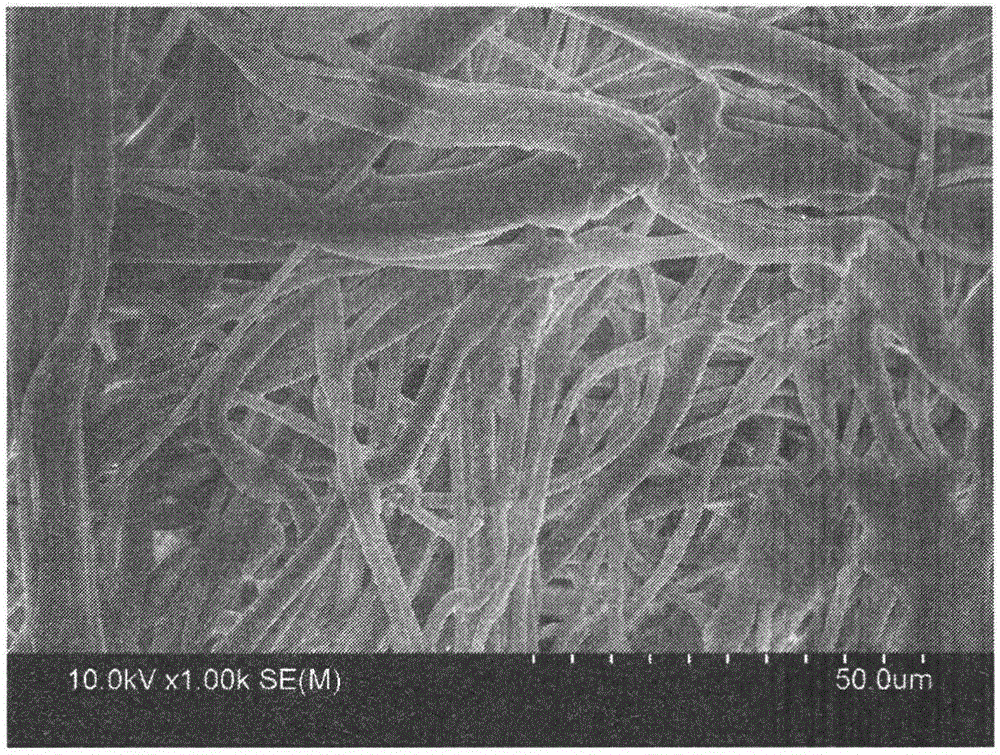

ActiveUS9328211B2Fine fiber diameterImprove hydrophilicityNon-fibrous pulp additionDrying solid materials without heatCelluloseOrganic solvent

A porous body that contains cellulose nanofibers having very thin fiber diameters and high hydrophilicity, and has a large specific surface area, and to provide a method of producing the porous body simply with low cost. A method of producing a porous cellulose comprises a process of lyophilizing a mixed liquid containing cellulose nanofibers and a dispersion medium, wherein the dispersion medium is a mixed dispersion medium of water and an organic solvent dissolving in water, a concentration of the organic solvent in the mixed dispersion medium is 2 to 40 mass %, and a solid content concentration of the cellulose nanofibers in the mixed liquid is 0.001 to 5 mass %.

Owner:HOKUETSU KK +1

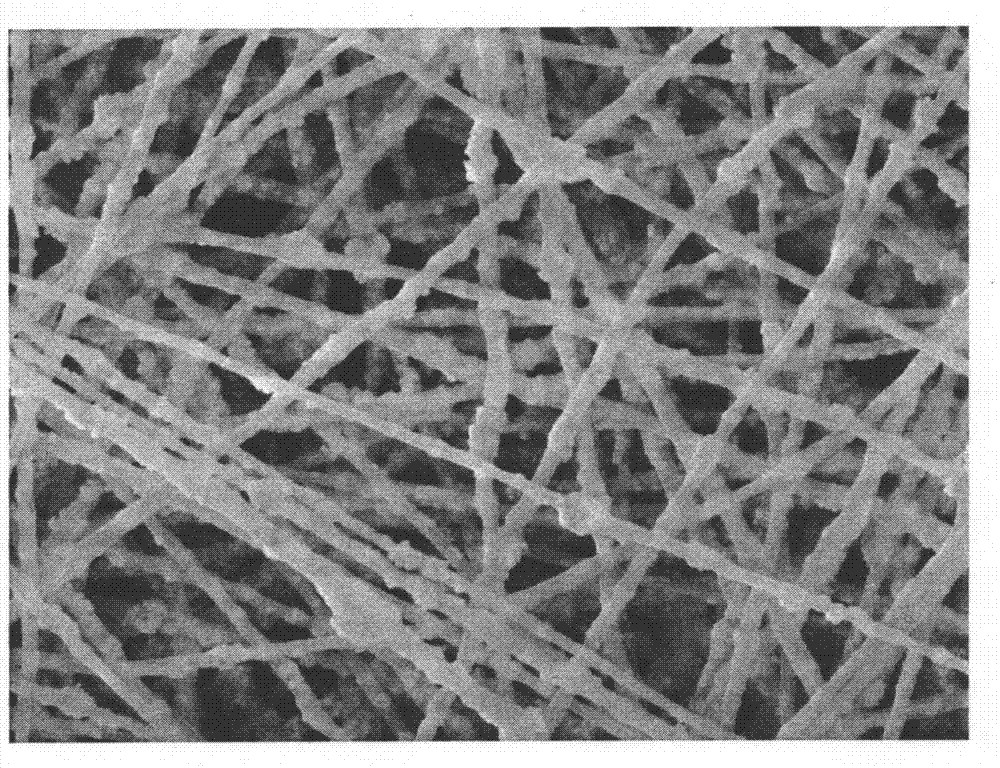

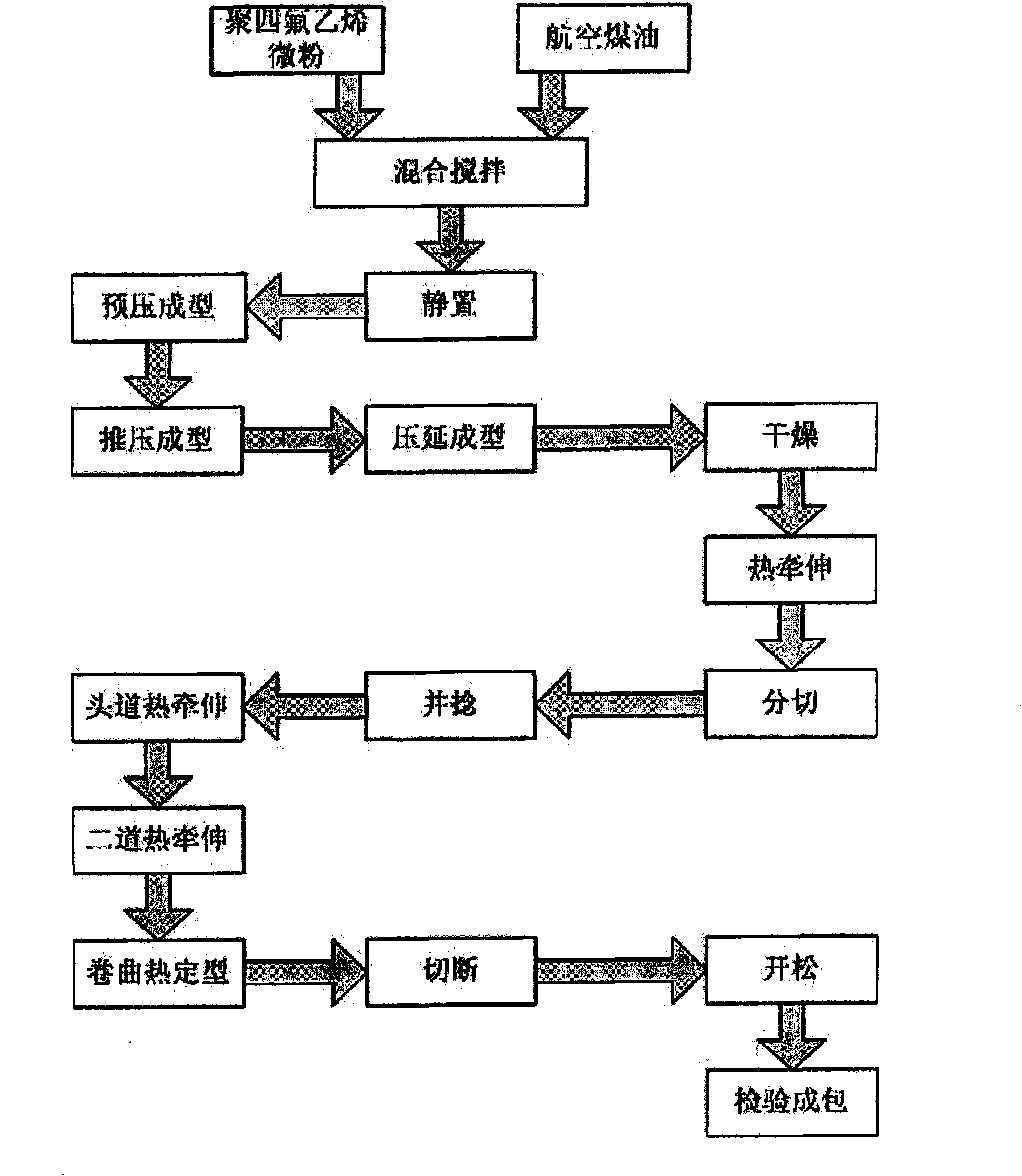

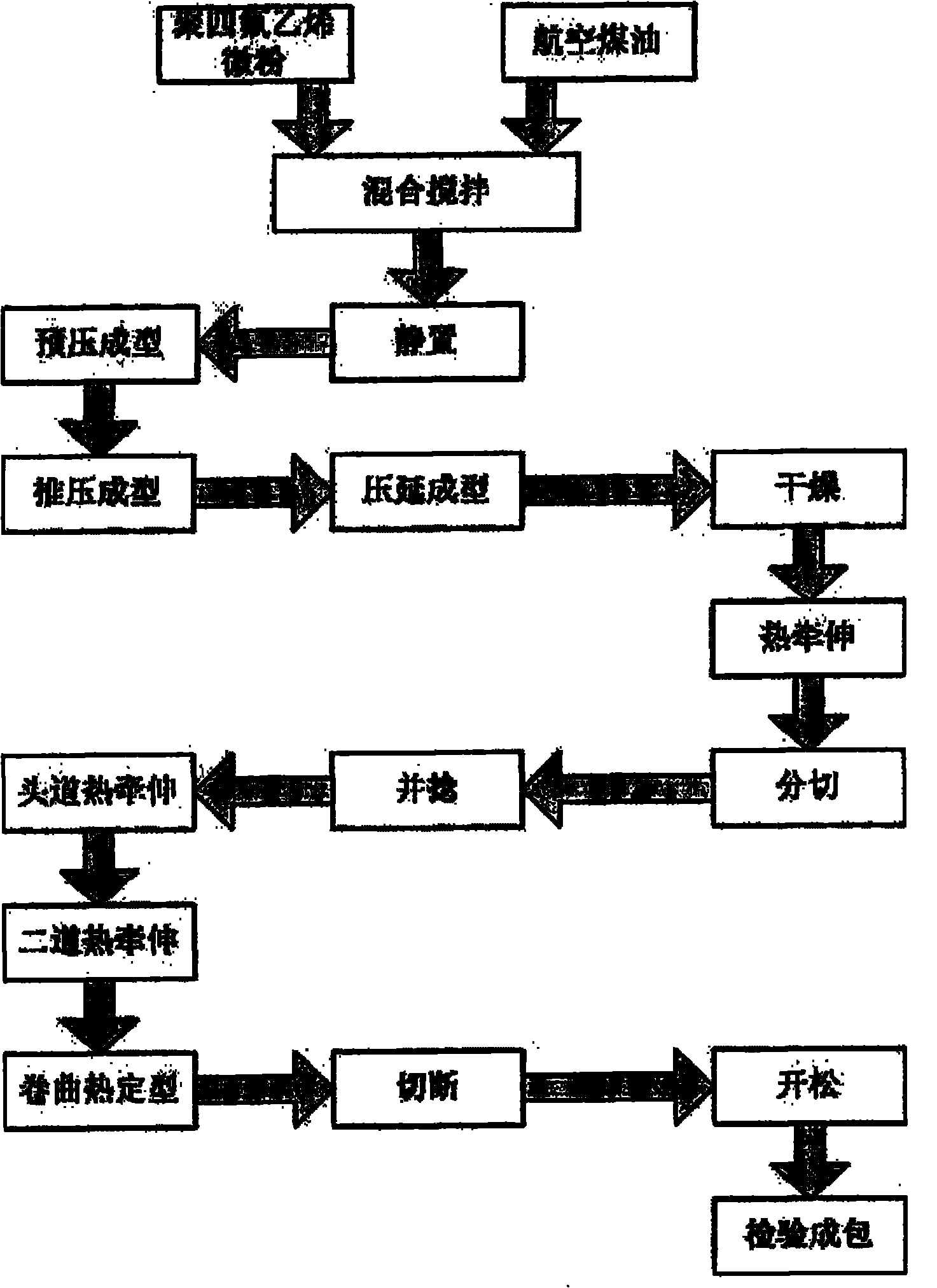

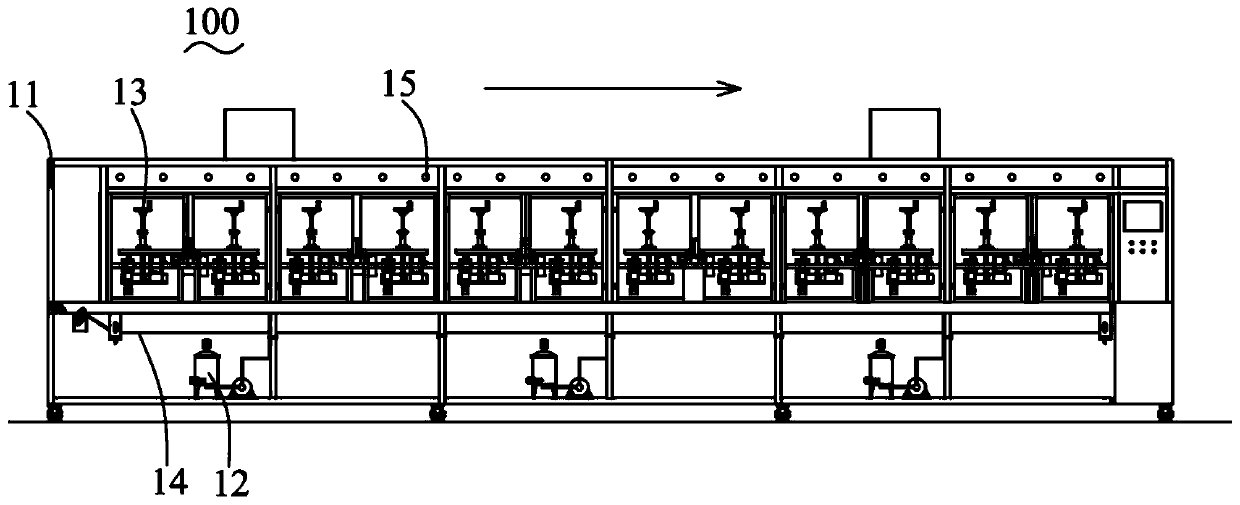

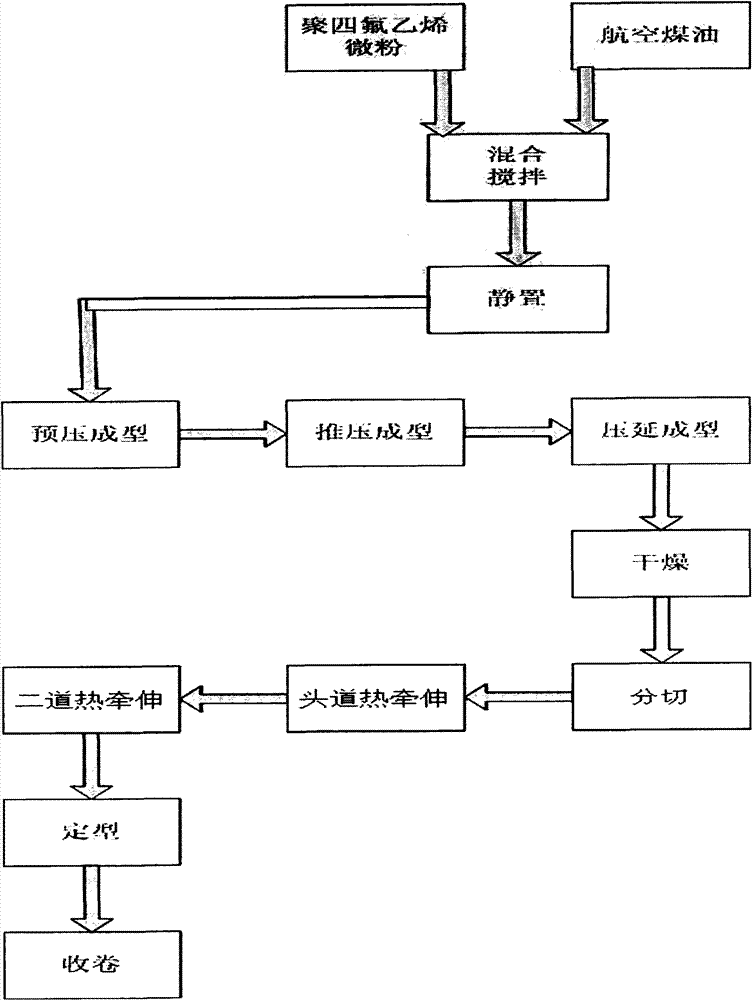

Preparation method of polytetrafluoroethylene chopped fiber

InactiveCN102071483ASimple processing equipmentEasy to operateFilament/thread formingMonocomponent halogenated hydrocarbon artificial filamentFiberPre compression

