Preparation method of transparent screen with PM2.5 fine particle filtering function

A transparent yarn and fine particle technology, applied in the field of screen window manufacturing, can solve the problems of limited filtering capacity of fine particles, poor air permeability and transparency, and large screen window aperture, etc., and achieve the effect of small fiber diameter, high transparency and good air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

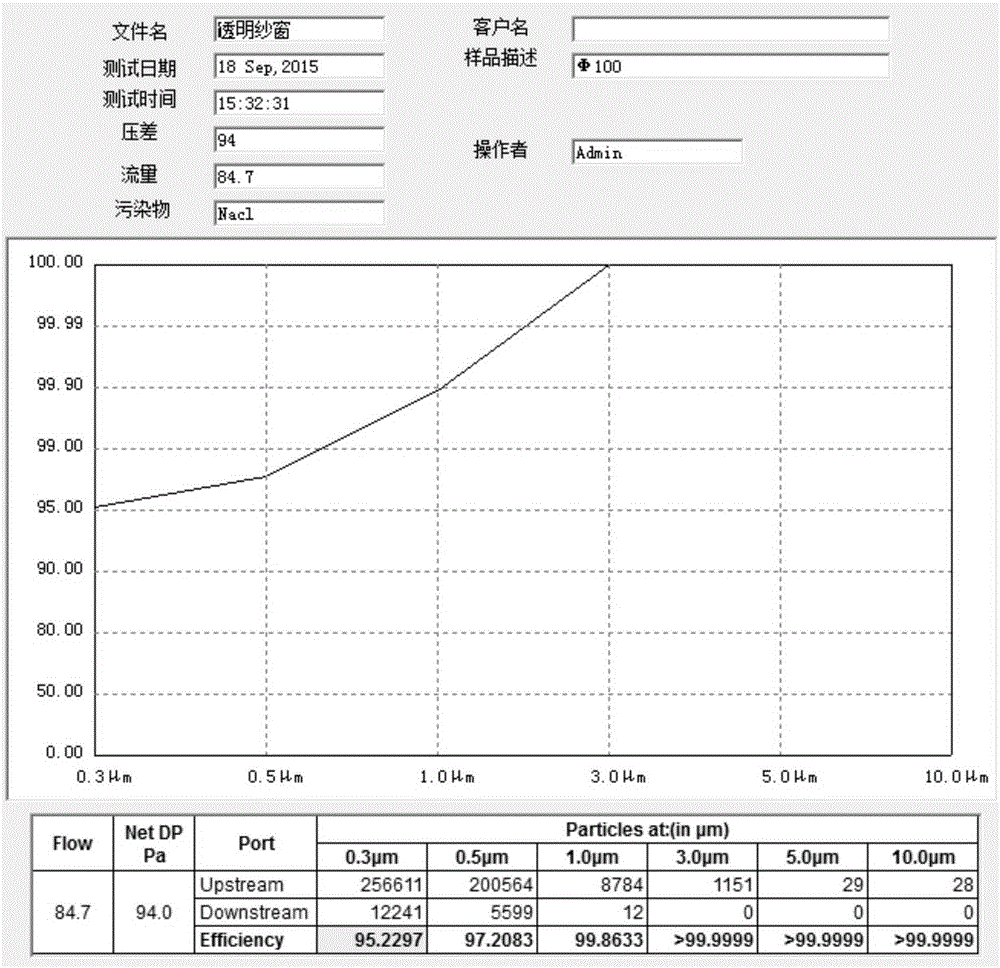

[0026] 7 g of polyacrylonitrile was added to 93 g of dimethylformamide, and fully stirred at 50° C. for 2 h to obtain a PAN / DMF spinning solution with a mass fraction of 7 wt %. Pour the solution into a tank equipped with a metal cylindrical electrode, use nylon gauze as the base, and carry out electrospinning under the conditions of an output voltage of 70Kv, a receiving distance of 14cm, a temperature of 30°C, and a humidity of 35%. A composite gauze with a nanofibrous film was obtained after 2 minutes of filamentation. The composite gauze was dried in hot air at 70° C. for 2 hours, and then cooled to room temperature naturally, and finally a transparent gauze with a filtration efficiency of 95% and a transparency of 75% was obtained.

