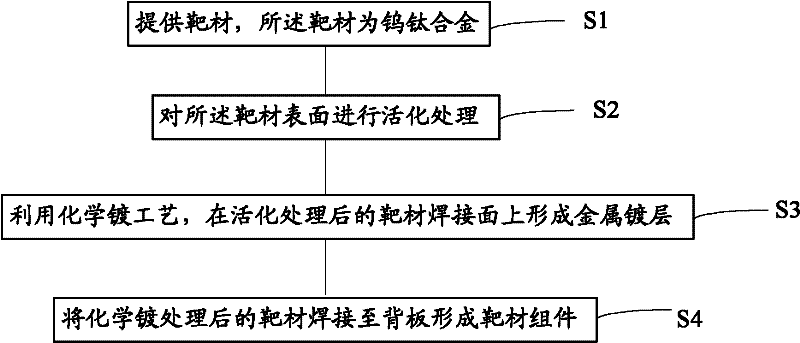

Method for manufacturing tungsten titanium alloy target structure

A production method and tungsten-titanium alloy technology, which are applied in metal material coating technology, manufacturing tools, metal processing equipment, etc., can solve the problem of not meeting the requirements of semiconductor targets, low bonding strength of tungsten-titanium alloy targets and backplates, etc. problem, to achieve high bonding strength and achieve the effect of industrialized production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0075] Take 3N5, 4N5 or 5N tungsten-titanium alloy target as an example to illustrate the process steps and results of the present invention:

[0076] (1) Polish each surface of the tungsten-titanium alloy target (230mm in length, 202mm in width, and 12mm in thickness), first use 160# water-based sandpaper to polish each surface of the target for 10 minutes (min); then Use 400# water-based sandpaper to continue to polish each surface of the target for 8 minutes (min), so that a smooth and bright grinding surface can be obtained;

[0077] (2) Clean each surface of the polished tungsten-titanium alloy target with pure water or deionized water for 5 minutes (min), and dry it;

[0078] (3) Sandblasting process is carried out on each surface of the tungsten-titanium alloy target material after drying; adopt No. 46 white corundum, the air pressure is 0.4MPa, the distance from the nozzle of the sandblasting gun to the surface of the target material is 15cm, and the nozzle The angle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com