The invention aims to provide polytetrafluoroethylene chopped fiber with high intensity, high uniformity and low production cost and preparation technology thereof. A process flow comprises the following steps of: mixing polytetrafluoroethylene micro powder and a lubricating agent; stirring; standing; performing pre-compression molding; performing push molding; performing rolling molding; drying; performing hot stretching; parting off; twisting; performing primary hot drawing; performing secondary hot drawing; curling and thermally forming; cutting off; loosening; and inspecting and packaging so as to obtain high-intensity polytetrafluoroethylene chopped fiber. In a manufacturing process, the temperature rises gradually from the primary hot stretching to the secondary hot stretching to the curling and thermally forming.

Owner:宋朋泽

High-content sodium alginate nanofiber membrane and electrostatic spinning manufacturing method thereof

InactiveCN105586716AHigh porosityFine fiber diameterFilament/thread formingNon-woven fabricsPorosityFiber

The invention provides a high-content sodium alginate nanofiber membrane and an electrostatic spinning manufacturing method thereof. The material is formed by sodium alginate or sodium alginate and polyvinyl alcohol, wherein the absolute content of the sodium alginate is 42.5 wt% to 100 wt%, and average diameter of the fiber is 100 nm to 150 nm. A solvent used in a preparation process of an electrostatic spinning solution is deionized water, and a surfactant is TX-100 which is certificated by US Food and Drug Administration. The manufacturing method is simple and feasible, and the high-content sodium alginate nanofiber membrane is not added with any hazardous substance. The manufactured sodium alginate nanofiber membrane is characterized by high content of sodium alginate, thin average diameter, and high porosity. The sodium alginate nanofiber membrane can be applied in the fields of wound dressing and tissue engineering (for example, a support material), etc.

Owner:TIANJIN TEDA JINSHAN PACKING MFR

Manufacture method of biodegradable non-woven material

InactiveCN101775705AExcellent thermodynamic propertiesFine fiber diameterSpinning head liquid feederMonocomponent copolyesters artificial filamentPolymer scienceDicarboxylic acid

The invention provides a manufacture method of a biodegradable non-woven material, which is characterized in that the method comprises the following steps: slicing and drying polyethylene succinate-co-p-benzene dicarboxylic acid butanediol ester; heating and fusing polymer slices in a screw rod extruding press; extruding fused mass from spinneret holes of a mold head; using high-pressure air flow for spraying and blowing at both sides of the spinneret holes when the fused mass is extruded from the spinneret holes of the mold head; tensioning the fused mass into superfine fiber; receiving the superfine fiber through a receiving roller; and forming a biodegradable PBST fused spraying non-woven material through the self adhesive effect of the superfine fiber. The non-woven material manufactured by the method of the invention has good thermodynamic performance, fine fiber diameter, good ventilation performance, soft hand feeling and the like, and also has excellent biodegrading capability. The product can be used in the fields of filtering materials, sanitation materials, package materials and the like, and belongs to a product with good development prospects and high added value.

Owner:DONGHUA UNIV

Porous cellulose body and method for producing same

ActiveUS20150093560A1Improve hydrophilicityLow costNon-fibrous pulp additionDrying solid materials without heatCelluloseOrganic solvent

A porous body that contains cellulose nanofibers having very thin fiber diameters and high hydrophilicity, and has a large specific surface area, and to provide a method of producing the porous body simply with low cost. A method of producing a porous cellulose comprises a process of lyophilizing a mixed liquid containing cellulose nanofibers and a dispersion medium, wherein the dispersion medium is a mixed dispersion medium of water and an organic solvent dissolving in water, a concentration of the organic solvent in the mixed dispersion medium is 2 to 40 mass %, and a solid content concentration of the cellulose nanofibers in the mixed liquid is 0.001 to 5 mass %.

Owner:HOKUETSU KK +1

Fibrous nonwoven mats containing polyethermid fibers

ActiveUS7250381B2Improve bindingReduce thermal shrinkageNon-fibrous pulp additionSynthetic resin layered productsPolyetherimidePolyresin

Fibrous nonwoven mats comprising polyetherimid fibers and a binder comprising a resin and an adhesion promoter, and method of making the mat are disclosed. These mats have several uses and are particularly suited as facer mats for fiber reinforced thermoplastic thermoformable materials. When used as a facer, the mat bonds to the thermoformable material and provides a resin rich outer layer and facilitates bonding to a decorative cover.

Owner:JOHNS MANVILLE CORP

Preparation method for fluoride-free waterproof and moisture permeable fibrous membrane with photocatalytic self-cleaning function

InactiveCN109881490AFine fiber diameterSmall apertureFibre typesMonocomponent synthetic polymer artificial filamentFiberPolymer dissolution

The invention provides a preparation method for a fluoride-free waterproof and moisture permeable fibrous membrane with a photocatalytic self-cleaning function. The preparation method is characterizedby comprising the steps that step 1, an electrospun fiber membrane is prepared, wherein a hydrophilic polymer which cannot be dissolved in water is dissolved in a solvent to prepare an electrostaticspinning solution, and a fiber membrane base material is prepared through electrostatic spinning; step 2, the fiber membrane base material is dipped in an environmental-friendly fluoride-free waterproof agent solution or emulsion at the indoor temperature, then pre-dried and baked; step 3, nano-particles with the photocatalytic performance are utilized for conducting coating finish on the obtainedelectrospun fiber membrane, the obtained electrospun fiber membrane is subjected to high-temperature drying, and the fluoride-free waterproof and moisture permeable fibrous membrane with the photocatalytic self-cleaning function is obtained. The water resistance pressure of the prepared environmental-friendly fluoride-free waterproof and moisture permeable fibrous membrane is greater than or equal to 100 kPa, the water vapor transmission amount of the prepared environmental-friendly fluoride-free waterproof and moisture permeable fibrous membrane is greater than or equal to 15,000 g / m<2> / d, the strength of the prepared environmental-friendly fluoride-free waterproof and moisture permeable fibrous membrane is greater than or equal to 30 Mpa, and the fluoride-free waterproof and moisture permeable fibrous membrane can effectively degrade organic pollutants adhering to the surface of the fluoride-free waterproof and moisture permeable fibrous membrane.

