Patents

Literature

107results about How to "Resistance to friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

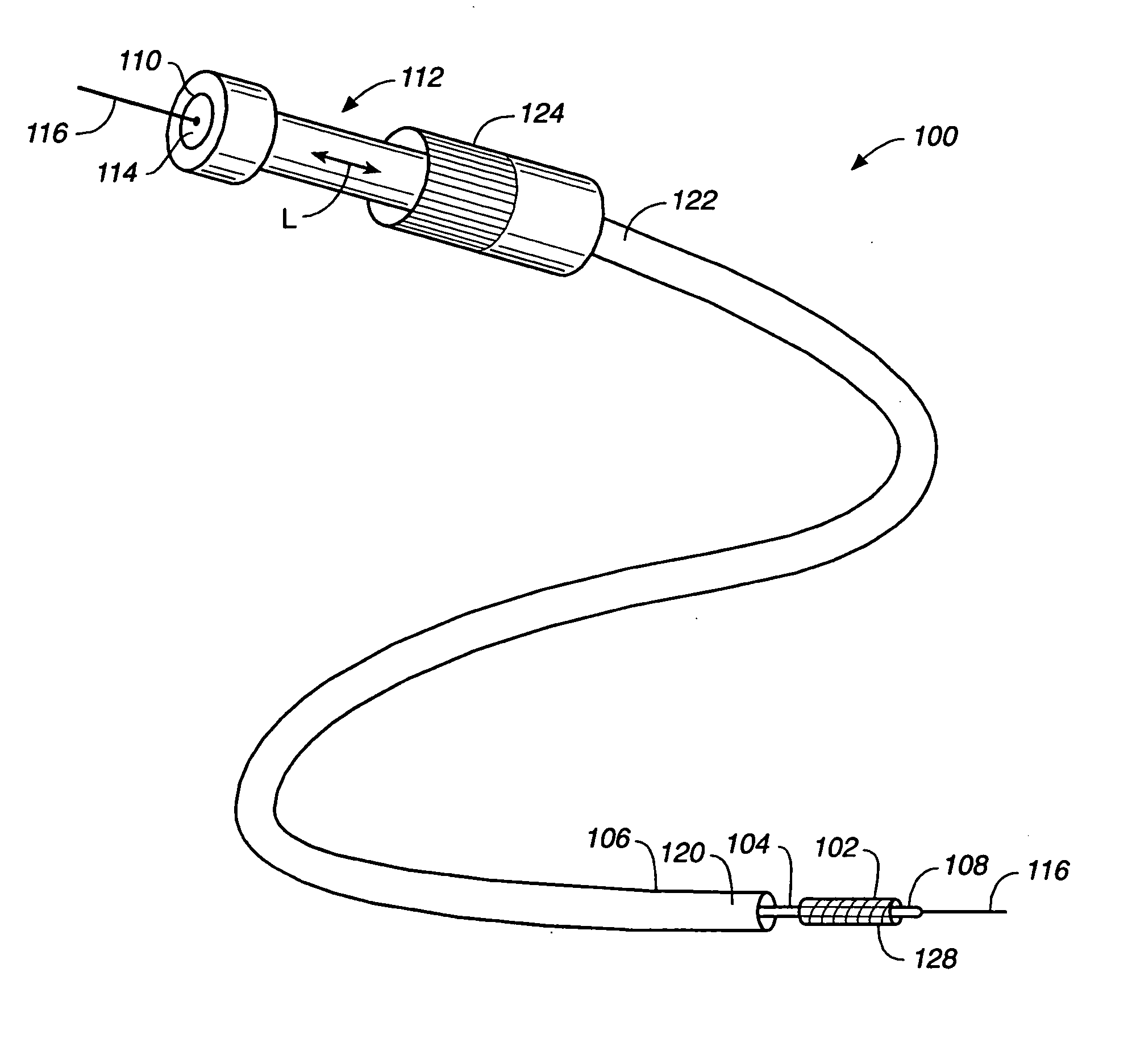

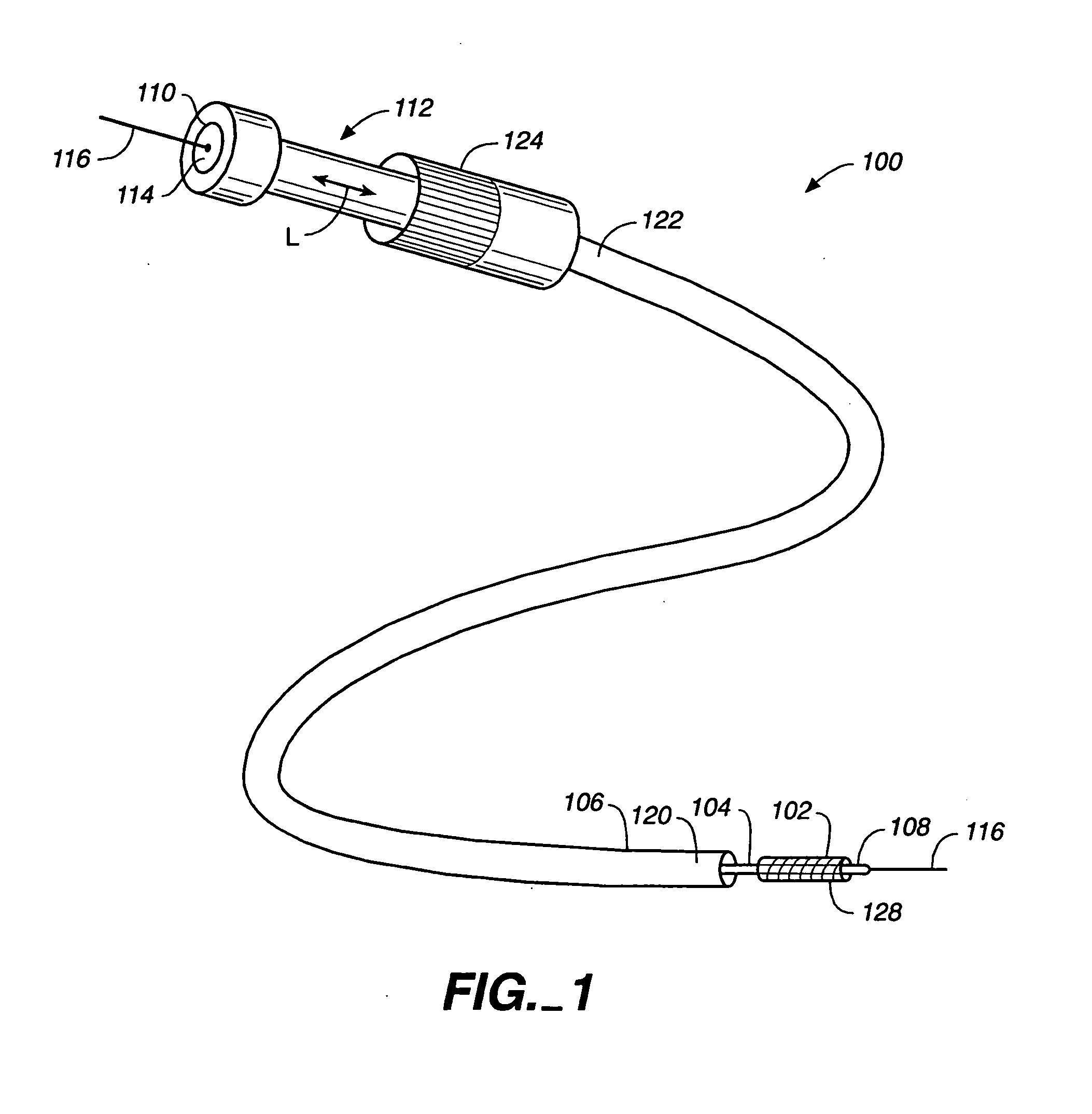

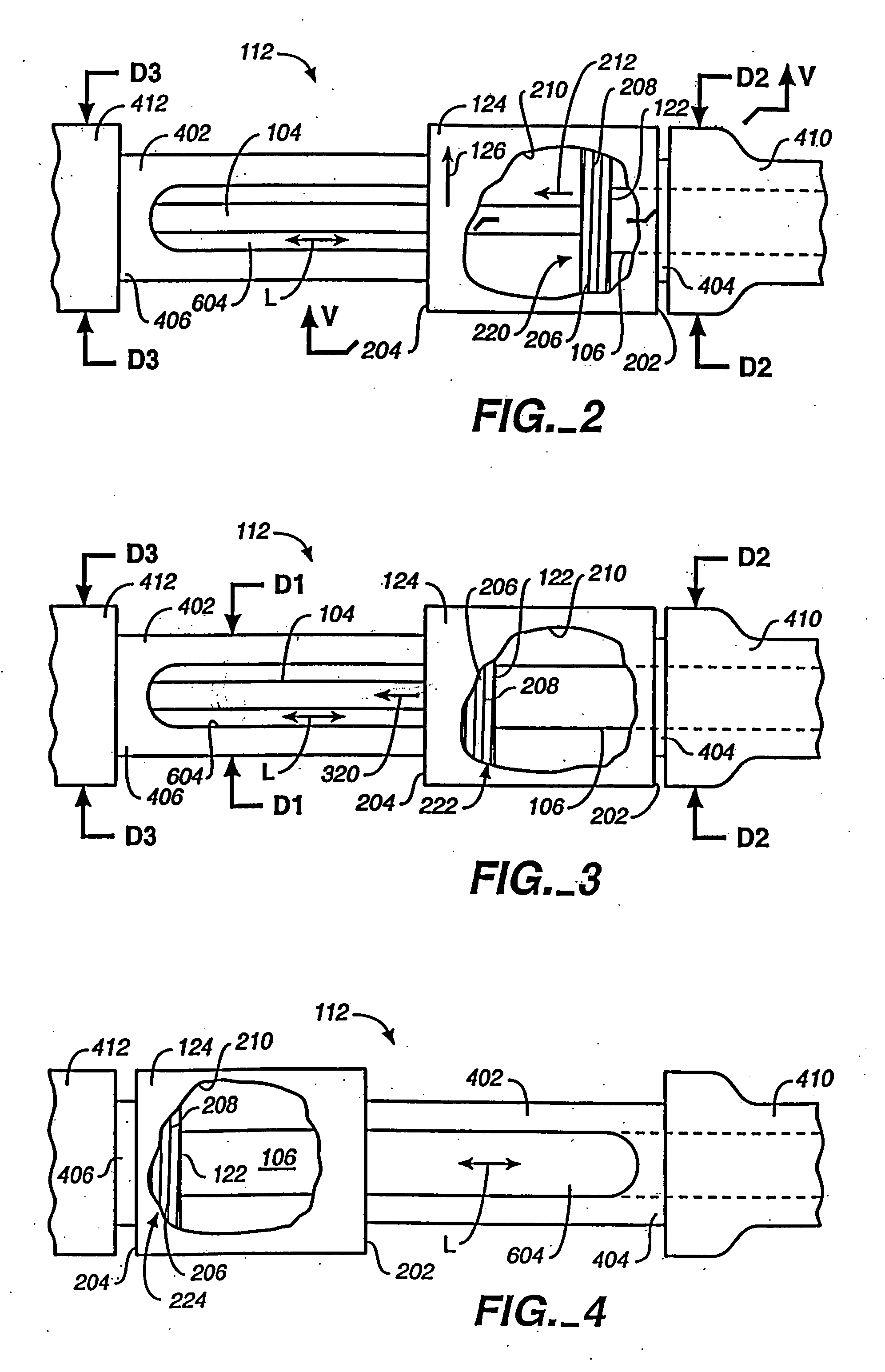

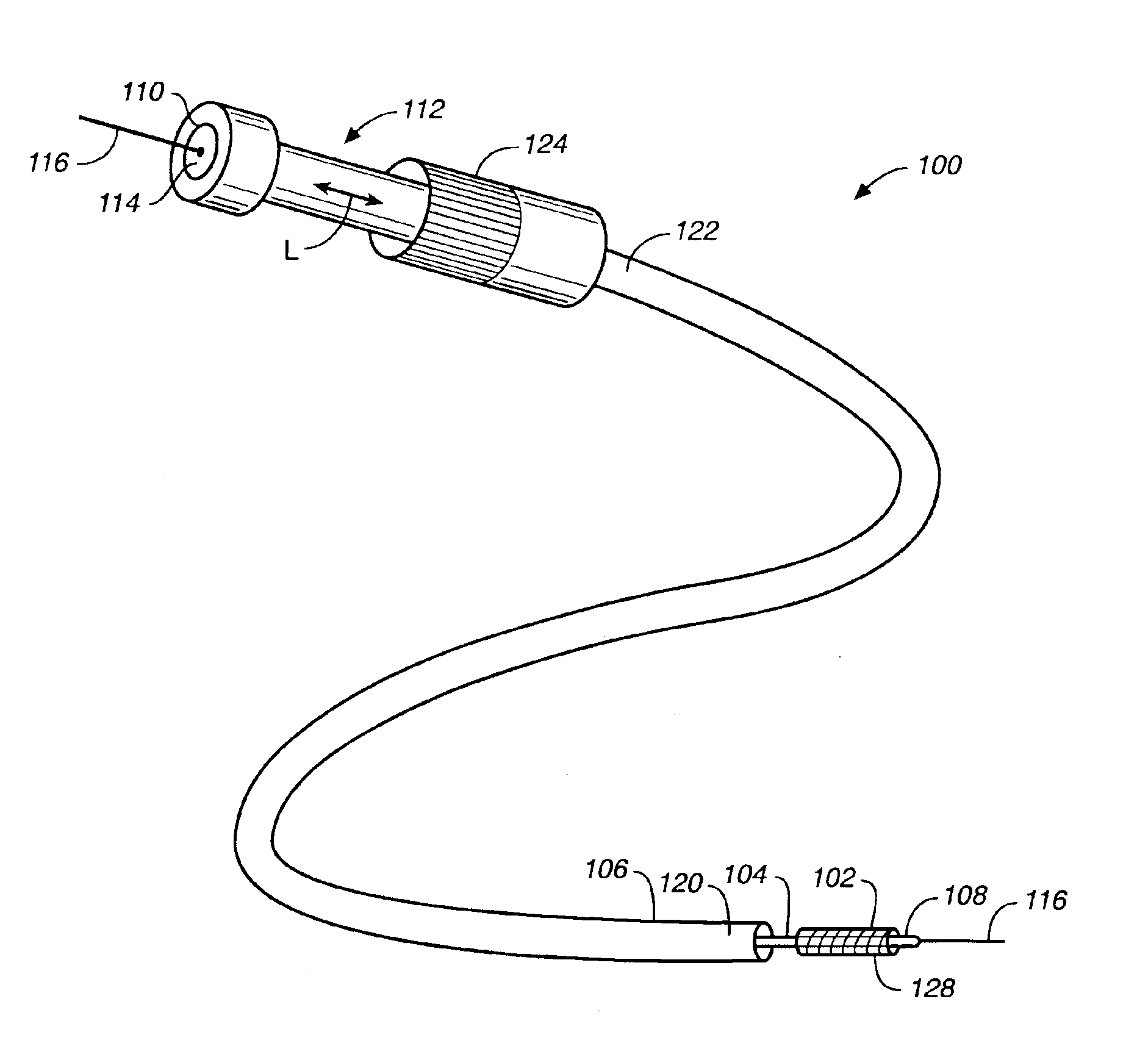

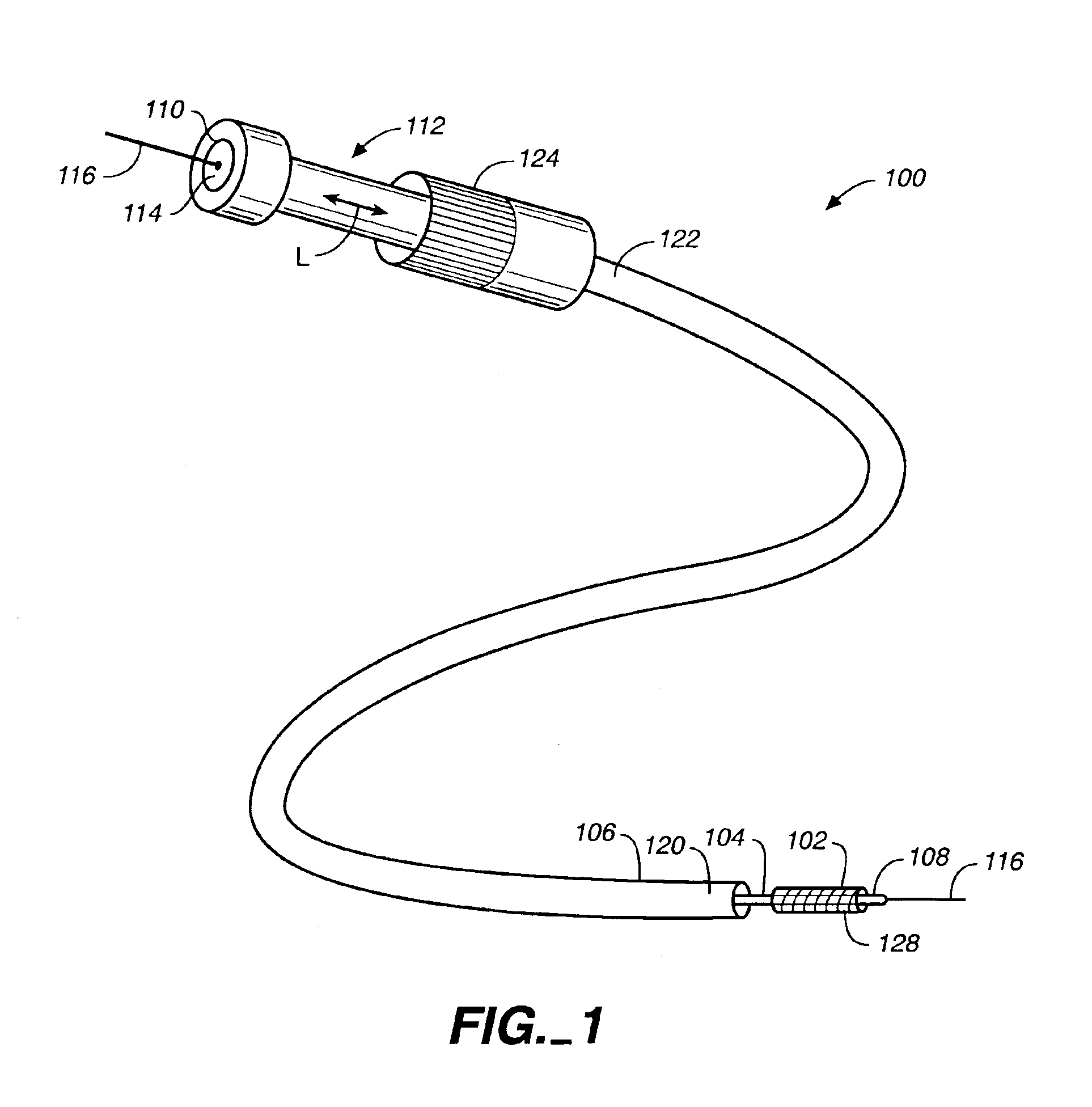

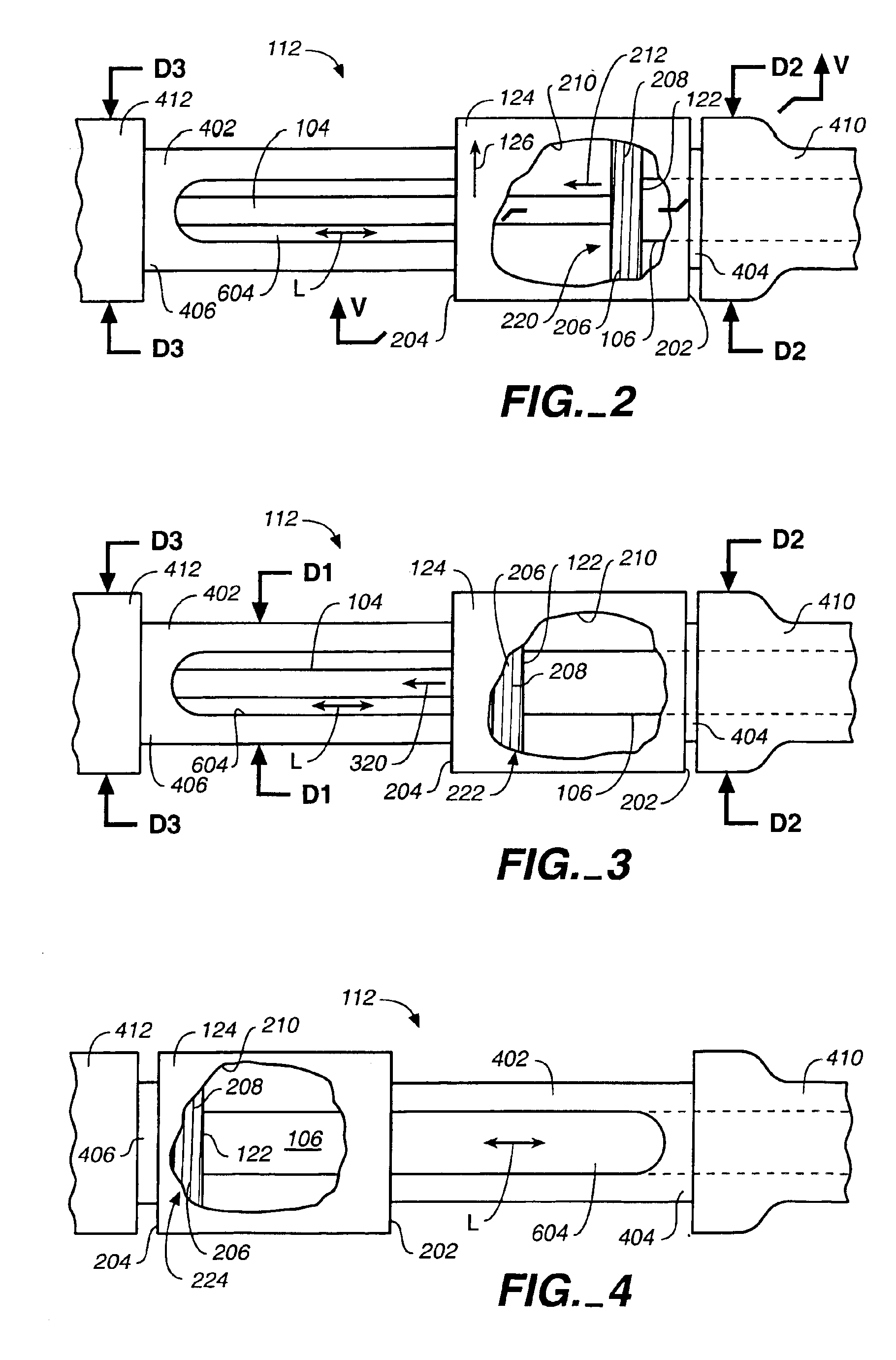

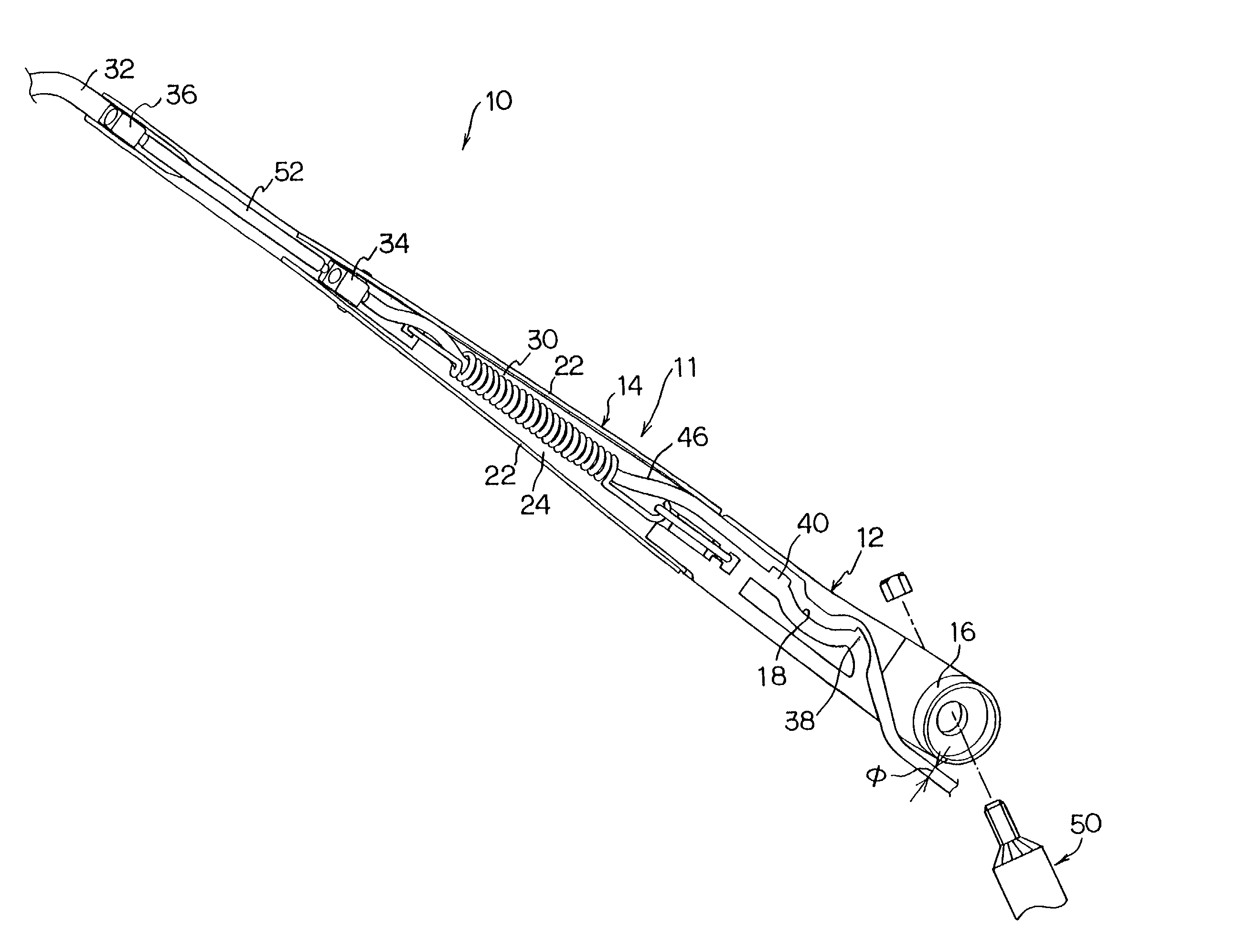

Integrated mechanical handle with quick slide mechanism

A method of deploying a prosthesis includes engaging a hub assembly of a handle to a threaded outer surface of a slide shaft of the handle; rotating the hub assembly to cause axial translation of the hub assembly and a sheath coupled to the hub assembly to initiate deployment of the prosthesis; disengaging the hub assembly from the threaded outer surface by pivoting a thread tooth of the hub assembly out of threaded engagement with the threaded outer surface; and sliding the hub assembly on the slide shaft to further retract the sheath and complete deployment of the prosthesis.

Owner:MEDTRONIC VASCULAR INC

Integrated mechanical handle with quick slide mechanism

A method of deploying a prosthesis includes restraining the prosthesis within a distal end of a sheath. A slide ring of a handle is rotated to initiate retraction of the sheath. In this manner, the prosthesis is initially very gradually released. The slide ring is then slid to complete retraction of the sheath and to deploy the prosthesis. In this manner, the sheath is easily and quickly retracted thus rapidly completing deployment of the prosthesis. Rapid deployment of the prosthesis facilitates faster procedure times, thus minimizing the period of time during which blood flow is occluded.

Owner:MEDTRONIC VASCULAR INC

Leather-Like Sheet And Method Of Manufacturing The Same

InactiveUS20090274862A1Dense feelingElegant surface appearanceFibre treatmentSynthetic resin layered productsFiberVitrification

A leather-like sheet composed of a microfine-fiber entangled body made of bundles of microfine fibers and an elastic polymer impregnated therein. The bundles of microfine fibers are composed of microfine monofibers having an average cross-sectional area of 0.1 to 30 μm2 and have an average cross-sectional area of 40 to 400 μm2. The bundles of microfine fibers exist in a density of 600 to 4000 / mm2 on a cross section taken along the thickness direction of the microfine-fiber entangled body. The elastic polymer contains 30 to 100% by mass of a polymer of ethylenically unsaturated monomer. The polymer of ethylenically unsaturated monomer is composed of a soft component having a glass transition temperature (Tg) of less than −5° C., a crosslinkable component, and optionally a hard component having a glass transition temperature (Tg) of higher than 50° C. and another component. The polymer of ethylenically unsaturated monomer is bonded to the microfine fibers in the bundles of microfine fibers. The leather-like sheet has a flexibility and hand such as dense feeling each resembling natural leathers and a high quality appearance. The leather-like sheet is highly stable in quality such as fastness and surface abrasion resistance and excellent in practical performance.

