A kind of pvc furniture film/pvf plastic film water-based adhesive and preparation method thereof

A water-based adhesive, plastic film technology, applied in the direction of adhesive types, ester copolymer adhesives, etc., can solve problems such as restricting applications, and achieve the effect of ensuring bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] (1) Preparation of the monomer phase of the core layer

[0053] At room temperature, 16.3kg of methyl methacrylate monomer (Guangzhou Zhongye Chemical Co., Ltd.), 10.2kg of methyl methacrylate monomer (Shanghai Mairuier Chemical Technology Co., Ltd.), 0.0014kg of 3-mercaptopropionic acid Isooctyl ester (Sinopharm Chemical Reagent Co., Ltd.) chain transfer reagent, 1.5kg of ER-40 (ADEKA company) nonionic emulsifier mixed, and stirred and dissolved at a speed of 450rpm for 30min to obtain the nuclear layer monomer phase;

[0054] (2) Preparation of shell monomer phase

[0055] At room temperature, 6.9kg of methyl methacrylate monomer (Guangzhou Zhongye Chemical Co., Ltd.), 5.3kg of methyl methacrylate monomer (Shanghai Mairuier Chemical Technology Co., Ltd.), 0.2kg of methylene succinic acid Monomer (Sinopharm Group Chemical Reagent Co., Ltd.), 0.16kg of 2-(perfluorohexyl) ethyl methacrylate monomer (Bailingwei Technology Co., Ltd.), 0.0008kg of 3-mercapto propionate iso...

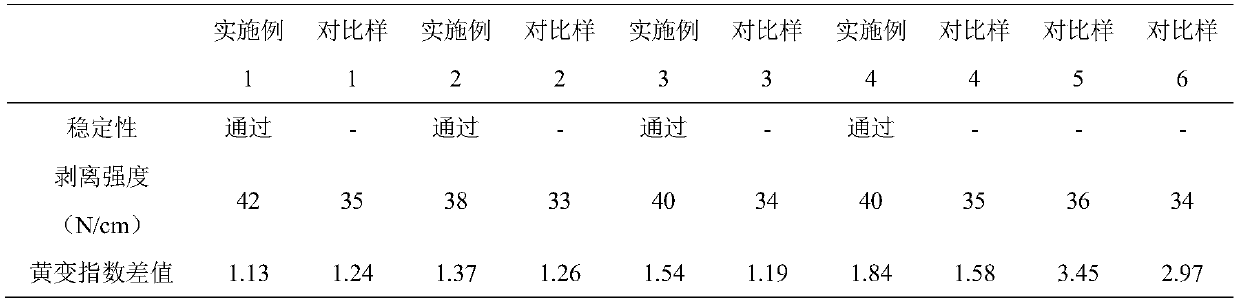

Embodiment 1

[0065] First, 70kg of bonding resin is added to a dispersing sand mill (SDF400 experimental dispersing sand mill, Jiangyin Shuangfeng Chemical Machinery Co., Ltd.), and stirring is started at a speed of 1500rpm; secondly, 15kg of deionized water, 12kg of ethanol (Suzhou Outer Chemical Co., Ltd.) mixed and added to the dispersion sand mill; then 0.7kg of LeAD177 wetting agent (Lijia Auxiliary Company), 0.4kg of DF 3163 defoamer (Deqian Company), 0.1kg of DeuAdd MB-16 preservative (Deqian Company), 1.8kg of Latekoll D thickener (BASF Company) were added in turn, and finally the stirring speed was adjusted to 2500rpm, Stir for 0.5h to filter and discharge to obtain the PVC furniture film / PVF plastic film water-based adhesive.

Embodiment 2

[0067] First, 30kg of bonding resin was added to a dispersing sand mill (SDF400 experimental dispersing sand mill, Jiangyin Shuangfeng Chemical Machinery Co., Ltd.), and started stirring at a speed of 1200rpm; secondly, 35kg of deionized water, 25kg of iso Propanol (Suzhou Outer Chemical Co., Ltd.) was mixed and added to the dispersion sand mill; then 0.6kg of LeAD177 wetting agent (Lijia Auxiliary Company), 0.2kg of DF 3163 defoamer (Deqian Company), 0.2kg of DeuAdd MB-16 preservative (Deqian Company), 9kg of Latekoll D thickener (BASF Company) were added in turn, and finally the stirring speed was adjusted to 2500rpm, stirring The material was filtered and discharged for 1 hour to obtain the PVC furniture film / PVF plastic film water-based adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com