Melt-blow non-woven material capable of effectively filtering PM 2.5 particles, preparation method and production device

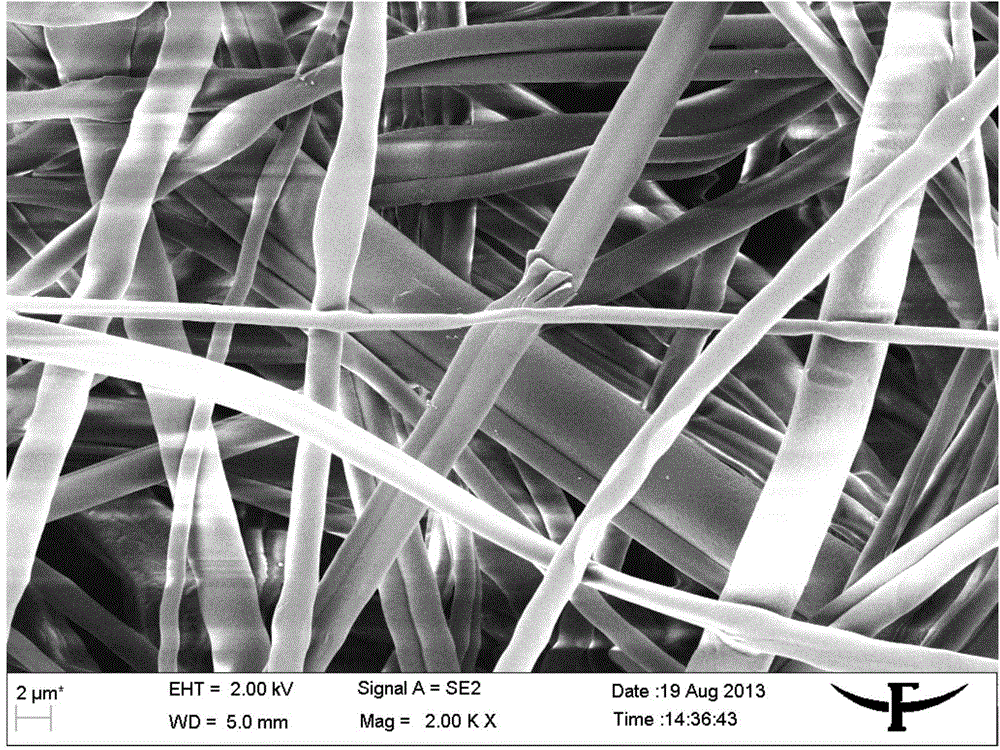

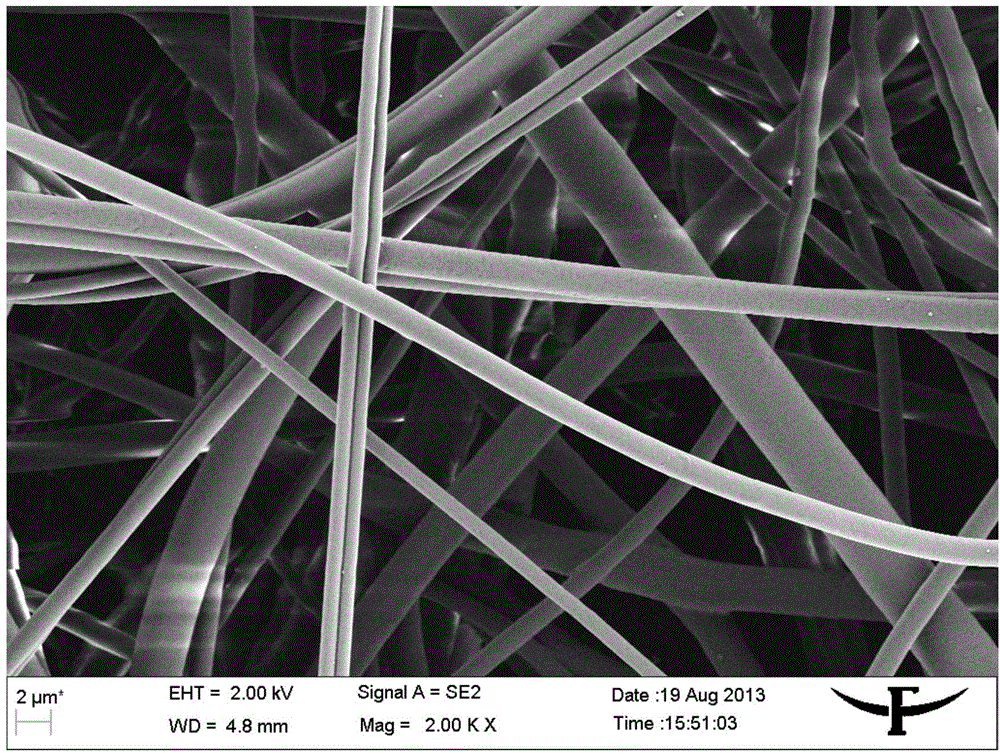

A high-efficiency filtration and melt-blown technology, which is applied in the preparation of melt-blown non-woven materials and the field of production devices for melt-blown non-woven materials, can solve the problems that melt-blown non-woven materials cannot meet the requirements for use, and achieves improved electret effect, The effect of reducing fiber fineness and small fiber diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The high-efficiency PM2.5 filter melt-blown non-woven material of this embodiment contains the following components in weight percentage: 96 parts of polypropylene, 3.8 parts of electret masterbatch, and 0.2 part of polyvinylidene fluoride.