Owner:KURARAY CO LTD

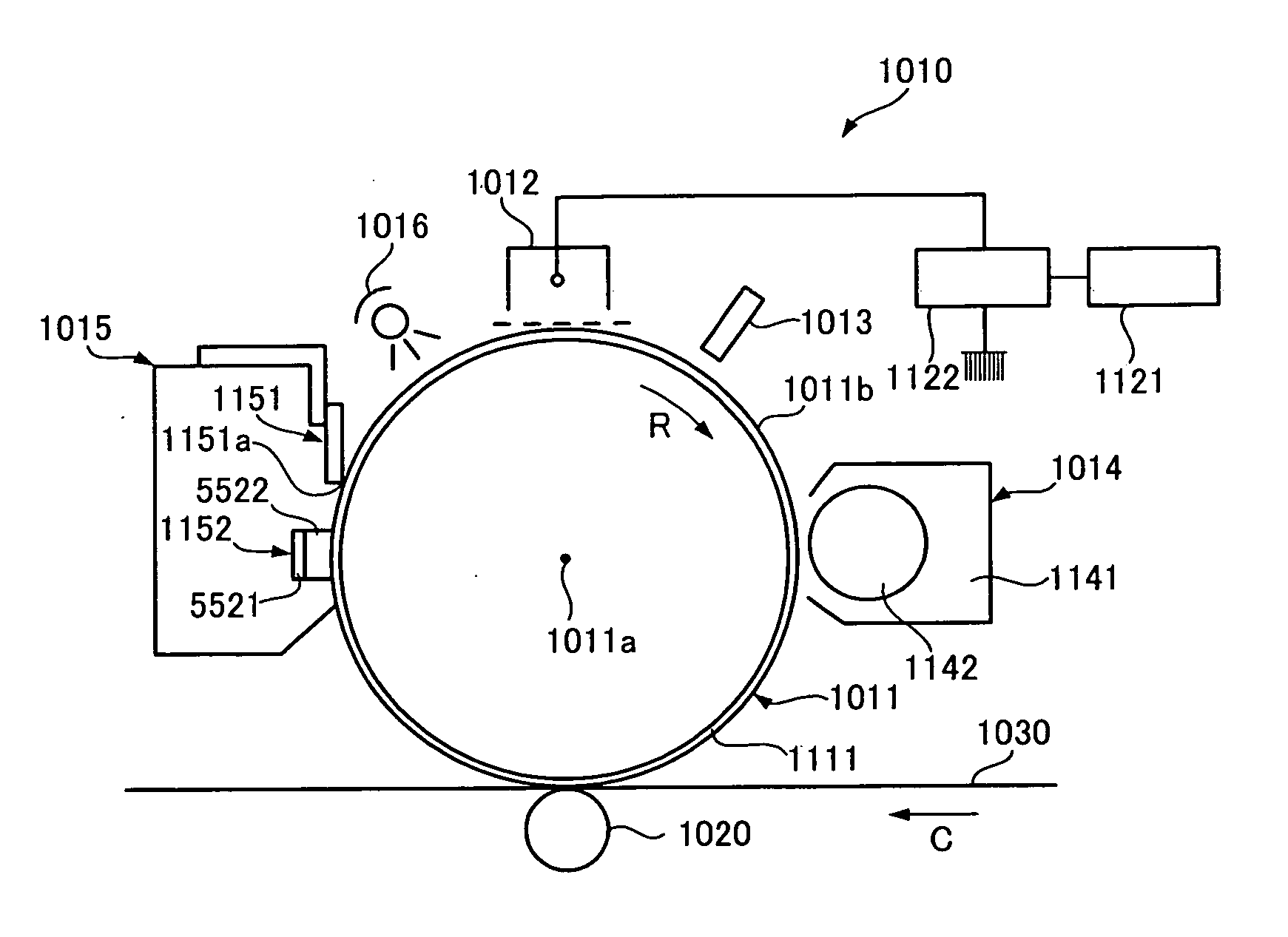

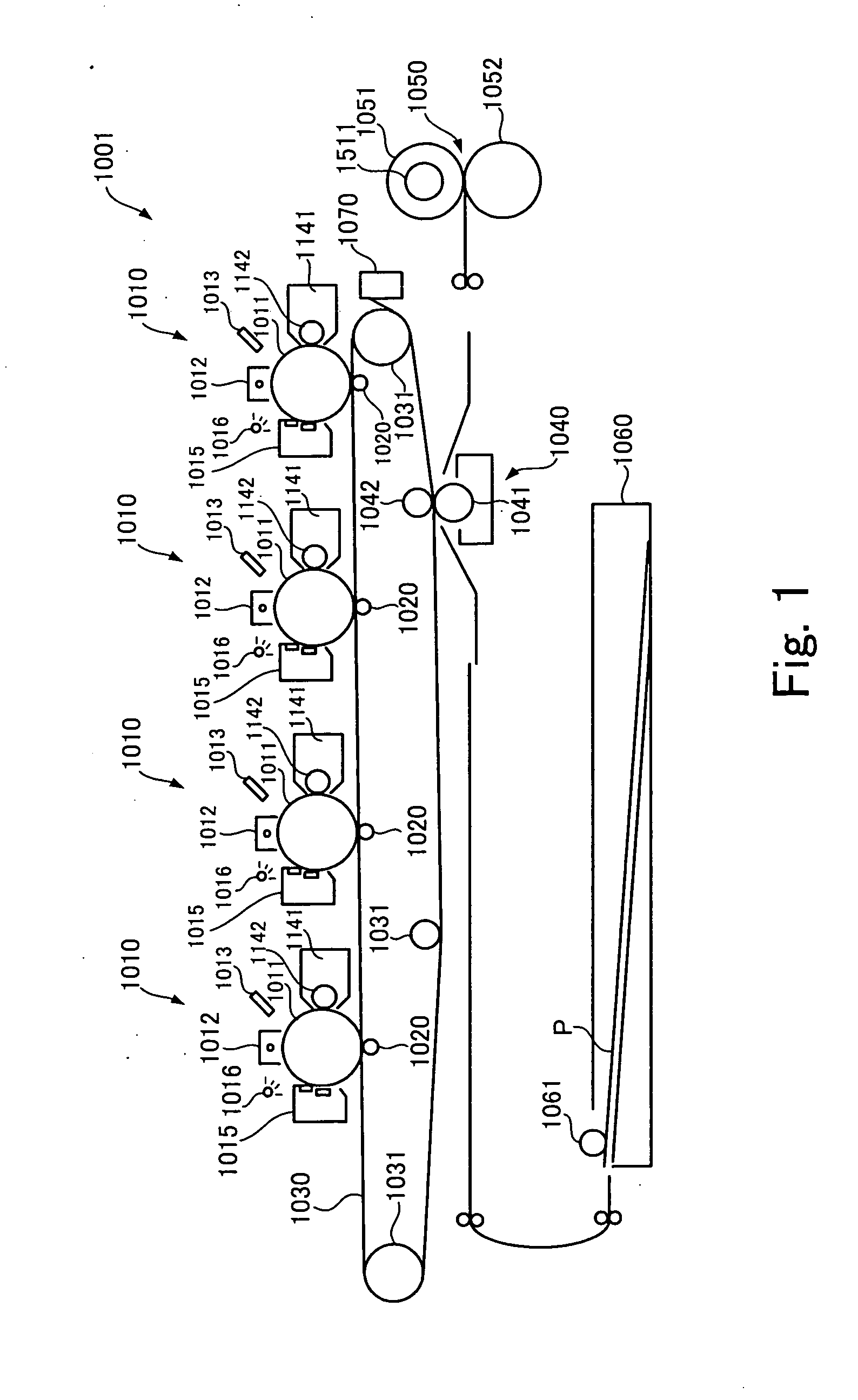

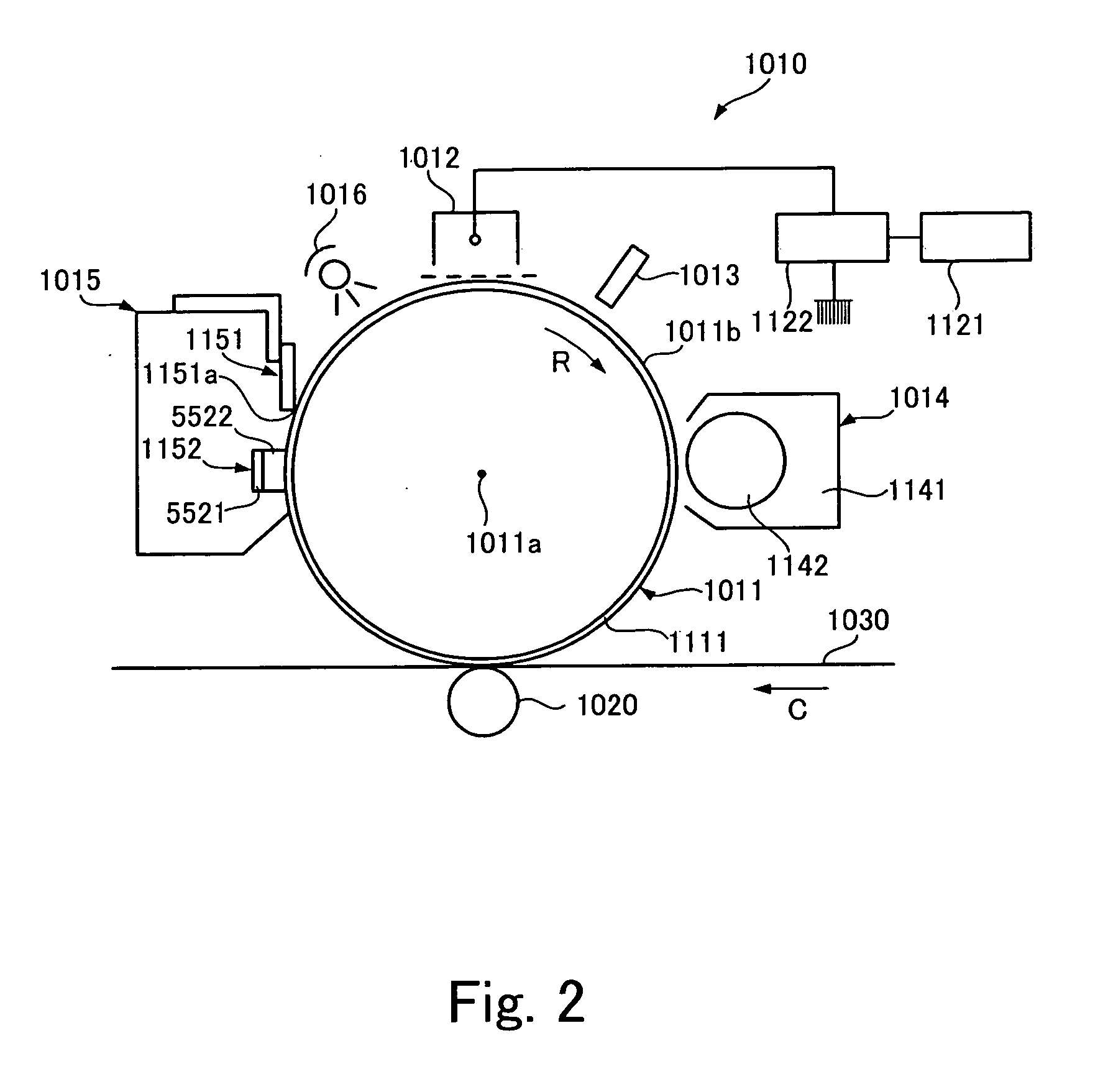

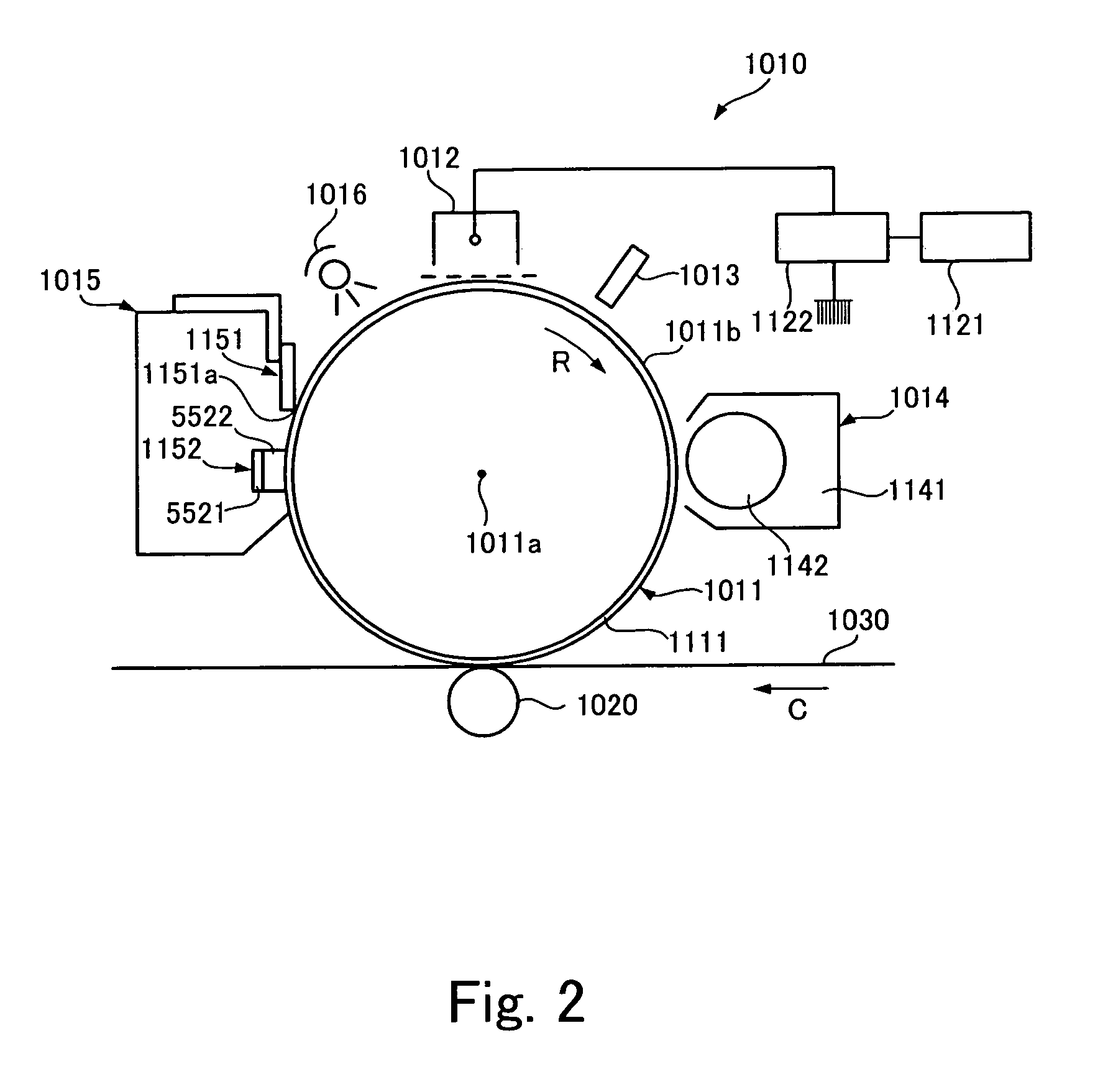

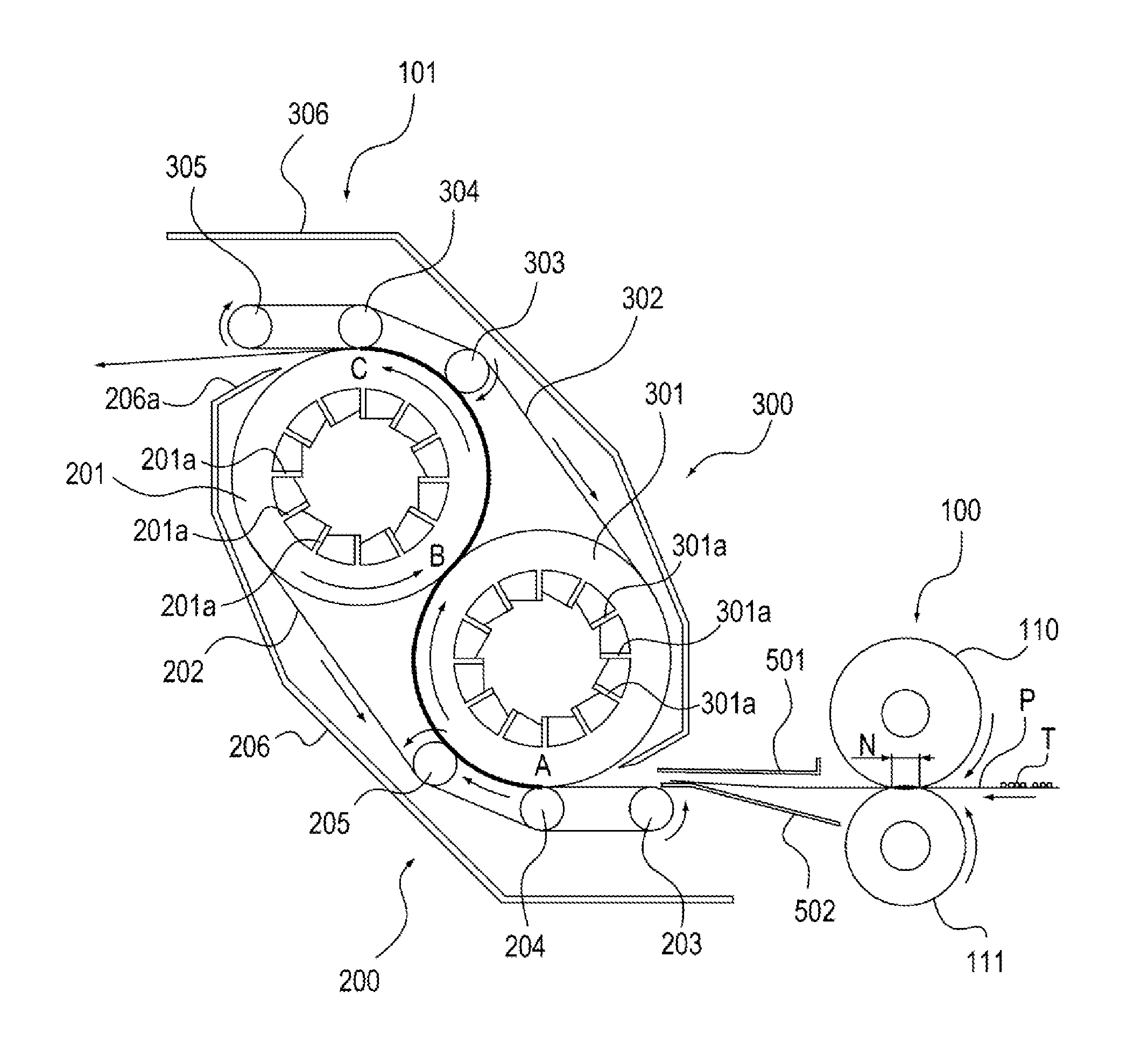

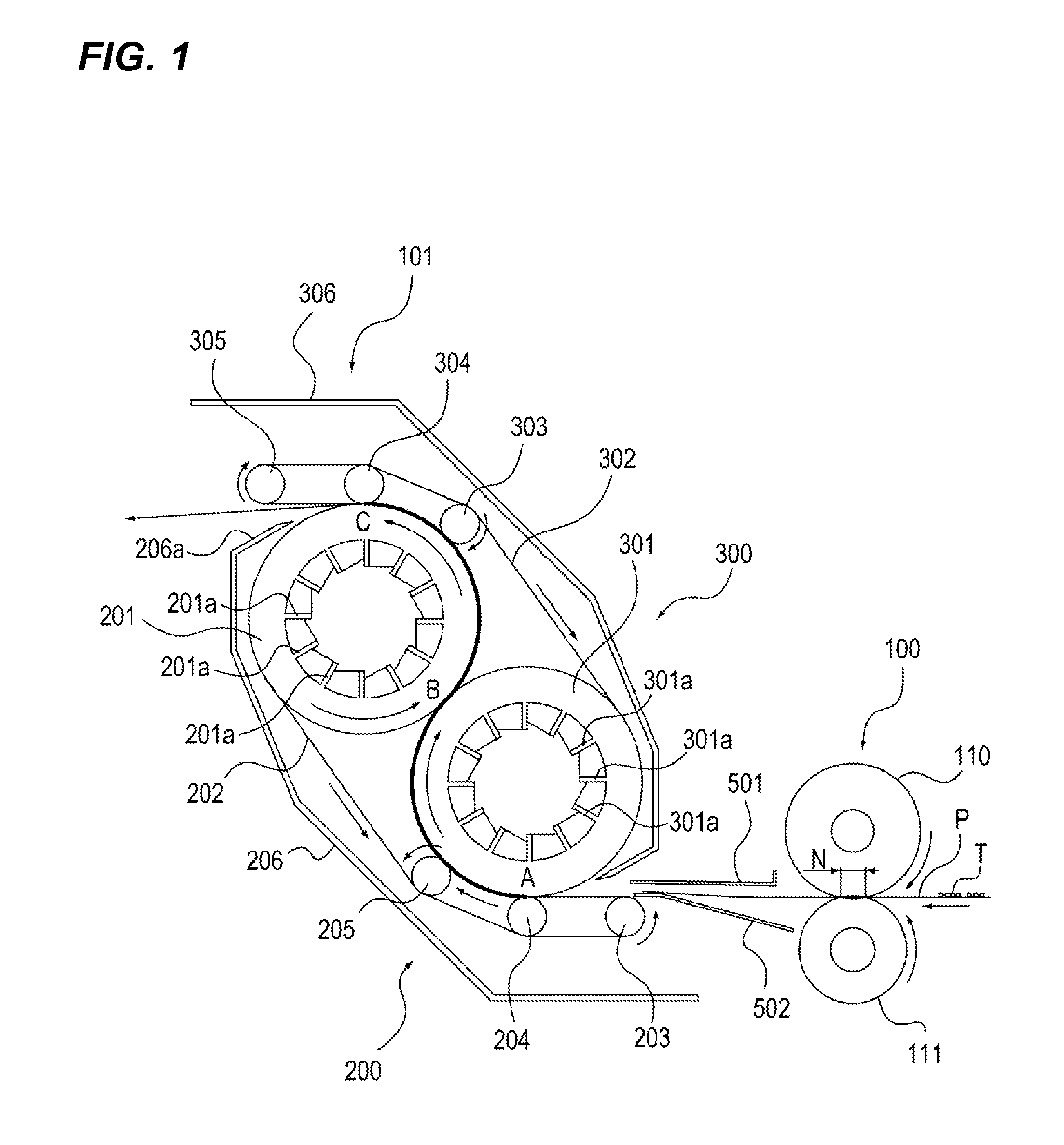

Cleaning unit and image forming apparatus

This invention relates to a cleaning unit comprising: a cleaning blade that keeps a front end of rubber material in contact with the surface with a pressure so as to scrape residual toner left on the surface of the photoreceptor and a fiber body having multiple fibers in contact with the surface of the photoreceptor in the upstream in the cyclic moving direction of the surface of the photoreceptor with respect to the cleaning blade, wherein the cleaning blade satisfies conditions A≧−2.5×B+102 and 6.3≦B≦19.6, where A designates a contact angle (°) with pure water under 23° C., 55% RH and B designates 100% modulus (MPa) at 23° C.

