Patents

Literature

329results about How to "Small fineness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

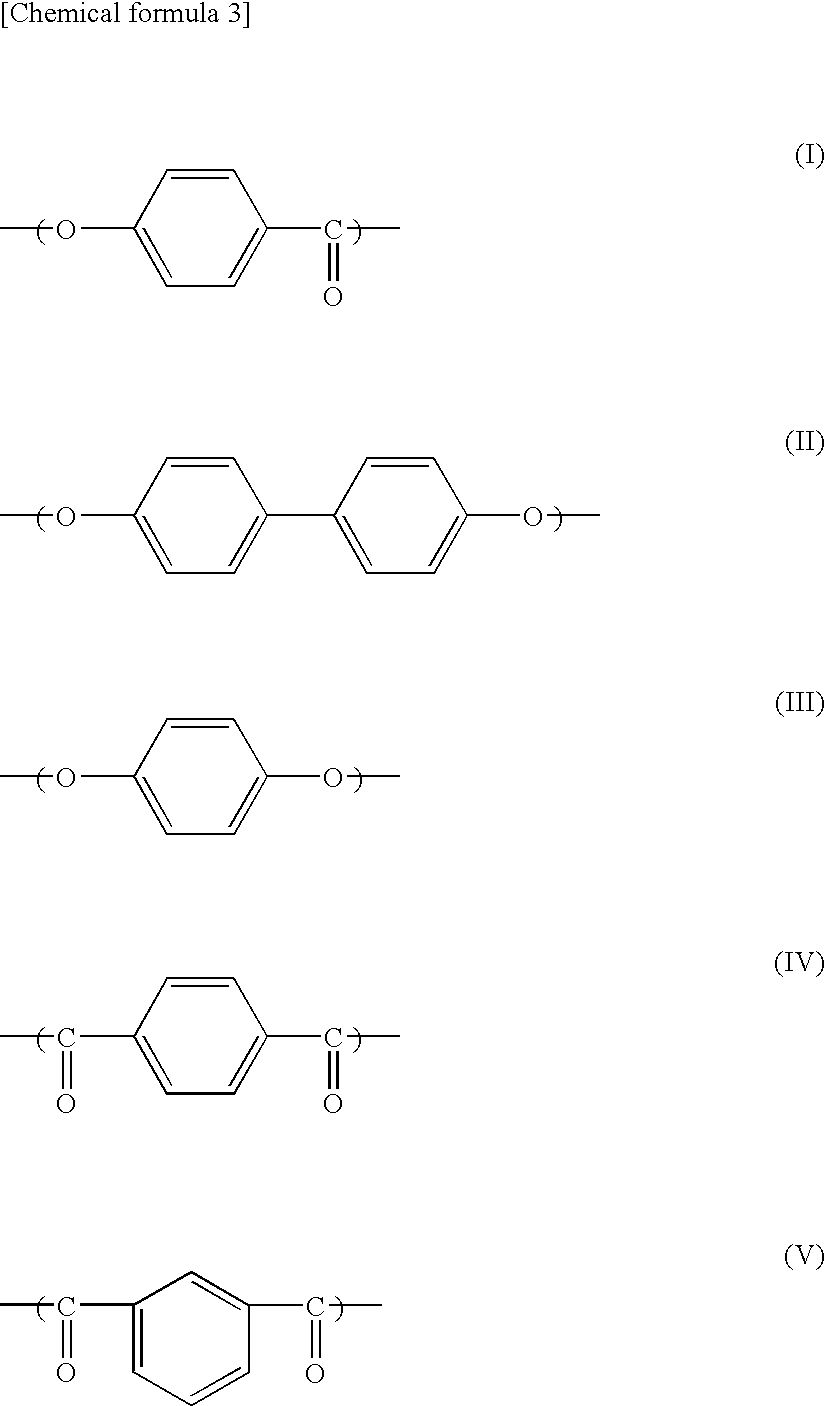

Leather-Like Sheet And Method Of Manufacturing The Same

InactiveUS20090274862A1Dense feelingElegant surface appearanceFibre treatmentSynthetic resin layered productsFiberVitrification

A leather-like sheet composed of a microfine-fiber entangled body made of bundles of microfine fibers and an elastic polymer impregnated therein. The bundles of microfine fibers are composed of microfine monofibers having an average cross-sectional area of 0.1 to 30 μm2 and have an average cross-sectional area of 40 to 400 μm2. The bundles of microfine fibers exist in a density of 600 to 4000 / mm2 on a cross section taken along the thickness direction of the microfine-fiber entangled body. The elastic polymer contains 30 to 100% by mass of a polymer of ethylenically unsaturated monomer. The polymer of ethylenically unsaturated monomer is composed of a soft component having a glass transition temperature (Tg) of less than −5° C., a crosslinkable component, and optionally a hard component having a glass transition temperature (Tg) of higher than 50° C. and another component. The polymer of ethylenically unsaturated monomer is bonded to the microfine fibers in the bundles of microfine fibers. The leather-like sheet has a flexibility and hand such as dense feeling each resembling natural leathers and a high quality appearance. The leather-like sheet is highly stable in quality such as fastness and surface abrasion resistance and excellent in practical performance.

Owner:KURARAY CO LTD

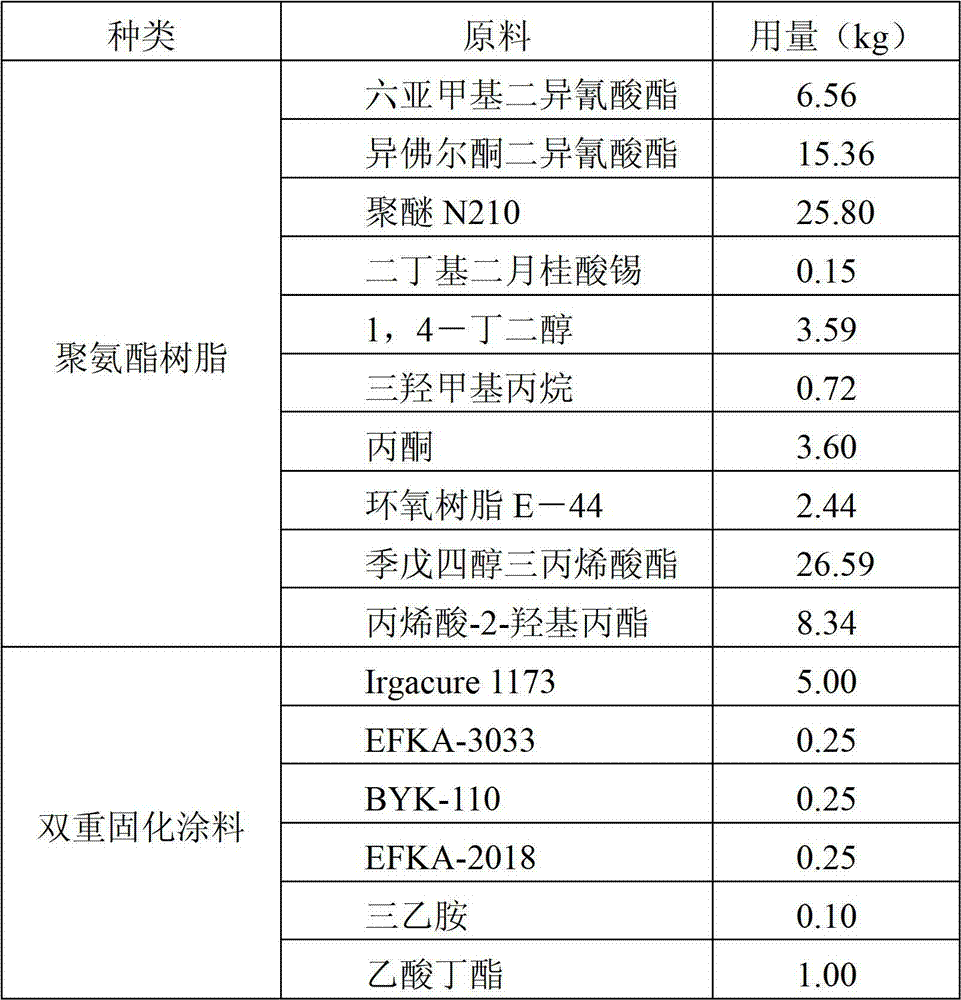

Multiple crosslinking ultraviolet light solidifying water polyurethane dispersoid and its preparation method and application

The invention discloses a multiple crosslink ultraviolet solidification aqueous polyurethane disperser, a relative preparation method and an application. The preparation method comprises synthesizing polyurethane initial polymerized compound I, synthesizing polyurethane prepolymer II, synthesizing polyurethane prepolymer III, synthesizing polyurethane acrylate oligomer and synthesizing ultraviolet solidification aqueous polyurethane disperser. The invention mainly utilizes aromatic diisocyanate, diatomic alcohol prepolymer, polyhydroxy carboxylic acid, epoxy resin and hydroxyl acrylate as raw materials, with better water dispersity and storage stability, which leads in light inducer, levelling agent, defoaming agent and thickener to prepare ultraviolet solidification aqueous wood paint better than solvent ultraviolet solidification photosensitive resin, with stable storage, low fineness, high rigidity, high brightness, better flow leveling property, better water resistance, better solvent resistance, excellent abrasion resistance, environment protection, easy process and fire hazard resistance.

Owner:SOUTH CHINA UNIV OF TECH

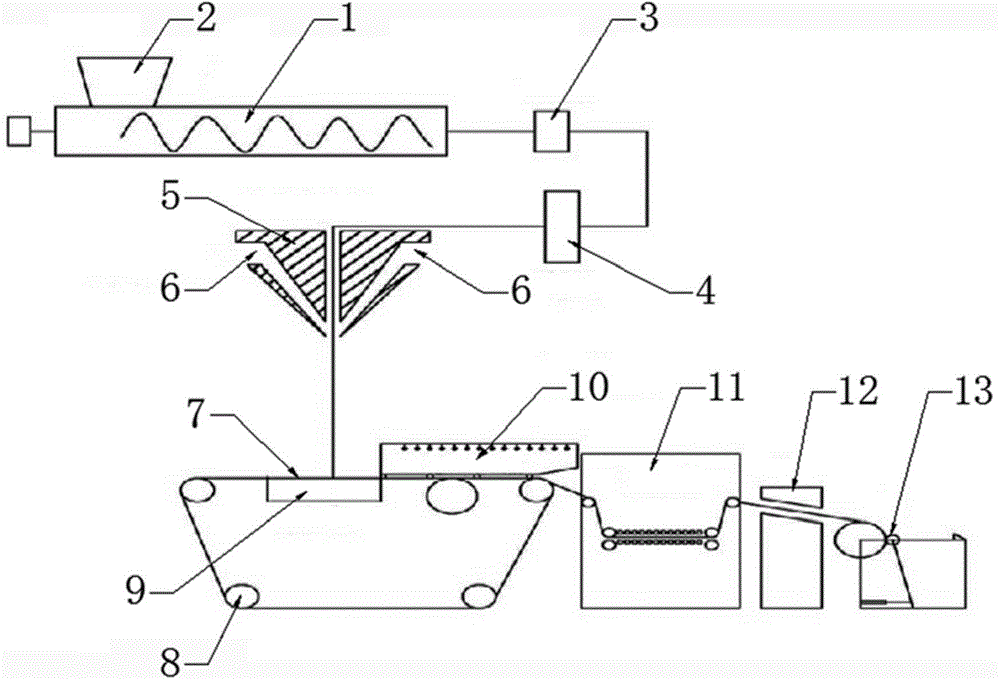

Melt-blow non-woven material capable of effectively filtering PM 2.5 particles, preparation method and production device

ActiveCN104153119AHigh filtration efficiencyImprove dust collection effectHeating/cooling textile fabricsUltrasonic/sonic fibre treatmentPorosityEngineering

The invention discloses a melt-blow non-woven material capable of effectively filtering PM 2.5 particles, a preparation method and a production device. The melt-blow non-woven material comprises, by weight percentage, 93-97 parts of polypropylene, 3-6 parts of electret master batch and 0.1-1 part of polyvinylidene fluoride. According to the melt-blow non-woven material capable of effectively filtering PM 2.5 particles, the polypropylene, the electret master batch and the polyvinylidene fluoride are compounded, the obtained melt-blow non-woven material is characterized by high porosity, the fiber diameter of smaller than two micrometers, large clogging capacity, high filtering efficiency and low resistance, an electret is good in charge storage performance after electret processing, the charge keeping rate can be above two years, and the electret can be used in a high-temperature and high-humidity environment. The product is environmentally friendly and free of pollution, has the advantages of being long in service life and wide in use range, and is particularly suitable for removing PM 2.5 particles in the air.

Owner:DO FLUORIDE CHEM CO LTD

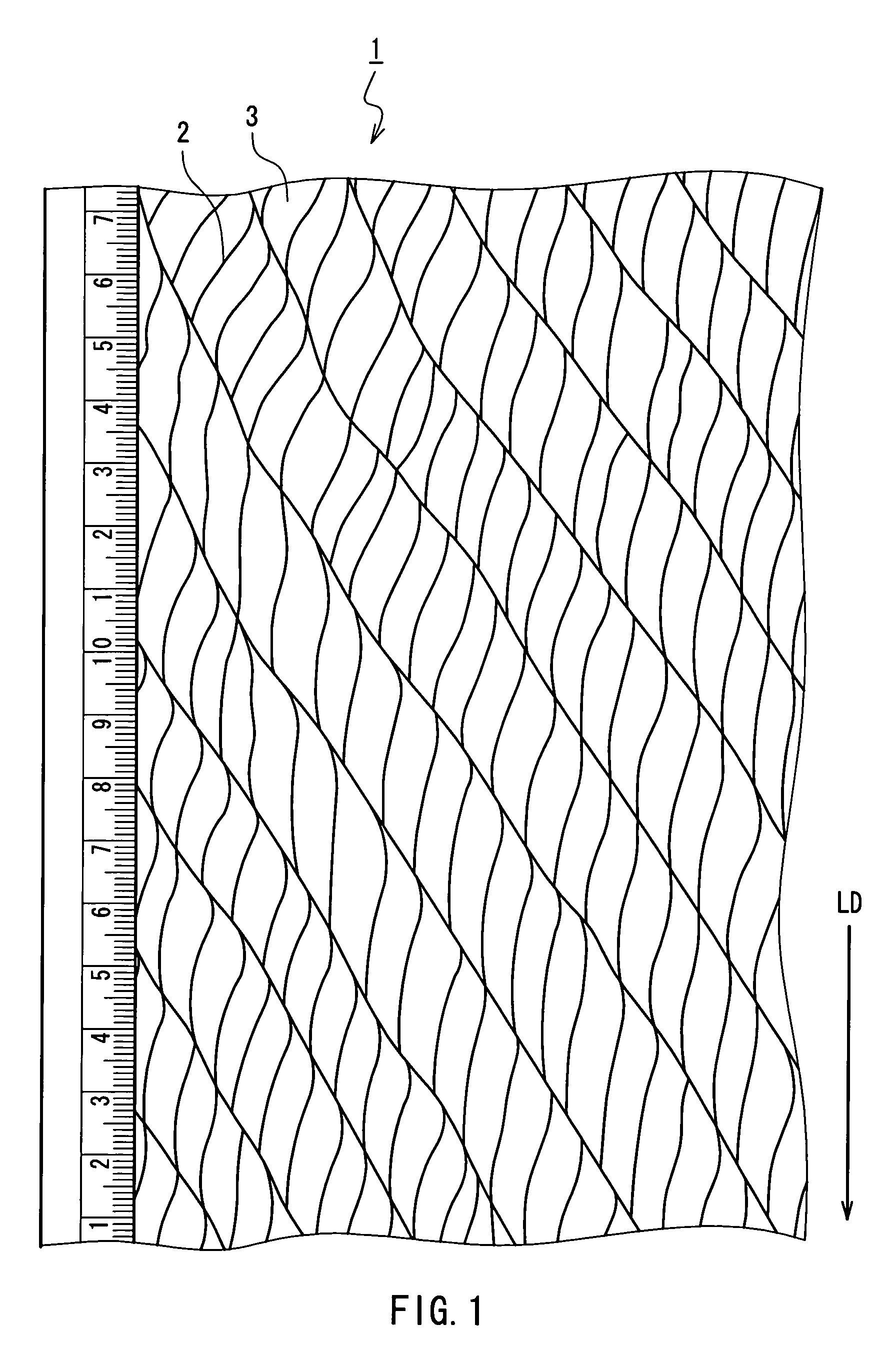

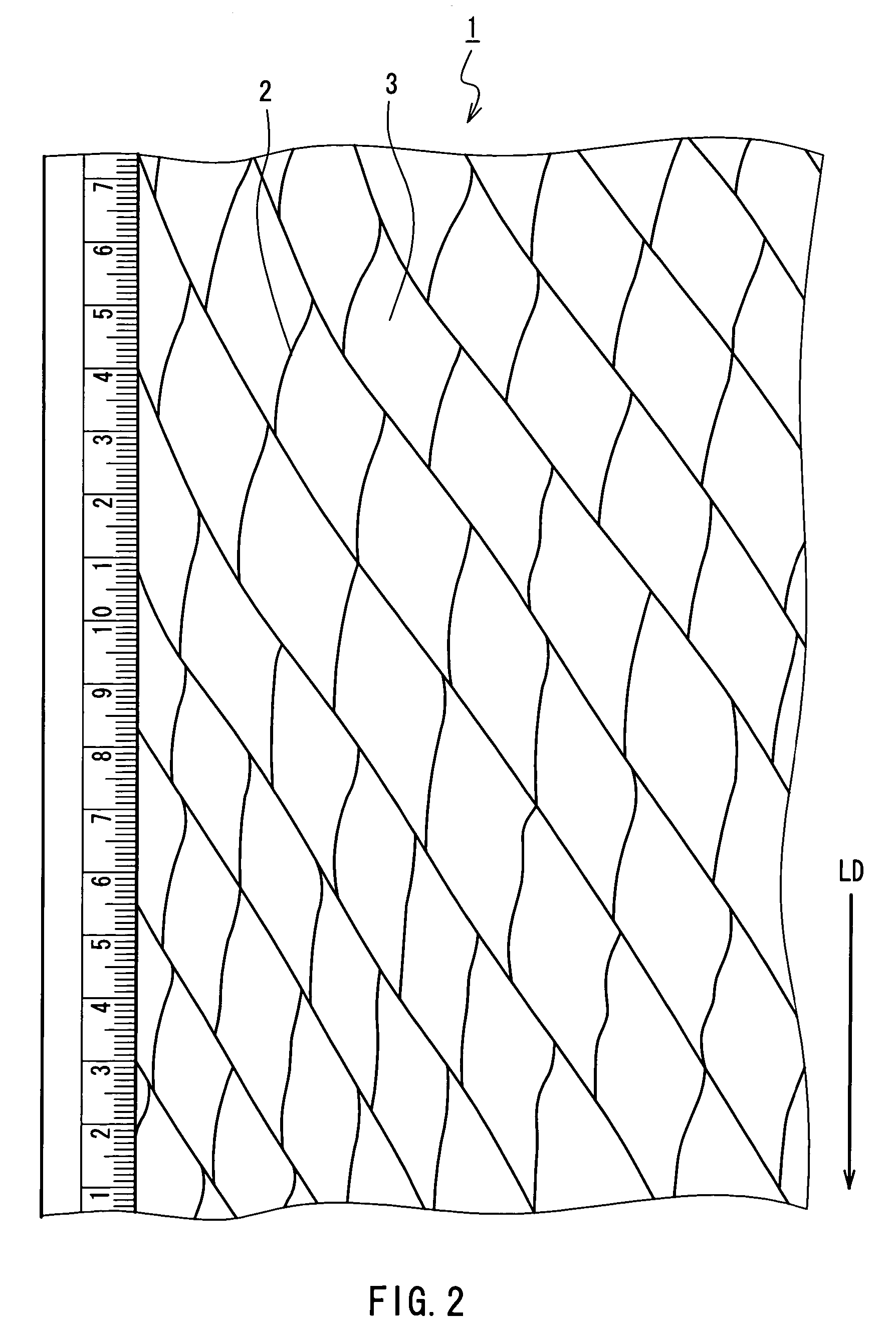

Woven or knit fabric and process for producing the same

InactiveUS20050202741A1Increases interlacement degreeTextureWeft knittingProtective fabricsPolyesterYarn

A woven or knit fabric comprising air-jet interlacing spun yarns comprising polyester fibers of low titanium oxide content; a woven or knit fabric comprising air-jet interlacing spun yarns comprising polyester staple fibers obtained by graft polymerization of a hydrophilic compound; a woven or knit fabric comprising air-jet interlacing spun yarns comprising side by side crimped staple fibers; a woven or knit fabric comprising air-jet interlacing spun yarns comprising low-shrinkage staple fibers and copolymerized polyester staple fibers; and a process for producing these. A woven or knit fabric of polyester staple fibers that is bulky, excelling in moisture retention, lightweightness, water absorptivity, quick dryability, etc. and exhibits excellent anti-pilling properties can be obtained.