Owner:DONGHUA UNIV

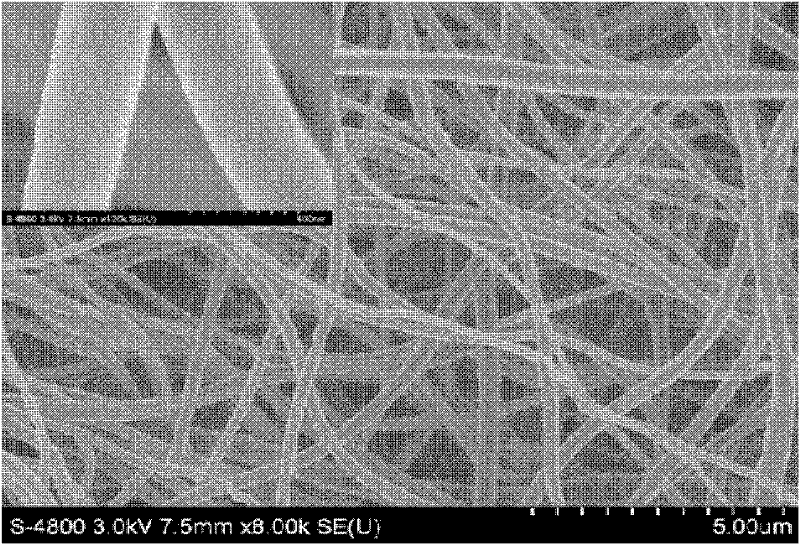

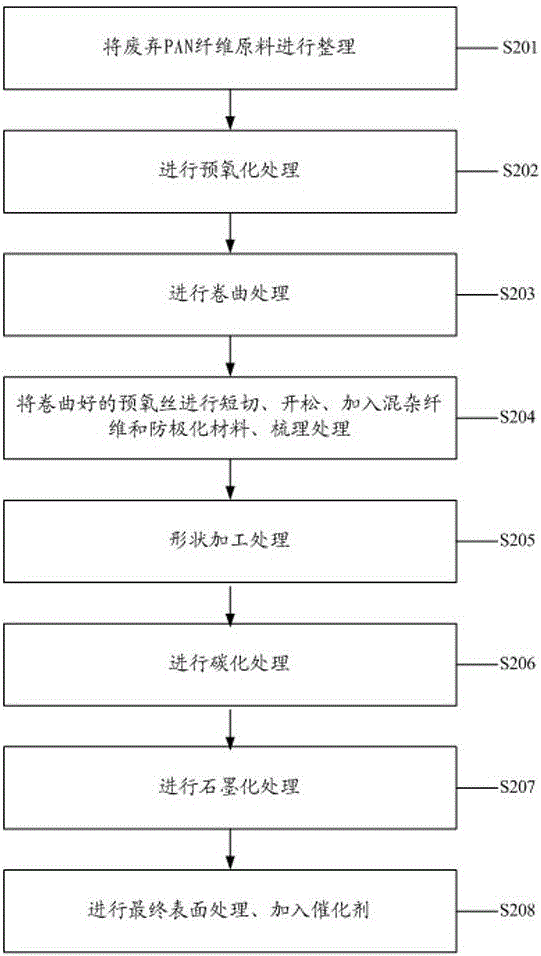

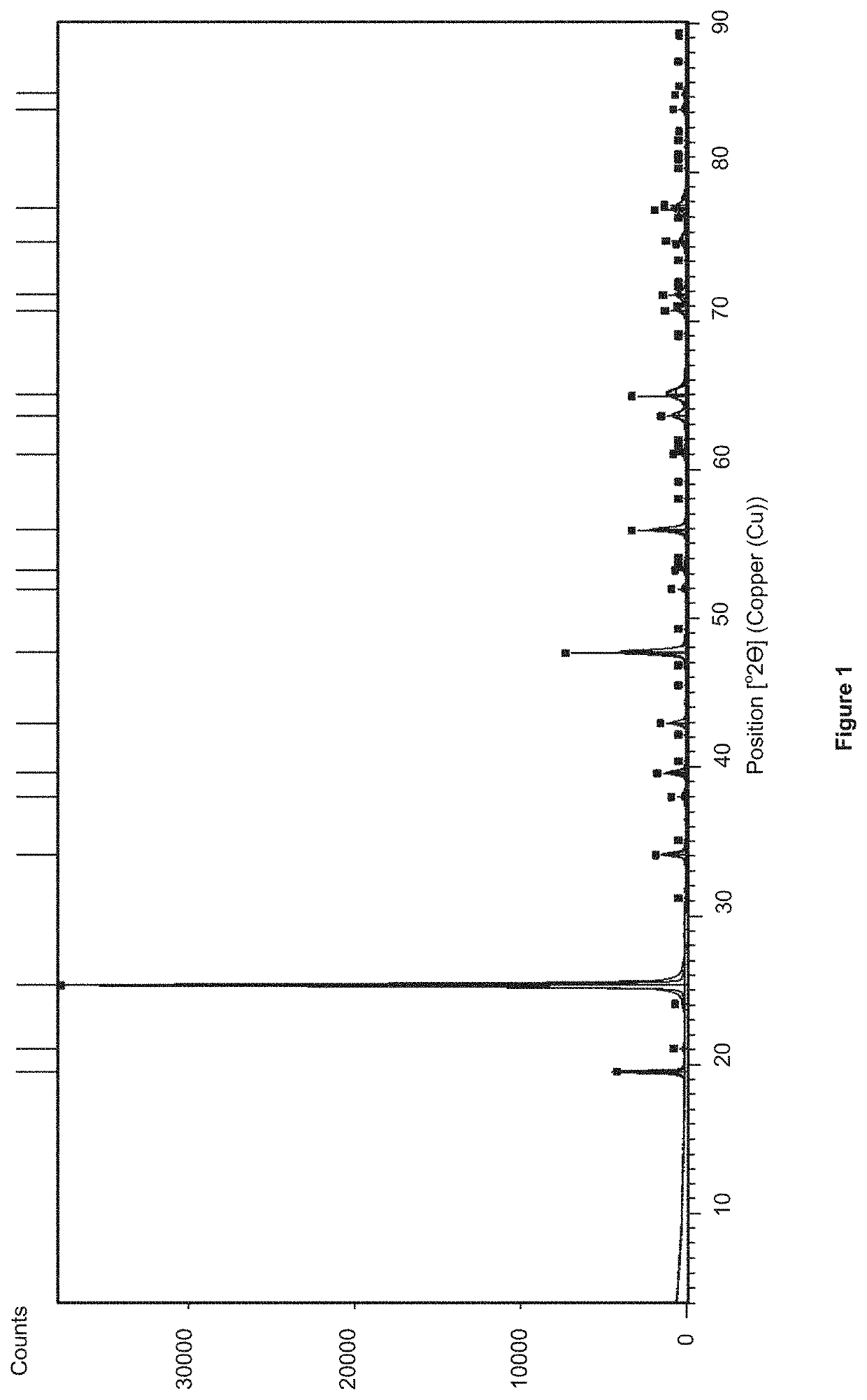

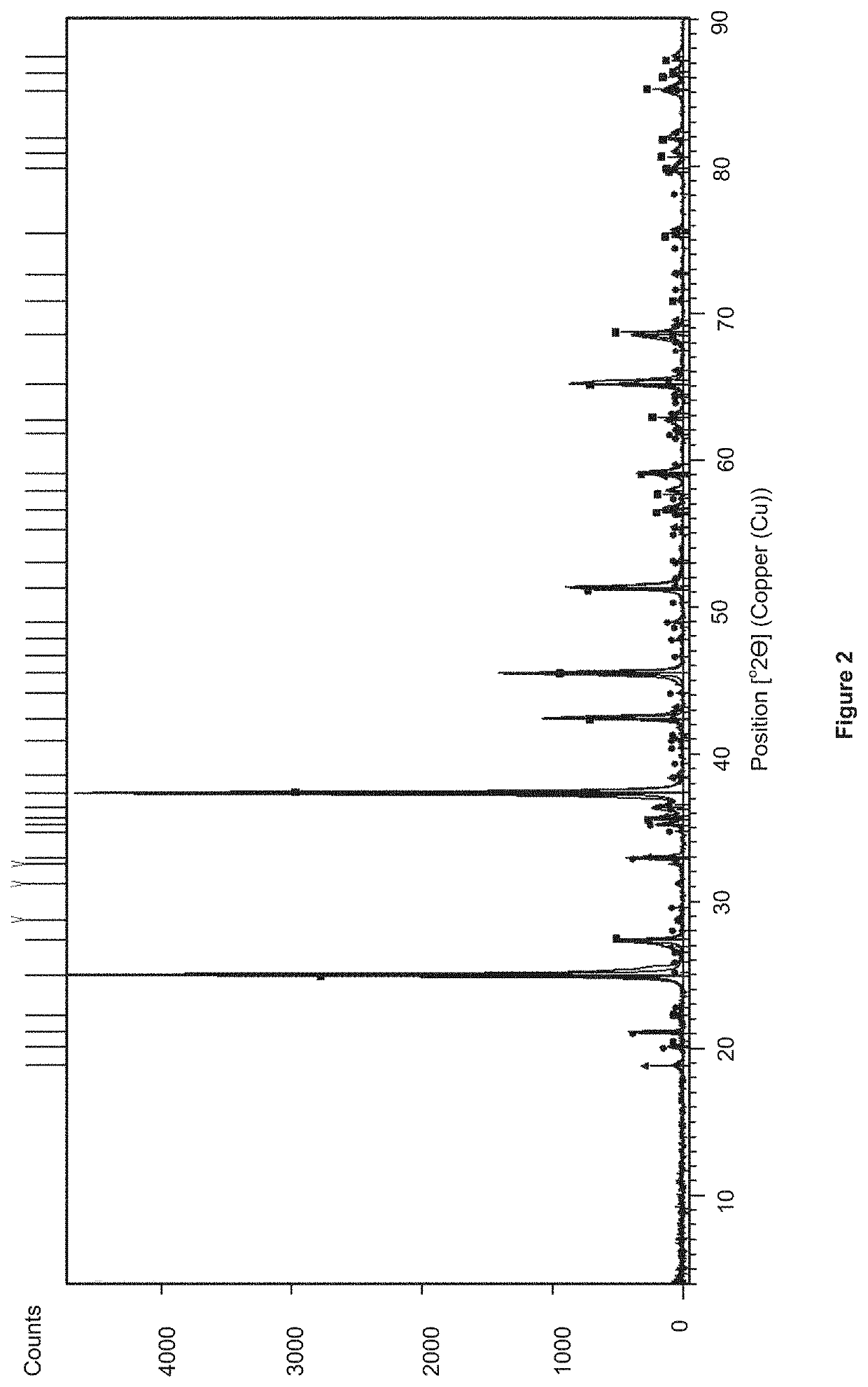

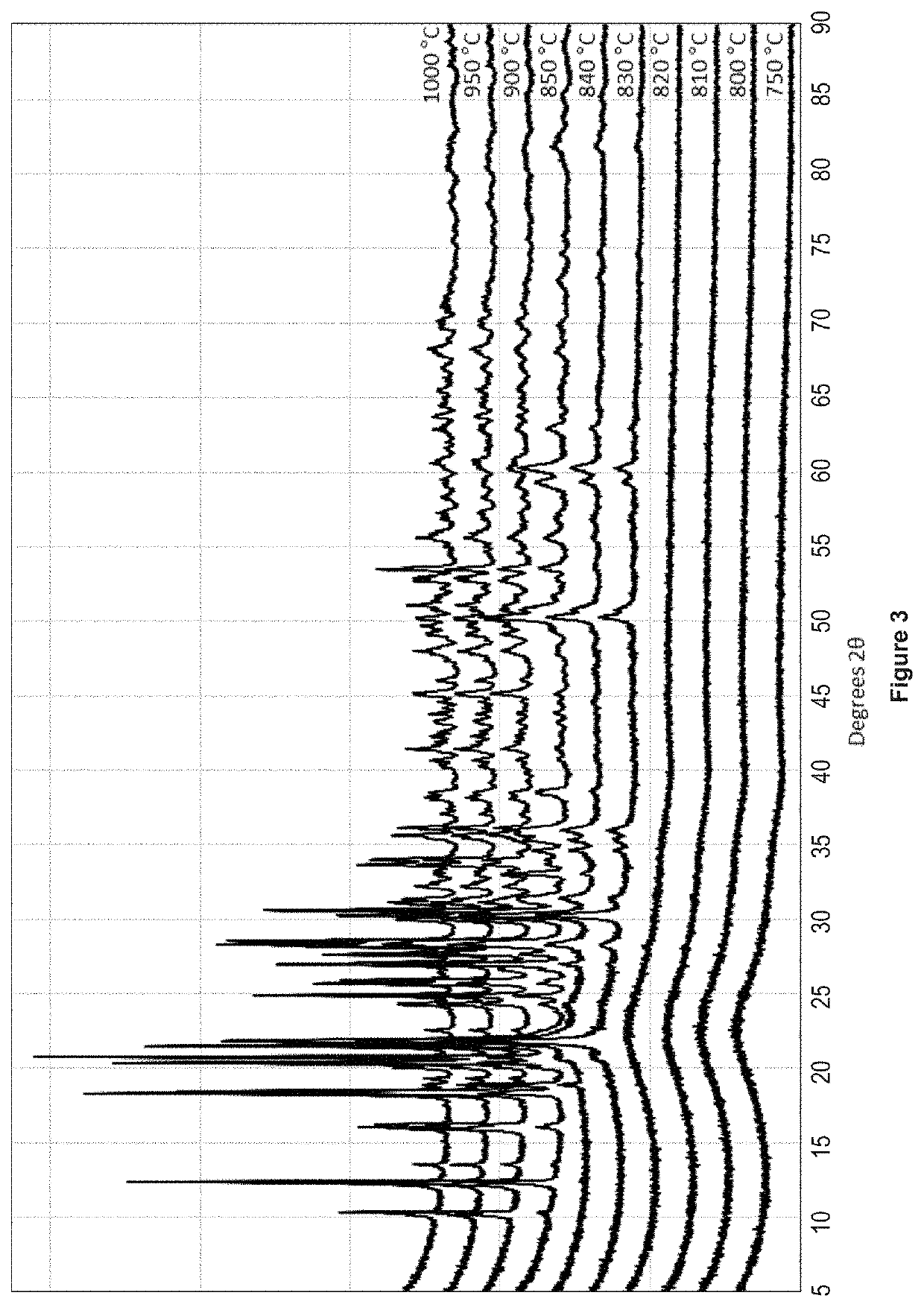

A preparation method of monolithic polyacrylonitrile carbon fiber electrode for desalination

InactiveCN102285706AHas a macroscopic integrityFine fiber diameterWater/sewage treatment by electrochemical methodsDispersed particle separationCapacitanceCarbonization

The invention relates to a preparation method for an integral polyacrylonitrile carbon fiber electrode for desalination, belonging to the technical field of novel carbon material preparation and water treatment. The method is based on an electrostatic spinning technique. Polyacrylonitrile is electro-spun into a film and then preoxidation, carbonization and activation are conducted. The prepared carbon fiber material has the characteristics of good macro integrity, small fiber diameter, large mass specific capacitance, high desalination capacity and the like. When electro-adsorption treatment is conducted to NaCl solution with initial concentration being 70mg / l under 1.6V direct-current voltage, the adsorption capacity of the carbon fiber electrode reaches 4.64mgNaCl / g and therefore a strong desalination capacity is reflected. The novel carbon fiber electrode can be widely used in fields such as bitter saline water and seawater desalination, water softening, heavy metal ion removal andthe like.

Owner:DALIAN UNIV OF TECH

Fibrous nonwoven mat and method

ActiveUS20060105662A1Reduce thermal shrinkageImprove flame resistanceNon-fibrous pulp additionSynthetic resin layered productsPolymer chemistryFiber

Fibrous nonwoven mats comprising polyetherimid fibers and a binder comprising a resin and an adhesion promoter, and method of making the mat are disclosed. These mats have several uses and are particularly suited as facer mats for fiber reinforced thermoplastic thermoformable materials. When used as a facer, the mat bonds to the thermoformable material and provides a resin rich outer layer and facilitates bonding to a decorative cover.

Owner:JOHNS MANVILLE CORP

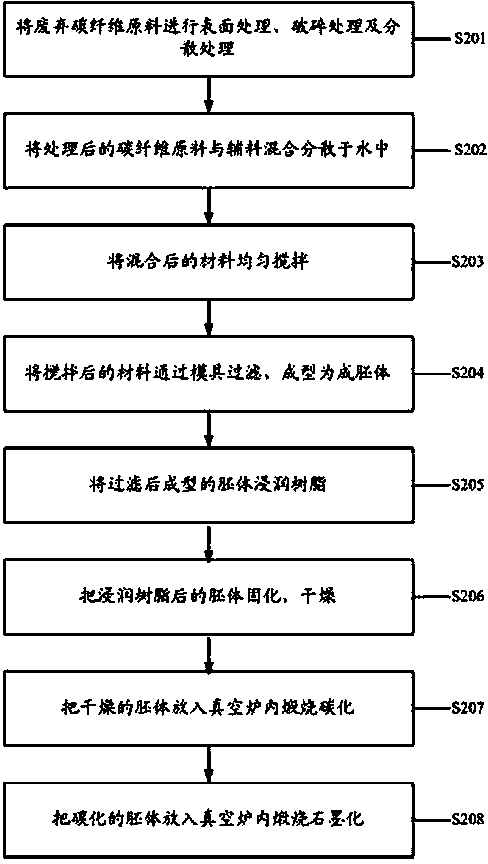

Compound thermal insulation material manufactured by using waste fibers and manufacturing method thereof

The invention provides a compound thermal insulation material manufactured by using waste fibers and a manufacturing method of the compound thermal insulation material and is applied to the field of insulation materials on a high-temperature furnace body. The compound thermal insulation material comprises basic materials and auxiliary materials, wherein the basic materials are waste fiber raw materials and are fiber raw materials which can be carbonized after being subjected to high-temperature calcination, the auxiliary materials comprise graphite, an adhesive and resin, and the waste fiber raw materials comprise one or multiple of polypropylene fibers, asphalt fibers, viscose, pre-oxidized fibers, phenolic fibers, carbon fibers, graphite fibers, wood fibers and cotton fibers. The compound thermal insulation material manufactured by adopting the materials according to the method have relatively thin fiber diameters, relatively small heat conductivity coefficient, relatively good ablation resistance and relatively good purity; and as the compound thermal insulation material is manufactured by using the waste fibers, the cost is reduced, and the benefits and the product competitive power of enterprises are increased.

Owner:上海骐碳复合材料科技有限公司

Fibrous nonwoven mat and method

InactiveUS20070246144A1Improve bindingReduce thermal shrinkageNon-fibrous pulp additionWood working apparatusPolymer sciencePolyetherimide

Fibrous nonwoven mats comprising polyetherimid fibers and a binder comprising a resin and an adhesion promoter, and method of making the mat are disclosed. These mats have several uses and are particularly suited as facer mats for fiber reinforced thermoplastic thermoformable materials. When used as a facer, the mat bonds to the thermoformable material and provides a resin rich outer layer and facilitates bonding to a decorative cover.