Owner:FUJIFILM BUSINESS INNOVATION CORP

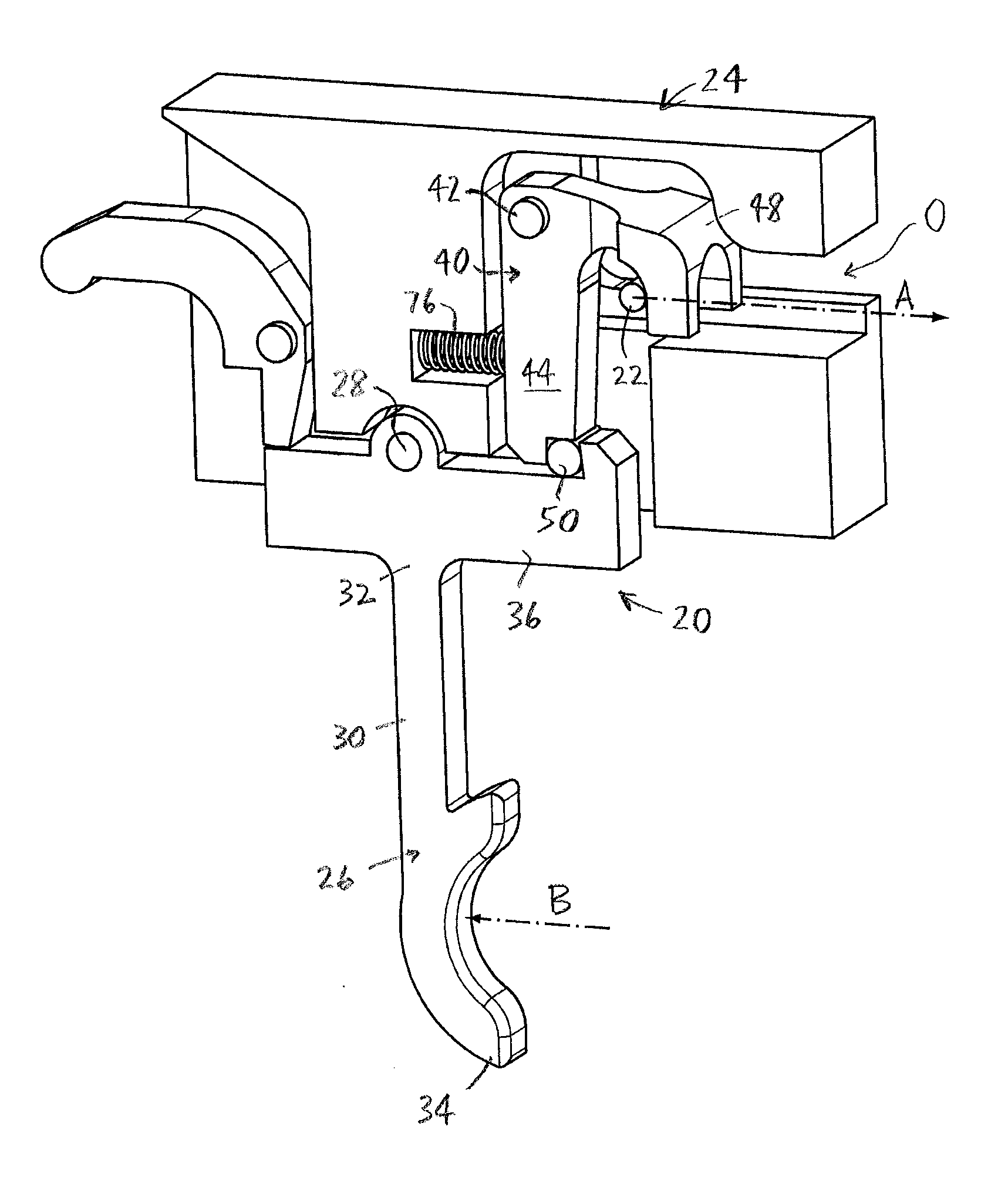

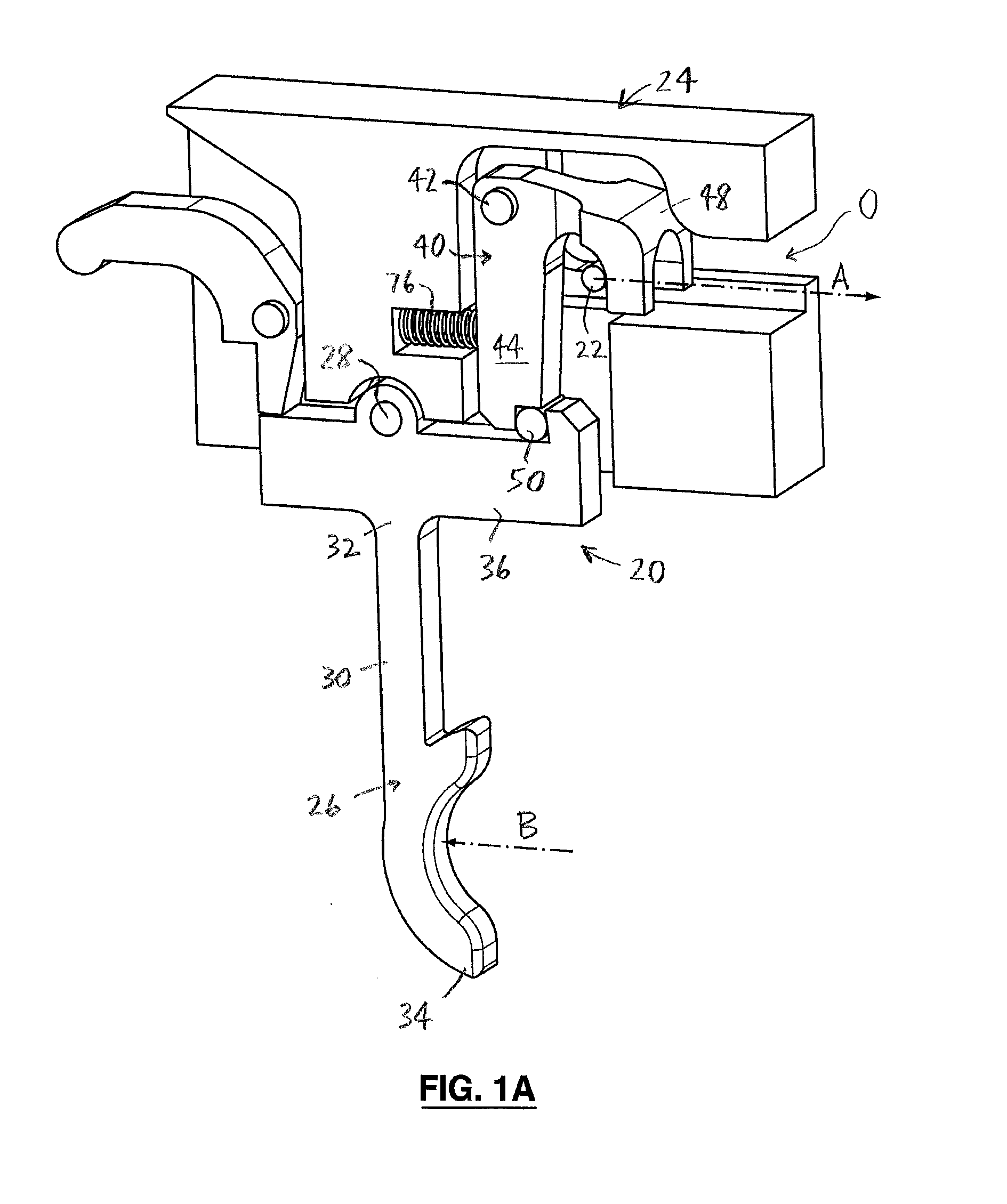

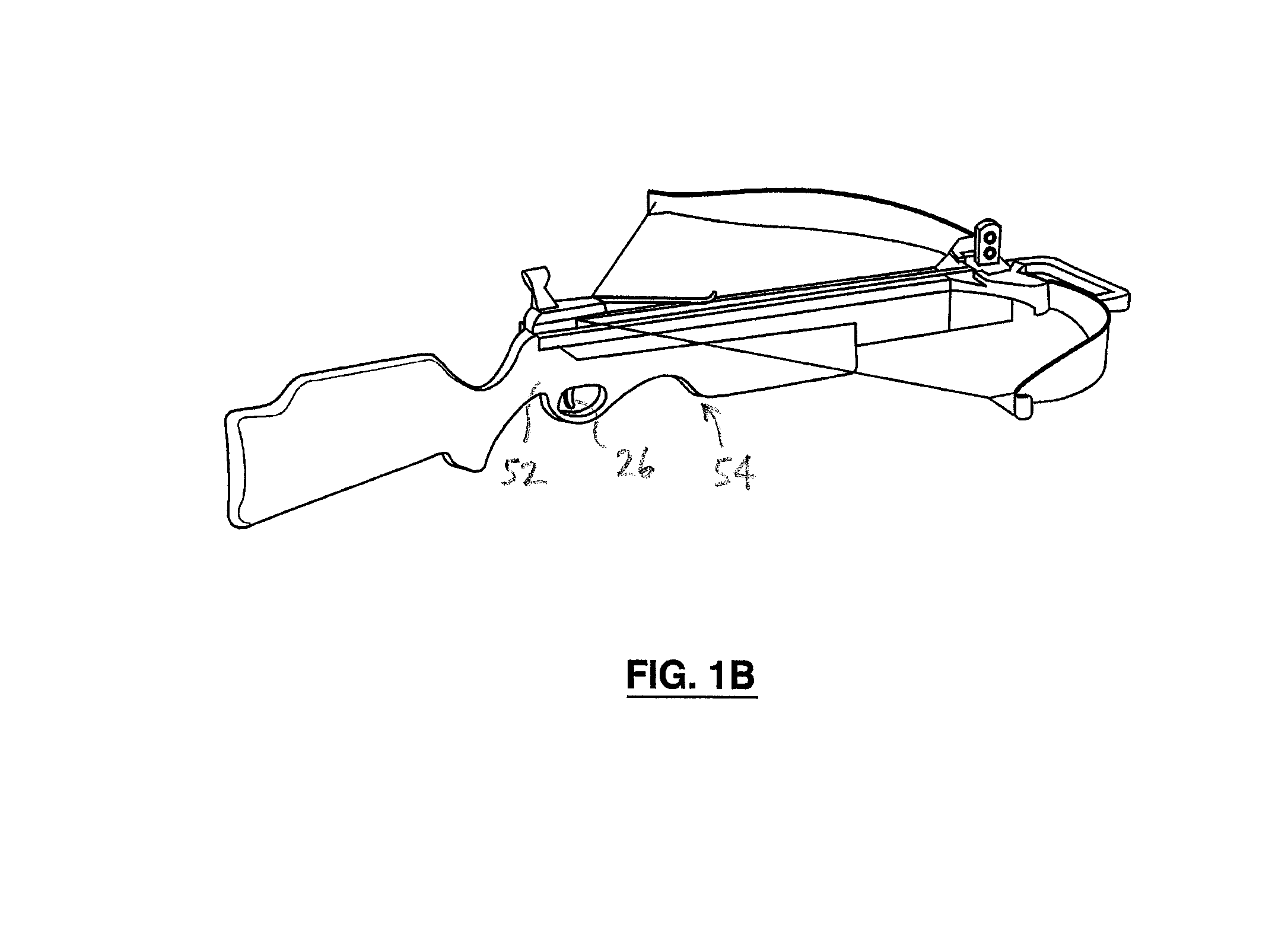

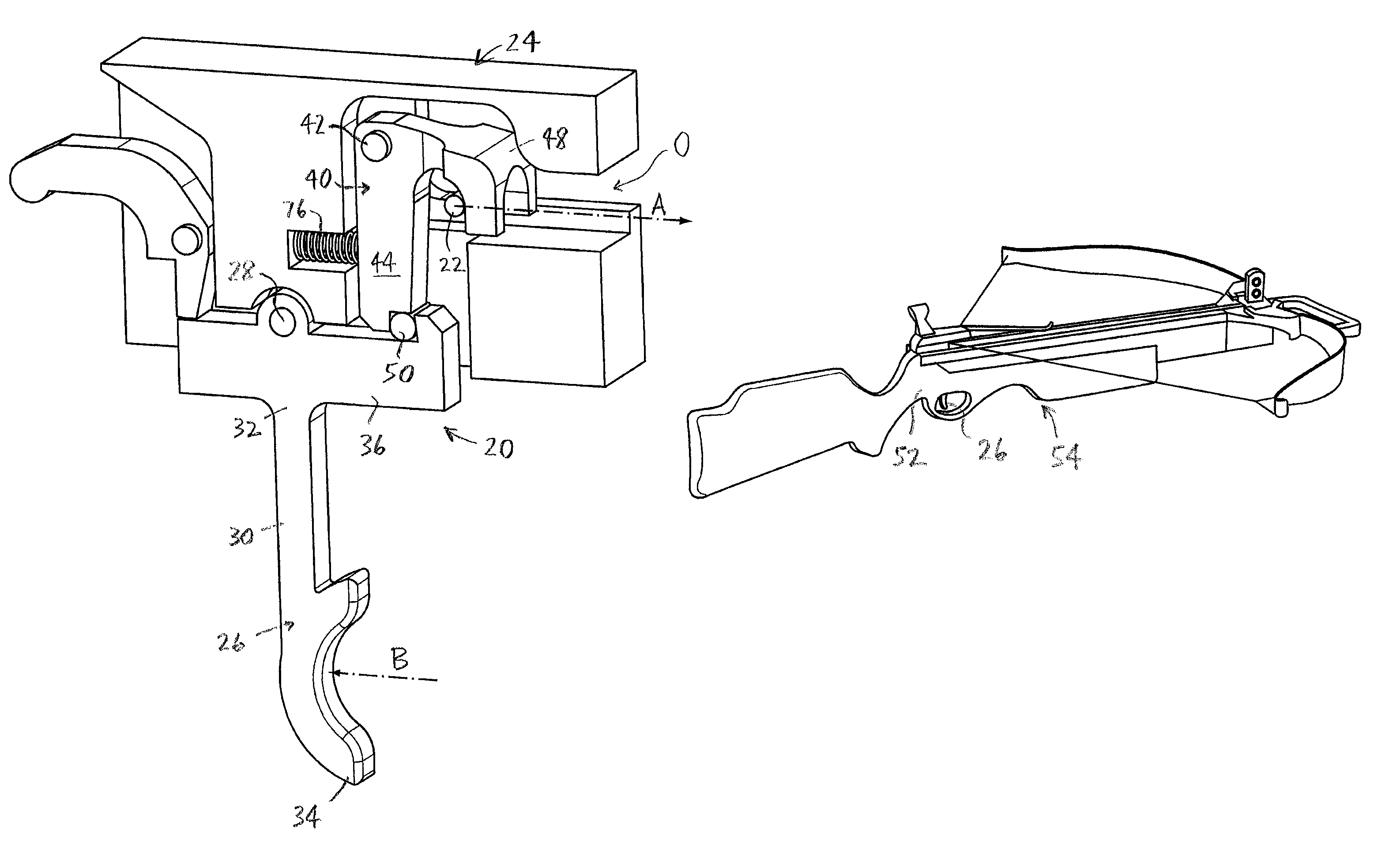

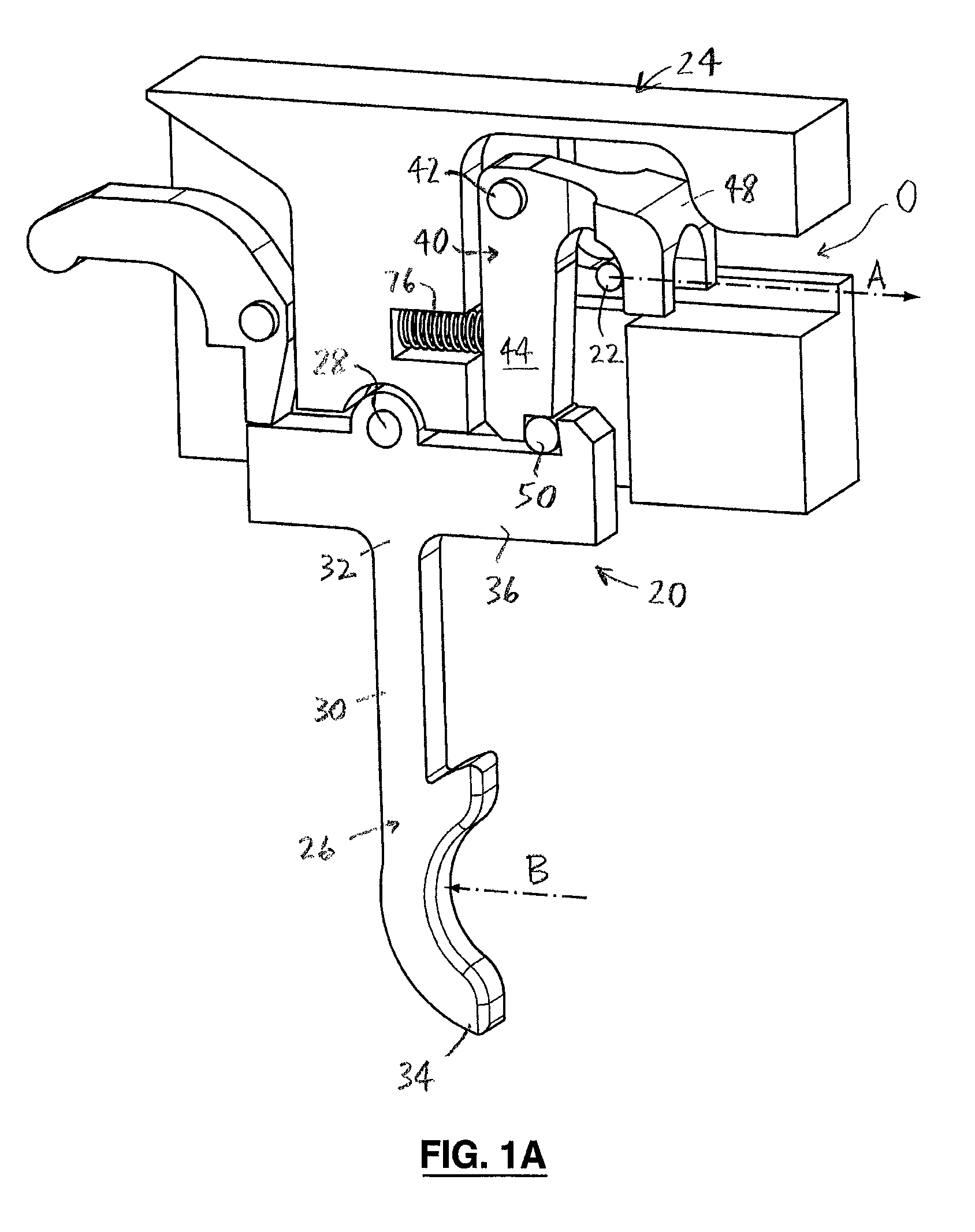

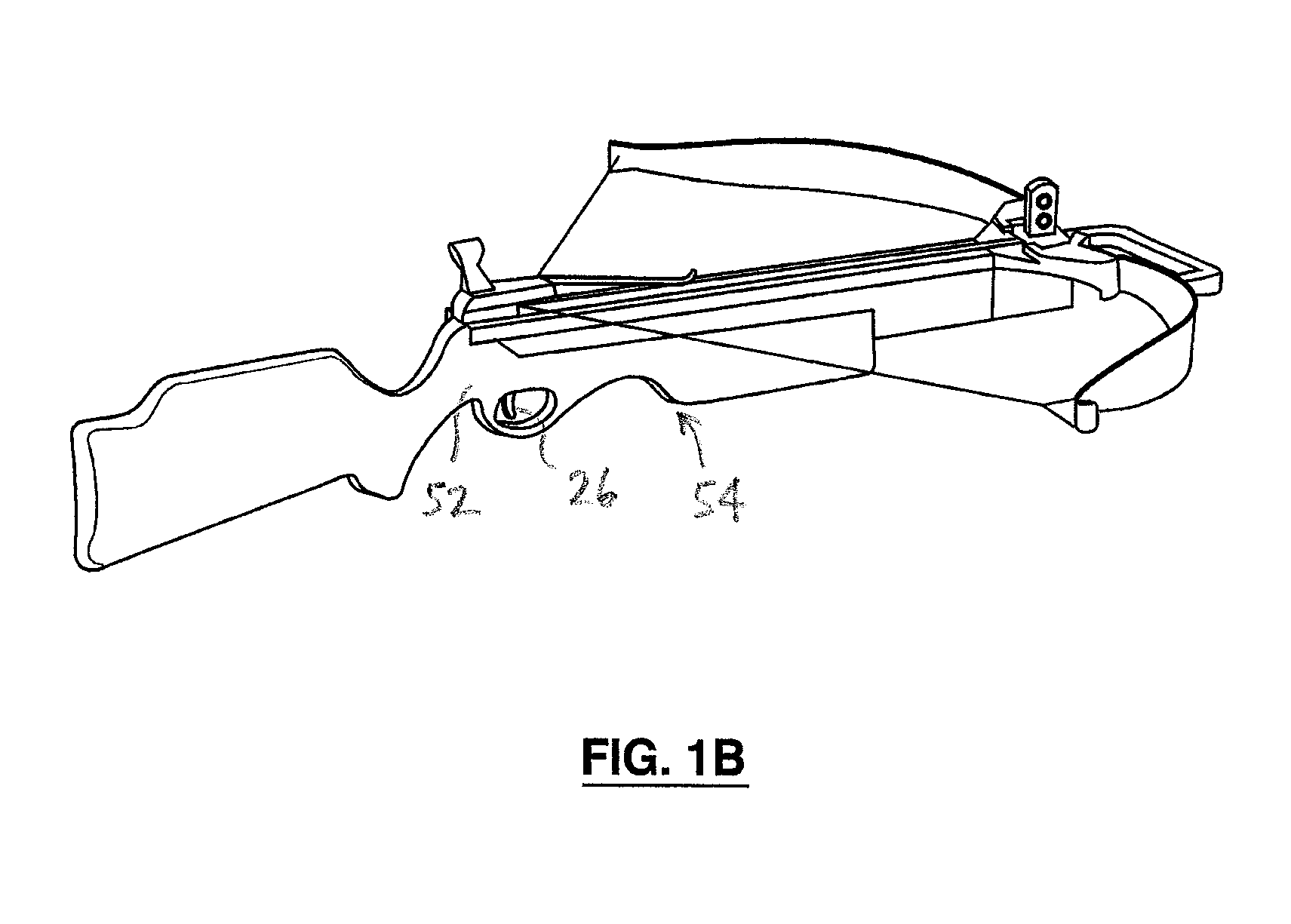

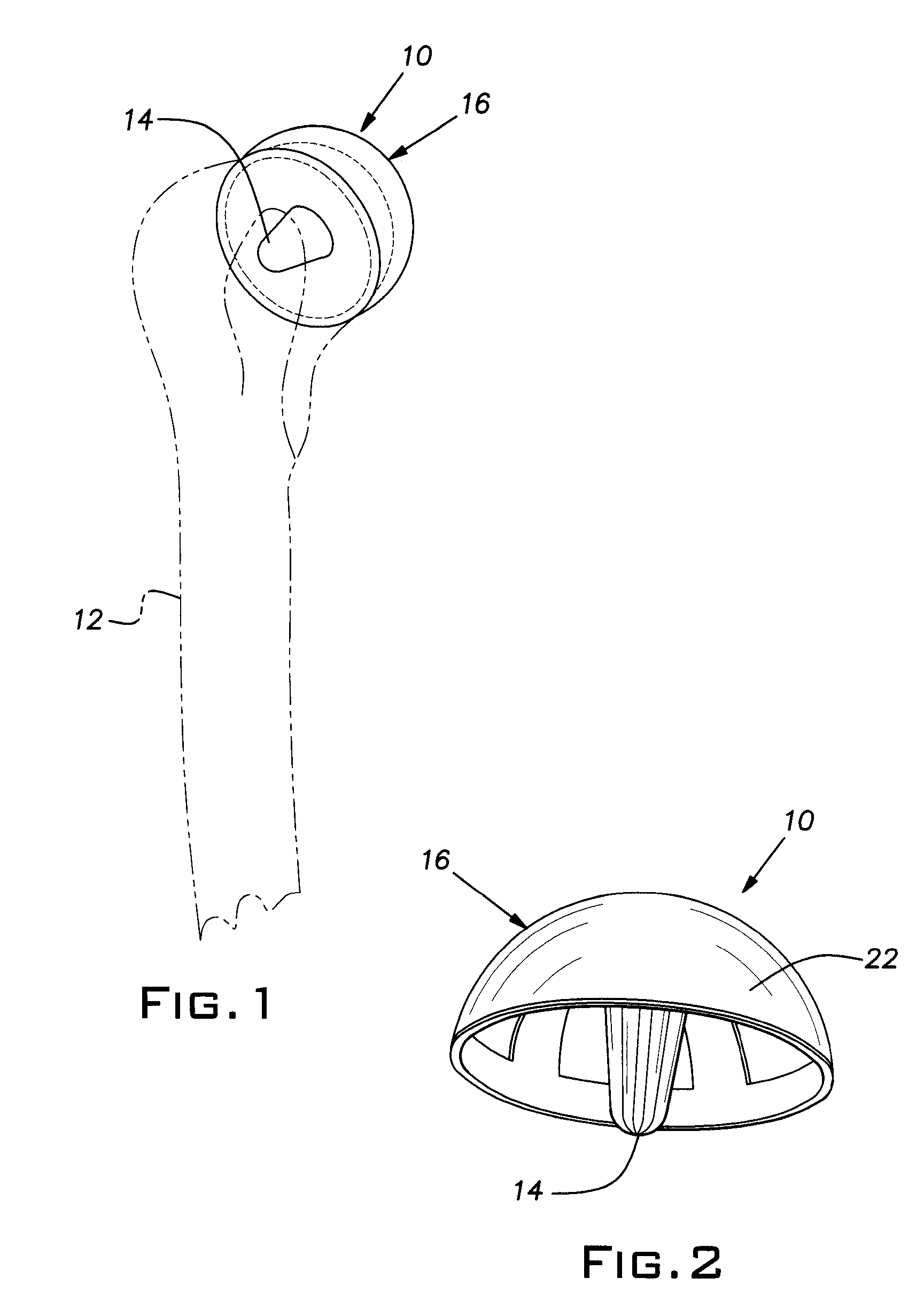

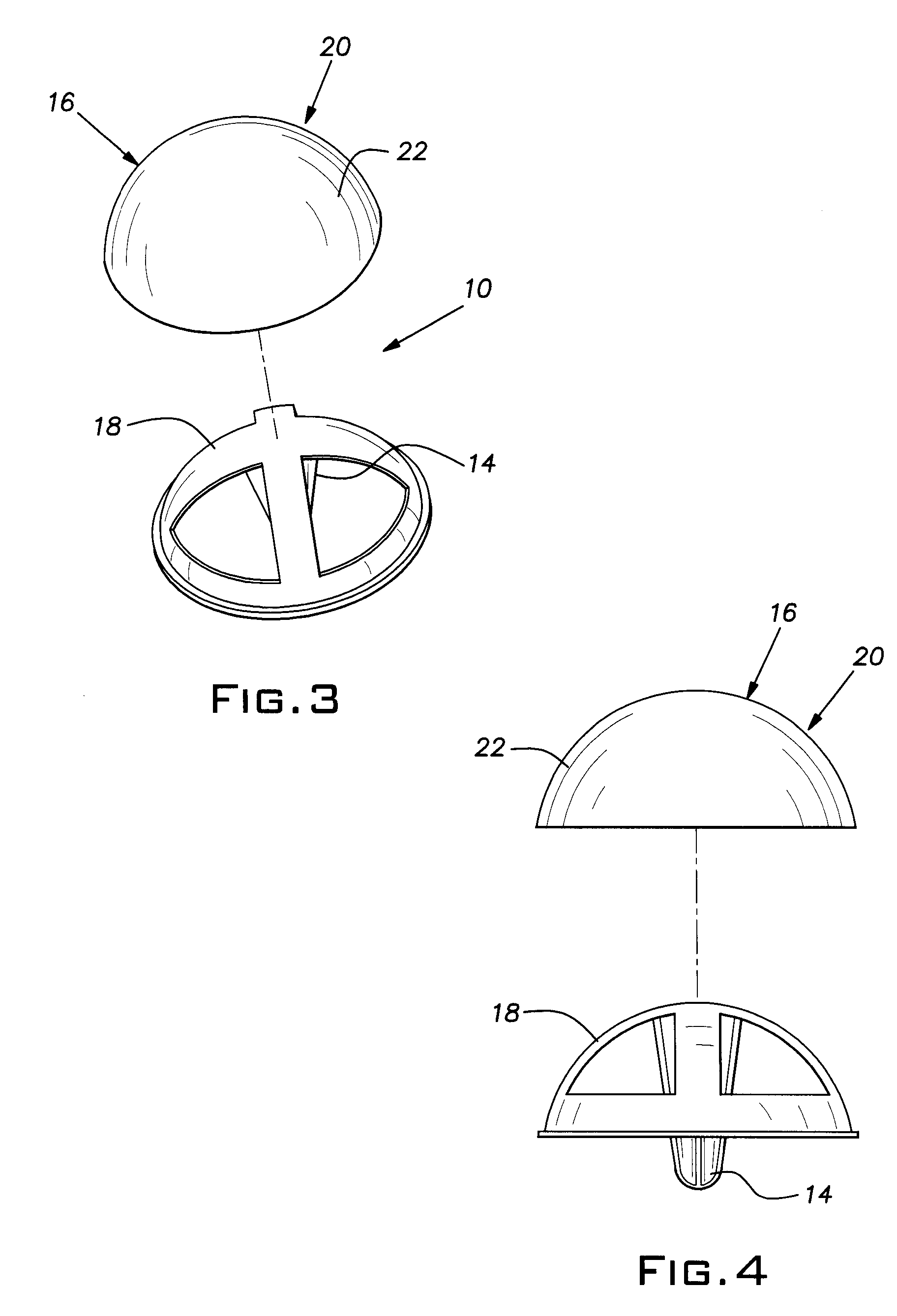

Trigger assembly

ActiveUS20140246003A1Resistance to frictionSafety arrangementFiring/trigger mechanismsMechanical engineering

A trigger assembly for activating a firing mechanism. The trigger assembly includes a trigger having a sear arm with a first sear surface, and a firing element including a body portion with a second sear surface and an engagement portion for engagement with the firing mechanism, for activating the firing mechanism. The trigger assembly also includes a captured roller positioned for engagement with the first and second sear surfaces. The trigger is pivotable between a load position, in which the captured roller is held between the first and second sear surfaces, and a release position, in which the second sear surface is disengaged from the captured roller and the firing element is released. The firing element is pivotable between a first position, in which the firing element is held by the captured roller, and a second position, in which the firing element is disengaged from the captured roller.

