Nano-fiber window screen material in multilayer lamination structure and lamination method of same

A nanofiber and multi-layer composite technology, which is applied in the direction of chemical instruments and methods, lamination, windows/doors, etc., can solve the problems of nanofiber functional layer structure damage and performance degradation, and achieve fine diameter, long service life and low cost. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

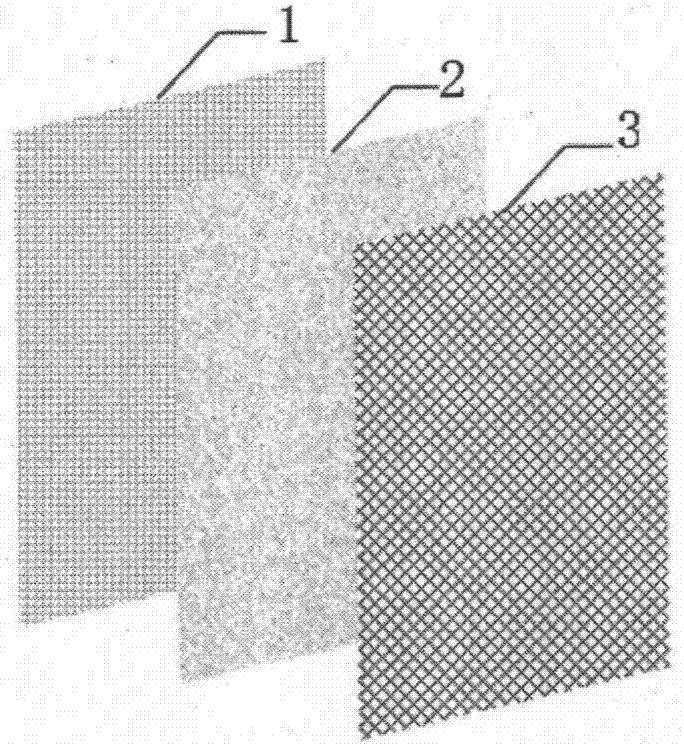

[0035] Such as figure 1 As shown, the nanofiber window screen material of the multi-layer composite structure includes a gauze base material 1, a nanofiber layer 2 and a cover layer 3 arranged in sequence from bottom to top, wherein the upper layer of the nanofiber layer 2 The surface is provided with fusion joints formed by solvent electrostatic spraying technology, and the covering layer 3 is bonded to the nanofiber layer 2 by means of the fusion joints by means of thermal bonding composite method.

[0036] The composite method of the nanofiber window screen material of the multilayer composite structure, the specific steps are:

[0037] (1) Nanofibers are deposited on the gauze substrate 1 to form a nanofiber layer 2. The specific operations are as follows:

[0038]The first step: dissolving polystyrene particles (80,000 molecular weight) in N,N-dimethylformamide, placing the solution on a magnetic stirrer and stirring for 10 hours to form a homogeneous solution; the homo...

Embodiment 2

[0044] Such as figure 1 As shown, the nanofiber window screen material of the multi-layer composite structure includes a gauze base material 1, a nanofiber layer 2 and a cover layer 3 arranged in sequence from bottom to top, wherein the upper layer of the nanofiber layer 2 The surface is provided with fusion joints formed by solvent electrostatic spraying technology, and the covering layer 3 is bonded to the nanofiber layer 2 by means of the fusion joints by means of thermal bonding composite method.

[0045] The composite method of the nanofiber window screen material of the multilayer composite structure, the specific steps are:

[0046] (1) Nanofibers are deposited on the gauze substrate 1 to form a nanofiber layer 2. The specific operations are as follows:

[0047] The first step: dissolving polystyrene particles (molecular weight 100,000) in N,N-dimethylformamide, placing the solution on a magnetic stirrer and stirring for 10 hours to form a homogeneous solution; the ho...

Embodiment 3

[0053] Such as figure 1 As shown, the nanofiber window screen material of the multi-layer composite structure includes a gauze base material 1, a nanofiber layer 2 and a cover layer 3 arranged in sequence from bottom to top, wherein the upper layer of the nanofiber layer 2 The surface is provided with fusion joints formed by solvent electrostatic spraying technology, and the covering layer 3 is bonded to the nanofiber layer 2 by means of the fusion joints by means of thermal bonding composite method.

[0054] The composite method of the nanofiber window screen material of the multilayer composite structure, the specific steps are:

[0055] (1) Nanofibers are deposited on the gauze substrate 1 to form a nanofiber layer 2. The specific operations are as follows:

[0056] The first step: dissolving polystyrene particles (molecular weight: 150,000) in N,N-dimethylformamide, placing the solution on a magnetic stirrer and stirring for 10 hours to form a homogeneous solution; the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com