Owner:JOHNS MANVILLE CORP

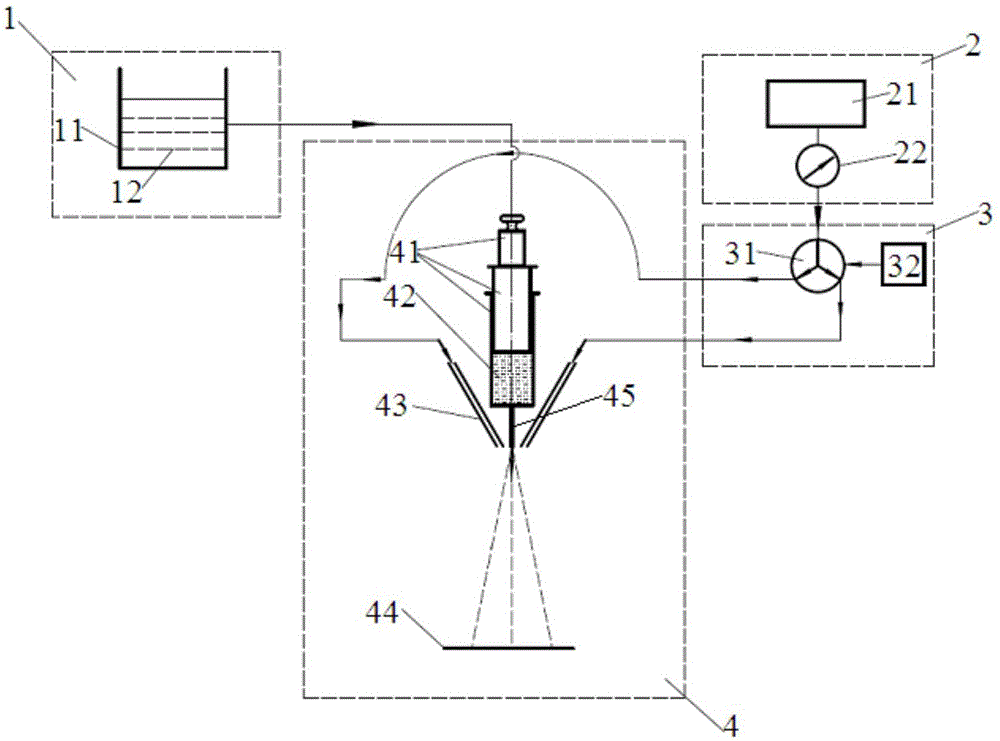

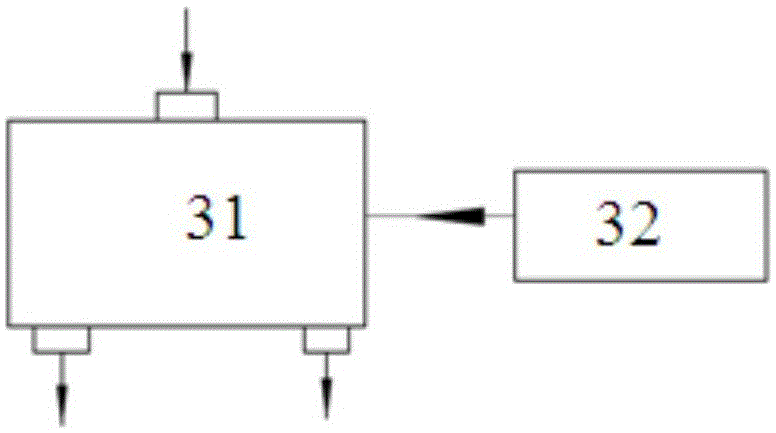

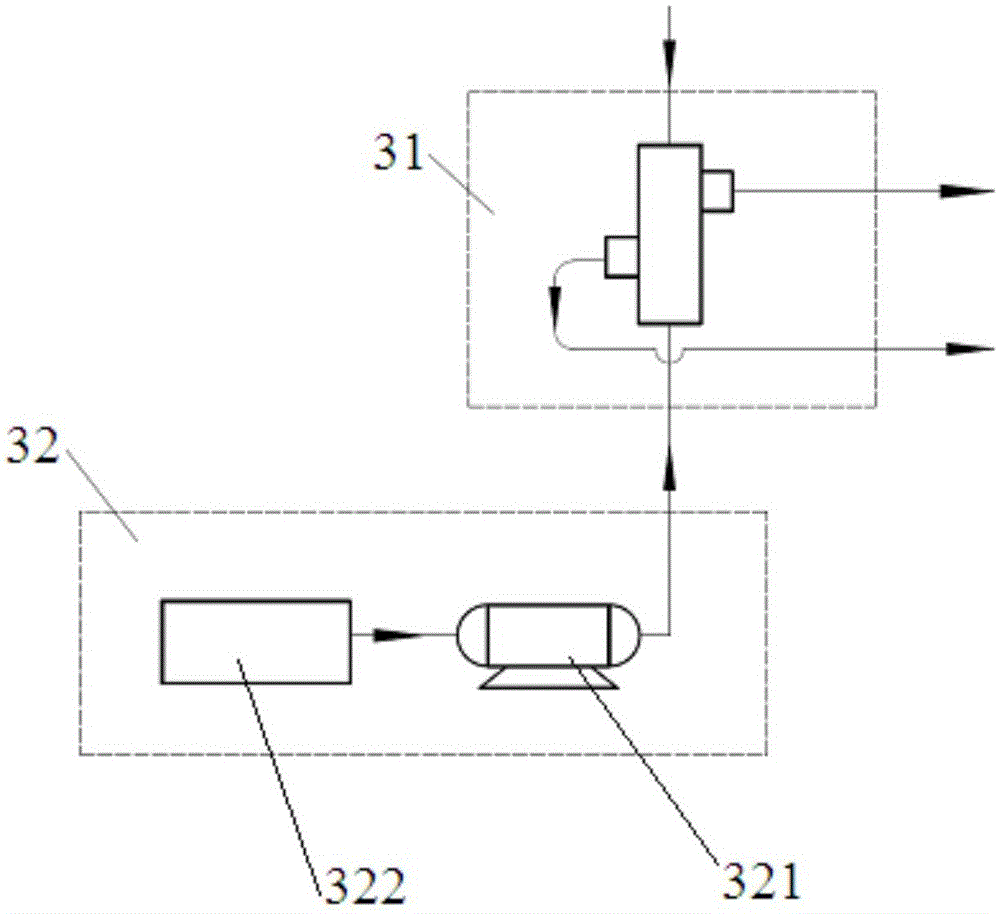

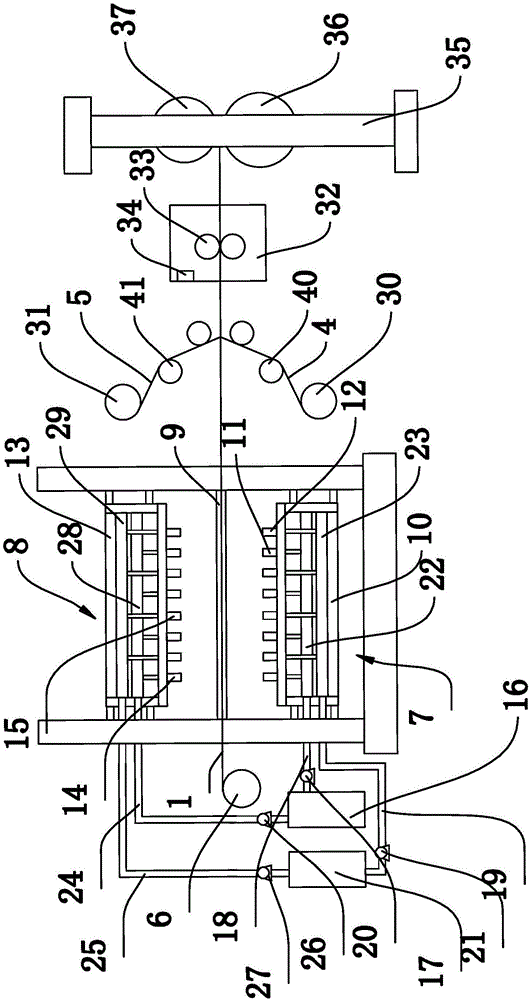

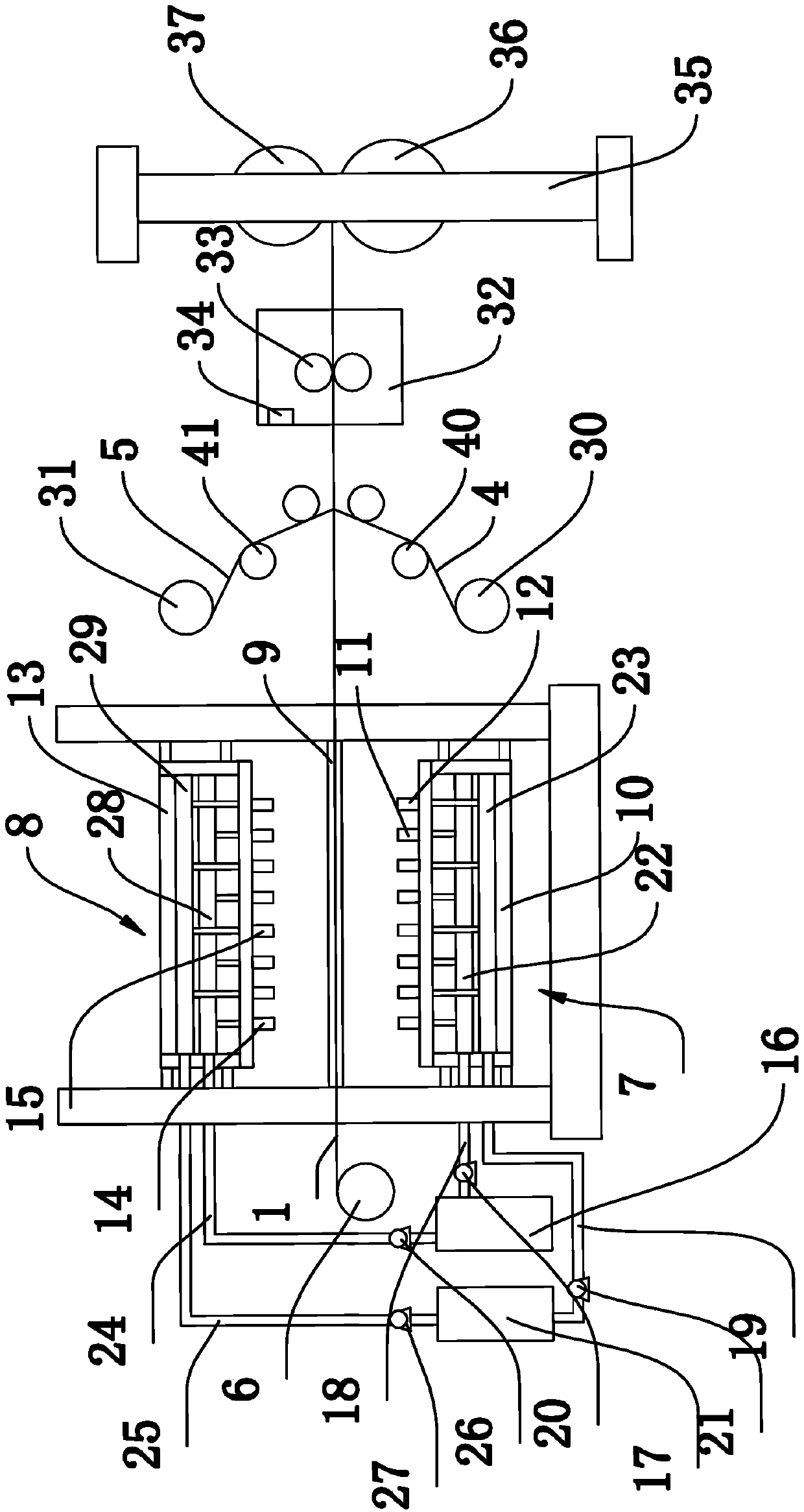

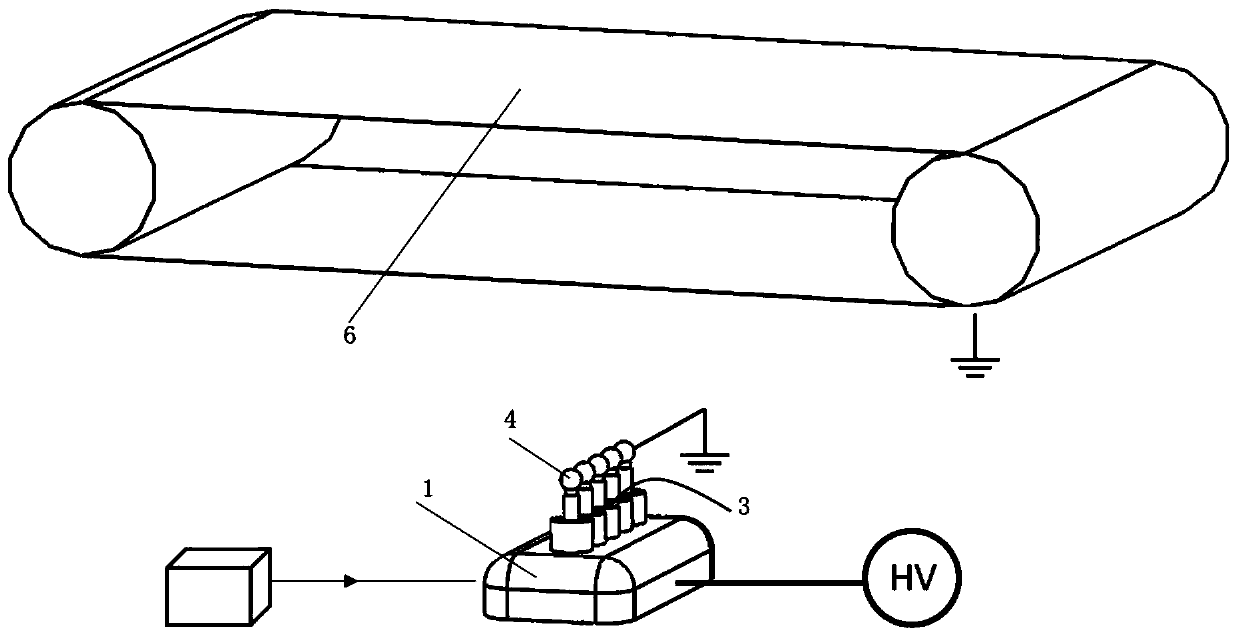

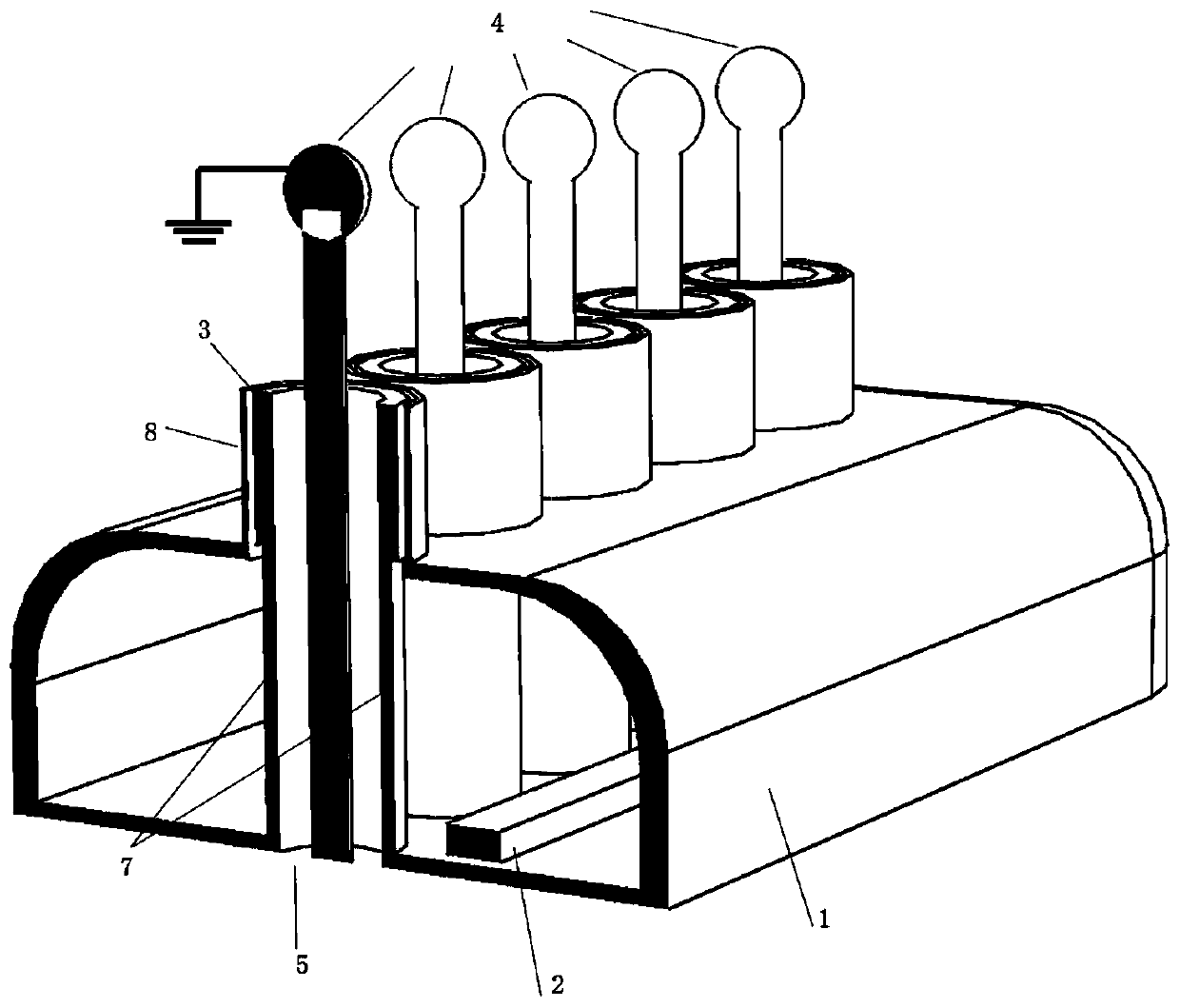

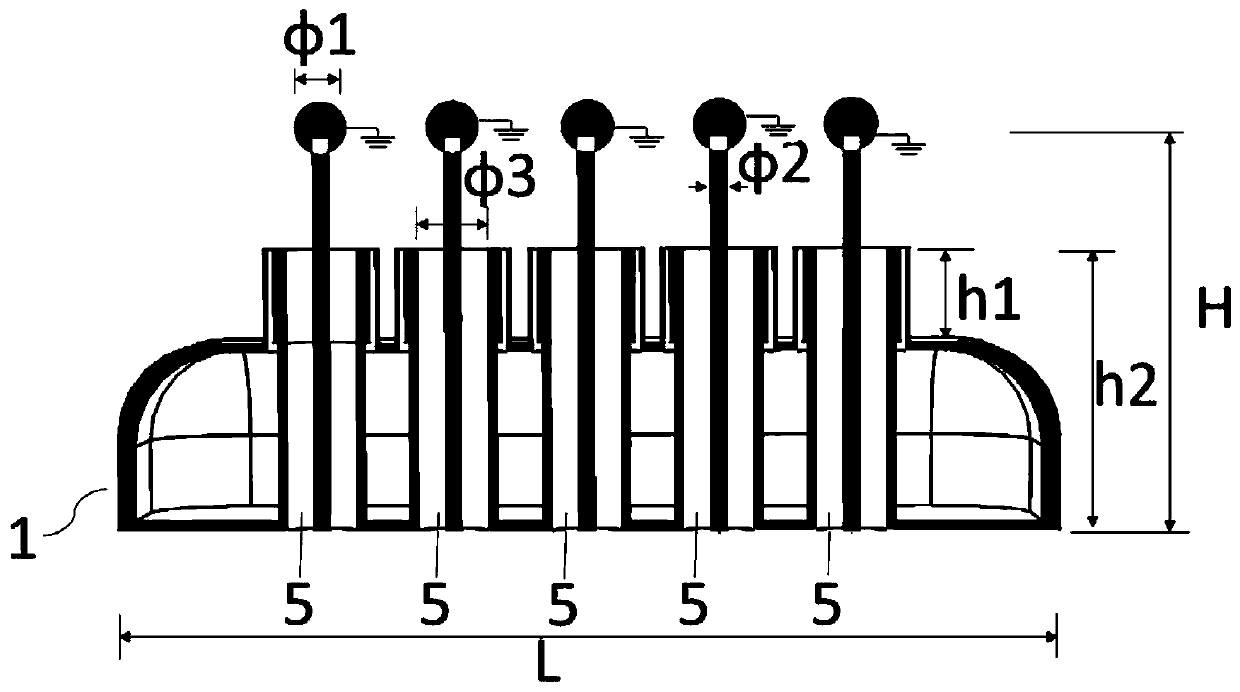

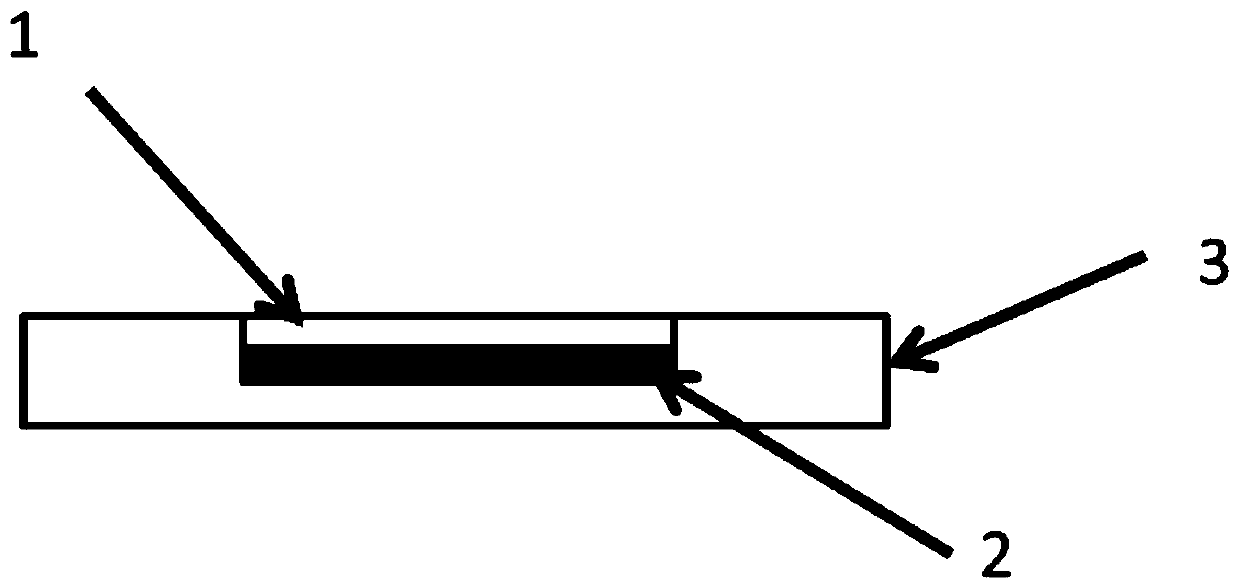

Spray non-woven spinning device and spray non-woven spinning method for producing micro-nanofibers

ActiveCN105040121AFine fiber diameterGood fiber web uniformityFilament/thread formingAirflowEngineering

The invention relates to a spray non-woven spinning device and a spray non-woven spinning method for producing micro-nanofibers. The spray non-woven spinning method comprises the following steps: firstly, making up polymer solution; setting a frequency parameter of alternating jet flow; injecting the solution into a solution storage chamber; turning on an airflow inlet unit; then, turning on a polymer solution inlet unit; extruding solution trickles from spinning orifices; congealing the sprayed solution trickles to a spinning receiving net forming device under the tensile impact of the alternating jet flow generated by an alternating jet flow generation unit to form a fiber net. Compared with the prior art, the spray non-woven spinning device achieves the goal that final fibers are further refined through the resonance action generated by the alternating jet flow, therefore the fibers are thinner in diameter, and the fiber net is better in evenness; the spray non-woven spinning device has another characteristic of being more energy-saving and environmental friendly, and the operation is convenient.