Owner:2360216 ONTARIO

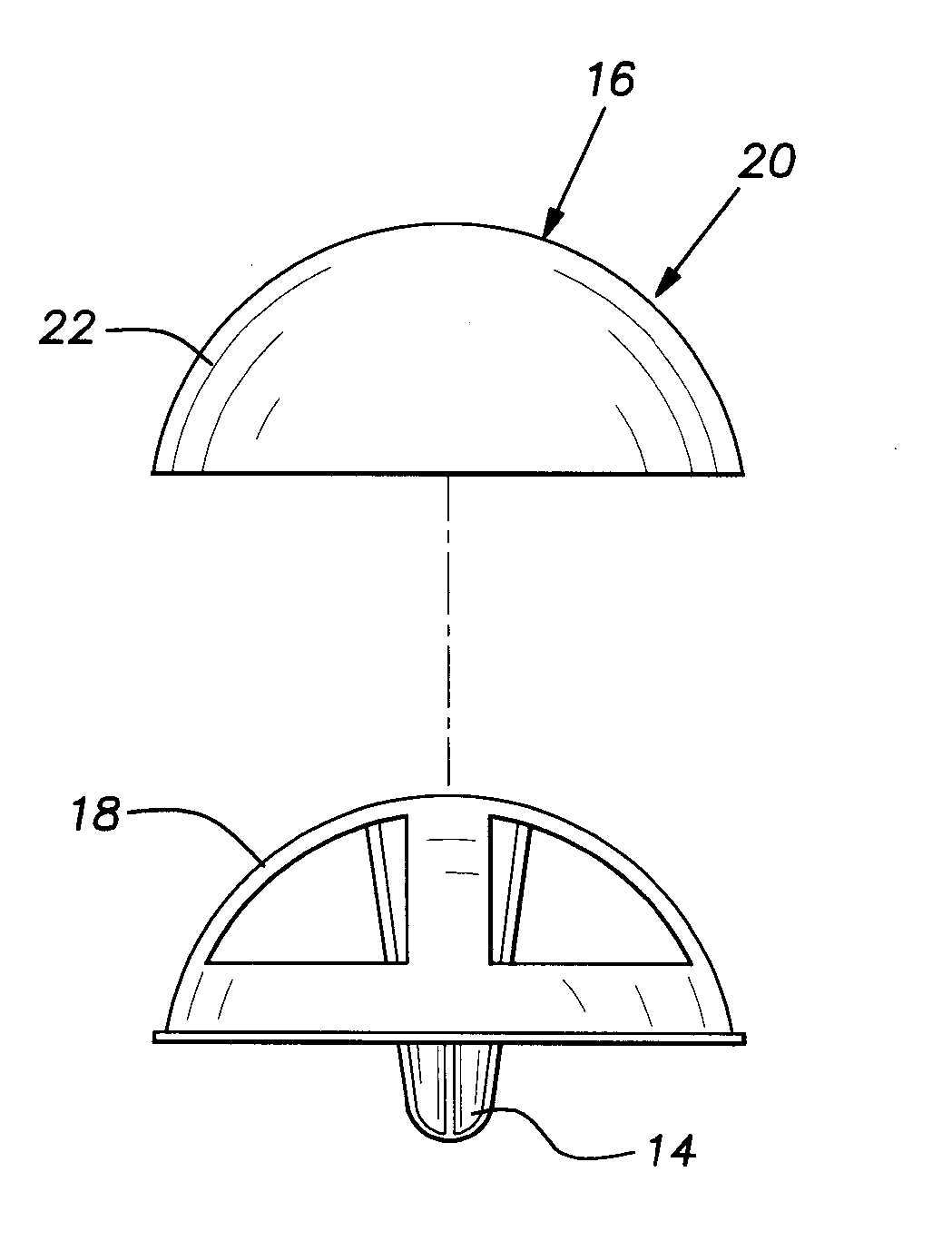

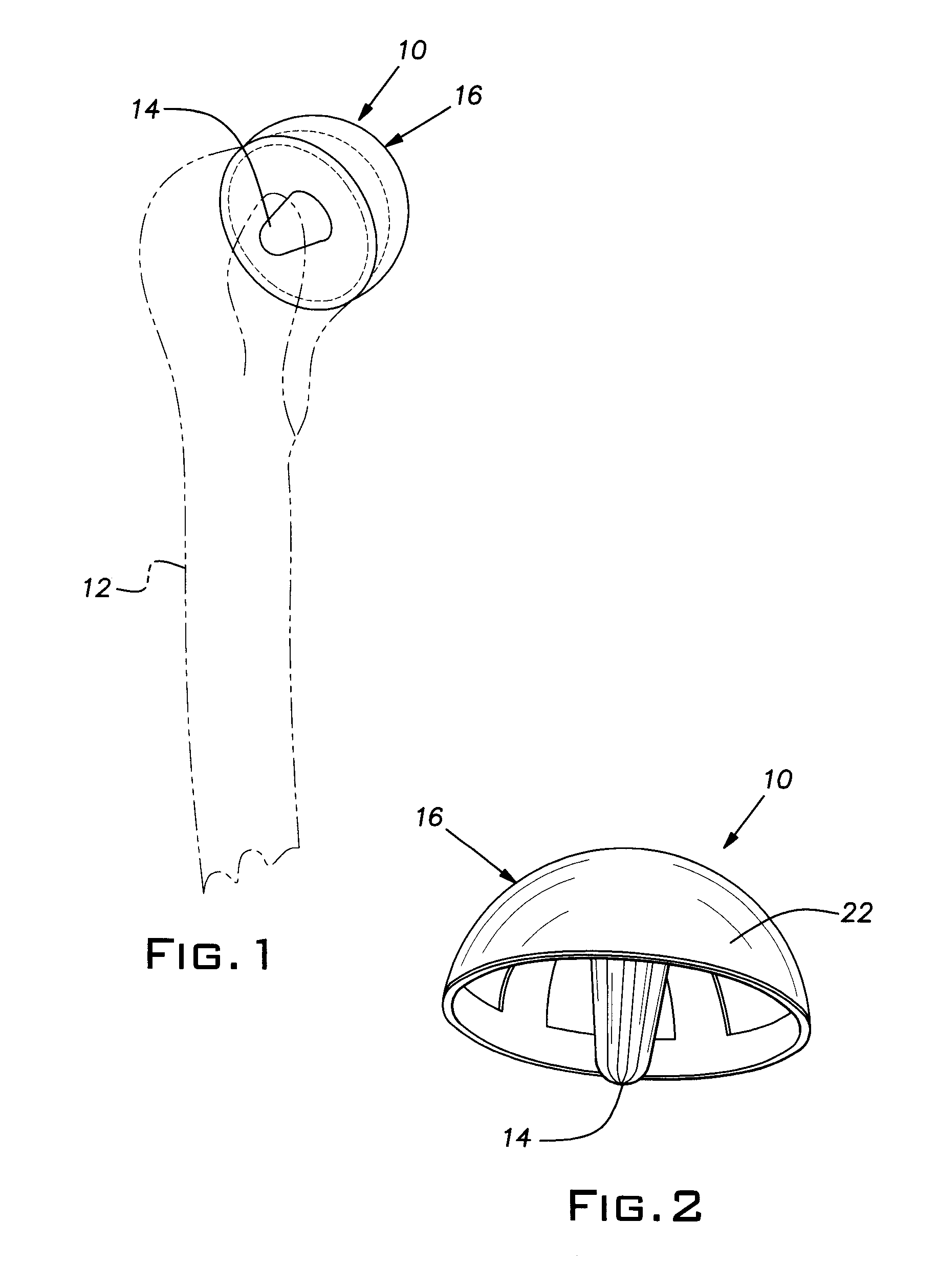

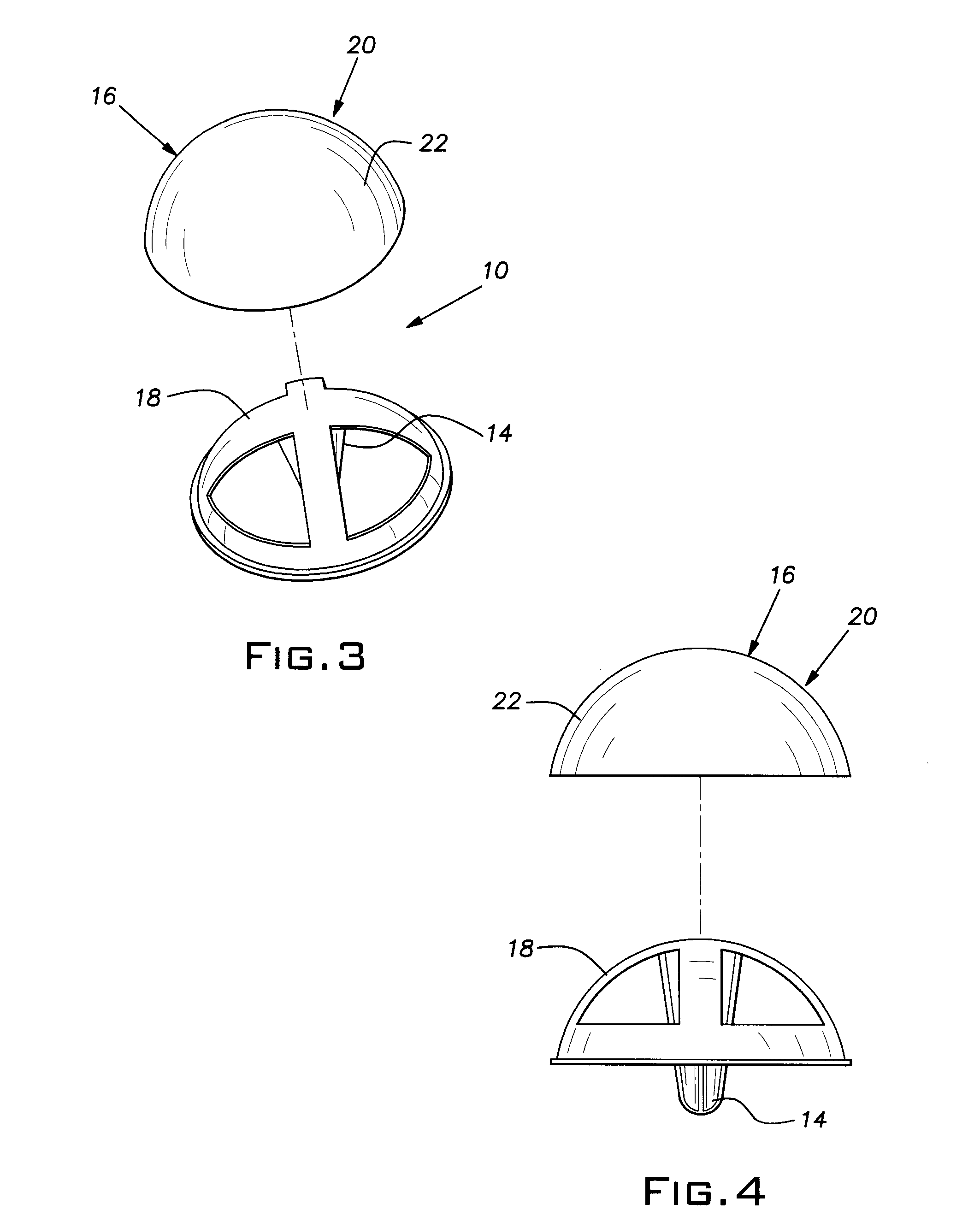

Orthopedic Implants Coated with Pyrolytic Carbon

InactiveUS20070156250A1Resistance to frictionResistant to wearImpression capsBone implantGas phaseTitanium

An orthopedic implant having a metal substrate with an articulating surface includes a coating for the articulating surface made of pyrolytic carbon. Typically, the substrate is made of a metal such as titanium or stainless steel, or alloys thereof. The pyrolytic carbon coating preferably is applied by vapor deposition.

Owner:SEITZ WILLIAM H JR +1

Trigger assembly

ActiveUS9097485B2Resistance to frictionSafety arrangementFiring/trigger mechanismsEngineeringMechanical engineering