Owner:TOYOBO CO LTD

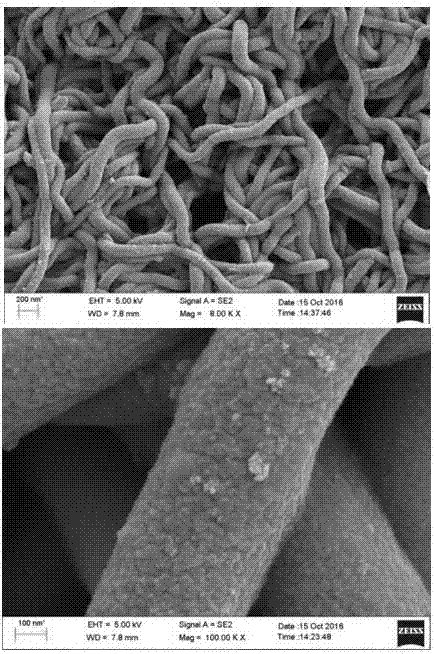

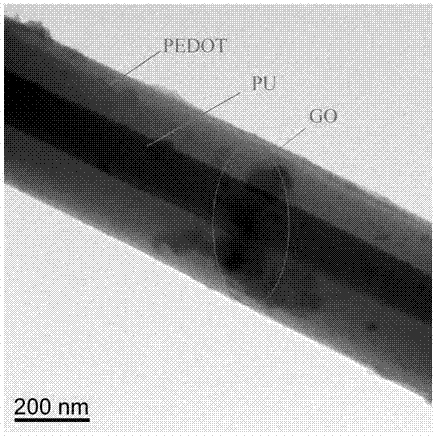

Flexible and extensible multifunctional nanofiber sensor and preparation method thereof

InactiveCN107192485ASmall finenessIncrease deposition polymerization rateFibre typesNanosensorsCopper wireIn situ polymerization

The invention discloses a flexible and extensible multifunctional nanofiber sensor and a preparation method thereof. An electrostatic spinned polyurethane nanofiber membrane doped with graphene oxide is used as a flexible matrix. An in-situ polymerization method is used to in-situ polymerize conductive polymer polythiophene on the surface of the polyurethane nanofiber doped with graphene oxide, and the polyurethane / polythiophene nanofiber membrane which is doped with graphene oxide and is provided with a skin-core structure is prepared. The surface of the nanofiber membrane is compounded with a gel membrane with a conductive copper wire to prepare the flexible and extensible multifunctional nanofiber sensor. The sensor can be used for detecting multi-mechanical stimulation environments with pressure, stretching, bending and the like, and has the advantages of high sensitivity and wide sensing range. In a human body monitoring system, the sensor can monitor pulse, heartbeat, muscle group vibration and other human health physiological indicators in real time, and can detect the full-range movement of a human body, including the movement of facial expressions and large and small joints.

Owner:ZHONGYUAN ENGINEERING COLLEGE

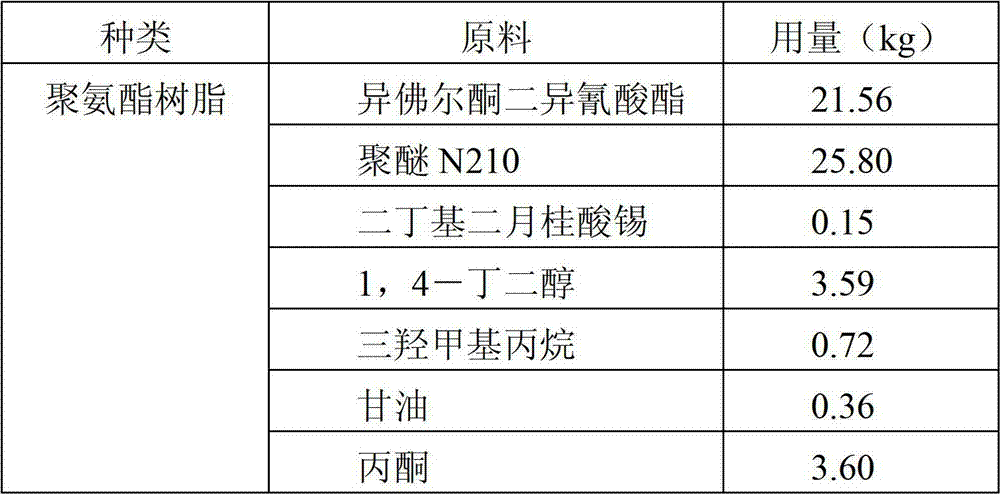

Humidity and ultraviolet dual-cured polyurethane woodware coating and preparation method thereof

The invention discloses humidity and ultraviolet dual-cured polyurethane woodware coating and a preparation method thereof. A synthesis method includes synthesizing initial polyurethane polymer I, polyurethane pre-polymer II, polyurethane pre-polymer III, polyurethane acrylate oligomer and ultraviolet cured woodware coating. The humidity and ultraviolet dual-cured polyurethane woodware coating is mainly prepared by aliphatic diisocyanate, dihydric alcohol pre-polymer, polyhydroxy acid, epoxy resin and hydroxy acrylic ester and the like, and by adding auxiliaries such as photoinitiators, flatting agents, defoamers, substrate wetting agents and catalysts, the ultraviolet cured woodware coating is prepared. The ultraviolet cured woodware coating can form films and be cured under irradiation of ultraviolet, also can be cured by humidity in the air within 5 hours at the room temperature, and has the advantages of high solid, NCO (isocyanate) group content and adhesion force, fine resistance to chemical corrosion, high film coating hardness and fine storage stability and the like, can be used for irregular coating surfaces, hone finished UV (ultraviolet) paint and UV colored paint and the like where cannot be irradiated by the ultraviolet.

Owner:广州常圣新材料科技有限公司

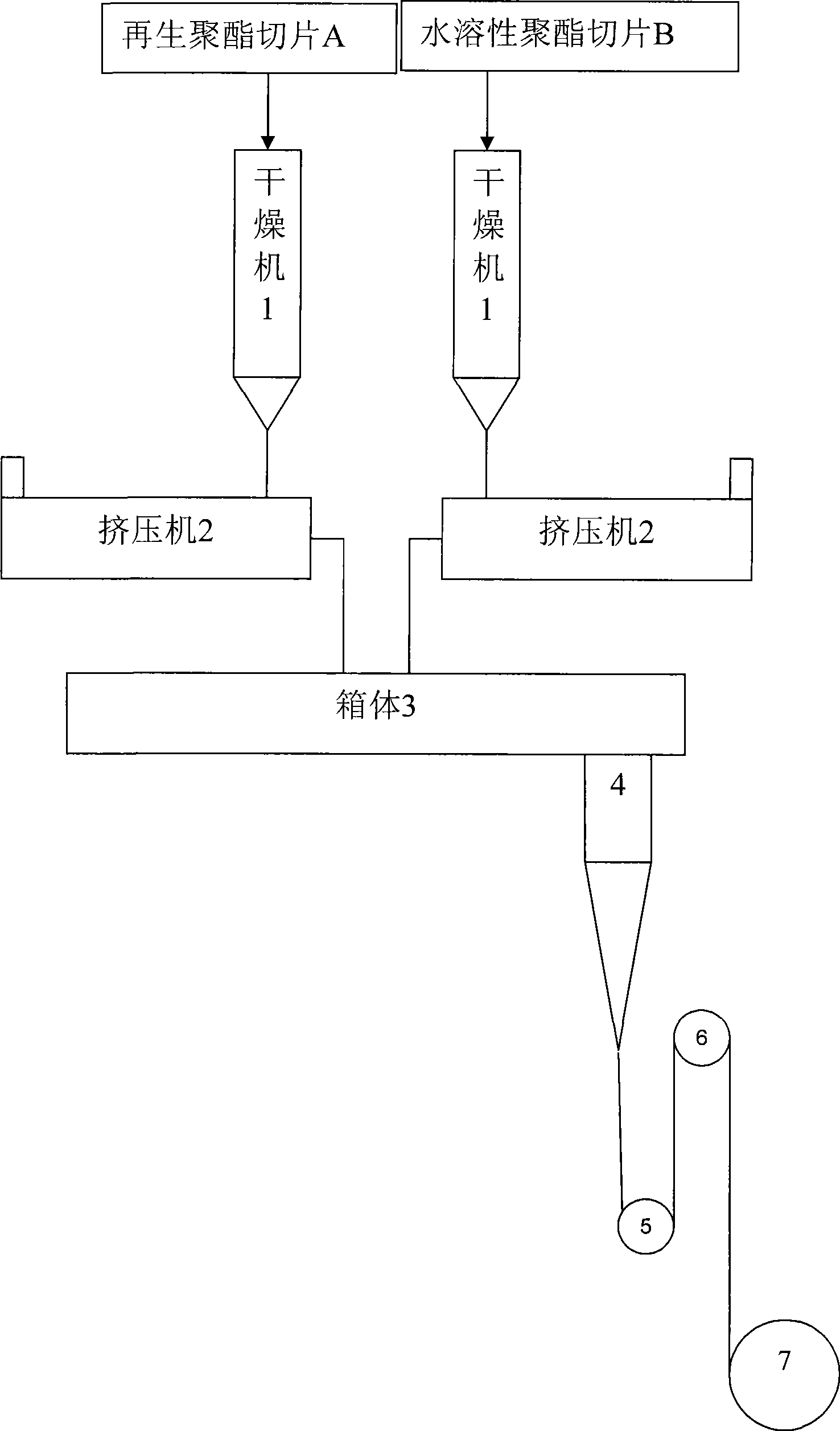

Superfine fibre material and producing method thereof

InactiveCN101429689ARaw materials are cheapSmall fiber finenessFilament forming substance formingSpinning head liquid feederPolyesterMicrofiber

The invention discloses a method for producing regenerated polyester ultrafine fiber based on bicomponent fiber production equipment. The method comprises the following steps: a regenerated polyester slice and a water soluble polyester slice are used as raw materials; after the two raw materials are subjected to crystallizing and drying, extruding and fusing respectively, the two raw materials are fed to a composite spinning manifold, are extruded through an insulated spinning metering pump with accurate measurement, and are distributed to each composite spinning component; the two components are compounded to be shaped according to shapes set by a spinneret component, are extruded to be shaped through side ram cooling and oiled by a nozzle tip, and are wound by a winding head to form a regenerated polyester ultrafine POY spinning cake; and then the spinning cake is processed to obtain an applicable ultrafine fiber through subsequent texturing. After the method is adopted, through adjusting the processing technology, the regenerated polyester raw material can be applied to high grade fiber so as to improve effective application of resource, and save cost. The method has double significances of economy and environmental protection.

