Aqueous hand-feeling coating and preparation method and use

A water-based, hand-feeling technology, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor adhesion, poor wear resistance, low hardness, etc., to improve hardness and wear resistance, Dense film and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] As a general inventive concept, the present invention also provides the preparation method of above-mentioned waterborne feel paint, comprises the following steps:

[0044] (1) Put the polyester-modified water-based elastic resin into the container, then put into the substrate wetting agent, dispersant, elastic powder, matting powder, some additives and water to mix, fully stir and disperse to obtain a mixed solution;

[0045] (2) Stirring the mixed solution in step (1) while adding polyester resin, remaining additives and water, stirring, filtering and dispersing to obtain a coating component;

[0046] (3) The coating component and the curing component are divided into packages to obtain a water-based touch coating.

[0047] The preparation method of the above-mentioned water-based touch paint has a simple preparation process. First, the modified water-based elastic resin is mixed with a substrate wetting agent, a dispersant, elastic powder, a matting powder, some additi...

Embodiment 1

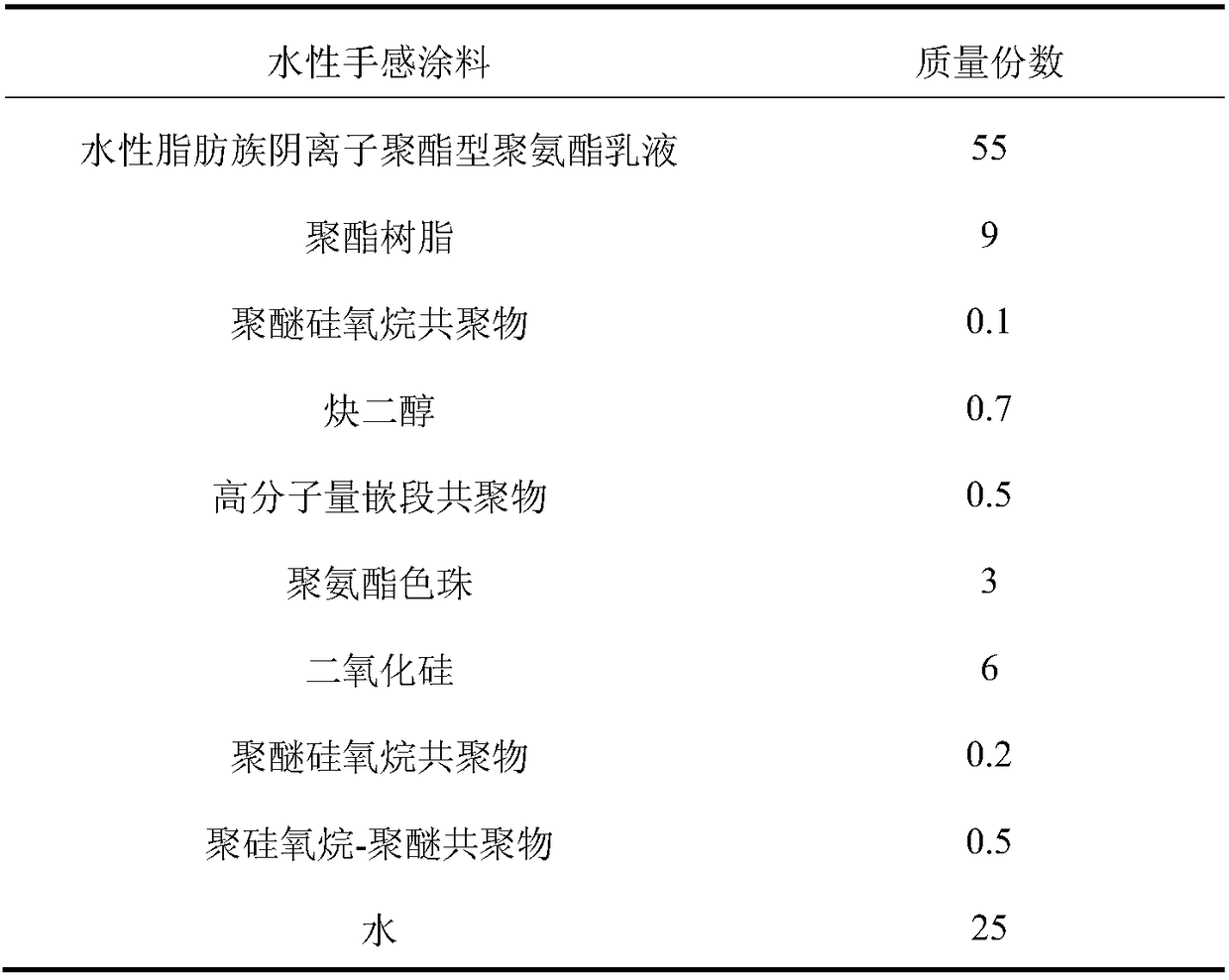

[0053] The parts by mass of the water-based feel paint in Example 1 are listed in Table 1.

