Coil pipe type double-dryness flow dividing and heat exchange evaporator

A coil-type, thermal evaporation technology, applied in evaporators/condensers, lighting and heating equipment, refrigeration components, etc., can solve the problems of easy scaling on the outer wall of the coil, large flow pressure drop in the tube, and pressure loss in the tube, etc. Achieve the effect of improving overall heat exchange efficiency, saving consumables and energy, and reducing resistance and pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

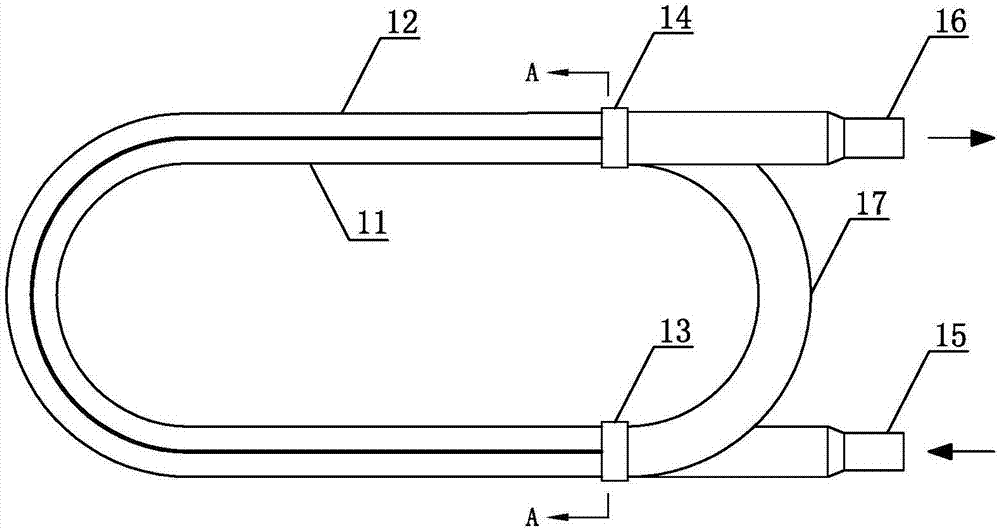

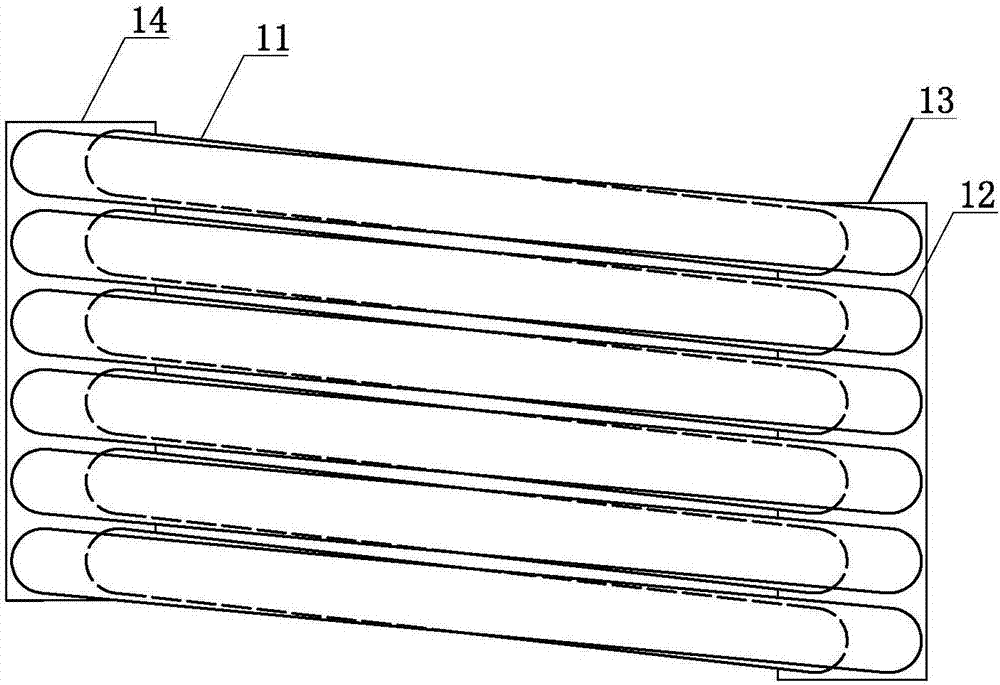

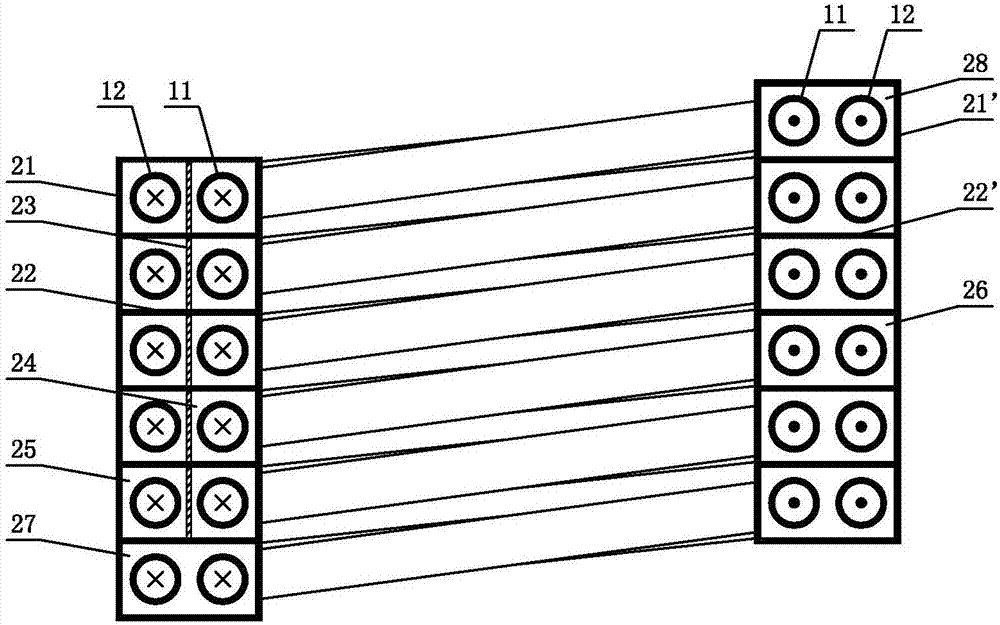

[0025] see Figure 1-Figure 9 , the coil-type double dryness split heat exchange evaporator includes six sets of interconnected heat exchange tube groups, the inlet end of the first heat exchange tube group is connected to the inlet pipe 15, and the outlet end of the tail group heat exchange tube group is connected to There is an outlet pipe 16, and the evaporating liquid is passed through the heat exchange tube group; specifically, the heat exchange tube group includes a high-quality heat exchange tube 11, a low-quality heat exchange tube 12 and a centrifugal shunt tube 17, wherein the centrifugal shunt The tube 17 is provided with a high dryness flow channel 34 and a low dryness flow channel 35, the side walls of the high dryness flow channel 34 and the side walls of the low dryness flow channel 35 communicate with each other; the high dryness flow ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com