Owner:无锡海丝路纺织新材料有限公司

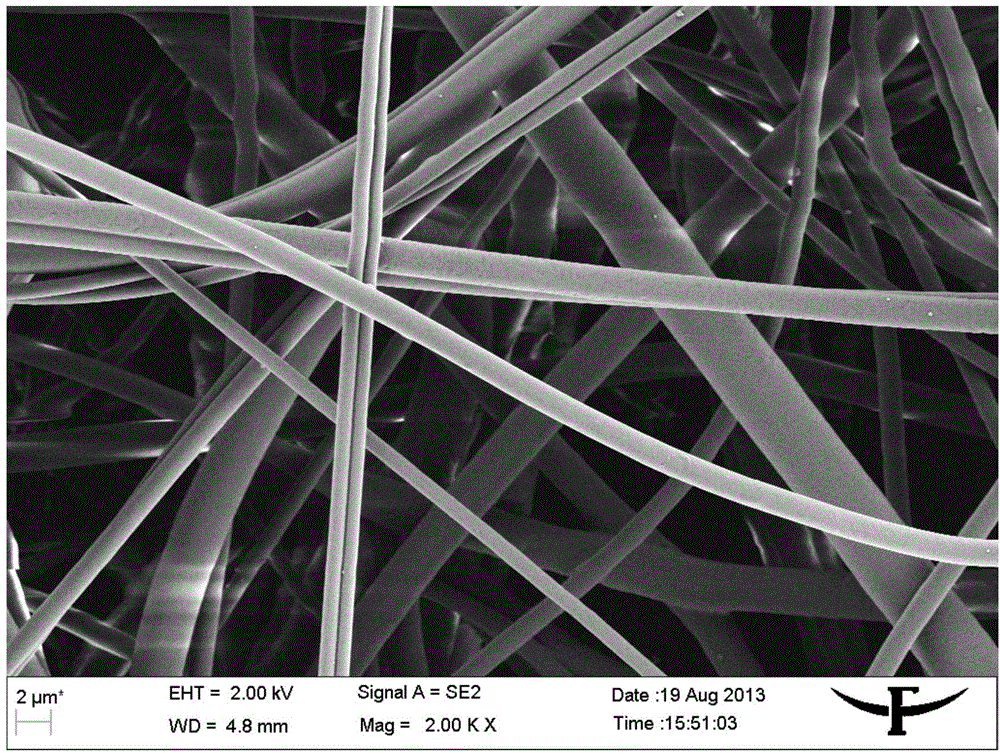

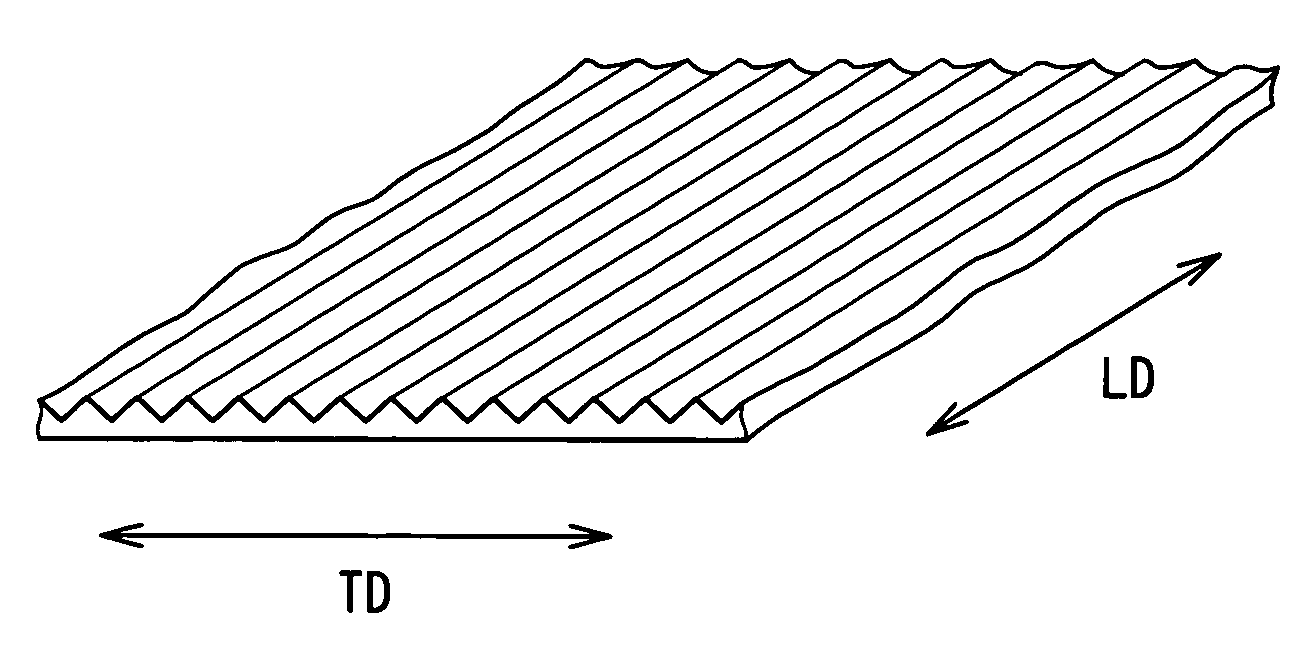

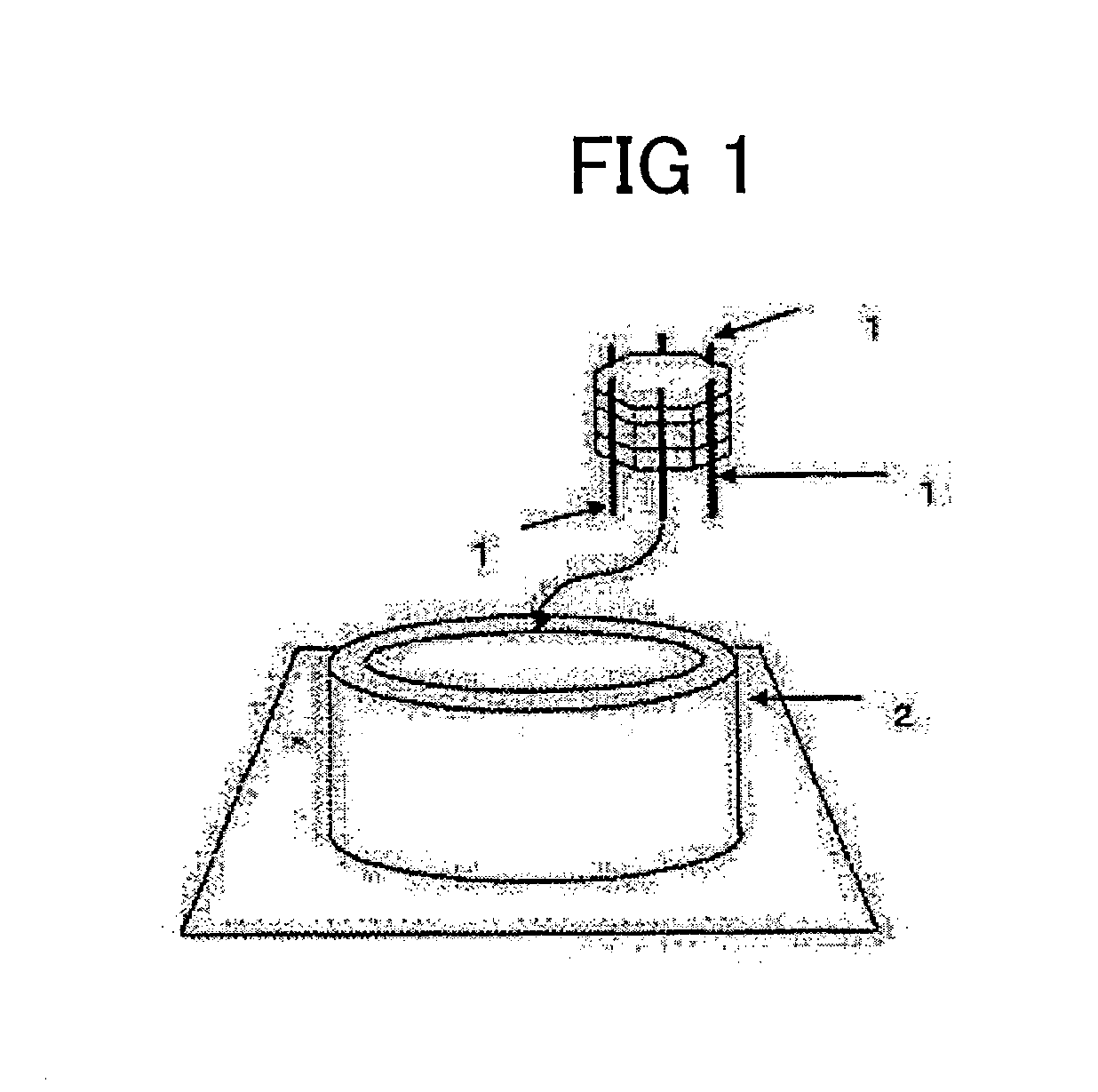

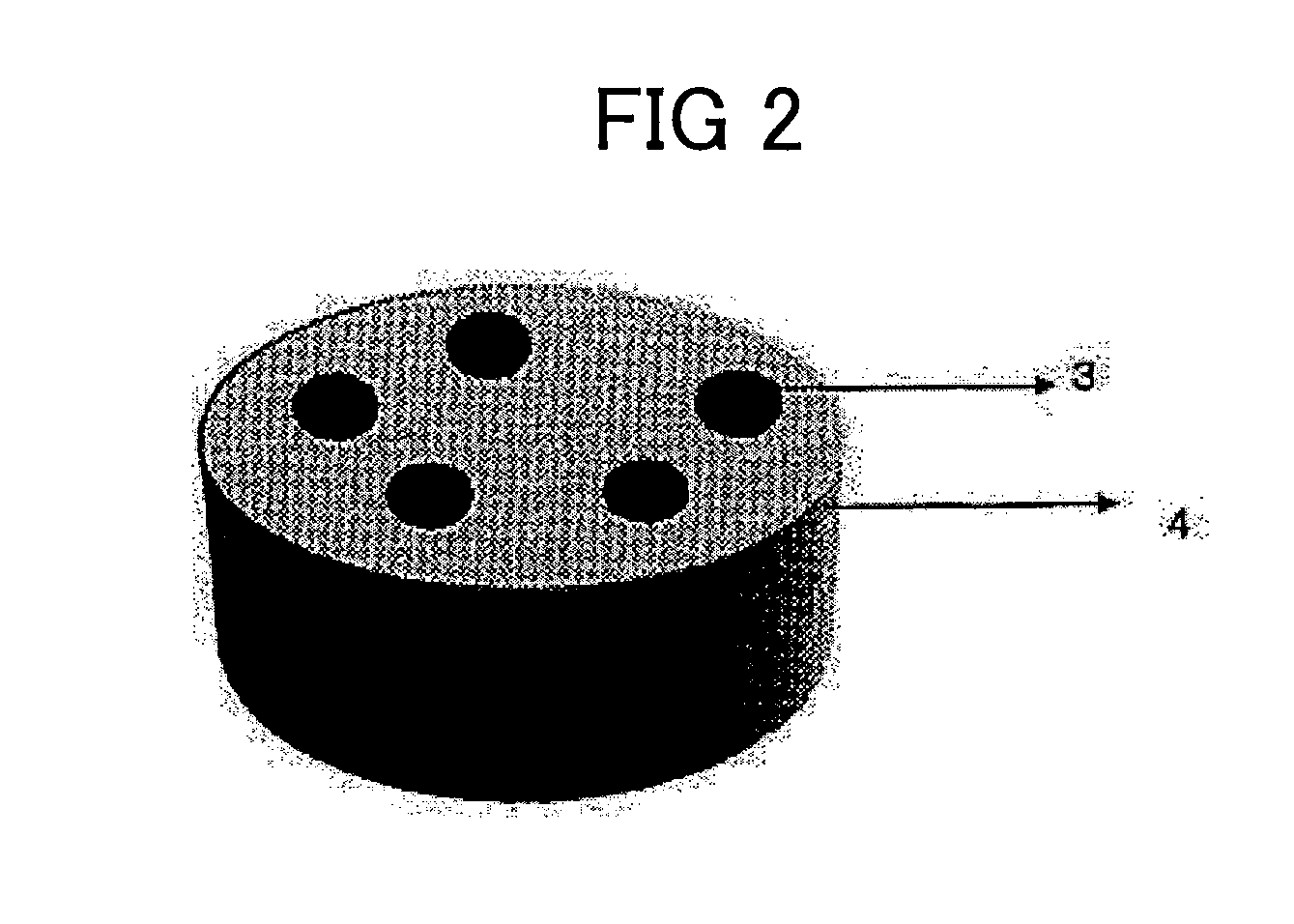

Polytetrafluoroethylene fiber and method for manufacturing the same

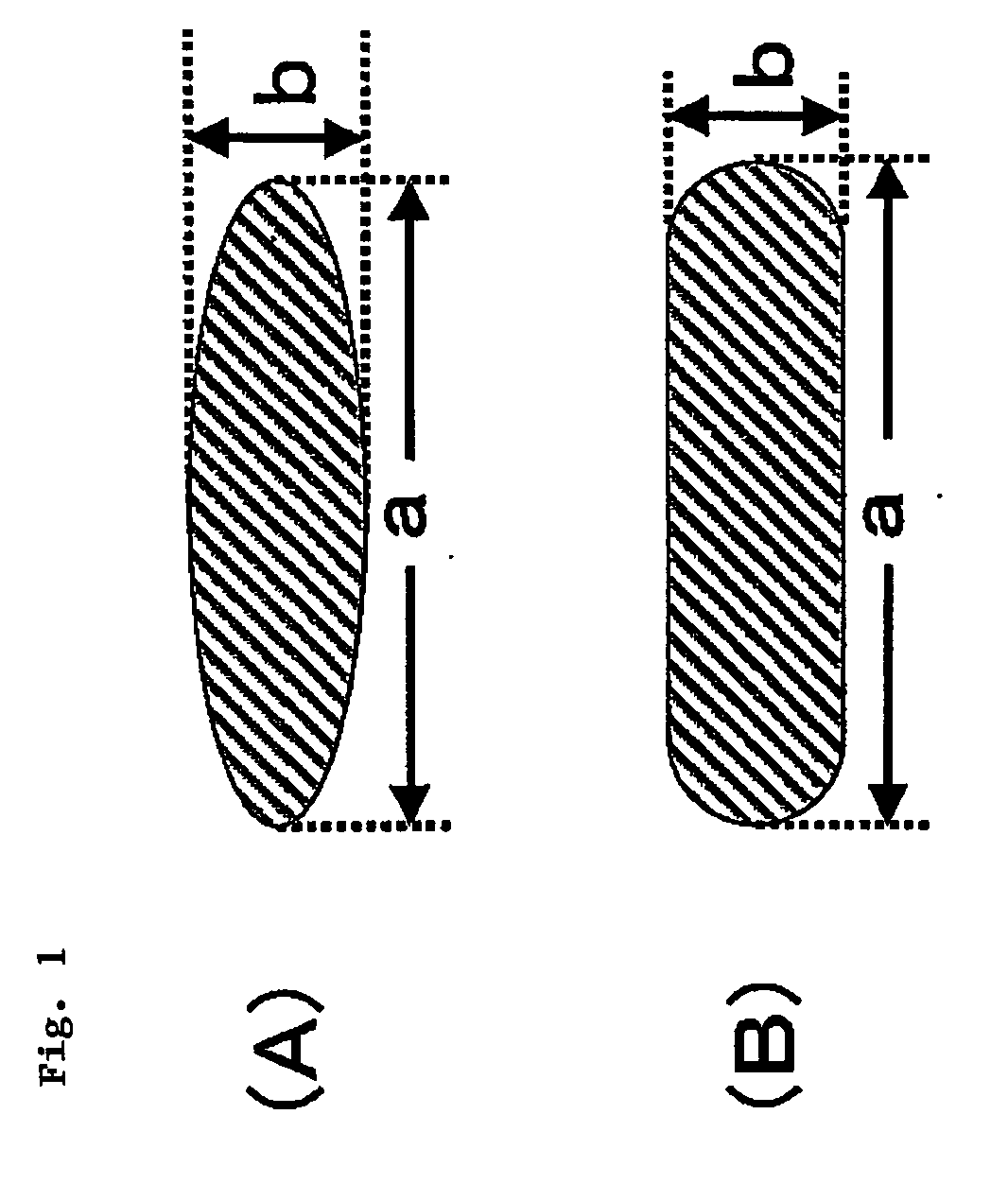

ActiveUS7108912B2Small finenessUniform finenessOther chemical processesSynthetic resin layered productsNetwork structureEngineering

A polytetrafluoroethylene (PTFE) fiber includes a filament obtained by partially slitting an oriented PTFE film in a lengthwise direction of the film. Emboss processing is conducted linearly along the lengthwise direction of the film and like a zigzag shape or a convexo-concave shape in a width direction of the film, followed by slitting, whereby the filament includes a network structure in which single fibrils that are opened partially are arranged regularly. A PTFE short fiber is obtained by cutting the above filament and includes a branch structure. Thereby, a PTFE fiber with a small average fineness of single fibrils, a uniform fineness and a single-peak distribution with the peak at a center of fineness and with a high production yield and uniform and stable branch structure can be provided and a method for manufacturing the PTFE fiber can be provided.

