Patents

Literature

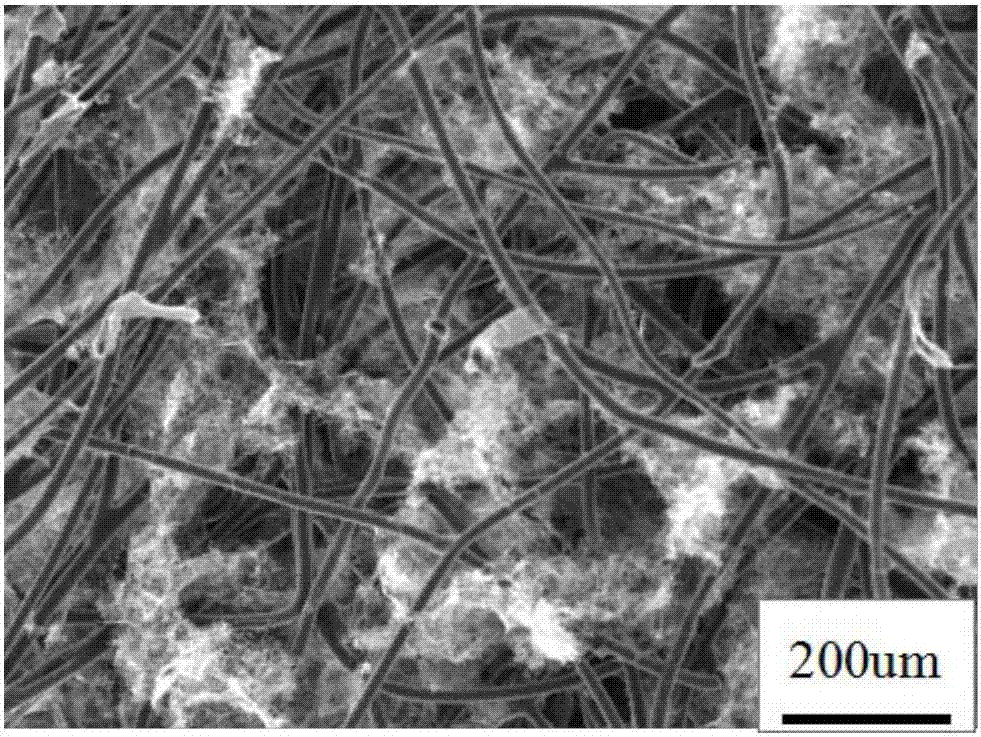

39results about How to "Reduced resistance pressure drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light-transmitting, breathable and static electricity repellent PM2.5 air filter membrane and preparation method thereof

ActiveCN104906970AHigh retention rateReduced resistance pressure dropSemi-permeable membranesFibre treatmentAir filterEngineering

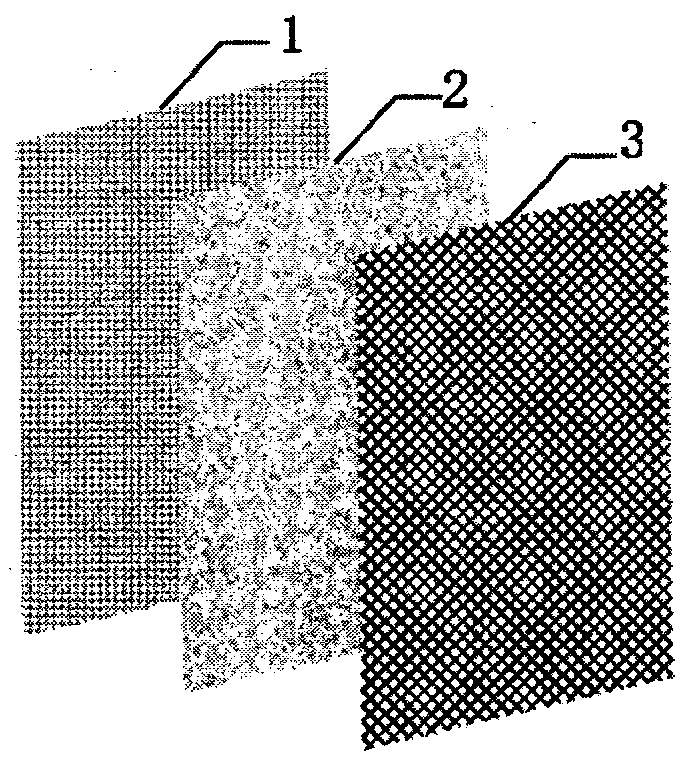

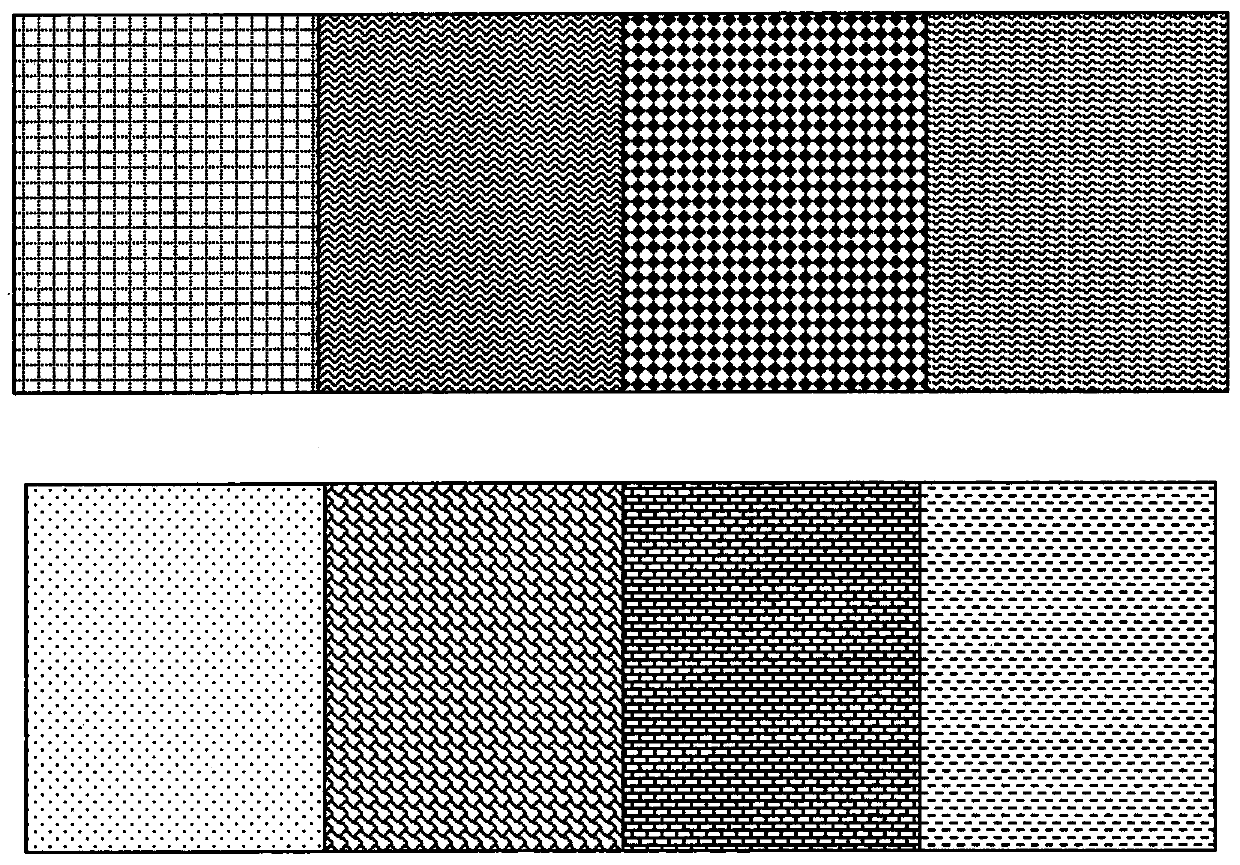

The invention discloses a light-transmitting, breathable and static electricity repellent PM2.5 air filter membrane and the preparation method thereof. The air filter membrane is characterized by being provided with at least one layer of non-woven fabric base material or screen net and at least one layer of ultrathin electrostatic spinning nano fiber layer. The preparation method comprises the steps of impregnating the non-woven fabric base material, the screen net or the ultrathin electrostatic spinning nano fiber layer in a tourmaline nano-particle containing suspension or spraying the tourmaline-containing nano particle suspension on the on-woven fabric base material, the screen net or the ultrathin electrostatic spinning nano fiber layer and drying, wherein the mass percentage of tourmaline nano particles in the suspension is 1-30%, the suspension further comprises a bonding agent, so that the tourmaline nano particles can be wrapped on the surface of the non-woven fabric base material, the screen net or the ultrathin electrostatic spinning nano fiber layer. The air filter membrane applied in a window screen is prepared by adopting the nano fiber technique and electrostatic repulsion and fine particulate matter PM2.5 is guaranteed to be blocked outside when a window is opened for ventilation.

