Patents

Literature

112results about How to "Small fiber diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

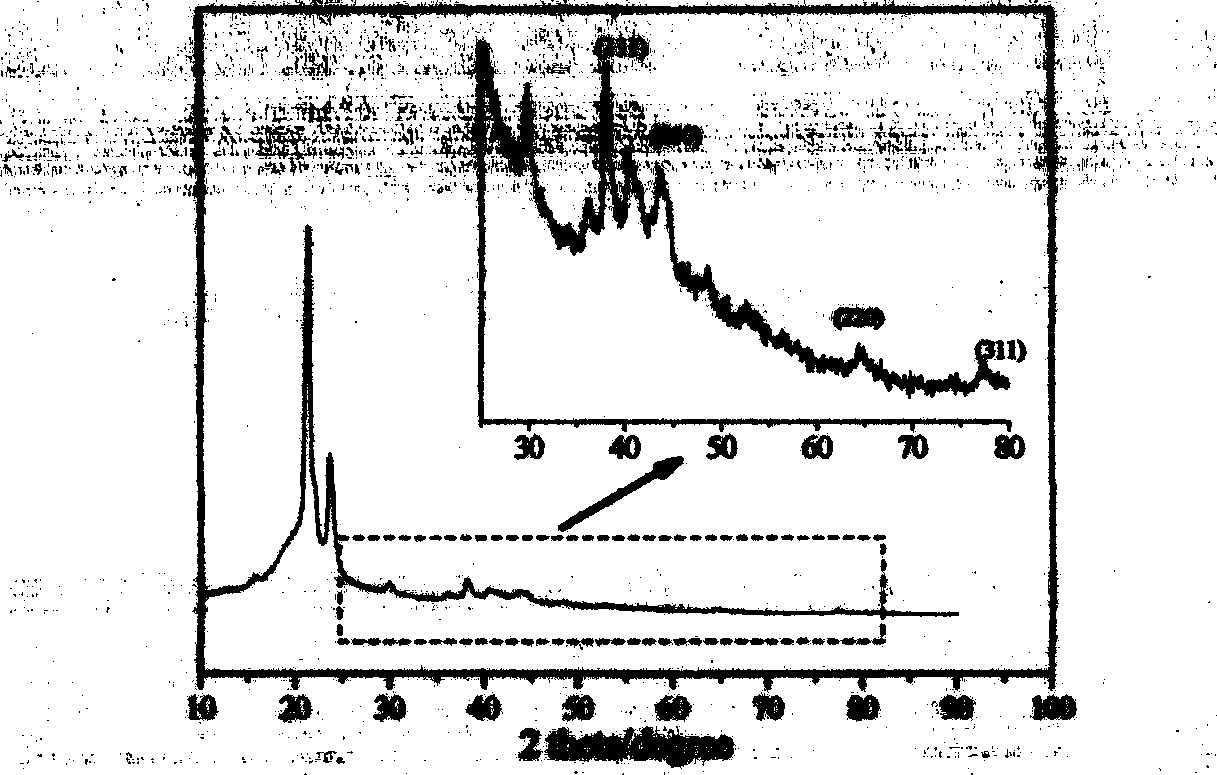

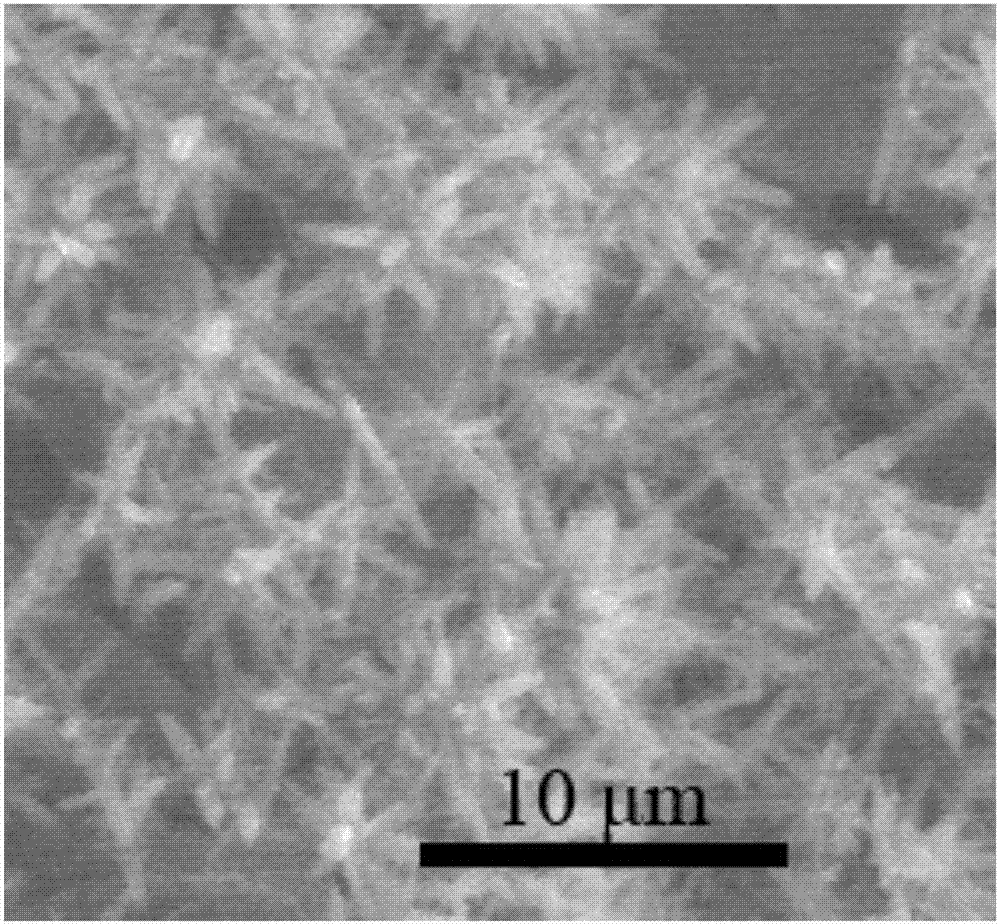

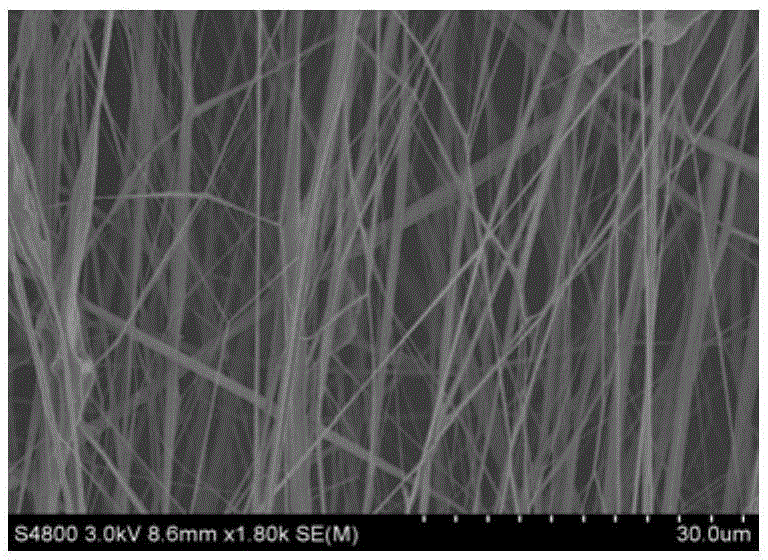

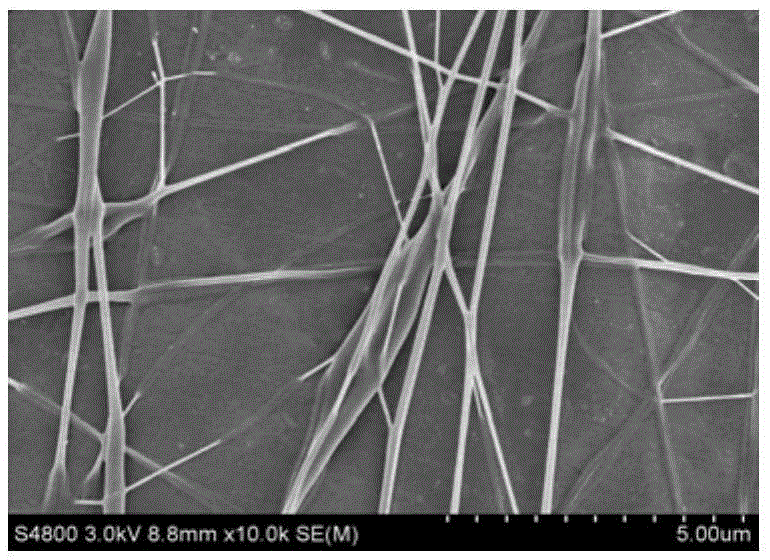

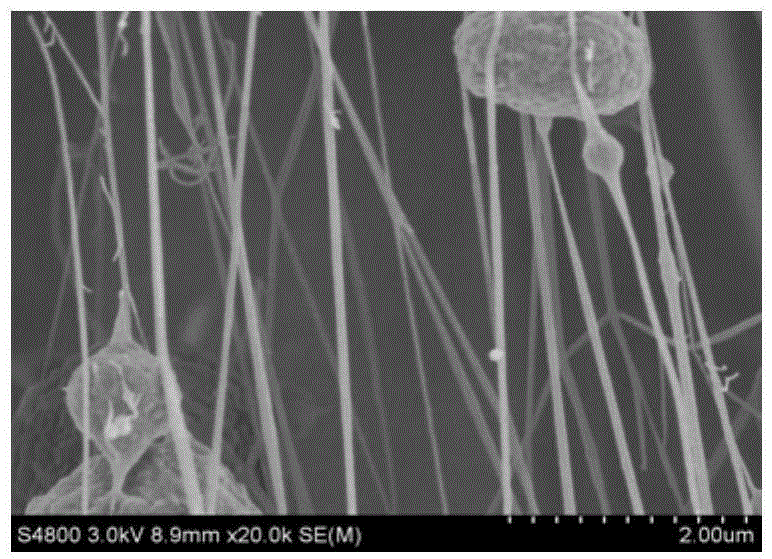

Preparation method of silicon-carbide-fibrofelt-enhanced silica aerogel composite material

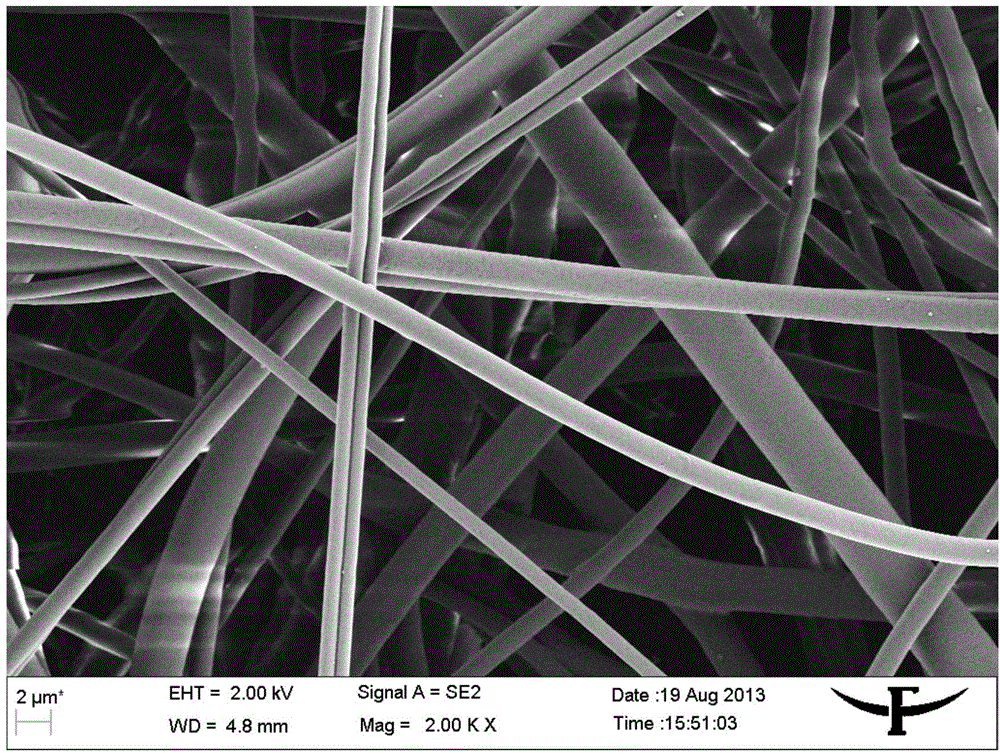

The invention relates to a preparation method of a silicon-carbide-fibrofelt-enhanced silica aerogel composite material, and relates to an aerogel composite material. According to the invention, a carbon-rich silicon carbide micro-nano ceramic fibrofelt with small fiber diameter, high porosity, communicating pores, fast impregnation speed, and good compatibility with a substrate is prepared with a static electro-spinning technology combined with a precursor conversion method; a silica sol is prepared with an acid-alkali two-step method; with an infiltration technology, the electro-spun silicon carbide ceramic fibrofelt or precast is soaked into the sol; and through processes such as gel process, aging, curing, solvent exchange, supercritical drying, and the like, the silicon-carbide-fibrofelt-enhanced silica aerogel composite material is obtained. The prepared composite material has the characteristics of low density, large specific surface area, super-hydrophobicity, low thermal conductivity, and the like. The strength and toughness of the material are also greatly improved. The carbon-rich silicon carbide fiber has an infrared shielding effect, such that composite material thermal insulation effect and ultra-high-temperature stability can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

Bone grafting materials

InactiveUS7241486B2High strengthHigh porosityBone implantSynthetic resin layered productsFiberGlass fiber

The present invention relates to porous bone filling materials prepared by sintering bioactive glass fibers in order to achieve a three dimensional block with interconnecting porosity. Due to the osteoconductive properties the bioactive glass fibers, in block form are an ideal scaffold for new tissue (e.g. bone or cartilage) formation to occur. The manufacturing parameters can be adjusted to achieve porosities as high as 90 vol-%, or the manufacturing parameters can be adjusted to prepare strong porous blocks useful in load bearing application.