Owner:YEU MING TAI CHEM INDAL

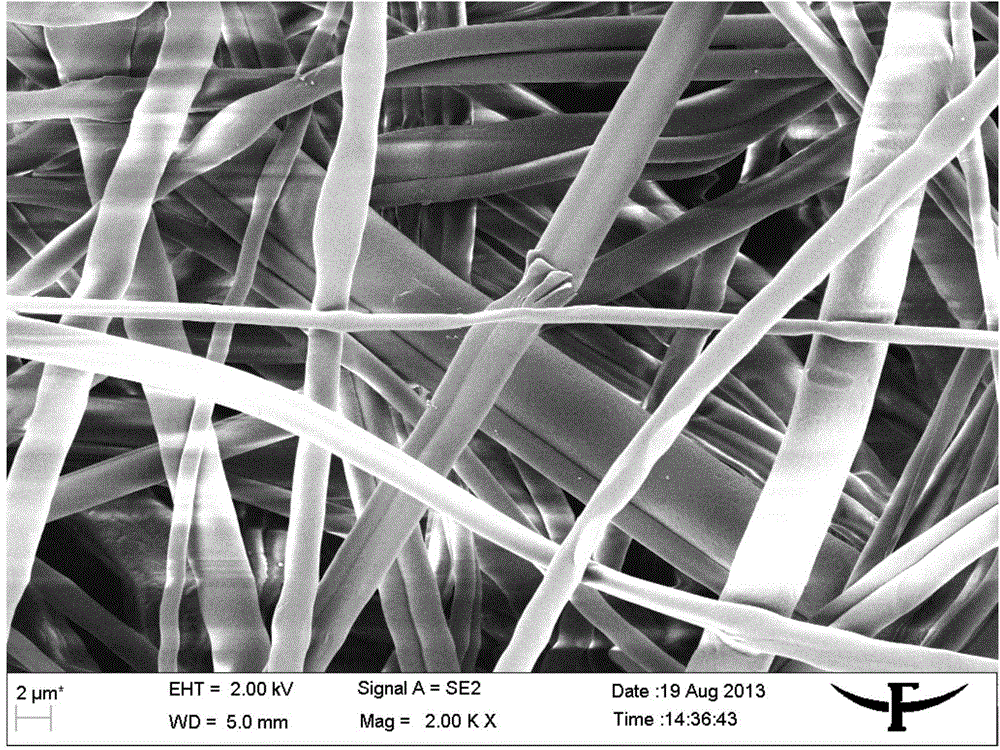

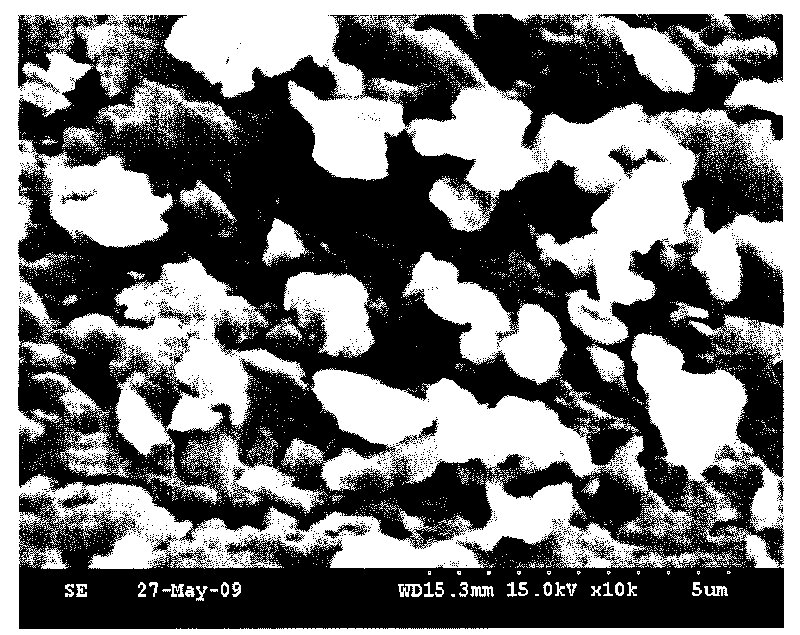

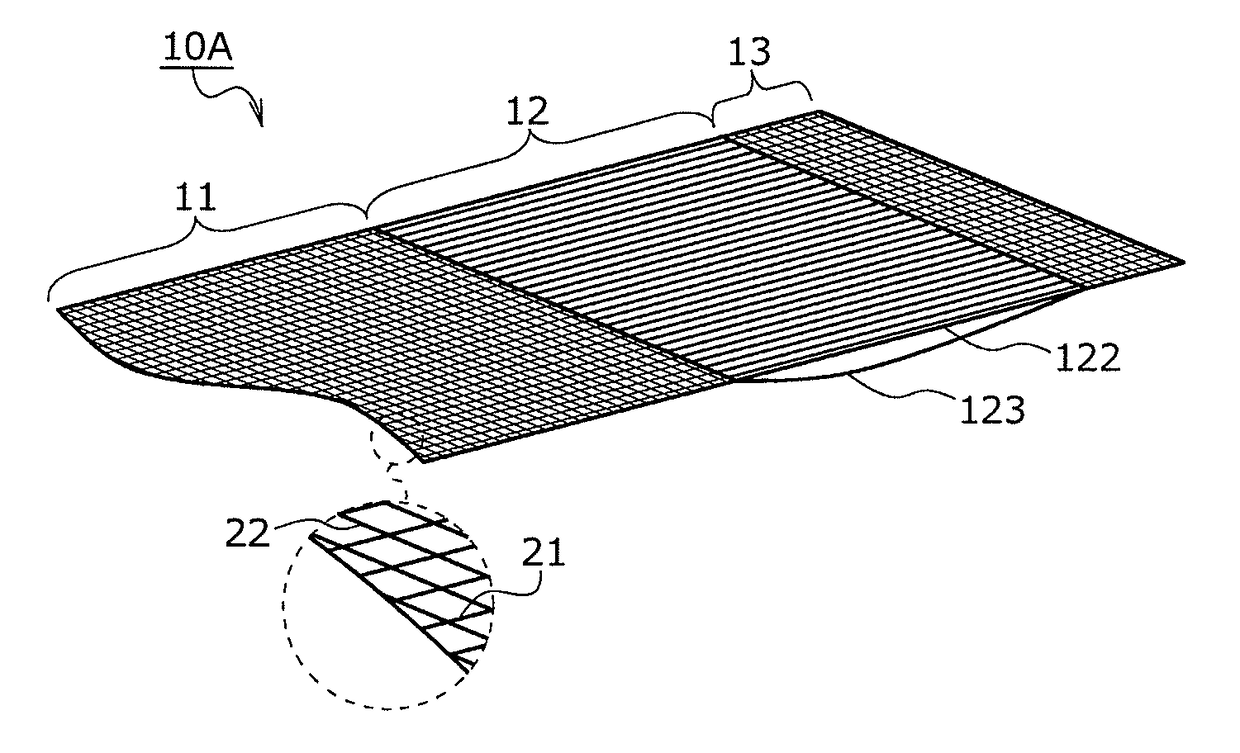

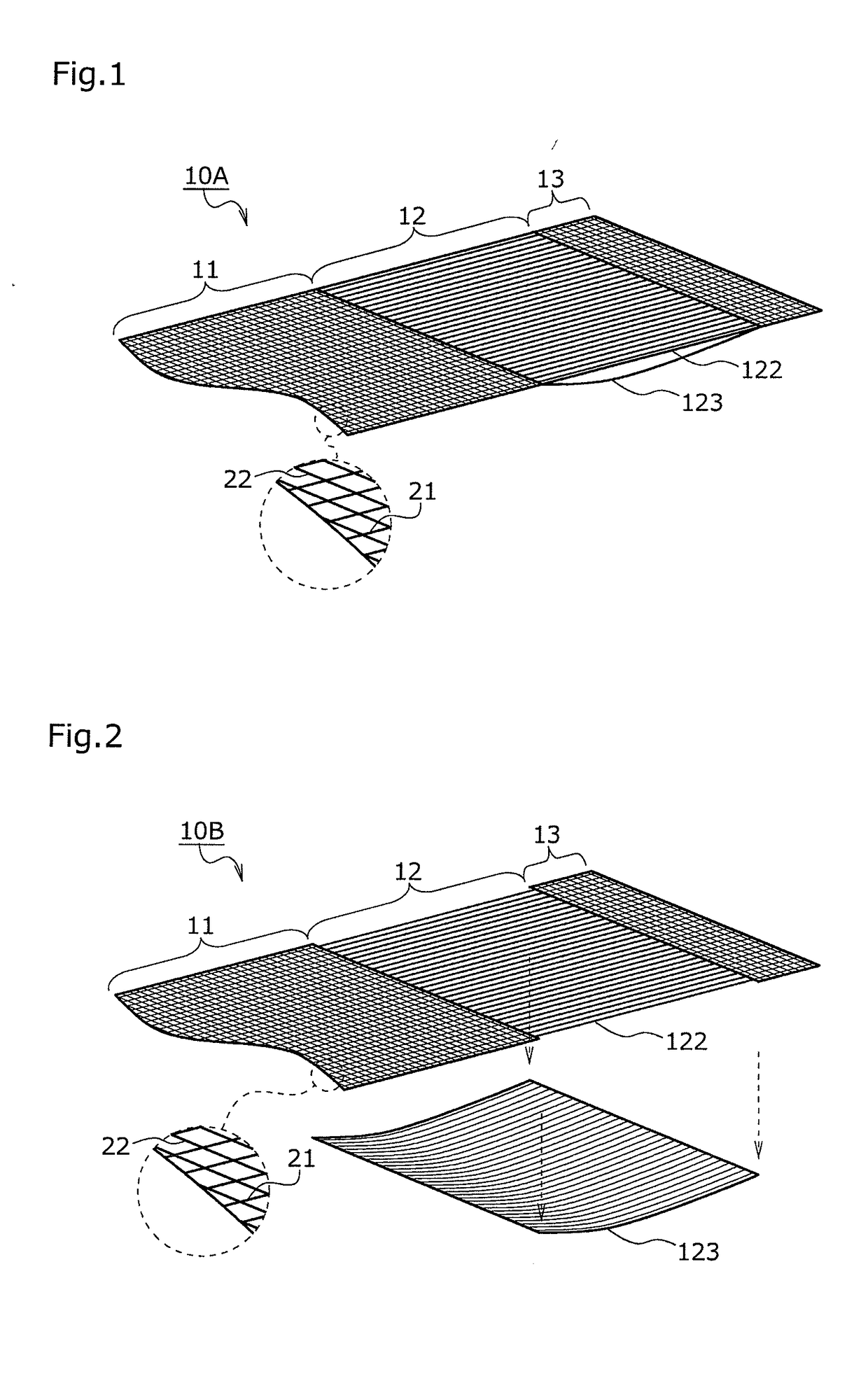

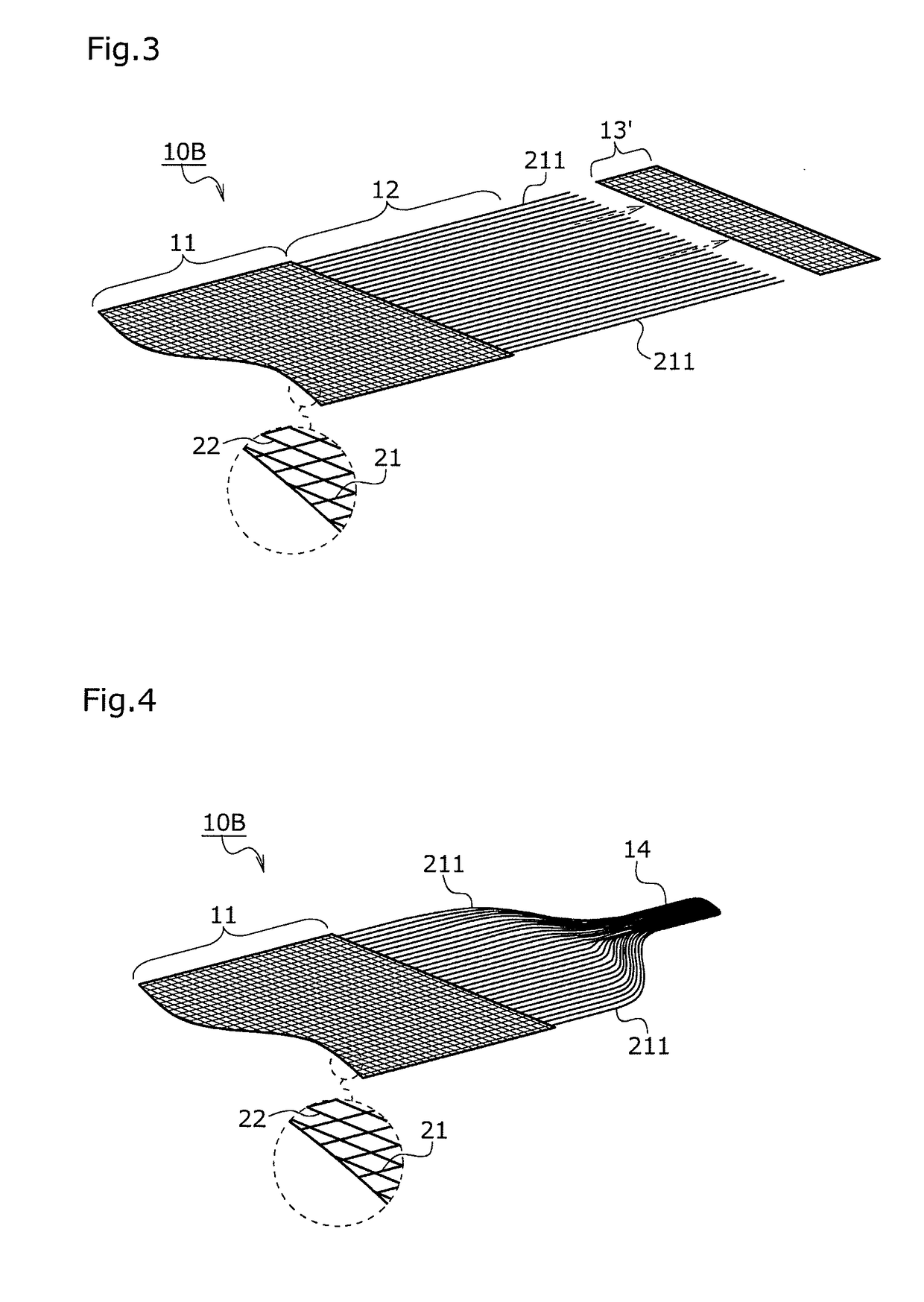

Non-woven fabric, and sheet and artificial leather produced from the same

InactiveUS6566287B1Satisfies requirementFine and uniform and fiber space structureSynthetic resin layered productsWoven fabricsNonwoven fabricElectron scanning microscopy

A non-woven fabric having such a structure that fine fibers having a small fineness are entangled with one another and a sheet obtained by impregnating the non-woven fabric with an elastic polymer satisfy the following requirements:the fine fibers should be obtained by splitting a strippable and splittable composite short fiber comprising at least two components; the fine fibers should have a monofilament size of 0.01 to 0.5 denier; the fine fibers should form a fine non-woven fabric structure that they are entangled with one another at random; the apparent density should be 0.18 to 0.45 g / cm3; the average area of spaces between fibers in the cross section of the non-woven fabric measured by the image analysis of an electron scanning microscope should be 70 to 250 mum2; and the non-woven fabric should have such a uniform structure that the standard deviation of the area of a space between fibers in the cross section of the non-woven fabric measured by the image analysis of the electron scanning microscope is 200 to 600 mum2.The non-woven fabric and sheet are advantageously used as a substrate for artificial leather.

Owner:TEIJIN LTD +1

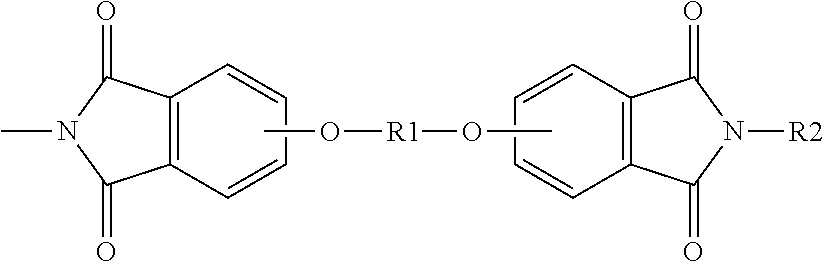

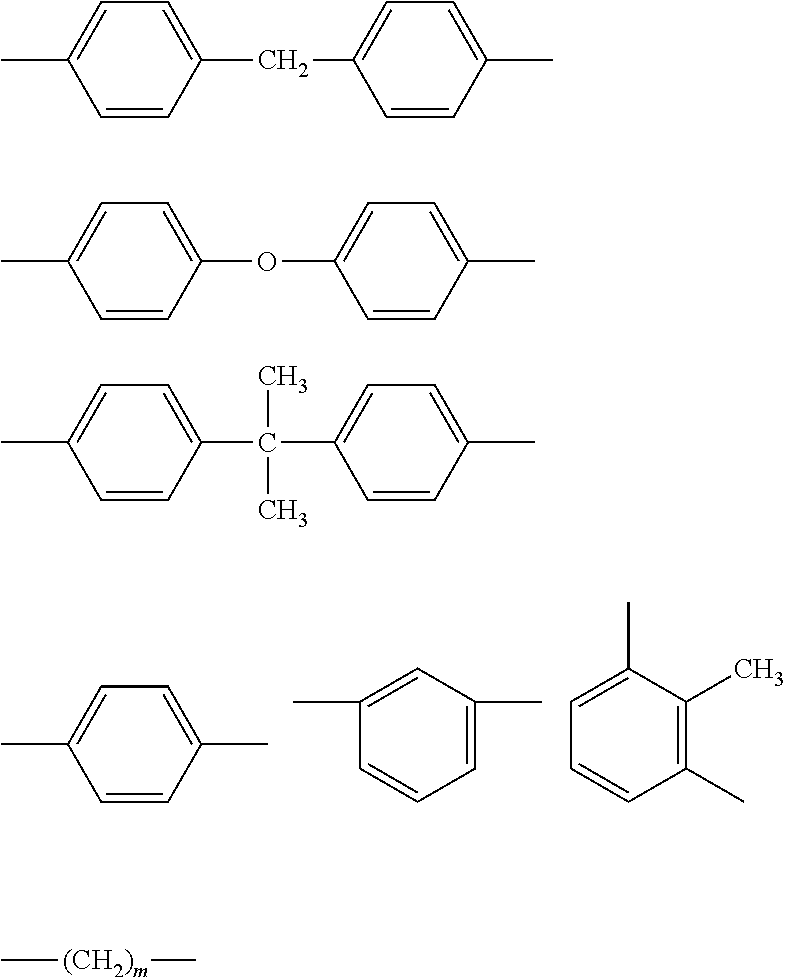

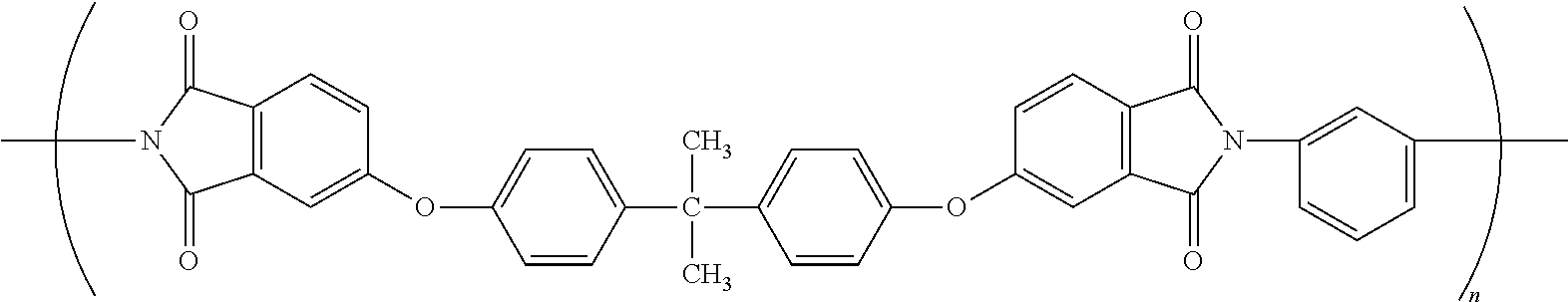

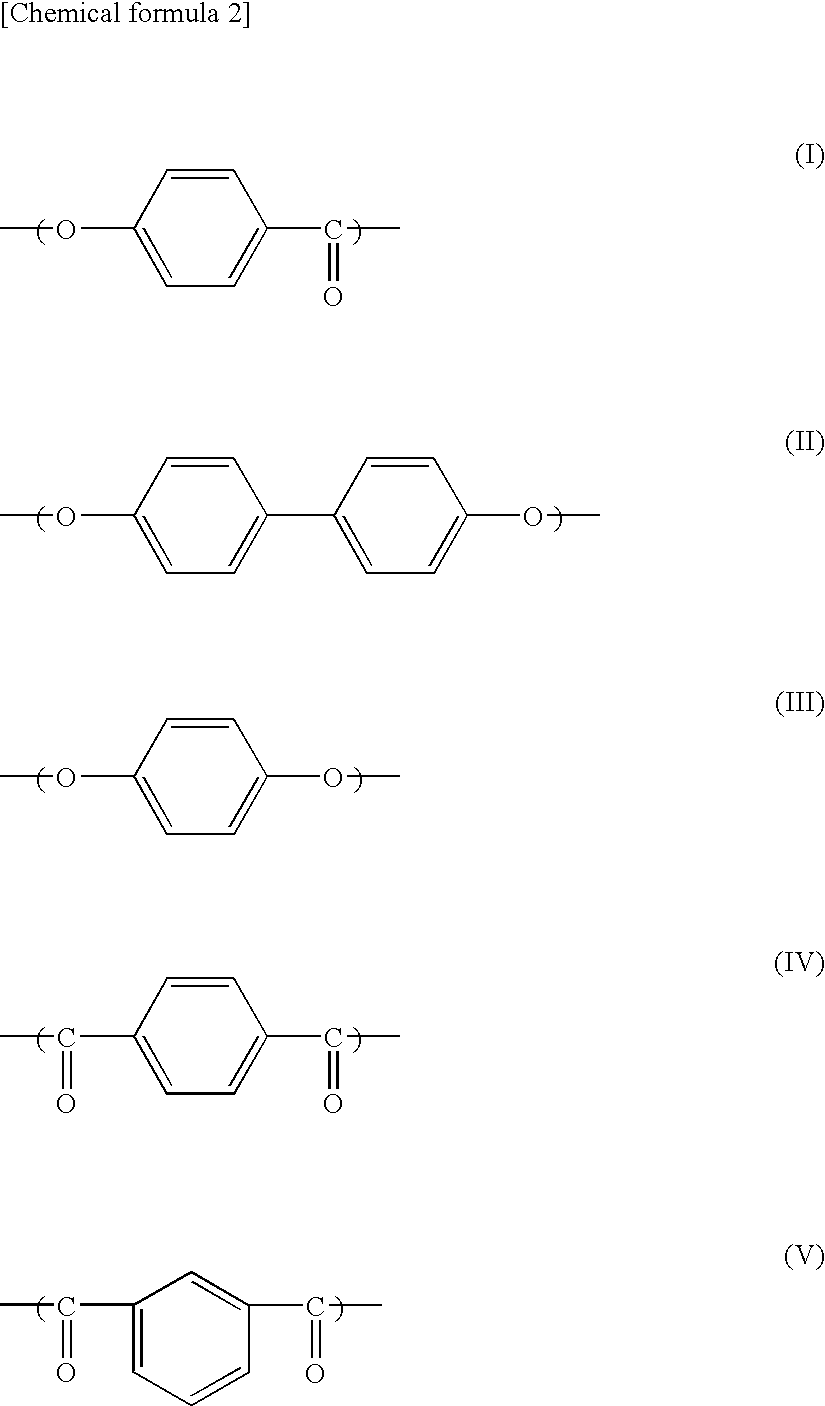

Amorphous polyetherimide fiber and heat-resistant fabric

ActiveUS20120015184A1Improve mechanical propertiesSmall single fiber finenessMonocomponent polyethers artificial filamentMelt spinning methodsPolymer sciencePolyetherimide

Provided are an amorphous polyetherimide fiber having not only a small single fiber fineness suitable for producing fabrics, and a fabric comprising the amorphous polyetherimide fiber. The fiber comprises an amorphous polyetherimide polymer having a molecular weight distribution (Mw / Mn) of less than 2.5, and having a shrinkage percentage under dry heat at 200° C. of 5% or less, and a single fiber fineness of 3.0 dtex or less. The fiber may have a tenacity at room temperature of 2.0 cN / dtex or greater.