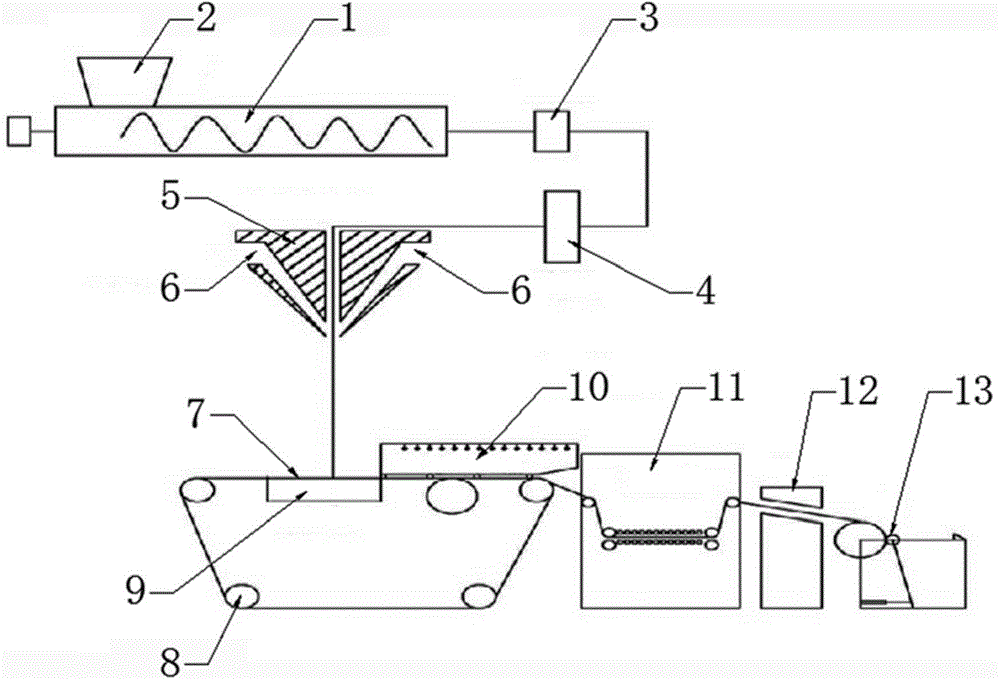

[0031] The preparation method of the melt-blown non-woven material of the high-efficiency filter PM2.5 of the present embodiment comprises the following steps:

[0032] 1) Mix polypropylene, electret masterbatch, and polyvinylidene fluoride evenly to obtain a mixture;

[0033] 2) Feed the mixture obtained in step 1) into the silo of the screw extruder, and melt and extrude it to form a melt. 180°C, 200°C, 220°C, 225°C;

[0034] 3) The melt is kept in the pipeline at a constant temperature of 225°C, and after being metered by a metering pump, it is sprayed out through a spinneret to form fibers. Melt blown cloth;

[0035] 4) The melt-blown cloth obtained in step 3) is subjected to infrared radiation heat treatment at a constant t...

Embodiment 2

[0040] The high-efficiency PM2.5 filter melt-blown non-woven material of this embodiment contains the following components in weight percentage: 95 parts of polypropylene, 4.8 parts of electret masterbatch, and 0.2 part of polyvinylidene fluoride.

[0041] The preparation method of the melt-blown non-woven material of the high-efficiency filter PM2.5 of the present embodiment comprises the following steps:

[0042] 1) Mix polypropylene, electret masterbatch, and polyvinylidene fluoride evenly to obtain a mixture;

[0043]2) Feed the mixture obtained in step 1) into the silo of the screw extruder, and melt and extrude it to form a melt. 180°C, 200°C, 220°C, 235°C;

[0044] 3) The melt is kept in the pipeline at a constant temperature of 235°C, and after being metered by a metering pump, it is sprayed out through a spinneret to form fibers. Melt blown cloth;

[0045] 4) The melt-blown cloth obtained in step 3) is subjected to infrared radiation heat treatment at a constant te...

Embodiment 3

[0049] The high-efficiency PM2.5 filter melt-blown non-woven material of this embodiment contains the following components in weight percentage: 94 parts of polypropylene, 5.8 parts of electret masterbatch, and 0.2 part of polyvinylidene fluoride.

[0050] The preparation method of the melt-blown non-woven material of the high-efficiency filter PM2.5 of the present embodiment comprises the following steps:

[0051] 1) Mix polypropylene, electret masterbatch, and polyvinylidene fluoride evenly to obtain a mixture;

[0052] 2) Feed the mixture obtained in step 1) into the silo of the screw extruder, and melt and extrude it to form a melt. 180°C, 210°C, 230°C, 245°C;

[0053] 3) The melt is kept in the pipeline at a constant temperature of 245°C, and after being metered by a metering pump, it is sprayed out through a spinneret to form fibers. Melt blown cloth;

[0054] 4) The melt-blown cloth obtained in step 3) is subjected to infrared radiation heat treatment at a constant t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com