Owner:INION

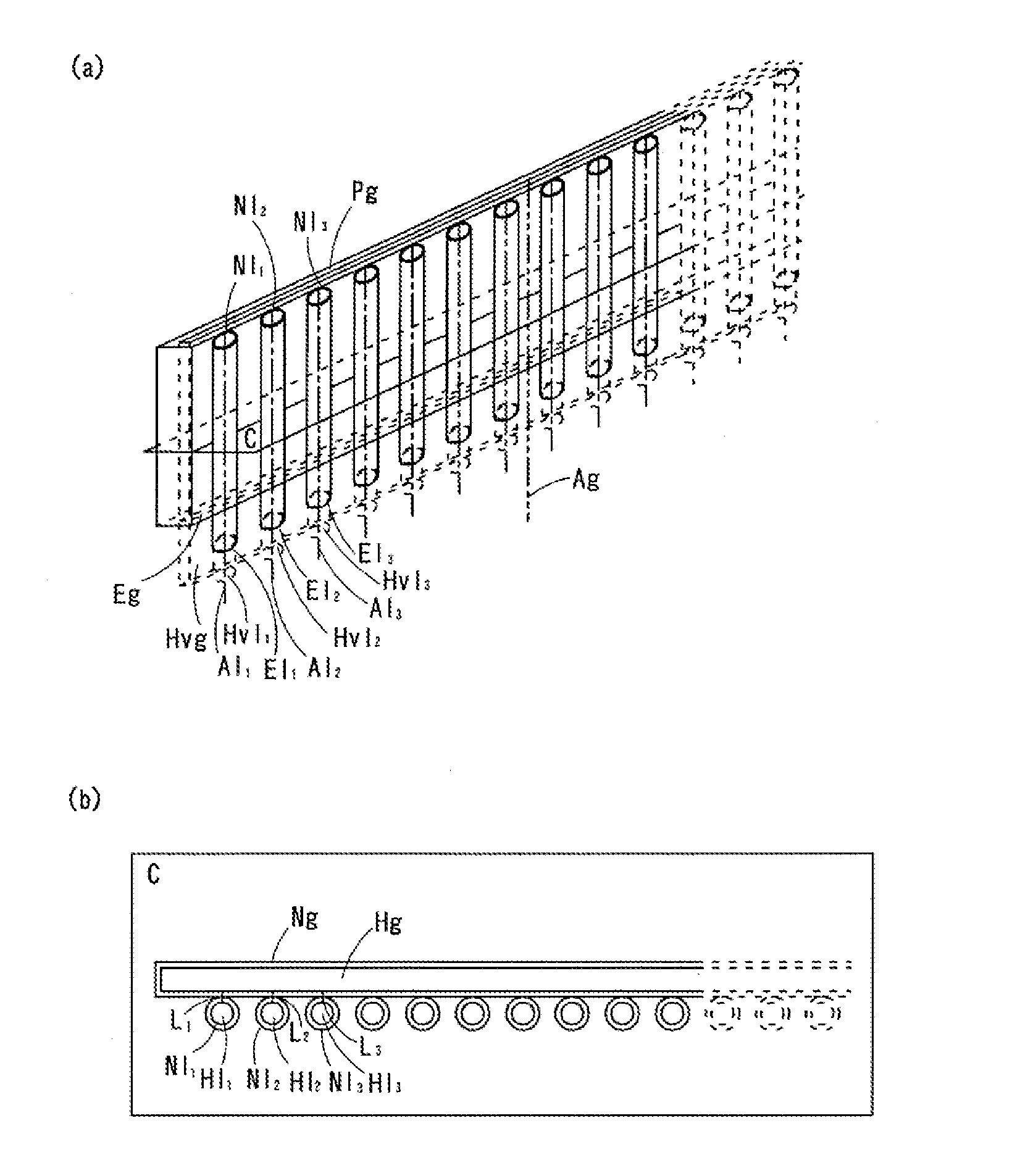

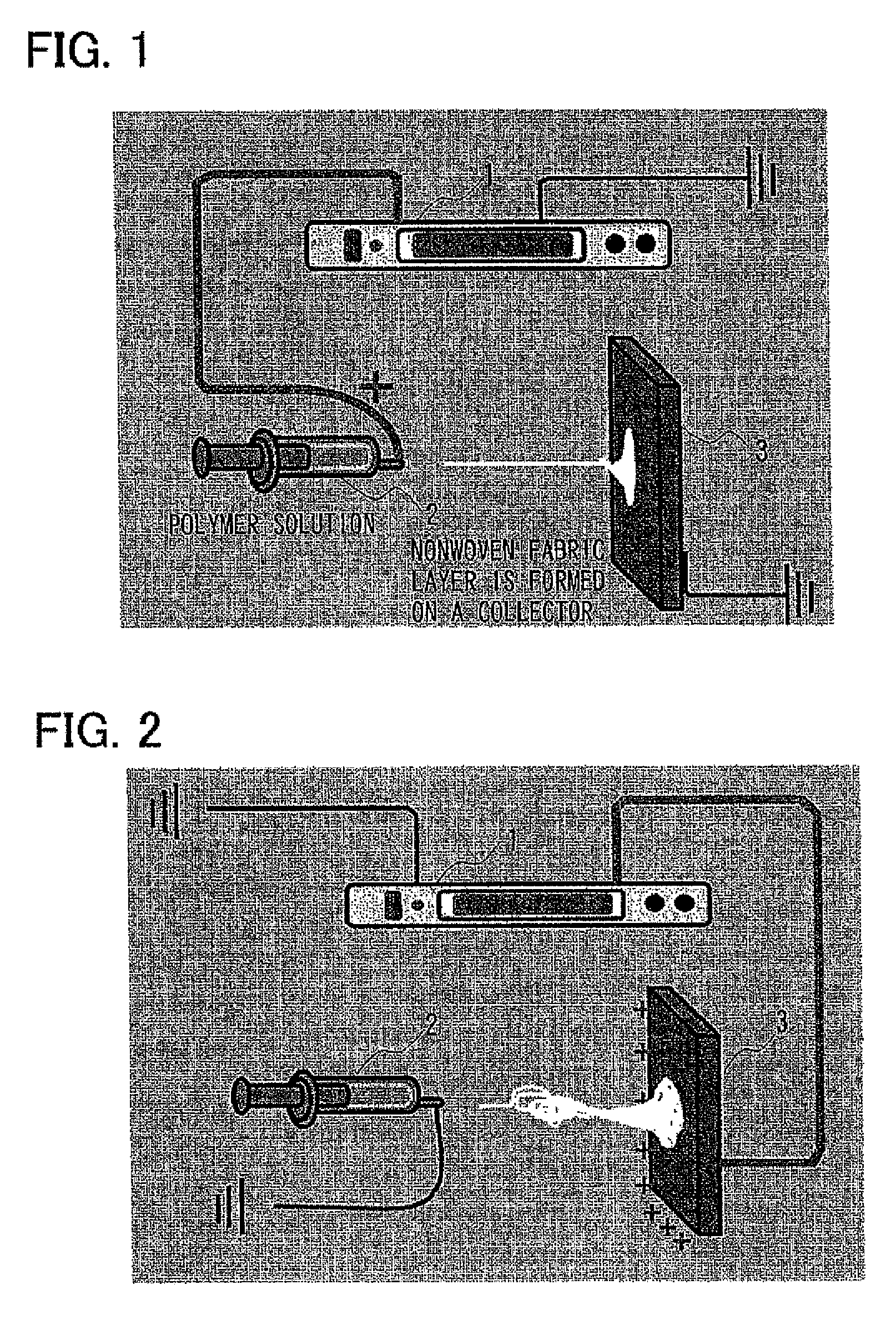

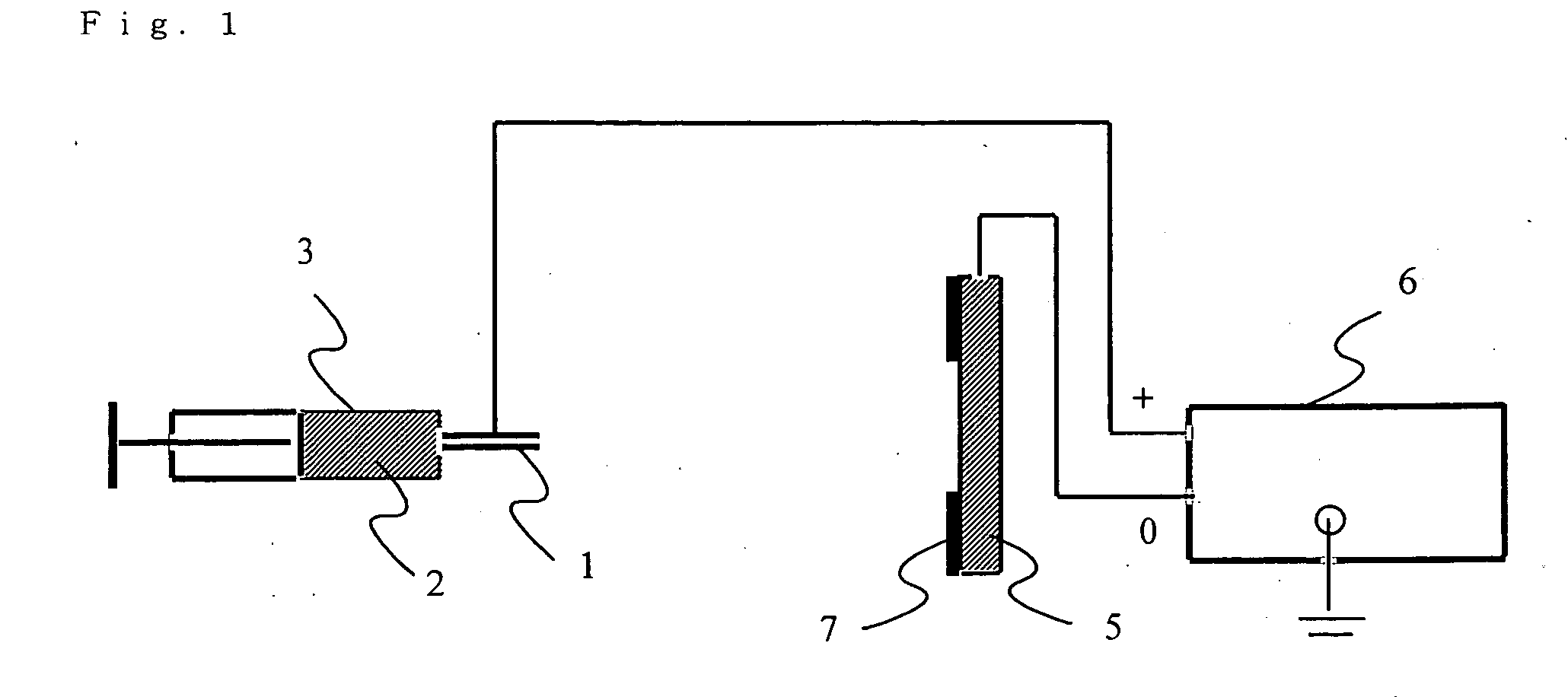

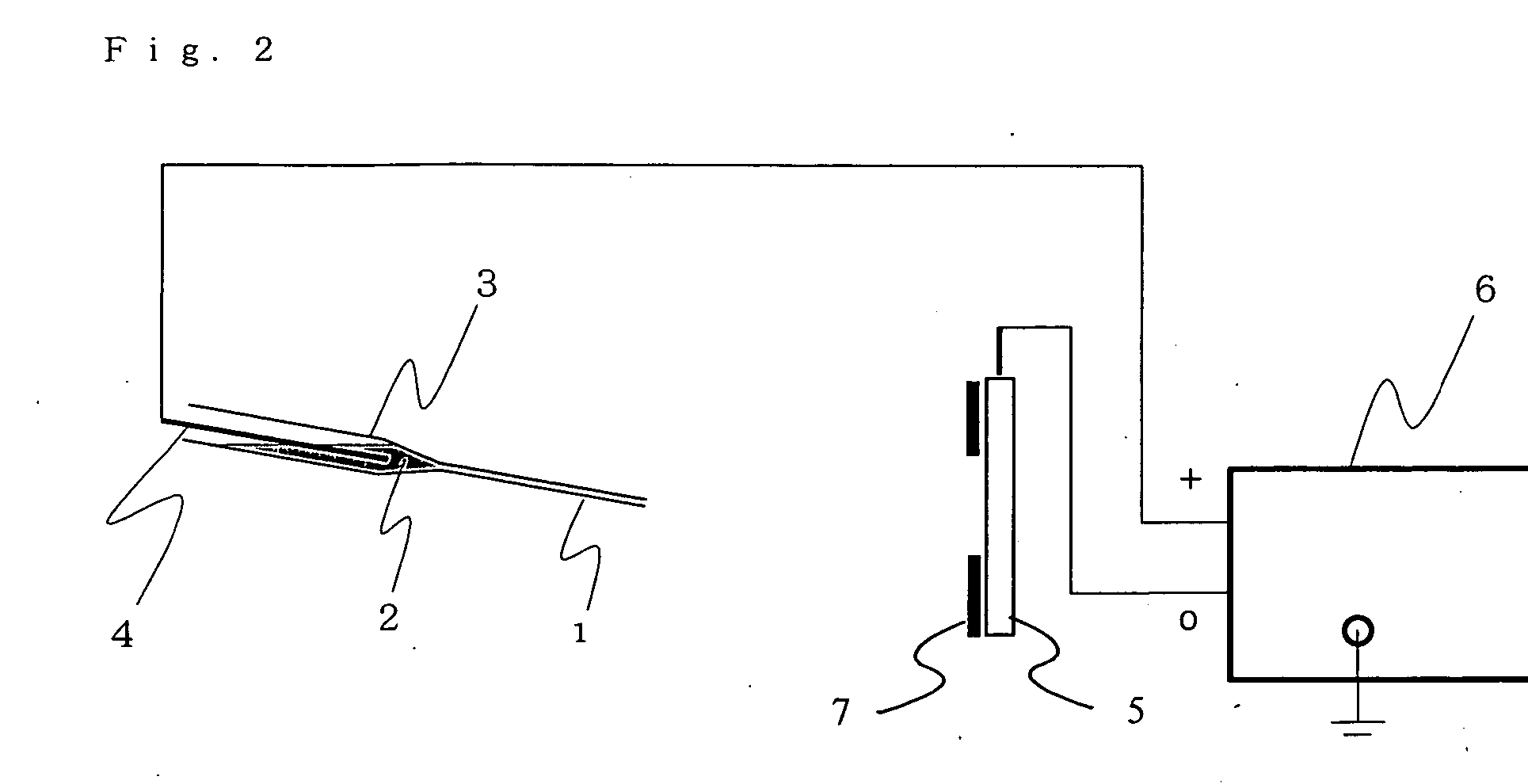

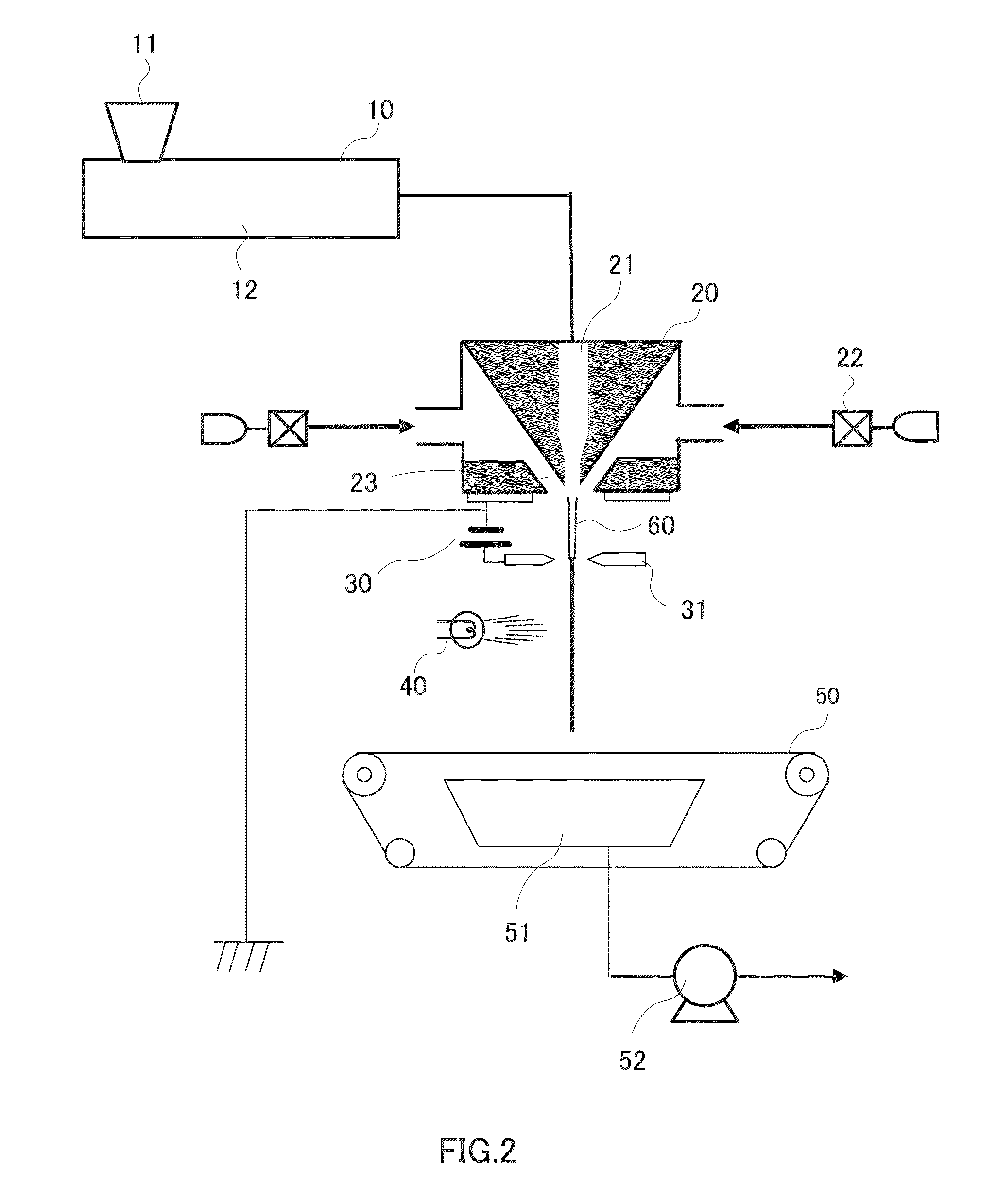

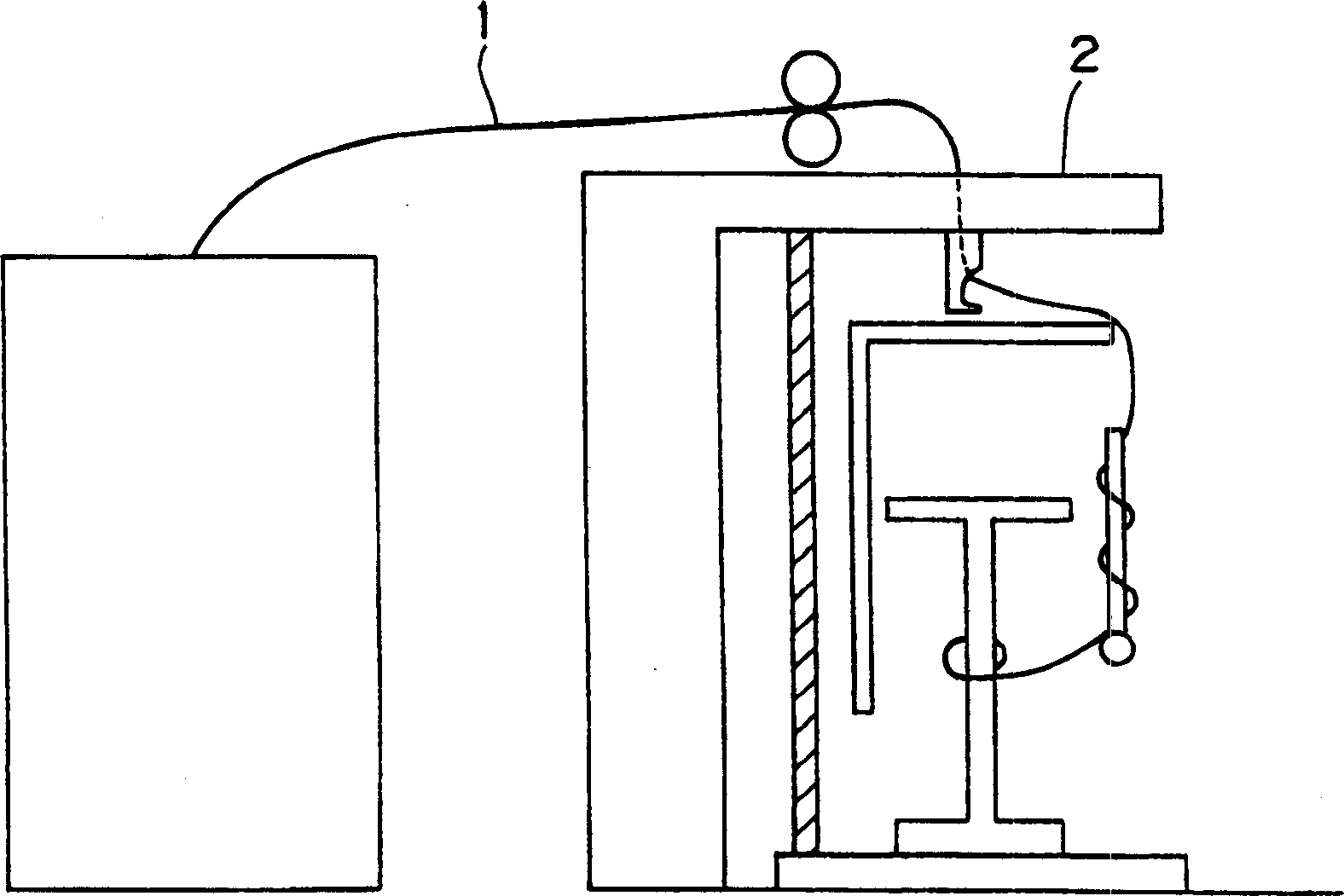

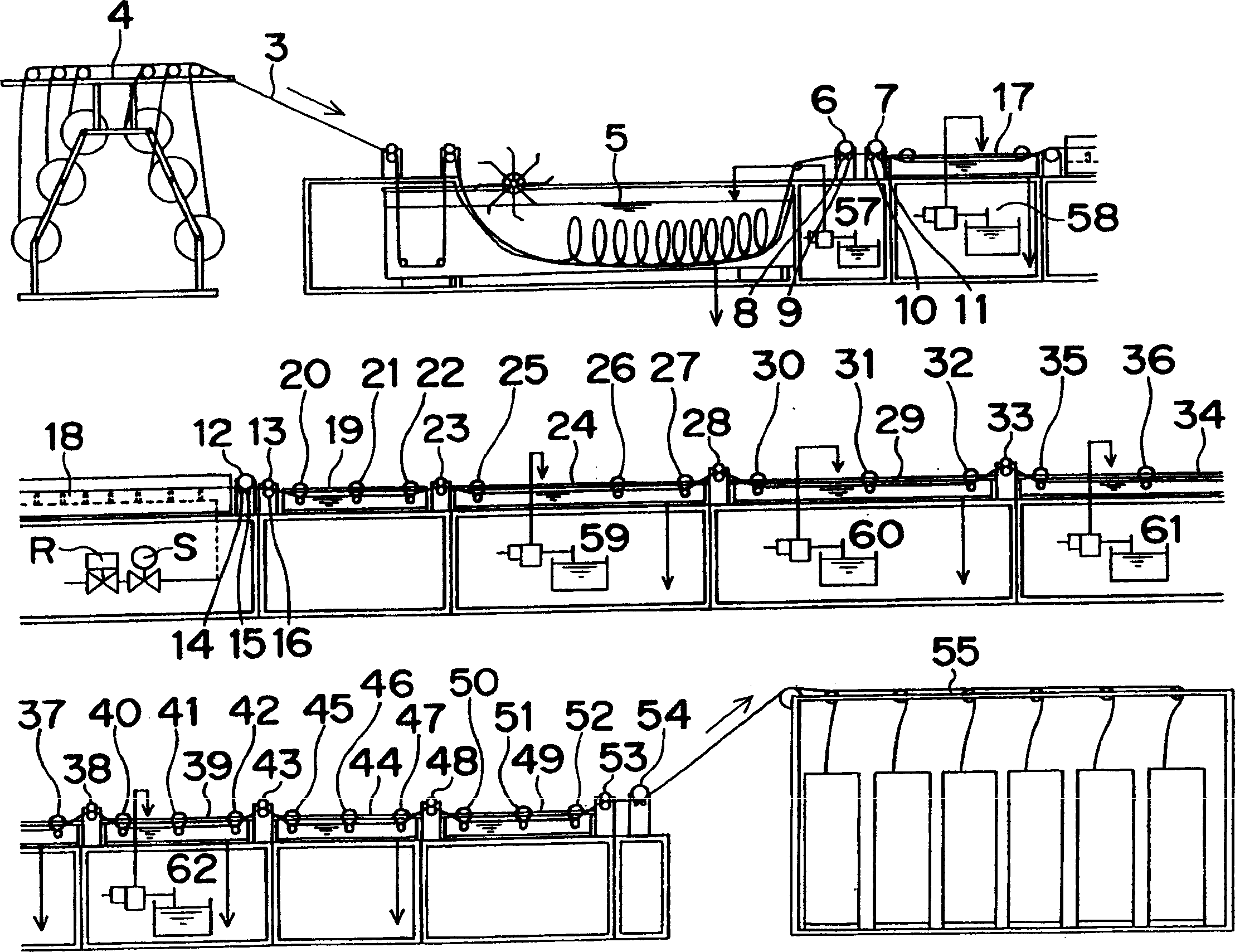

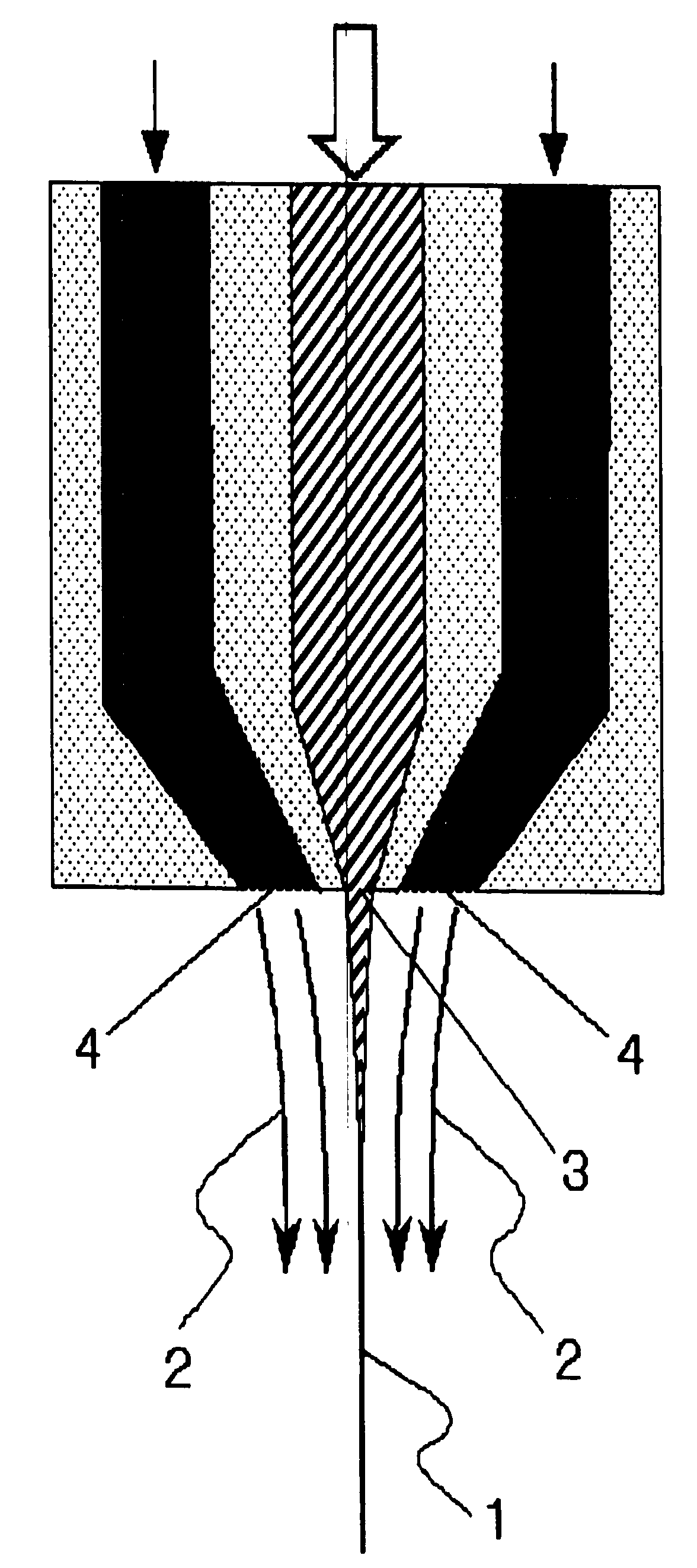

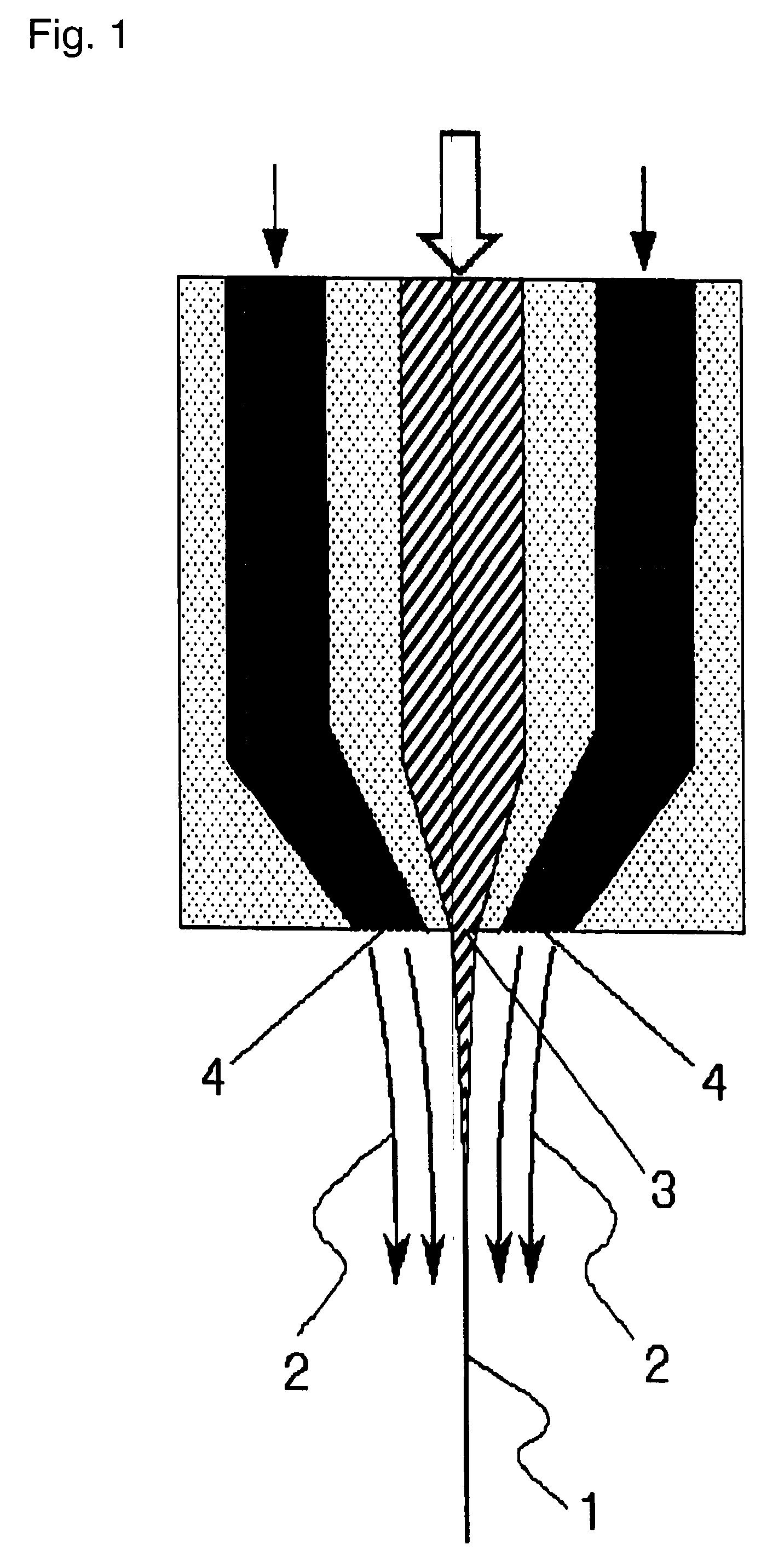

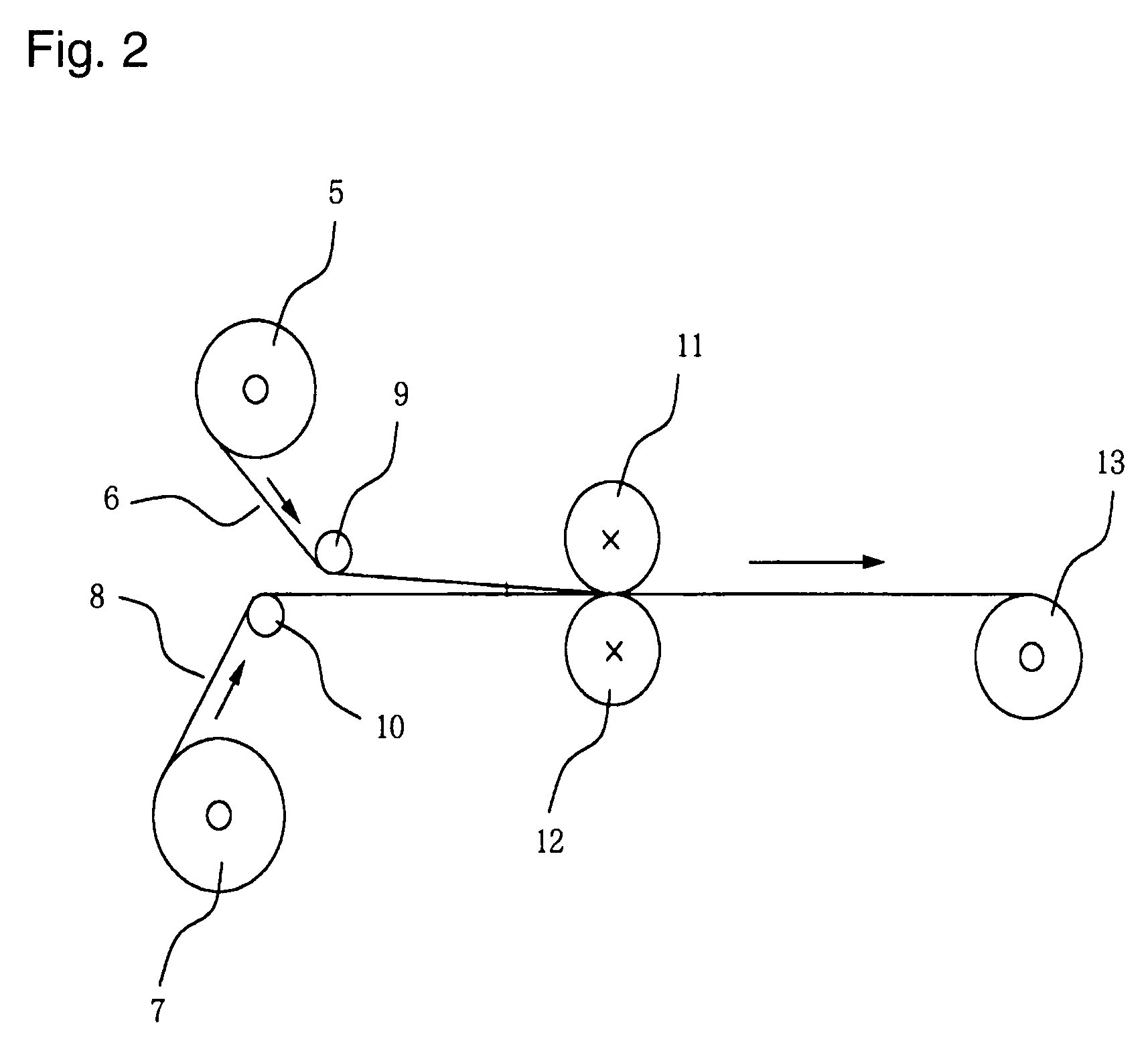

Spinning apparatus, apparatus and process for manufacturing nonwoven fabric, and nonwoven fabric

InactiveUS20110130063A1Smooth rotationImprove productivitySpinnerette packsCeramic shaping apparatusProduction rateManufactured apparatus

Provided are a spinning apparatus capable of stably spinning fibers having a small fiber diameter with a high productivity, an apparatus comprising the same for manufacturing a nonwoven fabric, a process for manufacturing a nonwoven fabric using the nonwoven fabric manufacturing apparatus, and a nonwoven fabric produced by the process.The spinning apparatus of the present invention comprises one or more exits for extruding liquid, which are capable of extruding a spinning liquid, and one or more exits for ejecting gas, which extend linearly and are located upstream of each of the exits for extruding liquid and which are capable of ejecting a gas, wherein a shearing force by the gas and its accompanying airstream can be single-linearly exerted on the spinning liquid extruded. The apparatus of the present invention for manufacturing a nonwoven fabric comprises a fibers collection means as well as the spinning apparatus. The process of the present invention for manufacturing a nonwoven fabric is a process using the apparatus for manufacturing a nonwoven fabric. The nonwoven fabric of the present invention is a nonwoven fabric produced by the process.

Owner:NIPPON BAIRIIN

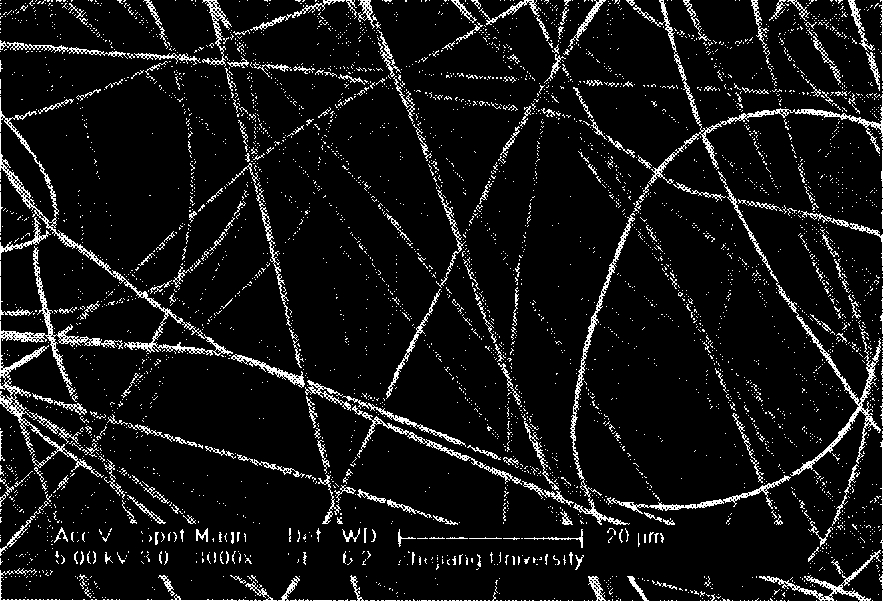

Polyacrylonitrile mesopore-macropore ultrafine carbon fiber and its preparation method

InactiveCN1884643ASmall fiber diameterLarge specific surface areaSemi-permeable membranesOther chemical processesSolventChemistry

The invention discloses a making method of polyacrylonitile hole-large hole ultra-fine carbon fiber, which comprises the following steps: dissolving polymerization to decompose completely under non-oxidizing environment through heat and polyacrylonitile or polyacrylonitile copolymer in the solvent; preparing super-fine fiber through high-pressure electrostatic spinning method; drying fiber; preoxidizing at 100-300 deg.c; carbonizing at 300-1800 deg.c in the nitrogen or other inert gas environment; decomposing heat-decomposable polymerization to remain 1-200 nanometer millipore in the fiber; fitting for certain large-size particle adsorption and separation (such as virus, bacteria and so on).