[0054] Table 1 The composition of each component of the water-based feel paint

[0055]

[0056] The preparation method of above-mentioned waterborne feel paint is as follows:

[0057] (1) Mix polyester-modified water-based elastic resin, polyether siloxane copolymer, acetylene glycol, high molecular weight block copolymer, polyurethane color beads, silica, part of polysiloxane copolymer and water , disperse at 1500r / min for 20min to a particle size of 15μm to obtain a mixed solution;

[0058] (2) Add polyester resin, polysiloxane-polyether copolymer, remaining polysiloxane copolymer and water to the mixed solution in step (1), stir at 1000r / min for 15min, and filter with 200 mesh to obtain a coating composition point.

[0059] (3) 80% by weight of the isocyanate curing agent in the curing component and 20% by weight of the diluent are mixed, filtered with 300 mesh, and the curin...

Embodiment 2

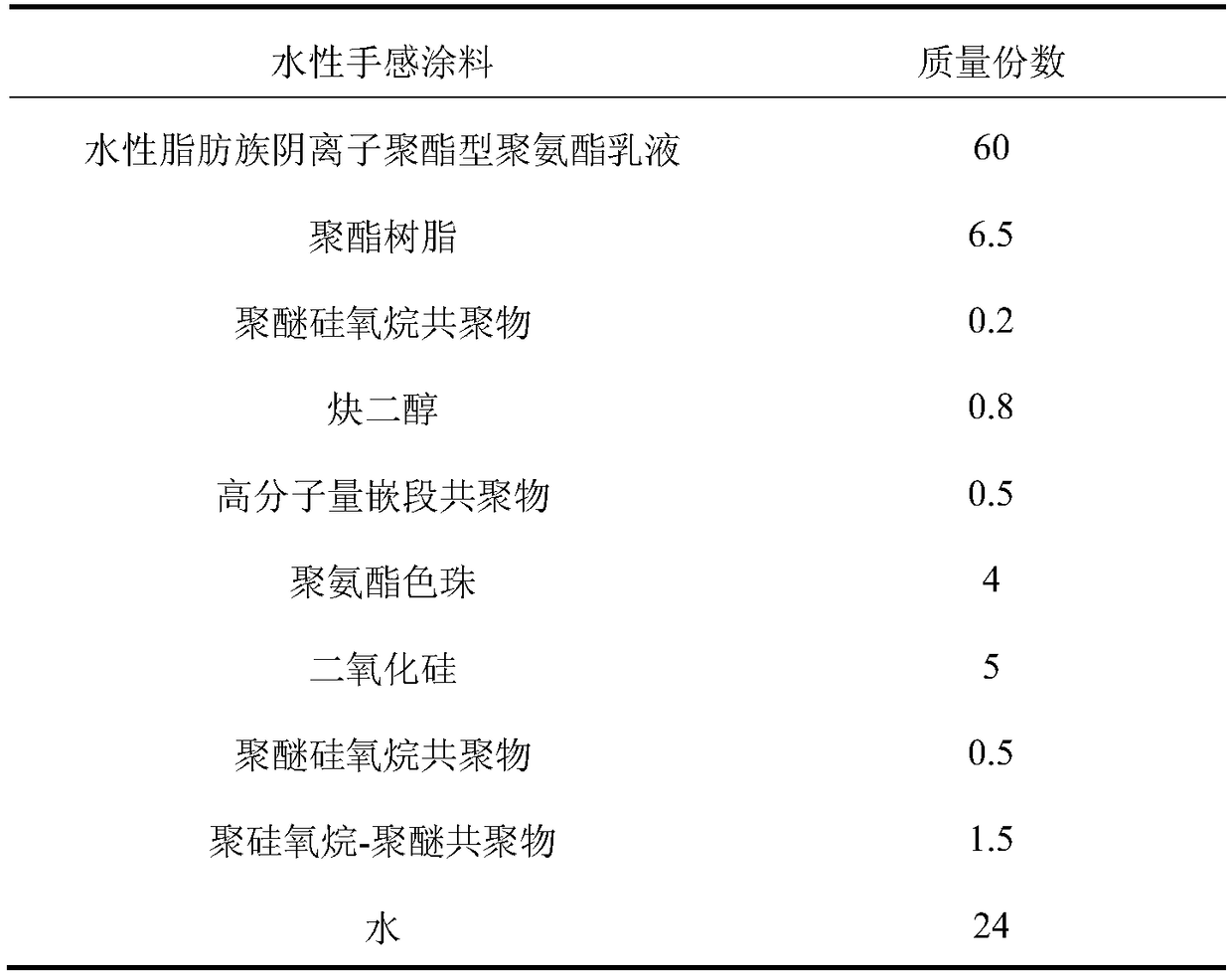

[0062] The parts by mass of the water-based feel paint in Example 2 are listed in Table 2.

[0063] Table 2 The composition of each component of the water-based feel paint

[0064]

[0065] The method for preparing the water-based feel paint in this embodiment is the same as that in Embodiment 1.

[0066] Add an appropriate amount of water to the above-mentioned water-based touch paint, spray it on the surface of the ABS+PC material, control the dry film thickness at 40 μm, bake at 90°C for 30 minutes, and test at 90°C for 8 hours. The test results refer to the table 4. The results show that the adhesion of the water-based touch paint is 5B, the hardness is H, and the hand feel is fine and smooth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com