Owner:KURARAY CO LTD

High solid content acrylic varnish, and preparation method and application thereof

The invention discloses a high solid content acrylic varnish which comprises the following raw materials in percentage by mass: 50-60% of hydroxy acrylic resin, 20-30% of polyurethane curing agent, 12.6-18% of organic solvent, 0.1-2% of wetting agent, 0.1-2% of flatting agent and 0.1-1% of antifoaming agent. The high solid content acrylic varnish disclosed by the invention can be applied in bamboo and wood tableware, is combined with a high solid content coating technology and technologies of cross-linked film curing and organic solvent removal and is a new development direction for bamboo and wood coatings and coating materials.

Owner:CARPOLY CHEM GRP

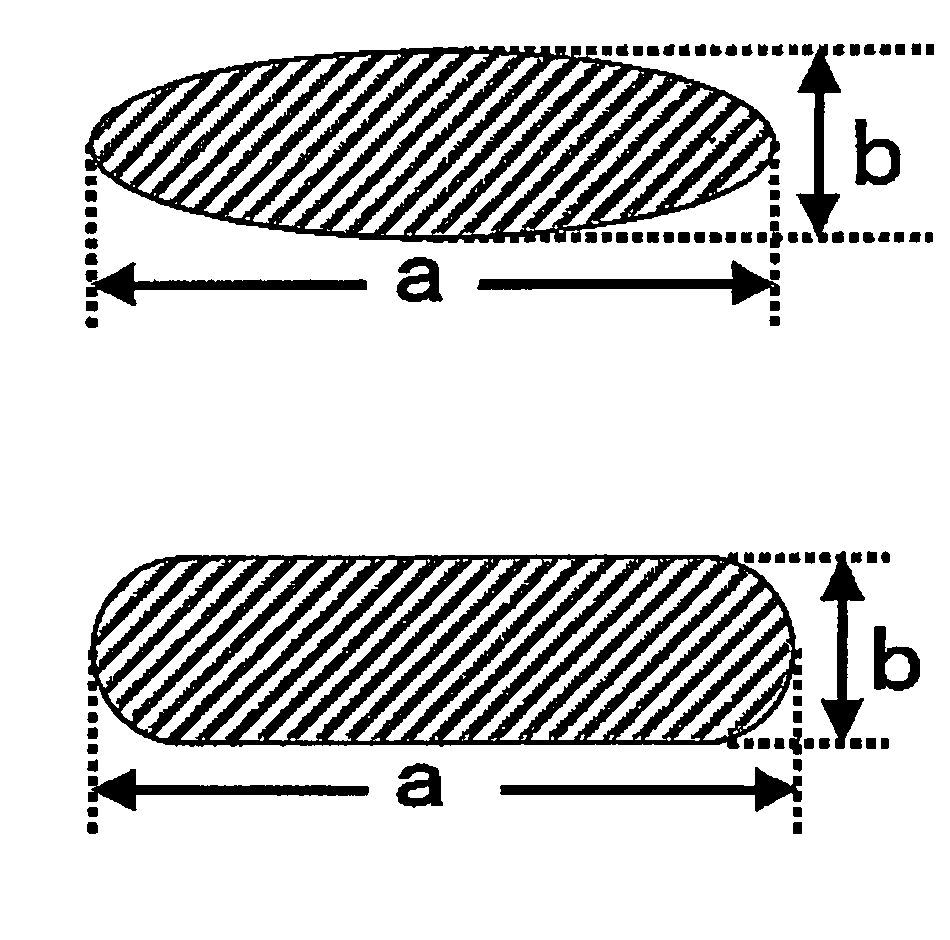

Base cloth for coated airbag and method for manufacturing the same

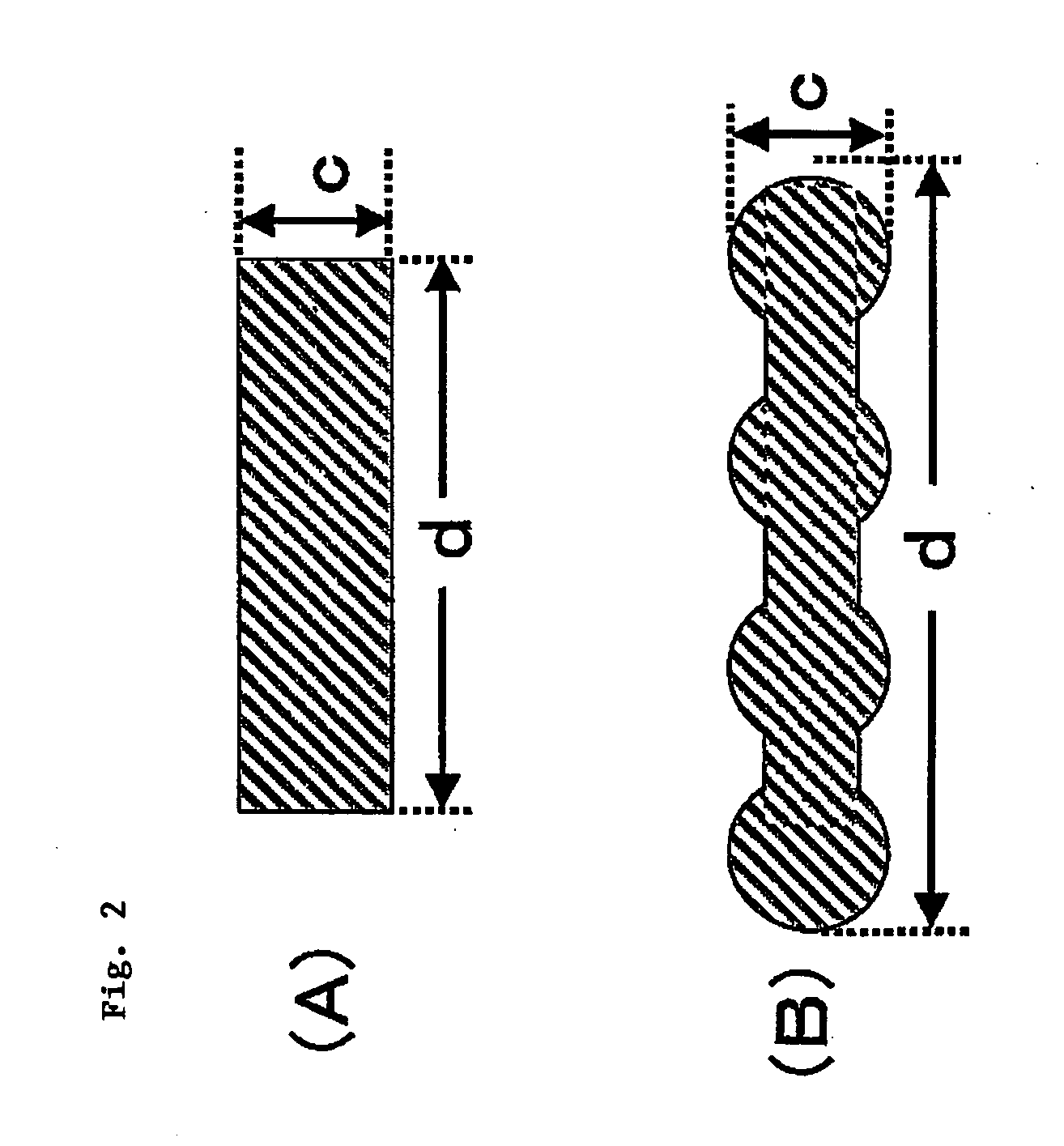

InactiveUS20050170723A1Thinner fabricSmall filament finenessPedestrian/occupant safety arrangementSynthetic resin layered productsElastomerYarn

A coated base fabric for airbags, which is fabricated by applying a resin elastomer to a base fabric formed of flattened cross-section yarns having a degree of filament cross-section flatness (that is, a ratio of the major axis length to the minor axis length of the filament cross-section) of from 1.5 to 8, and which is characterized in that the filaments are aligned in the base fabric in such a manner that the total average horizontal index (HI) represented by the following formula falls within a range of from 0.75 to 1.0, and the amount of the resin elastomer adhered to the fabric is from 0.1 to 60 g / m2: HI=(Σhi) / f wherein hi=cos θ, θ indicates the angle between the major axis direction of each filament and the horizontal direction of the fabric, f indicates the number of the filaments.

Owner:TORAY IND INC

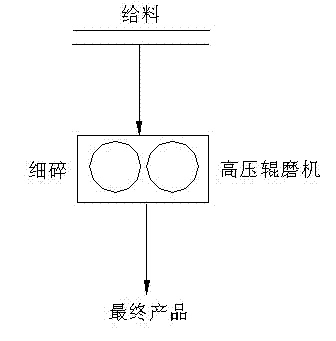

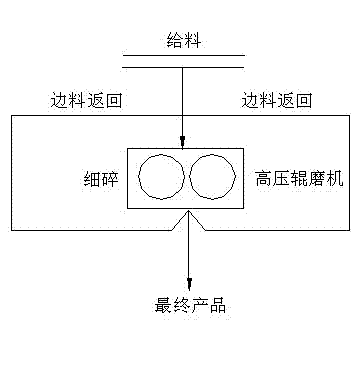

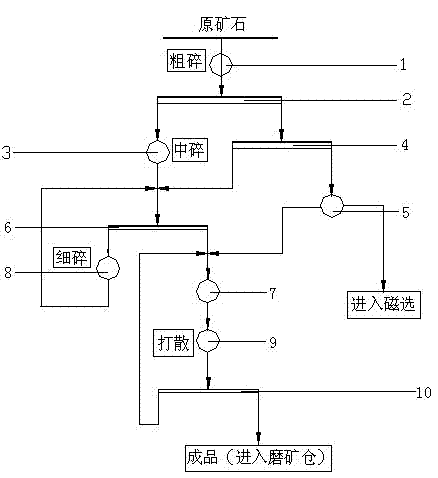

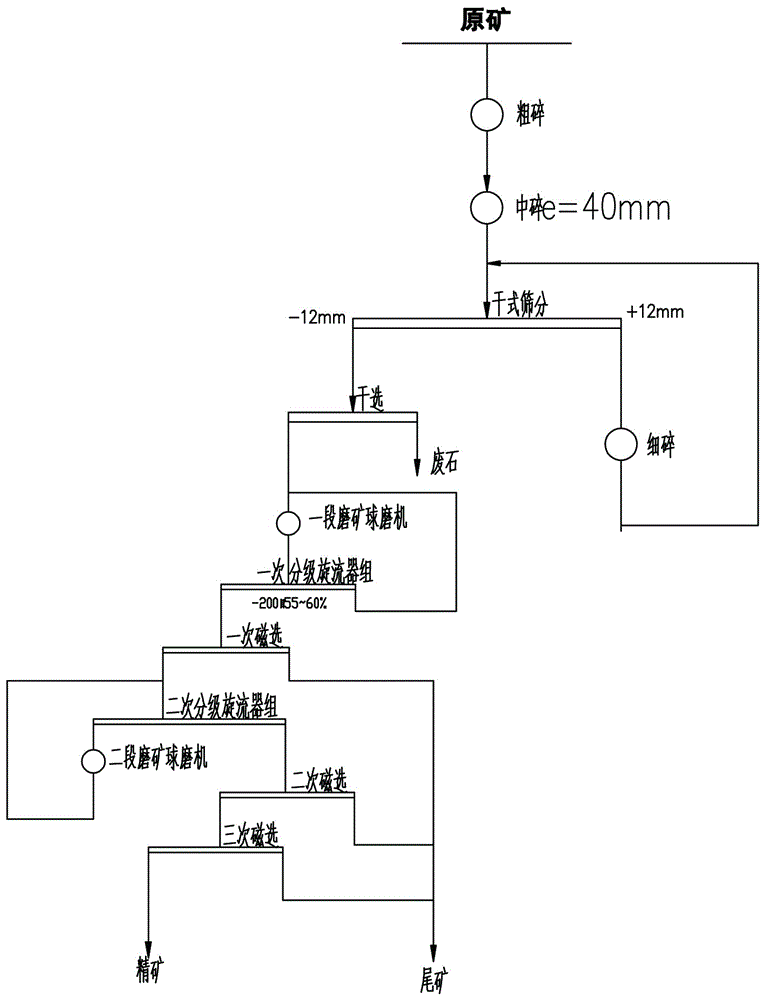

Method for crushing iron ore

ActiveCN102179284ASmall finenessReduce processing energy consumptionGrain treatmentsIronstoneClosed loop

The invention discloses a method for crushing an iron ore, comprising the following steps of primary crushing, ore washing and high pressure roller-milling, wherein the step of primary crushing uses a multi-level sieving cycling closed loop for crushing, and the step of high pressure roller-milling also uses a closed loop method; compared with the traditional crushing process flow, the process uses the production method of high pressure roller-milling scattering sieving closed loop process flow so that the range of the particle size of a final product is ensured to be narrow and the size thereof is uniform; the material in the final product of the ore is fully rolled and pressed by a high pressure roller miller so as to reduce the fineness of the material to the maximum degree, reduce the Bond index of the milling material, efficiently decrease the procedure energy consumption and steel ball consumption in milling operation and improve the selection index; moreover, the stable production process is ensured, the energy is saved and the consumption is reduced, much crushing and less milling are really realized, and the production capability of an ore factory is greatly improved.

Owner:TAIHE IRON MINE CHONGQING IRON & STEEL GROUP MINING +1

Carbon-fiber-precursor fiber bundle, carbon fiber bundle, and uses thereof

ActiveUS20130295811A1Simple structureSmall finenessFilament/thread formingMaintainance of heating chambersMeth-Fiber bundle

Provided are: a carbon fiber bundle which has a large value of single-fiber fineness and excellent productivity and which, despite this, contains few interlaced single fibers therein and has excellent spreadability; and precursor fibers which are suitable for use in producing the carbon fiber bundle. The precursor fibers are a carbon-fiber-precursor acrylic fiber bundle which comprises a polyacrylonitrile copolymer comprising 95-99 mol % acrylonitrile units and 1-5 mol % hydroxyalkyl (meth)acrylate units and which has a single-fiber fineness of 1.5-5.0 dtex. In the acrylic fiber bundle, the cross-section of each single fiber which is perpendicular to the fiber axis has a shape that has a roundness of 0.9 or less. The roundness is a value determined using equation (1) where S and L are the cross-sectional area and the circumferential length, respectively, of a single fiber which are obtained by examining, with an SEM, the cross-section of the single fiber which is perpendicular to the fiber axis and analyzing the obtained image.Roundness=4pS / L2 (1)

Owner:MITSUBISHI CHEM CORP

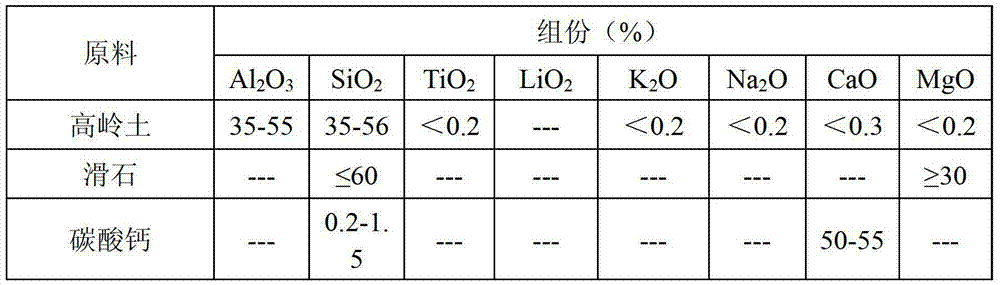

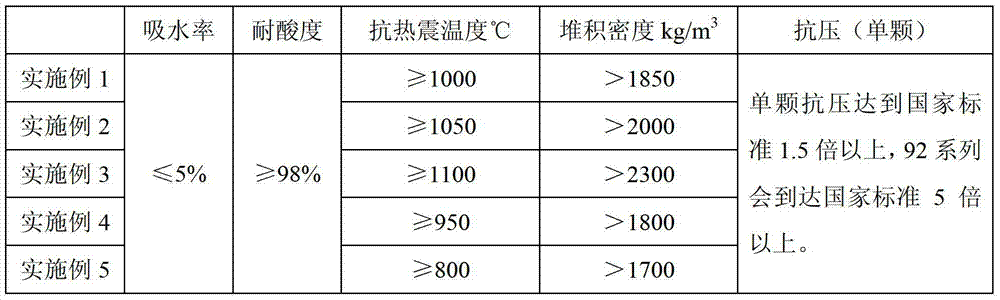

Method for preparing inert porcelain ball by using aluminum oxide dust-recovery powder

The invention discloses a method for preparing an inert porcelain ball by using an aluminum oxide dust-recovery powder and belongs to the technical field of new materials. A lot of aluminum oxide dust-recovery powder is used in the formulation of the method disclosed by the invention, the cost is obviously reduced, meanwhile a waste material is used and the environment is protected. According to the method disclosed by the invention, a composite sintering aid comprising calcium carbonate, talcum, and spodumene mineral powder is added into the formulation to facilitate the formation of magnesia-alumina spinel and mullite for enhancing in the product so as to improve the thermal shock resistance and strength of a product; a little kaolin is added into the formulation for improving the plasticity of a perform body, promoting molding conveniently and improving the strength of a green body; meanwhile in order to reduce the high energy consumption caused by wet ball milling, the powder for preparing the inert porcelain ball disclosed by the invention is subjected to continuous dry wet milling; the inert porcelain ball prepared by the method disclosed by the invention has the characteristics of high temperature resistance, high strength, good thermal shock resistance and the like, is excellent in comprehensive performance, and is completely suitable for requirements for a catalyst carrier and supporting performance in various industries.

Owner:JINGANG NEW MATERIALS

Yarn of blended spinning by combing cotton, bamboo fiber and wool

The invention discloses combed cotton, bamboo fiber and wool blended yarn which is characterized in that the yarn is blended with combed cotton, bamboo fiber and wool, wherein, the blending ratio of the combed cotton, bamboo fiber and wool is 40 percent to 60 percent: 20 percent to 30 percent: 10 percent to 20 percent; the bamboo fiber is cotton-type or tool-type and the specification is (1.11dtex to 2.22 dtex) X (38mm to 51mm). The bamboo fiber, the wool and the cotton are processed according to their own spinning process to prepare fiber strips, blended in a special drawing machine, and finally spun into yarn after roving and spinning procedures. The yarn not only is characterized by fineness, stable quality, hygroscopicity and chromaticity, strong air permeability, softness to touch and the like, but also has excellent antibacterial and bacteriostasis performance and solves the defect of poor spinnability of pure yarn bamboo fiber because of good length and neatness of combed cotton fiber.