Owner:ZHEJIANG UNIV

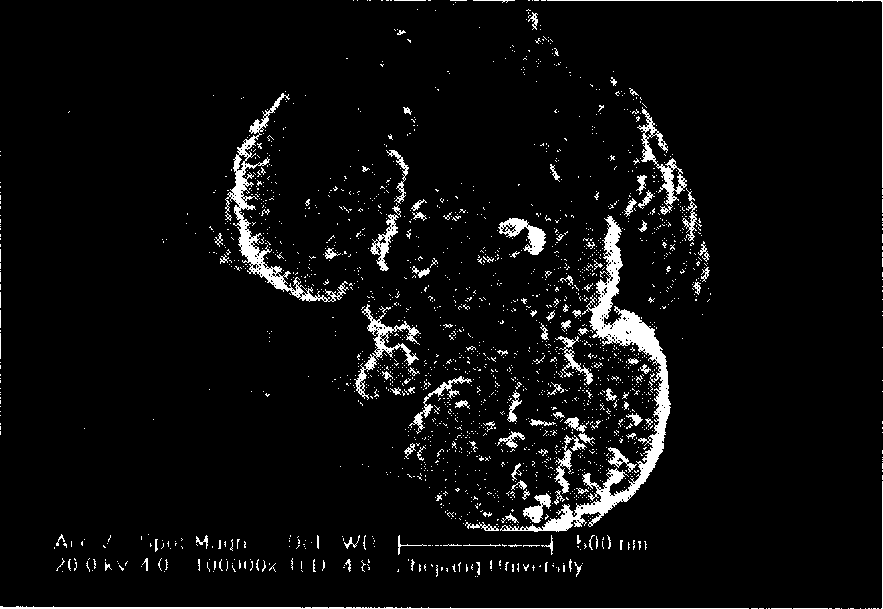

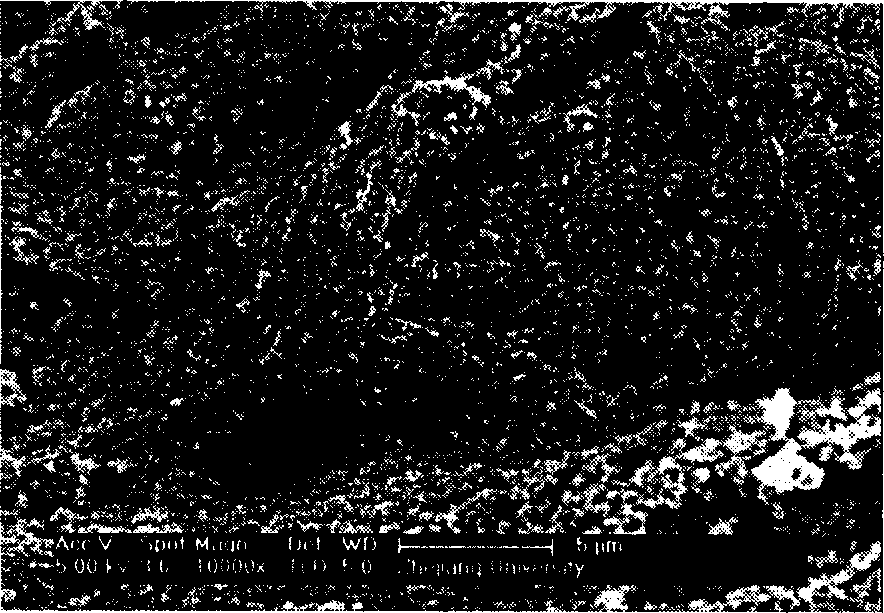

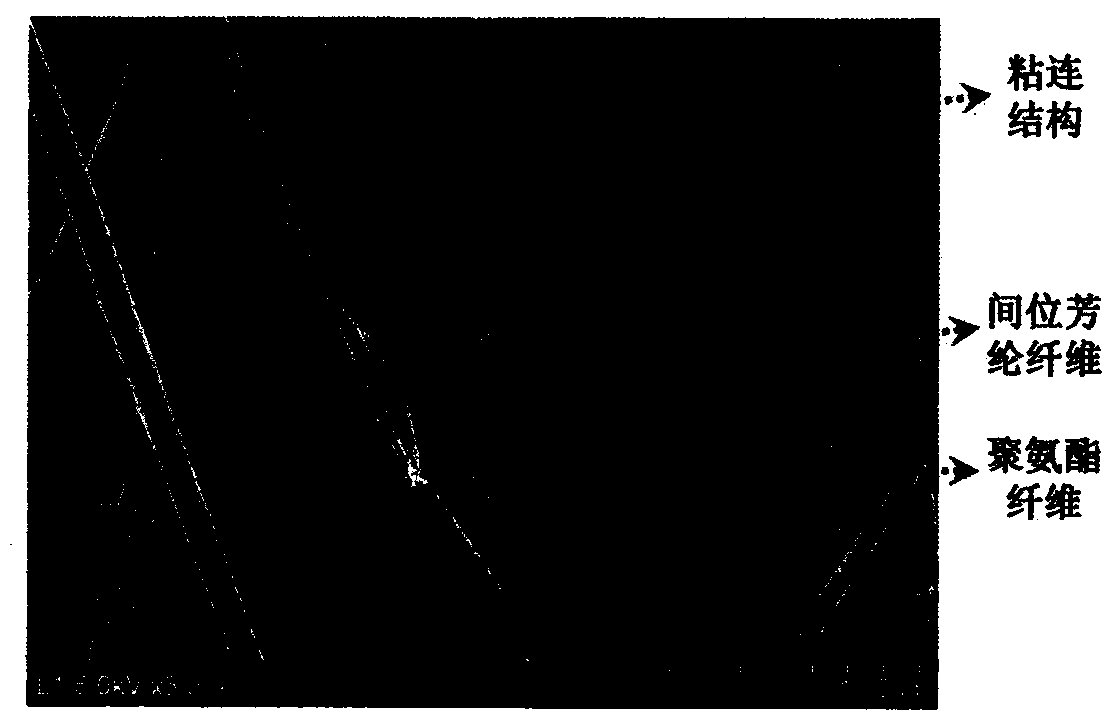

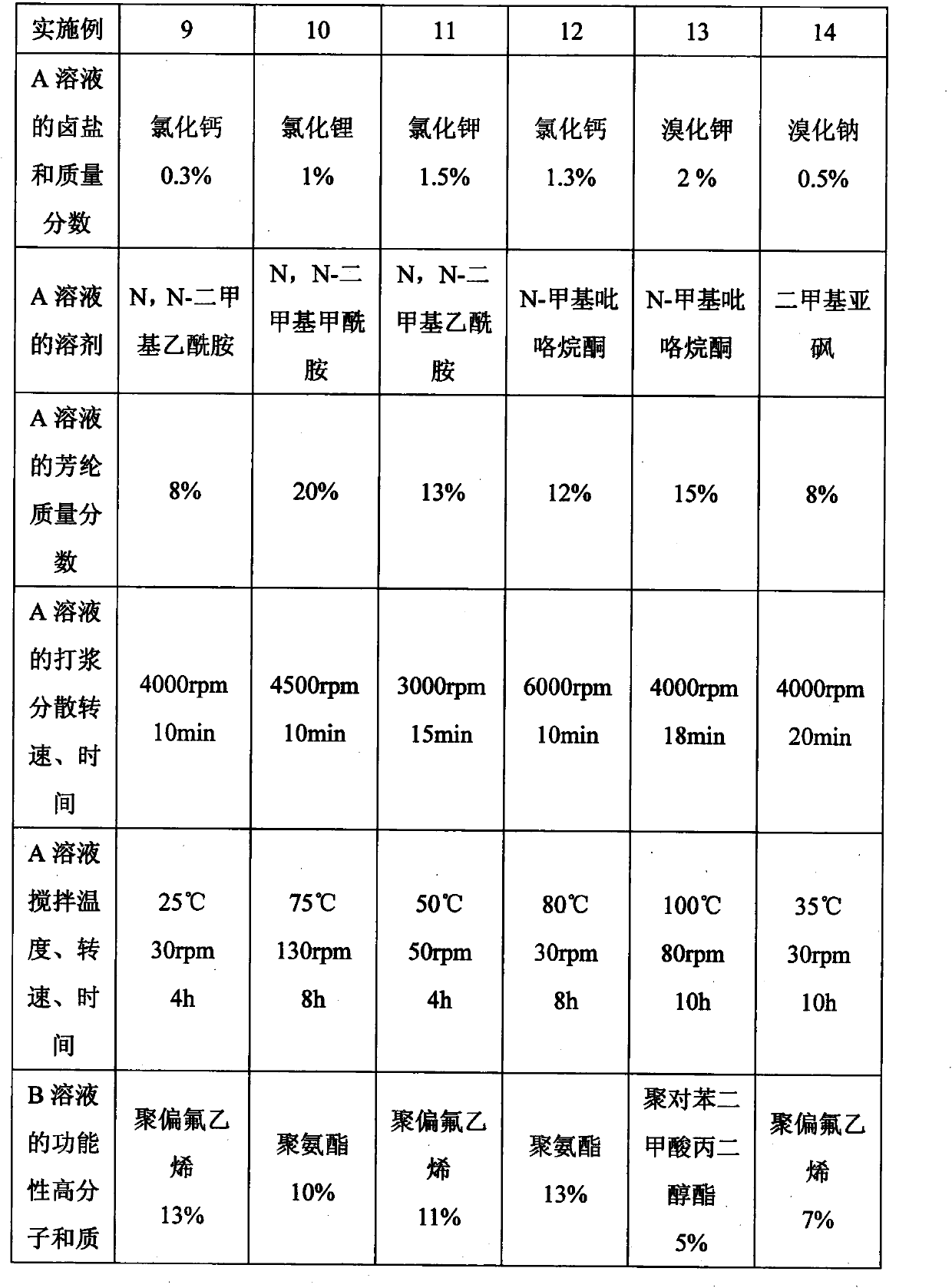

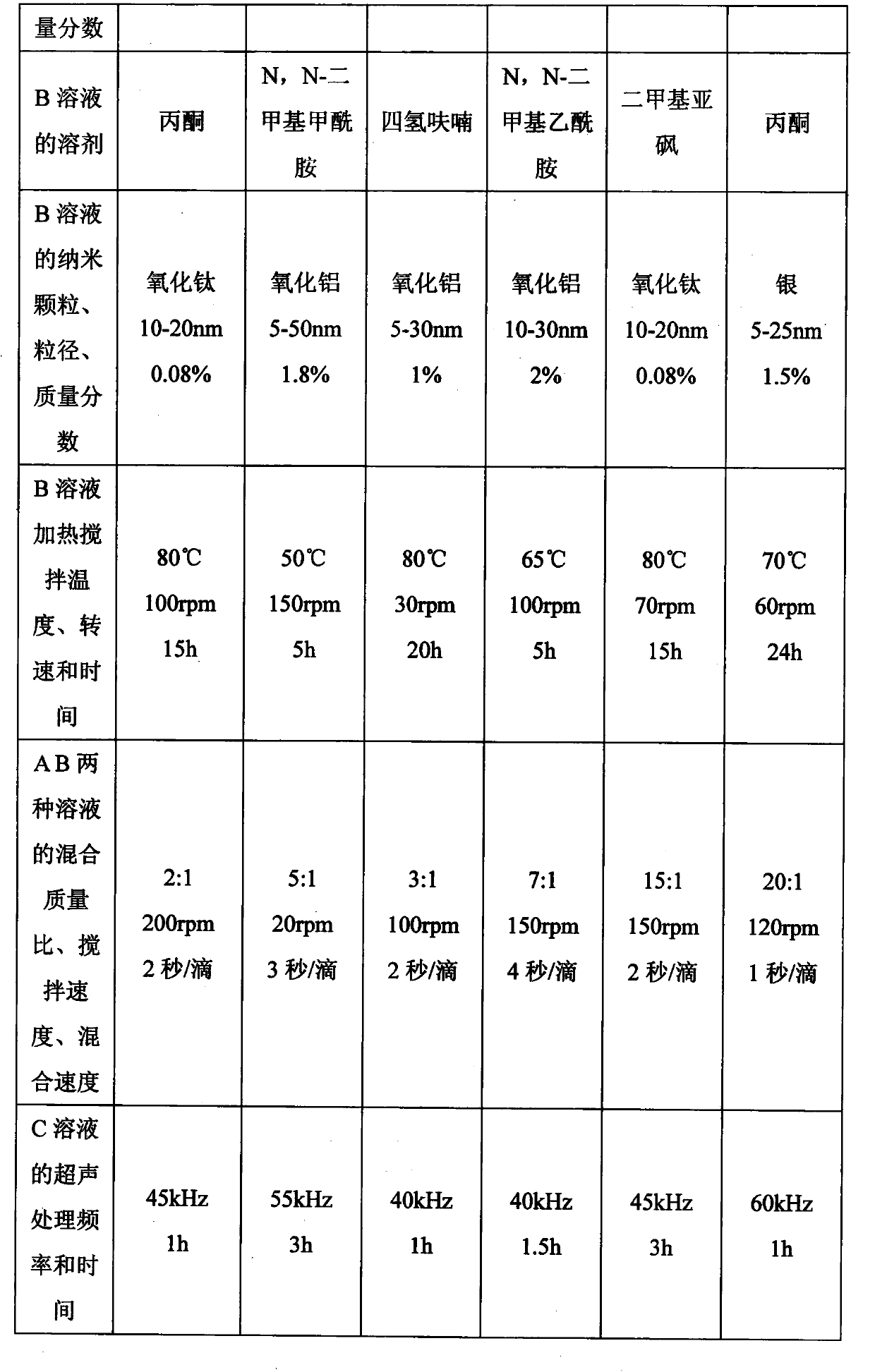

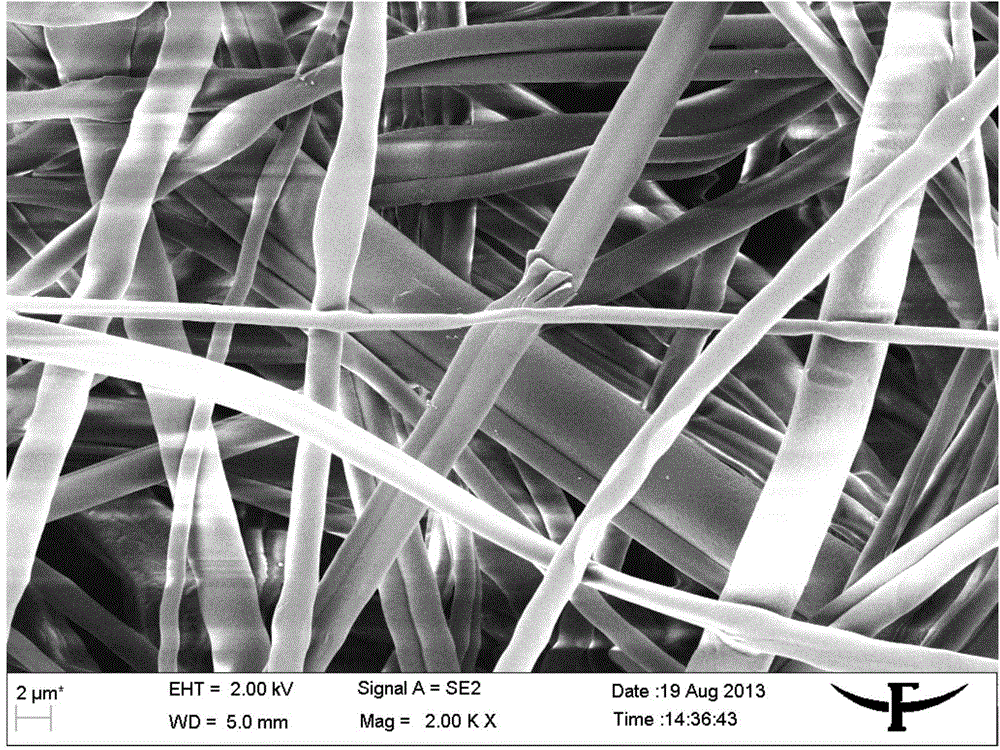

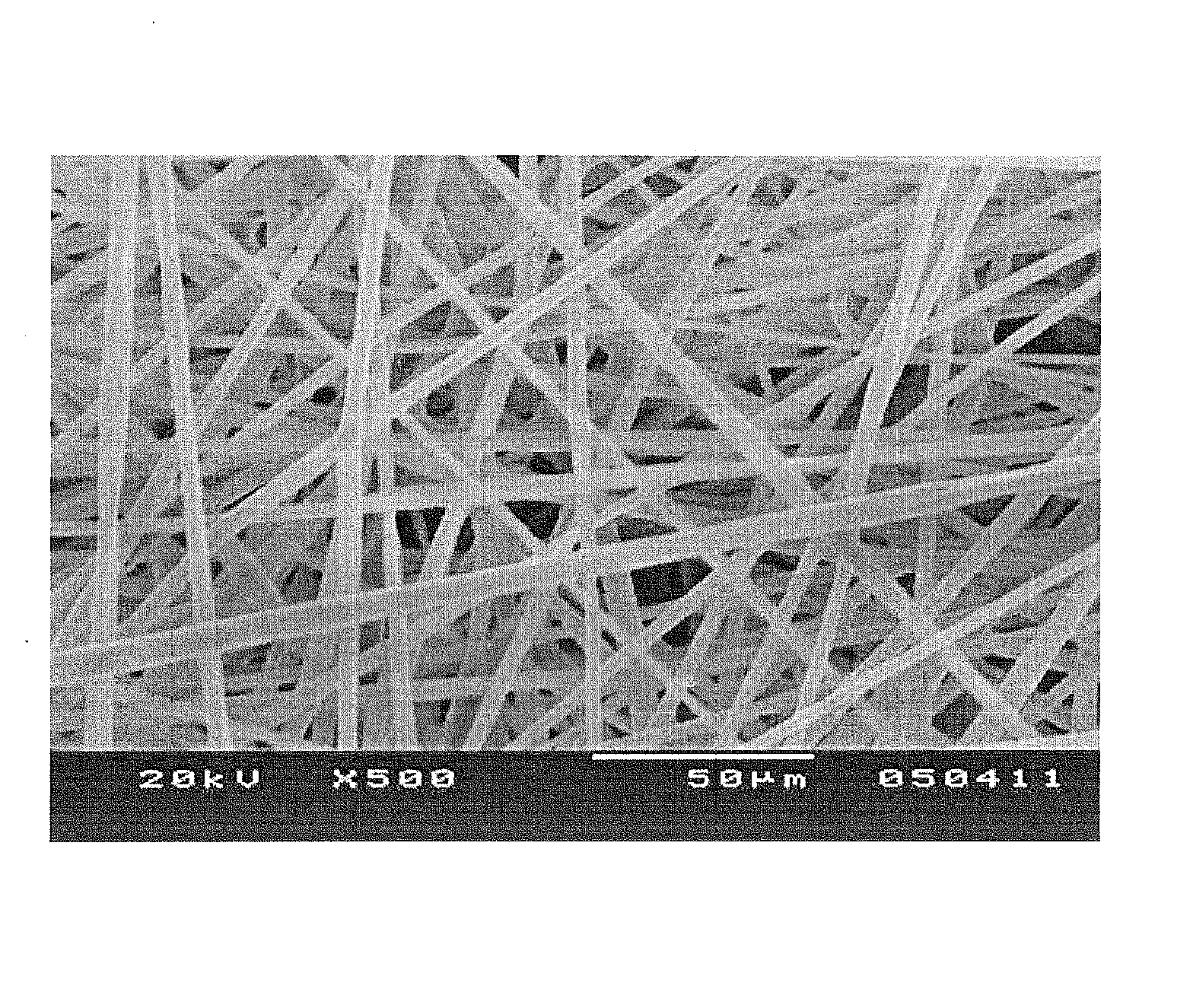

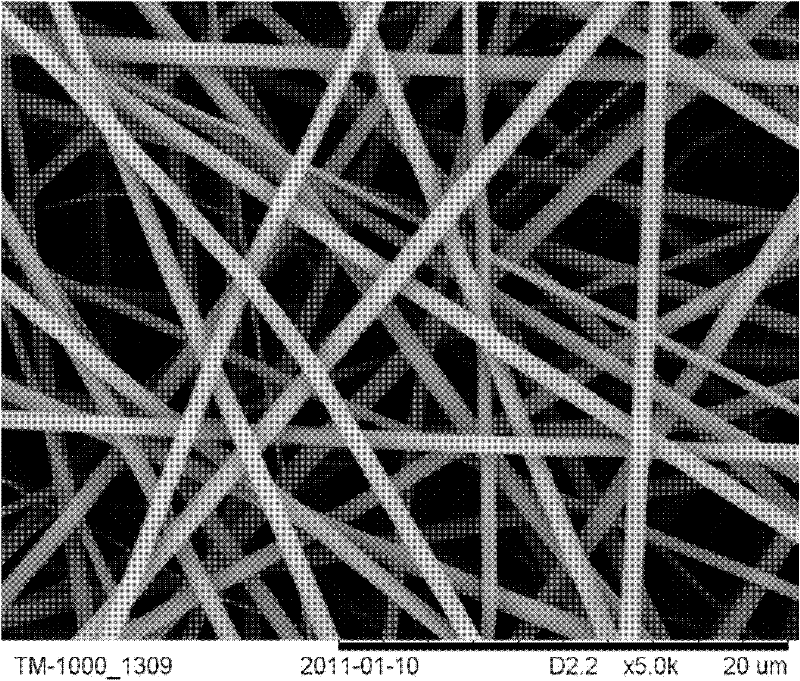

Preparation method for multi-component net-shaped nanofiber membrane

ActiveCN103806221AIncreased interaction surface areaImprove the degree of purificationFilament/thread formingNon-woven fabricsOrganic solventHalogen

The invention relates to a preparation method for a multi-component net-shaped nanofiber membrane. The preparation method includes the detailed steps that step1, mixing and beating are performed on meta-position aramid fibers, halogen salt and organic solvent by the mass ratio of 1:0.004-0.4:2.996-18.6, and a meta-position aramid fiber solution is prepared through mixing; step2, functionality high-molecular polymers and the solvent are mixed by the mass ratio of 1:5.4-98.99, then nano-particles are added, and heating and mixing are performed to prepare a functionality high-molecular solution, wherein the mass fraction of the nano-particles in the solution is 0.01-5%; step3, the meta-position aramid fiber solution obtained in the step1 and the functionality high-molecular solution obtained in the step2 are mixed by the mass ratio of 1:0.05-0.5 in a dripping mode, and then ultrasonic treatment is performed to obtain a spinning solution; step4, under the conditions of 20 DEG C-30 DEG C indoor temperature and 20-70% relative humidity, the spinning solution is used for electrostatic spinning, and finally the multi-component net-shaped nanofiber membrane with a 5nm-20nm net-shaped nanofiber diameter and reaches over 95% in net-shaped structure coverage rate is obtained. The preparation technology is simple and low in cost, tensile strength of material reaches 100MPa-2000MPa, and the functionality advantage is remarkable.

Owner:DONGHUA UNIV

Spun-bonded nonwoven fabric and fiber product

InactiveUS20120208422A1Small fiber diameterFeel goodPersonal careLayered productsFiber diameterNonwoven fabric

The present invention provides a spunbond nonwoven fabric made of a specific crystalline resin composition having a melt flow rate of 25 to 80 g / 10 min and a melting endotherm ΔH of 65 to 100 J / g. More particularly, the invention provides a polypropylene spunbond nonwoven fabric having a very small fiber diameter and providing an excellent feel to the touch, and a polypropylene spunbond nonwoven fabric exhibiting high softness.

Owner:IDEMITSU KOSAN CO LTD

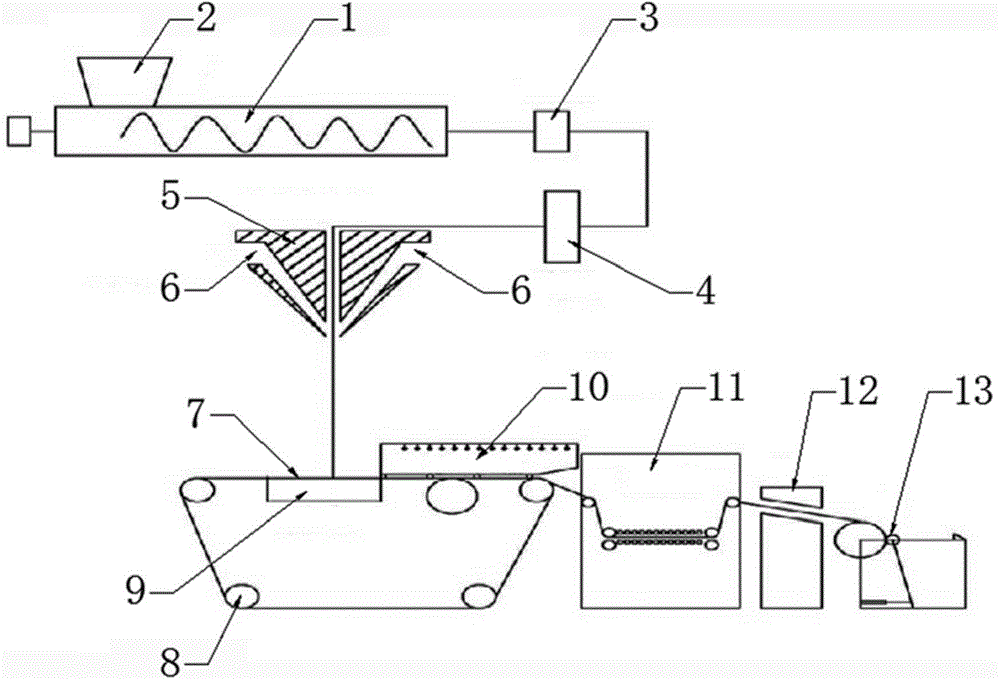

Melt-blow non-woven material capable of effectively filtering PM 2.5 particles, preparation method and production device

ActiveCN104153119AHigh filtration efficiencyImprove dust collection effectHeating/cooling textile fabricsUltrasonic/sonic fibre treatmentPorosityEngineering

The invention discloses a melt-blow non-woven material capable of effectively filtering PM 2.5 particles, a preparation method and a production device. The melt-blow non-woven material comprises, by weight percentage, 93-97 parts of polypropylene, 3-6 parts of electret master batch and 0.1-1 part of polyvinylidene fluoride. According to the melt-blow non-woven material capable of effectively filtering PM 2.5 particles, the polypropylene, the electret master batch and the polyvinylidene fluoride are compounded, the obtained melt-blow non-woven material is characterized by high porosity, the fiber diameter of smaller than two micrometers, large clogging capacity, high filtering efficiency and low resistance, an electret is good in charge storage performance after electret processing, the charge keeping rate can be above two years, and the electret can be used in a high-temperature and high-humidity environment. The product is environmentally friendly and free of pollution, has the advantages of being long in service life and wide in use range, and is particularly suitable for removing PM 2.5 particles in the air.

Owner:DO FLUORIDE CHEM CO LTD

Preparation method of sodium-ion battery cathode material Na3V2(PO4)3

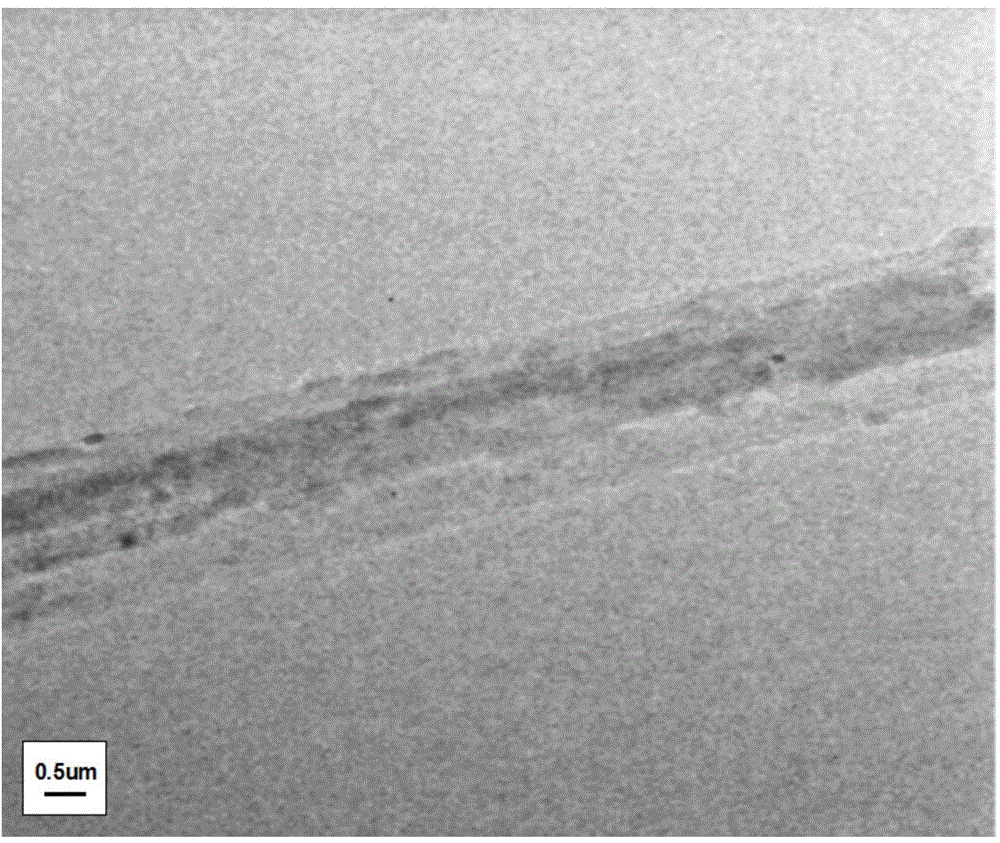

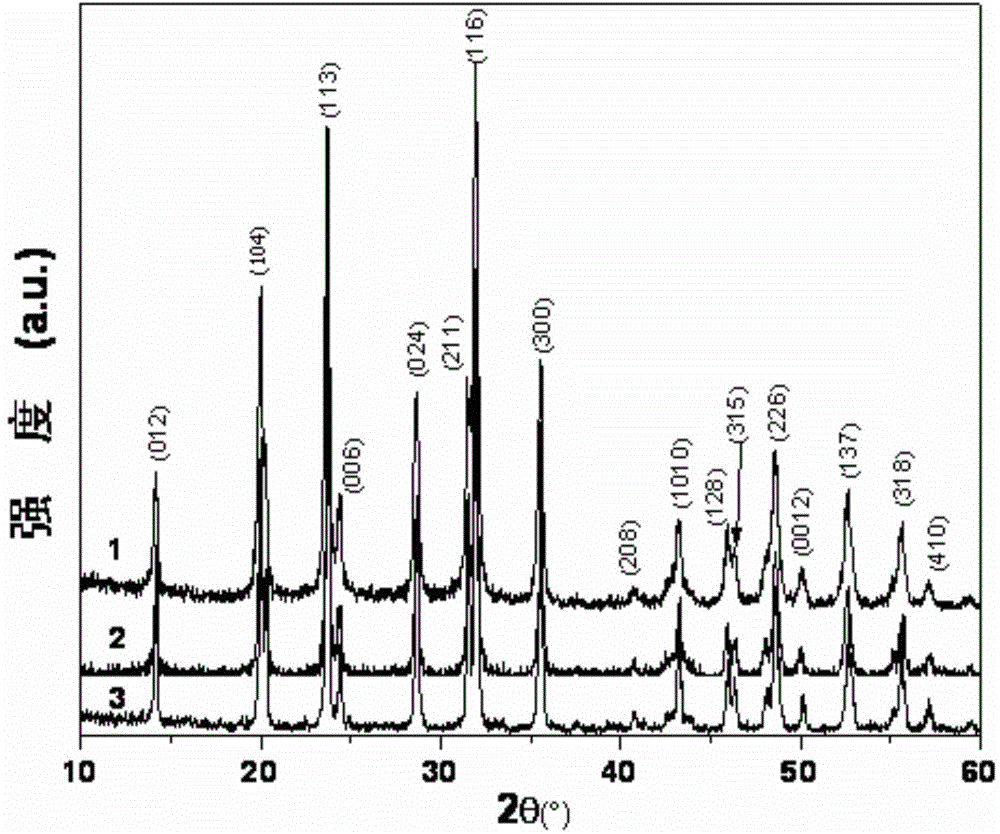

ActiveCN105098179AShallow embedding depthShort diffusion pathCell electrodesElectrical batteryPhysical chemistry

The invention discloses a preparation method of a sodium-ion battery cathode material Na3V2(PO4)3. The method comprises the following steps: (1) mixing a sodium salt, a vandic salt, phosphate, a complexing agent, a high-molecular compound and a solvent to obtain a Na3V2(PO4)3 spinning solution; (2) carrying out electrostatic spinning on the Na3V2(PO4)3 spinning solution to obtain a Na3V2(PO4)3 spinning precursor; and (3) collecting the Na3V2(PO4)3 spinning precursor, carrying out thermal treatment on the Na3V2(PO4)3 spinning precursor in an inert atmosphere and cooling the Na3V2(PO4)3 spinning precursor to obtain the sodium-ion battery cathode material Na3V2(PO4)3. According to the sodium-ion battery cathode material Na3V2(PO4)3 prepared by the method disclosed by the invention, high-capacity charging and discharging of the battery can be realized; and the cycle stability of the battery can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

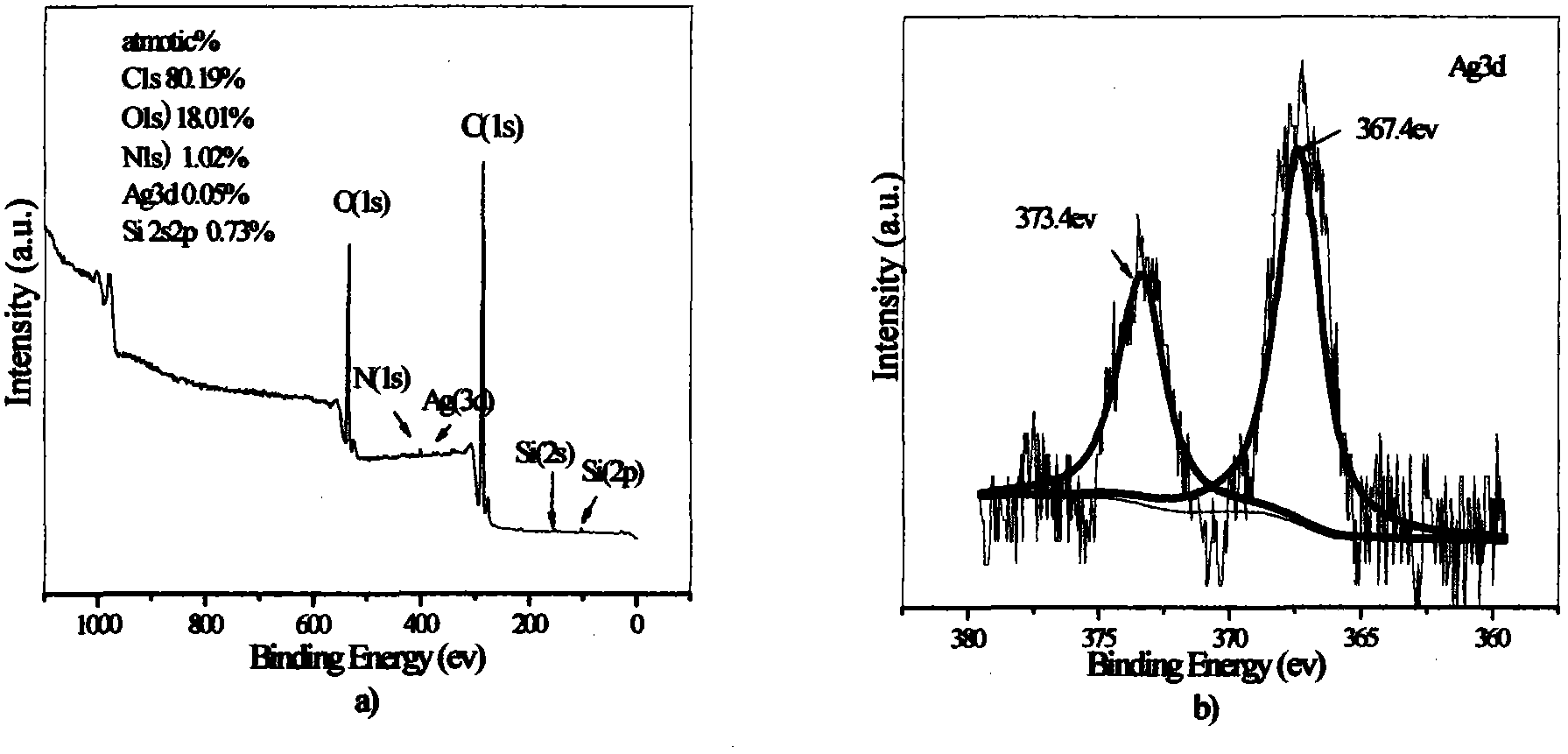

Method for preparing nano-silver-containing composite fibrous membrane capable of being used for medical dressings

InactiveCN103422255ASmall fiber diameterLarge specific surface areaAbsorbent padsNon-woven fabricsBiocompatibilityMaterials science

The invention relates to a method for preparing a nano-silver-containing composite fibrous membrane capable of being used for medical dressings. The composite fibrous membrane comprises nano-silver-containing polycaprolactone (PCL) / polyvinylpyrrolidone (PVP), and is prepared on the basis of an electrostatic spinning method. The method includes: (1) using N,N-dimethylformamide (DMF) as a reducing agent, reducing silver nitrate in water bath at the temperature of 80-95 DEG C, and stirring continuously for 4-7 hours to obtain a nano-silver colloid solution; (2), mixing the PCL and the PVP according to a certain proportion, dissolving the mixture in cosolvent dichloromethane, and stirring uniformly to obtain a mixed solution; (3) diluting the nano-silver colloid solution by certain times, adding the diluent into the mixed solution, and stirring uniformly to obtain electrostatic spinning liquid; (4) performing electrostatic spinning on the electrostatic spinning liquid to obtain the nano-silver-containing PCL / PVP composite fibrous membrane. The fibrous membrane has the advantages of good biocompatibility, hydrophilia and hydrophobicity controllability, high water absorption and the like; the surface of the fibrous membrane contains nano-silver, so that the fibrous membrane has strong antibacterial action and is suitable for preparing the medical dressings.