Owner:SHANGHAI UNIV OF ENG SCI

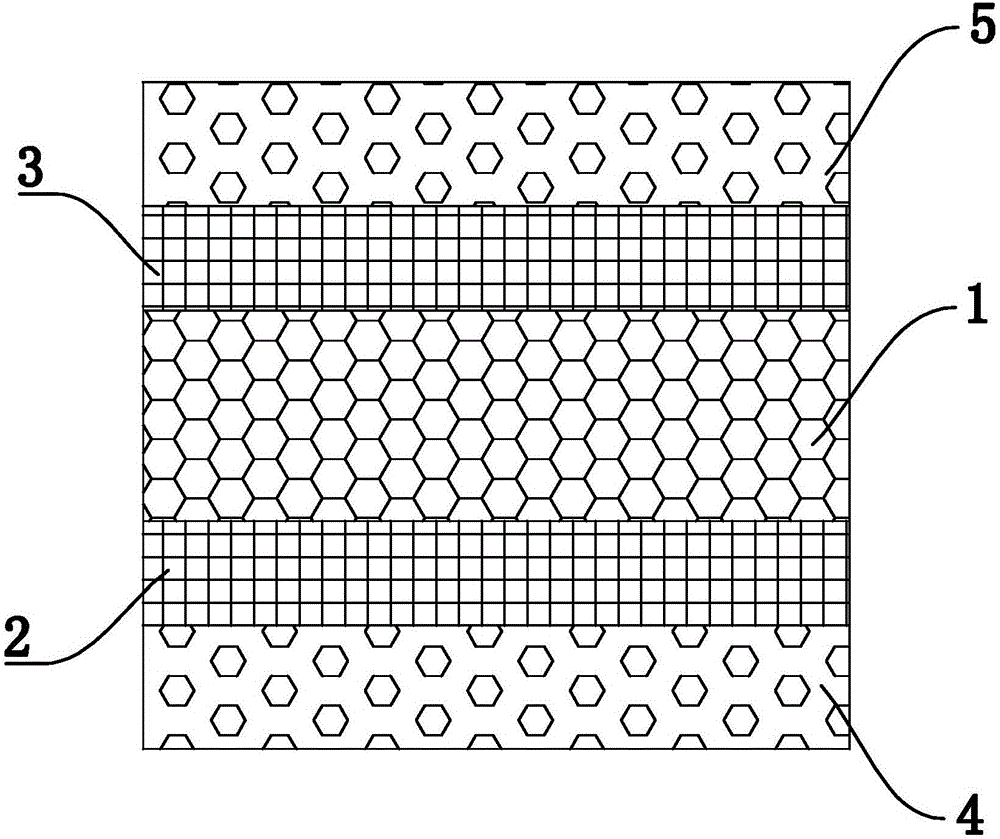

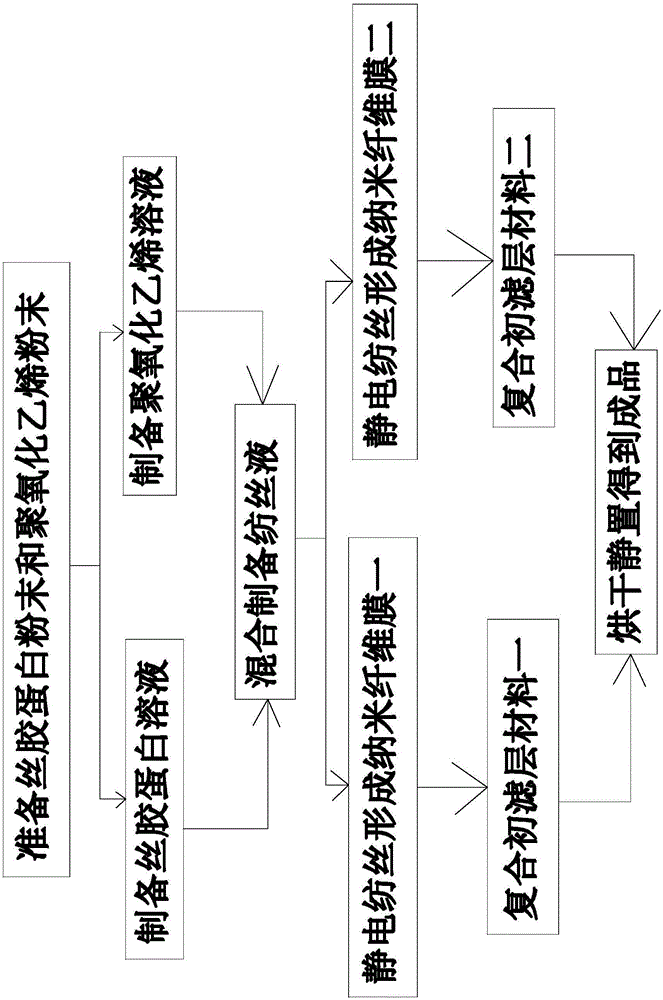

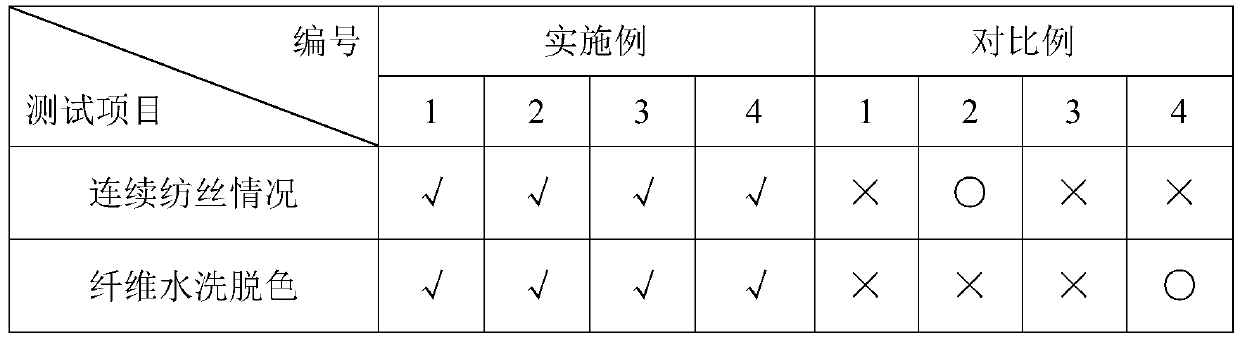

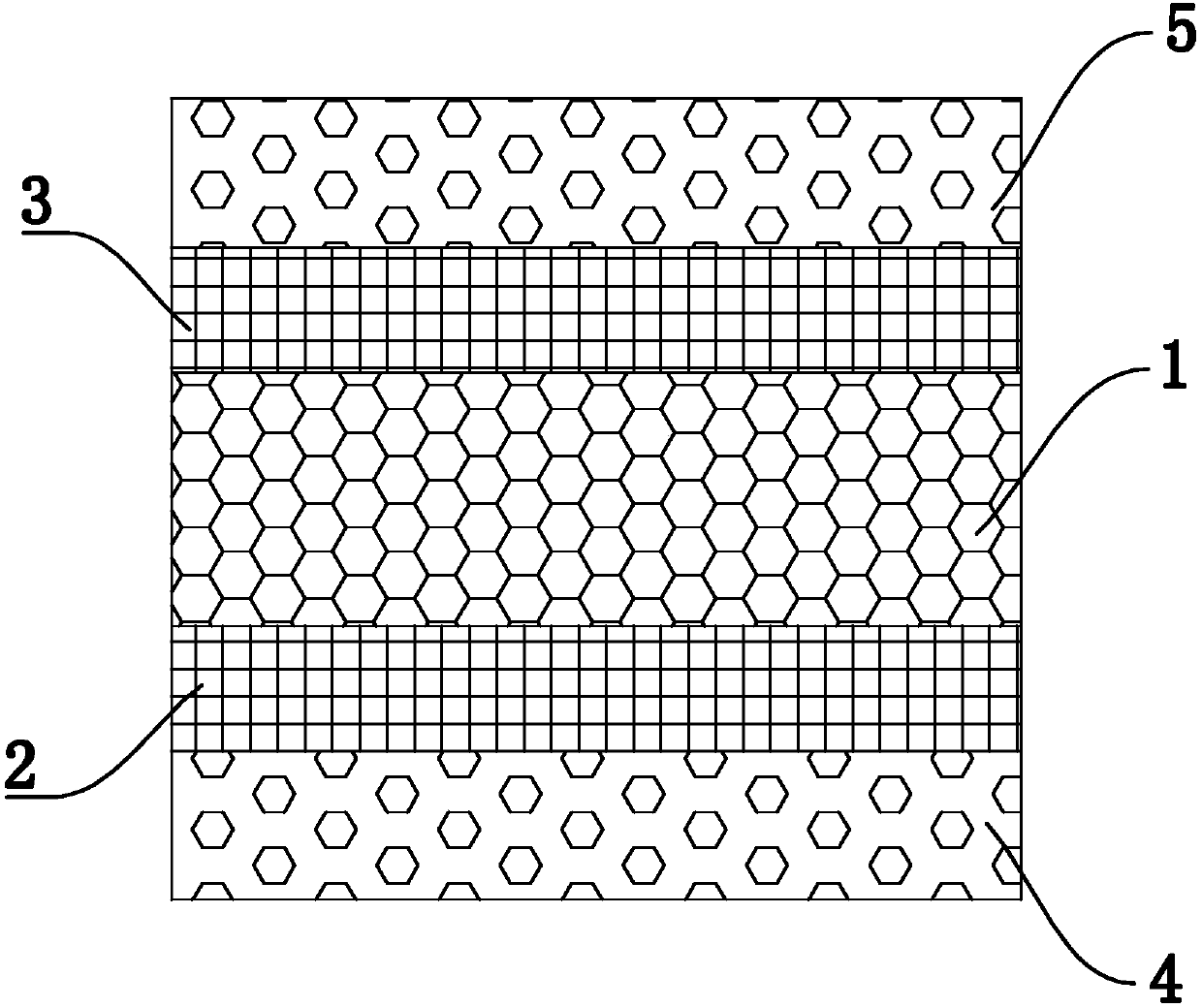

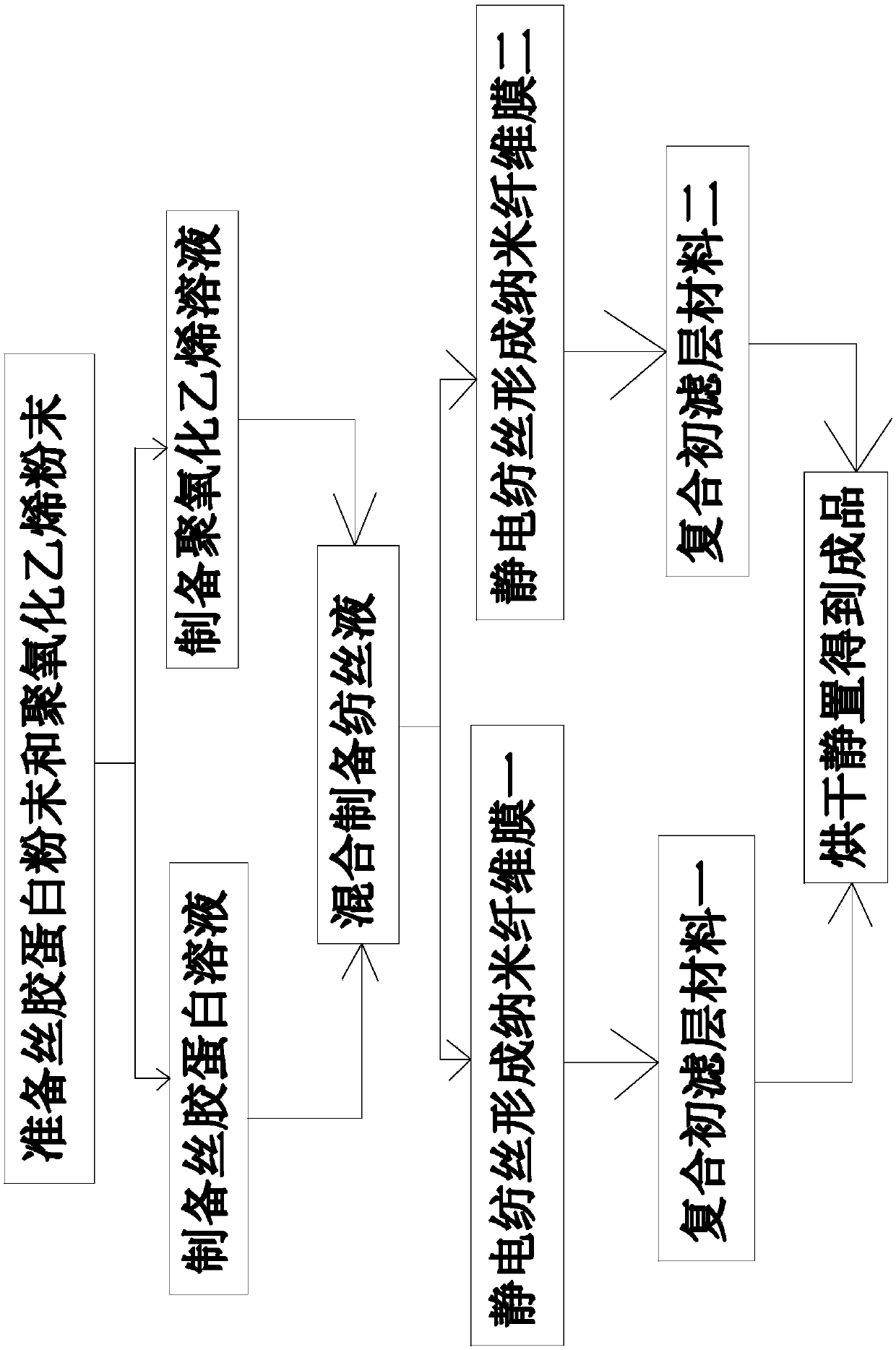

Preparation method of antibacterial nanofiber air filtering material

ActiveCN106476348AAntioxidantHas antibacterial propertiesLamination ancillary operationsSynthetic resin layered productsAir filterNanofiber

The invention provides a preparation method of an antibacterial nanofiber air filtering material. The preparation method comprises the following specific steps: (S1) preparing sericin powder and polyoxyethylene powder; (S2) dissolving the sericin powder in deionized water to form a sericin solution of different mass fraction; (S3) dissolving the polyoxyethylene powder in deionized water to form a polyoxyethylene solution of different mass fraction; (S4) mixing the sericin solution with the polyoxyethylene solution to form a spinning solution of different concentration; (S5) providing a base material, a primary filtering layer material I and a primary filtering layer material II; (S6) performing electrostatic spinning on the lower surface of the base material by an electrostatic spinning device to form a layer of nanofiber membrane I; (S7) performing electrostatic spinning on the upper surface of the base material by the electrostatic spinning device to form a layer of nanofiber membrane II; (S8) compounding the primary filtering layer material I on the surface of the nanofiber membrane I; (S9) compounding the primary filtering layer material II on the surface of the nanofiber membrane II: and (S10) drying and standing to obtain a finished product.

Owner:浙江坤孚智创科技有限公司

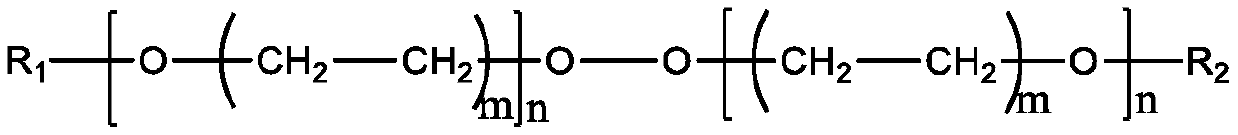

Color oil for ultra-high molecular weight polyethylene fiber and preparation method of color oil

InactiveCN109706534ADoes not fall offDo not migrateMonocomponent polyolefin artificial filamentPigment addition to spinning solutionPolymer scienceLiquid state

The invention discloses a preparation method of color oil for an ultra-high molecular weight polyethylene fiber. The method comprises the following steps that a) a dispersion agent with an anchoring structure is added to a polyethylene spinning solvent, dispersion is conducted for at least 0.1 h under the stirring state, a pigment with a modified surface is added for stirring, the mixed solution is placed for wetting, and a liquid-state color master pre-mixed solution is obtained; b) the liquid-state color master pre-mixed solution obtained in the step a) is subjected to high-speed dispersion,the temperature is controlled within 60-180 DEG C, free radical macromolecules and an initiator are added, and a modified liquid-state color master batch is obtained; c) the modified liquid-state color master batch obtained in the step b) is subjected to grinding dispersion or cutting dispersion, and the color oil for the polyethylene fiber is obtained. The fiber prepared through the color oil for the polyethylene fiber has the advantages that the fiber diameter is small, the color fastness and fastness to washing are high, and the pigment does not fall off or transfer.

Owner:SUZHOU SUNMUN TECH CO LTD

A kind of preparation method of antibacterial nanofiber air filter material

ActiveCN106476348BAntioxidantHas antibacterial propertiesLamination ancillary operationsSynthetic resin layered productsAir filterNanofiber

The invention provides a preparation method of an antibacterial nanofiber air filtering material. The preparation method comprises the following specific steps: (S1) preparing sericin powder and polyoxyethylene powder; (S2) dissolving the sericin powder in deionized water to form a sericin solution of different mass fraction; (S3) dissolving the polyoxyethylene powder in deionized water to form a polyoxyethylene solution of different mass fraction; (S4) mixing the sericin solution with the polyoxyethylene solution to form a spinning solution of different concentration; (S5) providing a base material, a primary filtering layer material I and a primary filtering layer material II; (S6) performing electrostatic spinning on the lower surface of the base material by an electrostatic spinning device to form a layer of nanofiber membrane I; (S7) performing electrostatic spinning on the upper surface of the base material by the electrostatic spinning device to form a layer of nanofiber membrane II; (S8) compounding the primary filtering layer material I on the surface of the nanofiber membrane I; (S9) compounding the primary filtering layer material II on the surface of the nanofiber membrane II: and (S10) drying and standing to obtain a finished product.

Owner:浙江坤孚智创科技有限公司

Non-woven fabric material and preparation method thereof

InactiveCN106003933AImprove performanceIncrease elasticityElectroconductive/antistatic filament manufactureFlame-proof filament manufactureNonwoven fabricAntibacterial property

The invention provides non-woven fabric. The non-woven fabric is prepared from the following components: 60-80 parts of polylactic acid, 20-30 parts of polyurethane, 10-20 parts of polyimide, 30-45 parts of chitosan, 5-10 parts of a flow modifier, 1-3 parts of alkyl sodium solfonate serving as an anti-static agent, 2-4 parts of epsilon-polylysine serving as an antibacterial agent and 3-6 parts of decabromodiphenyl serving as a flame retardant. The non-woven fabric is prepared with an electrostatic spinning method; four easy-to-degrade raw materials including polylactic acid, polyurethane, polyimide and chitosan are used for preparing a spinning solution, and the prepared non-woven fabric is bio-degradable and very environment-friendly; additionally, the non-woven fabric integrates functions of an antibacterial property, radiation protection, water repellency, static resistance and the like, can basically meet various medical demands and has a wide application range.

Owner:毛文明

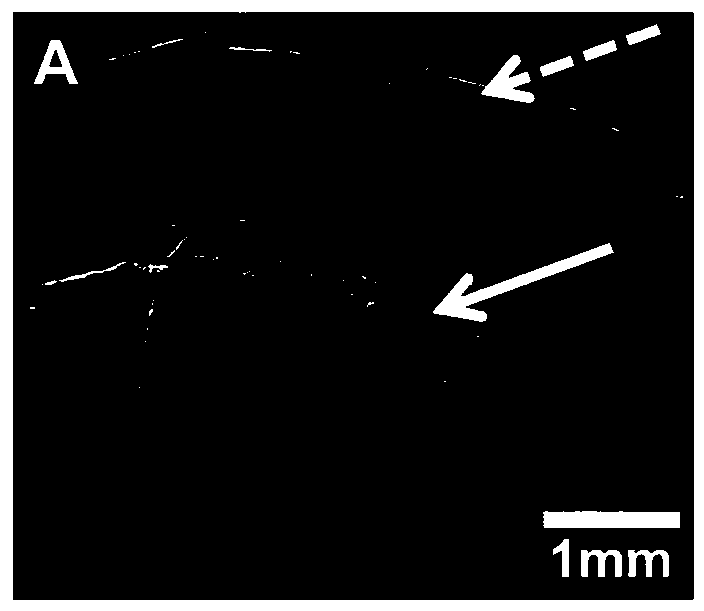

Leucocyte removal filter

ActiveUS9585997B2Good removal effectImprove permeabilityOther blood circulation devicesMembrane filtersWhite blood cellFiber diameter

Owner:KANEKA CORP

Superfine elastic non-woven fabric and preparation method thereof

ActiveCN110468505AClosely arrangedFine fiber diameterMonocomponent polyurethanes artificial filamentFilament/thread formingWoven fabricEngineering

The invention provides superfine elastic non-woven fabric prepared based on a plane-receiving centrifugal spinning device and a preparation method thereof.The preparation method is characterized in that polyurethane particles are dissolved in N,N-dimethylformamide to prepare a spinning solution, and then the spinning solution is injected into the plane-receiving centrifugal spinning device to perform centrifugal spinning.By reasonably setting the spinning parameters of centrifugal spinning, the spinning process is guaranteed to be smoothly carried out; the fiber diameter of the prepared superfine elastic non-woven fabric can reach 2.1+ / -1.1 mum; the arrangement is dense; the tensile strength can reach 18.59+ / -5.59 MPa; the elongation at break can reach 450+ / -20%; the method provided by theinvention is simple in operation process, suitable for large-scale mass production, and high in production efficiency.