Owner:上海展恒环保科技有限公司

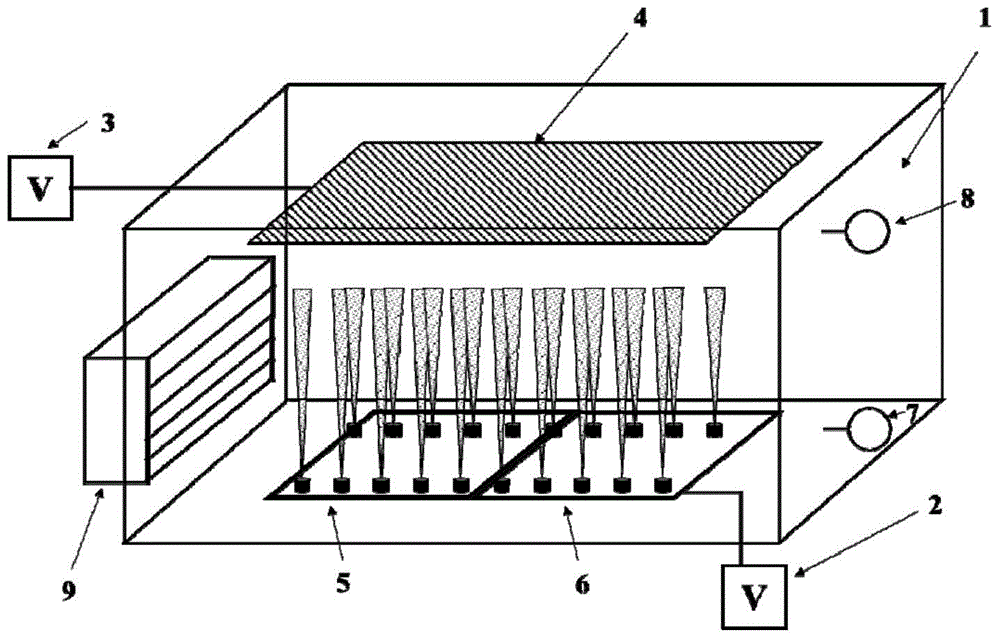

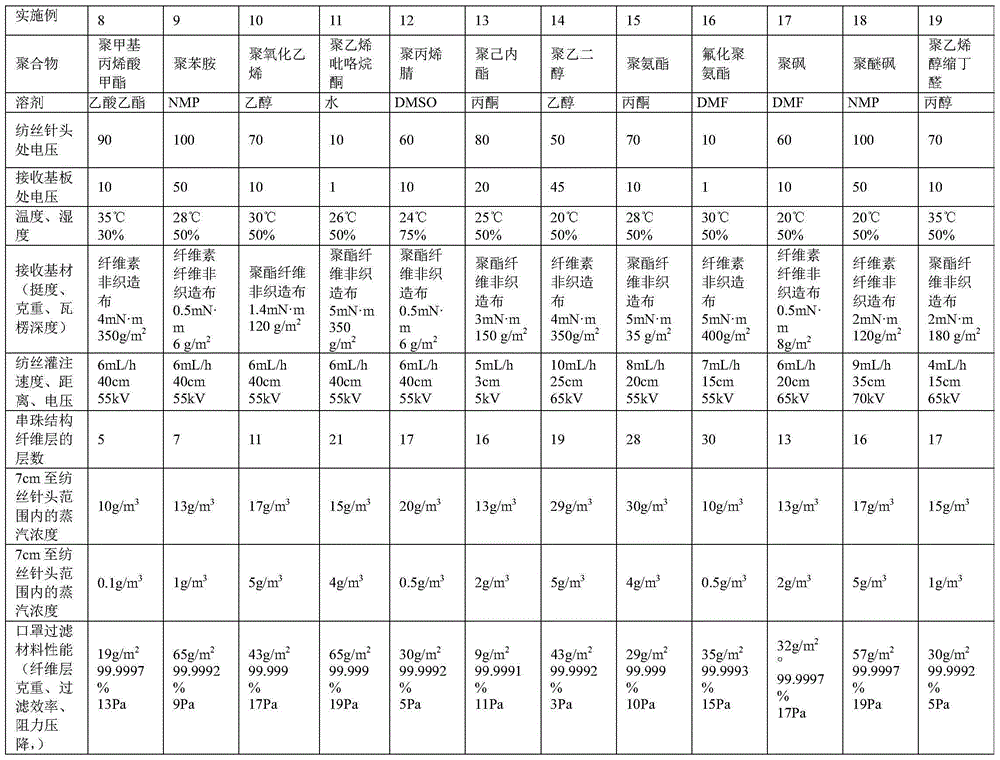

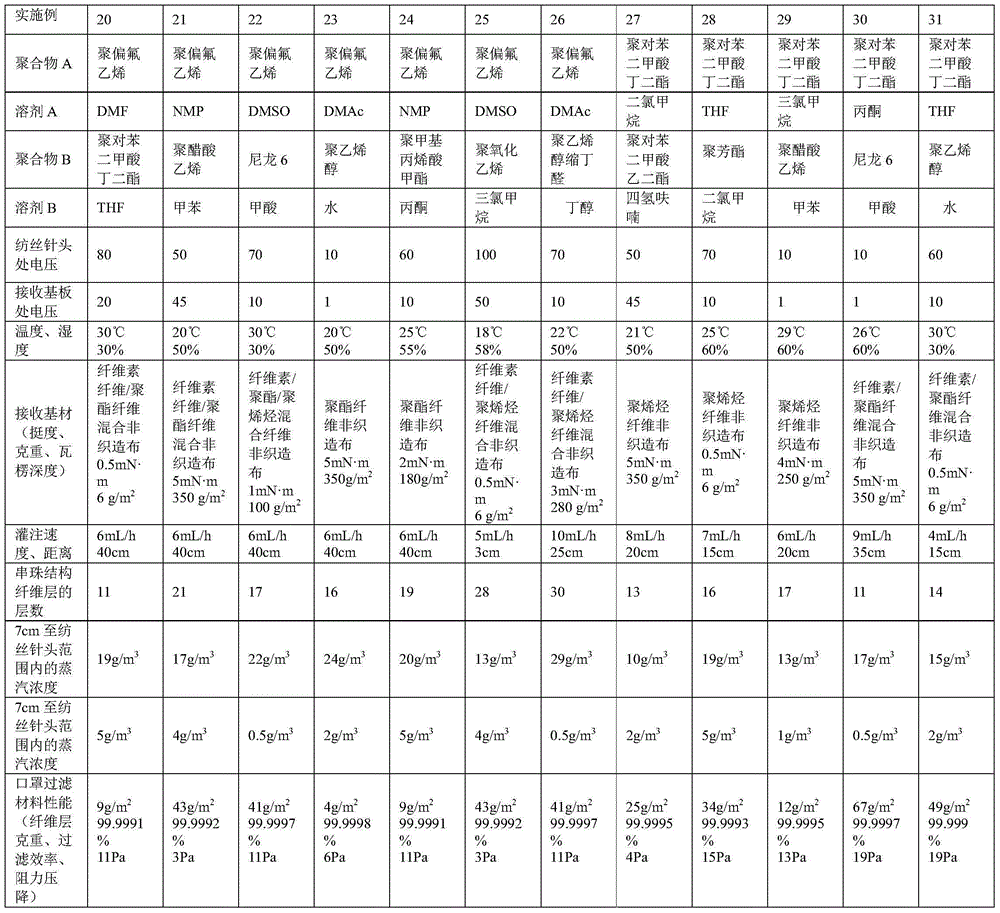

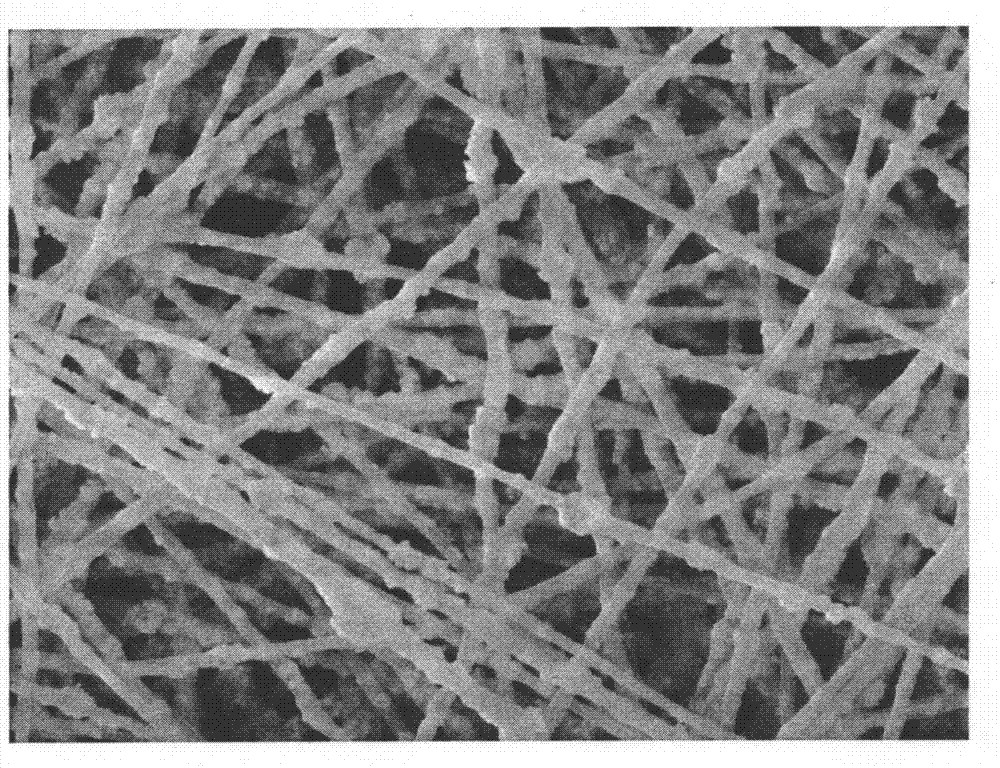

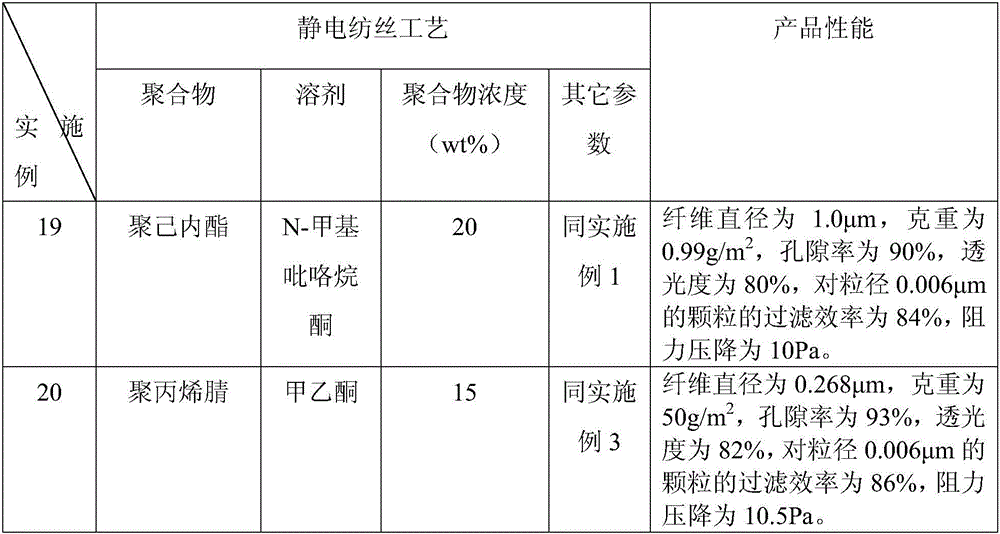

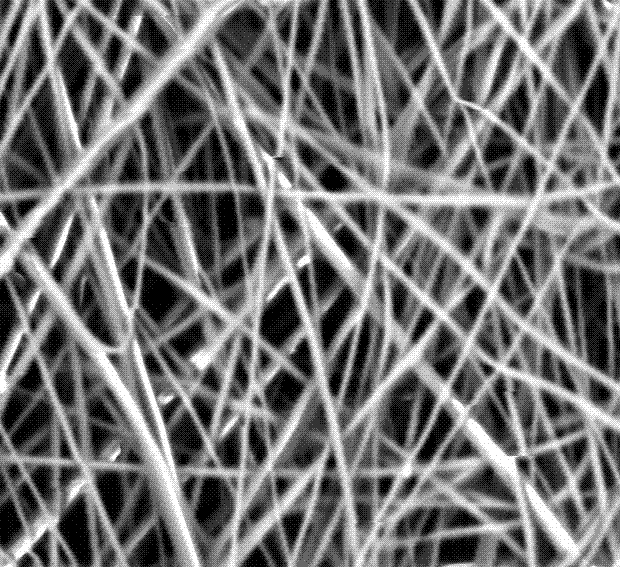

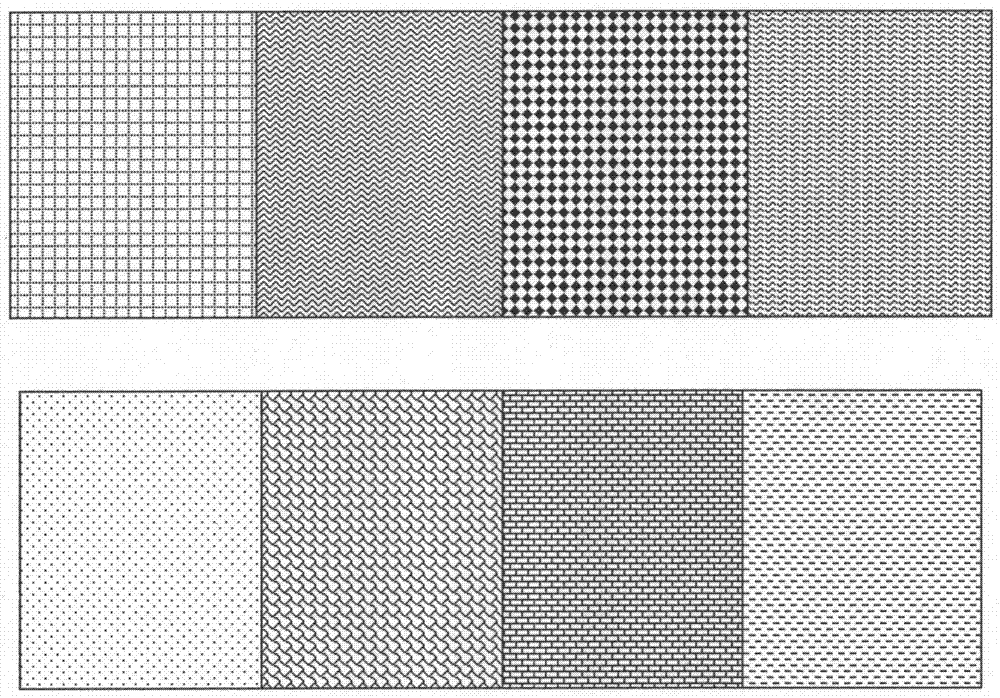

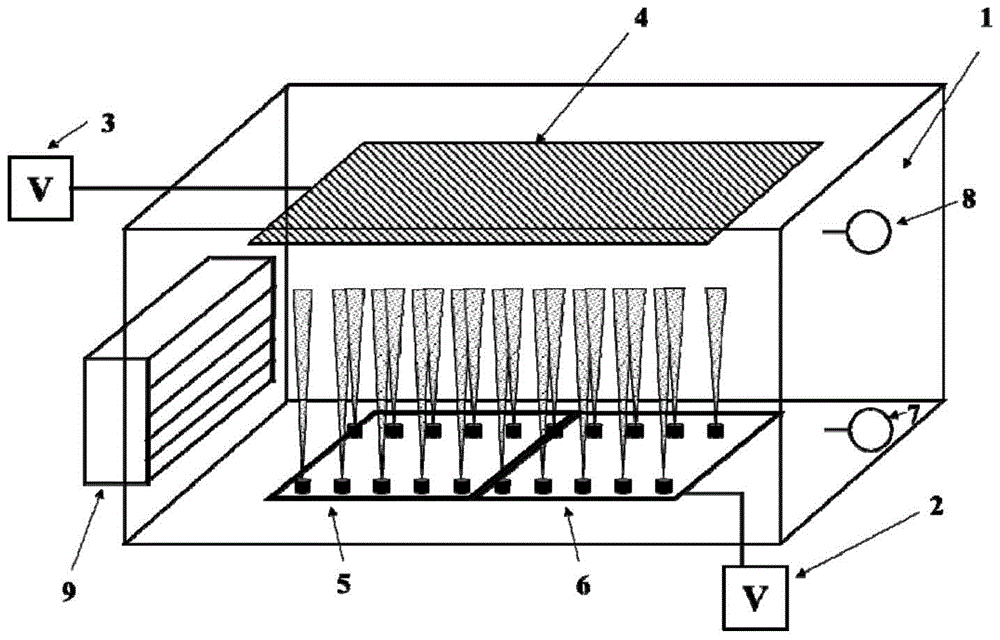

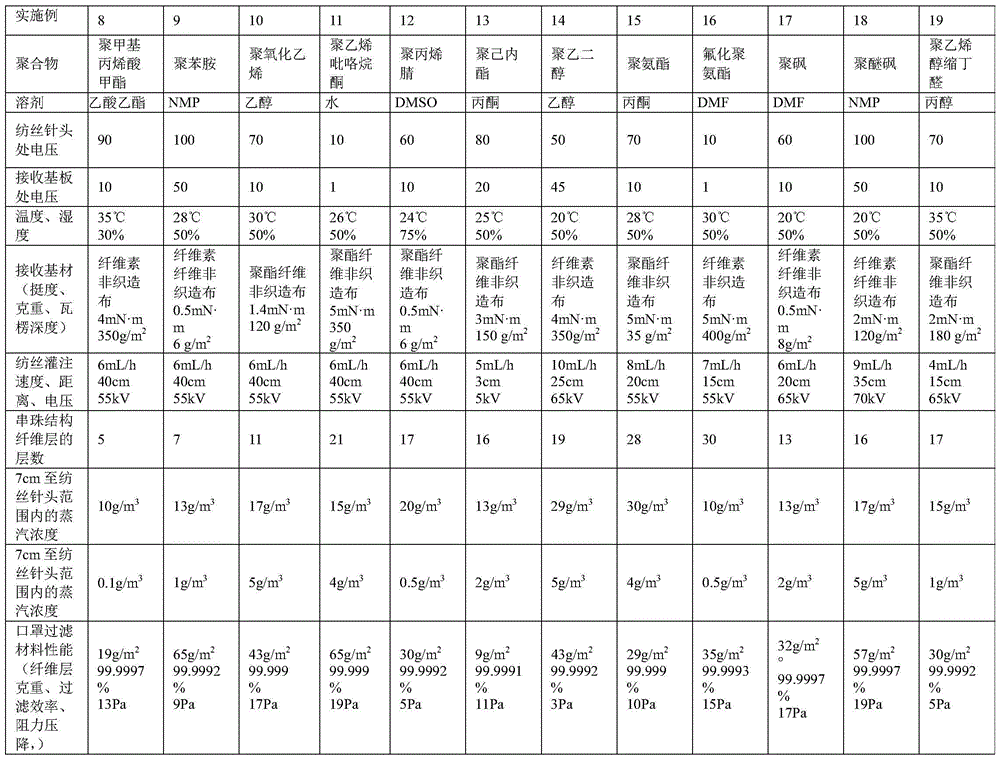

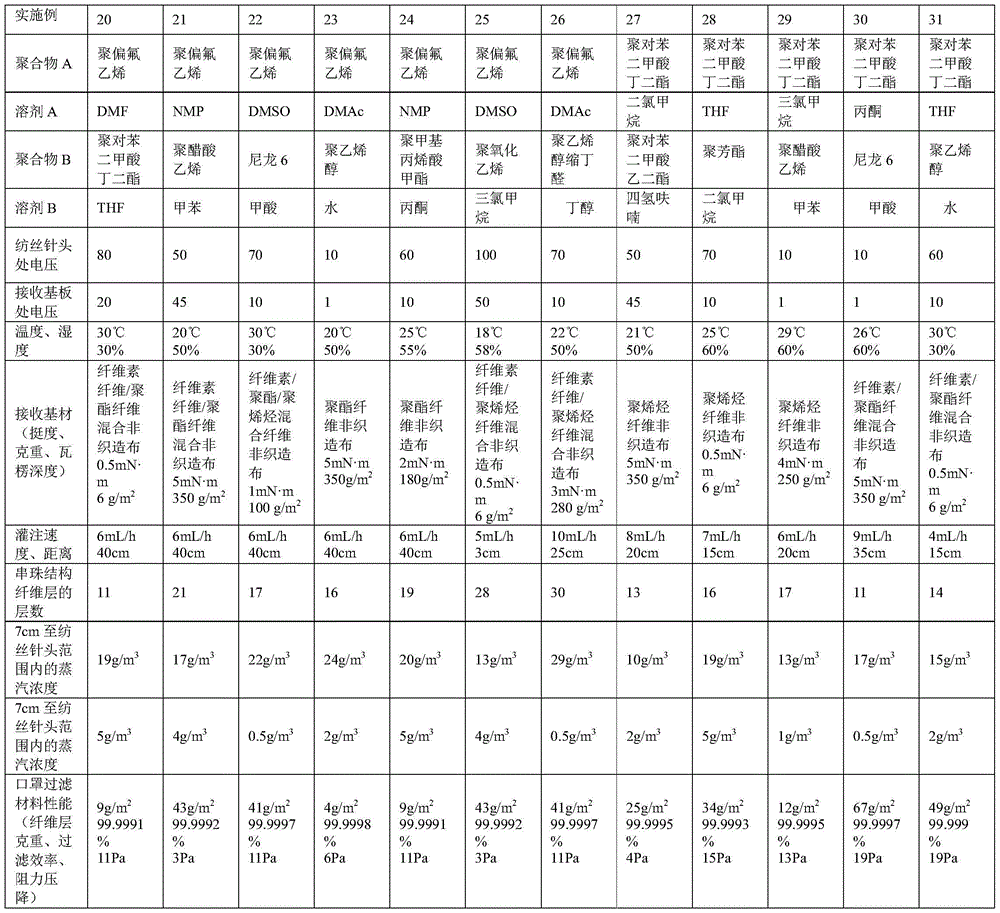

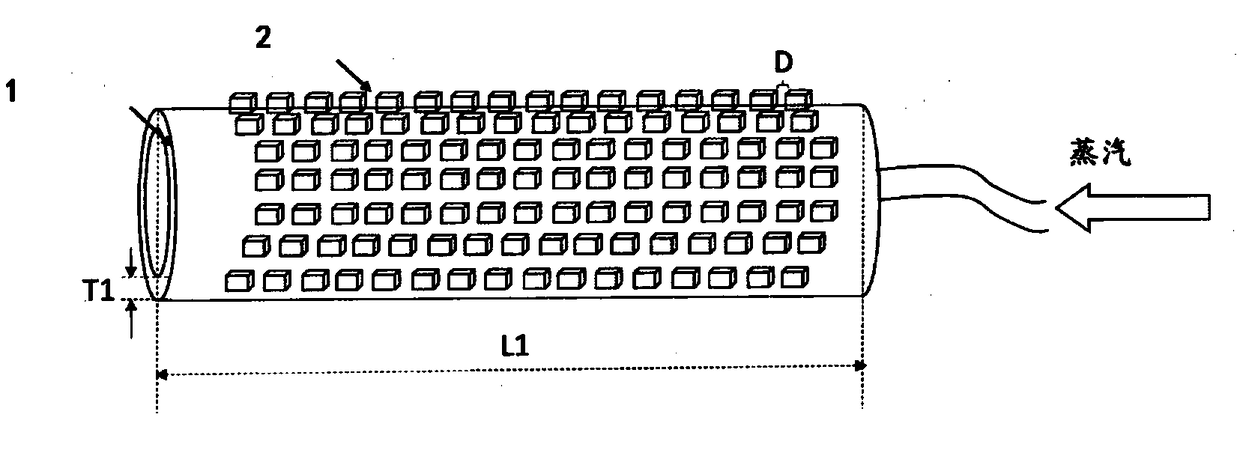

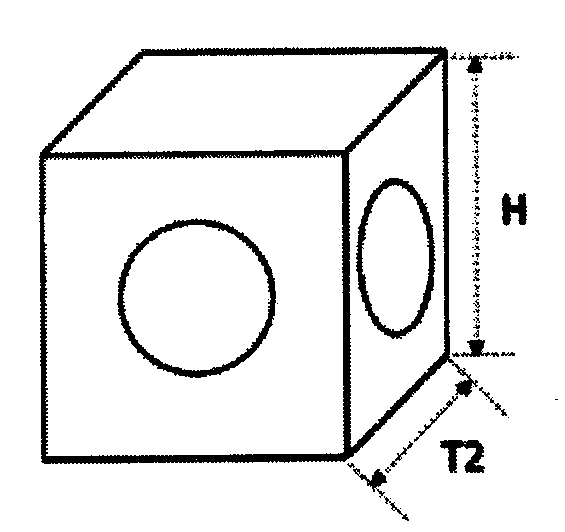

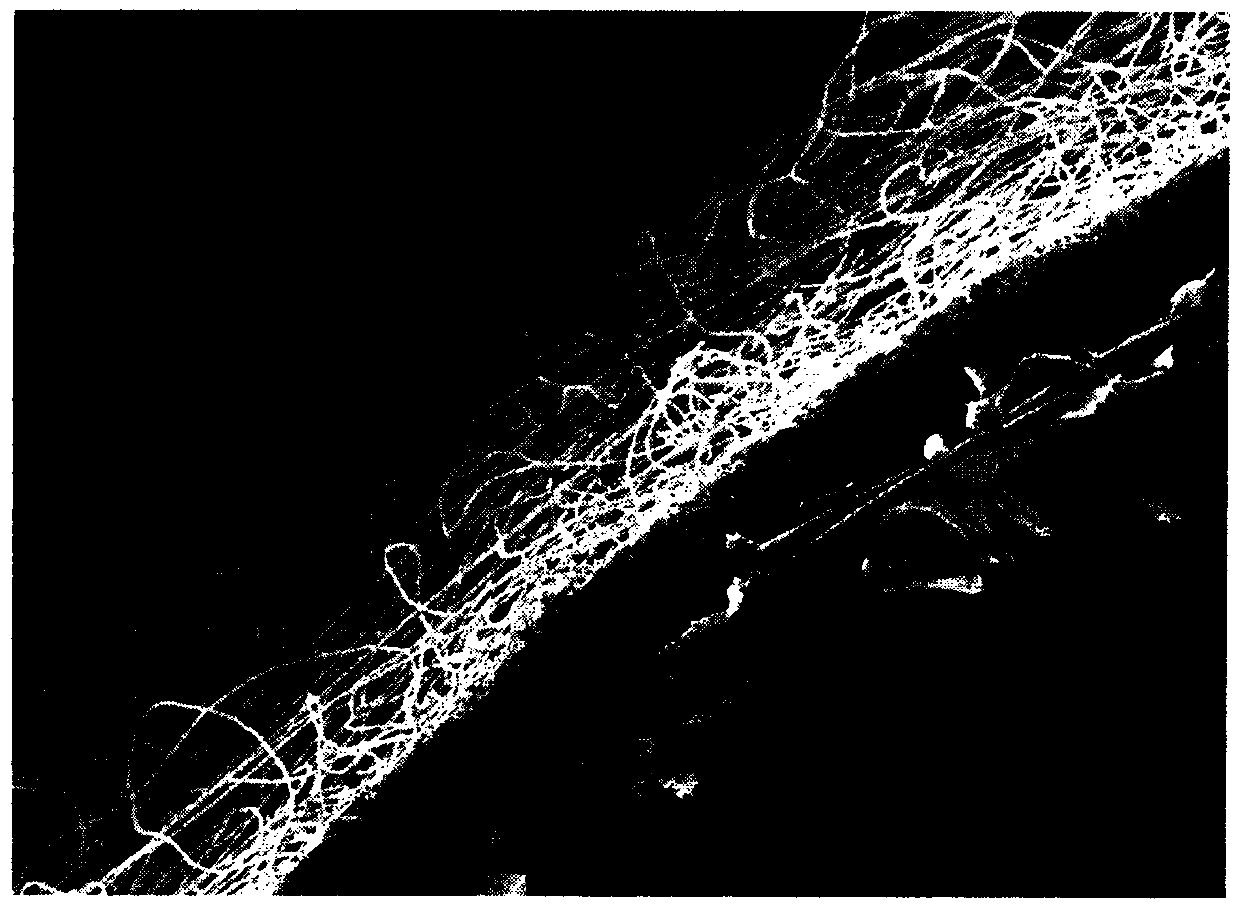

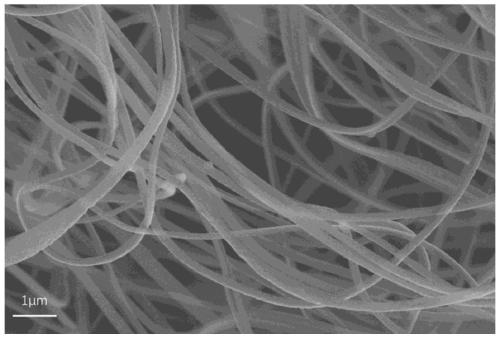

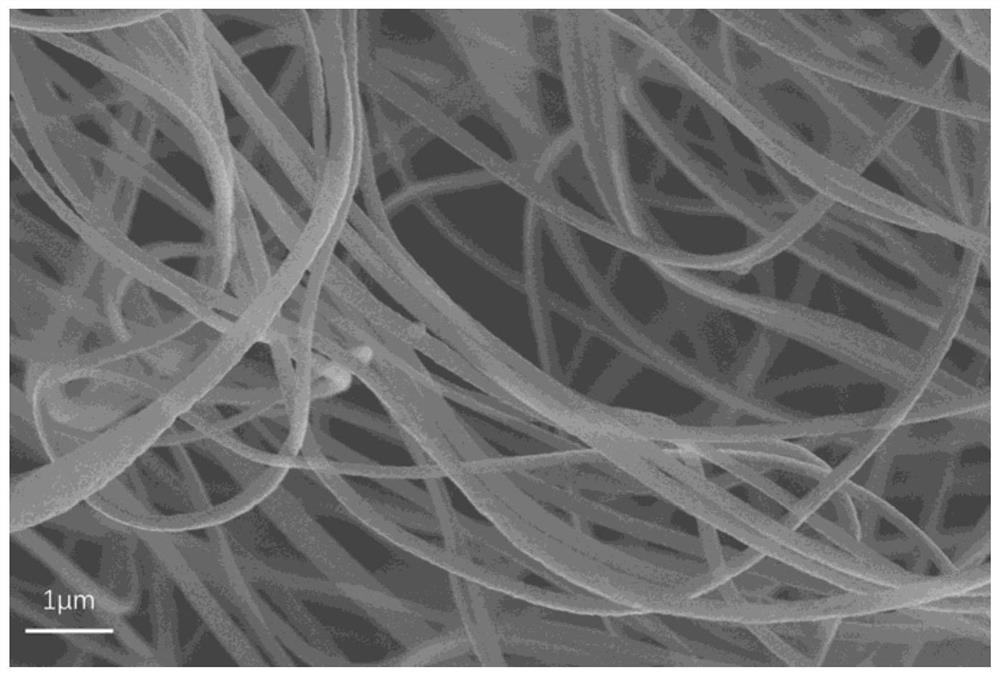

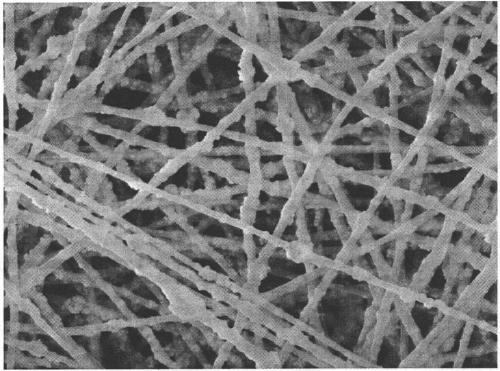

High-efficiency and low-resistance nanofiber air filtering material for gauze mask and preparation method of filtering material