Owner:2360216 ONTARIO

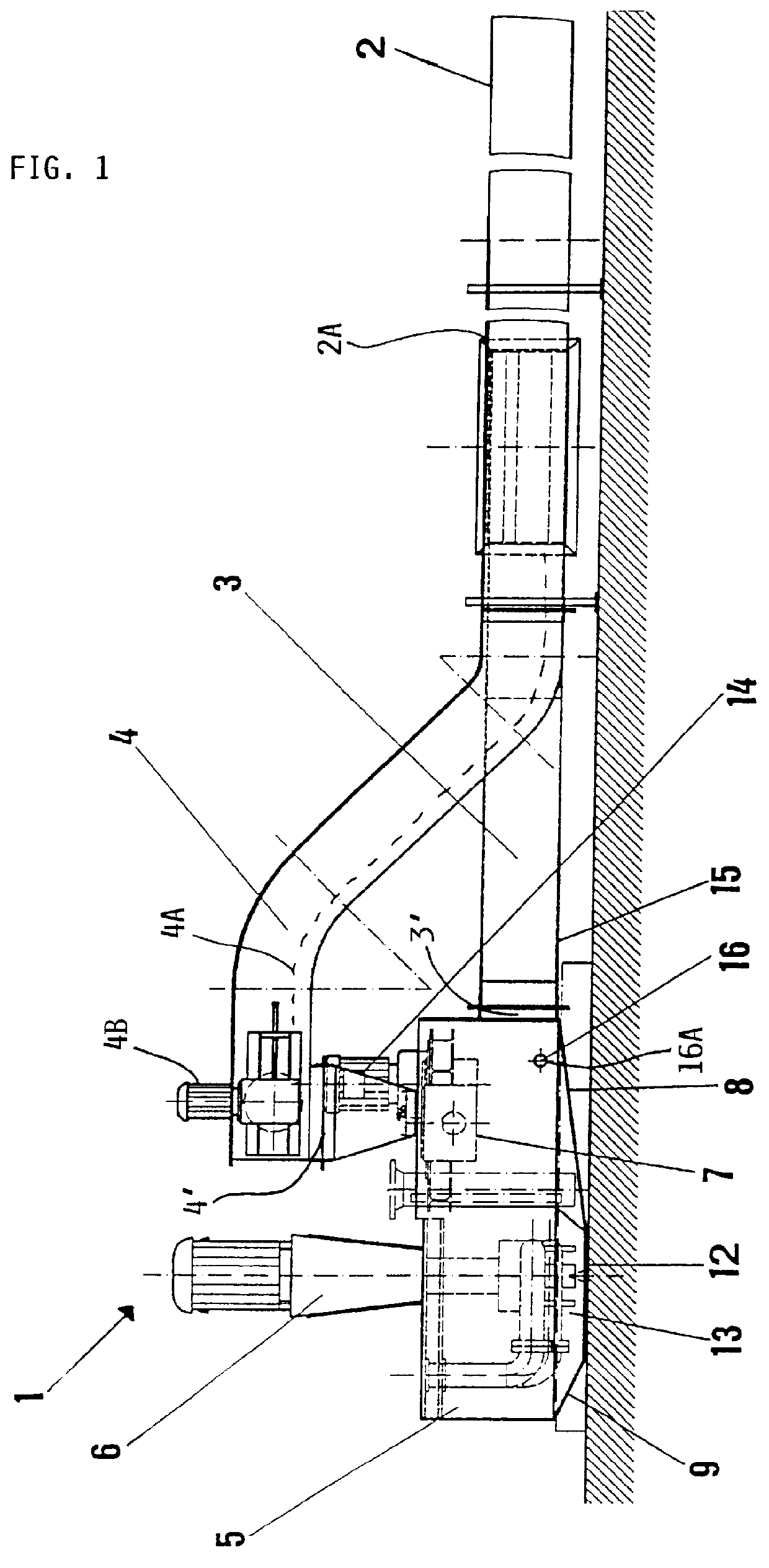

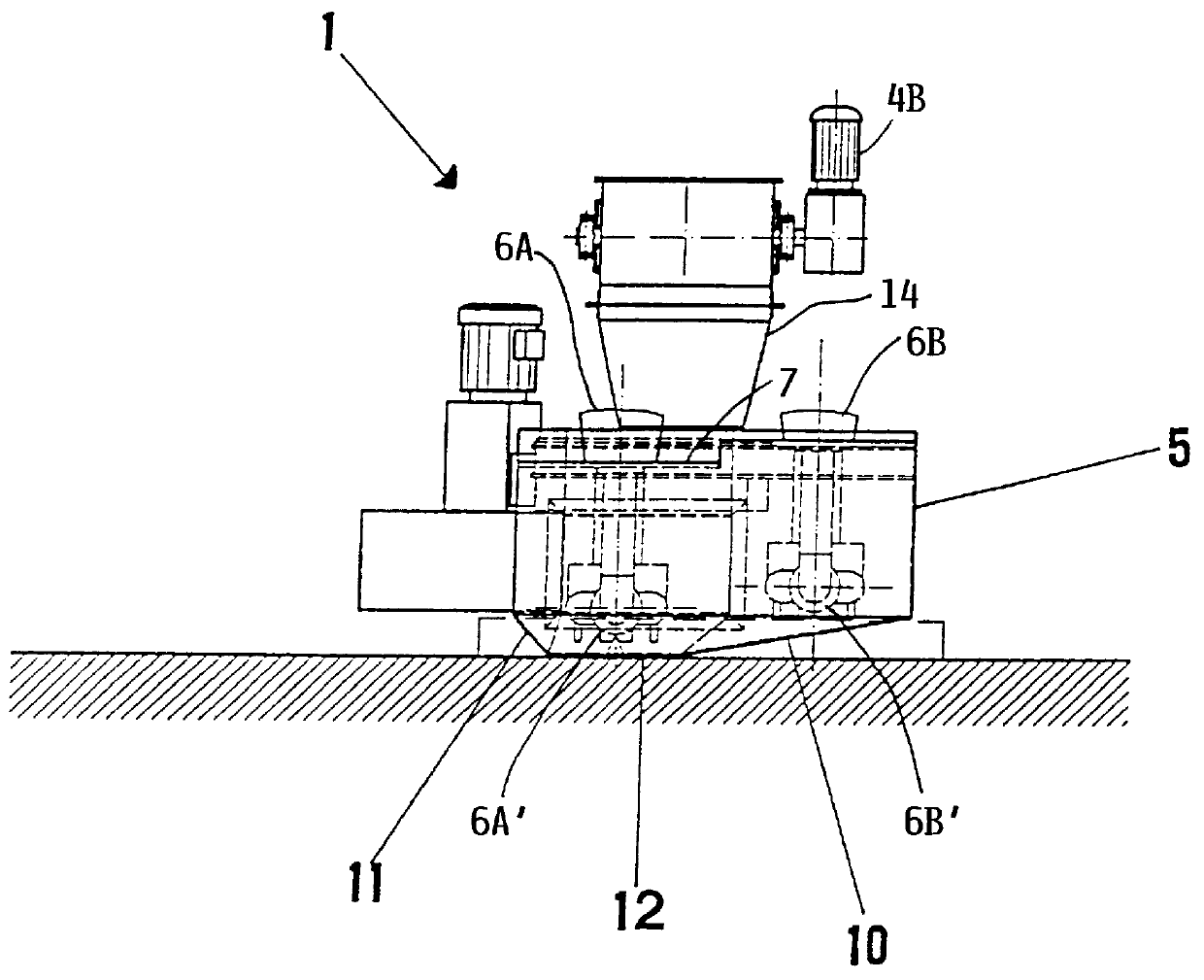

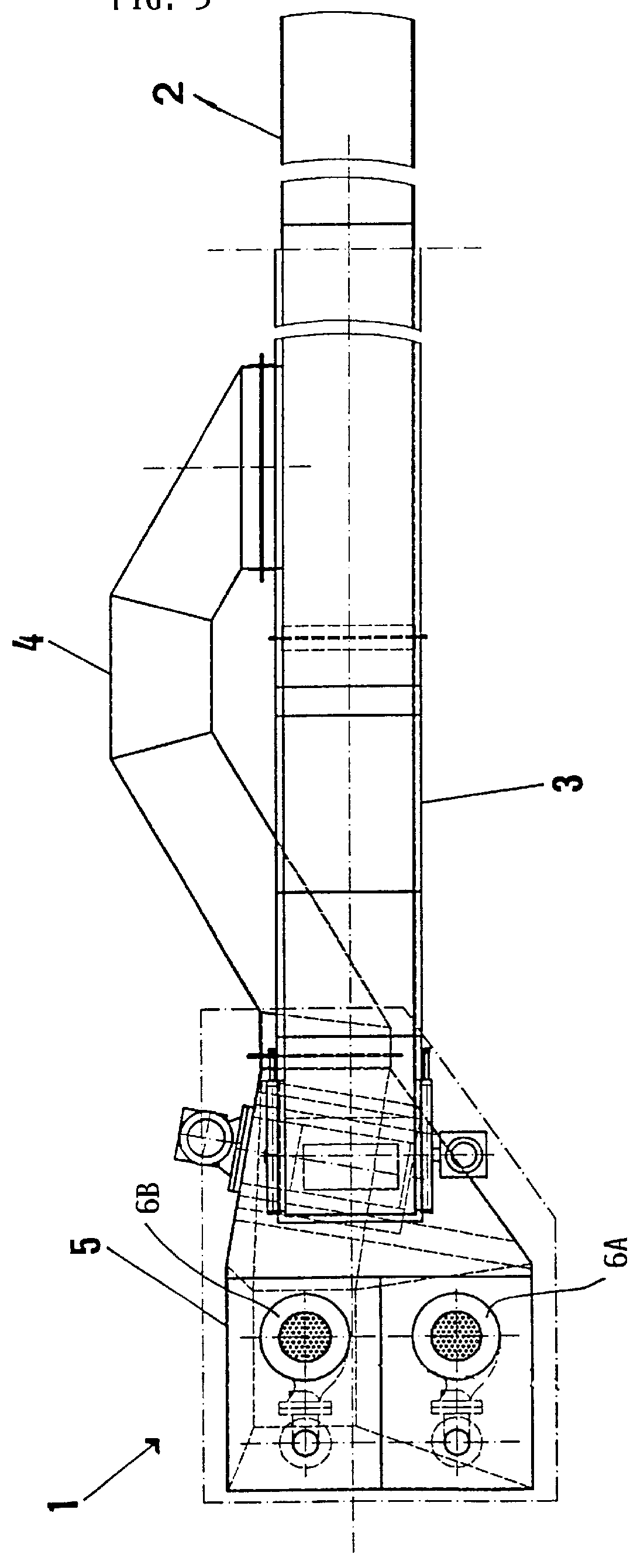

Pumping station for a cooling and lubricating fluid containing particulate matter

A pumping station for pumping a cooling and lubricating fluid containing particulate matter such as machining chips has a compact structure with a relatively low total structural height, while still assuring that the chips are conveyed with the fluid to the pump suction inlet, without settling-out or accumulating in the apparatus. The pumping station (1) includes a collecting container (5) with at least one pump (6) arranged therein, a chip breaker (7) and a supply conduit arrangement. The supply conduit arrangement includes a supply line (2) through which the cooling and lubricating fluid containing the machining chips is received from a machining tool or transfer station. Furthermore, two branch lines (3) and (4) are interposed and connected between the supply line (2) and the collecting container (5). A first branch line (3) conveys the fluid, from which the chips have been removed, with a slight downward slope toward the collecting container (5). The second branch line (4) conveys the chips that have been removed from the fluid flow. A scraper conveyor or the like conveys the chips upward through the second branch line (4), and the outlet end of the branch line (4) is arranged directly above the chip breaker (7), which in turn is arranged above the outlet end of the fluid conveying branch line (3). The comminuted chips thus fall from the breaker (7) directly into the flow of fluid, in which the chips are then entrained and carried along into the sump (13) of the collecting container (5), where the chips and fluid are sucked and pumped away by the pump (6).