Owner:WUHAN TEXTILE UNIV

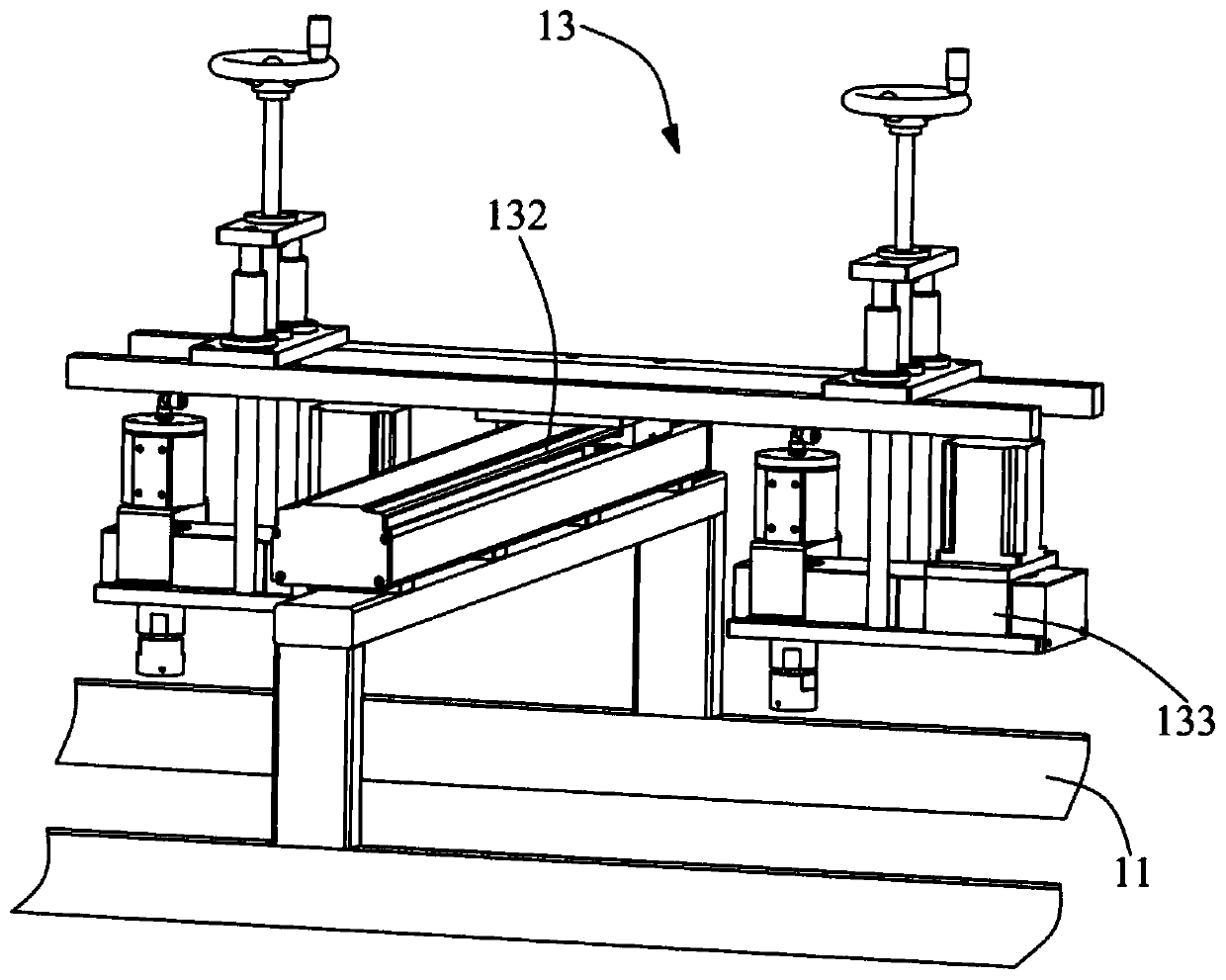

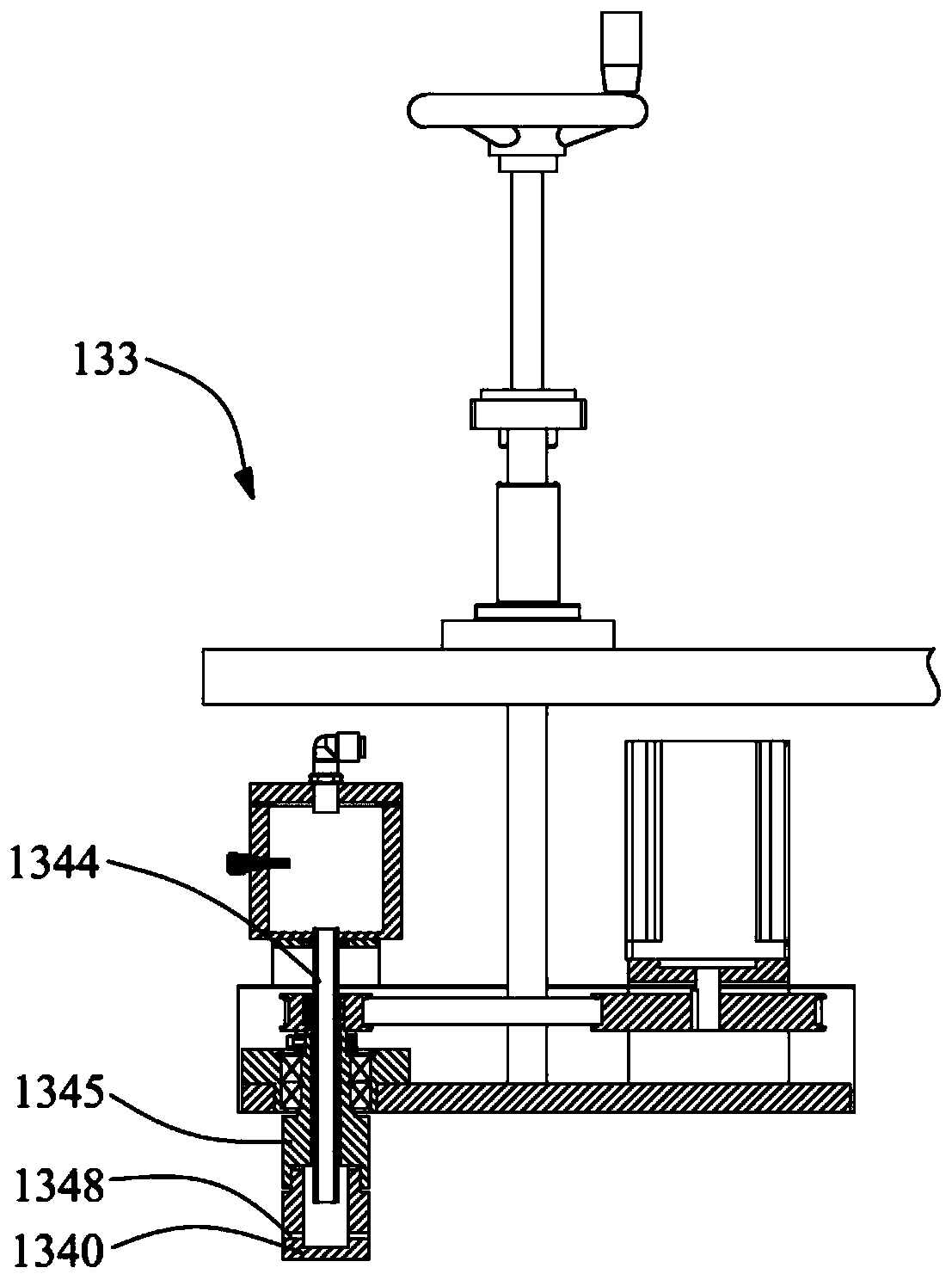

Manufacturing method of film split polytetrafluoroethylene fibers

ActiveCN102051703BWell mixedWeight optimizationFilament/thread formingMonocomponent halogenated hydrocarbon artificial filamentPre compressionHigh intensity

The invention aims to provide a manufacturing method of film split polytetrafluoroethylene fibers with high intensity, high uniformity and low production cost. A process comprises the following steps of: mixing polytetrafluoroethylene micro-powder and a lubricant; stirring; standing; performing pre-compression molding; performing press molding; performing calendaring molding; drying; cutting; performing primary hot stretching; performing secondary hot stretching; performing heat shaping; and winding so as to obtain high-intensity polytetrafluoroethylene fibers. In the manufacturing process, temperatures during drying, cutting, primary hot stretching, secondary hot stretching and heat shaping rise in turn.

Owner:ZHEJIANG HONGSHENG NEW MATERIAL TECH GRP CO LTD

Melt-blow oil absorption material

InactiveCN106245235AImprove melt indexLow proportional densityOther chemical processesNon-woven fabricsPorosityAbsorption saturation

The invention discloses a melt-blown oil-absorbing material, which is characterized in that the melt-blown fiber body includes two thermoplastic polymers, polystyrene and polypropylene, and the mass percentage of polystyrene and polypropylene is: polypropylene 70%~ 95%, polystyrene 5% to 30%. The melt-blown oil-absorbing material of the present invention has the characteristics of fine fiber diameter, fluffy structure, high porosity, and low density, and the crystallinity of the fiber is low, which greatly improves the oil absorption ratio and oil absorption rate of the product. The melt-blown oil-absorbing material of the present invention The oil absorption rate can be as high as 15.8g / g, and the absorption saturation can be reached within 4 minutes.

Owner:TIANJIN POLYTECHNIC UNIV

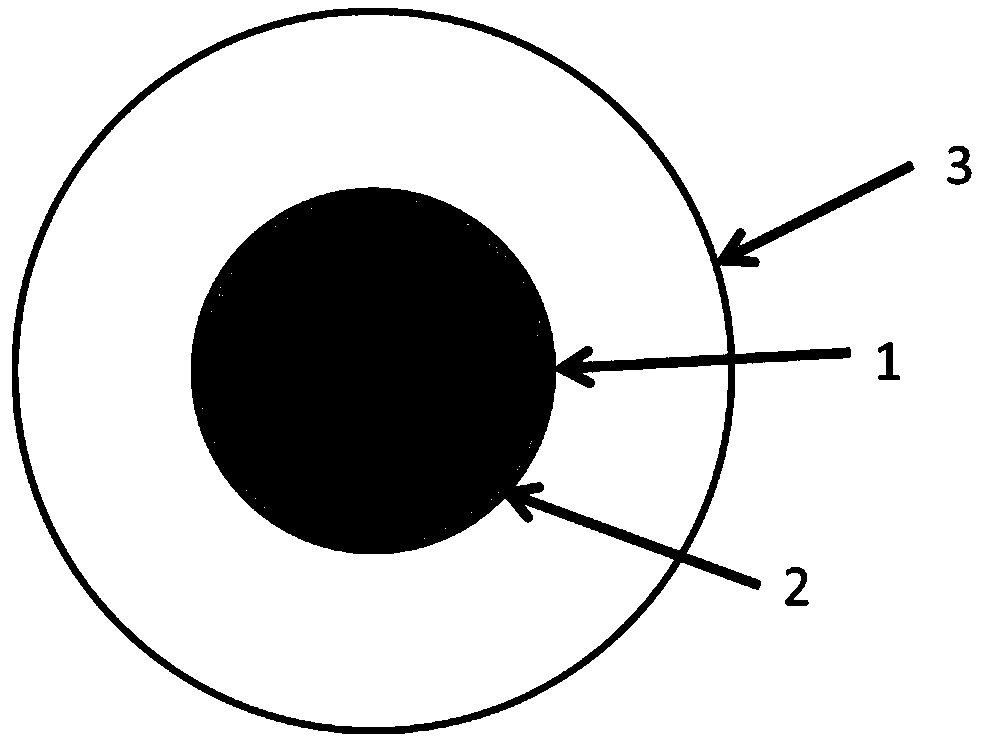

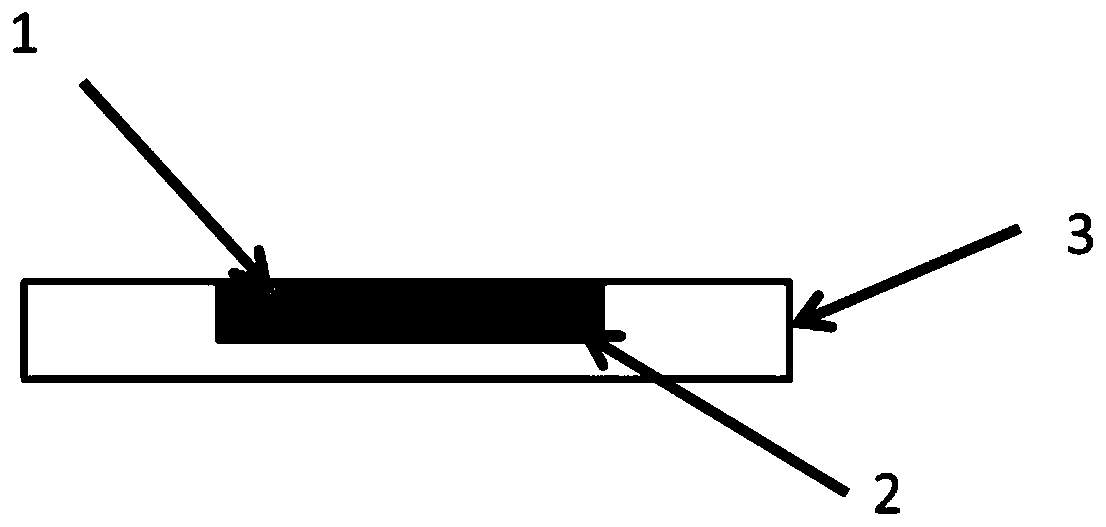

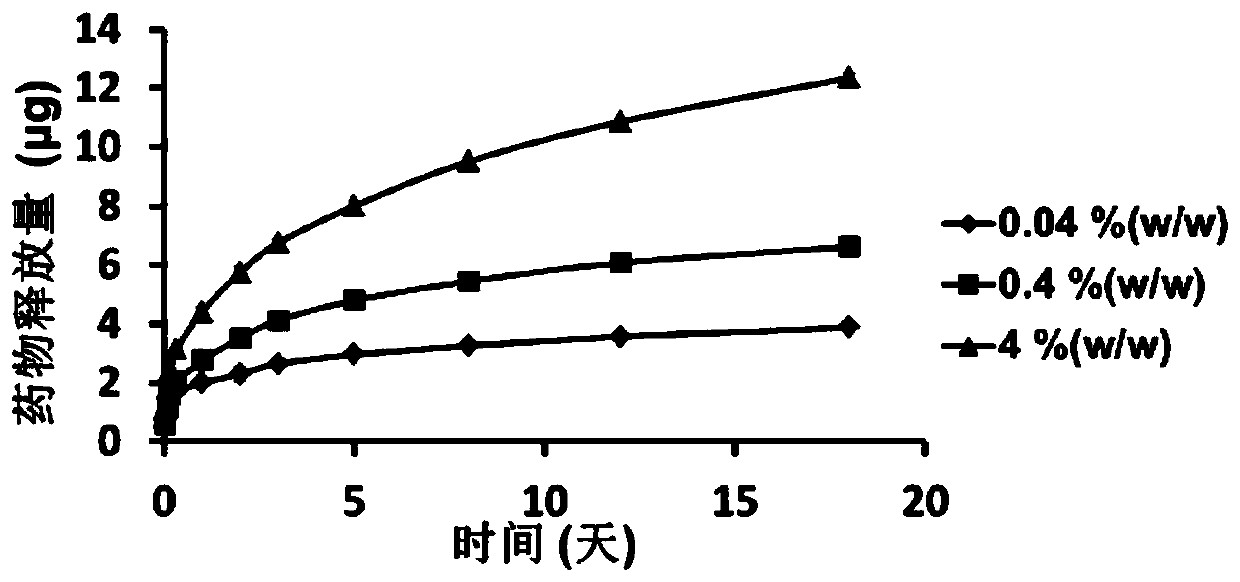

Double-layer composite drug-loading adhering patch and preparation method and application thereof

ActiveCN109908110ALarge specific surface areaHigh porosityAntipyreticAntisepticsPorosityTherapeutic effect

The invention discloses a double-layer composite drug-loading adhering patch and a preparation method and application thereof and belongs to the technical field of biological medical materials. The preparation method includes: mixing a burst-release drug with high polymer, mixing a sustained-release drug with high polymer, using electrostatic spinning equipment to prepare a burst-release drug layer and a sustained-release drug layer, and compositing the burst-release drug layer and the sustained-release drug layer with an adhering film to obtain the double-layer composite drug-loading adheringpatch. When the double-layer composite drug-loading adhering patch is used, the burst-release drug layer and the sustained-release drug layer can load different types of drugs to form gradient release so as to achieve an optimal curative effect. The double-layer composite drug-loading adhering patch has the advantages that a nanofiber membrane serving as the carrier is high in specific surface area, high in porosity, moisture-permeable and air-permeable, low in fiber diameter, capable of increasing drug loading quantity and the like, the high porosity is beneficial to cell growth and proliferation and can promote the fast healing of wounds, the moisture and air permeability can simulate the natural environment of a mucous membrane or the skin and is beneficial to the neogenesis cell growth of the wounds, and the low fiber diameter can provide more growth loci for the cells and can accelerate wound healing.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Antibacterial handmade washing soap and preparing method thereof

InactiveCN108048264AImprove surface activityFine fiber diameterBiocideSurface-active non-soap compounds and soap mixture detergentsMolecular sieveRoom temperature

The invention discloses antibacterial handmade washing soap. The soap comprises nanometer titania, negative ion antibacterial agent, molecular sieve, grease, surface active agent, sodium hydroxide andwater. The invention further provides a preparing method of the antibacterial handmade washing soap. The method includes the following steps of evenly mixing sodium hydroxide and water, adding the grease to be saponified to prepare a saponification solution, adding the surface active agent to the saponification solution to be evenly mixed, adding nanometer titania, the negative ion antibacterialagent and the molecular sieve to be evenly mixed, adding the mixture into a mold to be standing and be solidified at the room temperature, conducting demolding, and placing the soap in a ventilating and dry place to be aired to prepare the antibacterial handmade washing soap. The prepared handmade washing soap is excellent in antibacterial and decontamination effect and simple in preparation process.

Owner:跨越生物科技(滁州)有限公司

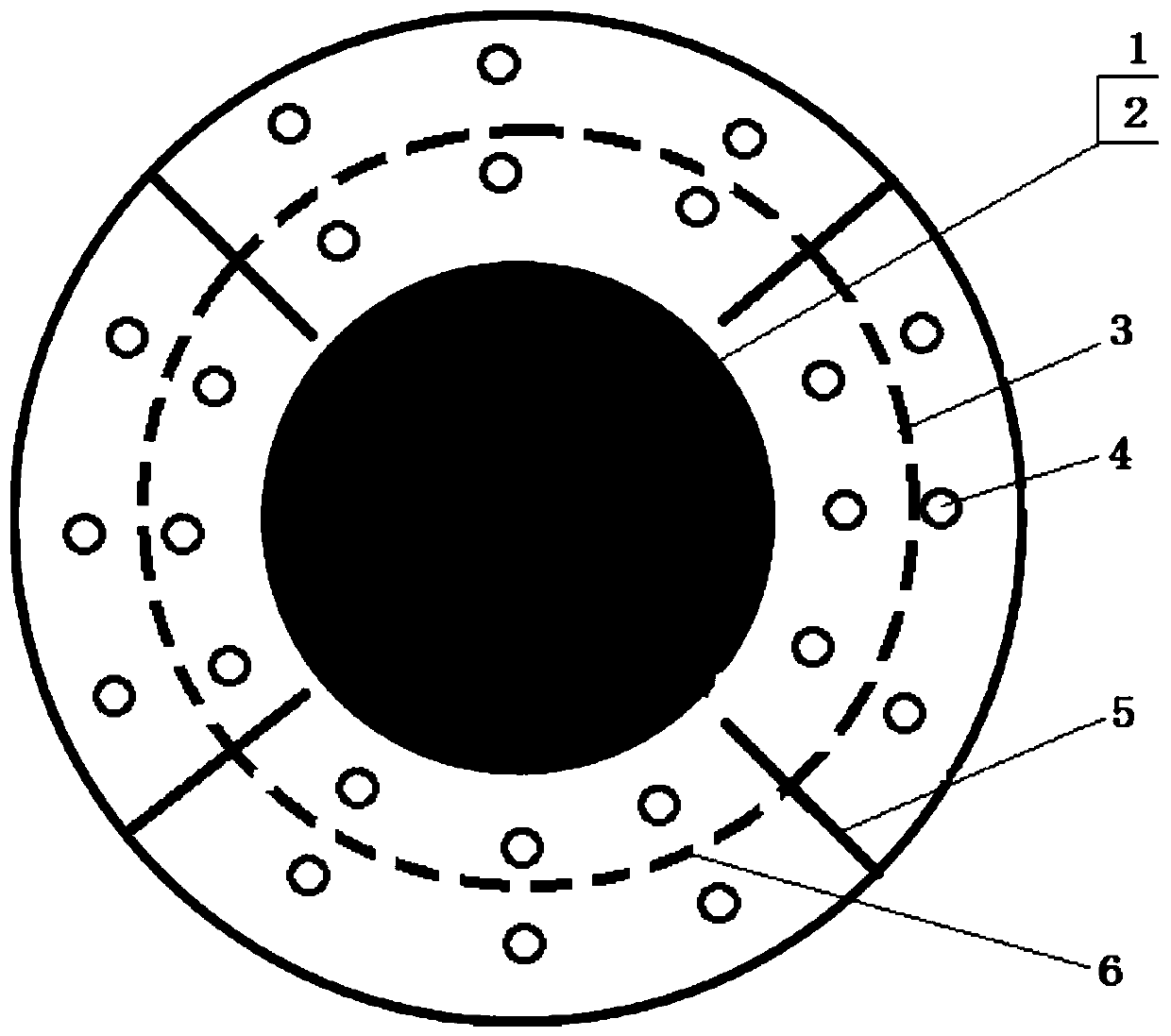

A novel needle-free electrospinning device and spinning method thereof

The invention relates to a novel needleless electrospinning device and a spinning method thereof. The novel needleless electrospinning device includes a spinning liquid storage unit, a spinning forming unit and a spinning collecting unit, wherein the spinning forming unit includes a spinning liquid cavity, a charged electrode, a spinning slit, an intermediate electrode and an air flow passage, thecollecting unit includes a collecting electrode board, a first electrostatic field is formed between the charged electrode and the collecting electrode board, a second electrostatic field is formed between the charged electrode and the intermediate electrode, the spun fiber is ejected by the spinning solution in the spinning solution cavity through the spinning slit under the action of the secondelectrostatic field, and the spun fiber is collected to the collecting electrode board under the guide action of the air flow passage and the action of the first electric field. The needleless electrospinning device is advantaged in that electrospinning having properties of high uniformity, more yield, longer range and finer fiber diameters can be provided.