Owner:WUYI UNIV

Preparation method of waterproof moisture-permeable nanofiber composite membrane

InactiveCN110438659AImprove performanceSmall fiber diameterSilicaElectro-spinningWater vaporLiquid water

The invention relates to a preparation method of a waterproof moisture-permeable nanofiber composite membrane, and belongs to the technical field of textile materials. According to the preparation method, polyacrylonitrile is taken as a main raw material, polyvinylidene fluoride and polyurethane are added, the waterproof and moisture-permeable nanofiber composite membrane is prepared, and the waterproof and moisture-permeable membrane prepared from polyacrylonitrile nanofibers has the characteristics of high porosity, fine fiber diameter and small pore diameter. The waterproof and moisture-permeable effect of the fiber membrane is effectively improved, the hydrophobic microporous membrane is preliminarily obtained by blending polyacrylonitrile, polyvinylidene fluoride and polyurethane through a solution, the waterproof moisture-permeable membrane with a certain welding structure is obtained in combination with heat treatment, penetration of liquid water is effectively prevented, polyurethane is a block polymer, polar groups such as hydrophilic groups which exist on a macromolecular chain segment provide a carrier for water vapor transfer, meanwhile, the polyurethane has a certain hydrophobic property by the hydrophobic group on the chain segment, and by addition of the polyurethane, the nanofiber composite membrane has excellent comprehensive performance.

Owner:欧名龙

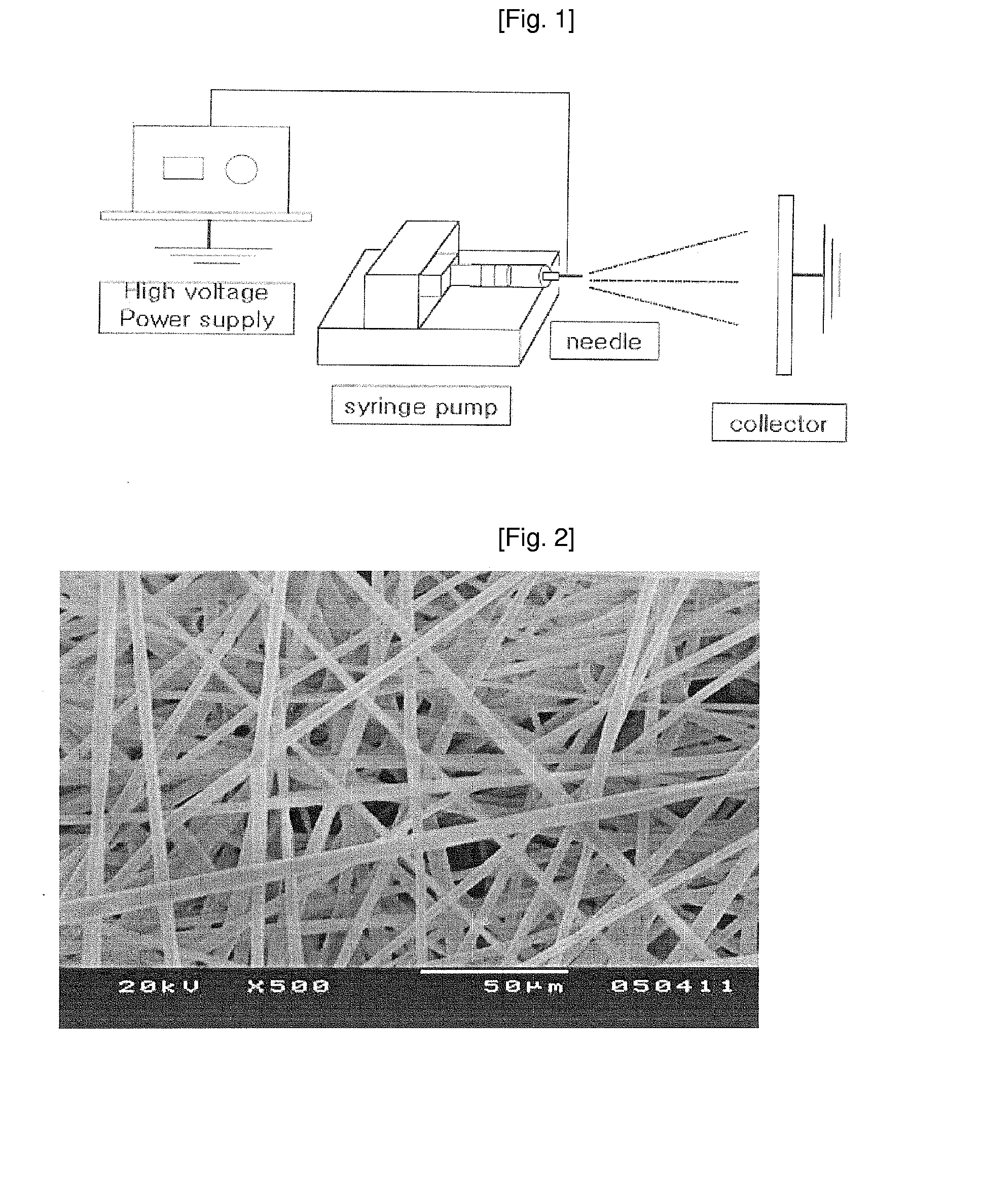

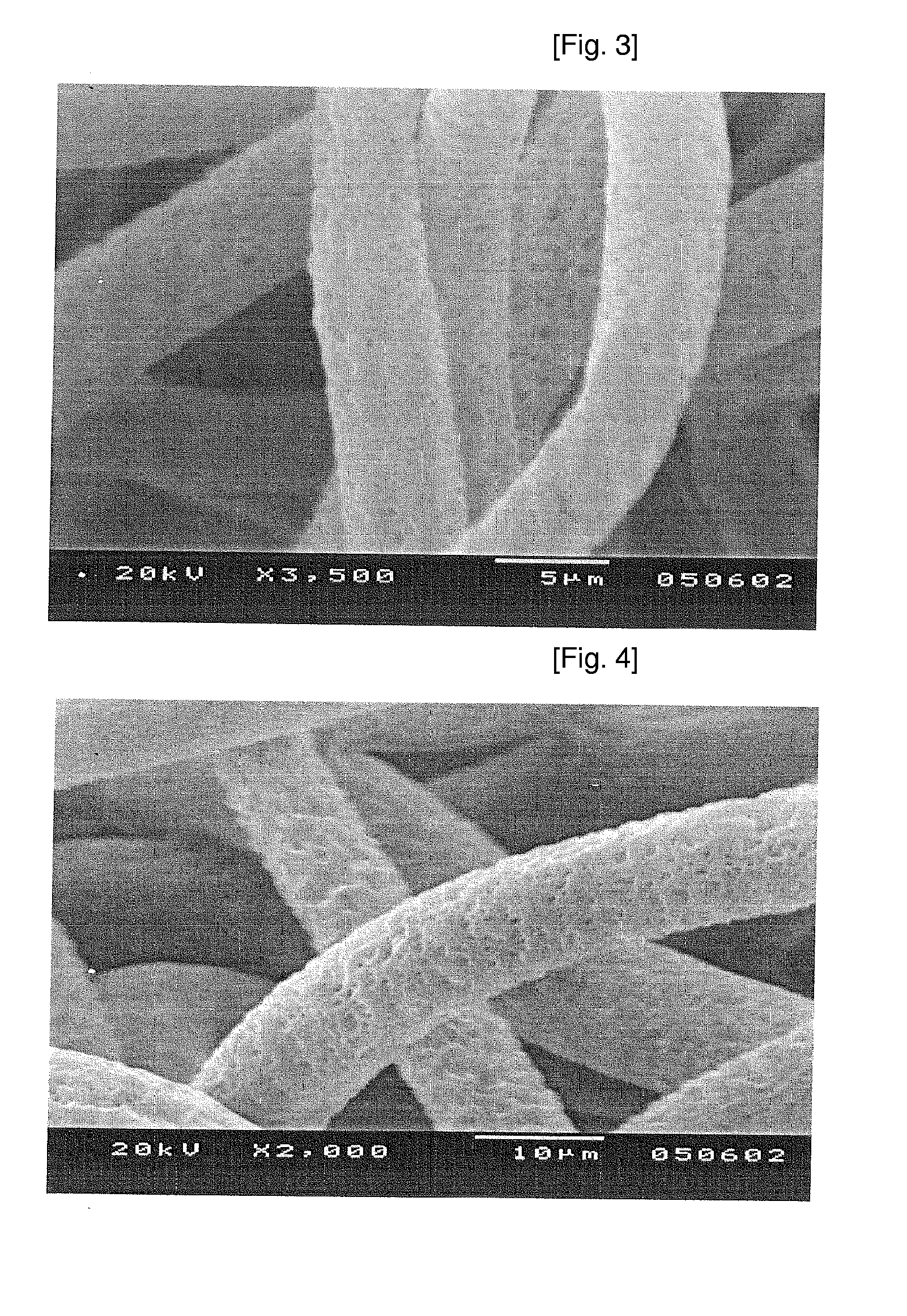

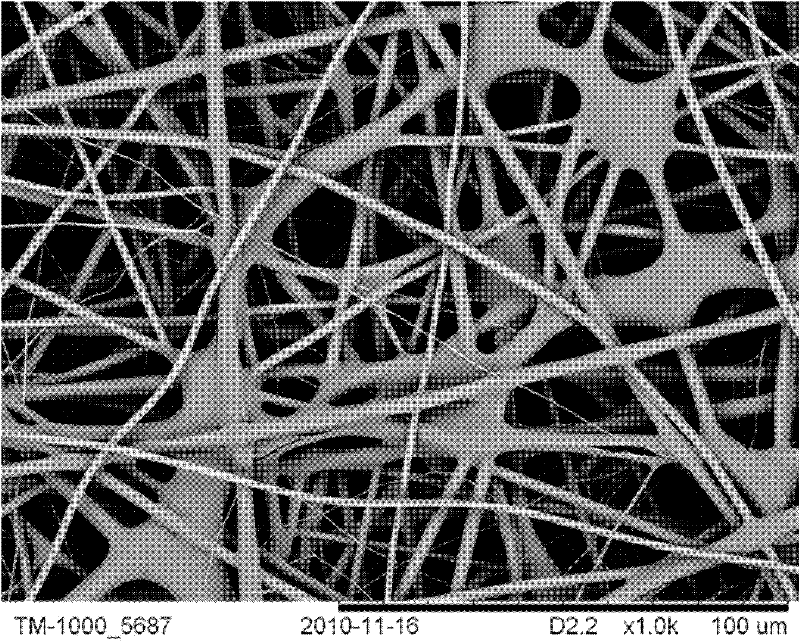

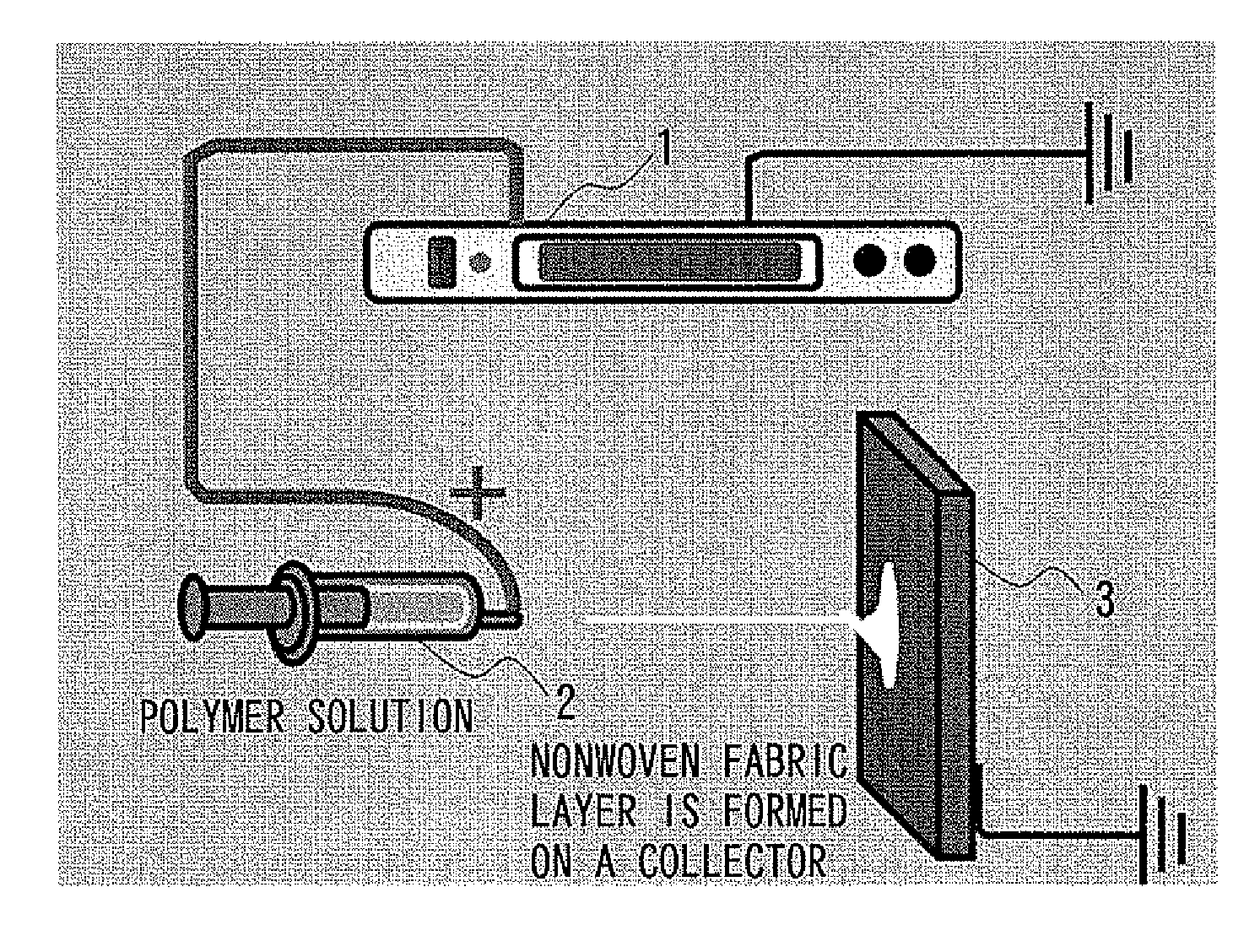

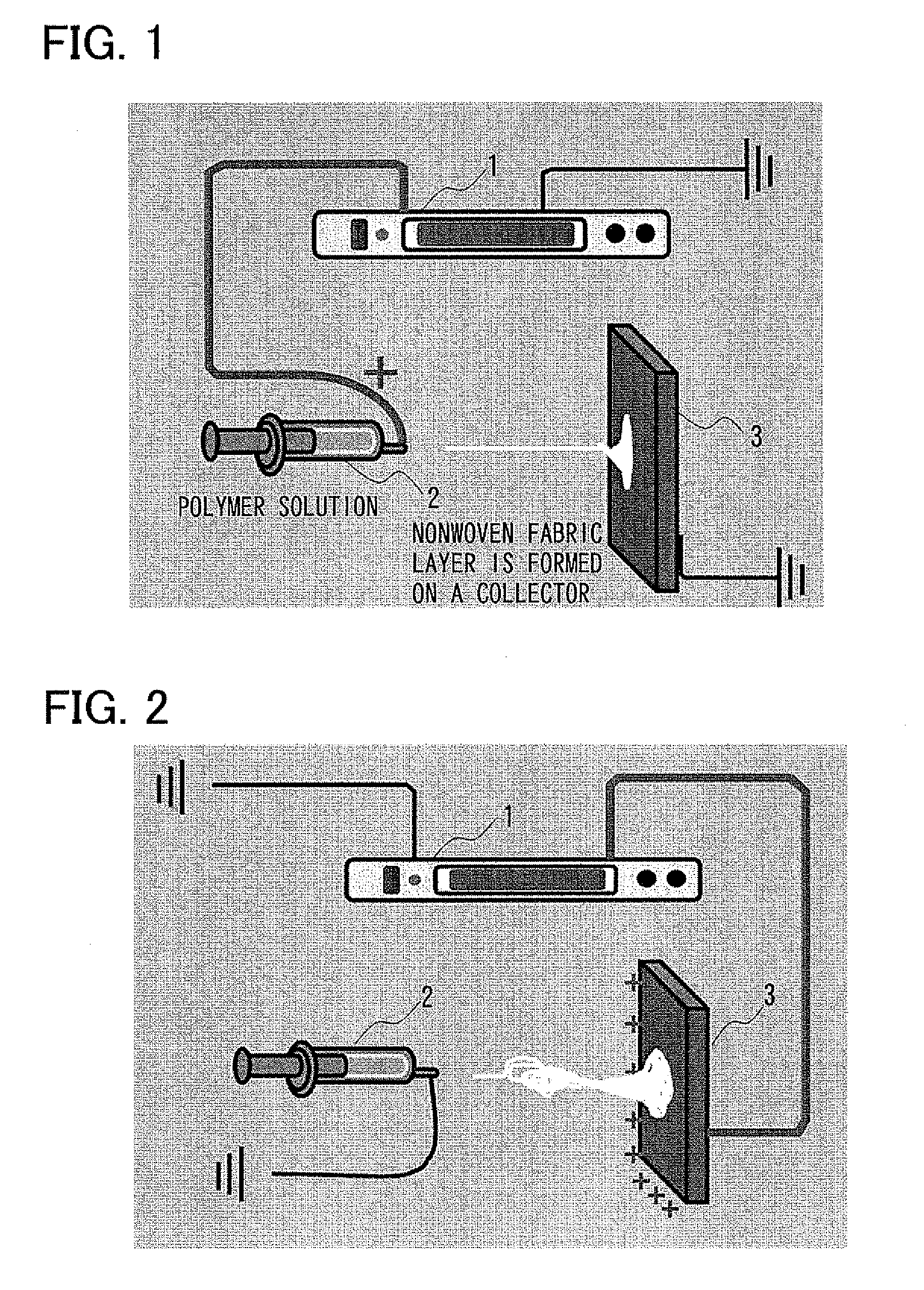

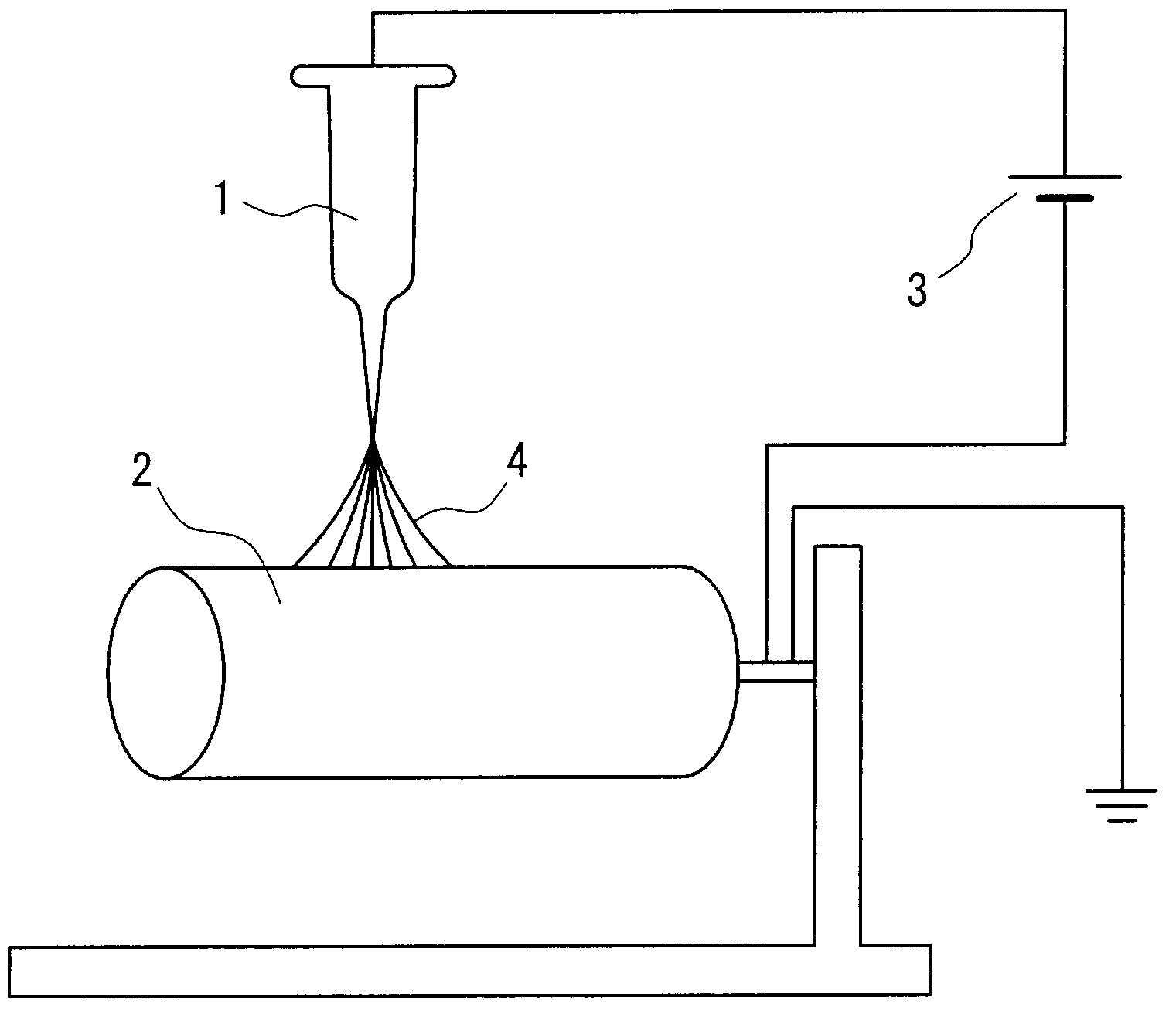

Fibrous 3-Dimensional Scaffold Via Electrospinning For Tissue Regeneration and Method For Preparing the Same

InactiveUS20080233162A1Small fiber diameterRegular formBiocideNanomedicineCell adhesionAdhesion process

The present invention relates to a fibrous 3-dimensional porous scaffold via electrospinning for tissue regeneration and a method for preparing the same. The fibrous porous scaffold for tissue regeneration of the present invention characteristically has a biomimetic structure established by using electrospinning which is efficient without wasting materials and simple in handling techniques. The fibrous porous scaffold for tissue regeneration of the present invention has the size of between nanofiber and microfiber and regular form and strength, so that it facilitates 3-dimensional tissue regeneration and improves porosity at the same time with making the surface area contacting to a cell large. Therefore, the scaffold of the invention can be effectively used as a support for the cell adhesion, growth and regeneration.