ActiveCN104645715ANo adhesionFluffy structureFiltration separationProtective garmentComposite nanofibersAir filter

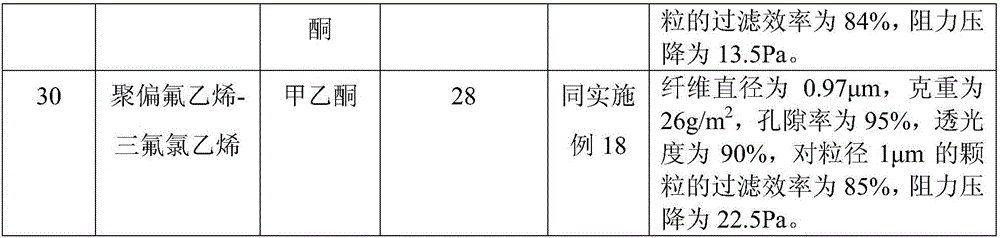

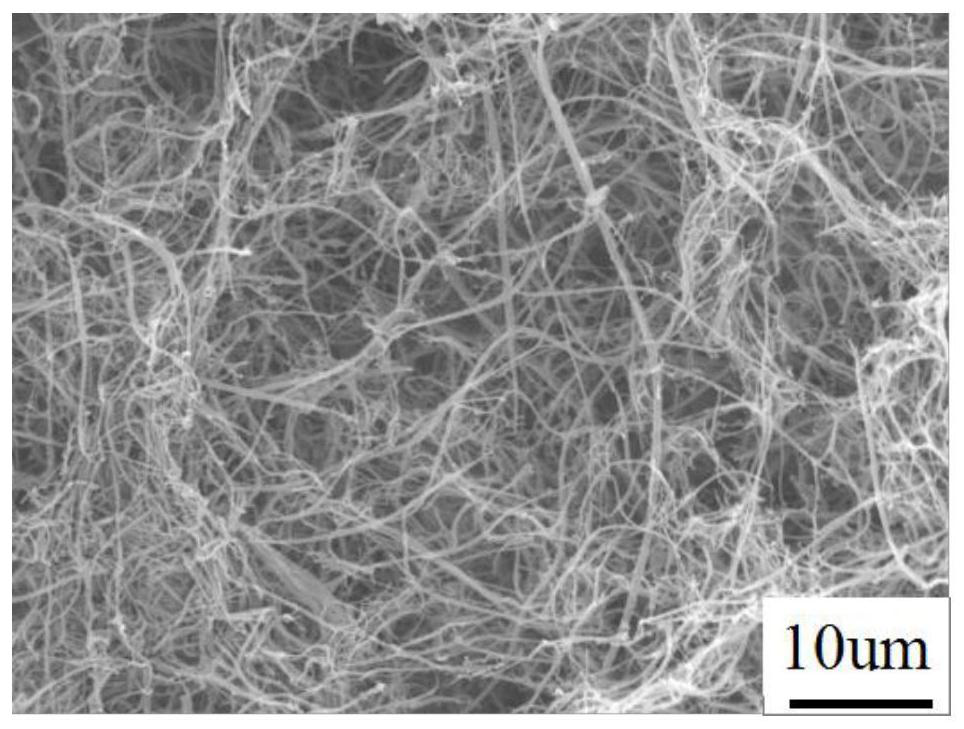

The invention relates to a high-efficiency and low-resistance nanofiber air filtering material for a gauze mask and a preparation method of the filtering material. According to the preparation method, by virtue of a steam field compensation and control technology, an equal-electric voltage spinning technology and a nanofiber structure with a bead structure and innovatively introducing single fibers in an electrostatic spinning process, the high-efficiency and low-resistance nanofiber air filtering material which is free of adhesion between fibers and fluffy in structure, has a three-dimensional cavity and is in a net communication structure is obtained in a one-step molding manner. According to the high-efficiency and low-resistance nanofiber air filtering material for the gauze mask, the filtering efficiency on granules which are 0.006-2.5 microns can reach over 99.999%; and the piezoresistance is less than 30Pa. The high-efficiency and low-resistance nanofiber air filtering material is simple in preparation technology, low in cost, high in filtering efficiency and small in resistance pressure drop, and has a wide application prospect in the field of individual protective masks.

Owner:DONGHUA UNIV

Composite nano fiber filtration material with photocatalysis/anti-bacterial functions and preparation method of filtration material

ActiveCN107497182AIncrease spinning speedSolve problems such as easy blockageDispersed particle separationElectro-spinningFiberSpinning

The invention relates to a composite nano fiber filtration material with photocatalysis / anti-bacterial functions and a preparation method of the filtration material. The filtration material comprises a supporting layer and a nano fiber filtration layer which adheres to the surface of the supporting layer, the nano fiber layer is uniformly filled with an photocatalyst and an antibacterial agent, and the preparation method comprises the following steps: 1, preparing a spinning liquid: dispersing a certain amount of the photocatalyst and the antibacterial agent into a solution uniformly to form a dispersion liquid, performing ultrasonic treatment, and adding a high polymer to form a stable and uniform electrostatic spinning solution; 2, performing electrostatic spinning: setting up electrostatic spinning parameters, and performing stretching on the spinning polymer solution at solid metal wire tips for wire production by utilizing an assembled needle head; and 3, performing slight dissolving treatment on the surface of the composite nano fiber filtration material by adopting solvent vapour recovery at a certain releasing speed to obtain the final composite nano fiber filtration material with the photocatalysis / the anti-bacterial functions. The composite nano fiber filtration material effectively solves a problem that the liquid outlet end of a current needle head / spray nozzle used for the electrostatic spinning is easy to block, can be directly used for decomposition of organic pollutants, inactivation of microorganism pathogenes and the like under visible light, and has excellent filtration performance at the same time.

