Novel surface treatment method of phosphorus, aluminum and zirconium-coated TiO2

A surface treatment, phosphorus aluminum technology, applied in the direction of dyeing physical treatment, inorganic pigment treatment, chemical instruments and methods, etc., can solve the problem of light stability retention rate, dispersion and weather resistance, unreachable coloring effect, high cost, Harmful to health and other issues, to achieve high weather resistance, retention rate guarantee, promote hydrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

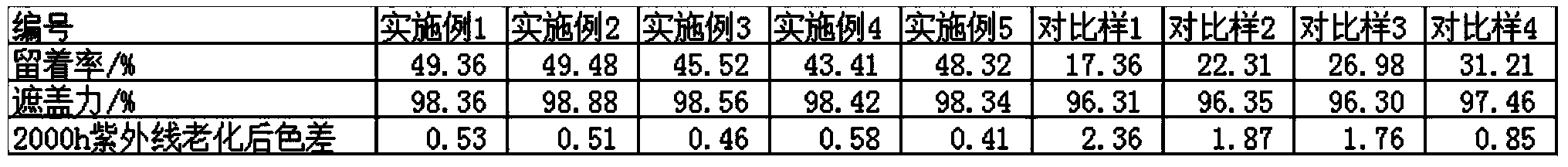

Examples

Embodiment 1

[0032] A new type of phosphorus-aluminum-zirconium-coated TiO in this embodiment 2 The method of surface treatment is to add phosphate in the process of beating and dispersing the crude rutile titanium dioxide, and add phosphate, zirconium salt and aluminum salt to TiO2 in the inorganic surface treatment. 2 particles are surface-coated, compared to other coated TiO 2 The method of surface treatment, the sources of raw and auxiliary materials used in this example are convenient, sufficient, low in cost and low in risk factor. Compared with using expensive cerium salt as coating raw material, although it can increase the weather resistance of titanium dioxide, cerium Salt has a toxic effect on human lungs and is extremely irritating, which will cause breathing difficulties for titanium dioxide production personnel and endanger the health of production personnel, and metal cerium is also extremely harmful to the environment.

[0033] The specific processing steps of this embodimen...

Embodiment 2

[0049] A new type of phosphorus-aluminum-zirconium-coated TiO in this embodiment 2 The method for carrying out surface treatment, its treatment steps are:

[0050] 1) Weigh 800g of crude rutile titanium dioxide and crush it in a crusher, sieve it with a 450μm test sieve, use deionized water to make a slurry with a concentration of 800g / L, and use a high-speed mixer at a speed of 550rpm After stirring for 15 minutes, add sodium hexametaphosphate solution with a concentration of 100g / L, the mass ratio of sodium hexametaphosphate solution to slurry is 5‰, control the pH to 9.5, and carry out grinding and dispersion.

[0051] 2) Disperse the dispersed slurry in step 1) with 8.3m 3 The speed of / h is added to the sand mill for grinding to further reduce the particle size and increase the dispersion.

[0052] 3) Dilute the ground slurry in step 2) to a concentration of 300g / L, raise the temperature to 58°C, and keep it warm until the surface treatment is completed, and the rotatio...

Embodiment 3

[0060] A new type of phosphorus-aluminum-zirconium-coated TiO in this embodiment 2 The method for carrying out surface treatment, its treatment steps are:

[0061] 1) Weigh 900g of crude rutile titanium dioxide and crush it in a crusher, sieve it with a 450μm test sieve, and use deionized water to make a slurry with a concentration of 900g / L of the crude product after sieving, and use a high-speed mixer at a speed of 580rpm After stirring for 20 minutes, add sodium hexametaphosphate solution with a concentration of 120g / L, the mass ratio of sodium hexametaphosphate solution to slurry is 4.5‰, control the pH to 10.5, and carry out grinding and dispersion.

[0062] 2) Disperse the slurry in step 1) with 11m 3 The speed of / h is added to the sand mill for grinding to further reduce the particle size and increase the dispersion.

[0063] 3) Dilute the ground slurry in step 2) to a concentration of 320g / L, raise the temperature to 62°C, and keep it warm until the surface treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com