Method for crushing iron ore

A crushing method and iron ore technology, applied in the field of iron ore crushing, can solve the problems such as the inability to minimize the grinding workload, the inability to return coarse-grained minerals, and the low material content, and to improve the sorting index. , The effect of reducing the Bond work index and reducing the energy consumption of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

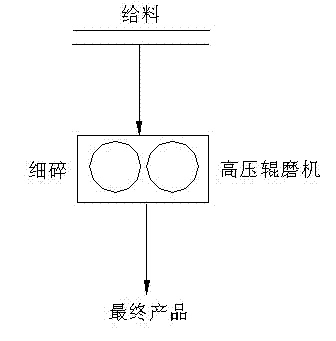

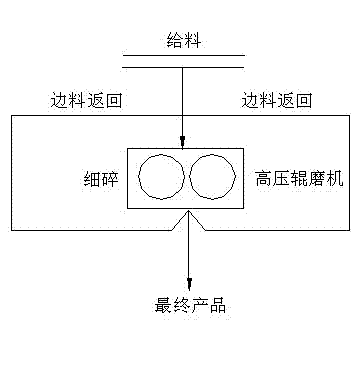

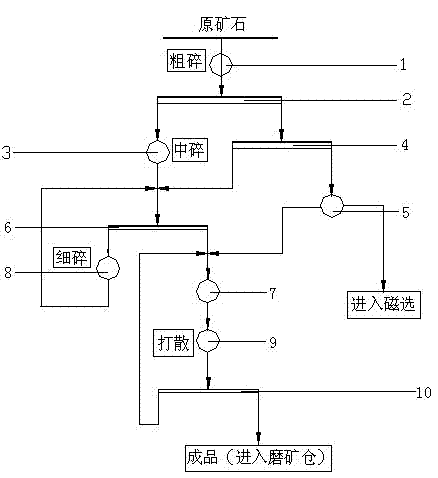

[0018] attached figure 1 Process Flow Diagram for Open Circuit Application of High Pressure Roller Mill; Attached figure 2 Process flow chart for semi-open circuit application of high pressure roller mill; attached image 3 It is a process flow diagram of the present invention; as shown in the figure (the + sign in the figure indicates that it is greater than, and the - sign indicates that it is less than, for example: +50mm indicates that the particle size is greater than 50mm): the iron ore crushing method described in this embodiment includes the following Steps: primary crushing, ore washing and high-pressure roller mill; the primary crushing steps are: the iron ore with a particle size of less than 1000mm is coarsely crushed by a jaw crusher 1 (1200×1500) (the discharge particle size is -250mm) , feed the obtained material into the fixed bar sieve 2 for screening, the distance between the fixed bar sieve is 50mm, and then the sieved material (particle size greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com