Novel warmth retention textile material for lining

A textile material and lining technology, which is applied in the field of new thermal textile materials for lining, can solve the problems of uneven product thickness, single applicable product variety, difficulty in carrying, storage and transportation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

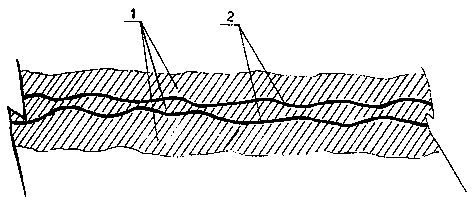

[0007] as attached figure 1 As shown, the present invention consists of a textile web 1 and a film 2. A plastic film 2 is laid between each layer of fiber webs 1, and the fiber web 1 and the film 2 are fixed to each other by needling, so that several layers of fiber webs and spacer films are combined into a whole. The film used is 60-100μ polyethylene film, which has the characteristics of good tensile strength, thin thickness, softness, not easy to harden in low temperature environment, and certain shrinkage rate after acupuncture. The production equipment used is a carding machine produced by ordinary wool spinning and a needle punch machine produced by non-woven fabrics. Feed the wool fiber into the carding machine and comb it into a net, lay the net, spread the plastic film on the fiber net transfer curtain, make the fiber net and the film compound for the first time, and then pass through the needle punching machine. After the needle punching, some wool fibers are worn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com