Owner:DONGHUA UNIV

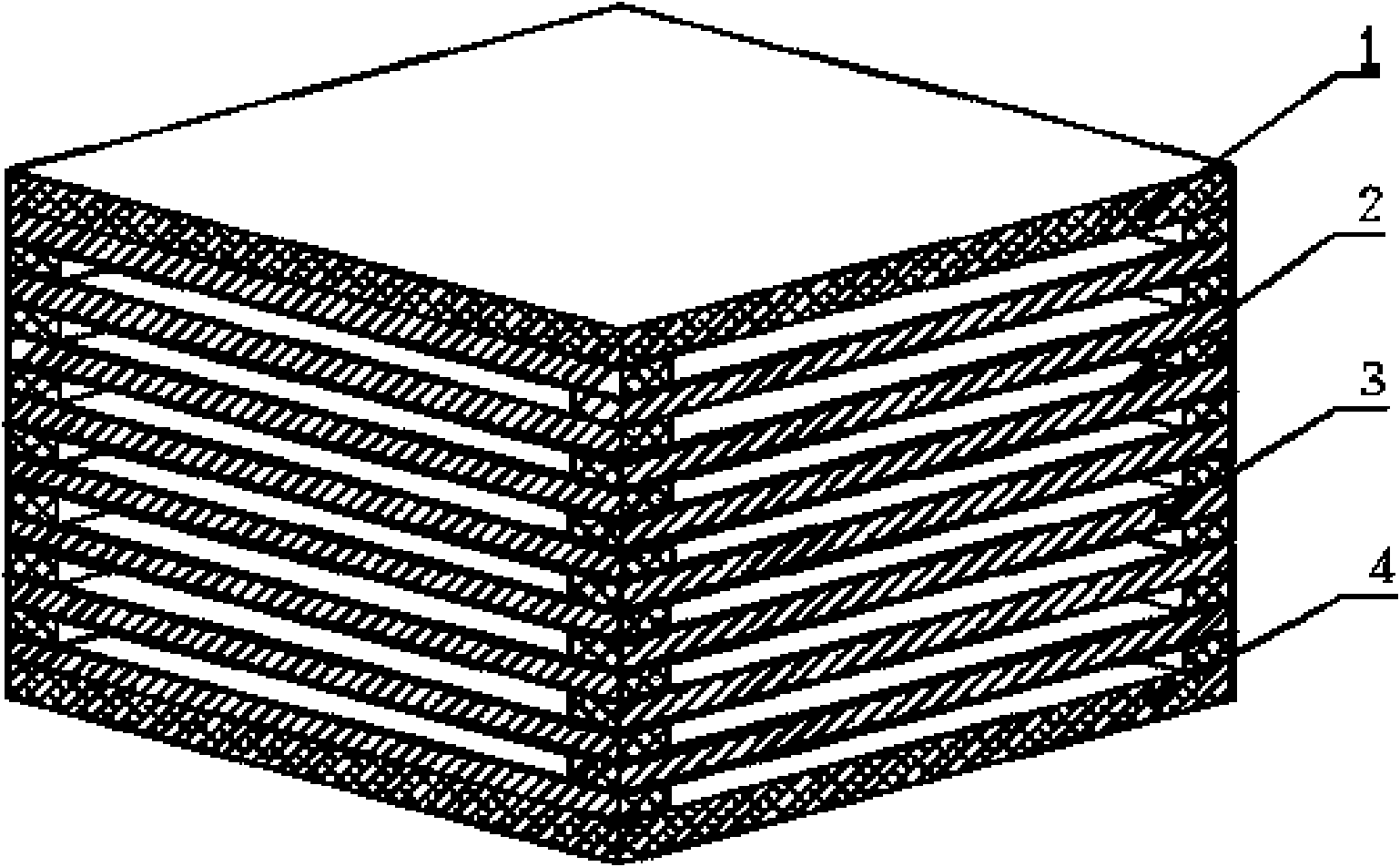

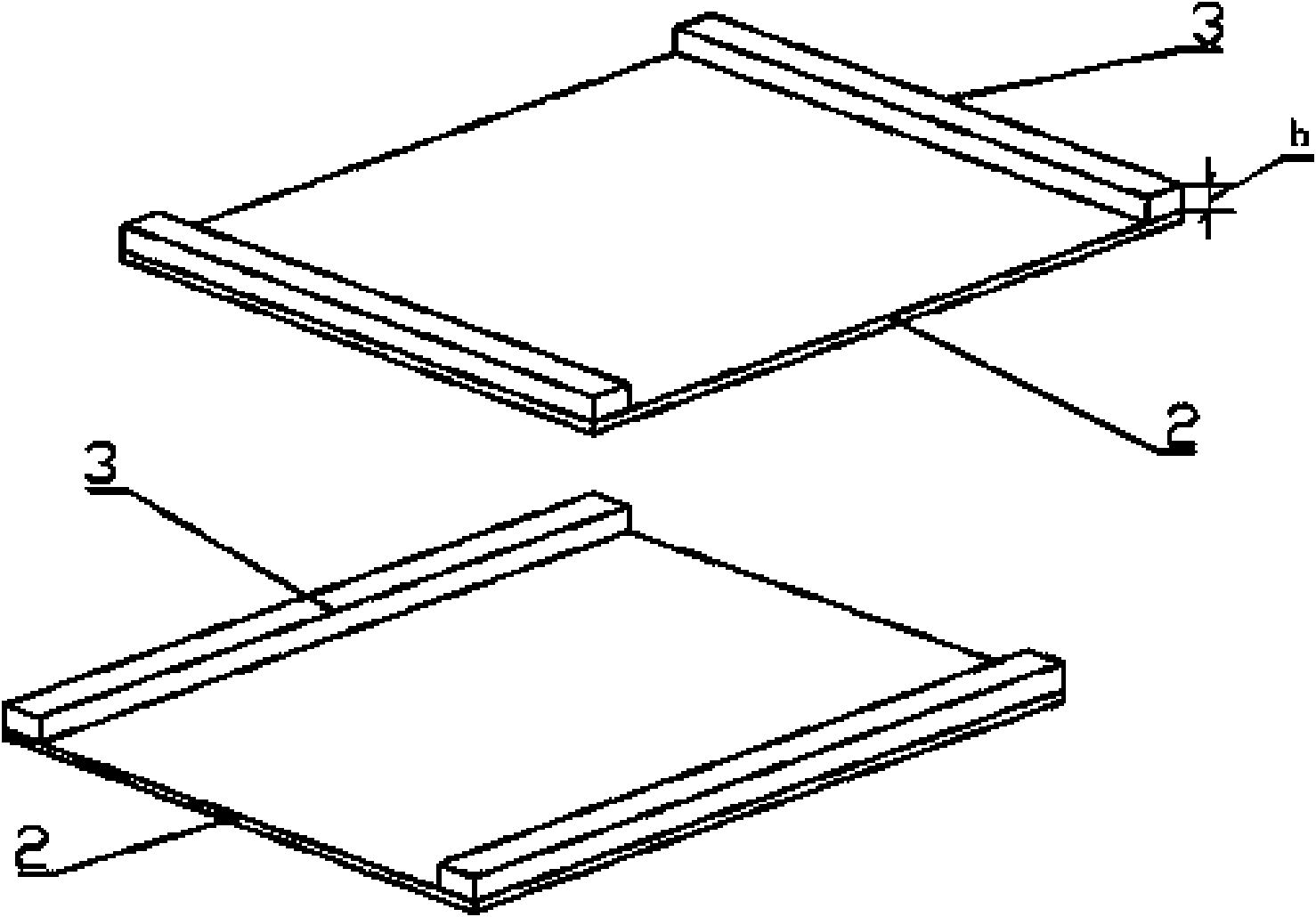

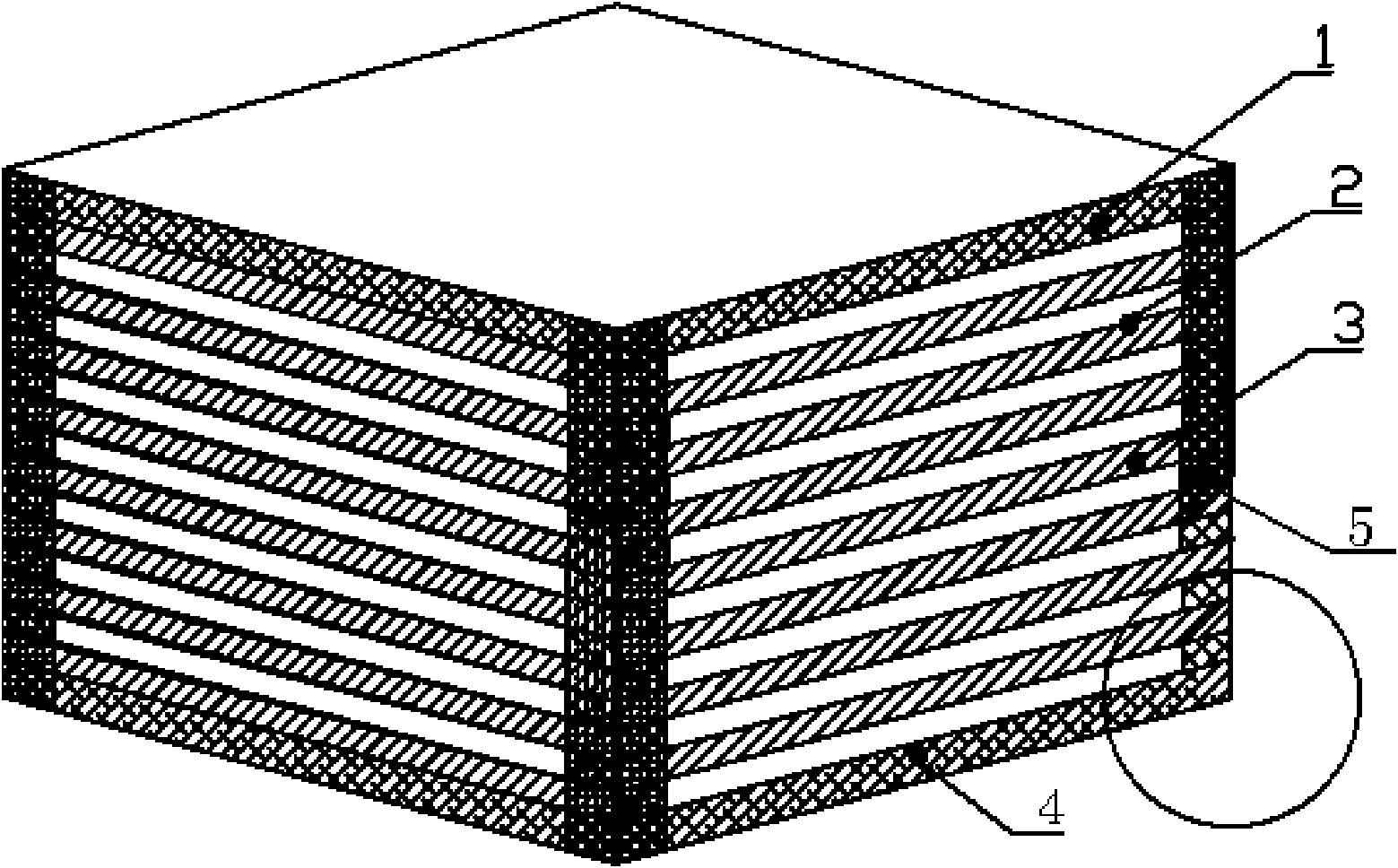

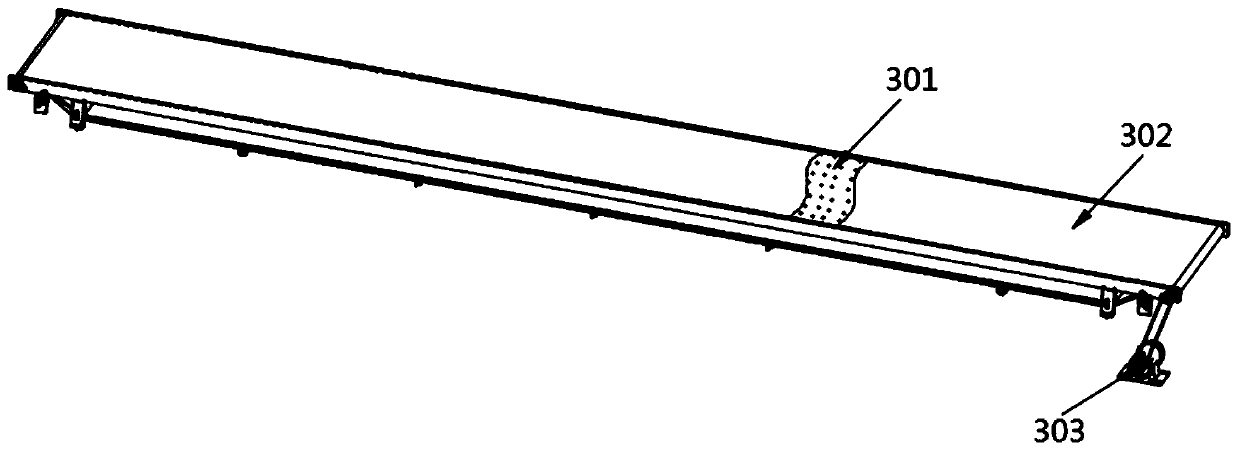

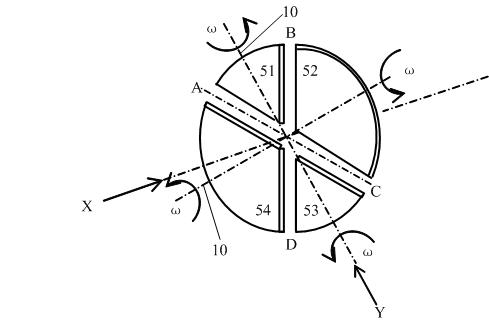

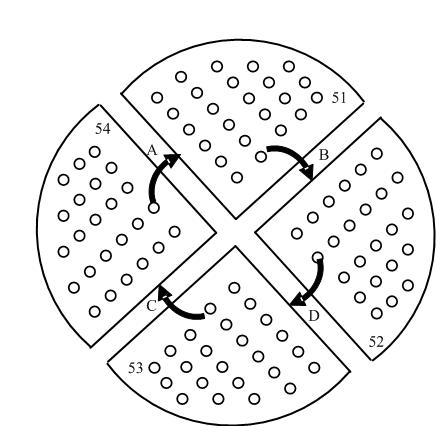

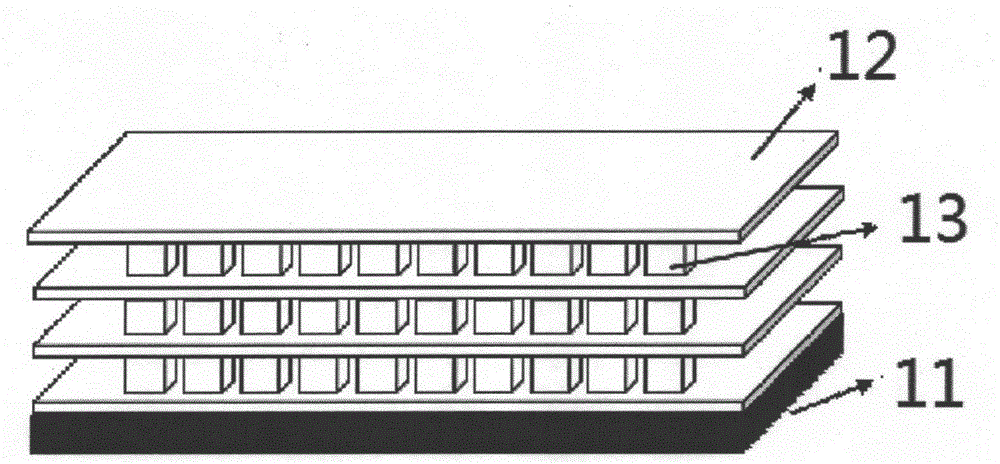

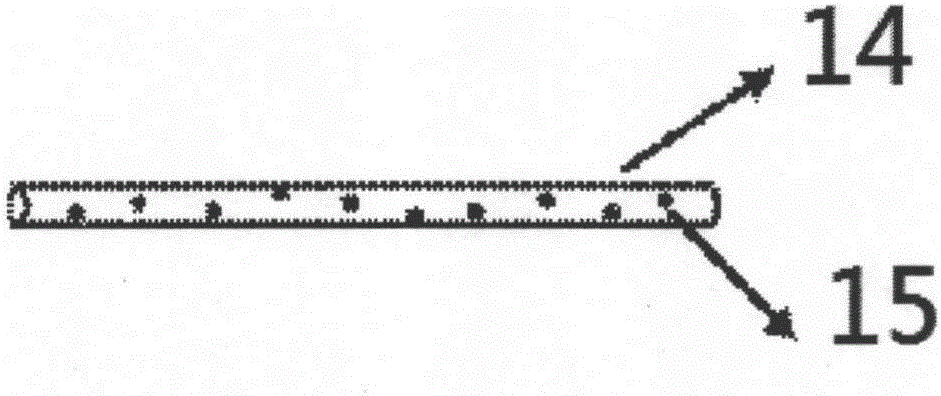

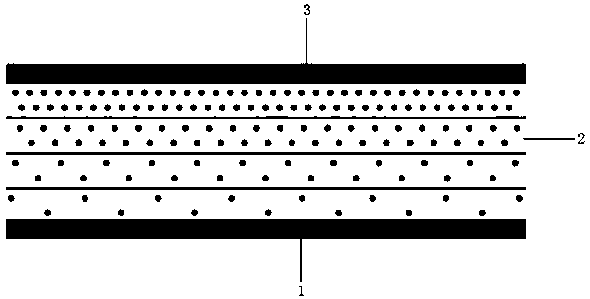

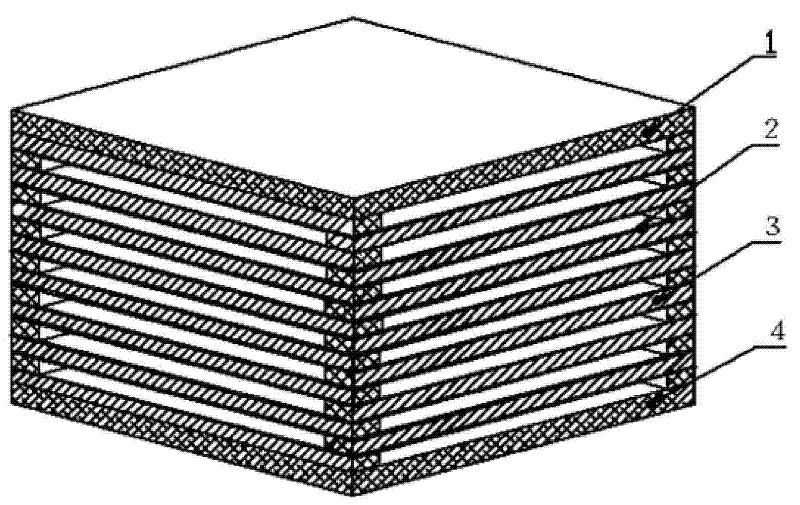

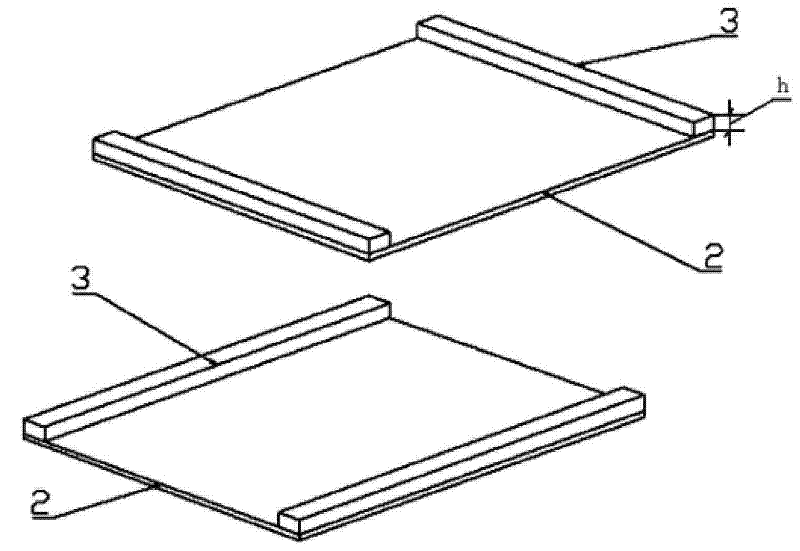

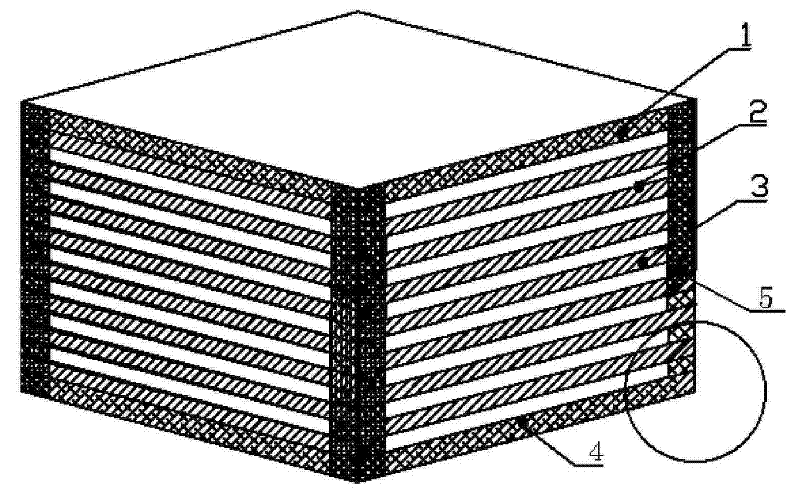

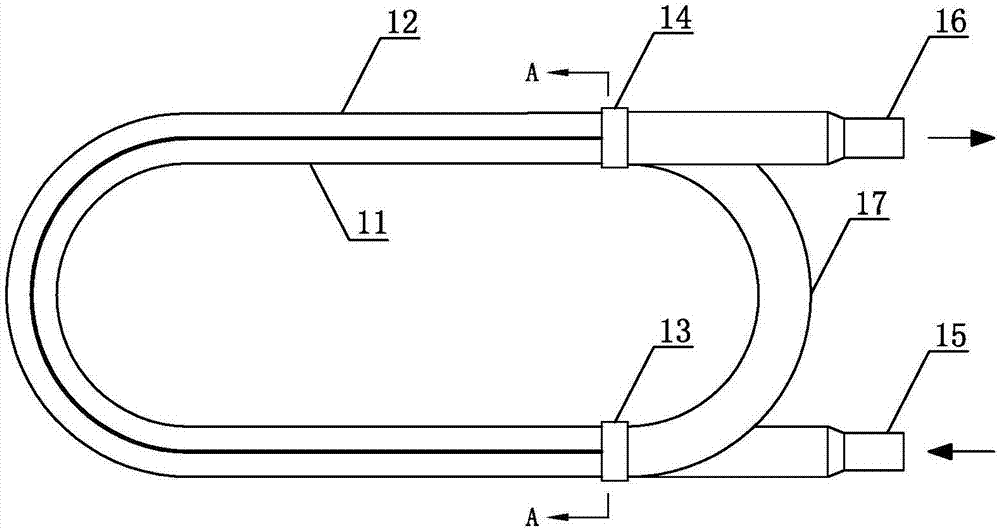

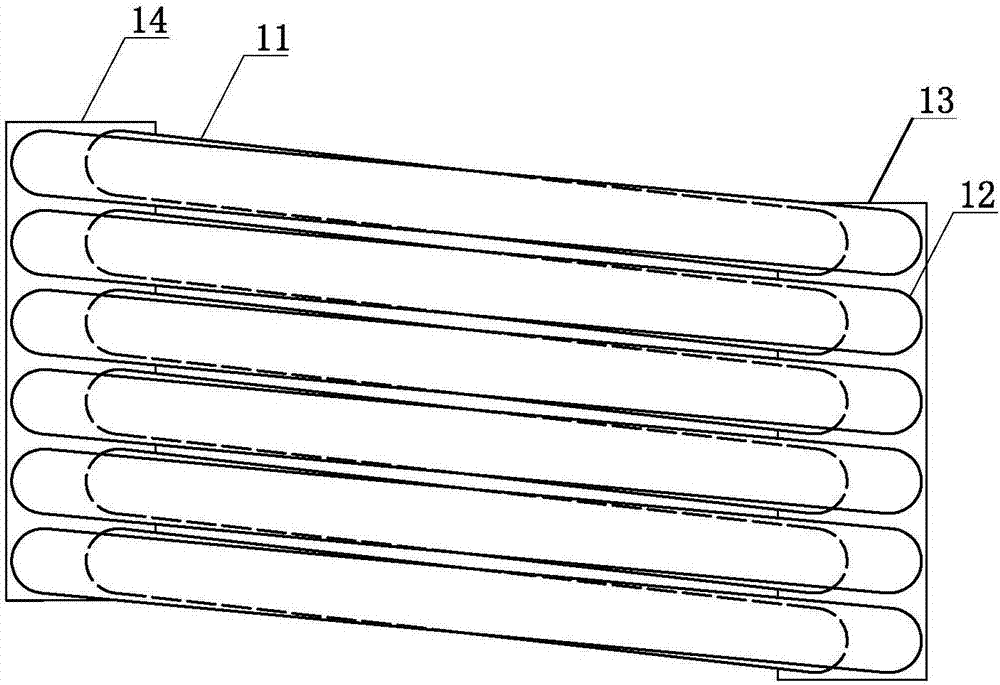

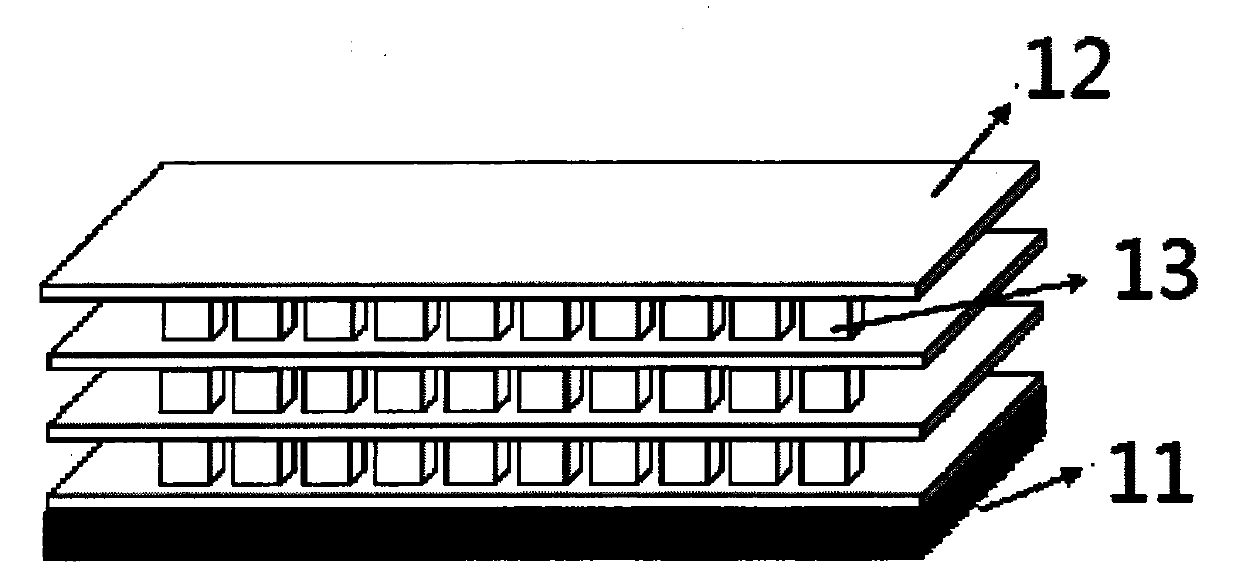

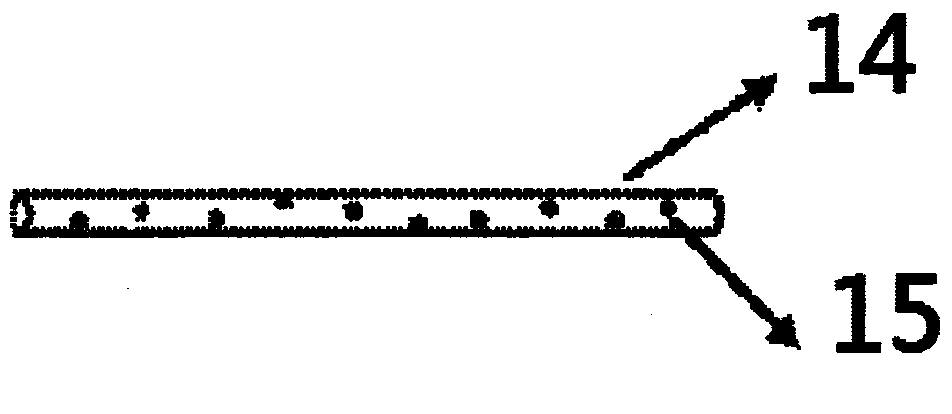

Core body of flat-plate heat exchanger for fresh air ventilator

InactiveCN101650141AAchieve low speed turbulent flowReduce thermal resistanceLaminated elementsStationary plate conduit assembliesFresh airEngineering

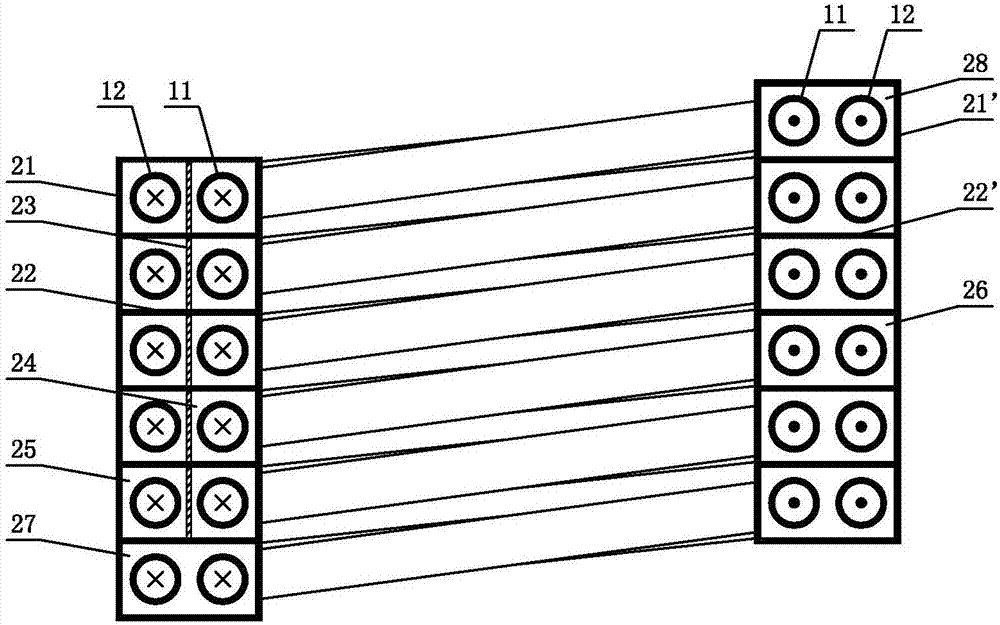

The present invention discloses a core body of a flat-plate heat exchanger for a fresh air ventilator, which comprises quadrangular plastic heat exchanging membranes, a top plate in the same shape asthat of the plastic heat exchanging membranes, a bottom plate and sealing strips. The upper surfaces on the near edges of two opposite edges of the plastic heat exchanging membranes with odd number are fixedly connected with the lower surfaces on the near edges of two opposite edges of the plastic heat exchanging membranes with even number through the sealing strips to form first airflow channels,the upper surface on the near edges of another two opposite edges of the plastic heat exchanging membranes with even number are fixedly connected with the lower surfaces on the near edges of two opposite edges of the other plastic heat exchanging membranes with odd number through the sealing strips to form second airflow channels crisscrossed with the adjacent first airflow channels, the top plate is fixedly connected with the uppermost plastic heat exchanging membranes through the sealing strips, and the bottom plate is fixedly connected with the lowermost plastic heat exchanging membranes through the sealing strip. The present invention has the advantages of favorable heat transfer performance, high heat exchanging efficiency, low weight and cost, simple structure, low production and running cost, convenient installation and easy integration with constructions.