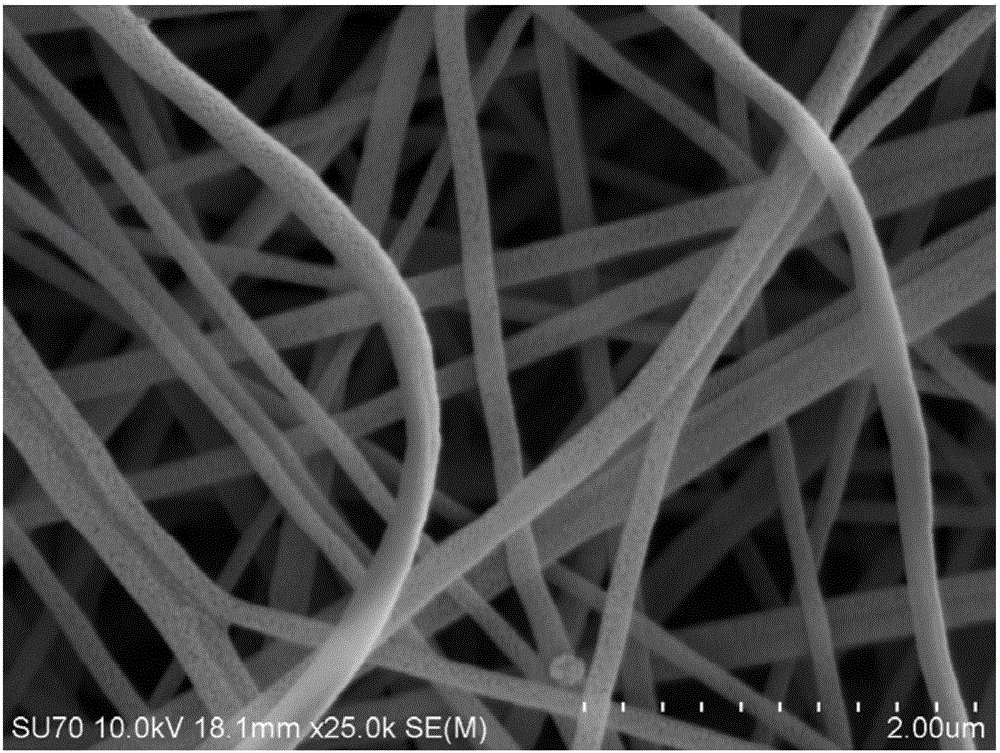

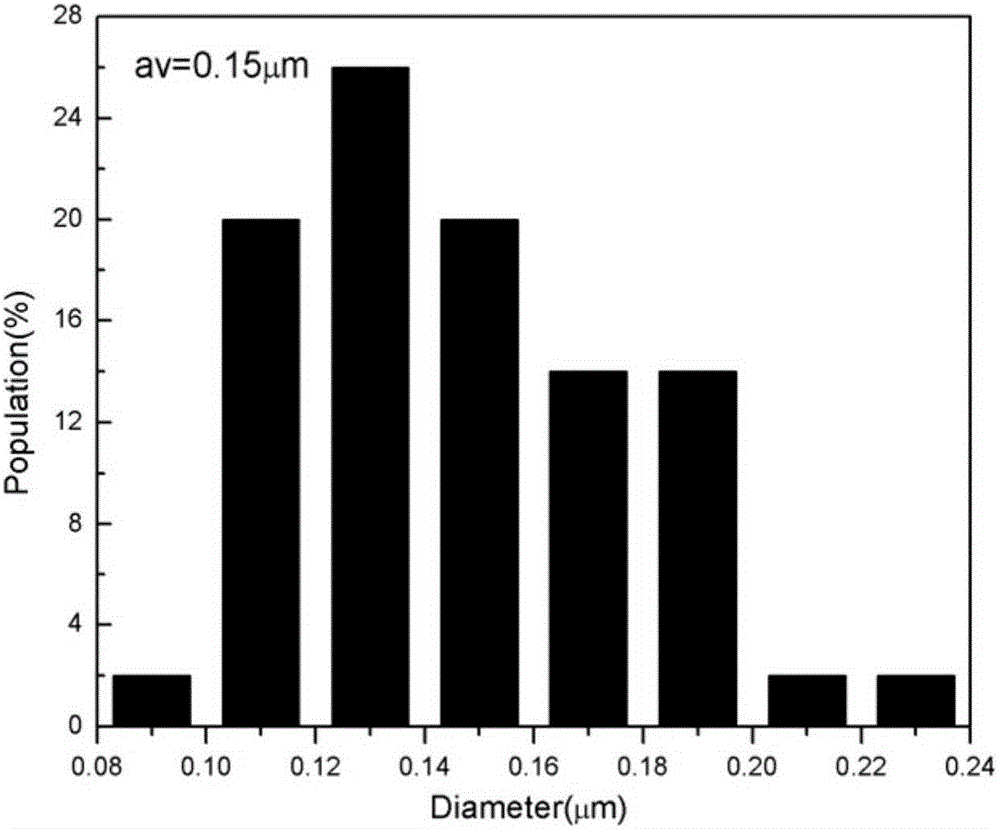

[0027] The microscopic appearance of the nanofiber film on the transparent gauze of the present embodiment is as follows: figure 1 As shown, the fiber diameter distribution is as figure 2 As shown, the filtration efficiency test results of...

Embodiment 2

[0029] 7 g of polyacrylonitrile was added to 83 g of dimethylformamide, and fully stirred at 50° C. for 2 h to obtain a PAN / DMF spinning solution with a mass fraction of 7 wt %. Pour the solution into a tank equipped with a metal cylindrical electrode, use nylon gauze as the base, and carry out electrospinning under the conditions of an output voltage of 70Kv, a receiving distance of 14cm, a temperature of 30°C, and a humidity of 35%. A composite gauze with a nanofibrous film was obtained after 1 minute of filamentation. The composite gauze was dried in hot air at 70° C. for 2 hours, and then naturally cooled to room temperature to finally obtain a transparent gauze with a filtration efficiency of 90% and a transparency of 80%.

Embodiment 3

[0031] 10 g of polyacrylonitrile was added to 90 g of dimethylformamide, and fully stirred at 50° C. for 2 h to obtain a PAN / DMF spinning solution with a mass fraction of 10 wt %. Pour the solution into a tank equipped with metal cylindrical electrodes, use nylon gauze as the base, and carry out electrospinning under the conditions of an output voltage of 70Kv, a receiving distance of 12cm, a temperature of 30°C, and a humidity of 35%. A composite gauze with a nanofibrous film was obtained after 2 minutes of filamentation. The composite gauze was dried in hot air at 70° C. for 2 hours, and then naturally cooled to room temperature to finally obtain a transparent gauze with a filtration efficiency of 80% and a transparency of 75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com