Owner:江阴市茂达棉纺厂有限公司

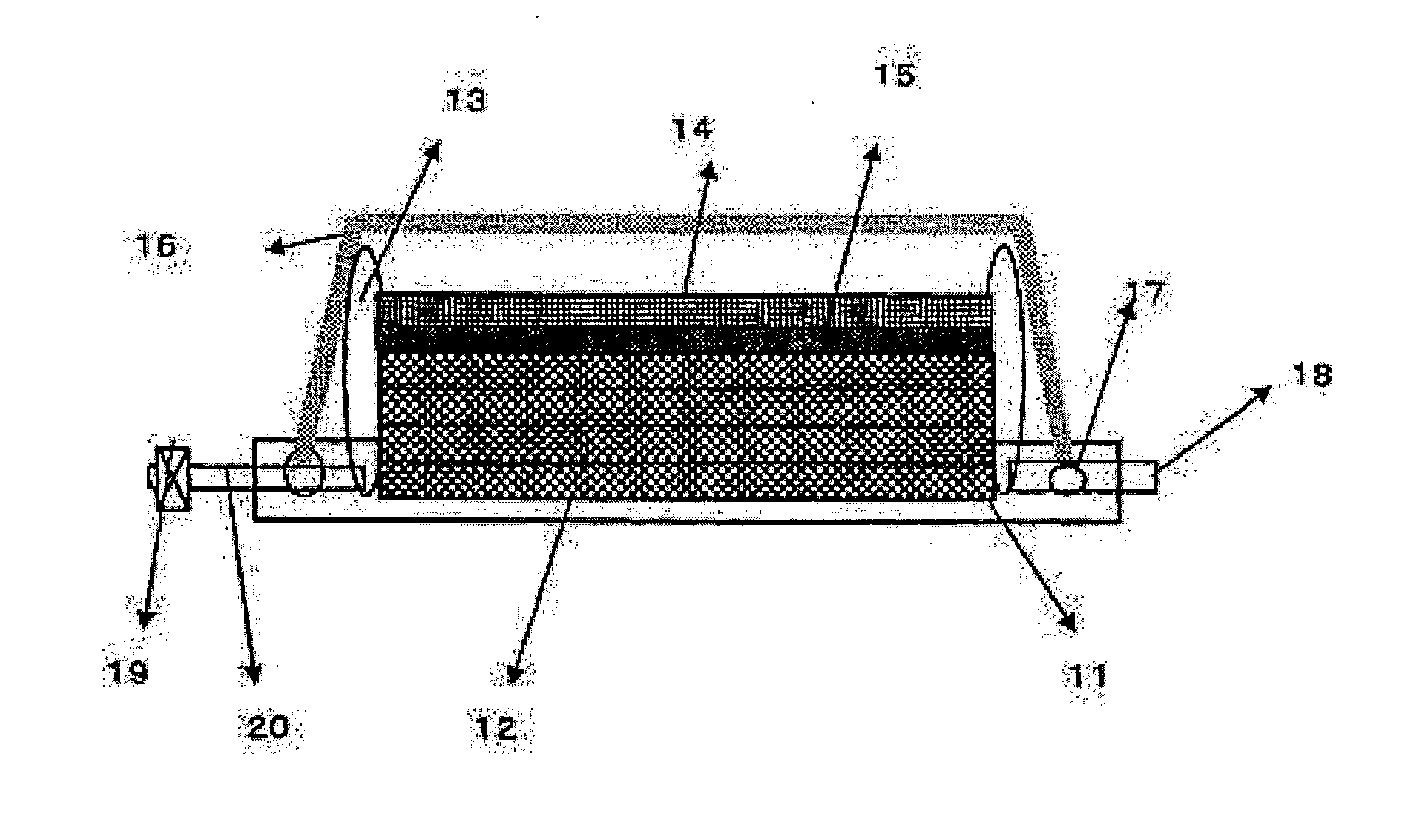

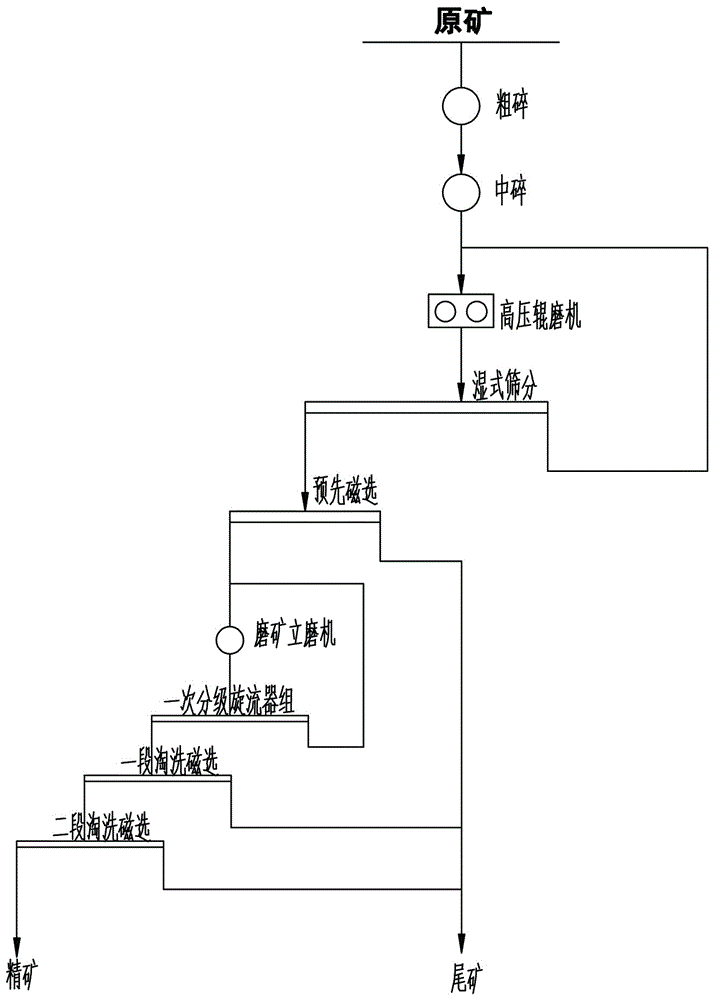

Crushing-ore milling-magnetic separation technique for magnetic iron ore

InactiveCN106824508AReduce the number of auxiliary equipmentSignificant energy savingWet separationMagnetiteClosed loop

The invention relates to a crushing-ore milling-magnetic separation technique for magnetic iron ore. The technique comprises the step that raw ore is crushed into 0 mm-50mm through coarse crushing and middle crushing, and the technique is characterized by further comprising the following steps that middle crushed products are directly fed into a closed loop system formed by a high-pressure roller mill and a constant thickness screen; high-pressure roller mill products are fed into a pre-selection wet-type magnetic separator to be subjected to pre-selection wet-type magnetic separation, and concentrate and tailings are selected correspondingly; the pre-selection wet-type magnetic separation concentrate is fed into a vertical mill machine for milling, vertical mill machine products are fed into a primary classification whirlcone for classification, primary classification is conducted, the products with the diameters being below 0.074 mm are fed into a two-stage washing magnetic separator for separating operation, and the products with the diameters being above 0.074 mm are returned to the vertical mill machine; and concentrate of two-stage washing magnetic separator separating operation is final concentrate with the grade being 67.00%, and the pre-selection wet-type magnetic separation tailings and two-stage washing magnetic separator tailings are combined into final tailings. The crushing-ore milling-magnetic separation technique for the magnetic iron ore has the advantages that the technological process is shortened, energy consumption is reduced, and cost is reduced.

Owner:中冶北方(大连)工程技术有限公司

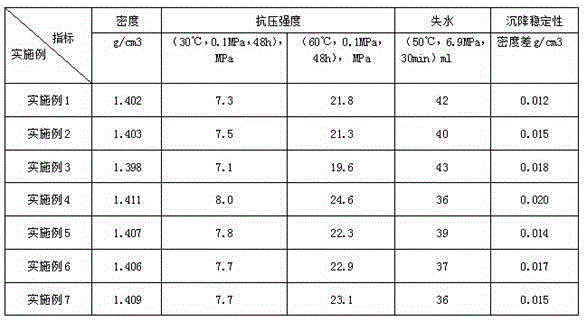

Floating-bead-free low-density oil well cement paste

ActiveCN105255465AImprove early strengthImprove cementing qualityDrilling compositionFilling materialsOil well

The invention discloses floating-bead-free low-density oil well cement paste and belongs to the technical field of oil and gas well cementation. The cement paste is prepared from 10-30% of cementing material A, 15-50% of cementing material B, 2-48% of filling material, 1-3% of fluid loss agent, 1-4% of early strength agent and 0.5-1.5% of dispersing agent. The cementing material A is one of G-grade oil well cement, D-grade oil well cement and ordinary Portland cement. The cementing material B is superfine ordinary Portland cement. The cement paste has the advantages of being low in cost, low in density, and high in early strength, density stability and quality stability.

Owner:JIAHUA SPECIAL CEMENT

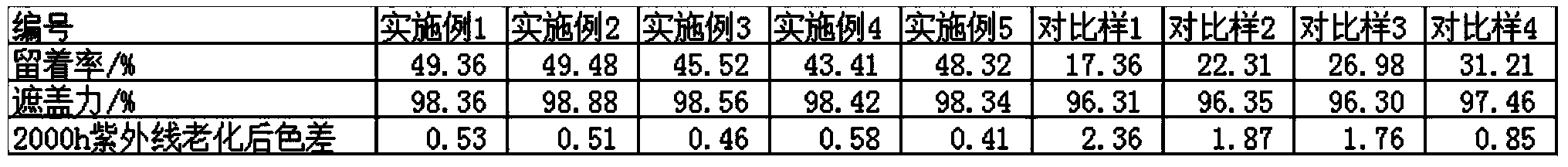

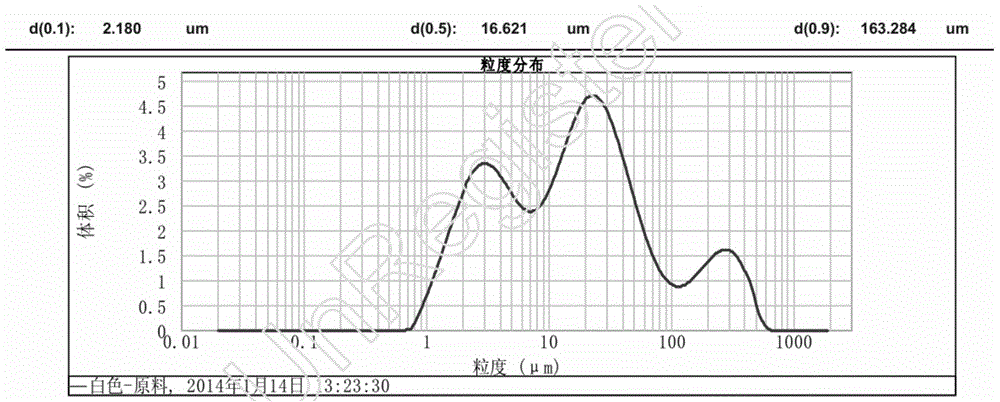

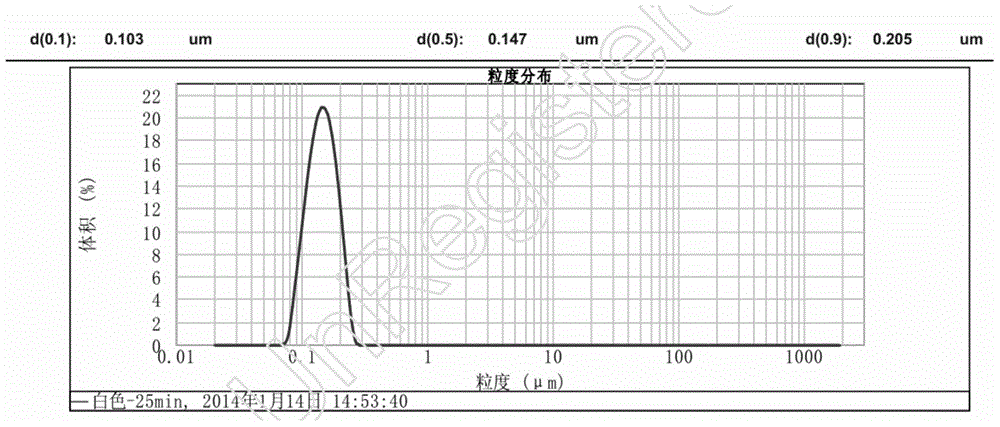

Novel surface treatment method of phosphorus, aluminum and zirconium-coated TiO2

ActiveCN104031432AGood dispersionEvenly dispersedPigment physical treatmentColor effectWeather resistance

The invention discloses a novel surface treatment method of phosphorus, aluminum and zirconium-coated TiO2, belonging to the technical field of titanium dioxide. The method comprises the following steps: 1) crushing crude rutile titanium dioxide into slurry, adding alkaline phosphorus-containing compound solution, and conducting milling and dispersion; 2) adding the dispersed slurry into a sand mill for milling; 3) diluting and heating the milled slurry; 4) adding an acidic phosphorus-containing compound solution and regulating pH value; 4) adding zirconium salt solution and alkaline solution, regulating the pH value and curing for 1-2h; 6) adding acidic aluminum salt solution, regulating the pH value and curing for 0.5-2h; 7) adding acidic aluminum salt solution and alkaline aluminum salt solution, and regulating the pH value and curing for 1-2h; and 8) adding alkaline solution so that the pH value of the slurry is up to 7.2-7.5, and curing for 1-2h; and 9) conducting organic surface treatment. The titanium dioxide prepared has higher photostability, covering capability, retention, dispersibility, weather resistance and coloring effect.

Owner:ANHUI JXTB GRP

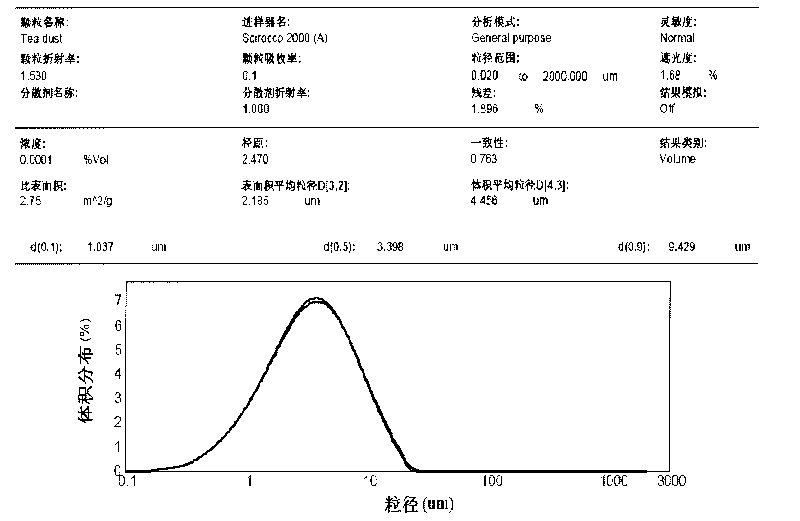

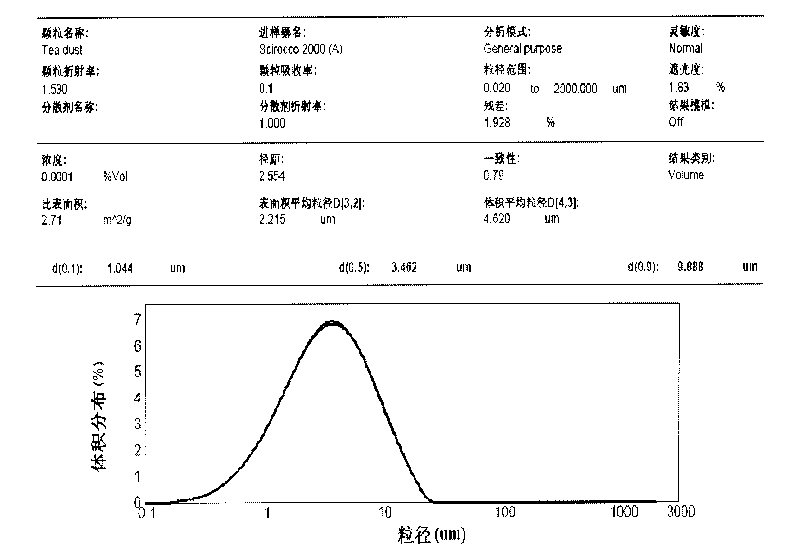

Method for preparing ultrafine tea powder

InactiveCN101715844AChange shape featuresFine granularityCosmetic preparationsToilet preparationsGreen teasGreen tea (dietary)

The invention discloses a method for preparing ultrafine green tea powder and belongs to the technical field of deep machining of tea leaves. The method comprises the following steps: screening middle-grade and low-grade summer and autumn fresh green tea leaves in accordance with national pollution-free production standard; spreading the tea leaves, performing fixation on the tea leaves by combining steam heat and frying technology, drying the tea leaves by novel microwave grading technology, and performing low-temperature ultrafine pulverization to prepare the ultrafine green tea powder with D50 more than or equal to 2,500. The method for preparing the ultrafine green tea powder is characterized by simple process, reasonable steps, low cost, and suitability for industrialized production. The ultrafine tea powder produced by the method has complete breaking of cell wall, and high uniformity and dispersibility. During processing, nutrient components and pharmacologic components of green tea are retained to the maximum; a chemical additive can be widely replaced; the shelf life of food is prolonged; food is endowed with natural emerald green color and specific tea flavor; dietary fiber, active polysaccharide and other substances of the green tea are fully utilized; tea drinking is changed into tea eating; and products can be widely used in the fields of food, cosmetics, commodity and the like.