Owner:江苏纳纤新材料科技有限公司

Double-layer nanofiber membrane composite drug-carrying adhesive patch and preparation method thereof

The invention discloses a double-layer nanofiber membrane composite drug-carrying adhesive patch and a preparation method thereof and belongs to the technical field of medical and biomedical materials. A burst release medicament layer, a slow release medicament layer and an adhesive film of the nanofiber membrane structure are compounded, the burst release medicament layer and the slow release medicament layer can load different types of medicaments, reasonable distribution is carried out according to wound conditions, gradient release is formed, and the optimal treatment effect is achieved. The nanofiber membrane serving as a carrier has the advantages of being high in specific surface area, high in porosity, moisture-permeable, breathable, fine in fiber diameter and the like, can increase the loading amount of drugs, is high in porosity and beneficial to growth and proliferation of cells, promotes rapid healing of a wound surface, can simulate the natural environment of mucosa or skin through moisture-permeable, is beneficial to growth of new cells of the wound surface, can provide more growth sites for the cells through fine fiber diameter and can accelerate wound surface repair.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Inorganic fiber using fly ash as main raw material and manufacturing method thereof

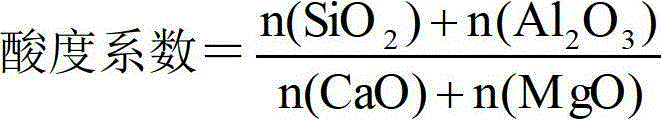

ActiveCN103539361BImprove water resistanceIncreased durabilityGlass making apparatusBasaniteThermal insulation

The invention discloses an inorganic fiber with coal ash as a main raw material and a manufacturing method of the inorganic fiber. A residue obtained after the inorganic fiber taking the coal ash as the main raw material is fired at the temperature of 550 DEG C for 30min contains the following components in percentage by weight: 39.0-48.0% of SiO2, 10.0-20.0% of Al2O3, 20.0-28.0% of CaO, 2.5-10.5% of Fe2O3, 3.5-10.5% of MgO, 0.2-2% of Na2O, 0.2-2.0% of K2O and 0.2-2.5% of TiO2. The inorganic fiber disclosed by the invention has favorable water resistance and durability, a relatively high acidity coefficient, relatively low shot content, a relatively small fiber diameter, very high tensile strength and a relatively low heat conductivity coefficient, can be used as a sound absorption material, a thermal insulation material and the like and can be used for completely replacing a rock wool board thermal insulation material made of a basalt fiber in the prior art.

Owner:ZHEJIANG XUANMING NEW MATERIALS +1

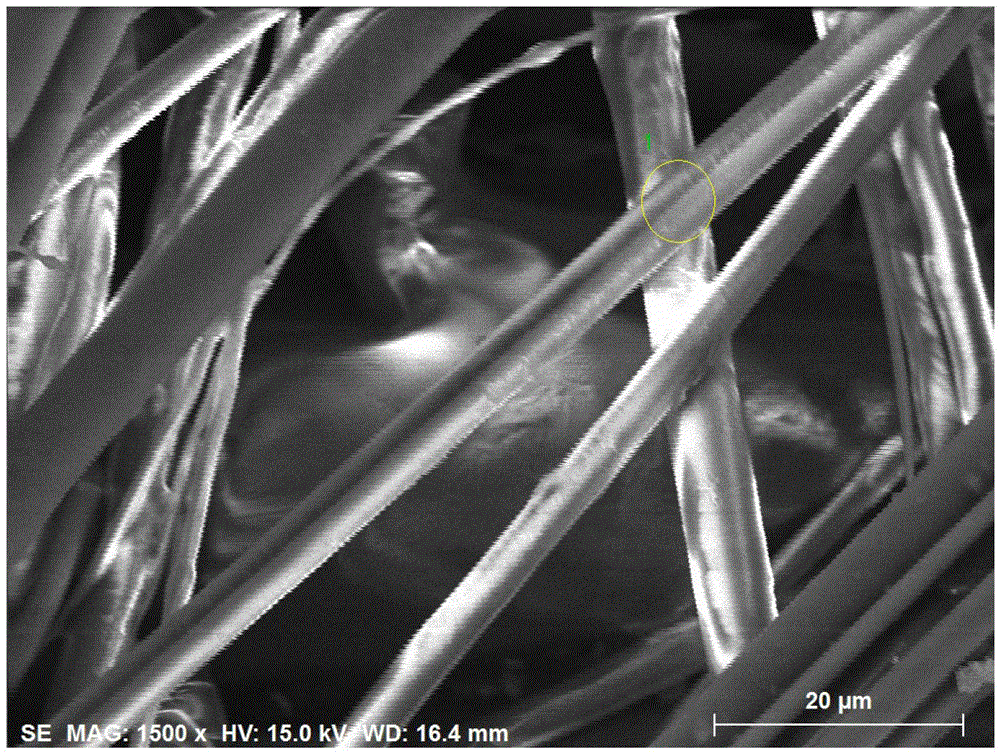

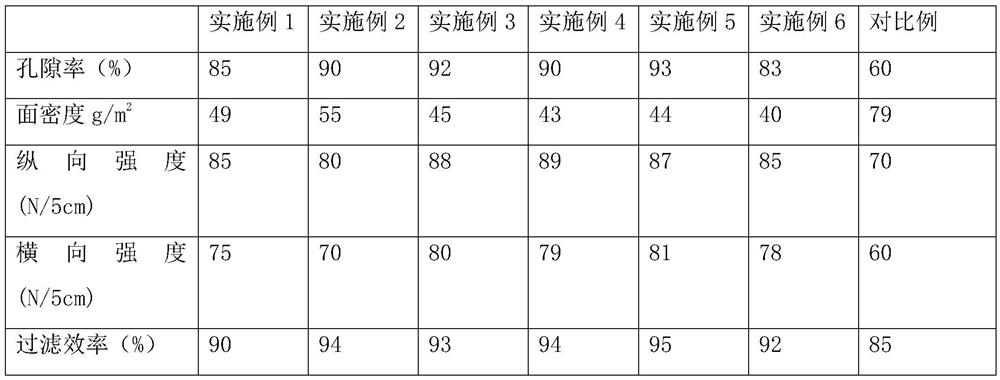

A kind of preparation method of superfine fiber non-woven filter material

ActiveCN112709004BSmall diameterFine fiber diameterFilament/thread formingFiltration separationFilter materialMaterials science

The invention discloses a method for preparing an ultrafine fiber nonwoven filter material and the ultrafine fiber nonwoven filter material prepared by the method. The invention uses magnetic force to split the ultrafine fiber original filaments. Alternating electromagnetic fields are arranged on both sides of the traveling route of the ultrafine fiber, and the direction of the magnetic field force on both sides of any point in the traveling direction of the ultrafine fiber original silk is opposite. The fine fiber raw silk can be fully and completely split into several independent superfine fibers combined with the subsequent beating process, which can make the splitting of the superfine fibers more complete, and the composition of the superfine fibers in the finally obtained nonwoven fiber web reaches more than 80%. , among them, the thicker raw silk fiber provides higher strength, and the finer superfine fiber provides excellent filtering effect, which not only ensures that the fiber mesh has sufficient strength as a filtering material, but also ensures that it has a good filtering effect .

Owner:LIANYUNGANG ARK IND

A kind of electrode material made of waste fiber and its manufacturing method

ActiveCN103474125BImprove efficiencyLow costCell electrodesCarbon-silicon compound conductorsElectrochemical responsePolymer science

The invention provides an electrode material made of waste fibers and belongs to the field of electrode materials applied to electrochemical reaction. The electrode material made of the waste fibers comprises basic materials, wherein the basic materials are fiber materials which are formed by carbonization of the waste fibers after the waste fibers are burnt at a high temperature, the waste fibers are burnt at the high temperature in a vacuum furnace or under the protection of the inert atmosphere, surface treatment is carried out finally, and the basic materials are formed by one or more of polypropylene cyanide fibers, pitch fibers, viscose, pre-oxidized fibers, phenolic fibers, carbon fibers, graphite fibers, wood fibers and cotton fibers. According to the electrode materials made of the waste fibers, due to the fact that the waste fibers are used, cost is reduced, benefit of an enterprise is improved, the competiveness of products is improved, and the electrode material is high in conductivity and high in electrochemical activity.

Owner:SHANGHAI QI JIE CARBON MATERIALS

Energy storage device and ionic conducting composition for use therein

ActiveUS11264614B2Fine fiber diameterAvoid formingCell seperators/membranes/diaphragms/spacersAluminium silicatesChemical physicsAlkaline earth metal

The present invention relates to an energy storage device comprising a silicate comprises a formula:MvM1wM2xSiyOz whereM is selected from the group consisting of Li, Na, K, Al, and MgM1 is selected from the group consisting of alkaline metals, alkaline earth metals, Ti, Mn, Fe, La, Zr, Ce, Ta, Nb, V and combinations thereof;M2 is selected from the group consisting of B, Al, Ga, Ge or combinations thereof;v, y and z are greater than 0;w and / or x is greater than 0;y≥x; andwherein MvM1wM2xSiyOz accounts for at least 90 wt % of the composition.

Owner:THERMAL CERAMICS UK

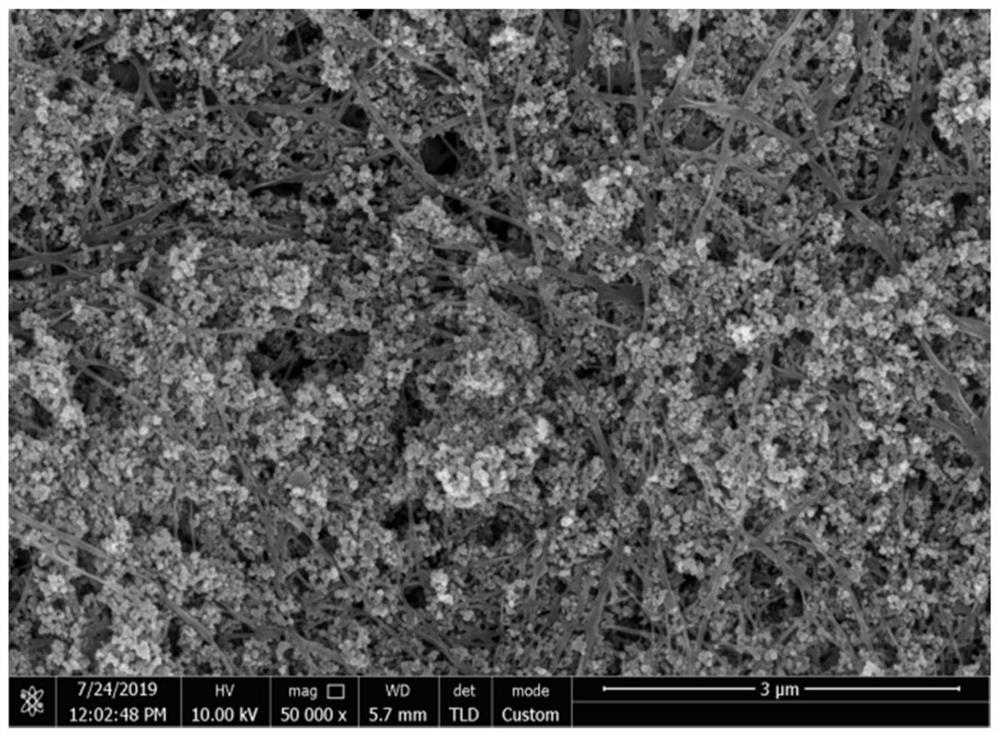

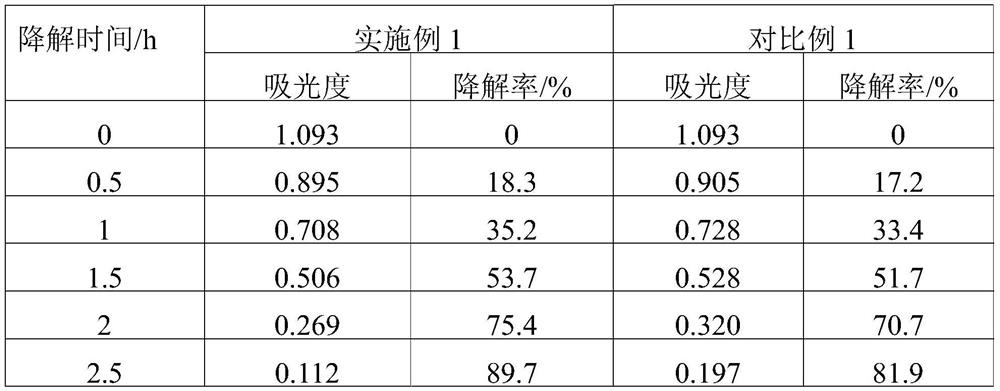

Photocatalytic nano composite material as well as preparation method and application thereof

ActiveCN112371174AImprove photocatalytic performanceImprove stabilityWater/sewage treatment by irradiationWater treatment compoundsActive agentSurface-active agents

The invention discloses a photocatalytic nano composite material as well as a preparation method and application thereof. The preparation method of the photocatalytic nano composite material comprisesthe following steps of: sequentially adding reduced graphene oxide, bacterial cellulose and a nano titanium oxide precursor into a mixed solution of a cosurfactant and a surfactant, mixing, adjustingthe pH value of the system to 7-9, and reacting to obtain the photocatalytic nano composite material BC-TiO2-RGO. The efficient photocatalytic nano composite material prepared by the invention has excellent photocatalytic performance and photocatalytic stability, has ideal photocatalytic degradability on printing and dyeing wastewater, is high in degradation efficiency and relatively high in reutilization degree and recovery rate, and has an ideal effect and does not affect the recycling of printing and dyeing wastewater when being used for treating printing and dyeing wastewater.

Owner:上海伊纯实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com