Owner:TIANJIN UNIV

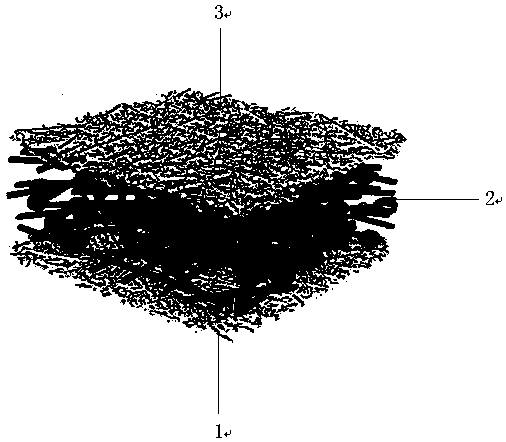

Three-dimensional zigzag nanofiber compound window screen and electrostatic spinning method thereof

ActiveCN106048901ALarge filter areaImprove filtration efficiencyInsect protectionFilament/thread formingFiberElectrospinning

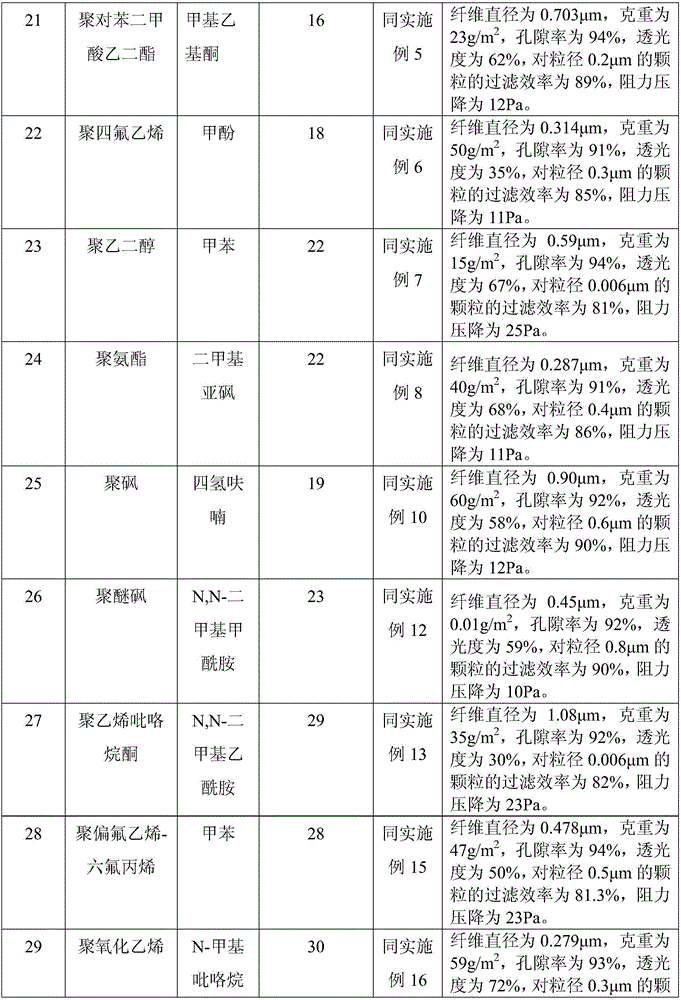

The invention relates to a three-dimensional zigzag nanofiber compound window screen and an electrostatic spinning method thereof. A zigzag template receiving technique, a needle head three-dimensional arrangement technique and a gradient electric field circulation spinning technique are adopted during an electrostatic spinning process so as to obtain a three-dimensional zigzag nanofiber compound film having an adhesive-fluffy stacked structure, i.e., the three-dimensional zigzag nanofiber compound window screen; the three-dimensional nanofiber compound window screen is characterized in that the gram weight is 0.01-70 g / m2, the efficiency for filtering particles having the diameter of 0.006-1 [mu]m is greater than or equal to 80%, the resistance pressure drop is less than 25 Pa, and the light transmittance is 30-90%. The three-dimensional nanofiber compound window screen is simple in preparation process, is low in cost, is high in filtering efficiency, is low in resistance pressure drop, and has wide application prospect in the fields of individual protection and indoor air purification.

Owner:DONGHUA UNIV

Micron fiber three-dimensional framework/polymer nanofiber composite filter material and preparation method thereof

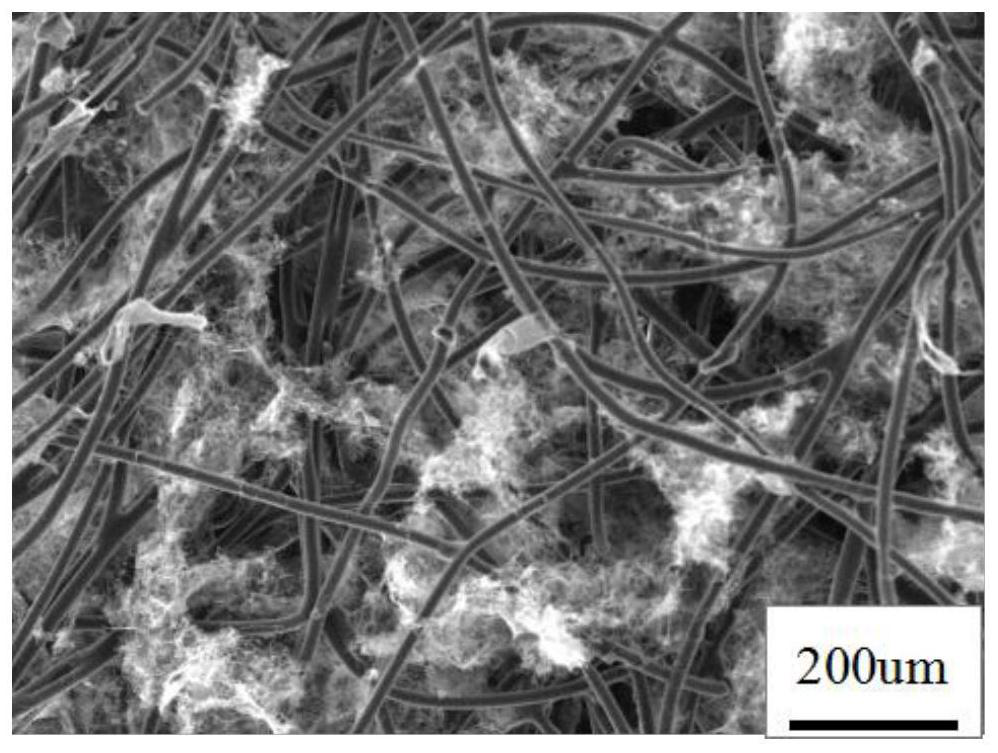

ActiveCN107137979ALarge specific surface areaImprove mechanical propertiesMembrane filtersFiltration separationAir filtrationPolymer science

The invention belongs to the field of textile materials and discloses a micron fiber three-dimensional framework / polymer nanofiber composite filter material and a preparation method thereof. The preparation method comprises the following steps: preparing polymer nanofibers by adopting a melt blending method; dispersing the polymer nanofibers and a crosslinking agent into a solvent to form a suspension, then soaking micron fiber nonwoven fabric skeletons into the suspension, carrying out freeze drying to form coagulation blocks, and then removing the solvent, so that a nonwoven material with polymer nanofiber aerogel gradiently distributed among the micron fiber nonwoven fabric skeletons is obtained. According to the invention, the adopted preparation technology is simple, raw materials are environment-friendly, conditions are mild, the composite filter material is applicable to industrialized mass production, and the composite filter material product has good flexibility as well as high efficiency and low resistance air filtration performance and can be applied to the field of efficient air purification.

Owner:WUHAN TEXTILE UNIV

Composite filtering material and preparation method thereof

ActiveCN110711430AImprove interception efficiencyAvoid poor interception abilityDispersed particle filtrationHollow filament manufactureMicro nanoSpinning

The invention provides a composite filtering material and a preparation method thereof. The composite filtering material is prepared by sequentially depositing and compounding fiber filtering layers from micron to submicron and then from micron to nanometer, and comprises a non-woven fabric primary-effect filter layer, a porous micro-nano fiber medium-effect filter layer, a cobweb nano fiber high-efficiency filter layer and a composite layer which is arranged between the adjacent filter layers and formed by fibers in the adjacent filter layers in an interpenetrating manner. The preparation method comprises the following steps: firstly, preparing the non-woven fabric primary-effect filter layer by using a plane receiving type centrifugal spinning process, and then sequentially receiving anddepositing the porous micro-nano fiber medium-effect filter layer and the cobweb nano fiber high-efficiency filter layer on the surface of the non-woven fabric primary-effect filter layer by using anelectrostatic spinning process to prepare the multi-stage structure composite filter material with the pore diameter changing along the thickness direction in a gradient manner. The composite filtering material not only has excellent air filtering performance, but also has photocatalysis and antibacterial performance.

Owner:JIANGSU YIMAO FILTER MEDIA CO LTD

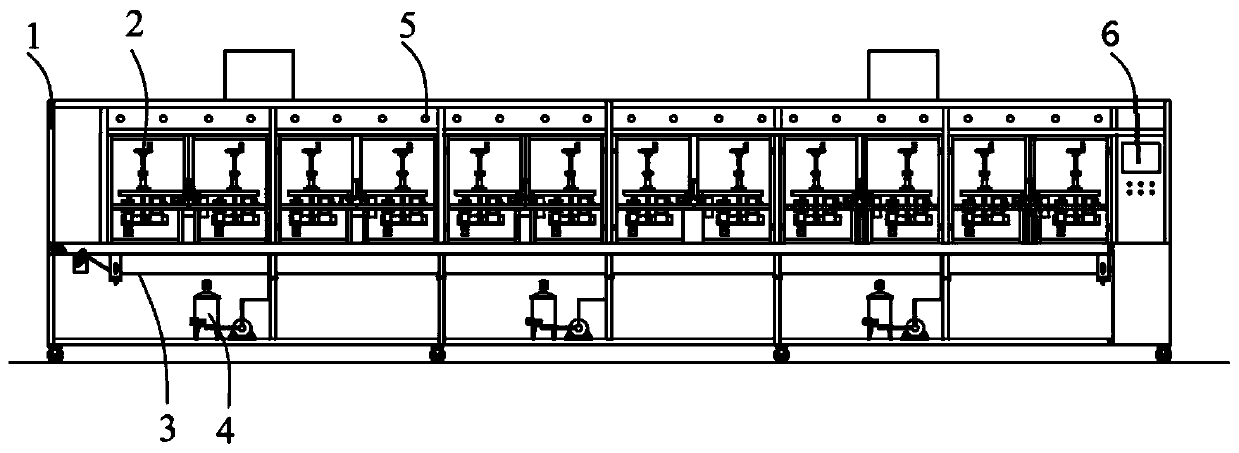

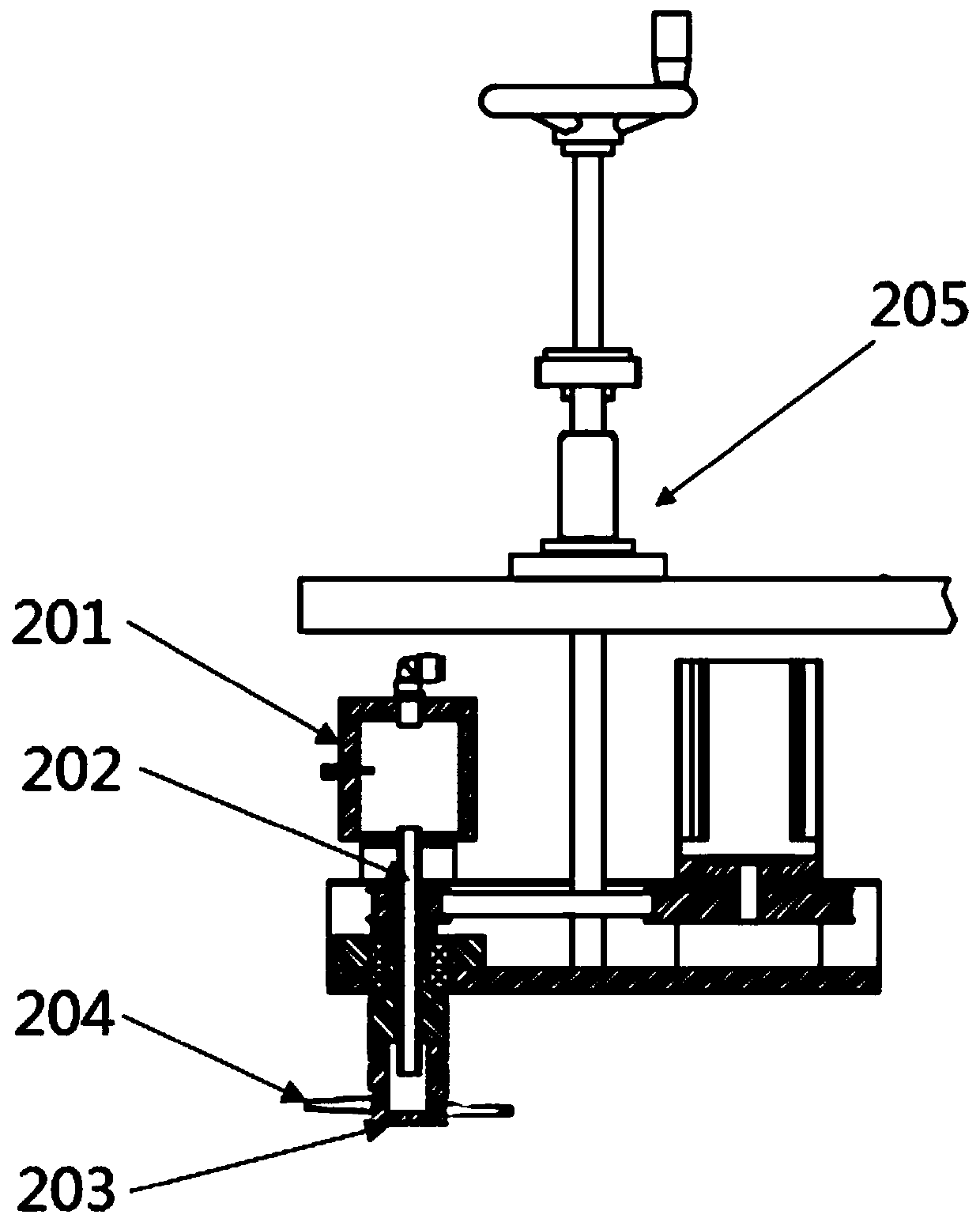

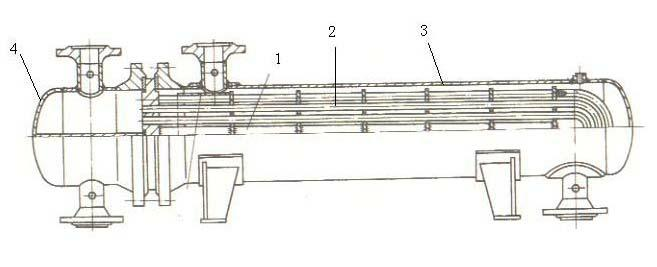

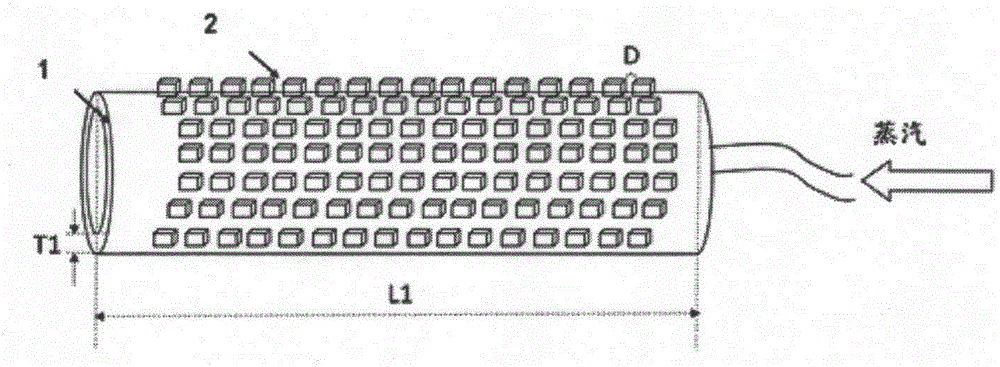

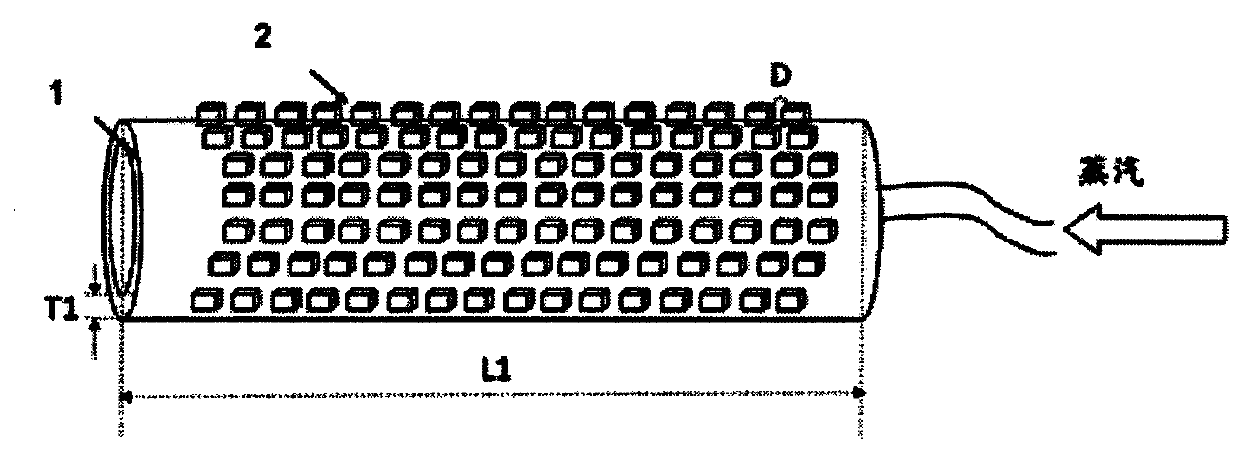

Discontinuous multi-strand spiral flow baffle plate shell-and-tube heat exchanger