Owner:MANN HUMMEL GMBH +1

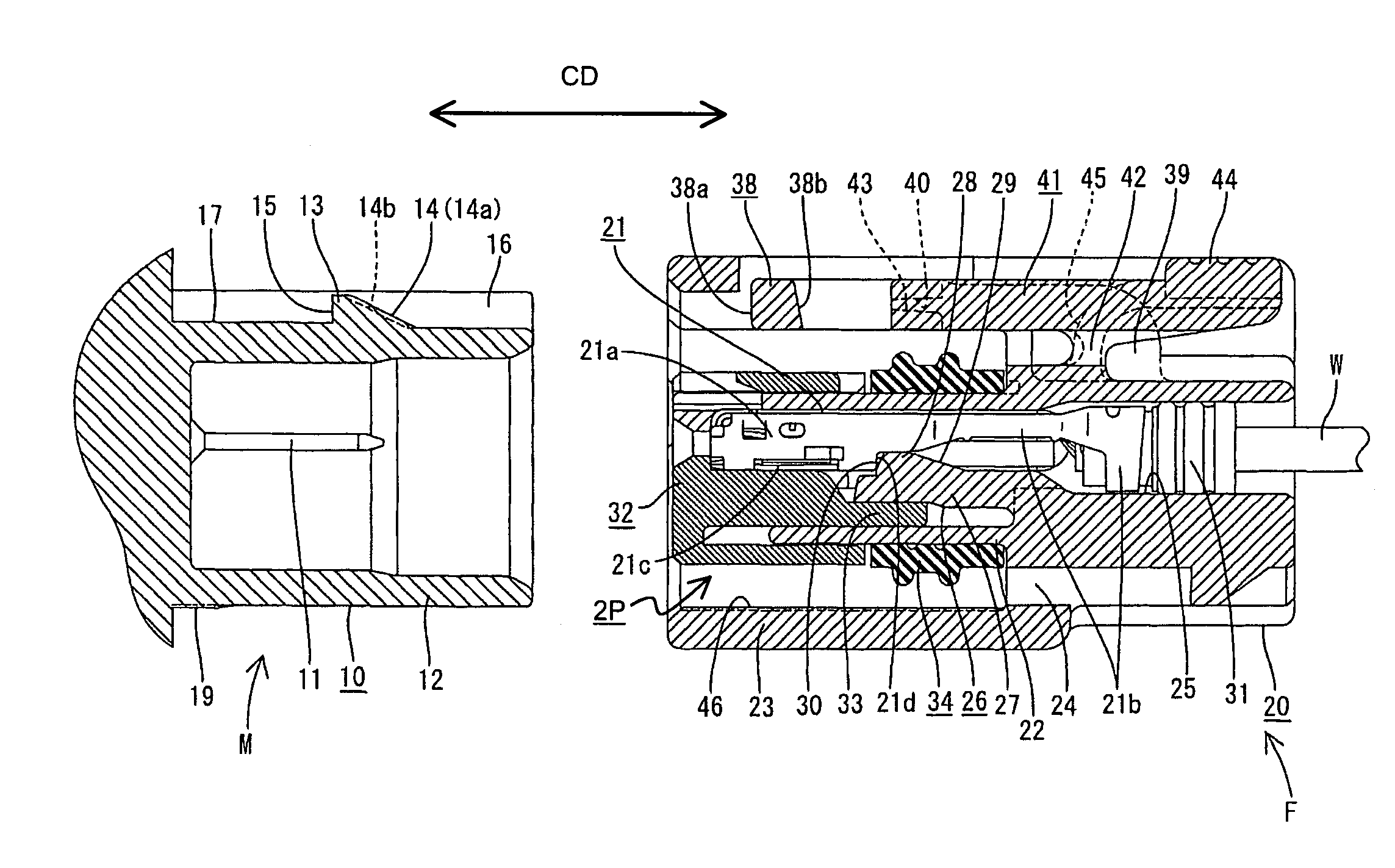

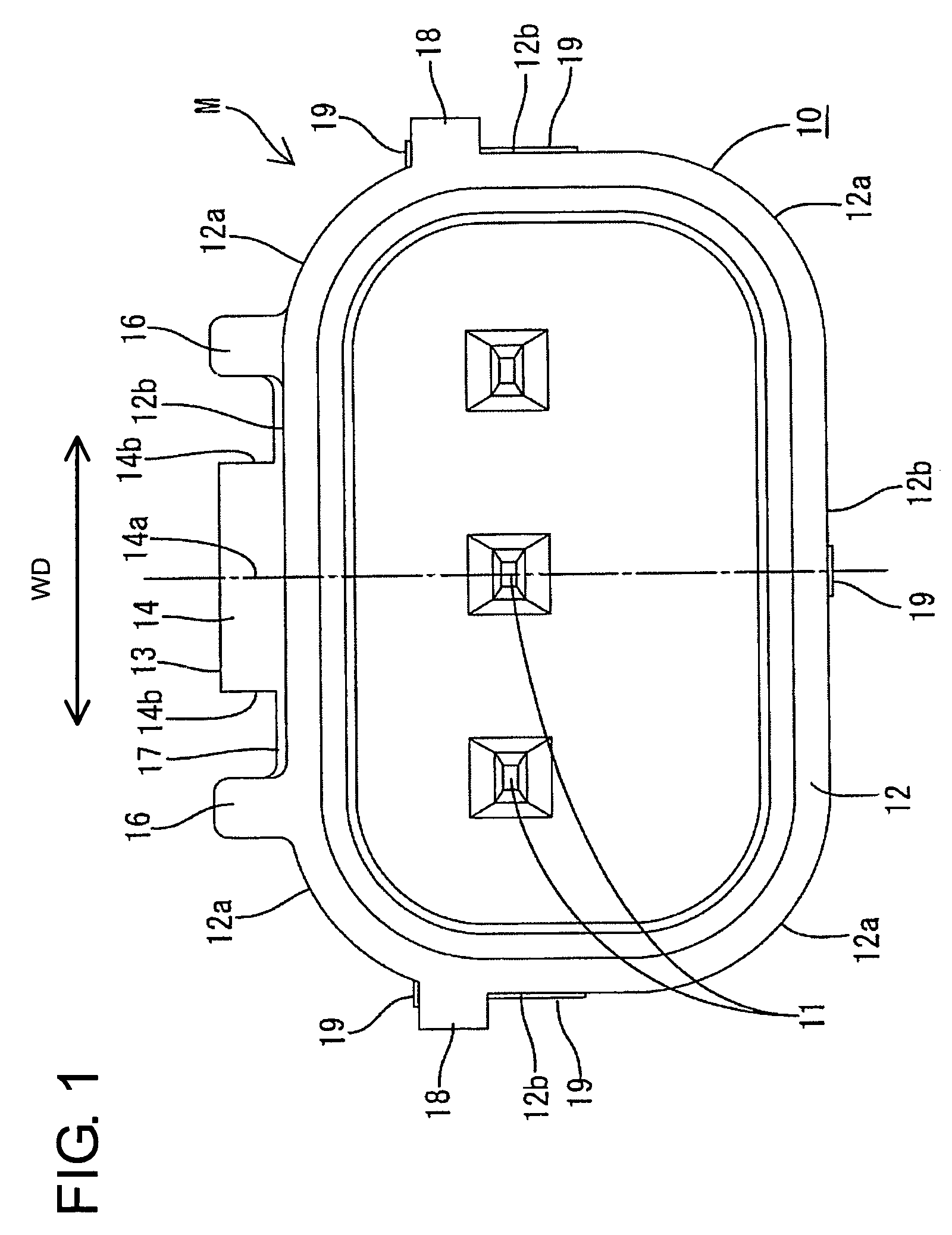

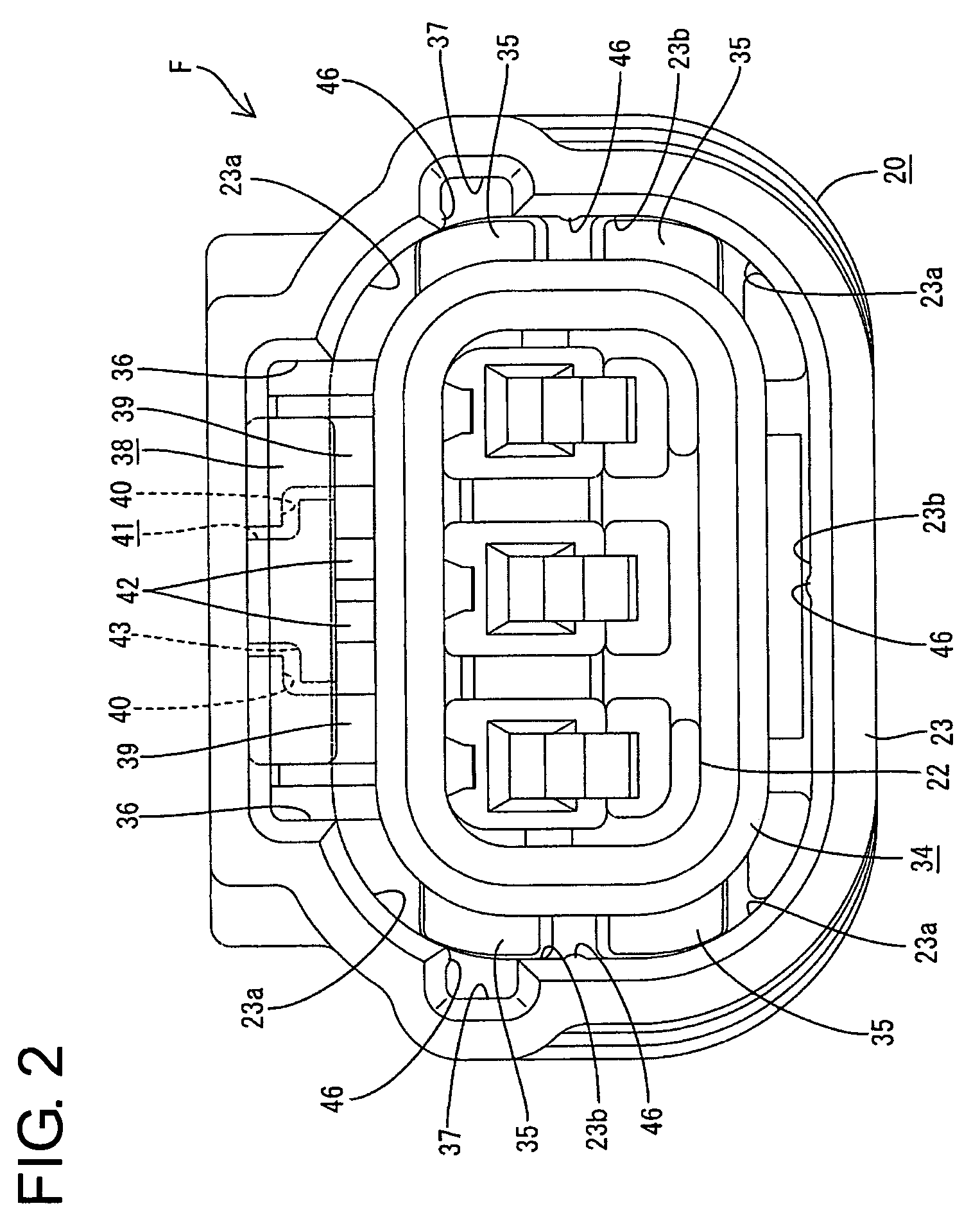

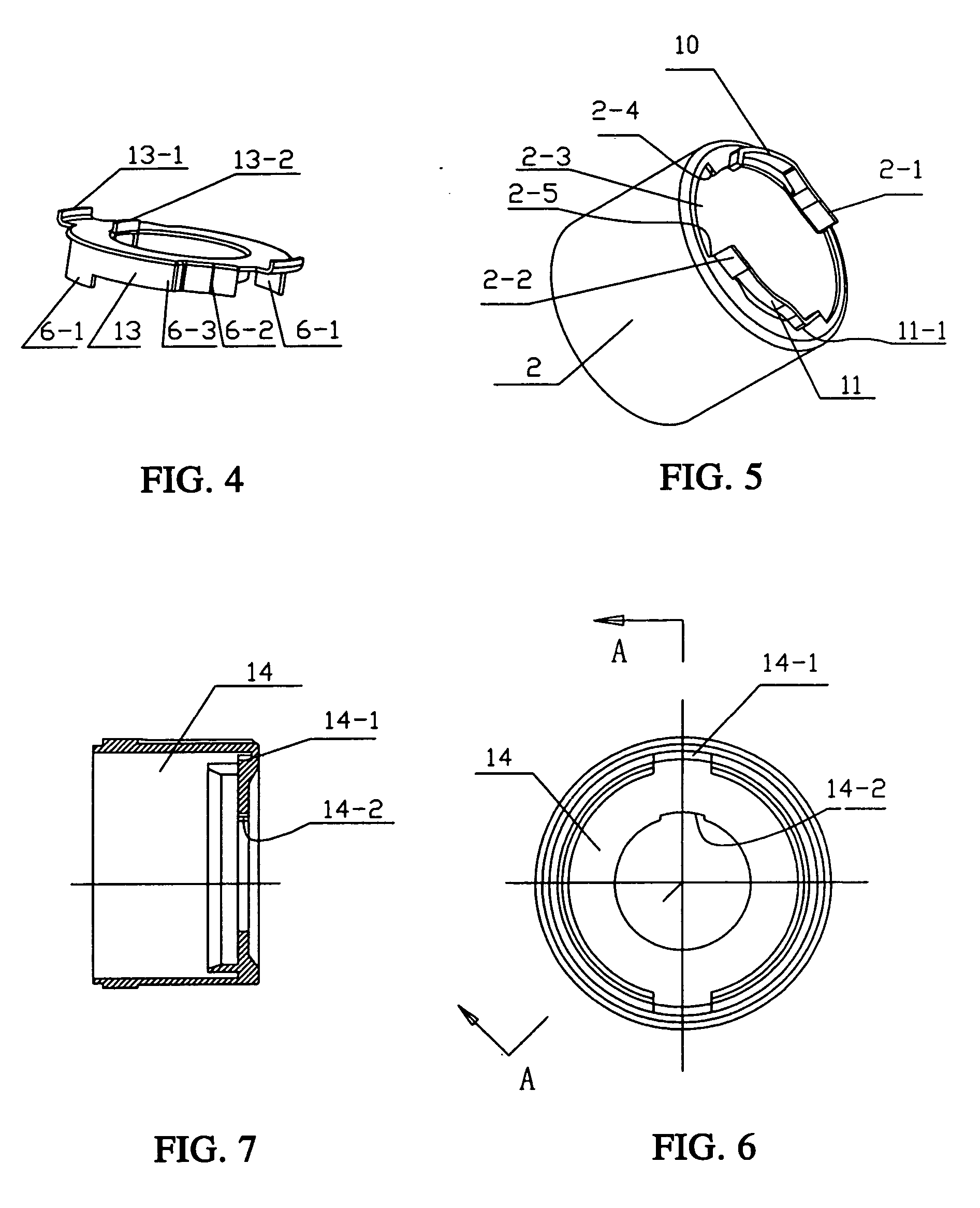

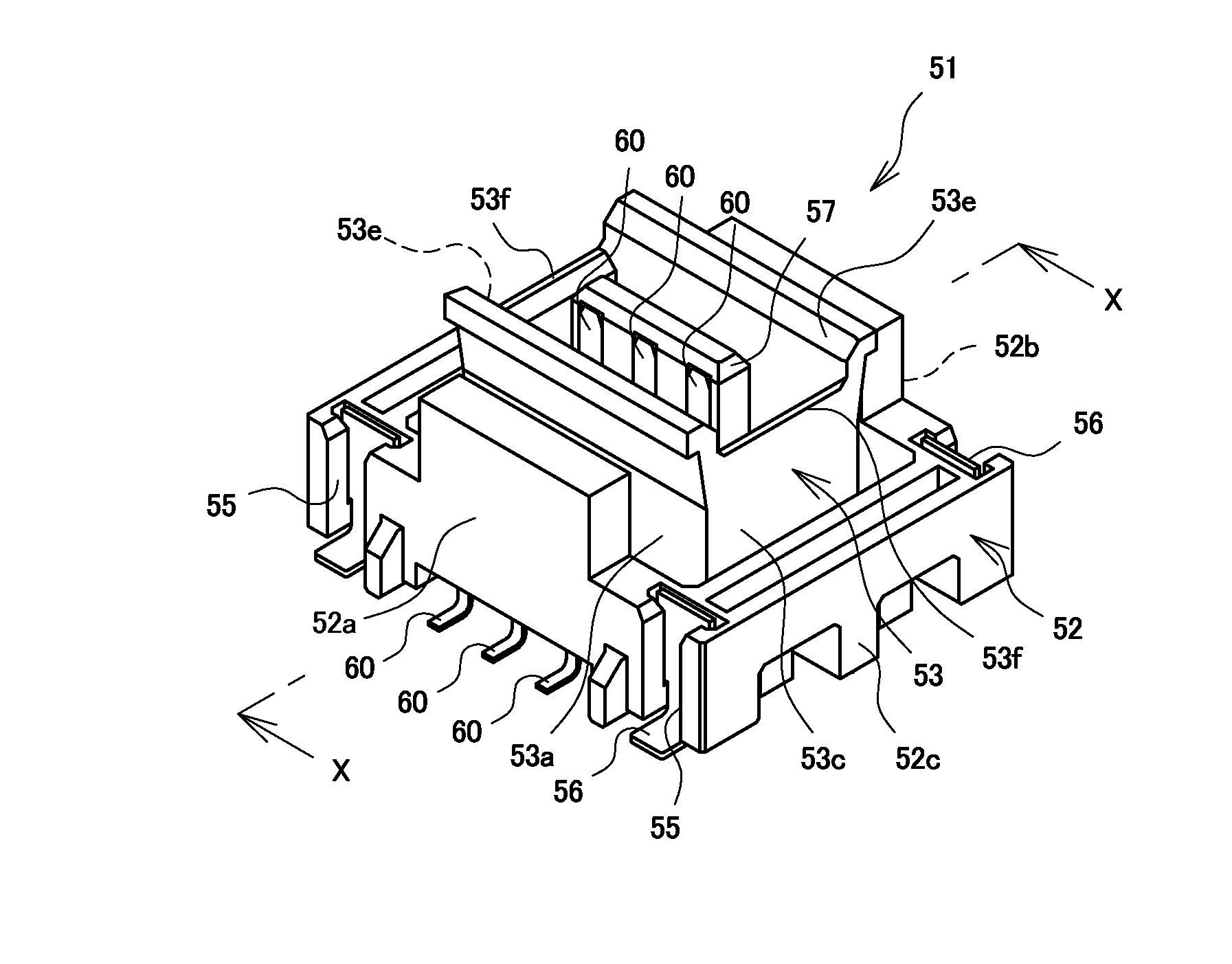

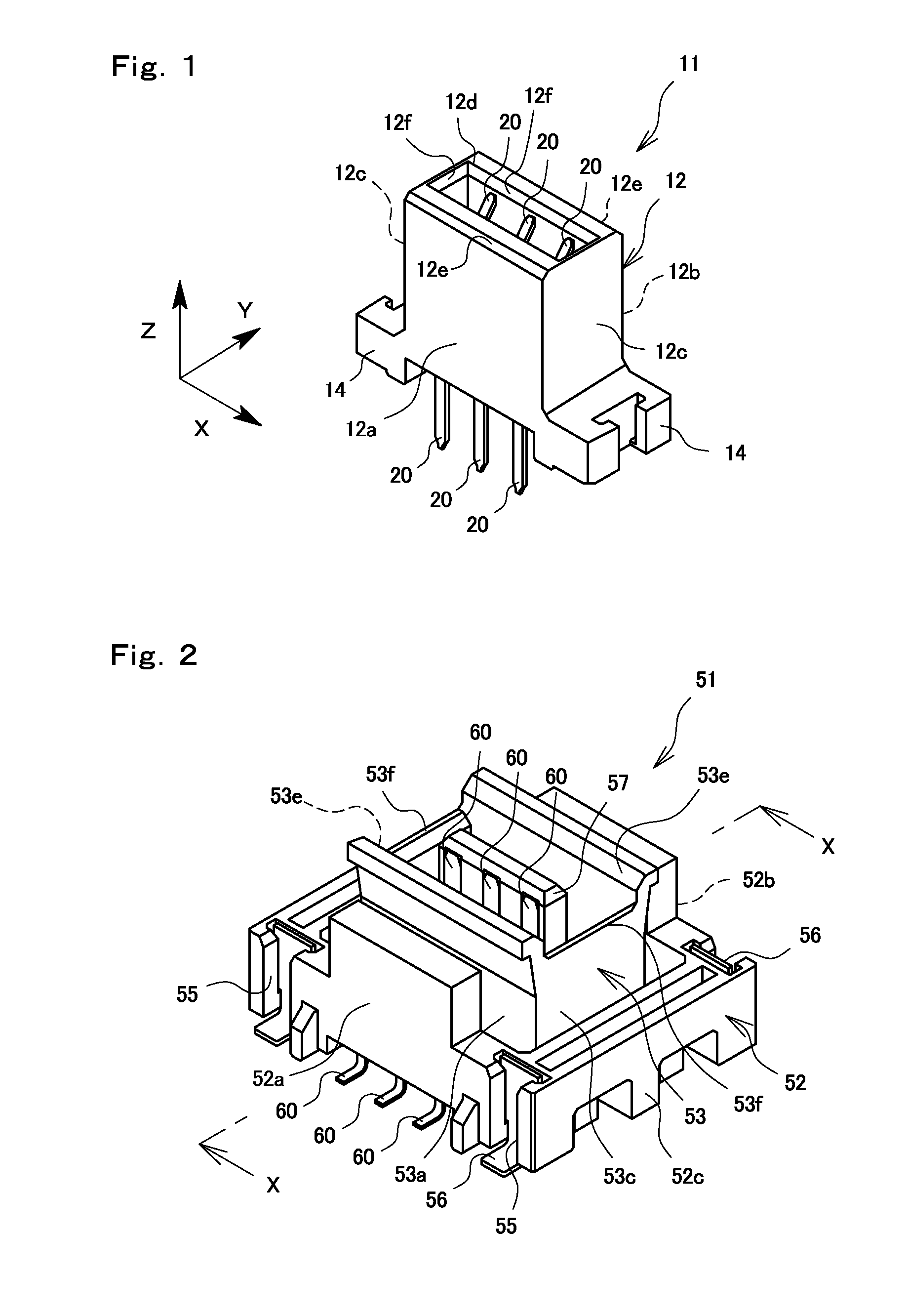

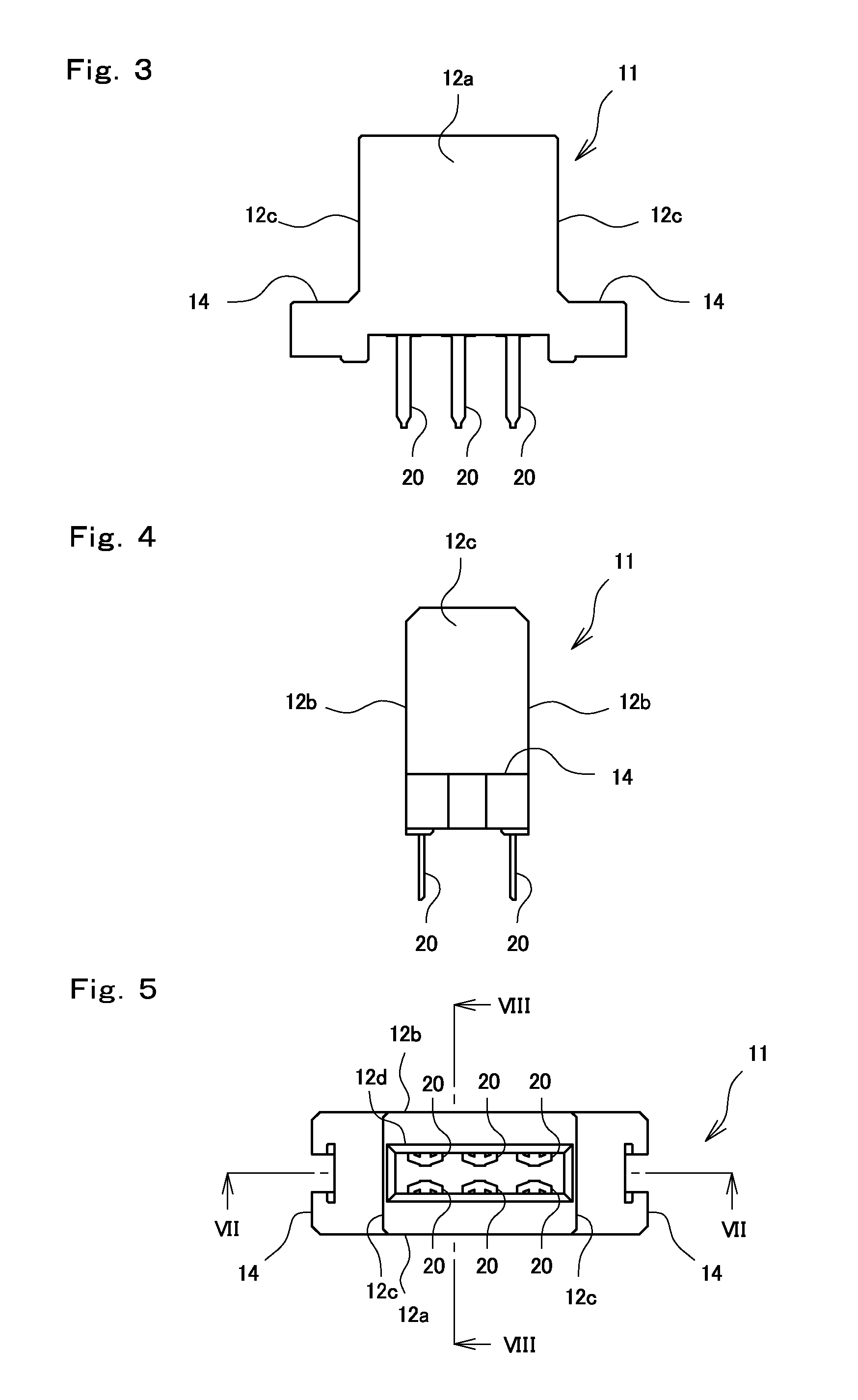

Connector

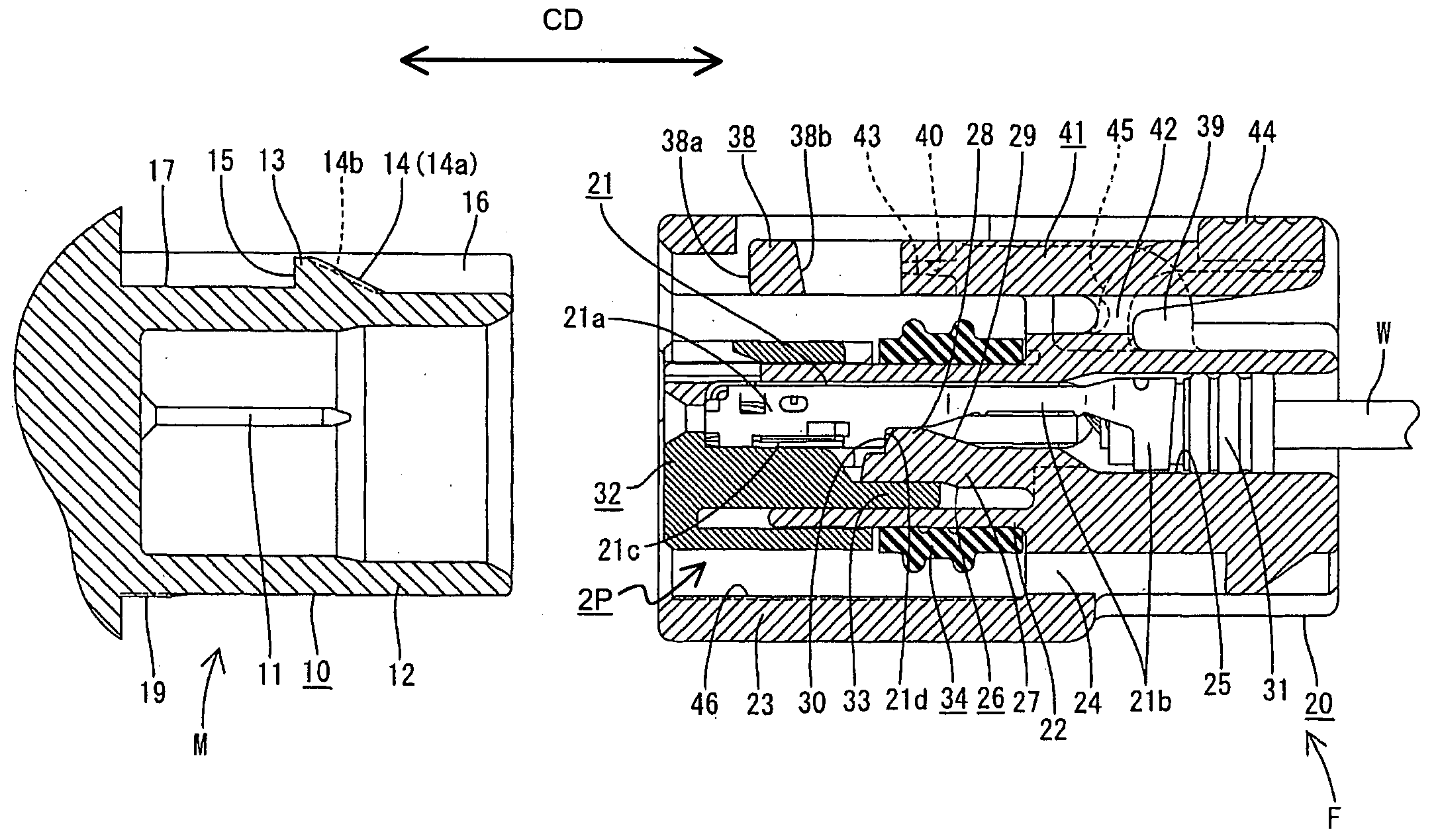

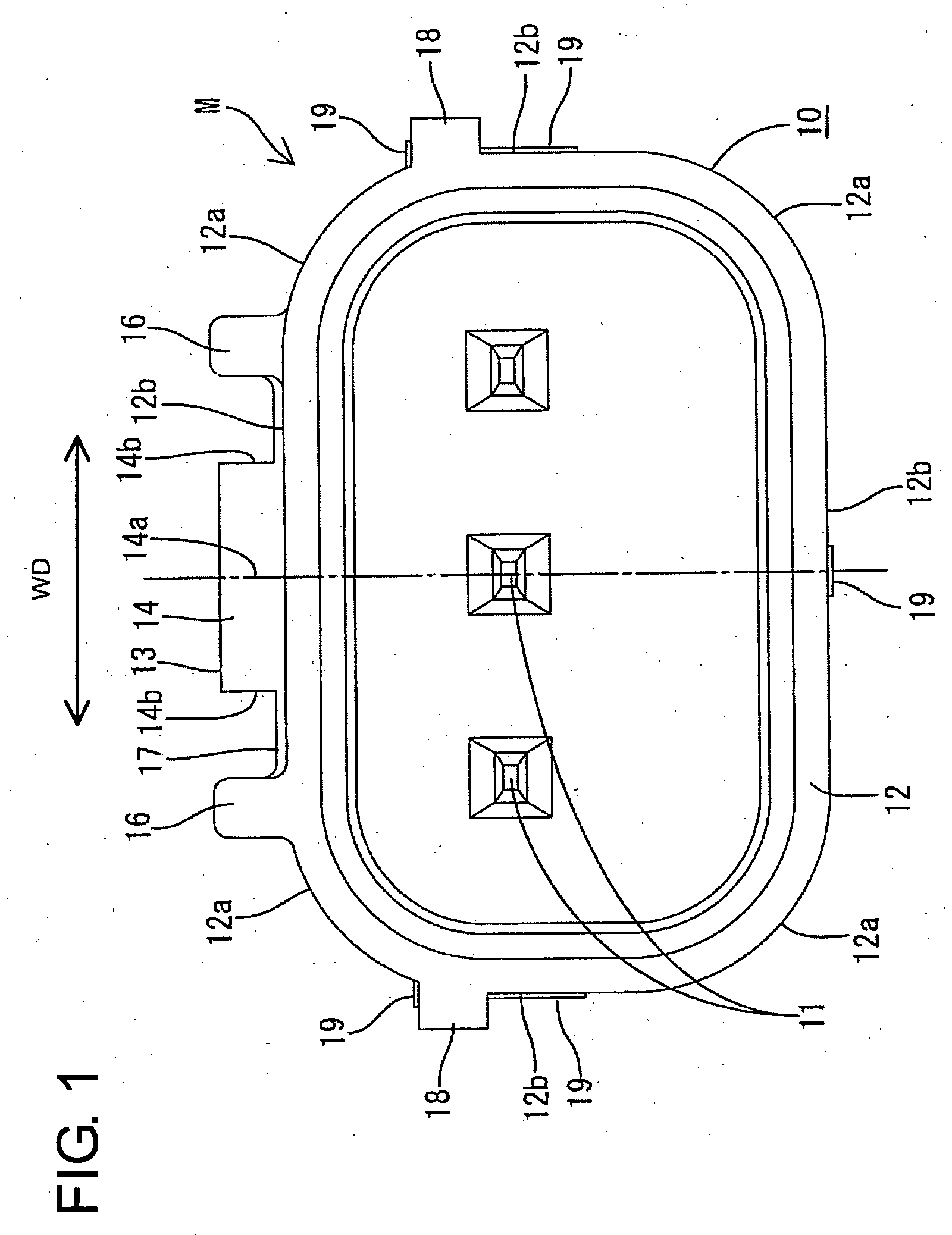

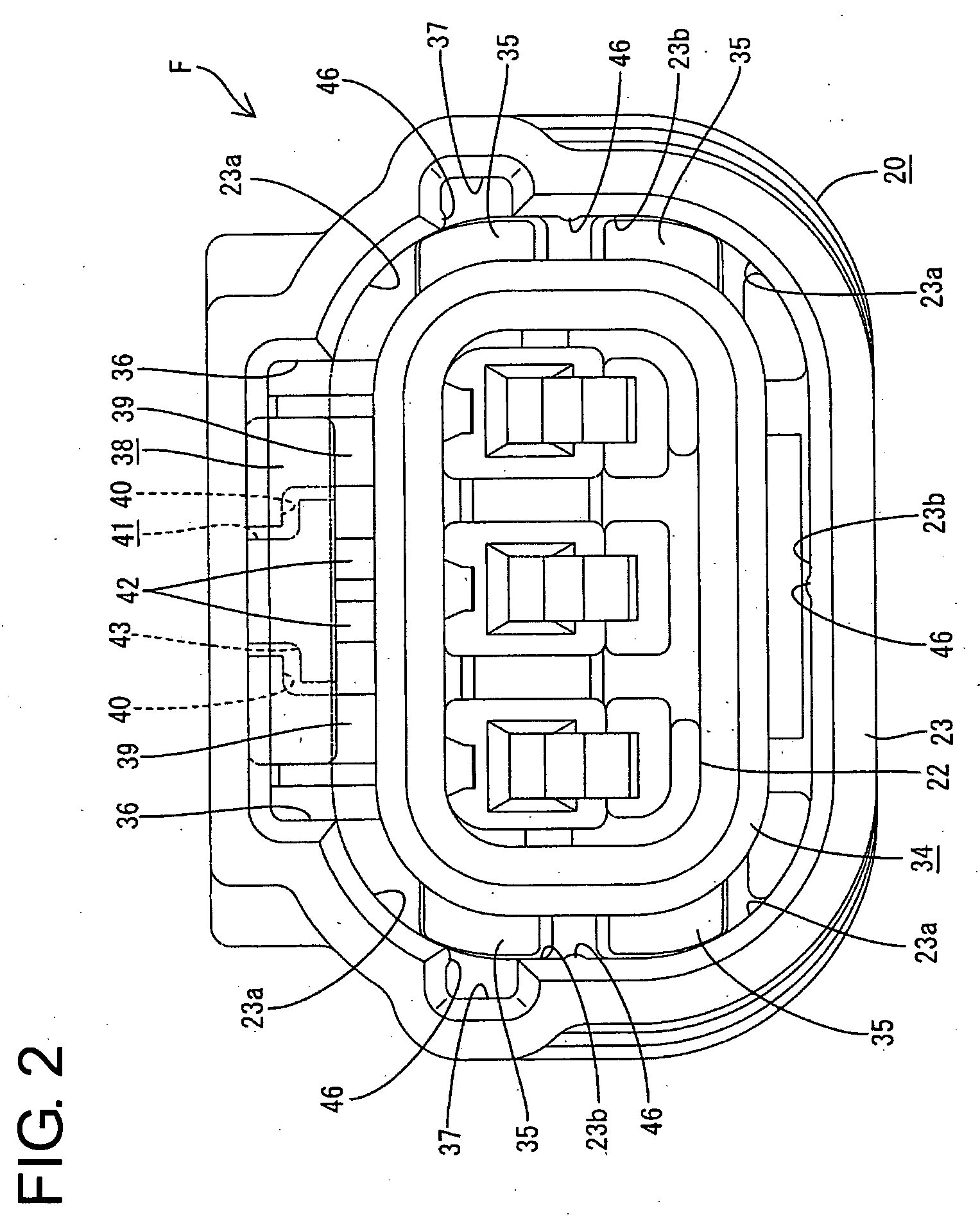

ActiveUS20050186842A1Prevent movementResistance to frictionElectrically conductive connectionsSecuring/insulating coupling contact membersEngineeringSliding contact

A female housing (20) has a resiliently deformable lock arm (38), whereas a male housing (10) is provided with an interlocking portion (13). During the connection of the two housings (10, 20), the lock arm (38) is temporarily deformed while being held in sliding contact with the interlocking portion (13). When the two housings (10, 20) are properly