Owner:EWHA UNIV IND COLLABORATION FOUND

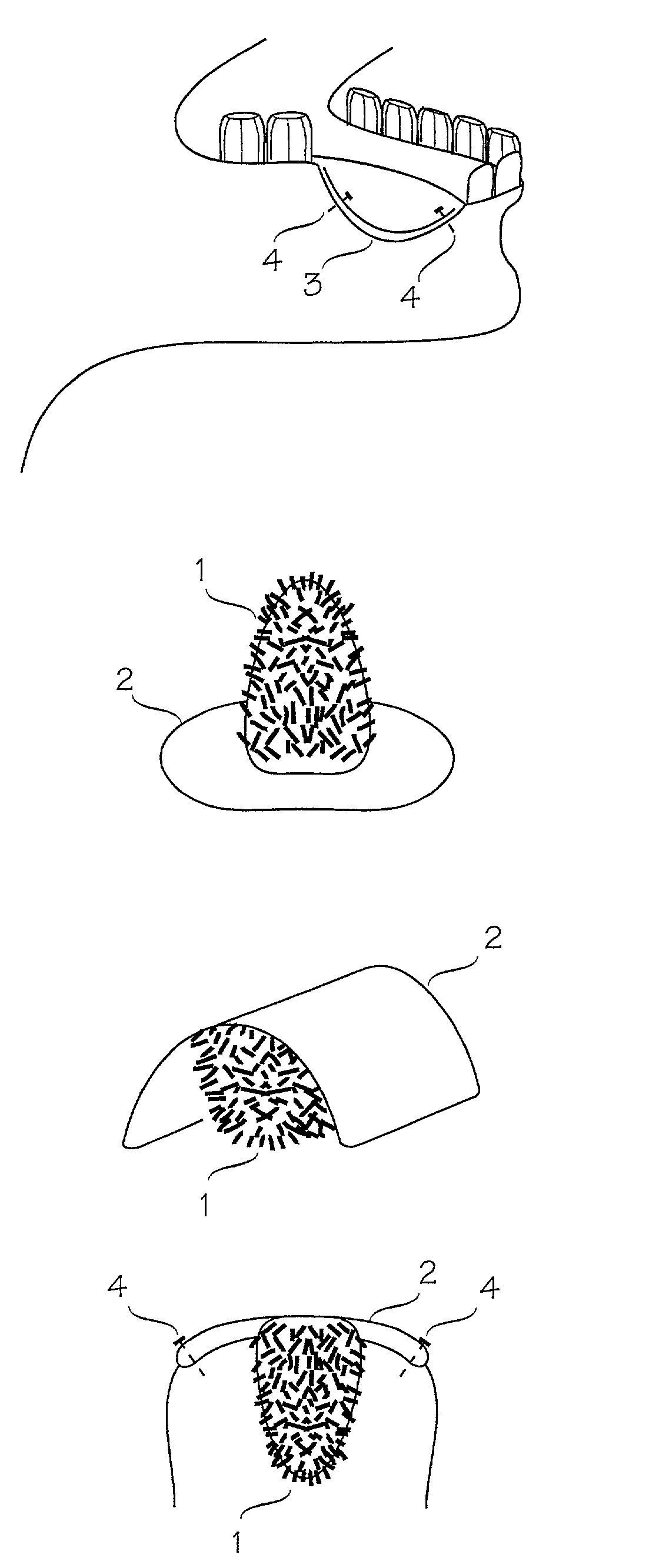

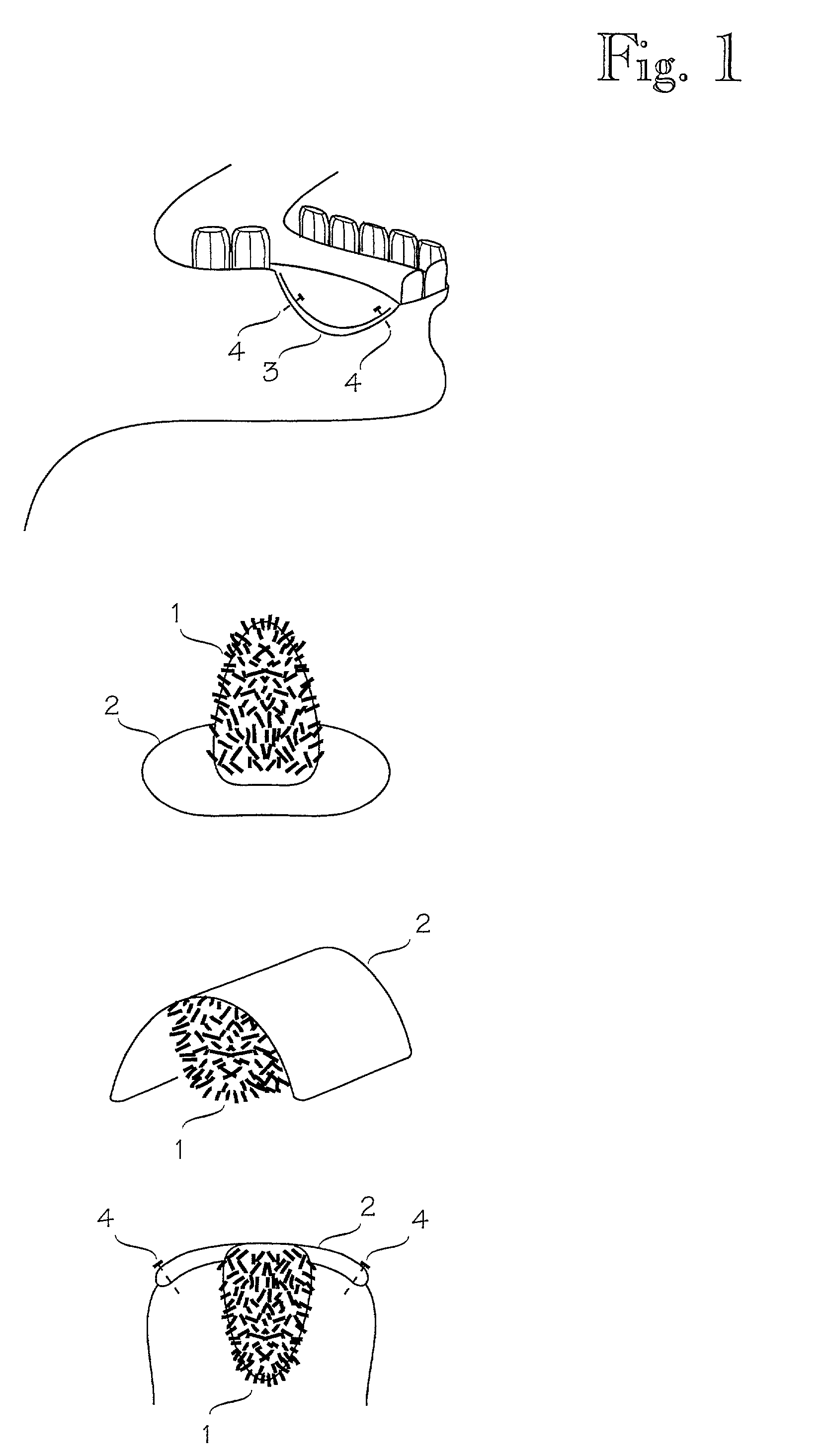

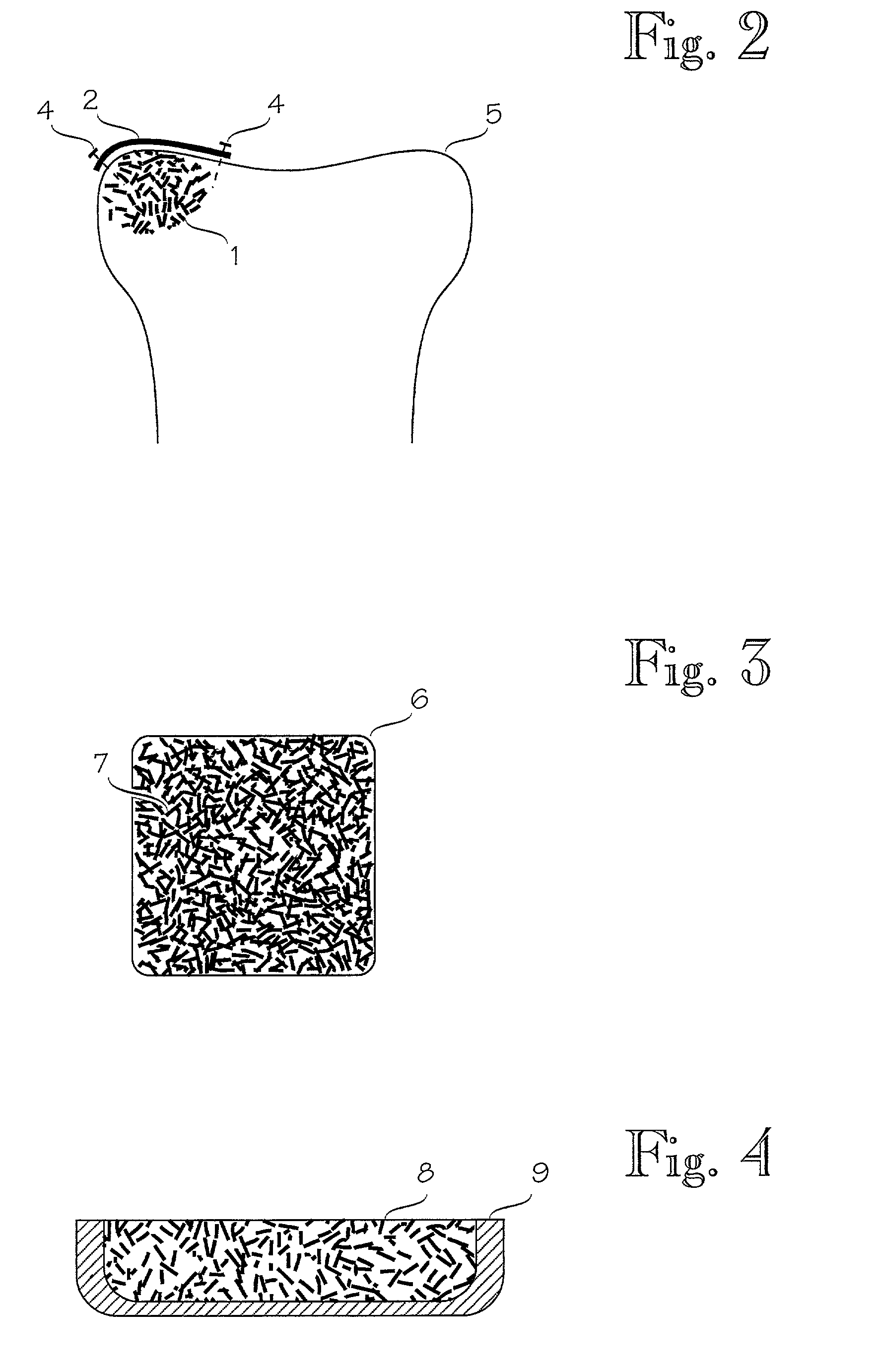

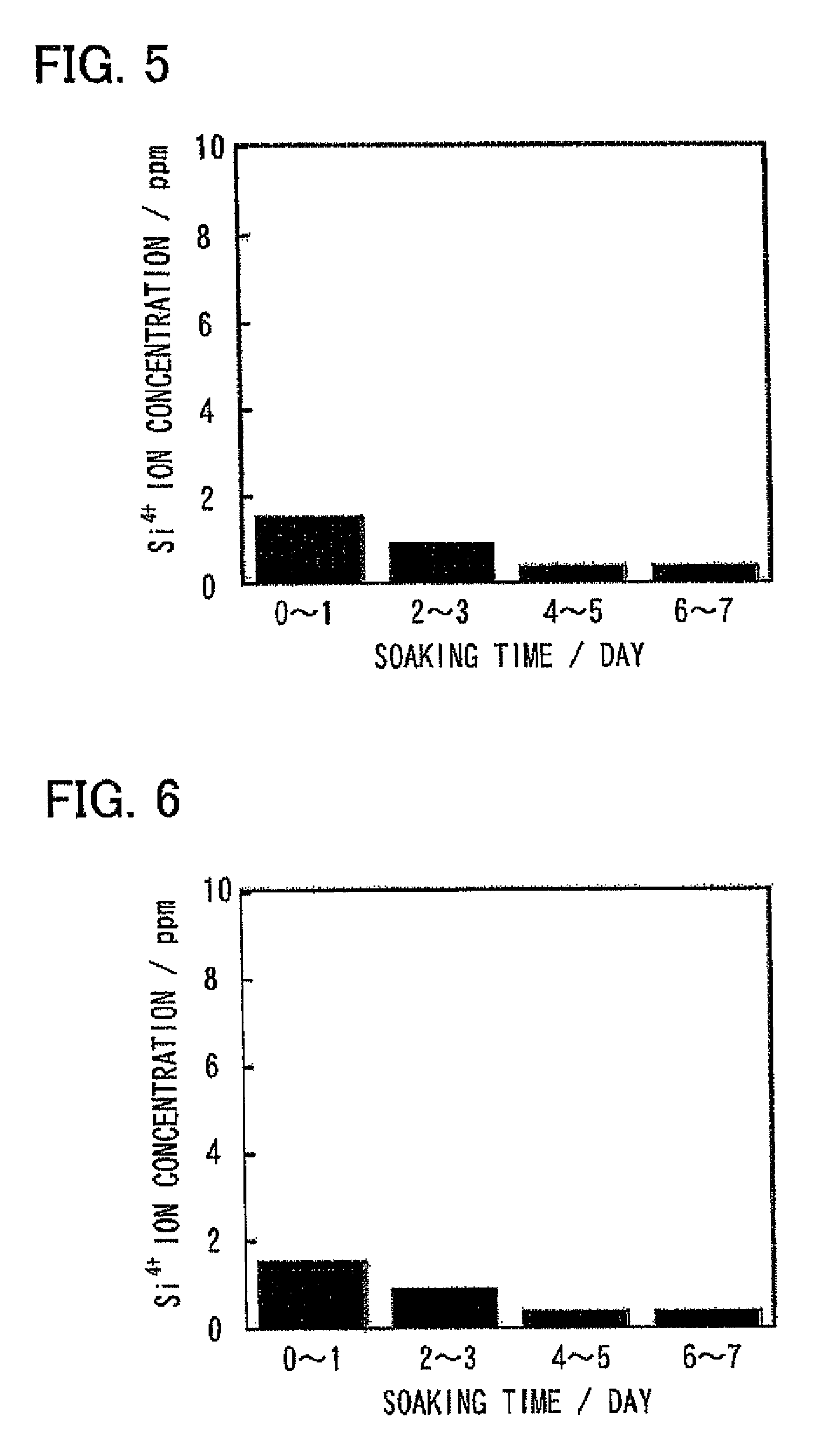

Fiber wadding for filling bone defects

ActiveUS8853298B2Speedup (acceleration)Improve adhesionImpression capsSurgical adhesivesFiberWadding

A fiber wadding for filling bone defects having a flocculent three-dimensional structure is disclosed. The fiber wadding includes a plurality of fibers that contain a biodegradable resin as a principal component and a siloxane. Outside diameter of the plurality of fibers of the wadding is from about 0.05 μm to about 30 μm. Bulk density of the fiber wadding is about 0.005-0.3 g / cm3.

Owner:NAGOYA INSTITUTE OF TECHNOLOGY +1

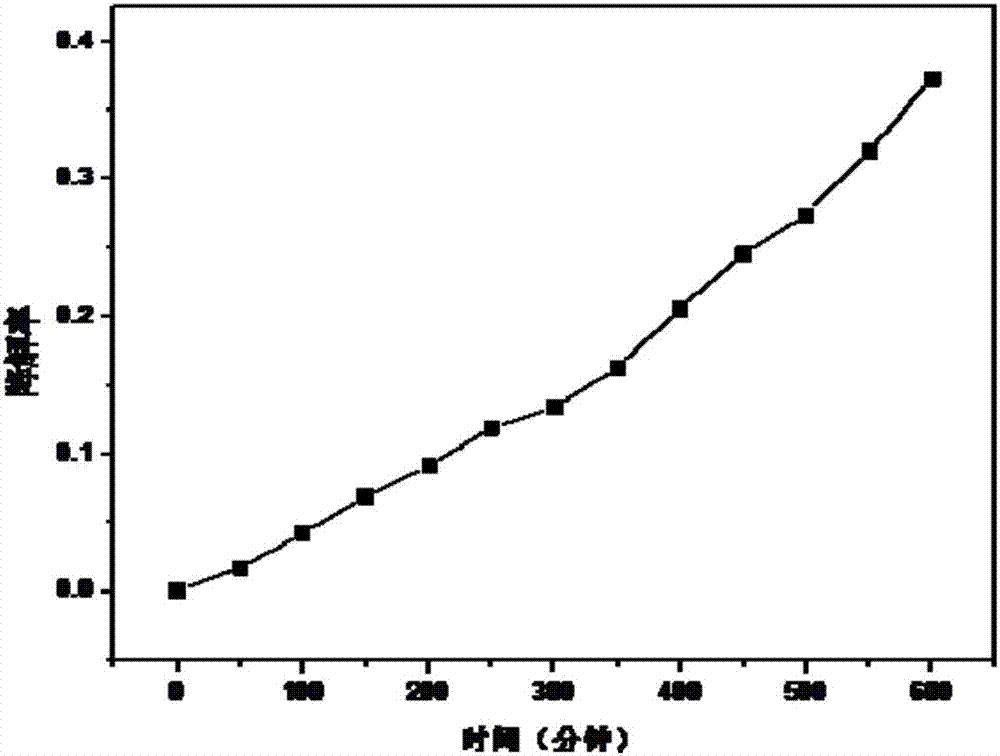

Method and product for loading semiconductor photocatalyst on surface of electrospun fiber

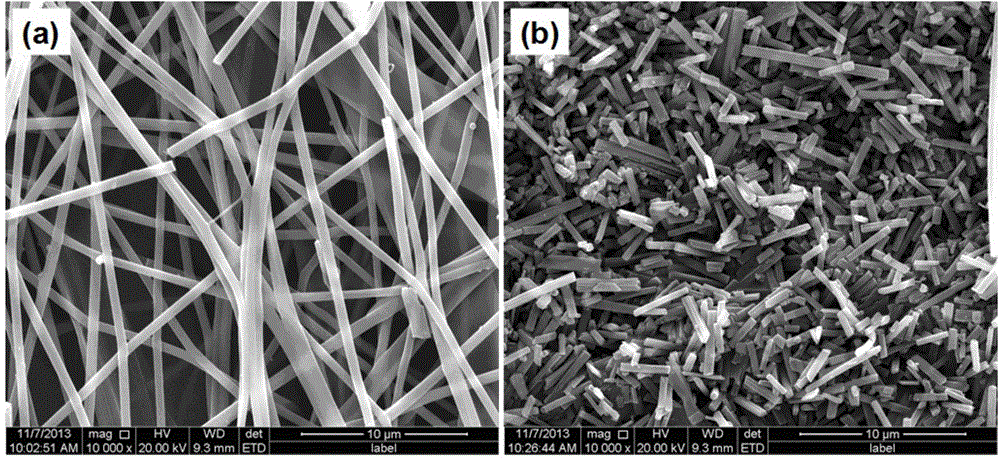

ActiveCN107096573AFlexibleNot easy to damageOrganic-compounds/hydrides/coordination-complexes catalystsFiberPhoto catalysis

The invention discloses a method and product for loading a semiconductor photocatalyst on the surface of an electrospun fiber. The method comprises the following steps: (1) preparing an electrospinning template fiber material; (2) preparing a reaction solution for synthesizing the semiconductor photocatalyst through a hydro-thermal method; (3) soaking the template fiber material obtained in the step (1) in the reaction solution obtained in the step (2), putting the reaction solution with the template fiber material in a closed hydro-thermal kettle to perform a hydro-thermal reaction, and synthesizing a nano semiconductor photocatalyst on a fiber surface of the template fiber material through the hydro-thermal method; and (4) performing cleaning and drying. The method is easy to operate, and can realize large-scale production, and an obtained product is a flexible material which is difficult to damage and high in photocatalytic efficiency, can be separated and recovered easily after use, and can be reused.

Owner:QINGDAO UNIV

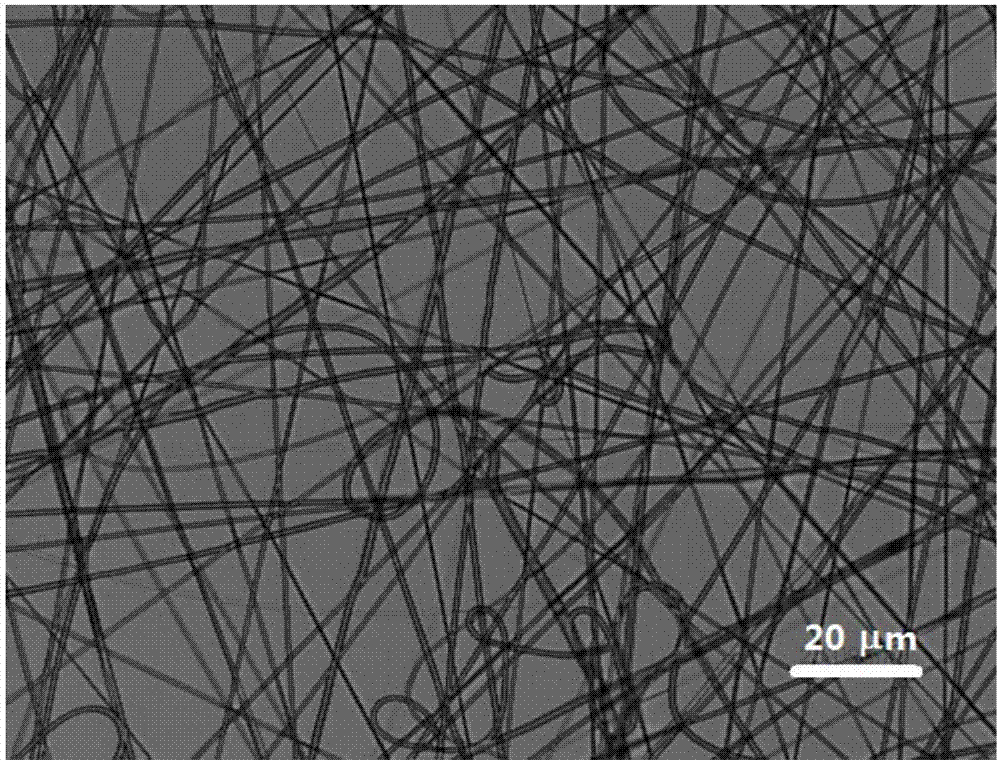

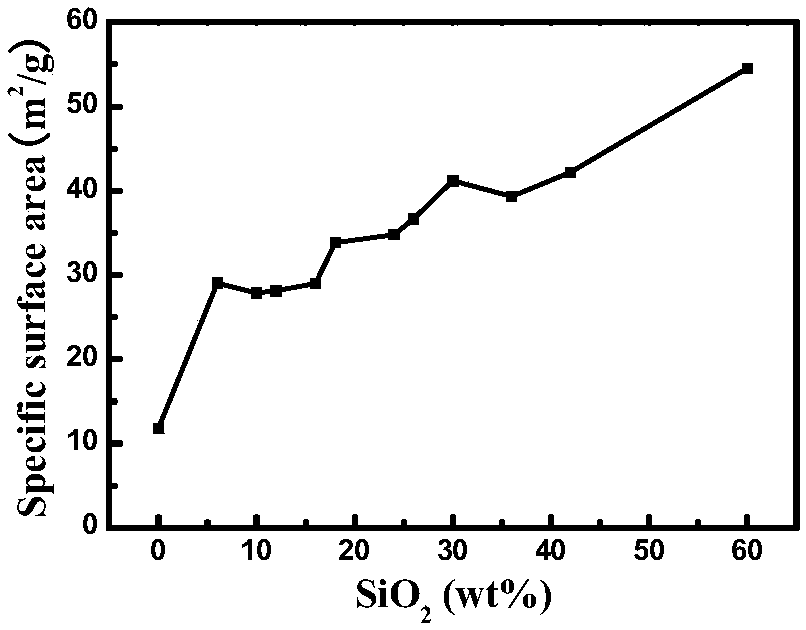

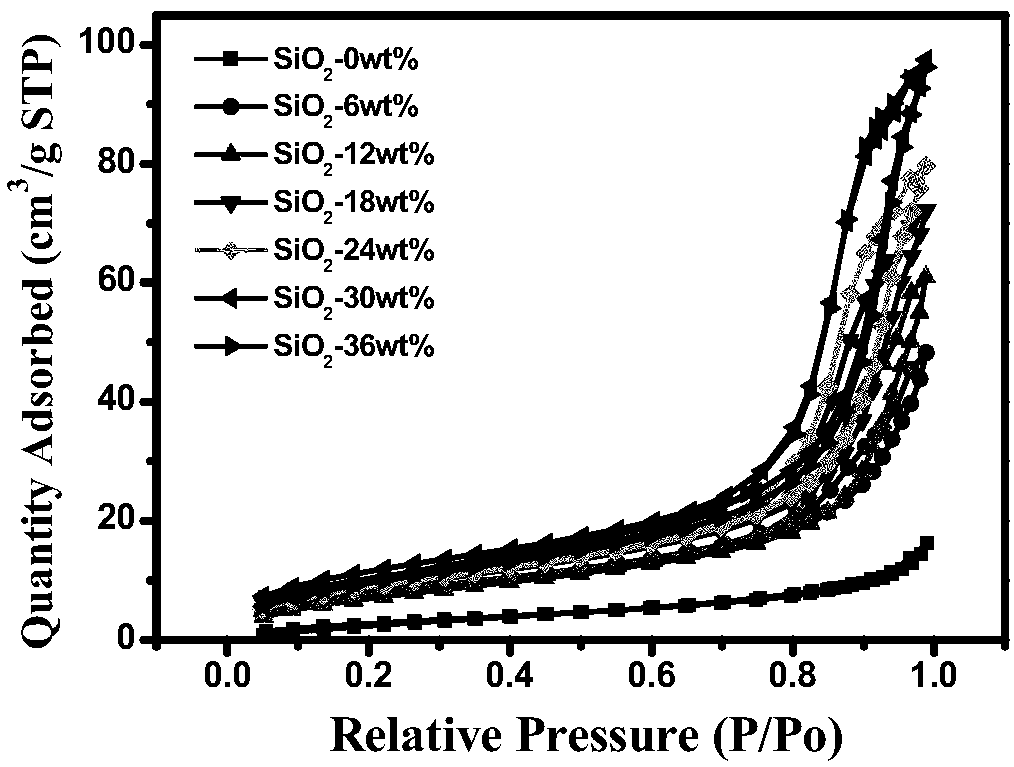

Preparing method of silicon dioxide aerogel nanofiber composite membrane

InactiveCN108035074ALow thermal conductivitySimple processFilament/thread formingNon-woven fabricsSilicon dioxidePolymer

The invention discloses a preparing method of a silicon dioxide aerogel nanofiber composite membrane, and relates to nanofiber composite membranes. The method comprises the steps of preparing a silicon dioxide aerogel / organic solvent dispersion liquid; preparing a polymer / SiO2 spinning solution; conducting electrostatic spinning on a polymer / SiO2; conducting post-treatment on the nanofiber composite membrane. Fibers of the prepared silicon dioxide aerogel nanofiber composite membrane are in needle shapes, the average diameter of the fibers is 200-300 nm, and the specific surface area of the silicon dioxide aerogel nanofiber composite membrane can reach 55 m<2> / g; the process is simple, the preparing condition is mild, and the obtained composite nanofiber membrane is large in specific surface area and small in fiber diameter and is expected to be applied to the fields of heat insulation, adsorption, catalysis, bioengineering and the like.

Owner:XIAMEN UNIV

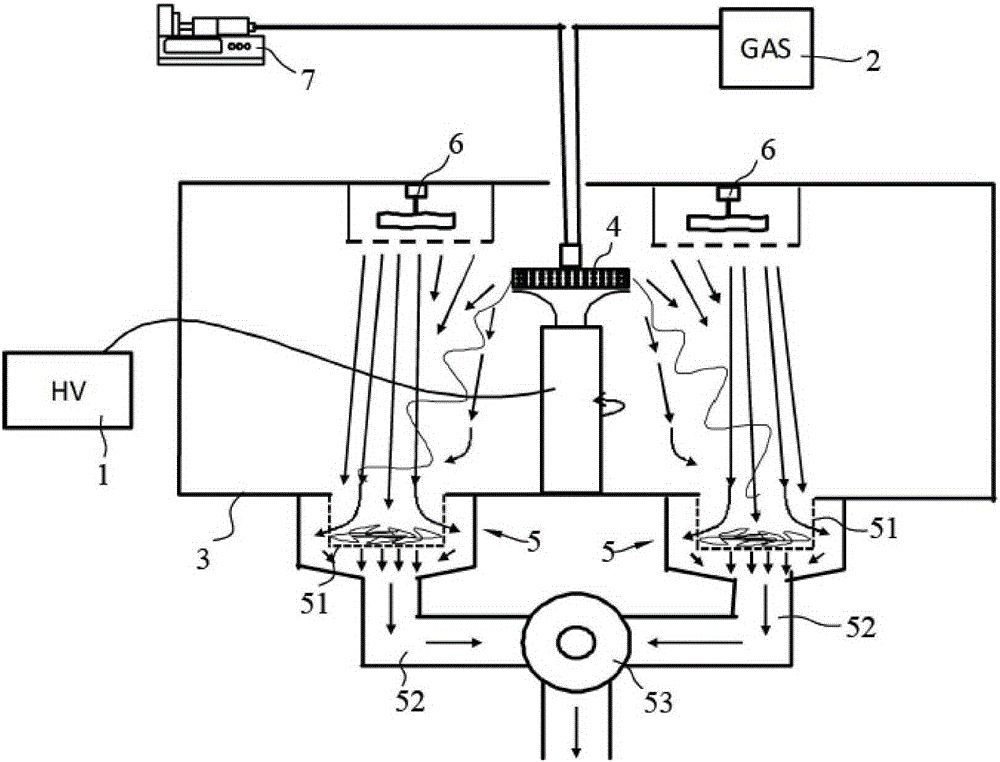

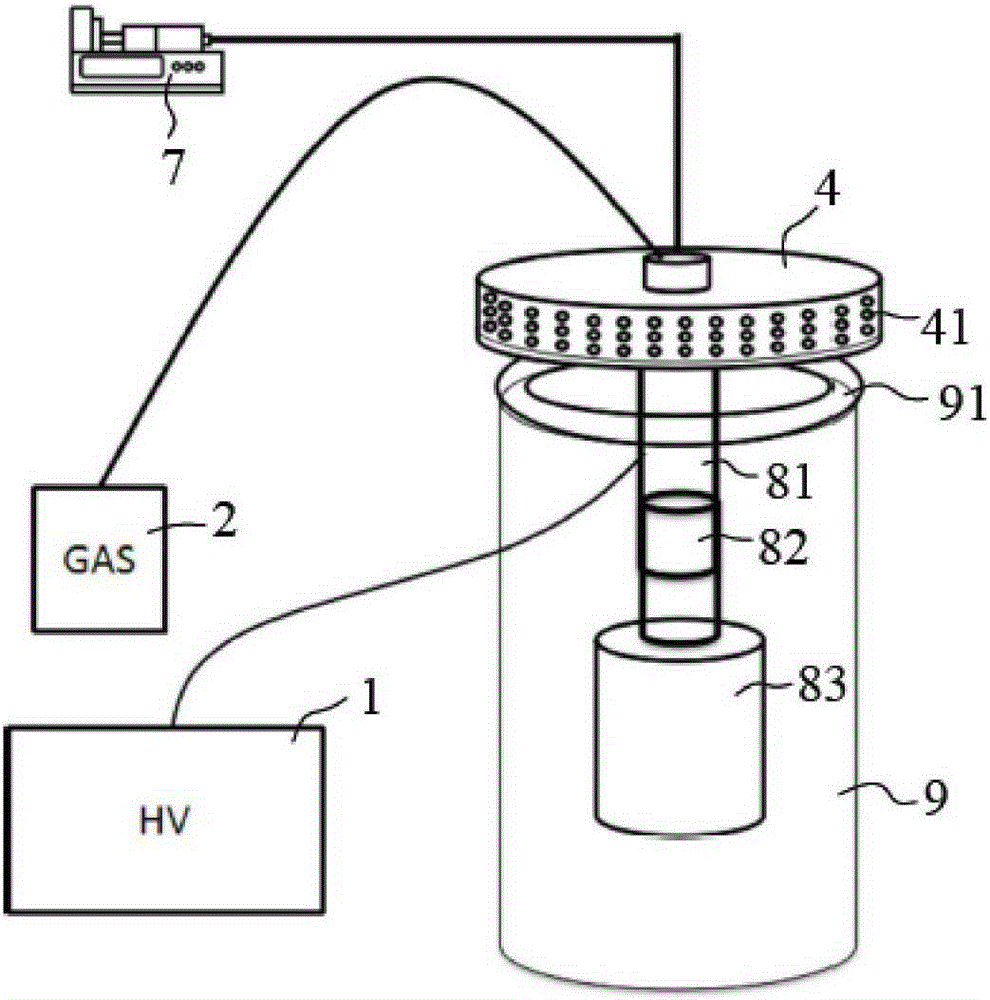

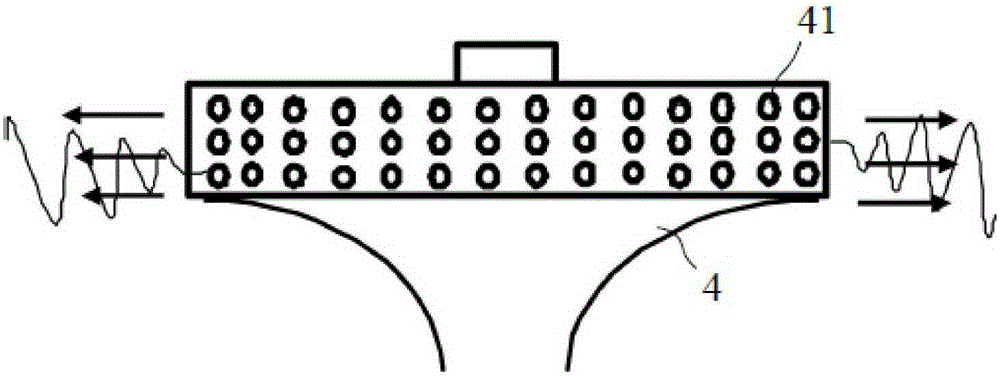

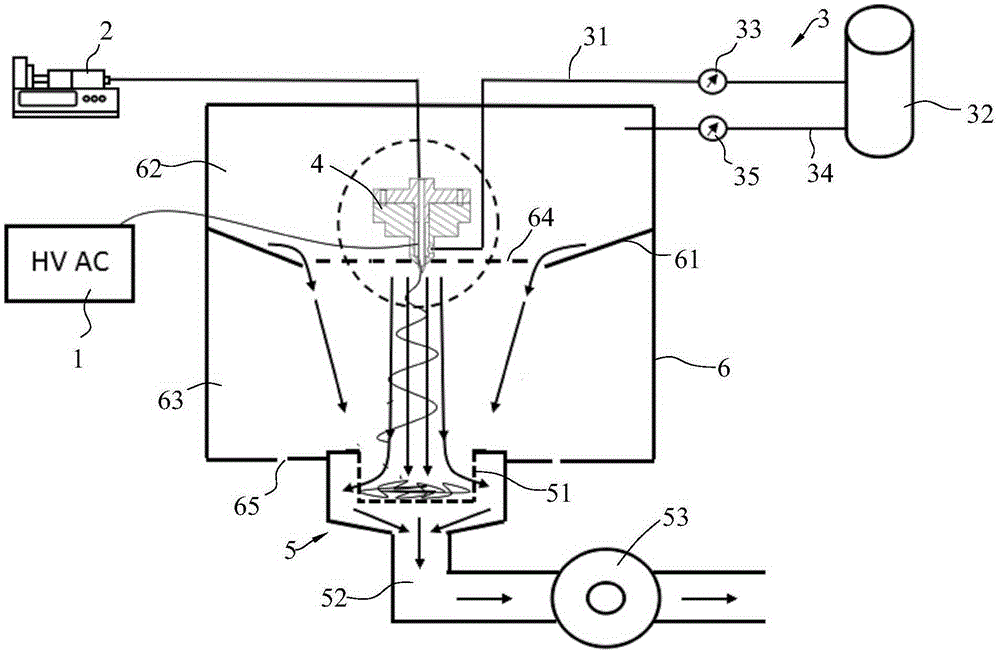

Centrifugal gas-electric spinning device by utilizing negative-pressure array

InactiveCN105350093AAirflow path controllableSimple structureNew-spun product collectionFilament/thread formingFiberEngineering

The invention discloses a centrifugal gas-electric spinning device by utilizing a negative-pressure array. The centrifugal gas-electric spinning device comprises a high-voltage alternating-current generator, an air supply device, a box body, a centrifugal sprayer, a centrifugal driving mechanism and negative-pressure receiving devices. The interior of the centrifugal sprayer is provided with a liquid storage cavity. Filament outlet holes are arranged in the centrifugal sprayer. Each negative-pressure receiving device comprises a collector, a negative-pressure pipe and a negative air-pressure generator. Negative-pressure pipe openings are formed by negative-pressure pipes in the bottom of the box body. Collectors are nested into the negative-pressure pipe openings. The multiple negative-pressure receiving devices are arrayed in an annular array with the centrifugal sprayer as the center. The high-voltage alternating-current generator is formed for generating an electric field. Airflow spraying out of the filament outlet holes is formed by the air supply device. The centrifugal gas-electric spinning device by utilizing the negative-pressure array has following beneficial effects: nanofibers are formed by sprayed polymers under airflow, an electric field, negative pressure and centrifugal force such that a three-dimensional structure is formed by nanofibers on the negative-pressure receiving devices; thickness of fiber disposition is increased; biological materials are better compatible and the application scope of technology materials is broad; and a support structure obtained is beneficial for cell growth of tissue engineering.