Owner:NANJING AGRICULTURAL UNIVERSITY

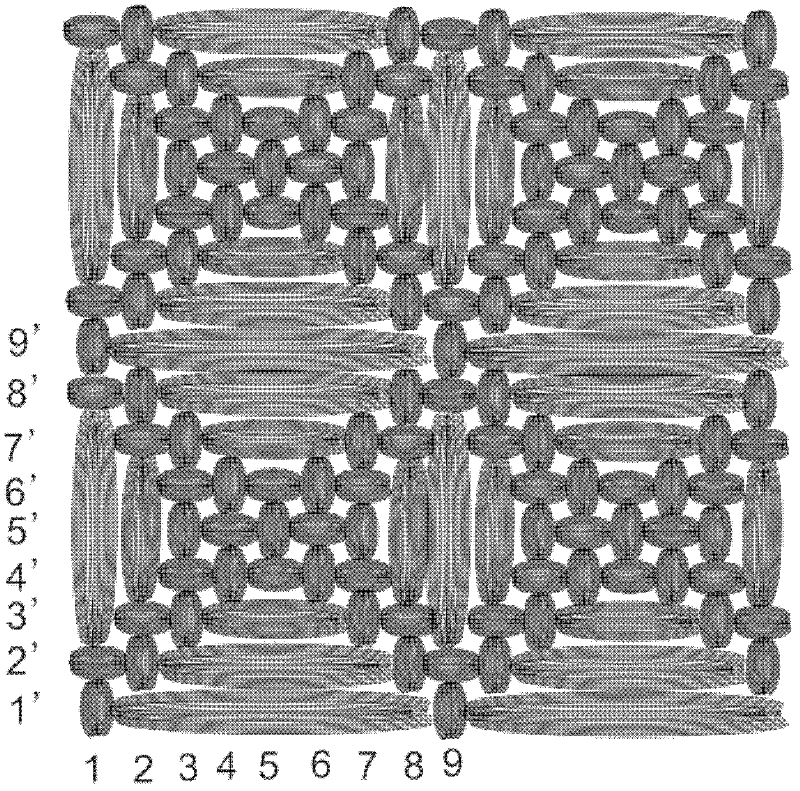

Super absorbent dust-free wiping cloth and manufacturing method thereof

InactiveCN102505253ALoose arrangementLarge specific surface areaCarpet cleanersFloor cleanersSuper absorbentLaser cutting

The invention discloses a super absorbent dust-free wiping cloth and a manufacturing method thereof. The wiping cloth is formed by interweaving warps and wefts and is characterized in that the dust-free wiping cloth is formed by circularly arranging square concave weave repeat units formed by interweaving the warps and the wefts along the warp direction and the weft direction respectively; at least one of the warp and the weft is formed by superfine fiber filaments; and in one weave repeat unit, the warps and the wefts are respectively arranged stepwise and upward in sequence from the central lowest point, and the floating length of the adjacent warps and the adjacent wefts on the steps increases in sequence to form concavo-convex patterns which are piled up alternately from low to high and have four high sides and low middle. The manufacturing method comprises the steps of beaming, drafting and reeding, weaving, weight reducing, tenter setting, laser cutting and packaging, thereby obtaining the super absorbent dust-free wiping cloth. The super absorbent dust-free wiping cloth has soft handfeel, good wiping effect and super absorbency and can be used in a dust-free room with a higher cleanliness requirement. The manufacturing method is simple and can be used for manufacturing the high-quality dust-free wiping cloth.

Owner:SHENZHEN SELEN SCI & TECH CO LTD

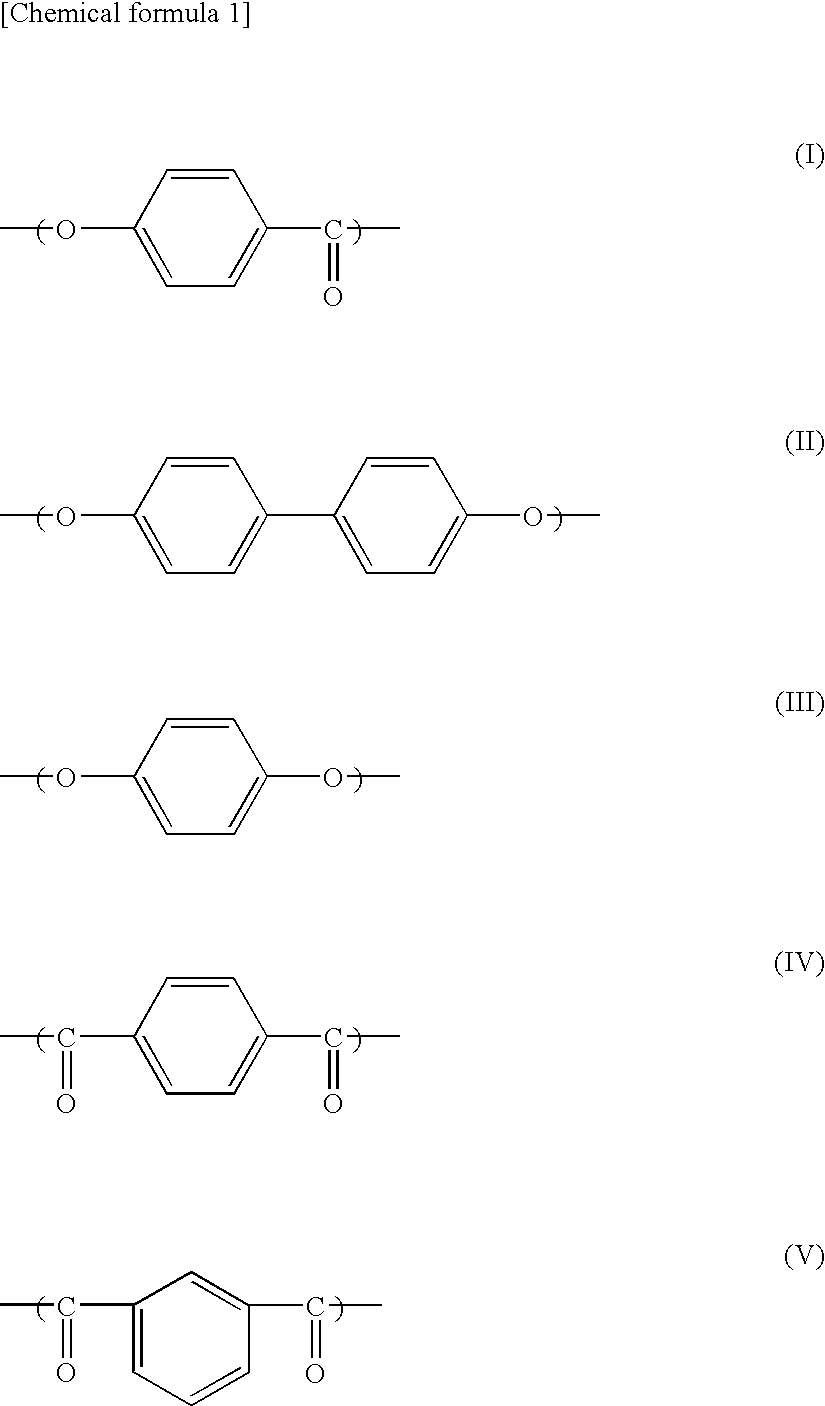

Liquid crystalline polyester fiber and process for production of the same

ActiveUS20100104870A1High elastic modulusHigh in strengthLayered productsOptical articlesPolyesterLiquid crystalline

A liquid crystalline polyester fiber which exhibits a half width of endothermic peak (Tm1) of 15° C. or above as observed in differential calorimetry under heating from 50° C. at a temperature elevation rate of 20° C. / min and a strength of 12.0 cN / dtex or more; and a process for production of the same. A liquid crystalline polyester fiber which is excellent in abrasion resistance and lengthwise uniformity and is improved in weavability and quality of fabric and which is characterized by a small single-fiber fineness can be efficiently produced without impairing the characteristics inherent in fabric made of liquid crystalline polyester fiber produced by solid phase polymerization, namely, high strength, high elastic modulus and excellent thermal resistance.

Owner:TORAY IND INC

High-thermal-conductivity single-component underfill adhesive and preparation method thereof

InactiveCN111500239AReduced responseLarge average distanceNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesive cementCarbide silicon

The invention belongs to the technical field of filling adhesives and especially relates to a high-thermal-conductivity single-component underfill adhesive prepared from the following components, by mass: 10 to 30 parts of polyurethane modified epoxy resin, 5 to 15 parts of a first filler, 5 to 10 parts of a second filler, 5 to 15 parts of a curing agent, 2 to 5 parts of a curing accelerator, 1 to5 parts of reactive diluent and 0.5 to 2 parts of a coupling agent. The first filler is spherical aluminum oxide, carbon nanotubes and silicon carbide, and the polyurethane-modified epoxy resin is prepared from a polyurethane prepolymer and epoxy resin through a reaction. The added spherical aluminum oxide, carbon nano tube and silicon carbide belong to fillers with high heat conductivity coefficient, insulation, low fineness and small specific gravity, generate a synergistic effect, and can meet the characteristics of high heat conductivity, quick flowability, high permeability and low viscosity of the underfill adhesive. And the heat generated by a chip is quickly transferred to the printed circuit board, so that the temperature of the chip is effectively reduced, and the heat dissipation efficiency of the chip is improved.

Owner:东莞市新懿电子材料技术有限公司

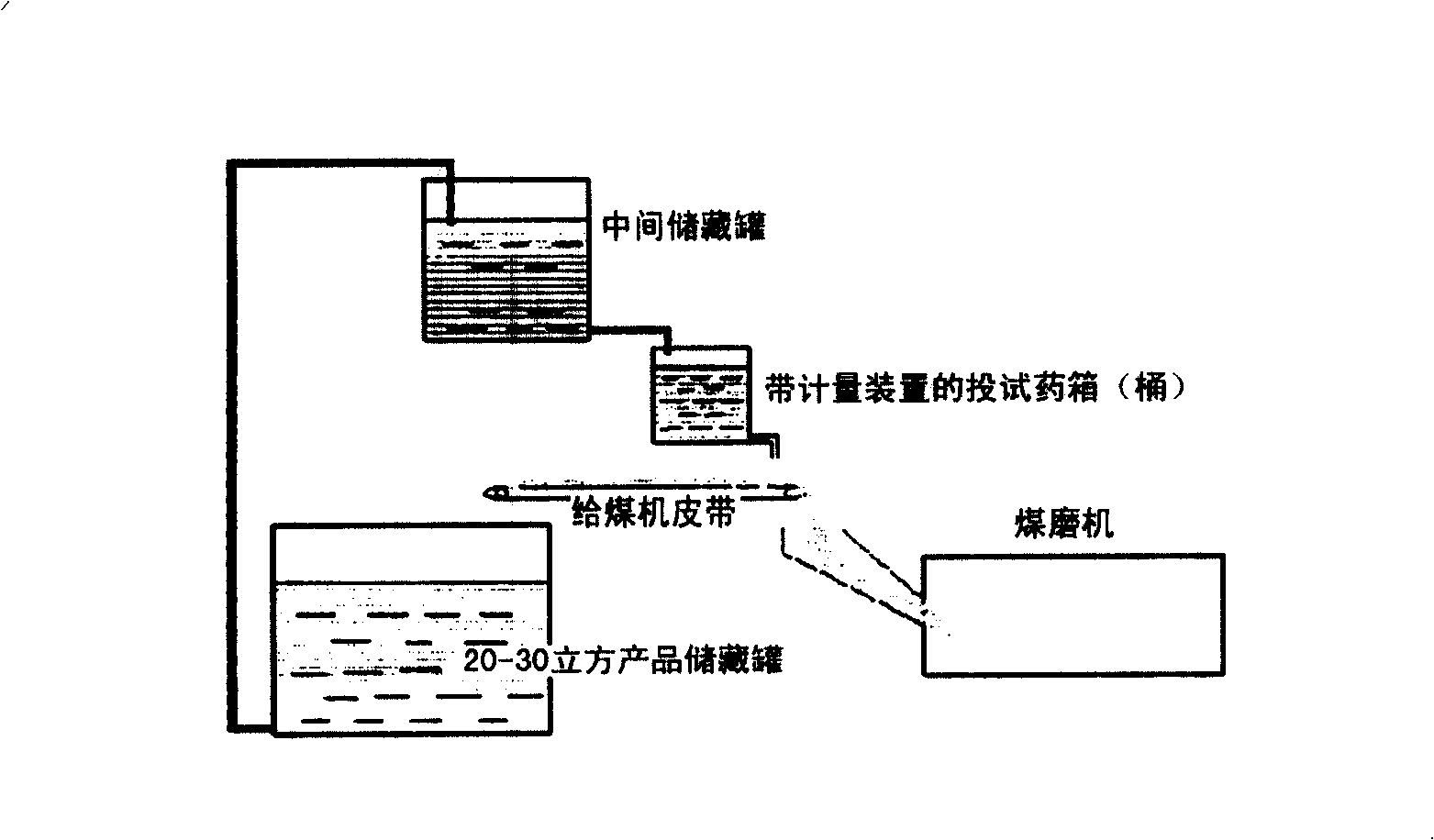

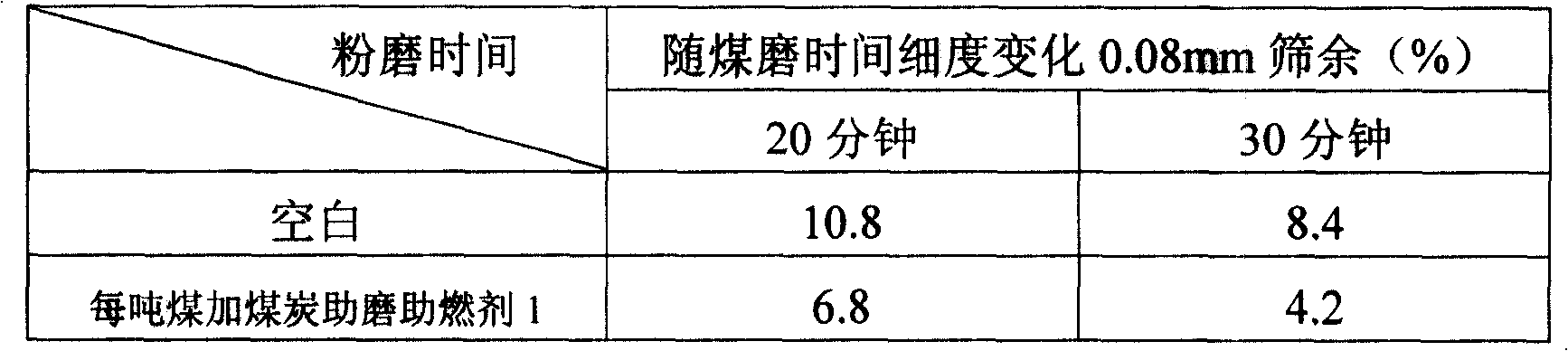

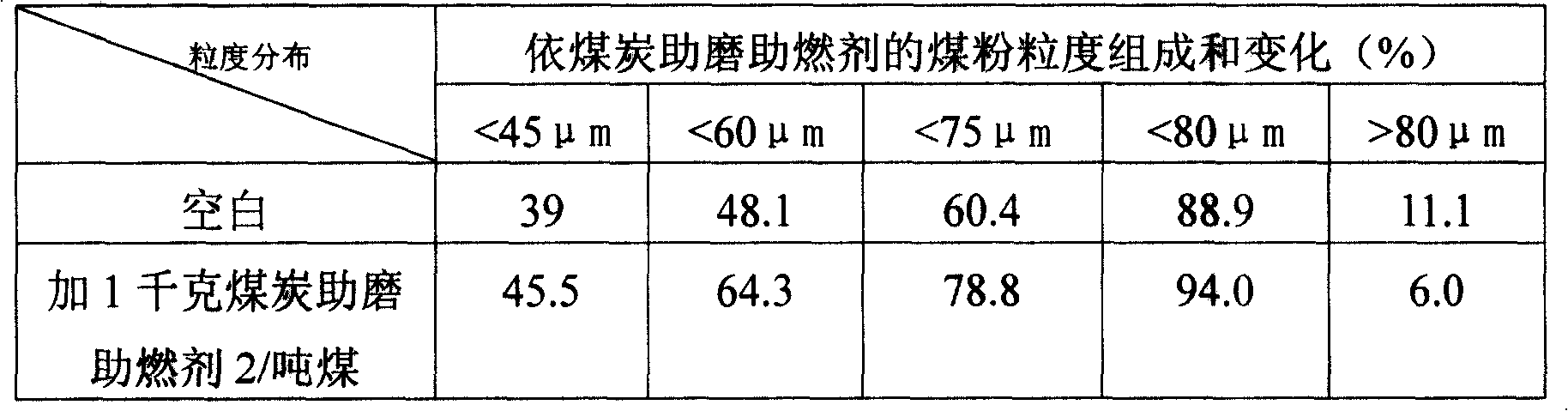

Grinding burning-rate accelerator for coal, preparation method and application thereof

The invention relates to a coal mill-supporting combustion improver, and a preparation method and application thereof. The coal mill-supporting combustion improver is prepared with the following materials by weight: 45 to 55 portions of nonpolar lipophilic mineral oil, 19 to 23 portions of lipophilic vegetable oil, 16 to 20 portions of emulsifying agent, and 9 to 14 portions of hydrophilic surfactant. The coal mill-supporting combustion improver has strong diffusibility and permeability. The hydrophilic surfacant in the coal mill-supporting combustion improver is a nonpolar surfactant, and has weak dispersibility over lipophilic mixture. Accordingly, with the help of the emulsifying agent, the property of lipophilic substance is reduced, and the quality of combustion is improved.

Owner:BEIJING GUOCHENG HUANWANG ELECTROMECHANICAL EQUIP

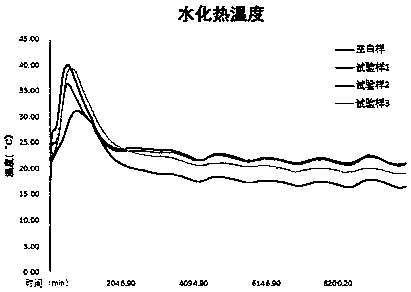

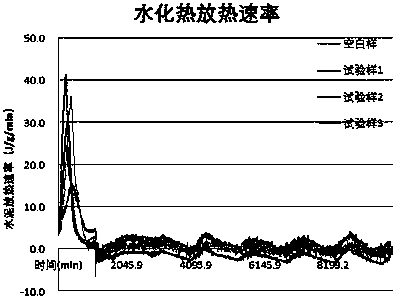

Cement grinding aid and preparation method thereof

The invention discloses a cement grinding aid and a preparation method thereof. The cement grinding aid is prepared from the following components by mass content: 5 to 10% of polyethylene glycol, 5 to10% of sorbitol, 1 to 3% of polyglycerol fatty acid ester, 5 to 10% of diethanolisopropanolamine, 5 to 10% triisopropanolamine, 1 to 5% of sodium hydroxide, 2 to 8% of sodium polyacrylate, 1 to 5% ofmicrocrystalline cellulose and the balance of water. The cement grinding aid disclosed by the invention has the beneficial effects that no matter which can affect concrete performance and building service life and has harm to human health is doped into the cement grinding aid, so that the cement grinding aid has safety and environmental friendliness; all the raw materials have a synergistic effect, so that cement fineness reduction is facilitated, reasonable particle size distribution of the cement grinding aid is guaranteed, an early hydration heat release rate of cement where mineral admixture is doped is reduced, and cement strength is improved; under the condition of guaranteeing cement strength and use, production cost can be reduced, and economical benefit and social benefit of cement production enterprises are improved.

