Waterborne self-luminous elastic coating and its preparation method and application

An elastic coating, self-luminous technology, used in luminescent coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of no self-luminous performance, poor wear resistance, poor adhesion, etc., and achieve a fine and smooth hand feel. The effect of cool, good elasticity and good luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] According to another aspect of the present invention, also provide a kind of preparation method as above-mentioned waterborne self-luminous elastic paint, comprise the following steps:

[0035] (1), mixing the modified oily elastic resin, an emulsifier and water for emulsification to obtain an emulsion;

[0036] (2), add water-based polyurethane elastic resin to the emulsion in step (1) while stirring and mix, then add substrate wetting agent, dispersant, matting powder and some auxiliary agents to mix and disperse to obtain a mixed solution;

[0037] (3), adding water-based energy storage material, luminescent material and remaining additives to the mixed solution in step (2) while stirring, dispersing and filtering to obtain the coating component;

[0038] (4) Mix the coating components and the curing agent components to obtain the water-based self-luminous elastic coating.

[0039] The preparation method of the water-based self-luminous elastic coating of the presen...

Embodiment 1

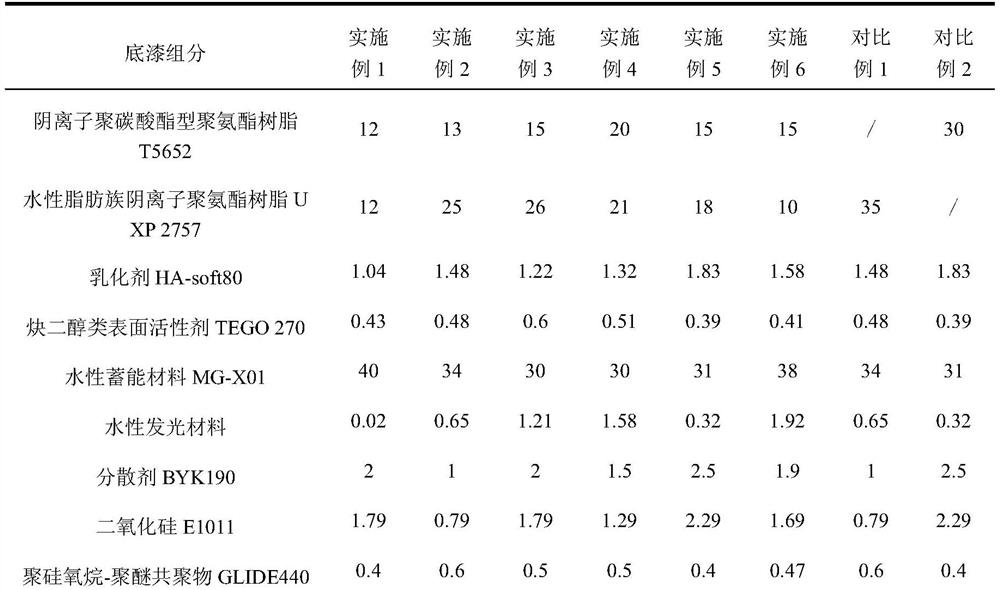

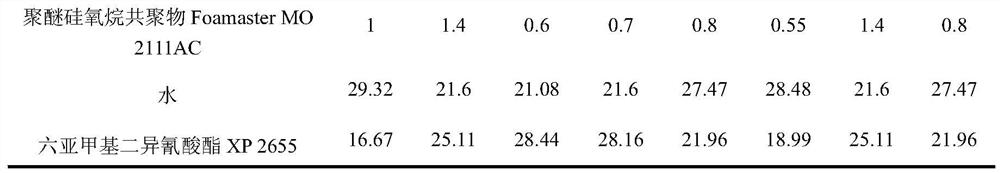

[0057] The parts by weight of the components of the water-based self-luminous elastic coating in Example 1 are shown in Table 1.

[0058] Table 1: The parts by weight of each component in the water-based self-luminous elastic coating of embodiment and the coating of comparative example

[0059]

[0060]

[0061] The preparation method of above-mentioned water-based self-luminous elastic paint, comprises the following steps:

[0062] (1), anionic polycarbonate polyurethane resin, emulsifier and water are mixed for emulsification, and the emulsification condition is 850r / min to disperse for 25min until full emulsification is completed to obtain an emulsion;

[0063] (2), add water-based aliphatic anionic polyurethane resin to the emulsion in step (1) while stirring, and then add acetylenic glycol surfactants, dispersants, silicon dioxide and part of polysiloxane-polyether Copolymer and polyether siloxane copolymer, dispersed, dispersed at 1300r / min for 23min to a fineness...

Embodiment 2

[0068] The parts by weight of the components of the water-based self-luminous elastic coating in Example 2 are shown in Table 1. The preparation method and application of the water-based self-luminous elastic coating are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com