Owner:GUANGDONG UNIV OF TECH

Preparation method of high-adsorbability cellulose diacetate composite electrostatic spinning nanofiber ordered porous film

ActiveCN105396563ACreate pollutionSmall fiber diameterOther chemical processesDispersed particle filtrationElectrospun nanofiberPolymer science

The invention discloses a preparation method of a high-adsorbability cellulose diacetate composite electrostatic spinning nanofiber ordered porous film. The preparation method comprises the following steps: dissolving cellulose diacetate and polycaprolactone, or cellulose diacetate and a lactic acid-glycolic acid copolymer, or cellulose diacetate and polyvinylpyrrolidone into an organic solvent so as to prepare a spinning solution, and preparing the cellulose diacetate composite electrostatic spinning nanofiber ordered porous film by adopting an electrostatic spinning method. The method disclosed by the invention is simple, and cannot pollute the environment in the preparation process. The prepared cellulose diacetate composite electrostatic spinning nanofiber ordered porous film has tiny fiber diameter, good pore diameter and order degree, is good in dry and wet state adsorption performances, is high in water absorption, can be applied to the flue gas and tobacco industry of the dry state and wet state adsorption and filtration separation industry, is wide in market application prospect, and has relatively high application value.

Owner:ZHEJIANG UNIV

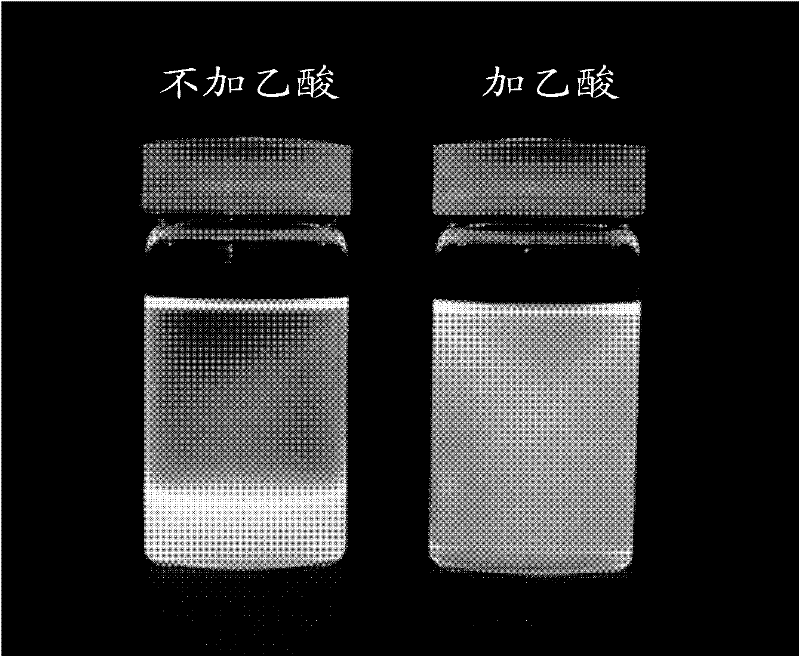

Method for preparing gelatin/polycaprolactone composite nanometer fiber membrane through electrostatic spinning

InactiveCN102242463AVolatile fastEasy to operateConjugated cellulose/protein artificial filamentsFilament/thread formingAcetic acidFiber

The invention relates to a method for preparing a gelatin / polycaprolactone composite nanometer fiber membrane through electrostatic spinning, comprising the steps of: (1) mixing gelatin with polycaprolactone, adding the mixture into trifluoroethanol or hexafluoroisopropanol, stirring, adding acetic acid and stirring till the solution is transparent so as to obtain a gelatin / polycaprolactone spinning solution; and (2) extracting the gelatin / polycaprolactone spinning solution, fixing on an electrostatic spinning device to carry out electrospinning, collecting fiber membranes, and drying in vacuum to obtain the gelatin / polycaprolactone composite nanometer fiber membrane. The method provided by the invention has the advantages of quickness, simpleness, convenience, low cost and good spinnability; the prepared composite nanometer fibers have smaller diameter and very good mechanical property and are suitable for batch preparation and mass production of the gelatin / polycaprolactone composite nanometer fiber membrane.

Owner:DONGHUA UNIV

Filter cartridge

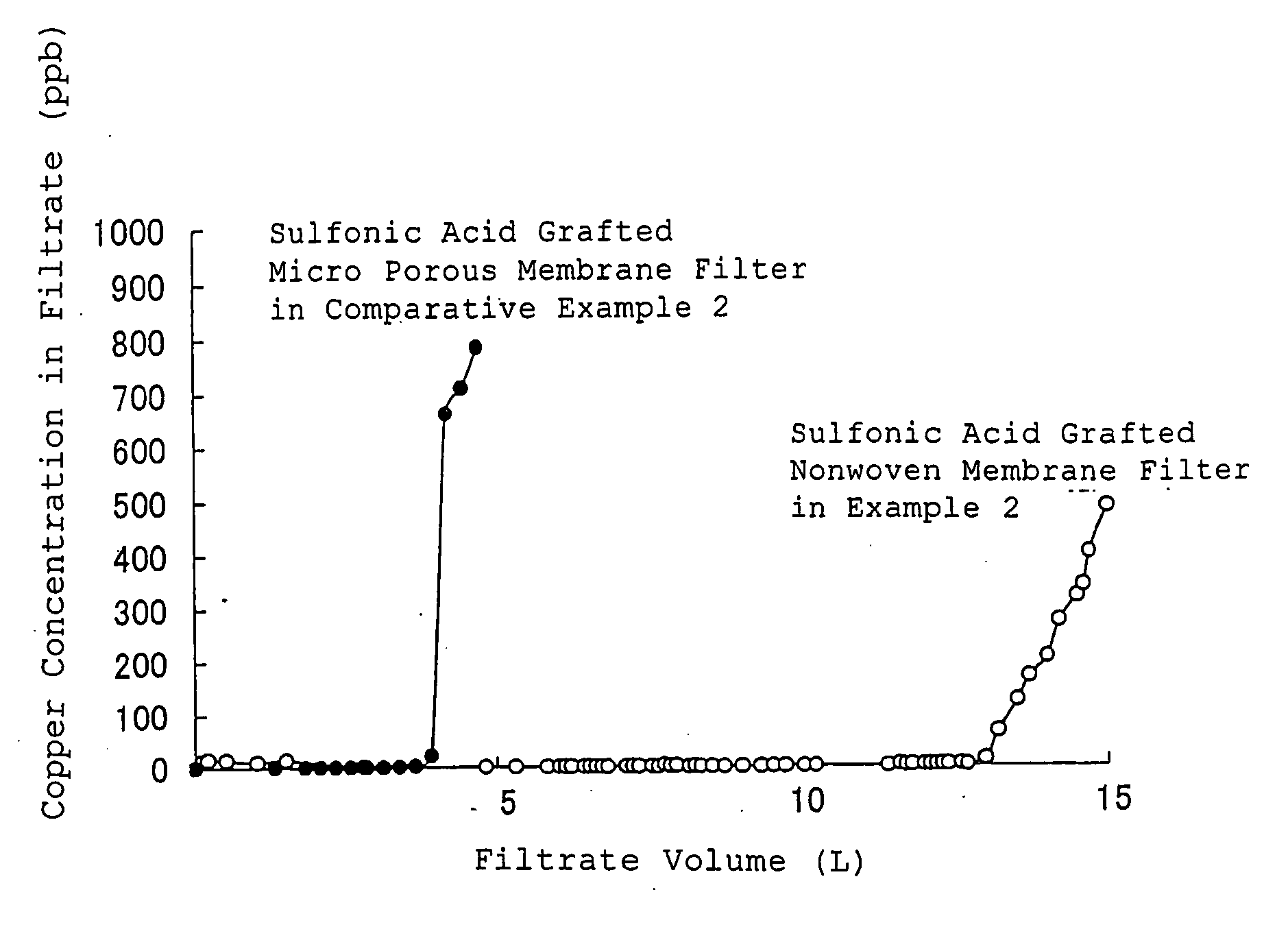

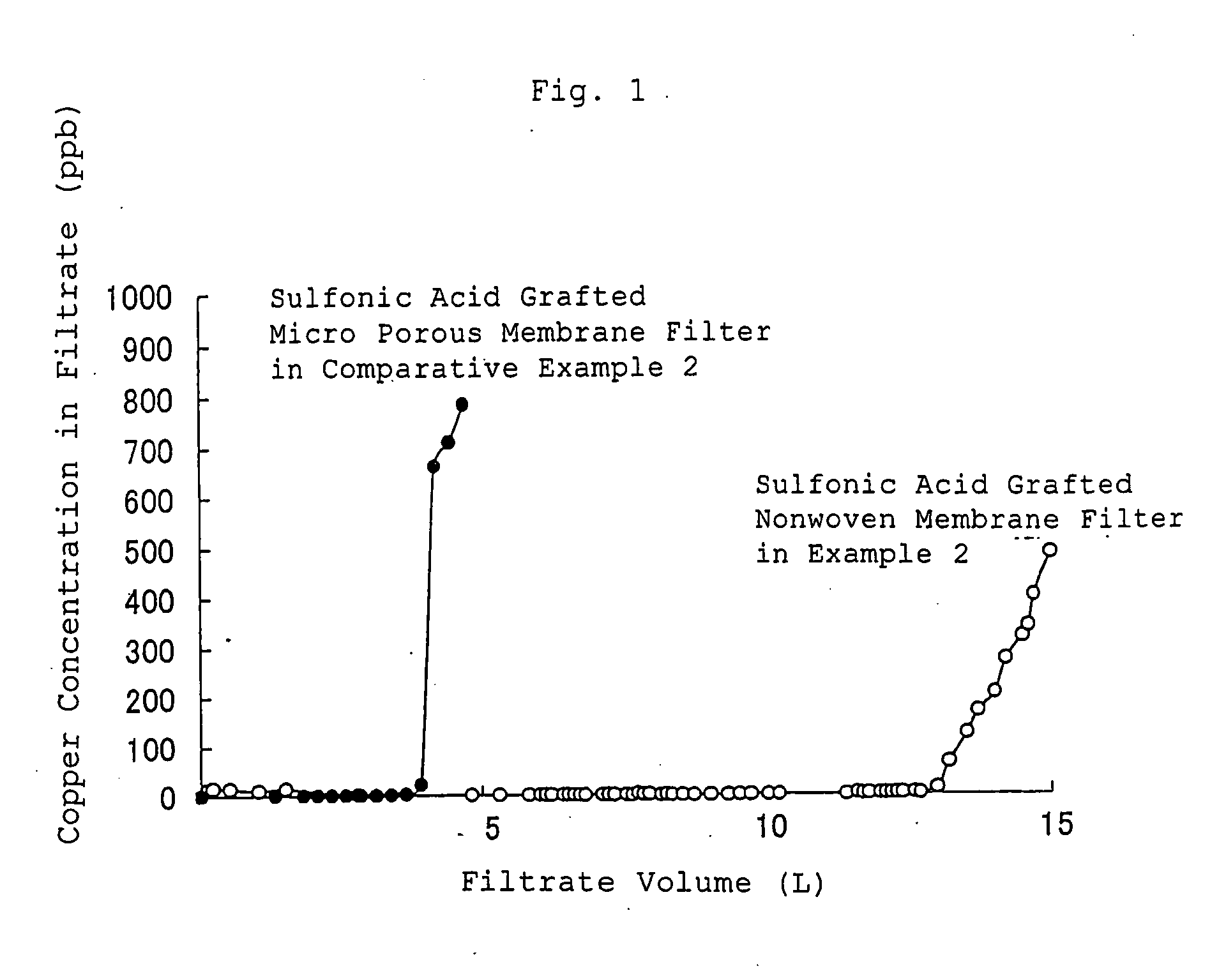

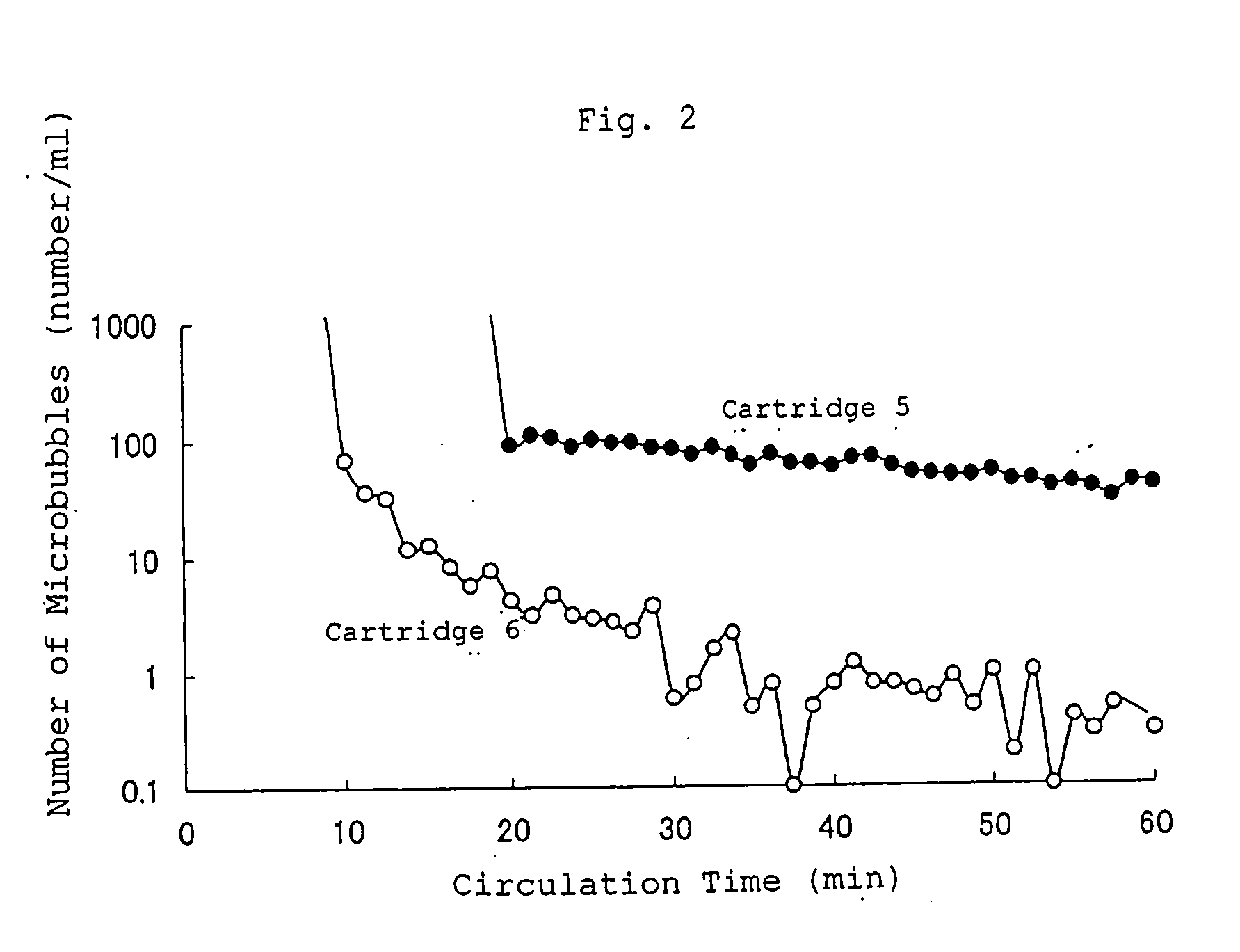

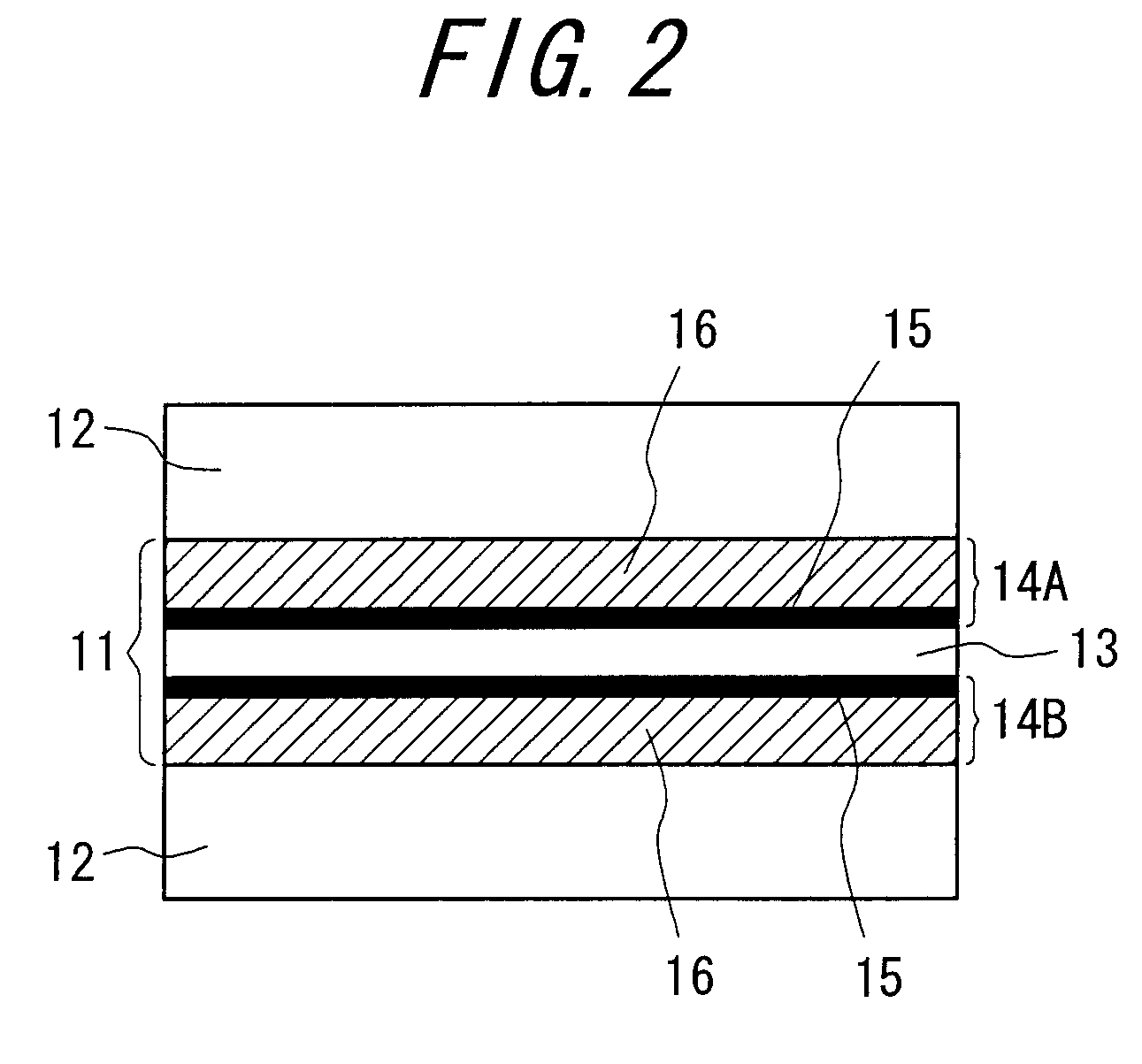

InactiveUS20050218068A1Efficient removalHigh mechanical strengthIon-exchange process apparatusSemi-permeable membranesIon exchangePorous membrane

The present invention has an object to provide a filter cartridge for purifying a chemical which can efficiently remove metal ions and impurities in the form of fine particles in a liquid to be filtered. The present invention provides, as the means to achieve the above described object, a filter cartridge comprising a fiber membrane material obtained by introducing ion exchange groups and / or chelate groups into an organic polymer fiber membrane base material having an average fiber diameter of 0.1 μm to 20 μm and an average pore size of 1 μm to 20 μm or a filter cartridge. And also present invention provides, as the means to achieve the above described object, comprising a bi-layered or laminated structure of filter membranes prepared from fiber membrane material obtained by introducing ion exchange groups and / or chelate groups into an organic polymer fiber membrane base material and a micro porous membrane material.

Owner:EBARA CORP +1

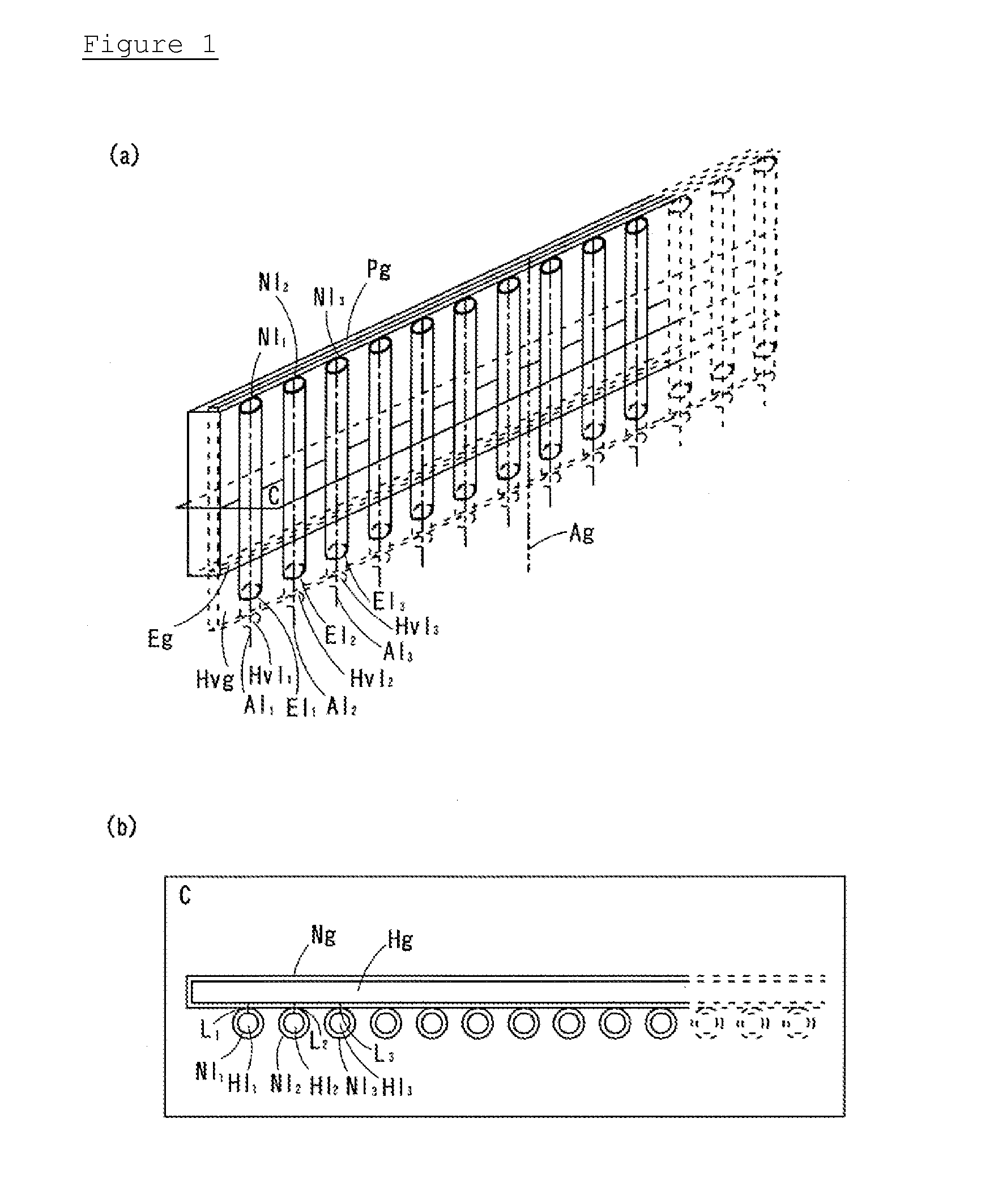

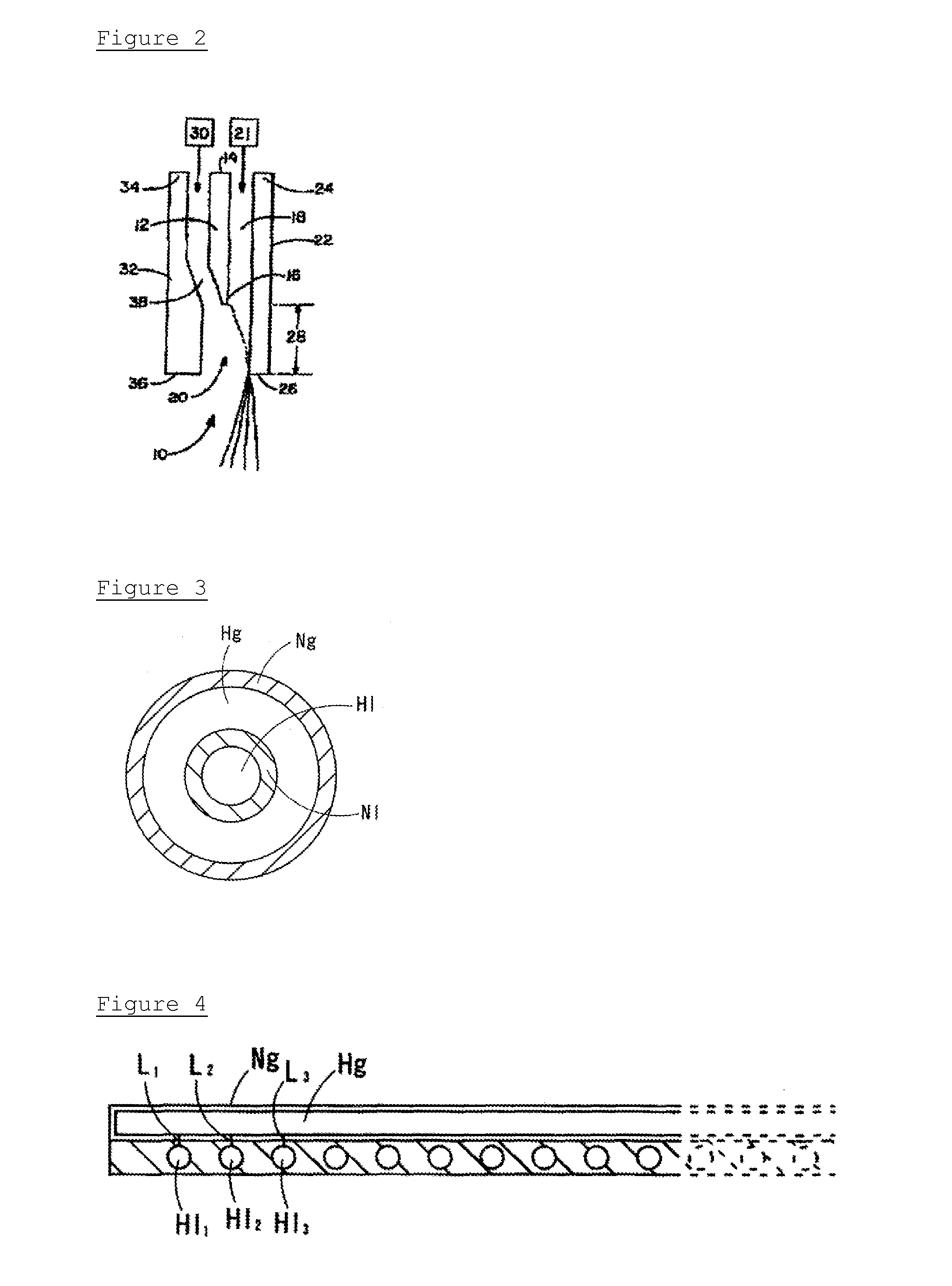

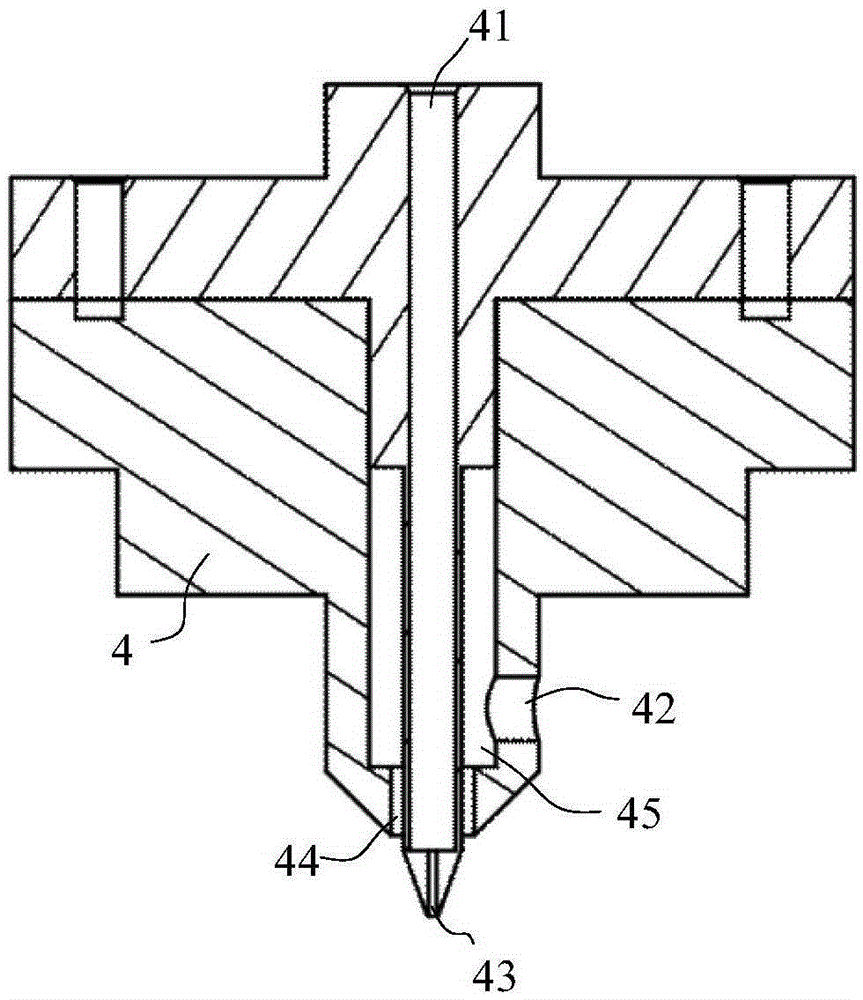

Preparation method and device for three-dimensional support for spinning by utilizing gas-electro spinning based on negative-pressure collection

ActiveCN105350089ASimple structureSimple processFilament/thread formingEngineeringAlternating current

The invention discloses a preparation method and device for a three-dimensional support for spinning by utilizing gas-electro spinning based on negative-pressure collection. A device comprises an alternating-current high-voltage generator, a liquid supply device, a gas liquid device, a coaxial sprayer and a negative-pressure collecting device. The coaxial sprayer is provided with a liquid outlet and a gas outlet. The gas supply device is used for conveying a spinning solution or melts to the coaxial sprayer and enabling melts to flow out of the liquid outlet. The gas liquid device can generate air flow blowing from the liquid outlet to the negative-pressure collecting device via the liquid outlet. The alternating-current high-voltage generator can form an alternating electric field between the coaxial sprayer and the negative-pressure collecting device. The negative-pressure collecting device comprises a collector, a negative-pressure pipe and a negative-pressure generator. The spinning solution or melts form solution jet flow or melt jet flow in the coaxial sprayer and the collector under effect of airflow and the alternating electric field.The preparation method and device for the three-dimensional support for spinning by utilizing gas-electro spinning based on negative-pressure collection have following beneficial effects: by adoption of spinning technology based on the negative-pressure collector, the nanofiber three-dimensional support featuring a broad range of preparation material, small fiber diameters, uniformly-distributed filament diameters, a loose structure, great thickness and superior mechanical properties is obtained and has great technological universality.

