A short process preparation method of copper-carbon composite material

A composite material and short-process technology, which is applied in the field of short-process preparation of carbon-copper composite materials, can solve the problems of high carbon content, increased process cost, and deteriorated material performance of copper-carbon composite materials, so as to achieve improved mechanical properties, excellent electrical properties, and improved The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

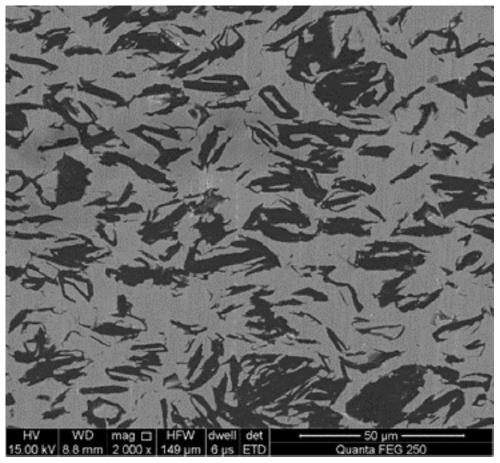

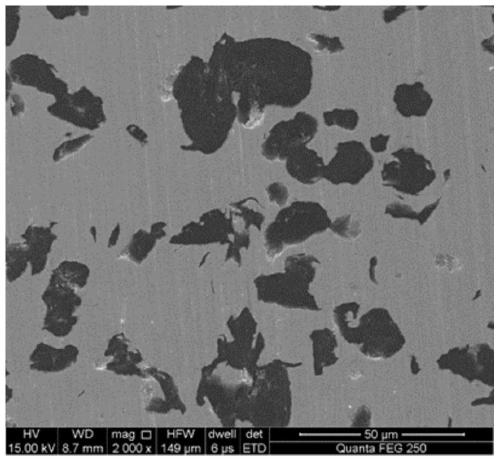

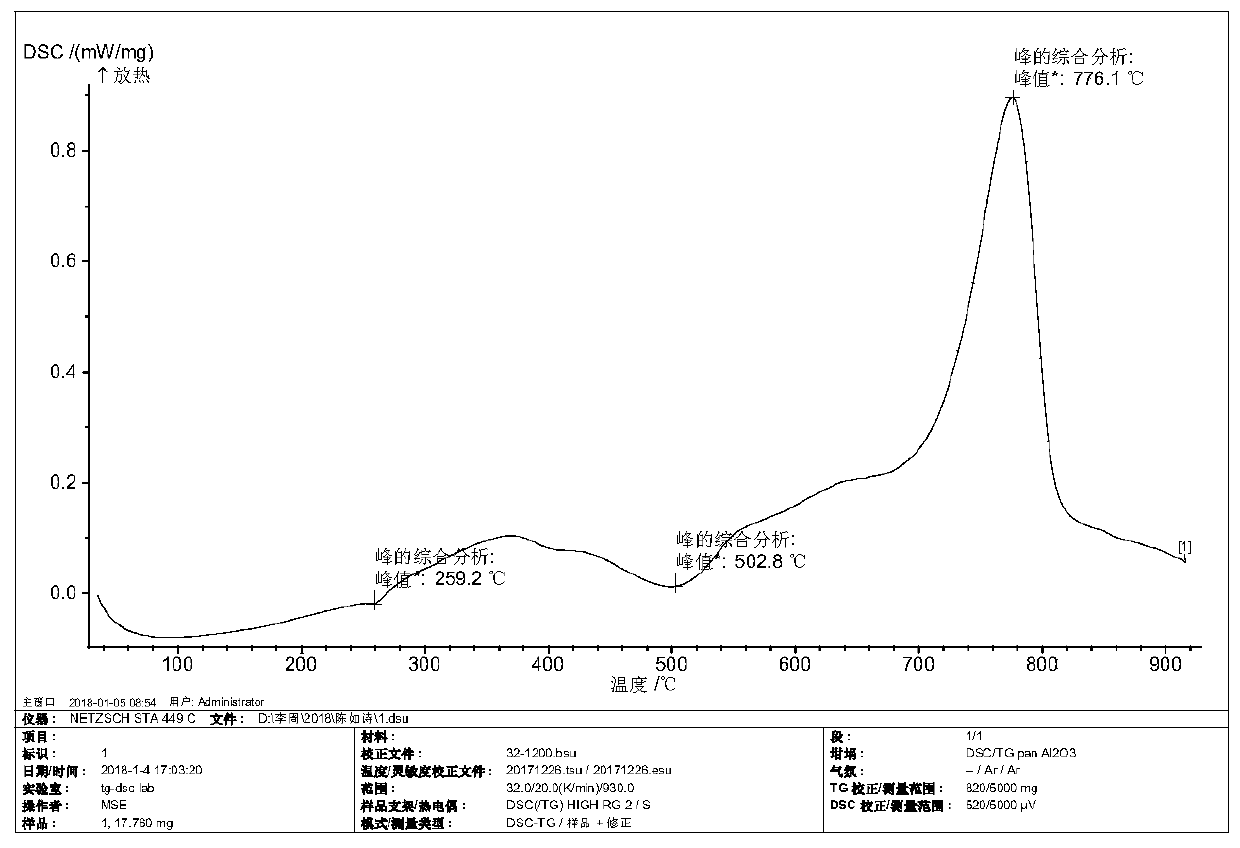

Embodiment 1

[0039] Select the copper oxide powder whose particle size range is 75-125 μm, the cuprous oxide powder whose particle size range is 75-125 μm, and the graphite powder whose particle size range is 30-80 μm as raw materials, and prepare the copper-carbon composite material according to the following steps, (1 ) Gas-protected ball milling: 10g cupric oxide powder, 90g cuprous oxide powder and 19g powdered graphite are packed into the ball milling tank of argon-filled planetary ball mill for ball milling, the ball-material ratio is 8:1, the rotating speed is 150rpm, and the ball milling time is 2 hours; (2) Vacuum hot pressing: cold press the mixed powder obtained in step (1) and put it into a copper sleeve, then put the copper sleeve into a vacuum hot press mold, and evacuate to 10 -3 Pa, after raising the temperature to 500°C at a rate of 10°C / min, pressurize at 15MPa, keep the temperature for 3h, then raise the temperature to 900°C at a rate of 15°C / min, pressurize at 40MPa, and...

Embodiment 2