Owner:DONGHAI CONSTR GRP

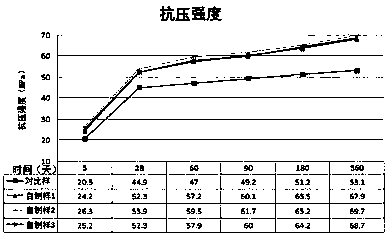

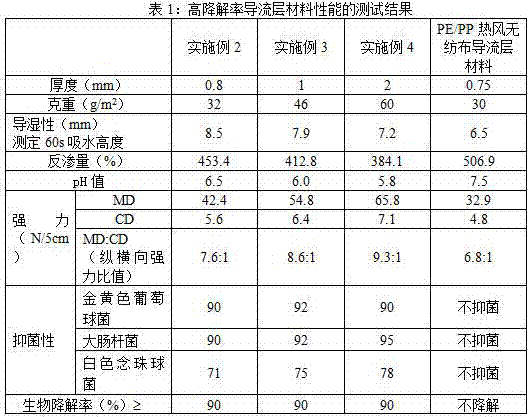

High-degradation rate diversion layer material and preparing method thereof

ActiveCN106974768AGood moisture conductivityImprove breathabilityAbsorbent padsBaby linensFiberPolymer science

The invention discloses a high-degradation rate diversion layer material and a preparing method thereof, and relates to the field of disposable hygiene products. The high-degradation rate diversion layer material is prepared through selection of polylactic acid fiber with different hydrophilicity and water repellency properties, different thicknesses and different melting points, and selection of reasonable technological parameters during reinforcing of a hot air oven. The prepared high-degradation rate diversion layer material is composed of an upper fibre web and a lower fibre web, wherein the upper fibre web is a disordered fibre web formed through air laying, the lower fibre web is a carded and directly laid web, and the upper fibre web and the lower fibre web are made into a high-degradation rate diversion layer with high using strength through hot air reinforcing. The technical problem that a diversion layer material is hard to degrade and poor in diversion performance, instant absorptivity and temporary liquid storage capacity, causing side leakage liability and serious reverse osmosis of disposable hygiene products is solved. The diversion layer material has excellent diversion performance, high liquid storage capacity, high instant absorptivity, and a high biodegradation rate.

Owner:CHANGSHU GOLD SPRING CHEM FIBERS & KNITTINGS

UV (ultraviolet) color paste capable of being used for optical fiber coloring printing ink and preparation method thereof

The invention relates to the technical field of optical fiber and pigment color pastes and particularly relates to an UV (ultraviolet) color paste capable of being used for optical coloring printing ink. The color paste is prepared from the following components in percentage by weight: 10-50% of pigments, 30-70% of an active diluent, 3-20% of polyurethane acrylate, 1-2% of a defoaming agent and 3-10% of a wetting dispersant, totaling 100%. The color paste has the advantages of being fast in grinding speed, bright in color and easy to distinguish, good in lightness, strong in covering power, strong in coloring power and the like and is particularly suitable for preparing optical fiber coloring printing ink.

Owner:武汉长盈通光电技术股份有限公司

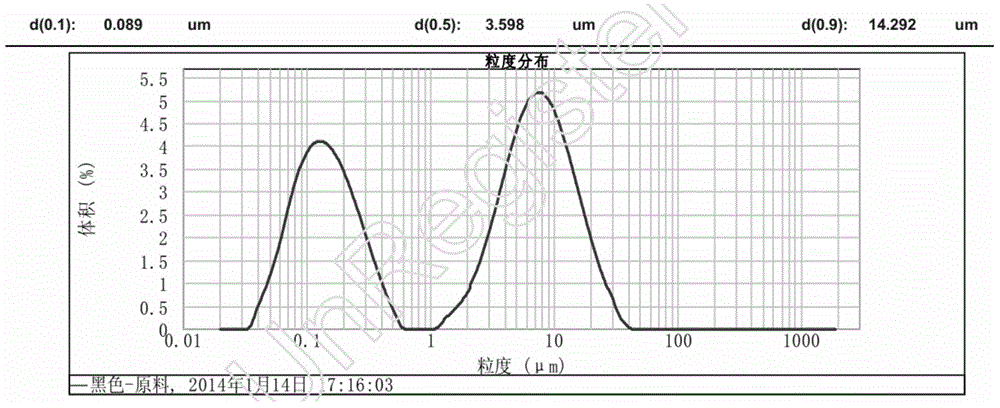

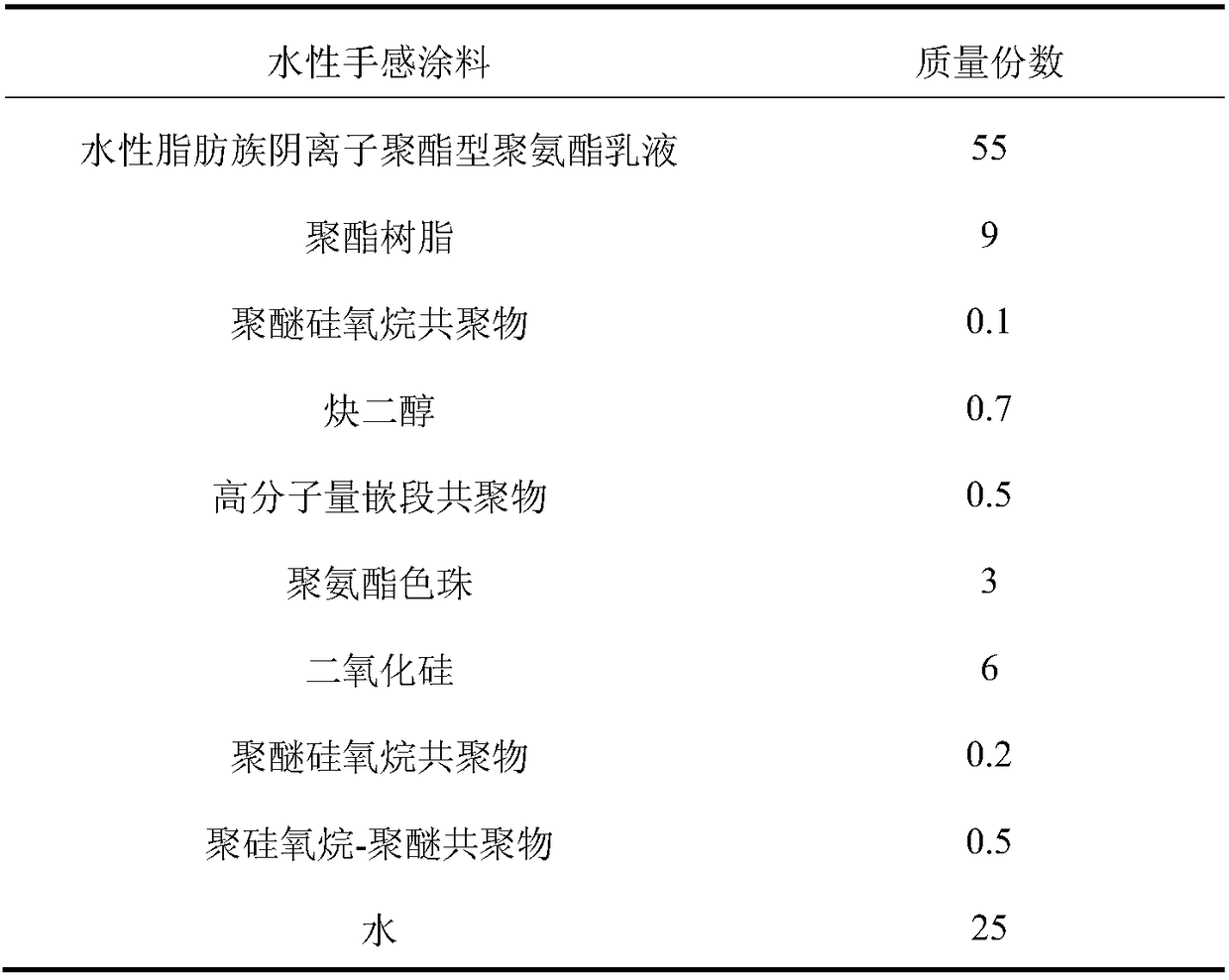

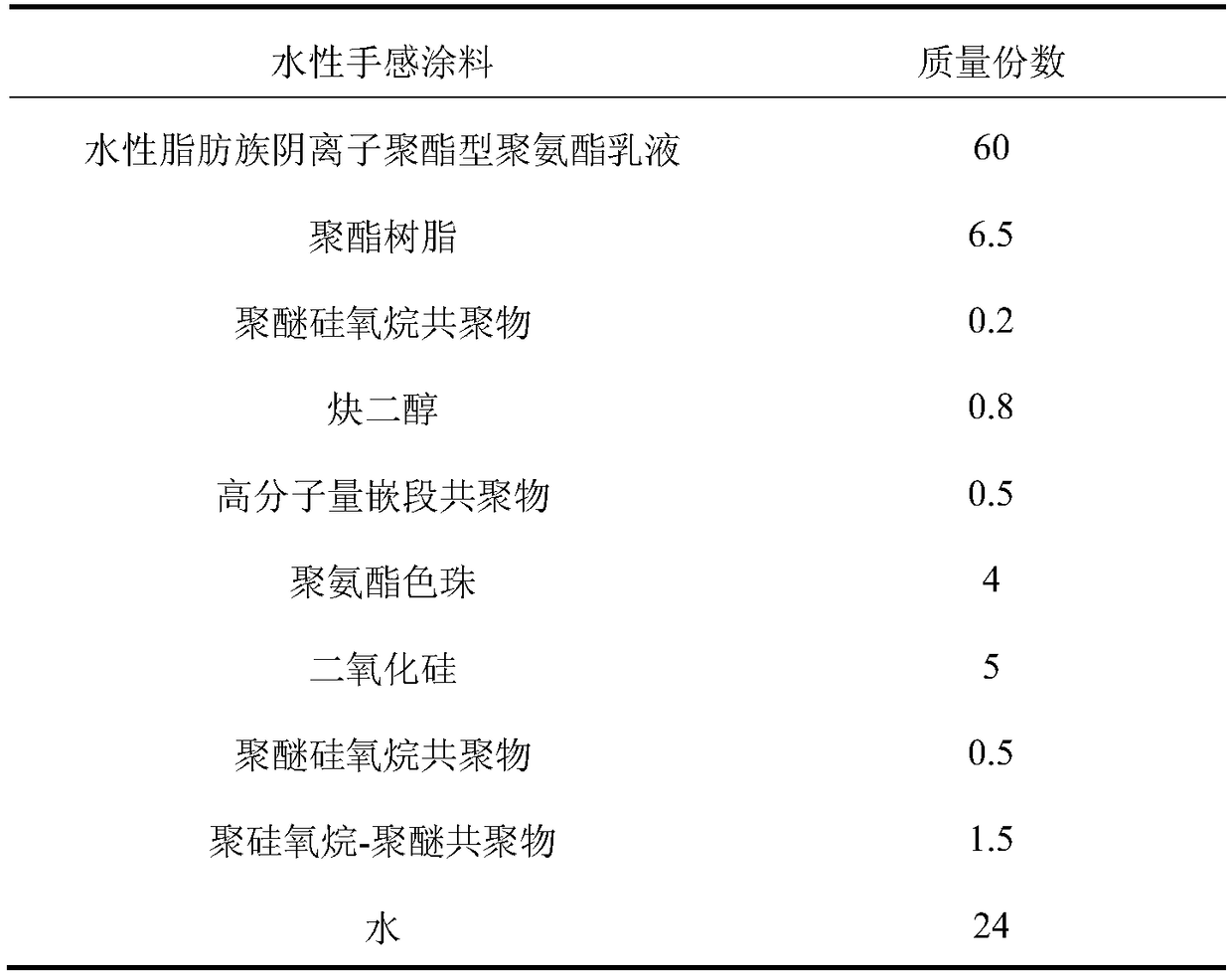

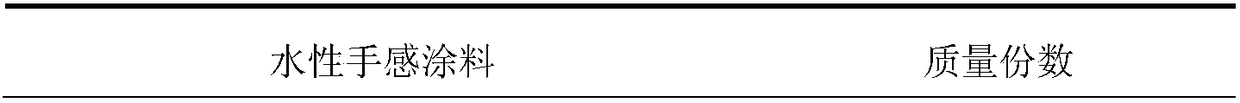

Aqueous hand-feeling coating and preparation method and use

InactiveCN109021804ADelicate and smooth feelSave materialPolyurea/polyurethane coatingsPolyester coatingsWater basedPolyester resin

The invention discloses an aqueous hand-feeling coating. The aqueous hand-feeling coating comprises, by weight, 40 to 60 parts of a polyester-modified water-based elastic resin, 5 to 10 parts of a polyester resin, 0.6 to 1.3 parts of a base wetting agent, 0.3 to 0.7 parts of a dispersing agent, 3 to 7 parts of elastic powder, 3 to 6 parts of matting powder, 0.7 to 2 parts of an aid and 23 to 32 parts of water. The aqueous hand-feeling coating has the characteristics of smooth paint, good adhesion and high hardness. A preparation method of the aqueous hand-feeling coating comprises two dispersion processes and physical mixing. Through the preparation method, the aqueous hand-feel coating has small particle sizes, is easy to disperse and is evenly distributed. The preparation method is simple and is suitable for large-scale use.

Owner:HUNAN SOKAN NEW MATERIAL

Water-based ink thermal transfer ribbon and preparation method thereof

InactiveCN106085019ASmall finenessImprove transfer effectFireproof paintsInk ribbonsWater basedEpoxy

The invention discloses a water-based ink thermal transfer ribbon which comprises a base, a release layer, an ink layer and a heat resistant coating, wherein one side of the base is coated with the release layer, the outer side of the release layer is coated with the ink layer, and the other side of the base is coated with the heat resistant coating; the ink layer is prepared from the following raw materials in parts by weight: 14-17 parts of waterborne polyurethane resin, 10-15 parts of epoxy resin, 18-23 parts of acrylic resin, 15-20 parts of carbon black, 8-12 parts of copper chromite black, 22-26 parts of kaolin, 9-13 parts of quartz powder, 2-5 parts of diatomite, 5-8 parts of polyethylene wax, 0.7-1.5 parts of polysiloxane defoaming agents and 0.5-1.0 part of chitosan. The invention further discloses a preparation method of the water-based ink thermal transfer ribbon. The prepared thermal transfer ribbon is free from toxic solvents such as methylbenzene and butanone, operating environments can be favorably improved, health of workers is ensured, and environmental protection requirements are met.

Owner:POMA IND SHANGHAI

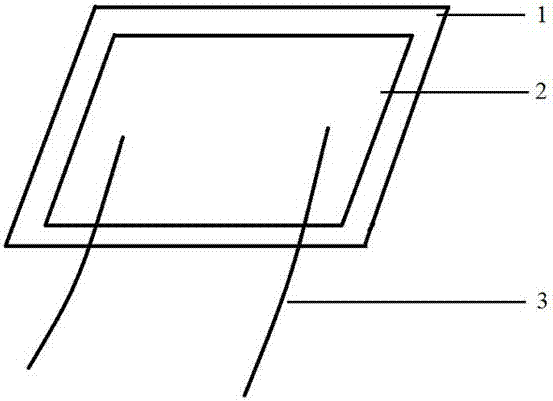

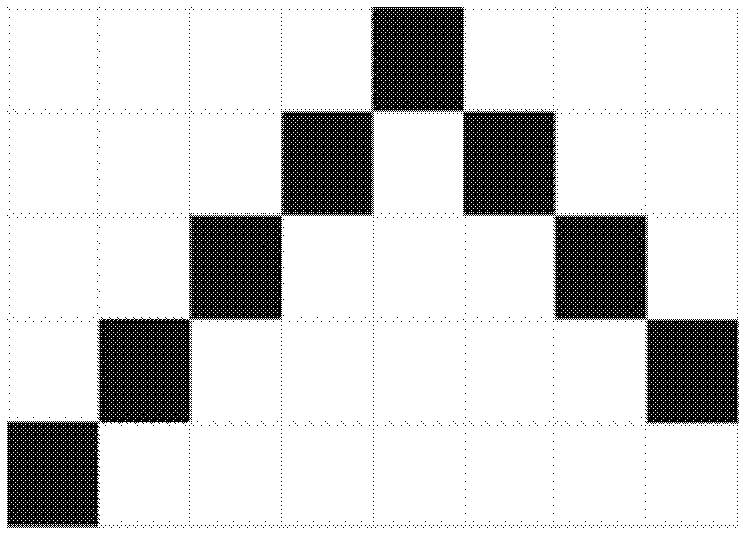

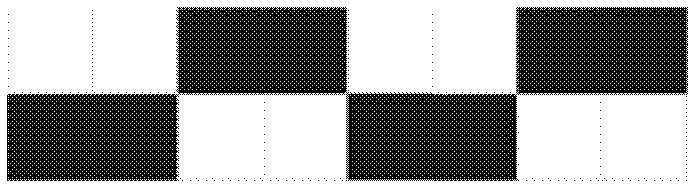

Woven fabric, method for manufacturing design woven fabric and method for manufacturing interior material

ActiveUS20170342607A1Improve protectionDirectional flexibilityMechanical apparatusLight guides detailsYarnLight guide

A woven fabric includes a first constituent yarn having an optical fiber yarn and a non-light guiding yarn and a second constituent yarn having a non-light guiding yarn. The woven fabric has a first region in which the first and second constituent yarns are woven in one layer and a second region which is positioned adjacent to the first region and in which the first and second constituent yarns and are woven in two or more separable layers. The woven fabric has an optical fiber layer and a back protecting layer as the separable layers. The optical fiber layer is a layer formed of the optical fiber yarns. The back protecting layer is a layer in which the non-light guiding yarn of the first constituent yarn and the non-light guiding yarn of the second constituent yarn are woven. Further, the woven fabric can further comprise a front protecting layer.

Owner:TOYOTA BOSHOKU KK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com