Owner:FOSHAN QINGZI PRECISION MEASUREMENT & CONTROL TECH

Inorganic Fibers, Fiber Structure and Process for Their Production

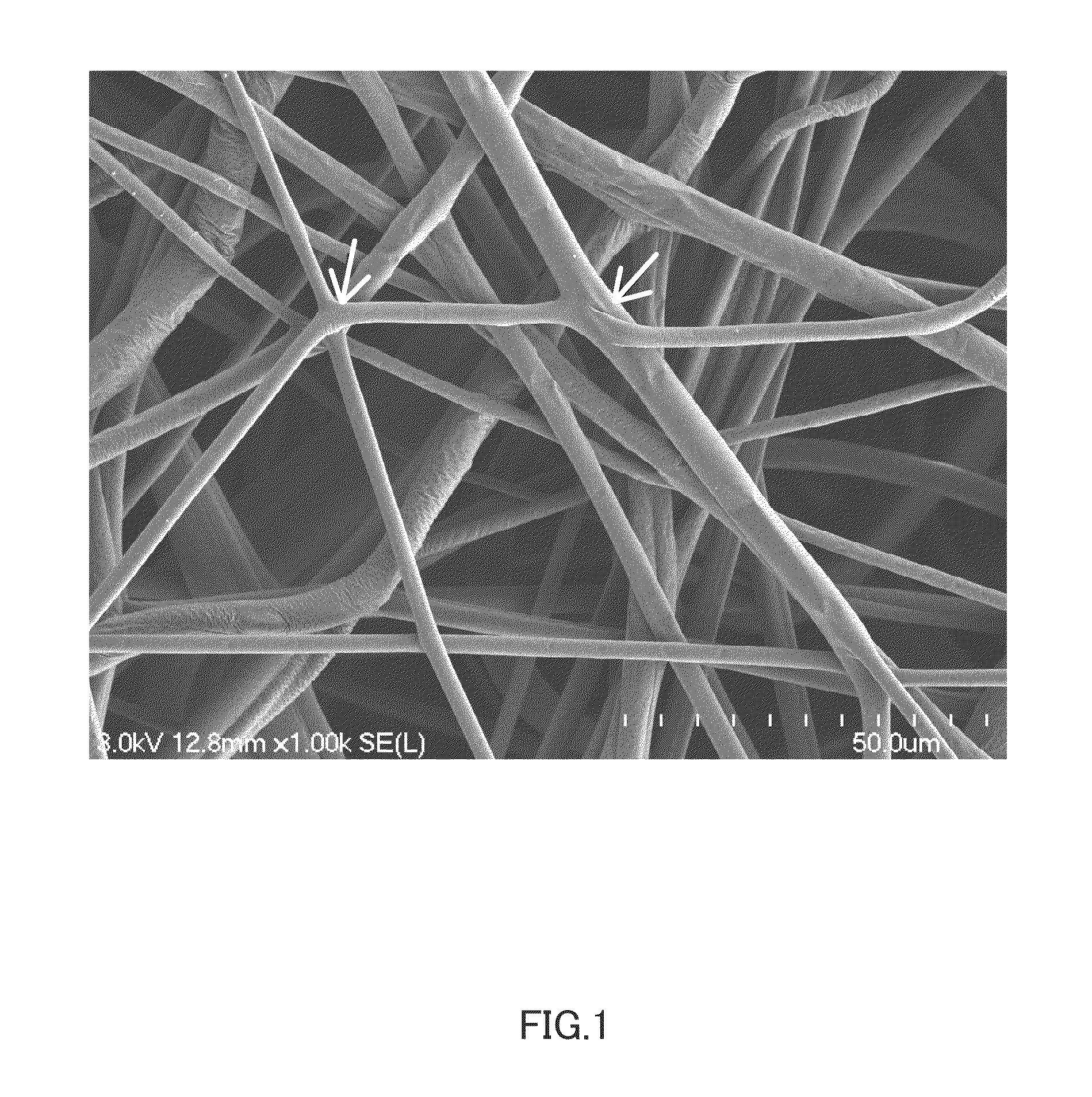

InactiveUS20080070037A1Small fiber diameterGlass making apparatusInorganic material artificial filamentsPolymer scienceOxygen

Inorganic fibers consisting substantially of silicon, carbon, oxygen and a transition metal, having a fiber size of no greater than 2 μm and having fiber lengths of 100 μm or greater.

Owner:TEIJIN LTD

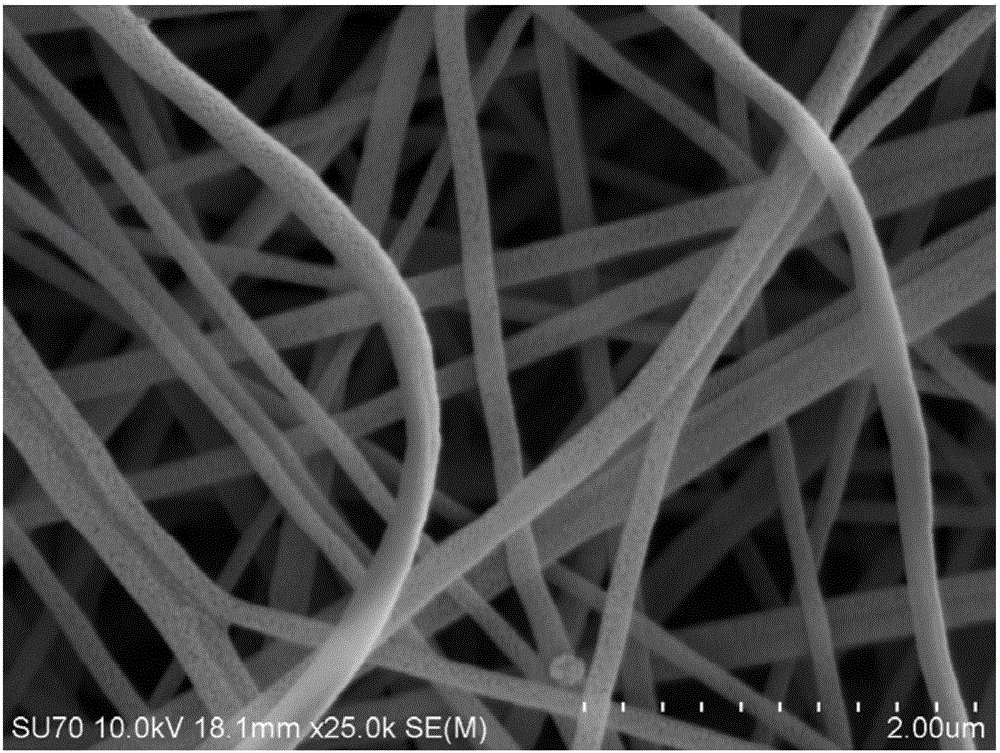

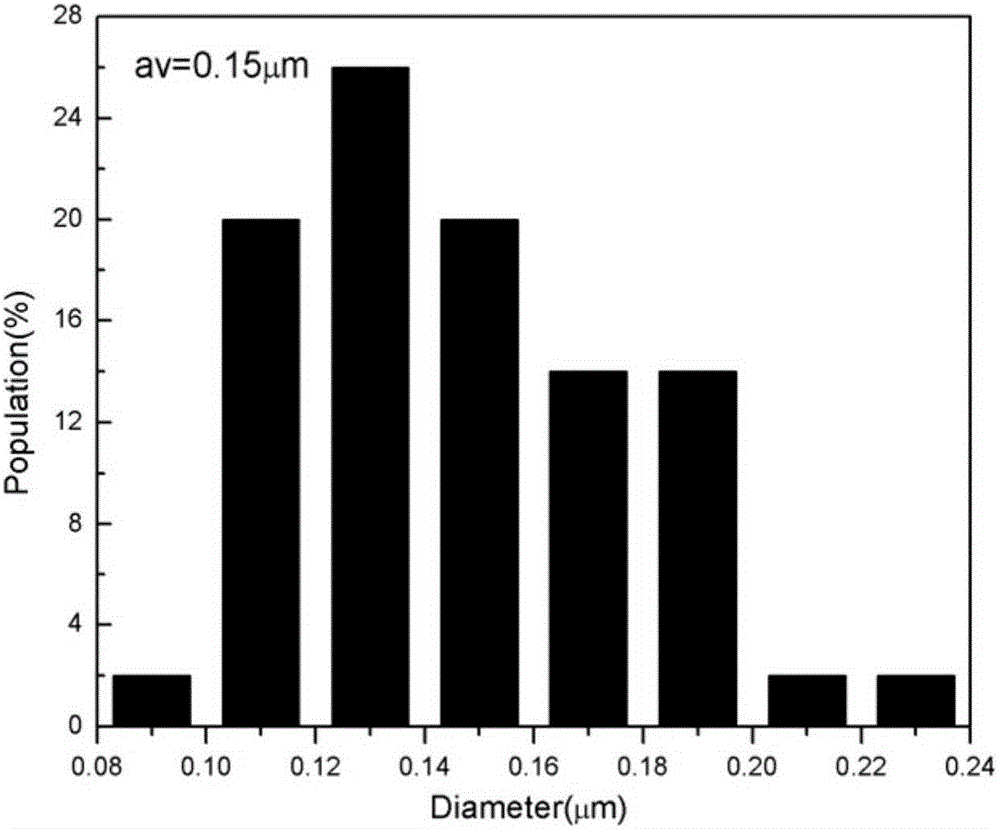

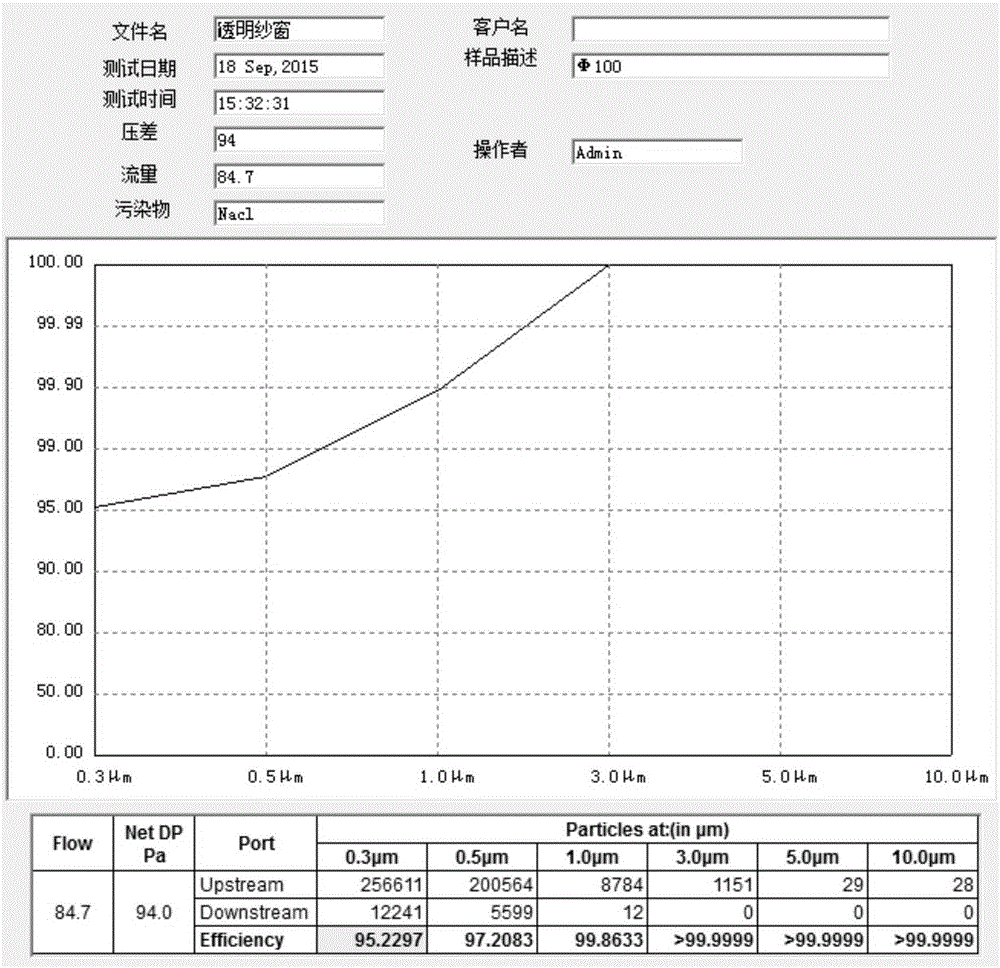

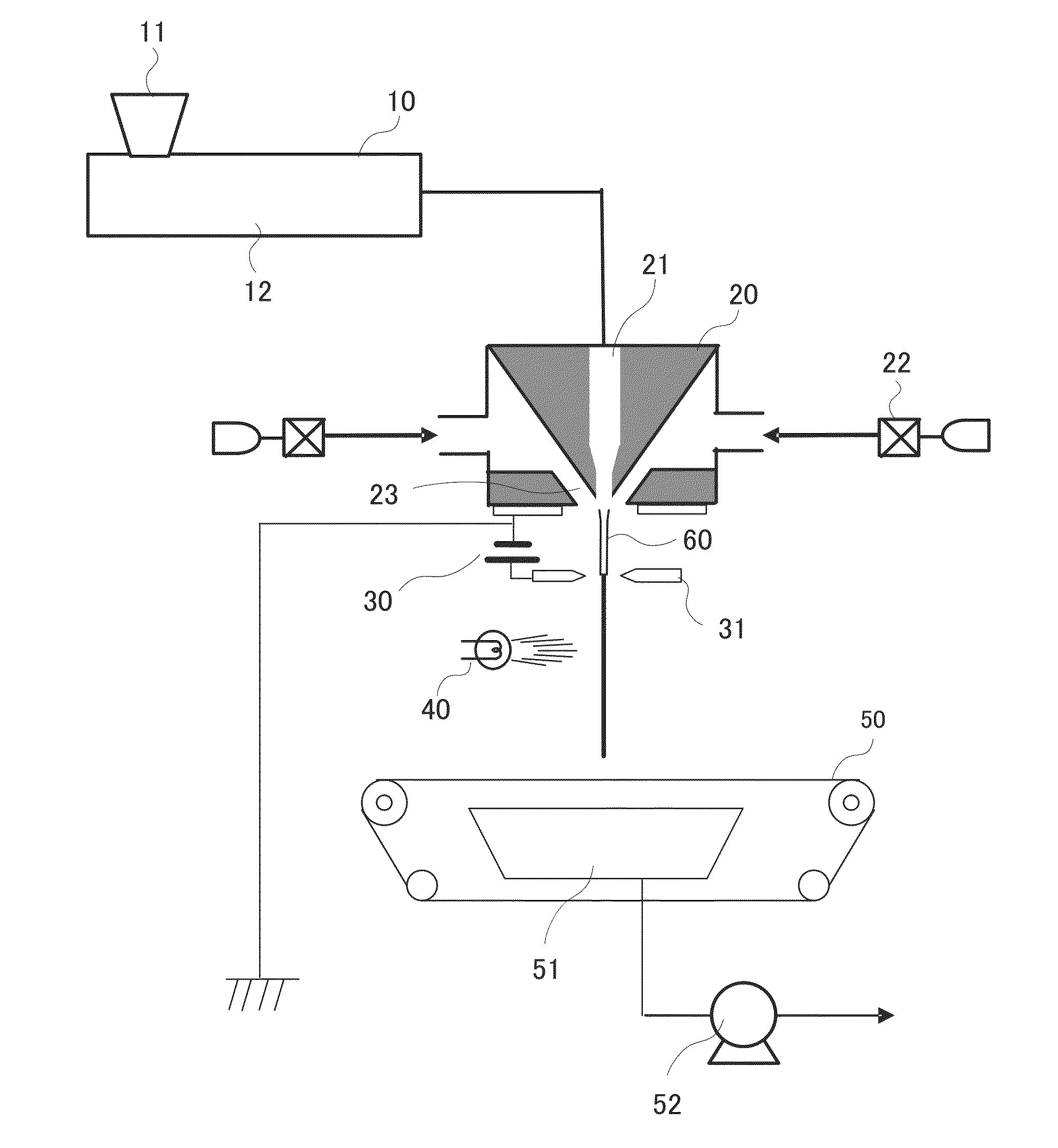

Preparation method of transparent screen with PM2.5 fine particle filtering function

ActiveCN105624922ASimple processSmall fiber diameterFilament/thread formingFiltration separationSolventIndoor air

The invention discloses a preparation method of a transparent screen with a PM2.5 fine particle filtering function. The preparation method comprises steps as follows: (1) dissolving a high-molecular polymer in a solvent, and performing stirring for dissolution at 48-55 DEG C for 1.5-2.5 h to prepare a spinning solution with the concentration of the high-molecular polymer being 6-20wt%; (2) preparing a nanofiber membrane on a nylon screen substrate by use of the spinning solution through electrostatic spinning to obtain a composite screen; (3) drying the composite screen in hot air at 65-75 DEG C for 1.5-2.5 h and naturally cooling the composite screen to the room temperature to obtain the transparent screen with the PM2.5 fine particle filtering efficiency being 70%-95% and the transparency being 40%-80%. The prepared transparent screen is high in transparency and good in breathability, has higher filtering efficiency for PM2.5 fine particles and is an excellent material in the indoor air filtering field.

Owner:LVNA TECH CO LTD

Non-woven fiber fabric, and production method and production device therefor

InactiveUS20130122771A1Small fiber diameterImprove flowLayered productsElectro-spinningSpinningPolymer science

The present invention provides a method for producing a non-woven fiber fabric by spinning a molten polymer. Thus, a non-woven fiber fabric which is substantially free from a solvent, different from the case of spinning a polymer solution, but yet has an extremely small fiber size (diameter of 0.5 μm or less) is provided. The non-woven fiber fabric comprises an olefin-based thermoplastic resin fiber, said fiber having an average fiber size of 0.01-0.5 μm, and said non-woven fiber fabric having an average pore size of 0.01-10.0 μm and being free from a solvent component.

Owner:MITSUI CHEM INC

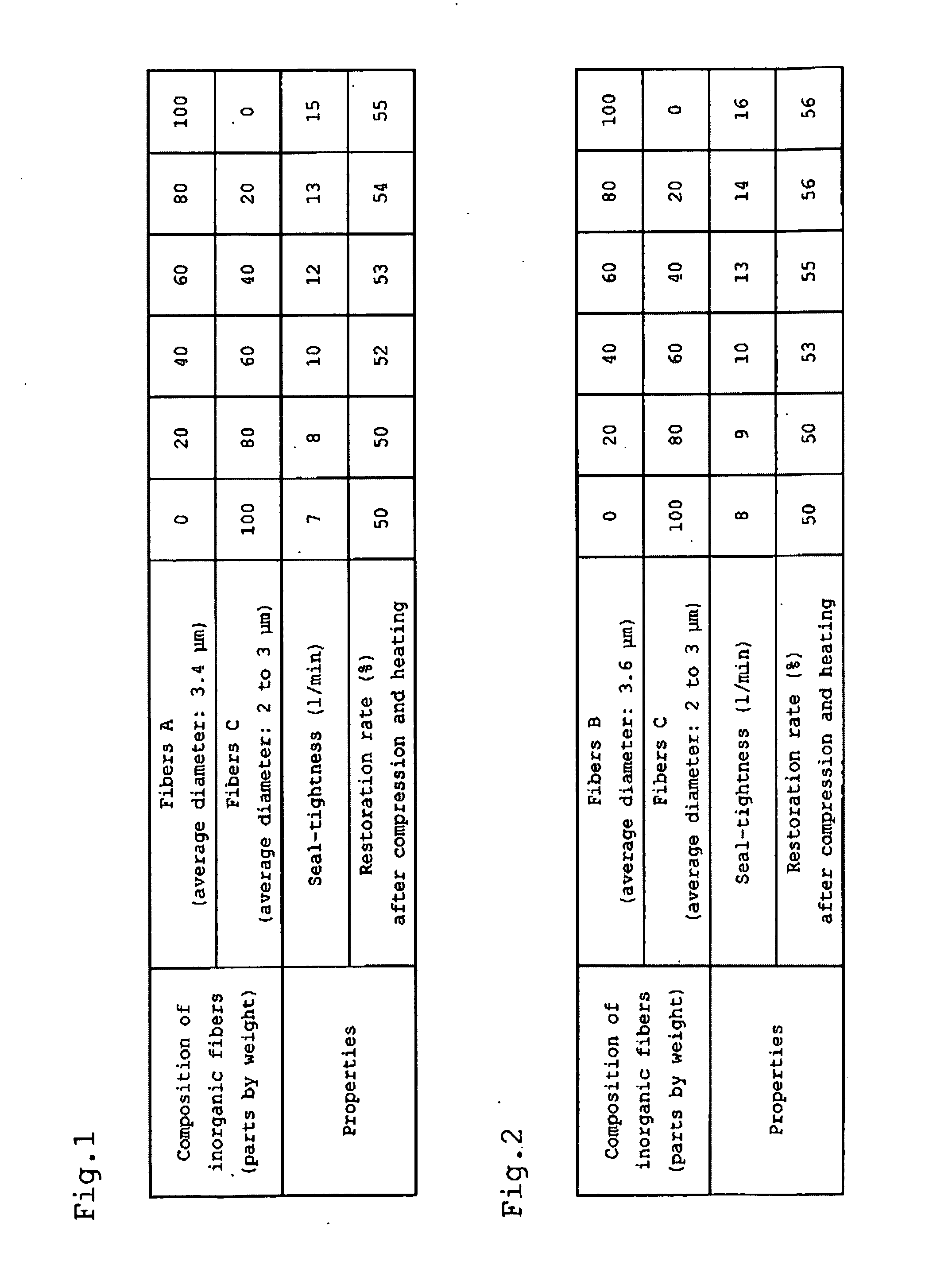

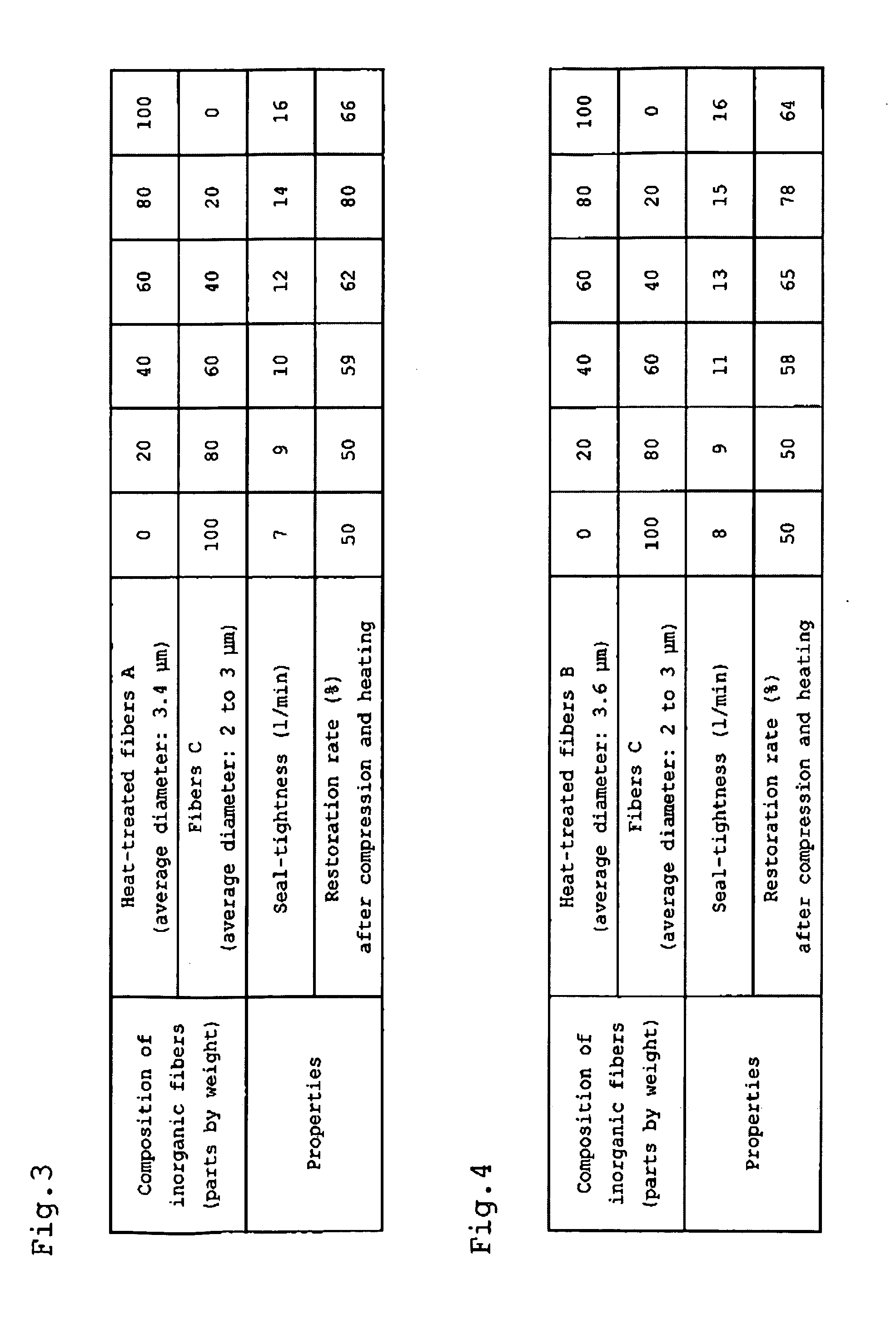

Inorganic fiber paper and method of producing the same

ActiveUS20120247695A1Improve sealingSmall fiber diameterInorganic fibres/flakesGlass making apparatusPolymer scienceFiber diameter

Inorganic fiber paper includes first biosoluble inorganic fibers having an average fiber diameter of 3 to 7 μm, second biosoluble inorganic fibers having an average fiber diameter of 2 to 3 μm, and a binder, the average fiber diameter of the second biosoluble inorganic fibers being smaller than that of the first biosoluble inorganic fibers.

Owner:NICHIAS CORP

Ultrafine polyactic acid fibers and fiber structure, and process for their production

InactiveUS20070172651A1Small fiber diameterImprove biodegradabilityMonocomponent copolyesters artificial filamentNon-woven fabricsPolymer scienceElectrospinning

A fiber structure is obtained by spinning of a solution of an L-lactic acid condensate and a D-lactic acid condensate by electrospinning. It is possible to provide a fiber structure comprising fibers with extremely small fiber diameters, as well as excellent heat resistance and biodegradability.

Owner:TEIJIN LTD

Thin-long hair fibre an dits production method

The present invention provides a fine-long animal hair fibre and its production method which can fix its stretched state, do not damage crimp recovery, reduce fibre diameter, increase fibre length and raise fibre glossiness. Its production includes the following steps: (a) for animal hair stripe, implementing twisting procedure; (b) soaking the twisted animal hair stripe in alkaline aqueous solution and making the animal hair stripe undergo the process of swelling and plasticity treatment; (c) reduction procedure for cutting disulfide bond in the swelling plasticity fibre; (d) drawing procedure for actually drawing the swelling plasticity fibre to 1.20-1.60 times; (e) using oxidant to oxidate the drawn animal hair fibre; and (f). using acid to make neutralization.

Owner:KURASHIKI BOSEKI KK

Scaffold with increased pore size

InactiveUS20100143435A1Quantity minimizationControl moreBiocideElectric discharge heatingFiberPore diameter

The invention relates to scaffolds for use as medical devices, for guided tissue regeneration and repair, wherein the relationship between fibre diameter and pore size in a scaffold is decoupled, thereby enabling the small fibre diameters required for cell attachment and proliferation and the large pore sizes needed for cell migration into the scaffold to be achieved.