InactiveCN102322766AReduced resistance pressure dropImprove assembly qualityHeat exchanger casingsEnhanced heat transferMechanical engineering

The invention discloses a discontinuous multi-strand spiral flow baffle plate shell-and-tube heat exchanger, which comprises a tube bundle, a tube shell and a tube box, wherein the tube bundle comprises heat exchange tubes, spiral flow baffle plates, distance tubes and tube plates; the heat exchange tubes pass through the spiral flow baffle plates in a row, and the two ends of the heat exchange tubes pass through tube holes of the tube plates and are connected with the tube plates; and the spiral flow baffle plates comprise two or more than two fan-shaped baffle plate groups, and the fan-shaped baffle plate groups are discontinuously distributed or partially discontinuously distributed and partially continuously distributed in the axis direction of the tube bundle. Compared with the prior art, the heat exchanger has the advantages that: technical prejudice is overcome; multiple discontinuously distributed fan-shaped baffle plate groups form multi-group discontinuous multi-strand spiral flow to realize reinforced heat transfer of the heat exchange tubes; the heat exchanger has the characteristics of low fluid resistance, high film heat transfer coefficient and good heat exchange efficiency; and the assembly quality of the tube bundle can be improved, the energy is saved, and meanwhile, the spiral flow baffle plate tube bundle with large shell diameter can be adopted.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

Functional filter material capable of releasing far infrared ray and preparation method thereof

InactiveCN106621840AShorten speedImprove far-infrared emissivitySemi-permeable membranesMembranesFiberEmissivity

The invention provides a functional filter material capable of releasing a far infrared ray and a preparation method thereof. The functional filter material capable of releasing the far infrared ray is characterized by comprising a base material and a nanofiber membrane arranged on the base material, the nanofiber membrane comprises at least one level unit, each level unit comprises a plane layer formed by nanofiber disordered gathering and a cavity structure formed by directionally arranging and stacking nanofiber, some or all cavity structures are filled with substances capable of releasing the far infrared ray, and the nanofiber is mixed with the substances capable of releasing the far infrared ray. The functional filter material capable of releasing the far infrared ray has the advantages of being high in filter efficiency, large in resistance pressure drop, high in far infrared emissivity and the like, and has the wide application prospect in the field of air filtering.

Owner:DONGHUA UNIV

A microbead/nanofiber composite air filter material with gradient structure and preparation method thereof

ActiveCN105999852BImprove filtration efficiencyIncrease dust holding capacityLayered product treatmentSynthetic resin layered productsAir filtrationCompound a

The invention relates to a microbead / nano-fiber composite air filtration material with a gradient structure and a preparation method thereof. The preparation method consists of: introducing microbeads into a nano-fiber layer, adjusting the mass ratio of a spinning solution for spinning the microbeads to a spinning solution for spinning the nano-fiber to control gradual increase of the microbead content along the filter material thickness direction from the bottom up, thus obtaining a microbead / nano-fiber layer with a gradient structure, and compounding a nonwoven substrate, the microbead / nano-fiber layer and a nonwoven covering layer by hot rolling process so as to obtain a sandwich structure composite air filtration material. According to the invention, the preparation process is simple, refitting of an electrospinning machine is not needed, the application range is wide, and the prepared composite filtration material has the advantages of high filtration efficiency, small resistance pressure drop, large dust holding capacity and long service life.

Owner:河北华纺纳米科技有限公司

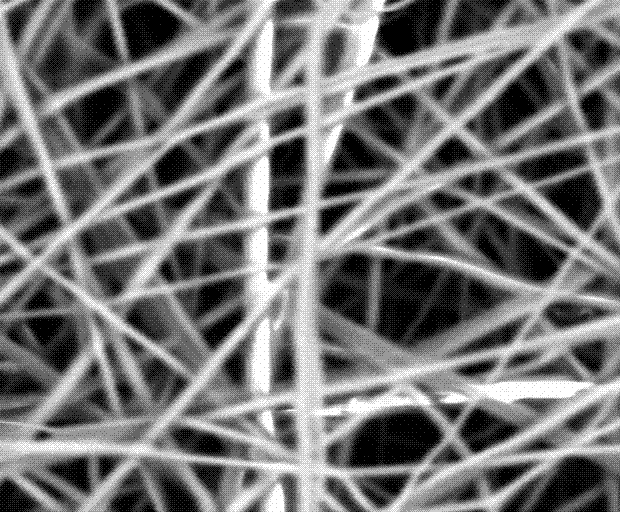

Micron fiber/nanofiber composite filter material and preparation method thereof

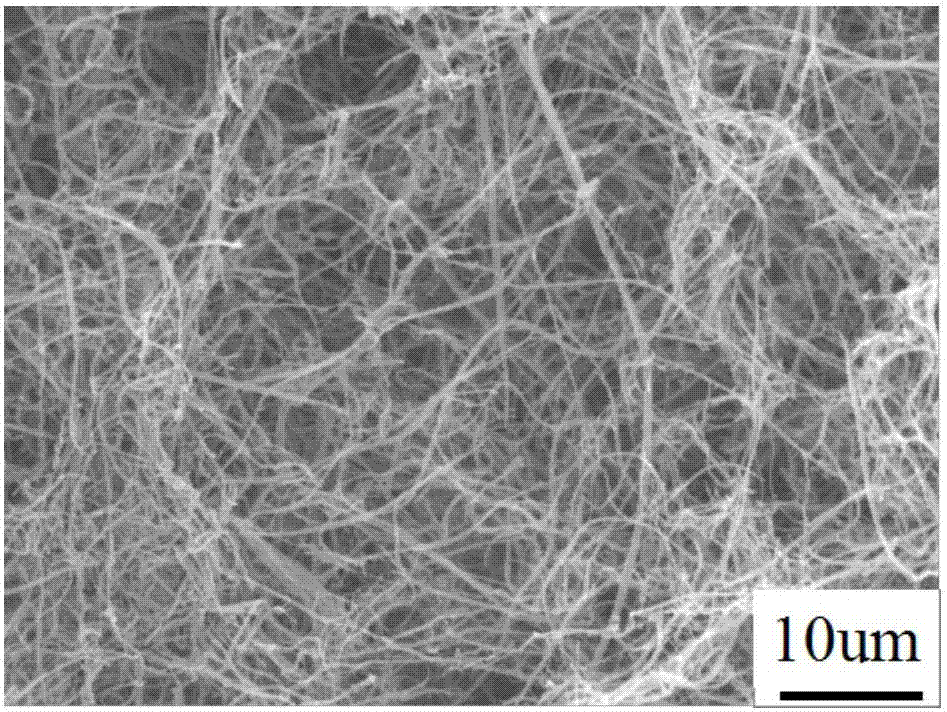

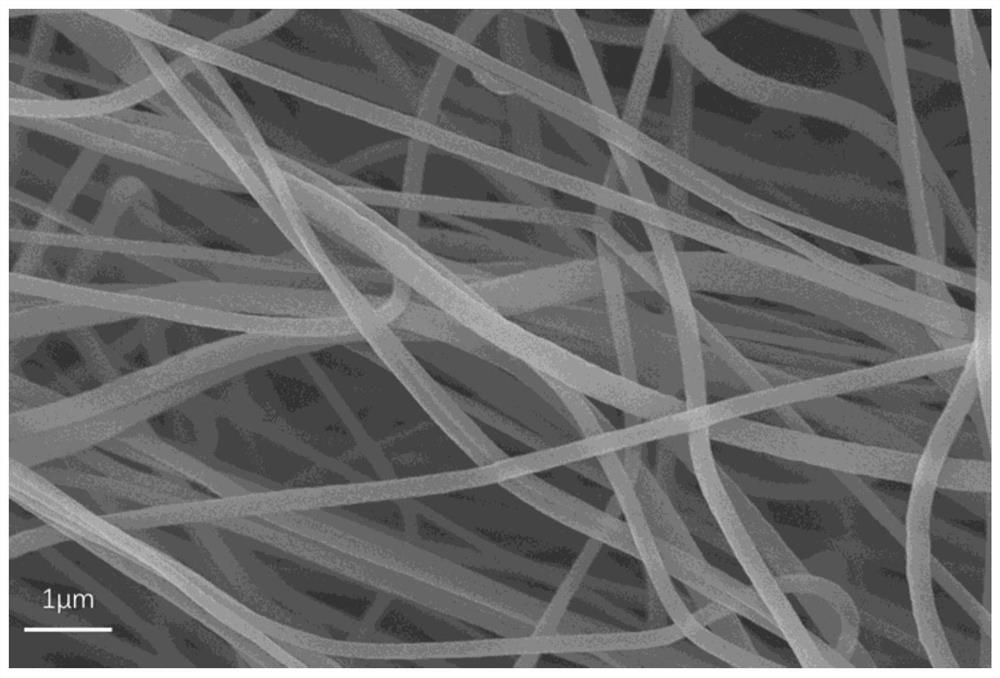

ActiveCN107366030AGood molding effectEasy to prepareFilament/thread formingMonocomponent polystyrene artificial filamentParticulatesSolvent vapor

The invention relates to a micron fiber / nanofiber composite filter material and a preparation method thereof. The preparation method includes: in an electrostatic spinning process, an annular gradient solvent vapor quick removing device is adopted for one-step forming on a receiving substrate to obtain the micron fiber and nanofiber integrated three-dimensional structural composite filter material according to a double-region isolation spinning control technique. Efficiency of the micron fiber / nanofiber composite filter material in filtering of 0.02-10micron particles reaches 99.95% or above, and resistance pressure drop is smaller than 40Pa. The preparation method is simple in process, controllability in fiber diameter and pore diameter is achieved, the obtained composite filter material is of micron / nano scale in fiber diameter and pore diameter, a great filtration performance is achieved, and the composite filter material is widely applicable to air purifying products such as mask filter elements, air purifiers and air conditioners.

Owner:DONGHUA UNIV

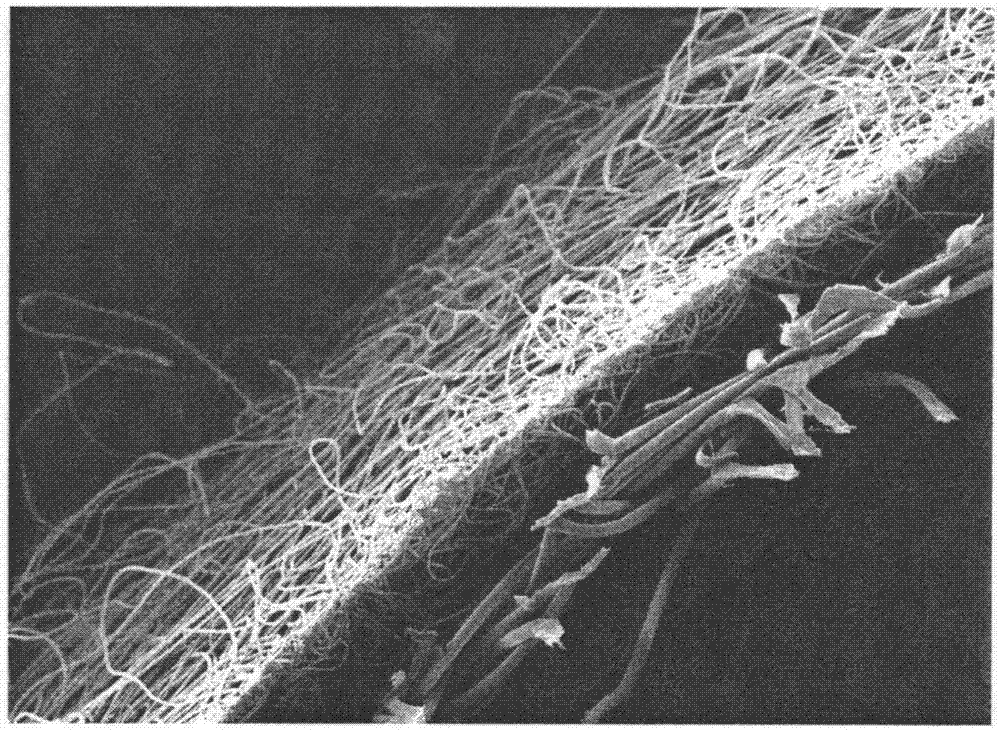

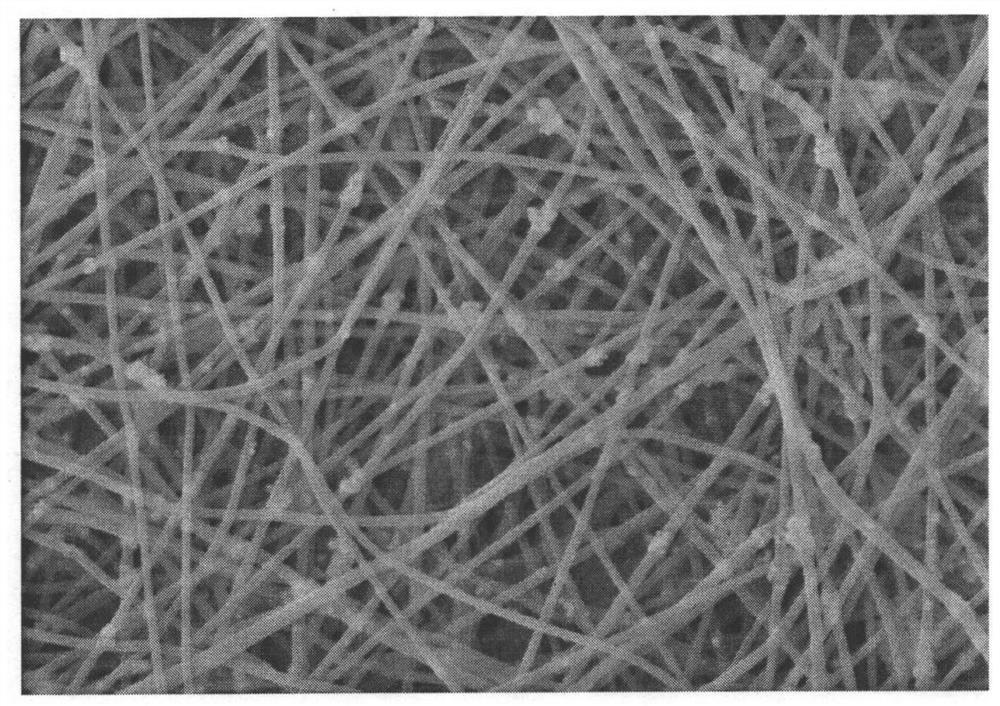

Nano spider web/beaded fiber composite air filter membrane and preparation method thereof

ActiveCN106984201BReduce resistanceReduced resistance pressure dropMembranesSemi-permeable membranesAir filtrationMicron scale

The invention relates to a nanometer spider-web / bead fiber composite air filtration film and a preparation method thereof. The filtration film comprises a nanometer spider-web receiving layer, a bead fiber layer and a nanometer spider-web covering layer which are arranged from bottom to top. The preparation method comprises the following steps: preparing a nanometer spider-web film containing a two-dimensional netty fiber film and one-dimensional nanometer fiber through a static net spraying technology, and depositing the nanometer spider-web film on the surface of an aluminum foil of a receiving roller to obtain a nanometer spider-web receiving layer; preparing bead fiber consisting of continuous nanometer fiber and beads with micron-scale diameters distributed on the continuous nanometer fiber through a static spinning technology, and depositing the bead fiber on the surface of the nanometer spider-web receiving layer; preparing the nanometer spider-web film through the static net spraying technology and depositing the nanometer spider-web film on the surface of the bead fiber layer so as to obtain a nanometer spider-web covering layer; and carrying out sufficient drying to obtain the nanometer spider-web / bead fiber composite air filtration film. The preparation process is simple, the structure adjustability of the filtration film is high, the filter efficiency is high, the resistance pressure drop is small, and the clogging capacity is high.

Owner:XINJI HUARUI FILTER PAPER CO LTD

A kind of preparation method of nanofiber air filter material with thickness combination with gradient structure

ActiveCN105926161BImplement hierarchical gradient filteringImprove filtration efficiencyElectro-spinningMembrane filtersAir filterNanofiber

The invention relates to a thick and fine combined nanofiber air filtering material with a gradient structure and a preparation method of the nanofiber air filtering material. The filtering material comprises a non-woven fabric base material, at least three thick and fine combined nanofiber filtering layers with the gradient structure and a non-woven fabric covering layer from bottom to top. The preparation method comprises steps as follows: relatively thick nanofibers are blended in relatively fine nanofibers uniformly, the content of the relatively thick nanofibers is controlled to be gradually increased from bottom to top in the thickness direction of the filtering material by adjusting the mass ratio of a spinning solution for spinning the relatively thick nanofibers to a spinning solution for spinning the relatively fine nanofibers, and the thick and fine combined nanofiber air filtering material with the gradient structure is obtained. The non-woven fabric base material, the thick and fine combined nanofiber filtering layers and the non-woven fabric covering layer are composited with a hot rolling process, and the air filtering material with a sandwich structure is obtained. The preparation process is simple, the fiber structure can be accurately controlled, the prepared filtering material has high filtering efficiency, the resistance pressure drop is small, the dust holding capacity is high, and the mechanical performance is good.