[0046] Select the copper oxide powder whose particle size range is 75-125 μm, the cuprous oxide powder whose particle size range is 75-125 μm, and the graphite powder whose particle size range is 30-80 μm as raw materials, and prepare the copper-carbon composite material according to the following steps, (1 ) Gas-protected ball milling: 10g cupric oxide powder, 90g cuprous oxide powder and 33g powdered graphite are packed into the ball milling tank of the planetary ball mill filled with argon for ball milling, the ball-to-material ratio is 8:1, the rotating speed is 150rpm, and the ball milling time is 2 hours; (2) Vacuum hot pressing: cold press the mixed powder obtained in step (1) and put it into a copper sleeve, then put the copper sleeve into a vacuum hot press mold, and evacuate to 10 -3 Pa, after raising the temperature to 500°C at a rate of 10°C / min, pressurize at 15MPa, keep the temperature for 3h, then raise the temperature to 900°C at a rate of 15°C / min, pressurize a...

Embodiment 3

[0049] Select the copper oxide powder whose particle size range is 75-125 μm, the cuprous oxide powder whose particle size range is 75-125 μm, and the graphite powder whose particle size range is 30-80 μm as raw materials, and prepare the copper-carbon composite material according to the following steps, (1 ) Gas-protected ball milling: 10g cupric oxide powder, 90g cuprous oxide powder and 45g powdered graphite are packed into the ball milling tank of argon-filled planetary ball mill for ball milling, the ball-material ratio is 8:1, the rotating speed is 150rpm, and the ball milling time is 2 hours; (2) Vacuum hot pressing: cold press the mixed powder obtained in step (1) and put it into a copper sleeve, then put the copper sleeve into a vacuum hot press mold, and evacuate to 10 -3 Pa, after raising the temperature to 500°C at a rate of 10°C / min, pressurize at 15MPa, keep the temperature for 3h, then raise the temperature to 900°C at a rate of 15°C / min, pressurize at 40MPa, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com