Owner:SMITH & NEPHEW INC

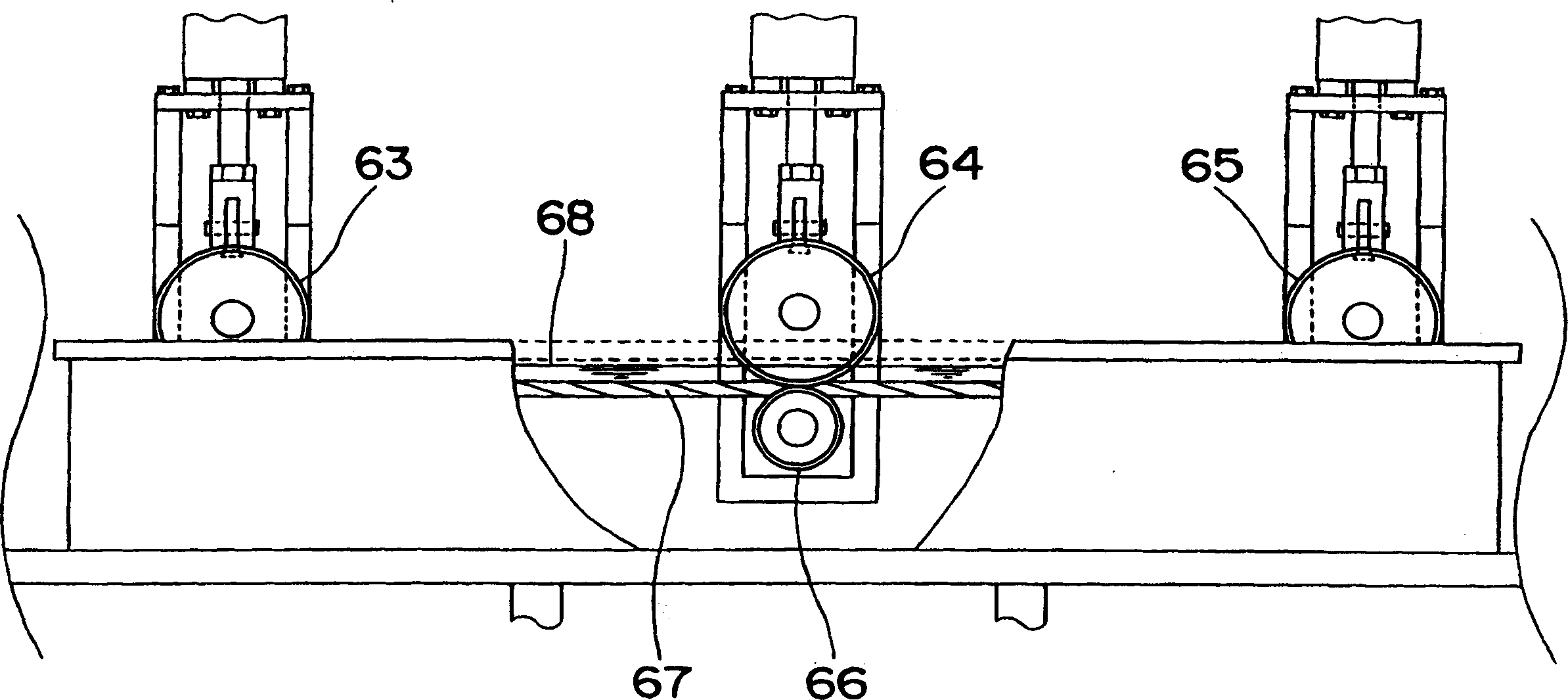

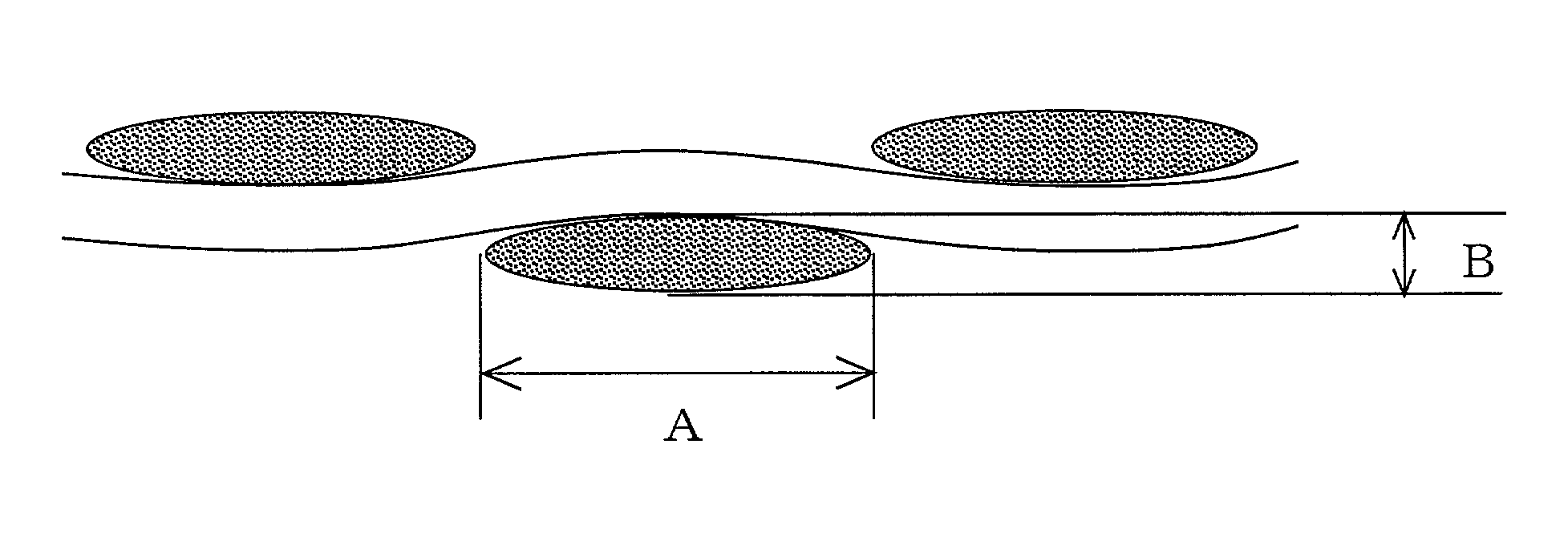

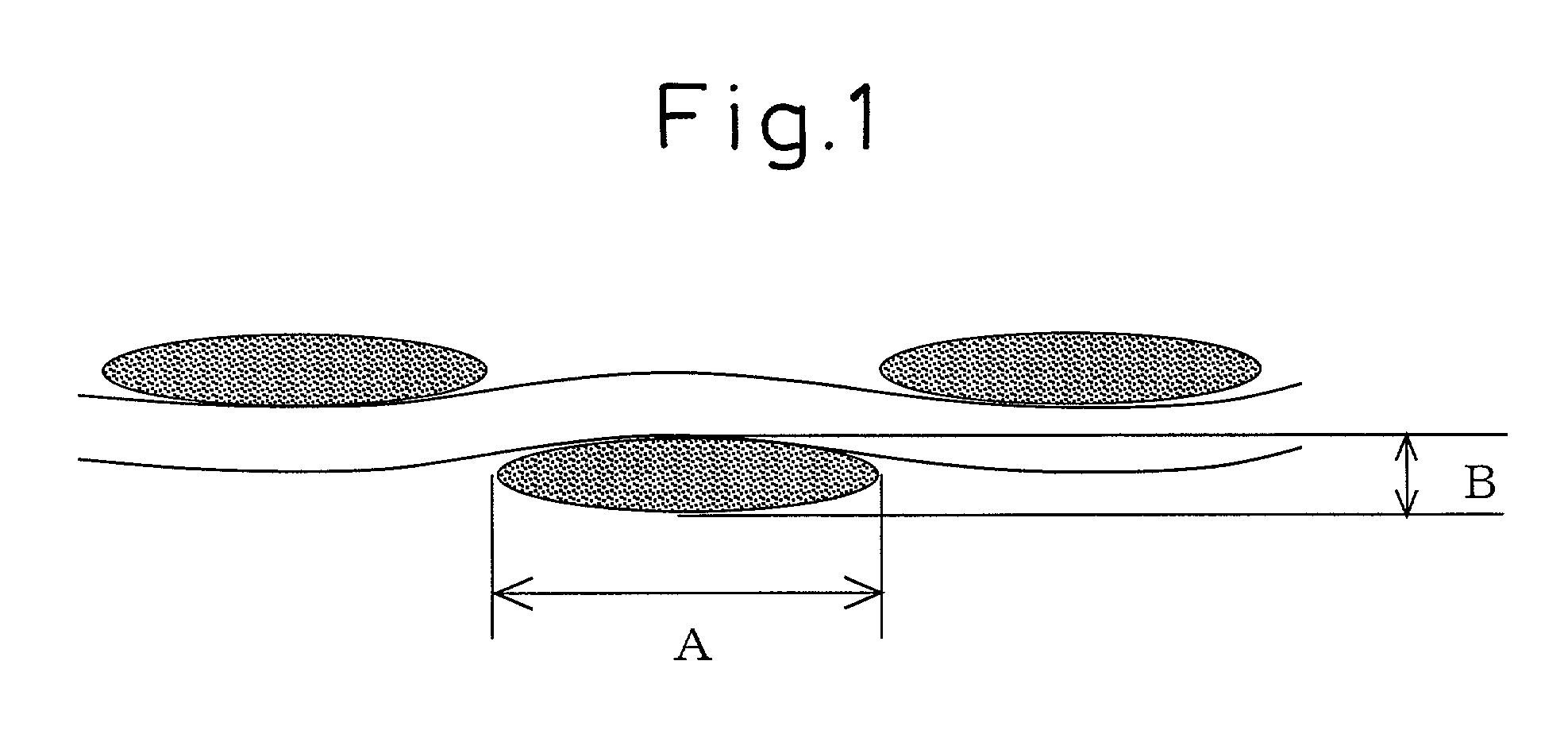

Glass cloth and printed wiring board

InactiveUS7049253B1Improve surface smoothnessImprove machinabilityPrinted circuit aspectsWoven fabricsHigh densitySingle fiber

The present invention is(1) a glass cloth composed of a group of warp yarns and a group of weft yarns wherein one of the group of the warp and weft yarns are arranged with substantially no gap between the yarns, and, in that group, a width A (μm) of a cross-section of the yarn arranged with substantially no gap, a single-fiber diameter L (μm) of the yarn, the number N of single-fibers constituting the yarn and a weaving density C (ends / 25 mm) of the glass cloth composed of the yarns satisfy the following equation (1-a):C×A / (25×L×N)≧1.0, and (1-a)(2) a glass cloth composed of a group of warp yarns and a group of weft yarns wherein both of the groups of the warp and weft yarns are arranged with substantially no gap between the yarns, and, in both the groups, a width A (μm) of a cross-section of the yarn, a single-fiber diameter L (μm) of the yarn, the number N of single-fibers constituting the yarn and a weaving density C (ends / 25 mm) of the glass cloth satisfy the following equation (1-b):C×A / (25×L×N)≧0.75. (1-b)The glass cloth according to the present invention is useful as a substrate for a printed wiring board. The printed wiring board using the glass cloth of the present invention as a substrate is capable of being bored with a laser beam to produce micro-holes (the roughness of the inner wall, the reproducibility and the roundness of the micro-holes are improved) therein, especially, is able to prepare uniform and small via-holes which are recently required for high-density wiring.

Owner:ASAHI SCHWEBEL

Nonwoven fabric made of an ethylene/tetrafluoroethylene copolymer

InactiveUS20090226690A1Excellent heat resistance and chemical resistanceSmall fiber diameterFilament/thread formingAbsorbent padsMelt viscosityPore diameter

It is an object of the present invention to provide a nonwoven fabric which is excellent in the heat resistance and the chemical resistance, of which the fiber diameter is small, which is excellent in the strength and of which the maximum pore diameter is small.A nonwoven fabric made of an ethylene / tetrafluoroethylene copolymer, characterized in that the nonwoven fabric is mutually fused continuous fibers of an ethylene / tetrafluoroethylene copolymer which has a melt viscosity of from higher than 100 to 1,500 Pa˜s at 240° C.

Owner:ASAHI GLASS CO LTD

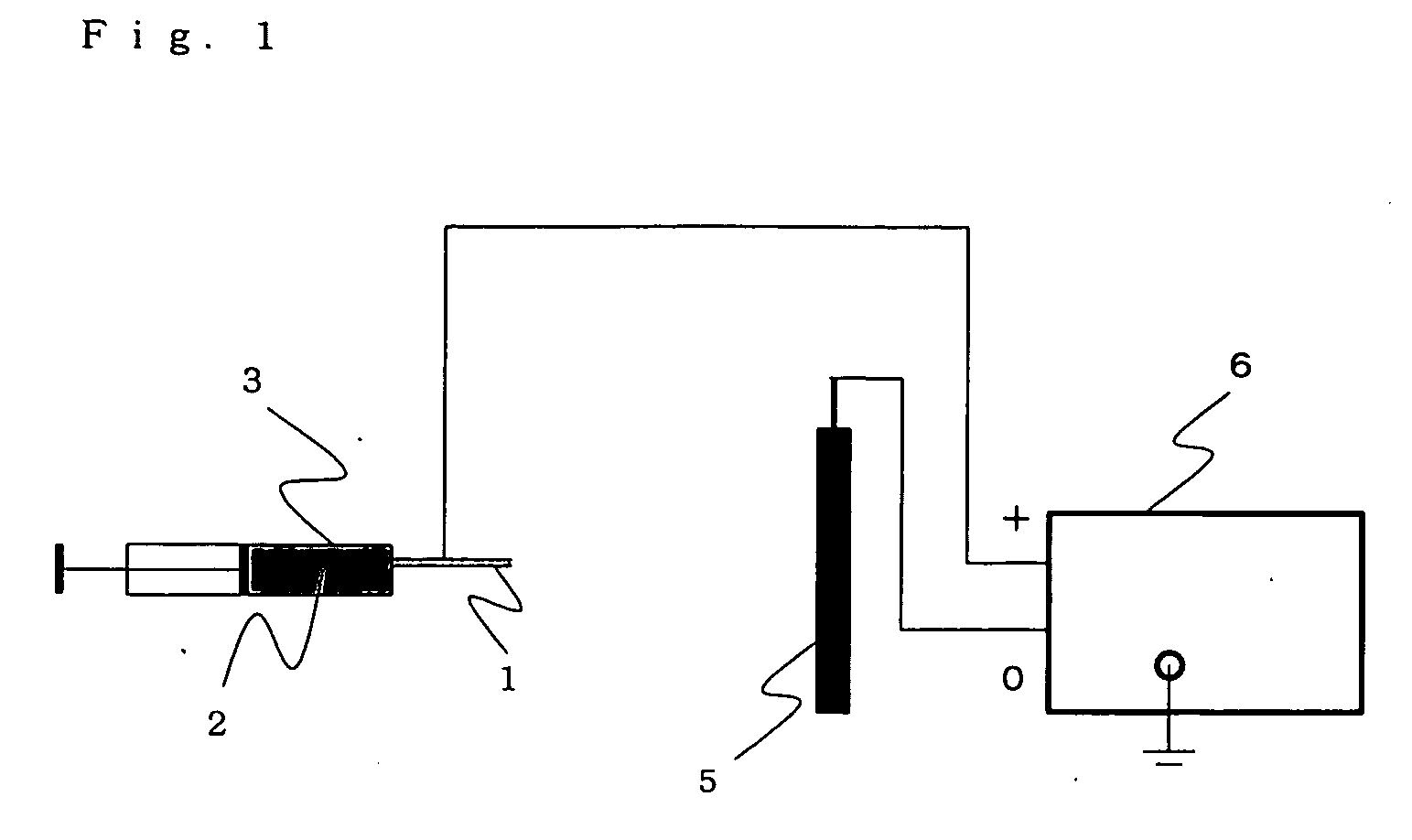

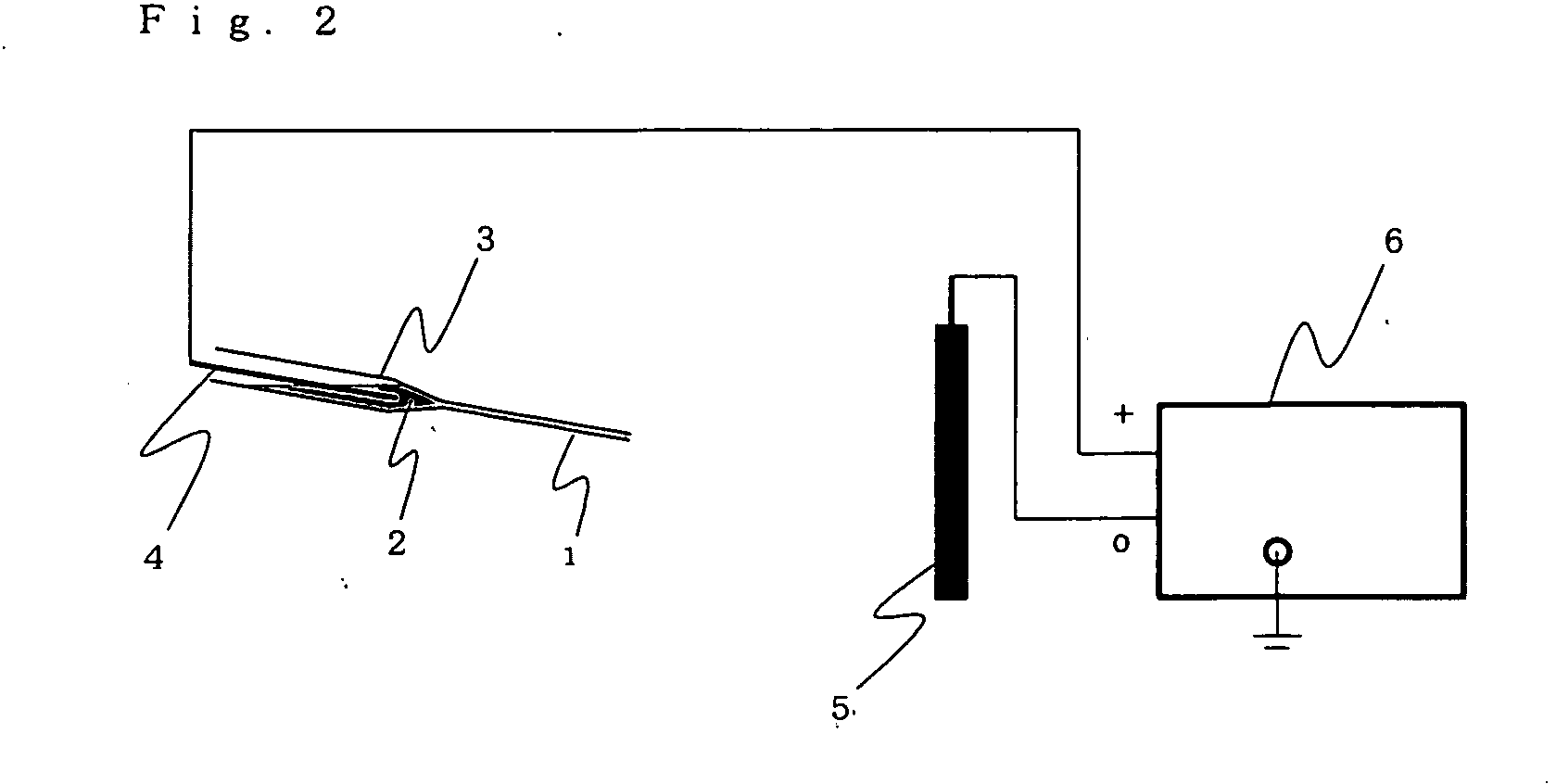

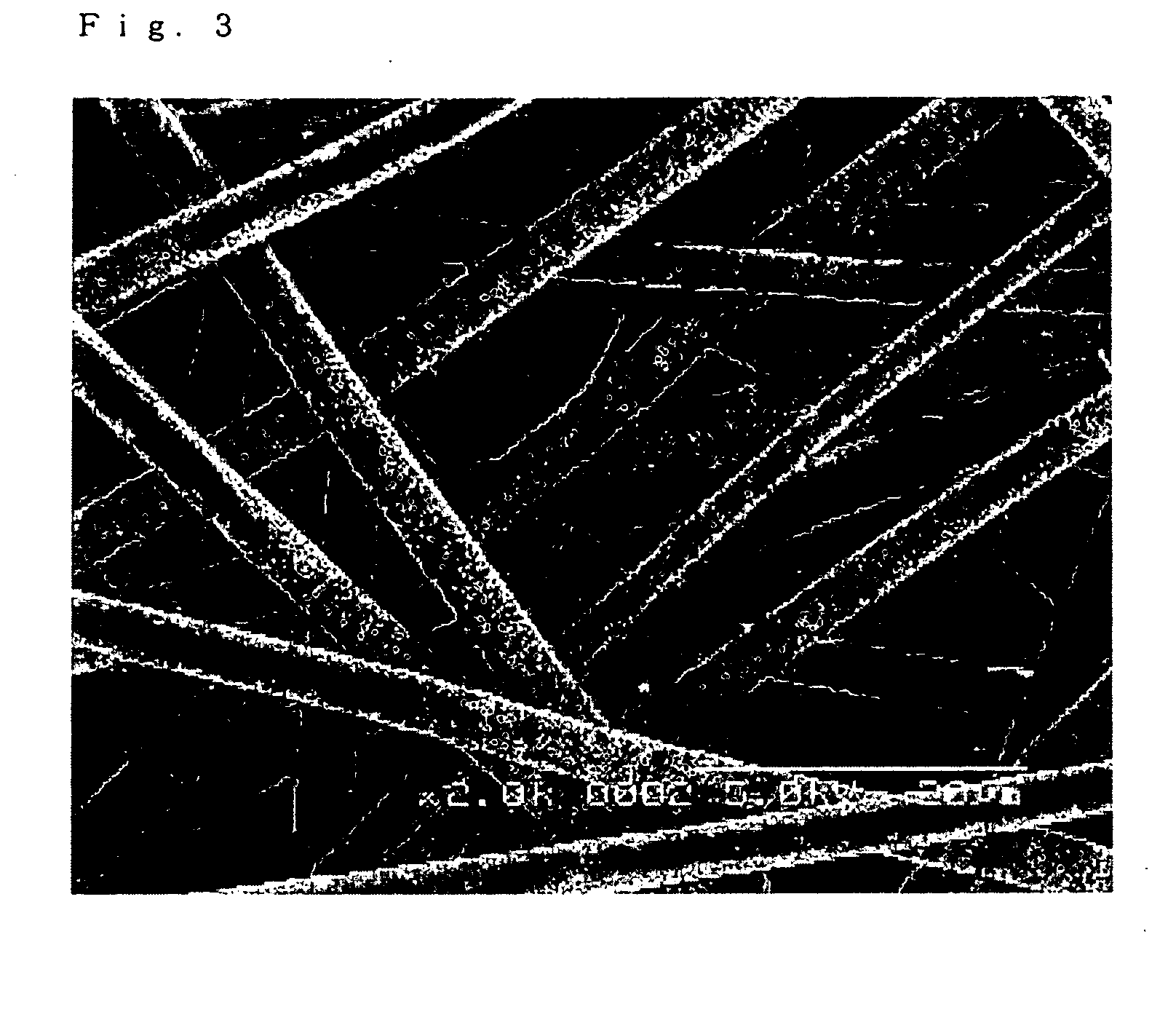

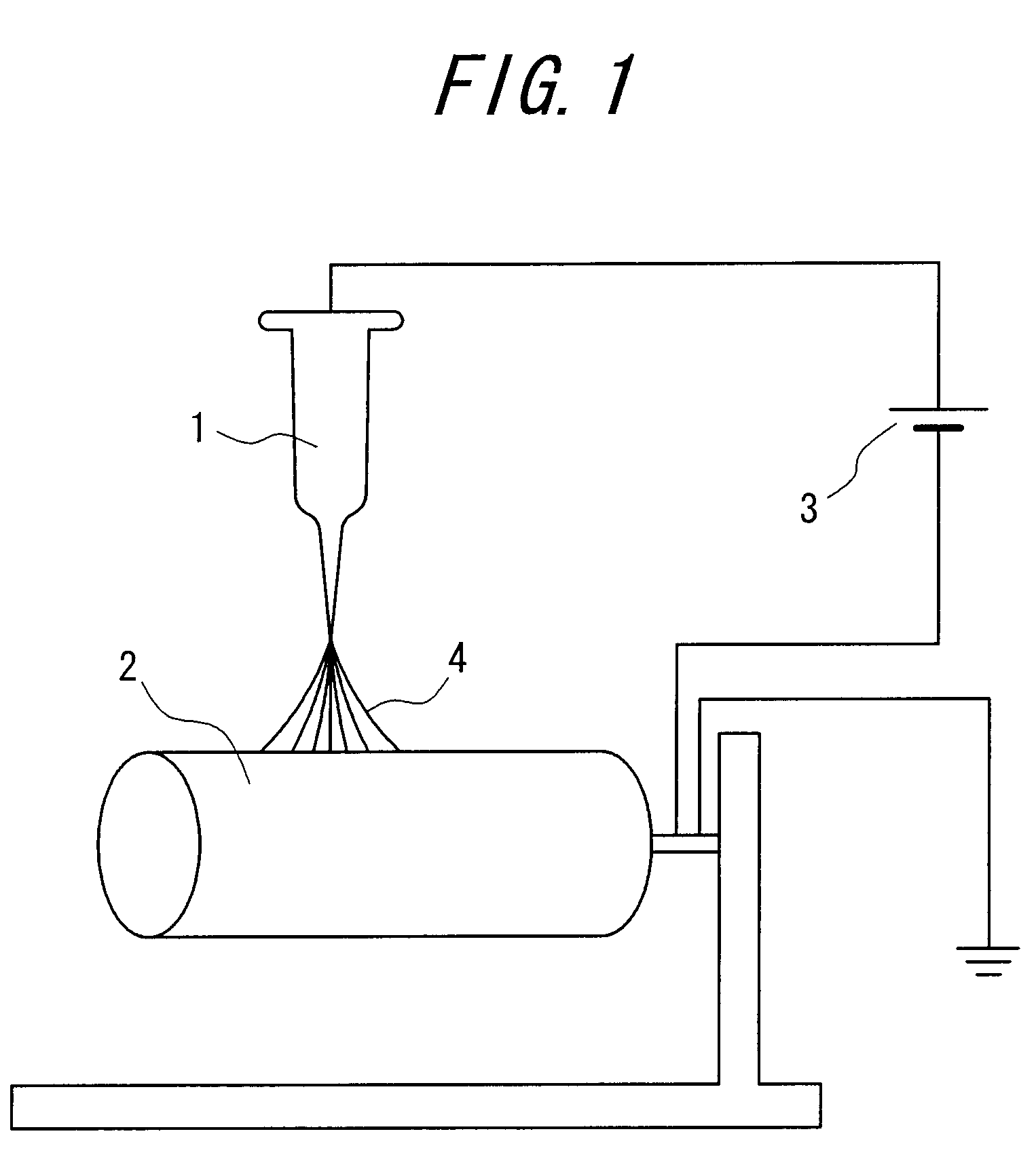

Material for filling bone defects and production method thereof

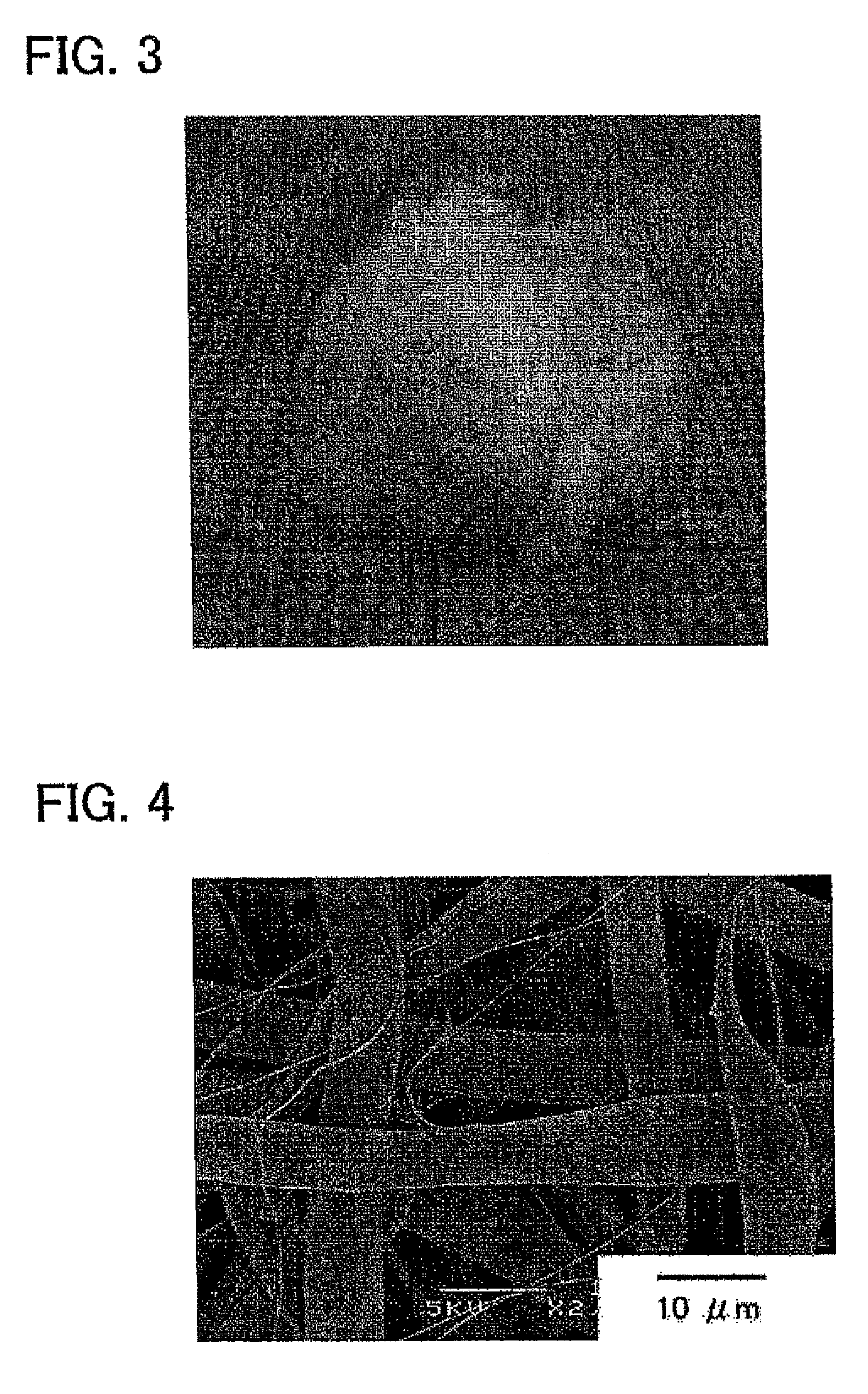

InactiveUS20110009522A1Low viscosityHigh viscosityImpression capsElectric discharge heatingElectrospinningSlurry

Disclosed is a material for filling bone defects having a three-dimensional steric structure. This material is produced by dissolving or suspending a substance in a solvent to give a solution or slurry, the substance containing a biodegradable resin as a principal component and bearing a siloxane; adding water to the solution or slurry to give a spinning solution, the water having a relative dielectric constant larger than that of the biodegradable resin; subjecting the spinning solution to electrospinning while applying a positive charge to a collector by a voltage supply and grounding a nozzle of a syringe without applying a charge thereto; thereby yielding the material on the collector.

Owner:ORTHOREBIRTH

Carbon fiber, porous support-carbon fiber composite and method for producing the same as well as catalyst structure, electrode for solid polymer fuel cell and solid polymer fuel cell

InactiveUS20090142647A1Small fiber diameterLarge specific surface areaCatalyst carriersElectric discharge heatingPolymer scienceMicrowave

This invention relates to a method for producing carbon fibers having a sufficiently small fiber diameter, and more particularly to (1) a method for producing carbon fibers, which comprising the steps of jetting a polymer material-containing solution by an electrospinning method to form a deposit layer of a fibrous substance comprising the polymer material and firing the deposit layer of the fibrous substance comprising the polymer material to produce carbon fibers, and (2) a method for producing carbon fibers, which comprising the steps of jetting a carbon black-dispersed and polymer material-containing solution by an electrospinning method to form a deposit layer of a fibrous substance comprising the carbon black-dispersed polymer material and irradiating microwaves to the deposit layer of the fibrous substance to produce carbon fibers.

Owner:BRIDGESTONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com