Owner:河北华纺纳米科技有限公司

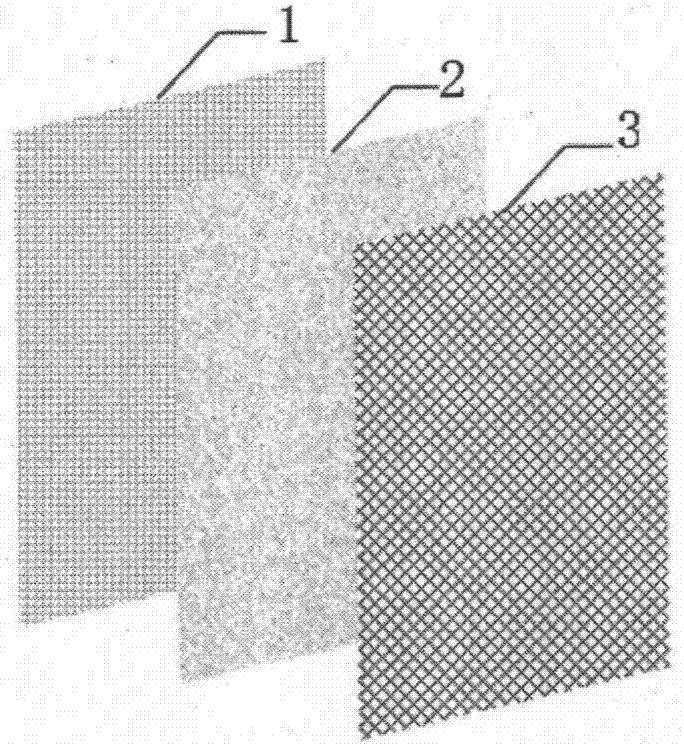

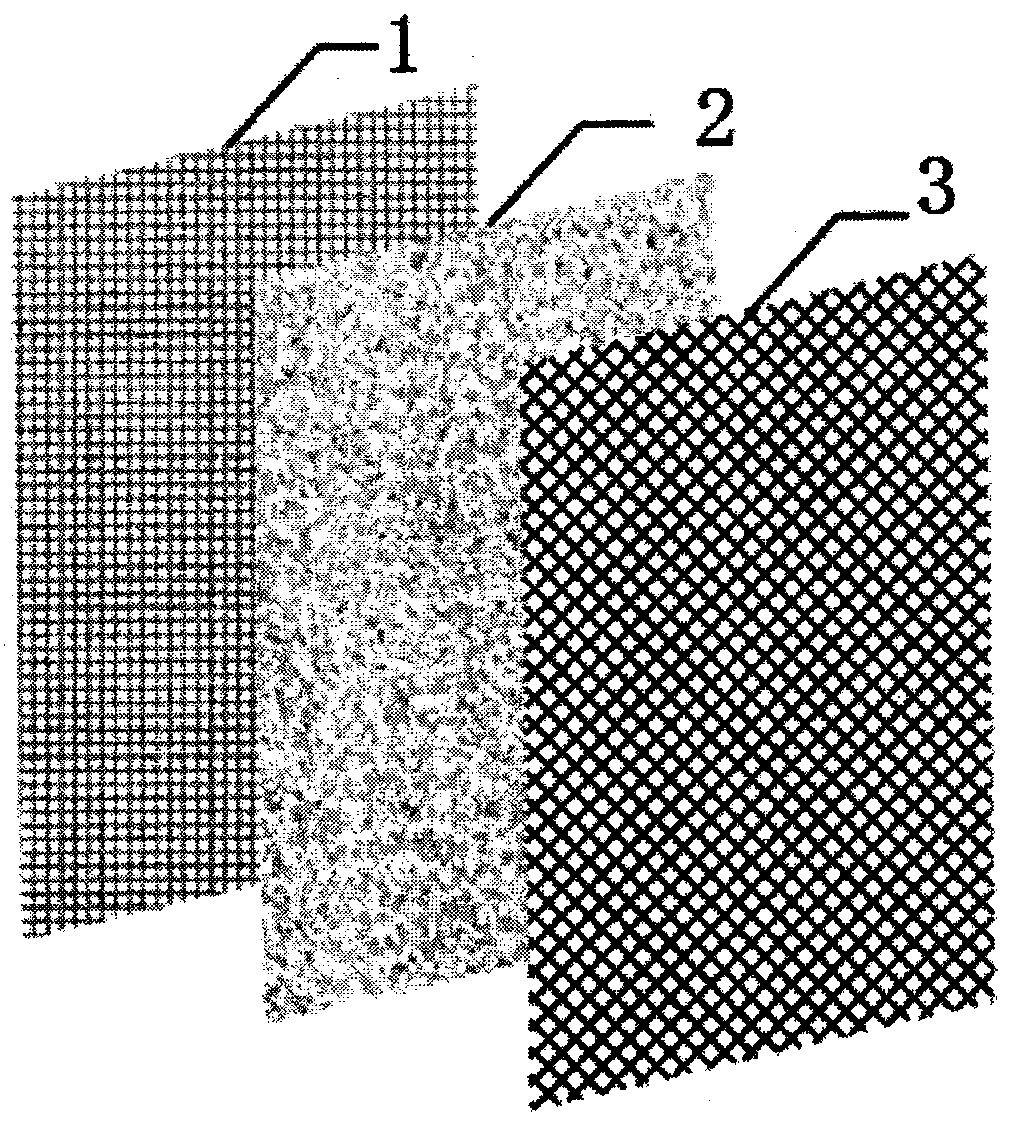

Nano-fiber window screen material in multilayer lamination structure and lamination method of same

ActiveCN107498960AAchieve a strong bondImprove bonding fastnessSynthetic resin layered productsInsect protectionNanofiberEngineering

The invention provides a nano-fiber window screen material in a multilayer lamination structure and a preparation method of same. The nano-fiber window screen material is characterized by including, in a successive arrangement from bottom to top, a mesh screen base material, a nano-fiber layer and a cover layer. Melt-connection points are formed on the upper surface of the nano-fiber layer through solvent electrostatic spraying technology; by means of a lamination method of thermal adhesion, the cover layer is adhered to the nano-fiber layer by means of the melt-connection points. The preparation method is simple in process and low in cost. The nano-fiber window screen material in the multilayer lamination structure is not less than 90% in filtering efficiency to particles being 0.008-2 [mu]m in size and is not more than 60 Pa in resistance pressure drop. The material has long service live and has great application prospect in the technical fields of indoor air purification and dust removal.

Owner:DONGHUA UNIV

High-efficiency and low-resistance nanofiber air filter material for masks and preparation method thereof

ActiveCN104645715BNo adhesionFluffy structureFiltration separationProtective garmentComposite nanofibersSpinning

Owner:DONGHUA UNIV

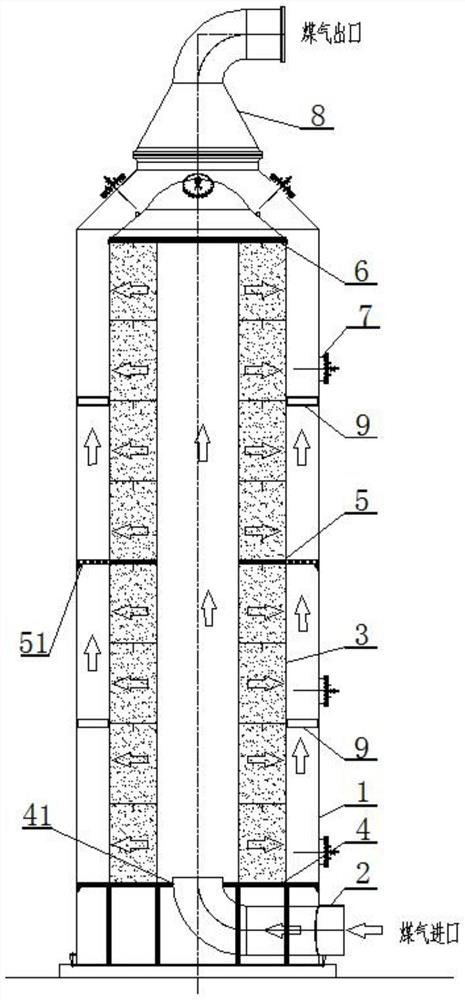

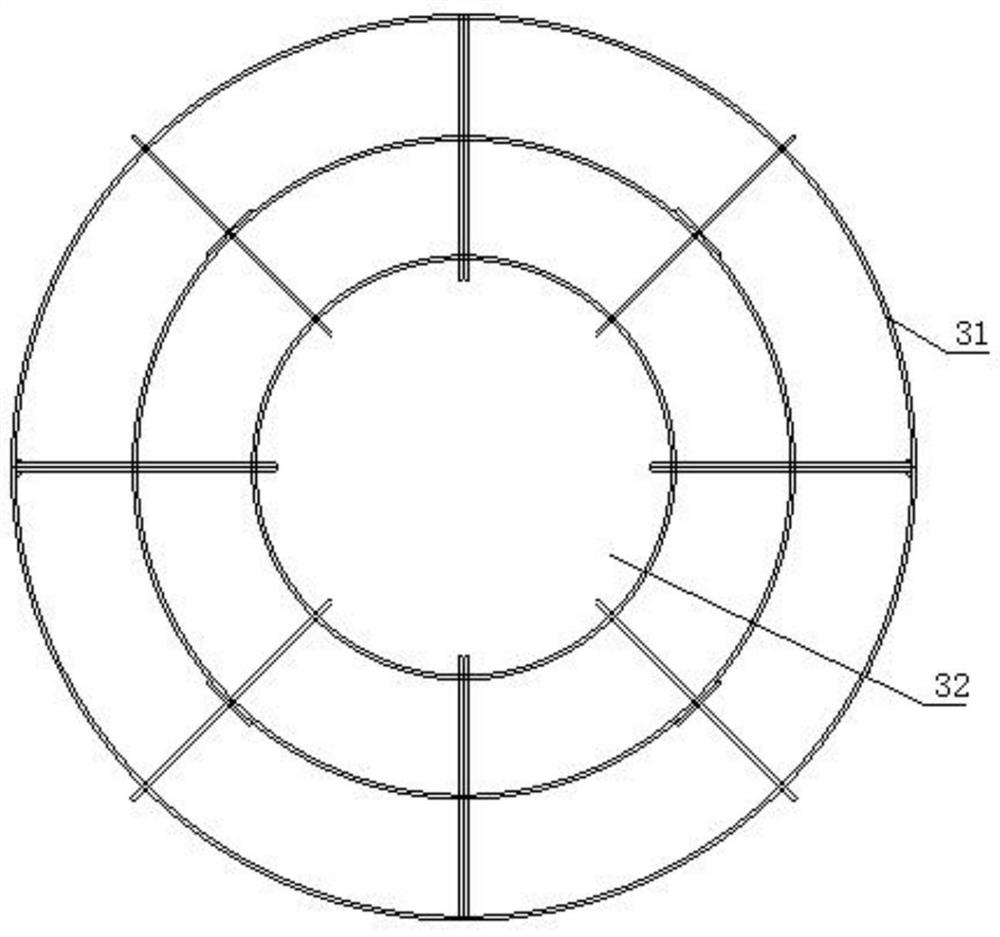

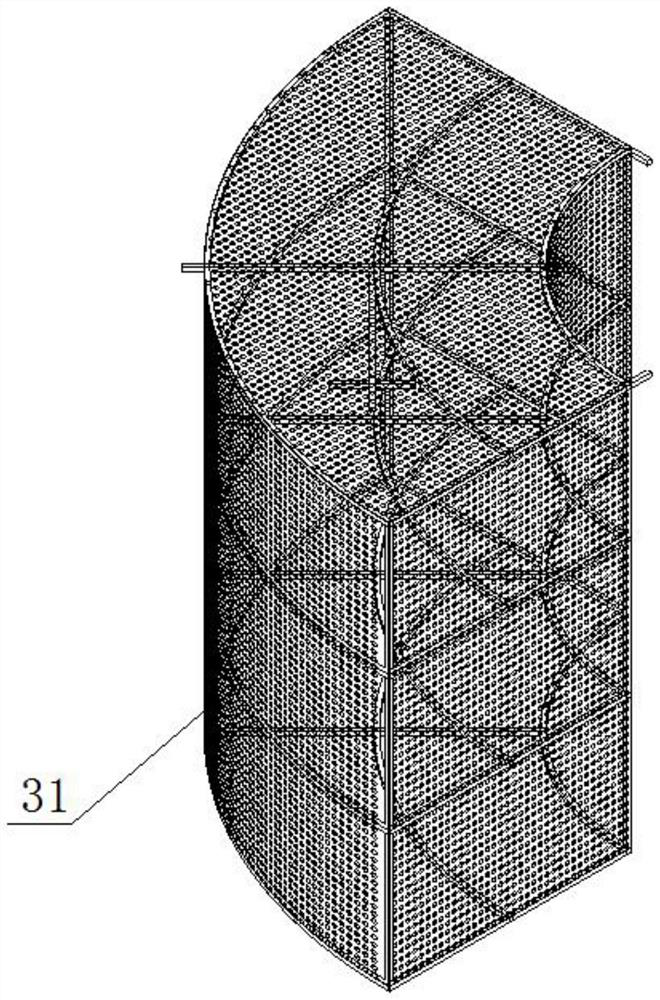

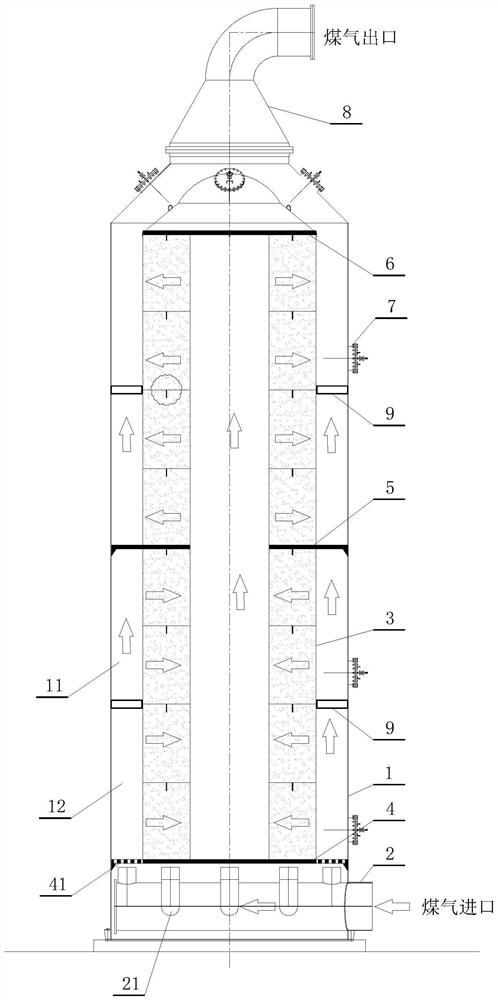

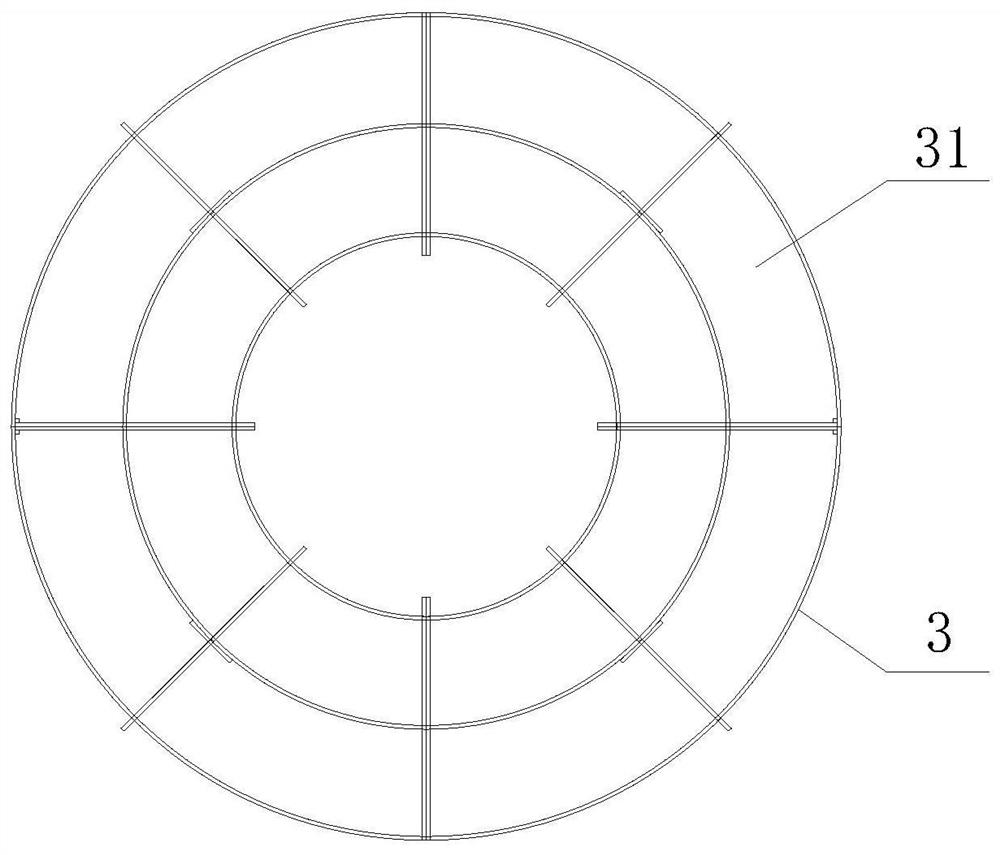

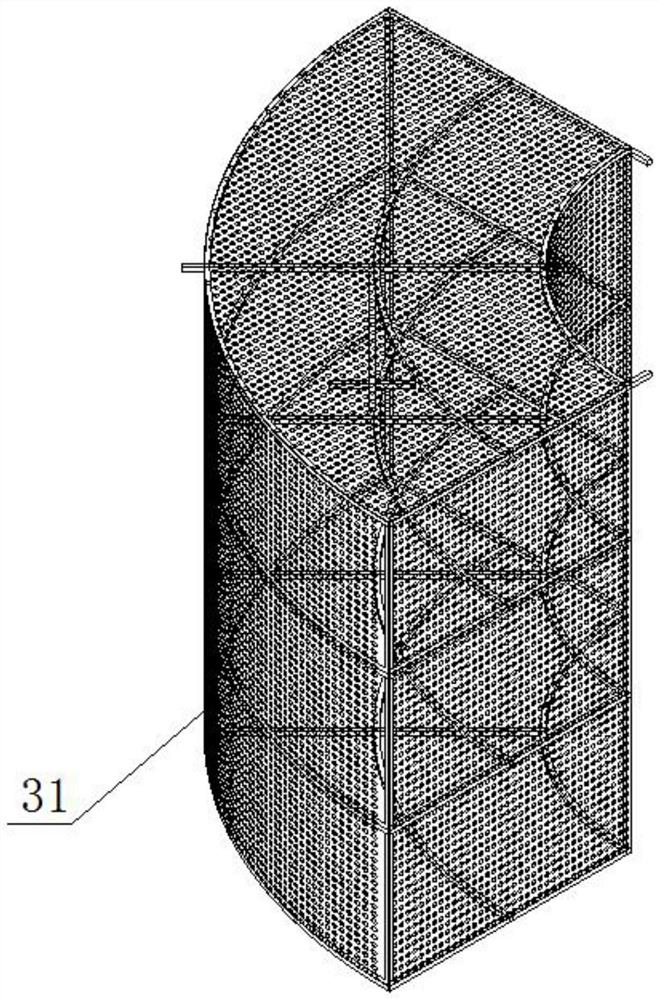

Novel blast furnace gas hydrolysis conversion tower

PendingCN113372966AEasy to installEasy to replaceGas purification by catalytic conversionBlast furnace detailsBlast furnace gasCatalysis

The invention discloses a novel blast furnace gas hydrolysis conversion tower, and belongs to the technical field of blast furnace gas hydrolysis towers. The tower comprises a hydrolysis tower shell, the bottom of the hydrolysis tower shell is connected with a coal gas inlet pipe, a filler module is arranged in the hydrolysis tower shell, a lower bracket plate is arranged at the bottom of the filler module, and a middle bracket plate is arranged on the outer ring of the middle of the filler module; an upper flow guide device is arranged at the upper part of the filler module; and an upper pipe orifice device is arranged at the top of the hydrolysis tower shell. The hydrolysis catalyst filler is modularized, the coal gas flow is guided by adopting newly developed tower internals so that the coal gas flow uniformly and slowly passes through the hydrolysis catalyst, the contact area and the contact time of the coal gas and the hydrolysis catalyst are ensured, the hydrolysis catalysis efficiency is greatly improved, and meanwhile, the coal gas resistance pressure drop is reduced, and the requirements of blast furnace gas hydrolysis conversion are met.

Owner:HUATIAN ENG & TECH CORP MCC

A kind of air filter material capable of releasing negative ions and preparation method thereof

ActiveCN106621571BIncrease concentrationFacilitated releaseDispersed particle filtrationFilament/thread formingAir filterNanofiber

Owner:DONGHUA UNIV

A kind of anti-ultraviolet nanofiber composite screen window and preparation method thereof

ActiveCN107605387BIncrease spinning speedSolve problems such as easy blockageSynthetic resin layered productsInsect protectionFiberSolvent vapor

The invention discloses an ultraviolet-proof nano-fiber composite screen window and a production method thereof. The production method includes: using an electrostatic spinning combined needle to perform stretching and silk yielding of a spinning solution doping a ultraviolet screening agent on a sharp end of a solid metallic wire, and depositing the silk on a screen window basal material; using recovered solvent vapor to perform slight soluble treatment on a surface of a nano-fiber layer at a certain releasing speed; and fusing the covering protection layer, the nano-fiber layer and the screen window basal material through an ultrasonic composition method, and acquiring the ultraviolet-proof nano-fiber composite screen window. The problem that the conventional electrostatic spinning needles / sprayer outlet ends are blocked can be solved, the ultraviolet-proof nano-fiber composite screen window can prevent ultraviolet light and has excellent filtering performance; the ultraviolet transmittance of the composite screen window is less than or equal to 2.5%, the ultraviolet-proof coefficient level is greater than 40; for particles whit the size of 0.3-10 [mu]m, the filtering efficiencyof the composite screen window is greater than or equal to 90%; the resistance pressure drop is 10-30 Pa, and the light transmittance is greater than or equal to 68%; and the ultraviolet-proof nano-fiber composite screen window has wide development prospect in an indoor air filter market.

Owner:DONGHUA UNIV

A kind of microfiber/nanofiber composite filter material and preparation method thereof

ActiveCN107366030BGood molding effectEasy to prepareFilament/thread formingMonocomponent polystyrene artificial filamentSolvent vaporSpinning

The invention relates to a micron fiber / nanofiber composite filter material and a preparation method thereof. The preparation method includes: in an electrostatic spinning process, an annular gradient solvent vapor quick removing device is adopted for one-step forming on a receiving substrate to obtain the micron fiber and nanofiber integrated three-dimensional structural composite filter material according to a double-region isolation spinning control technique. Efficiency of the micron fiber / nanofiber composite filter material in filtering of 0.02-10micron particles reaches 99.95% or above, and resistance pressure drop is smaller than 40Pa. The preparation method is simple in process, controllability in fiber diameter and pore diameter is achieved, the obtained composite filter material is of micron / nano scale in fiber diameter and pore diameter, a great filtration performance is achieved, and the composite filter material is widely applicable to air purifying products such as mask filter elements, air purifiers and air conditioners.

Owner:DONGHUA UNIV

Novel blast furnace gas dechlorination and hydrolysis conversion integrated tower

PendingCN113372962AReduced resistance pressure dropGuaranteed contact areaGas purification by catalytic conversionGas contaminants removalBlast furnace gasCatalysis

The invention discloses a novel blast furnace gas dechlorination and hydrolysis conversion integrated tower, and belongs to the technical field of blast furnace gas towers. The tower comprises a tower body shell, an inlet gas distribution pipe is arranged at the bottom of the tower body shell, a lower bracket plate is arranged at the bottom of the tower body shell, flow guide holes are formed in the plate face of the lower bracket plate at intervals, a middle bracket plate is arranged in the middle of the tower body shell, the middle bracket plate divides the interior of the tower body shell into a hydrolysis tower body and a dechlorination tower body, and filler modules are arranged in the hydrolysis tower body and the dechlorination tower body. The dechlorination and hydrolysis catalyst filler is modularized and convenient to mount and replace, the coal gas flow is guided by adopting a specific internal structure design, so that the coal gas flow passes through the dechlorination and hydrolysis catalyst sequentially, uniformly and slowly, the contact area and the contact time of the coal gas and the dechlorination and hydrolysis catalyst are ensured, and the resistance pressure drop of the coal gas is reduced while the dechlorination and hydrolysis catalysis efficiency is greatly improved.

Owner:HUATIAN ENG & TECH CORP MCC

Melt-blown fiber/nano fiber/glass fiber composite filter material and its preparation

ActiveCN107497181BImprove adhesionImprove bonding fastnessSynthetic resin layered productsGlass/slag layered productsAir filtrationNanofiber

The invention provides a melt-blowing fiber / nano fiber / glass fiber composite filter material and a preparation of same. The composite filter material includes, successively from bottom to top, a glass fiber base material, a nano fiber layer and a melt-blowing fiber cover layer, wherein melt-joint points, through solvent electrostatic spraying technology, are formed on the upper surface of the nano fiber layer, so that the melt-blowing fiber cover layer is bond to the nano fiber layer by means of the melt-joint points through a hot-binding lamination method. The composite filter material has simple preparation process and low cost, is not less than 95% in filtration efficiency to particles in 0.01-10 [mu]m and is not more than 70 Pa in resistance pressure drop, is long in service life, and has great application prospect in the field of air filtration.

Owner:DONGHUA UNIV

Electret nanofiber filtering material and preparation method thereof

ActiveCN111249805AImprove filtering effectReduced resistance pressure dropHuman health protectionElectro-spinningPolymer scienceSpinning

The invention provides an electret nanofiber filtering material and a preparation method thereof, belongs to the technical field of new materials, and solves the technical problem of low filtering efficiency of fine particles in air due to unstable electret performance of the electret nanofiber filtering material in the prior art. The filtering material is prepared from a spinning solution throughelectrostatic spinning, and the spinning solution comprises the following components in parts by weight: 5-30 parts of a polymer, 1-10 parts of thiophene dipole molecules, and 60-94 parts of a solvent, wherein the thiophene dipole molecules are a compound with a dipole structure of an electron donor-pi conjugated system-electron acceptor. The thiophene dipole molecules and the polymer are dissolved together, the air filtering material with high PM2.5 filtering performance, low resistance pressure drop and ideal performance stability is prepared through an electrostatic spinning technology, and the air filtering material has the advantages of being simple in preparation method and low in production cost.

Owner:XIAMEN UNIV OF TECH

A kind of electret nanofiber filter material and preparation method thereof

ActiveCN111249805BImprove filtering effectReduced resistance pressure dropHuman health protectionElectro-spinningAir filtrationPolymer science

The invention provides an electret nanofiber filter material and a preparation method thereof, which belongs to the technical field of new materials, and solves the problem that the electret nanofiber filter material in the prior art has unstable electret performance, which causes fine particles in the air to be polluted. Technical problems with low filtration efficiency. The filter material is prepared from spinning solution by electrospinning, wherein the spinning solution includes the following components in parts by weight: 5-30 parts of polymers; 1-10 parts of thiophene dipole molecules; and 60-94 parts of solvent; wherein, the thiophene-based dipole molecule is a compound having a dipole structure of electron donor-π conjugated system-electron acceptor. In the present invention, the thiophene type dipole molecules and the polymer are co-dissolved, and the electrospinning technology is used to prepare high PM 2.5 The air filter material with filtering performance, low resistance pressure drop, and maintaining ideal performance stability has the advantages of simple preparation method and low production cost.

Owner:XIAMEN UNIV OF TECH

Core body of flat-plate heat exchanger for fresh air ventilator

InactiveCN101650141BAchieve low speed turbulent flowReduce thermal resistanceLaminated elementsStationary plate conduit assembliesFresh airEngineering

The present invention discloses a core body of a flat-plate heat exchanger for a fresh air ventilator, which comprises quadrangular plastic heat exchanging membranes, a top plate in the same shape as that of the plastic heat exchanging membranes, a bottom plate and sealing strips. The upper surfaces on the near edges of two opposite edges of the plastic heat exchanging membranes with odd number are fixedly connected with the lower surfaces on the near edges of two opposite edges of the plastic heat exchanging membranes with even number through the sealing strips to form first airflow channels, the upper surface on the near edges of another two opposite edges of the plastic heat exchanging membranes with even number are fixedly connected with the lower surfaces on the near edges of two opposite edges of the other plastic heat exchanging membranes with odd number through the sealing strips to form second airflow channels crisscrossed with the adjacent first airflow channels, the top plate is fixedly connected with the uppermost plastic heat exchanging membranes through the sealing strips, and the bottom plate is fixedly connected with the lowermost plastic heat exchanging membranes through the sealing strip. The present invention has the advantages of favorable heat transfer performance, high heat exchanging efficiency, low weight and cost, simple structure, low production and running cost, convenient installation and easy integration with constructions.

Owner:TIANJIN UNIV

A kind of composite nanofiber filter material with photocatalytic/antibacterial function and preparation method thereof

ActiveCN107497182BIncrease spinning speedSolve problems such as easy blockageDispersed particle separationElectro-spinningFiberSpinning

The invention relates to a composite nano fiber filtration material with photocatalysis / anti-bacterial functions and a preparation method of the filtration material. The filtration material comprises a supporting layer and a nano fiber filtration layer which adheres to the surface of the supporting layer, the nano fiber layer is uniformly filled with an photocatalyst and an antibacterial agent, and the preparation method comprises the following steps: 1, preparing a spinning liquid: dispersing a certain amount of the photocatalyst and the antibacterial agent into a solution uniformly to form a dispersion liquid, performing ultrasonic treatment, and adding a high polymer to form a stable and uniform electrostatic spinning solution; 2, performing electrostatic spinning: setting up electrostatic spinning parameters, and performing stretching on the spinning polymer solution at solid metal wire tips for wire production by utilizing an assembled needle head; and 3, performing slight dissolving treatment on the surface of the composite nano fiber filtration material by adopting solvent vapour recovery at a certain releasing speed to obtain the final composite nano fiber filtration material with the photocatalysis / the anti-bacterial functions. The composite nano fiber filtration material effectively solves a problem that the liquid outlet end of a current needle head / spray nozzle used for the electrostatic spinning is easy to block, can be directly used for decomposition of organic pollutants, inactivation of microorganism pathogenes and the like under visible light, and has excellent filtration performance at the same time.

Owner:DONGHUA UNIV

A kind of nanofiber window screen material of multilayer composite structure and its composite method

ActiveCN107498960BAchieve a strong bondImprove bonding fastnessSynthetic resin layered productsInsect protectionNanofiberWindow screen

The invention provides a nano-fiber window screen material in a multilayer lamination structure and a preparation method of same. The nano-fiber window screen material is characterized by including, in a successive arrangement from bottom to top, a mesh screen base material, a nano-fiber layer and a cover layer. Melt-connection points are formed on the upper surface of the nano-fiber layer through solvent electrostatic spraying technology; by means of a lamination method of thermal adhesion, the cover layer is adhered to the nano-fiber layer by means of the melt-connection points. The preparation method is simple in process and low in cost. The nano-fiber window screen material in the multilayer lamination structure is not less than 90% in filtering efficiency to particles being 0.008-2 [mu]m in size and is not more than 60 Pa in resistance pressure drop. The material has long service live and has great application prospect in the technical fields of indoor air purification and dust removal.

Owner:DONGHUA UNIV

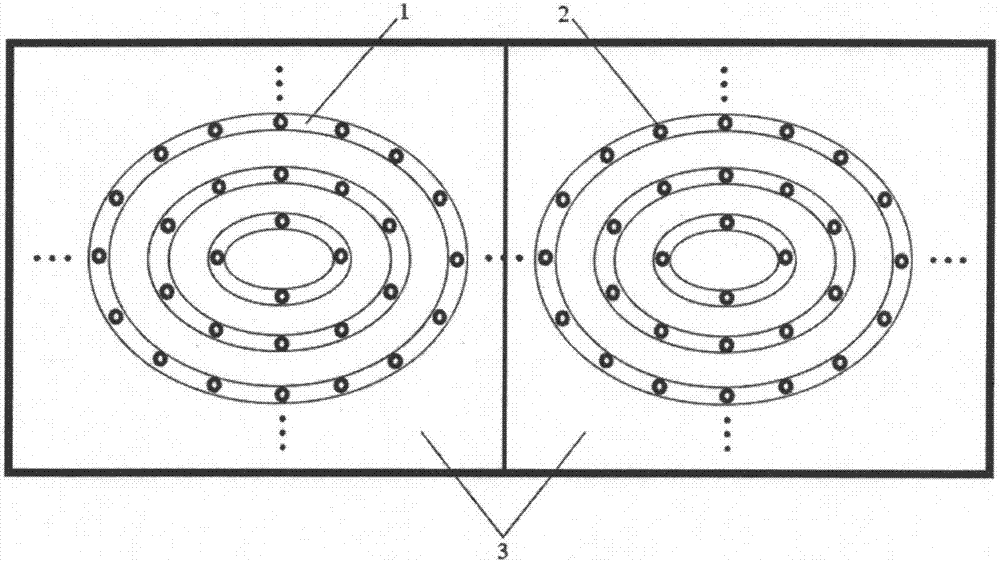

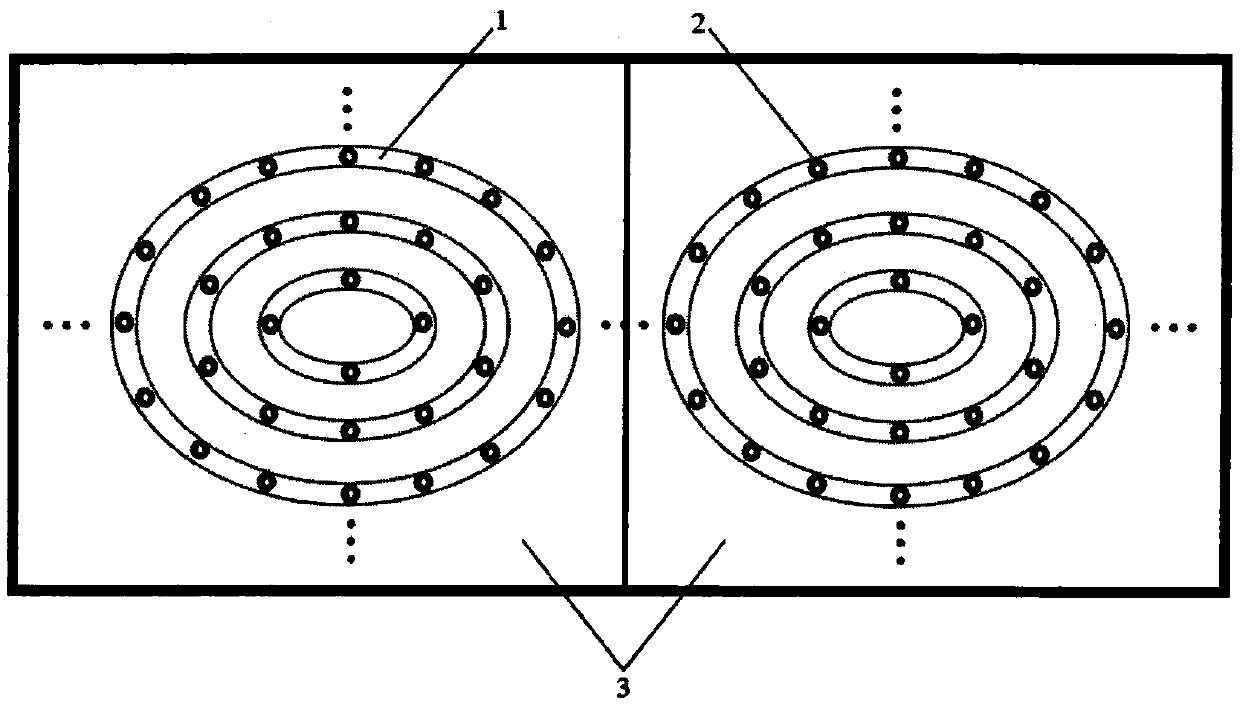

Coil pipe type double-dryness flow dividing and heat exchange evaporator

ActiveCN106949672AImprove heat transfer efficiencyReduce volumeEvaporators/condensersEngineeringEvaporator

A coil pipe type double-dryness flow dividing and heat exchange evaporator comprises heat exchange pipe sets, an inlet pipe and an outlet pipe. Each heat exchange pipe set comprises a high-dryness heat exchange pipe, a low-dryness heat exchange pipe and a centrifugal flow dividing pipe. Each centrifugal flow dividing pipe is internally provided with a high-dryness runner and a low-dryness runner. The side wall of each high-dryness runner and the side wall of the corresponding low-dryness runner communicate with each other. The inlet end of each high-dryness heat exchange pipe communicates with the inlet pipe or the high-dryness runner in the last heat exchange pipe set. The inlet end of each low-dryness heat exchange pipe communicates with the inlet pipe or the low-dryness runner in the last heat exchange pipe set. The outlet end of each high-dryness heat exchange pipe communicates with the outlet pipe or the high-dryness runner in the next heat exchange pipe set. The outlet end of each low-dryness heat exchange pipe communicates with the outlet pipe or the high-dryness runner in the next heat exchange pipe set. The coil pipe type double-dryness flow dividing and heat exchange evaporator has the characteristics of being simple and reasonable in structure, excellent in performance, small in size, good in heat exchange effect, savable in energy, environmentally friendly, low in manufacturing cost, easy to produce and achieve, safe, reliable, high in practicability and the like.

Owner:ZHONGKAI UNIV OF AGRI & ENG

A kind of microfiber three-dimensional framework/polymer nanofiber composite filter material and preparation method thereof

ActiveCN107137979BLarge specific surface areaImprove mechanical propertiesMembrane filtersFiltration separationAir filtrationPolymer science

The invention belongs to the field of textile materials and discloses a micron fiber three-dimensional framework / polymer nanofiber composite filter material and a preparation method thereof. The preparation method comprises the following steps: preparing polymer nanofibers by adopting a melt blending method; dispersing the polymer nanofibers and a crosslinking agent into a solvent to form a suspension, then soaking micron fiber nonwoven fabric skeletons into the suspension, carrying out freeze drying to form coagulation blocks, and then removing the solvent, so that a nonwoven material with polymer nanofiber aerogel gradiently distributed among the micron fiber nonwoven fabric skeletons is obtained. According to the invention, the adopted preparation technology is simple, raw materials are environment-friendly, conditions are mild, the composite filter material is applicable to industrialized mass production, and the composite filter material product has good flexibility as well as high efficiency and low resistance air filtration performance and can be applied to the field of efficient air purification.

Owner:WUHAN TEXTILE UNIV

Electret nanofiber high-efficiency filter material and preparation method thereof

ActiveCN111330355BSmall fiber diameterSmaller than surfaceDispersed particle filtrationElectrostatic separationAir filtrationPolymer science

The invention provides an electret nanofiber high-efficiency filter material and a preparation method thereof, which belong to the technical field of new materials, and solve the problem that the electret performance of the electret nanofiber filter material in the prior art is not stable, which leads to fine particles in the air. The technical problem of low particle filtration efficiency. The filter material is prepared by electrospinning a spinning solution, wherein the spinning solution includes the following components by weight: 0-30 parts of a polymer; 1-30 parts of a linear polarizable polymer; and 40-99 parts of solvent; wherein, the linear polarizable polymer is a linear polarizable polymer having a dipole structure side group of an electron donor-π conjugated system-electron acceptor. In the present invention, the linear polarizable polymer is dissolved together with the polymer, and the electrospinning technique is used to prepare a 2.5 The air filter material with filtering performance, low resistance pressure drop and maintaining ideal performance stability has the advantages of simple preparation method and low production cost.

Owner:XIAMEN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com