connected, the lock arm (38) is restored resiliently to engage the interlocking portion (13). A front surface (14) of the interlocking portion (13) to face the lock arm (38) during a connecting process is arcuate. Thus, only a widthwise middle (14a) of the interlocking portion (13) slides in contact with the lock arm (38) during a connecting operation.

Owner:SUMITOMO WIRING SYST LTD

Connector

ActiveUS7114983B2Resistance to frictionFirmly connectedElectrically conductive connectionsSecuring/insulating coupling contact membersSliding contact

A female housing (20) has a resiliently deformable lock arm (38), whereas a male housing (10) is provided with an interlocking portion (13). During the connection of the two housings (10, 20), the lock arm (38) is temporarily deformed while being held in sliding contact with the interlocking portion (13). When the two housings (10, 20) are properly connected, the lock arm (38) is restored resiliently to engage the interlocking portion (13). A front surface (14) of the interlocking portion (13) to face the lock arm (38) during a connecting process is arcuate. Thus, only a widthwise middle (14a) of the interlocking portion (13) slides in contact with the lock arm (38) during a connecting operation.

Owner:SUMITOMO WIRING SYST LTD

Orthopedic Implants Coated with Pyrolytic Carbon

InactiveUS20070225822A1Resistance to frictionResistant to wearImpression capsBone implantGas phaseTitanium

An orthopedic implant having a metal substrate with an articulating surface includes a coating for the articulating surface made of pyrolytic carbon. Typically, the substrate is made of a metal such as titanium or stainless steel, or alloys thereof. The pyrolytic carbon coating preferably is applied by vapor deposition.

Owner:SANTILLI ALBERT N +1

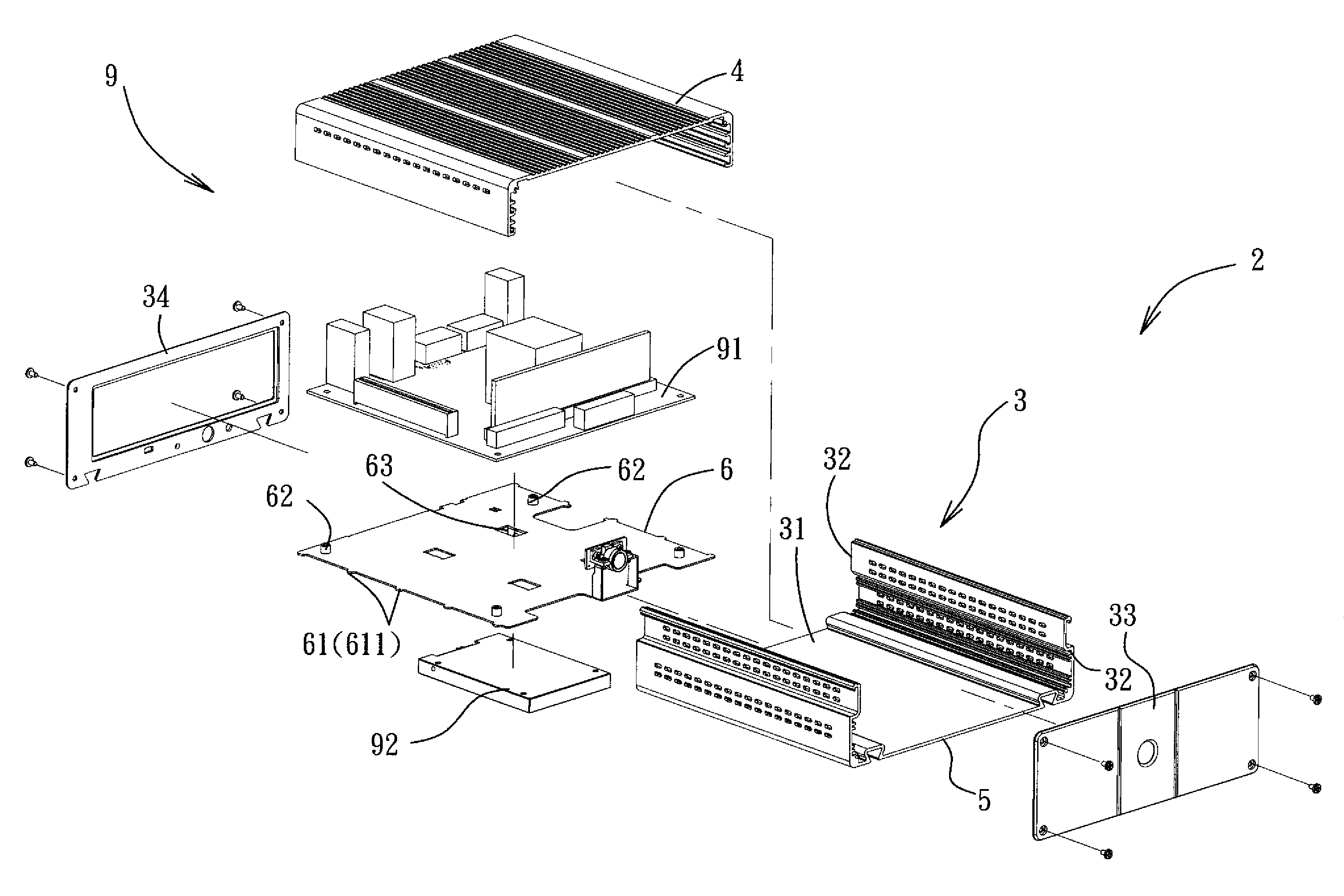

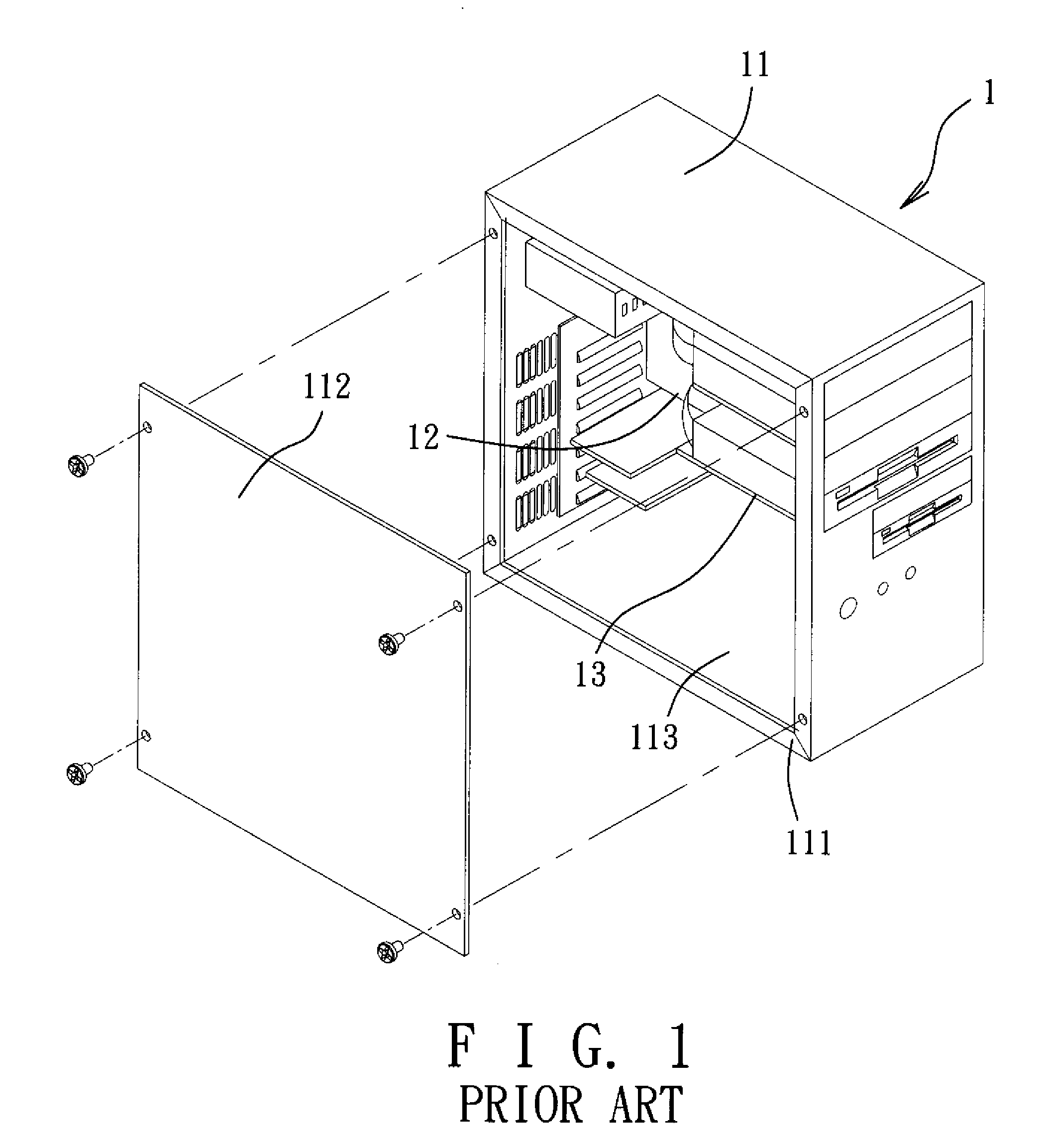

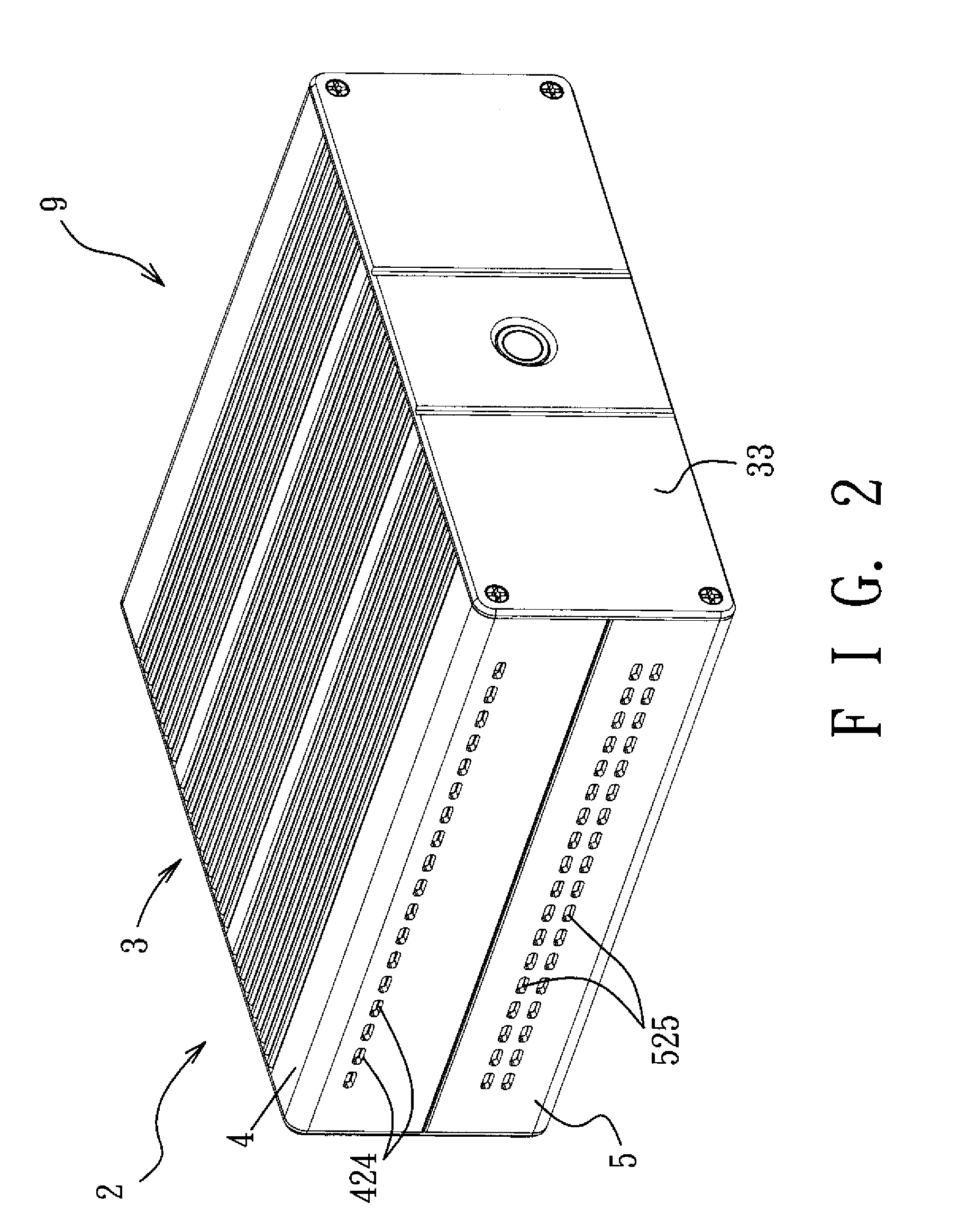

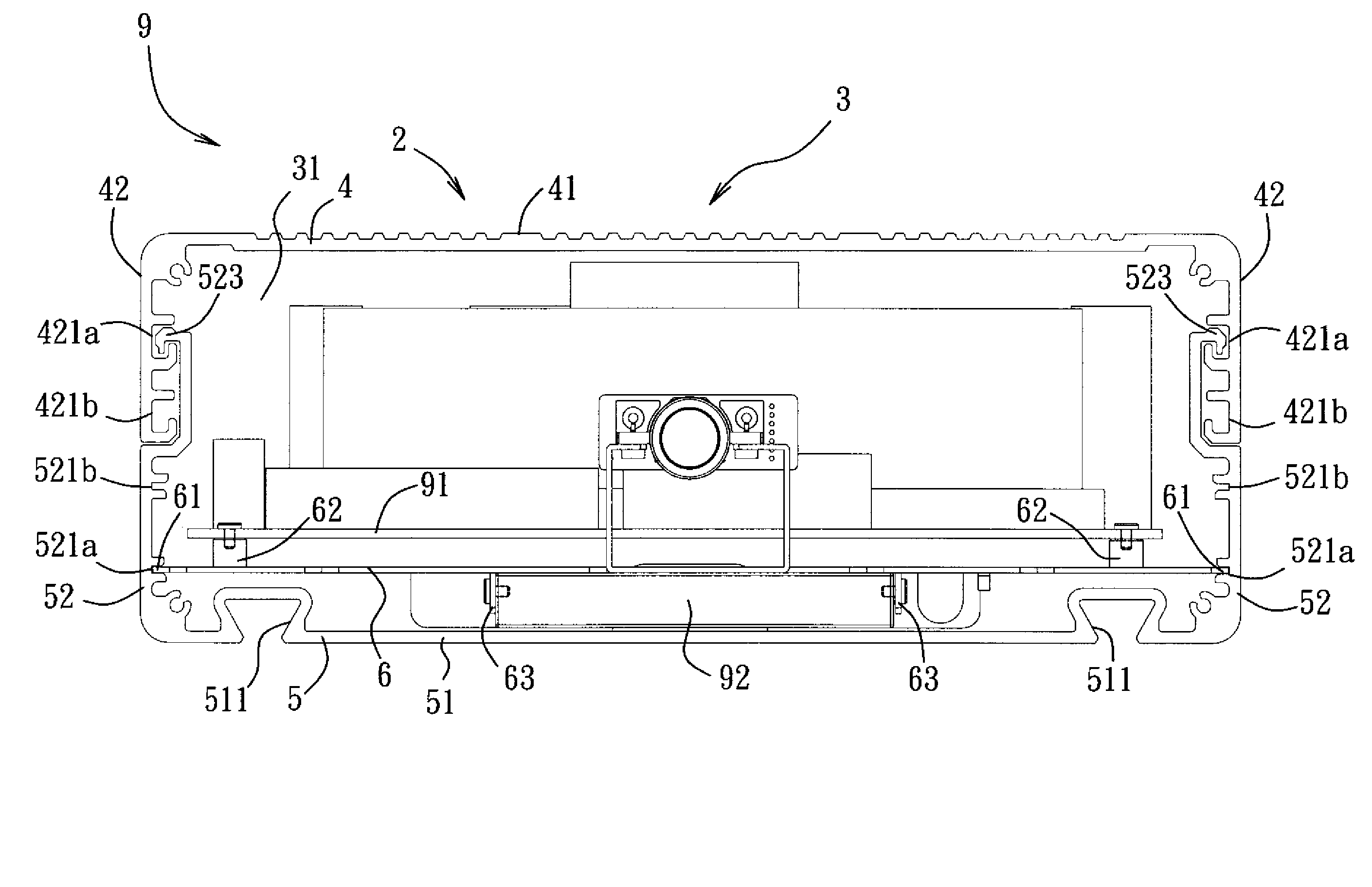

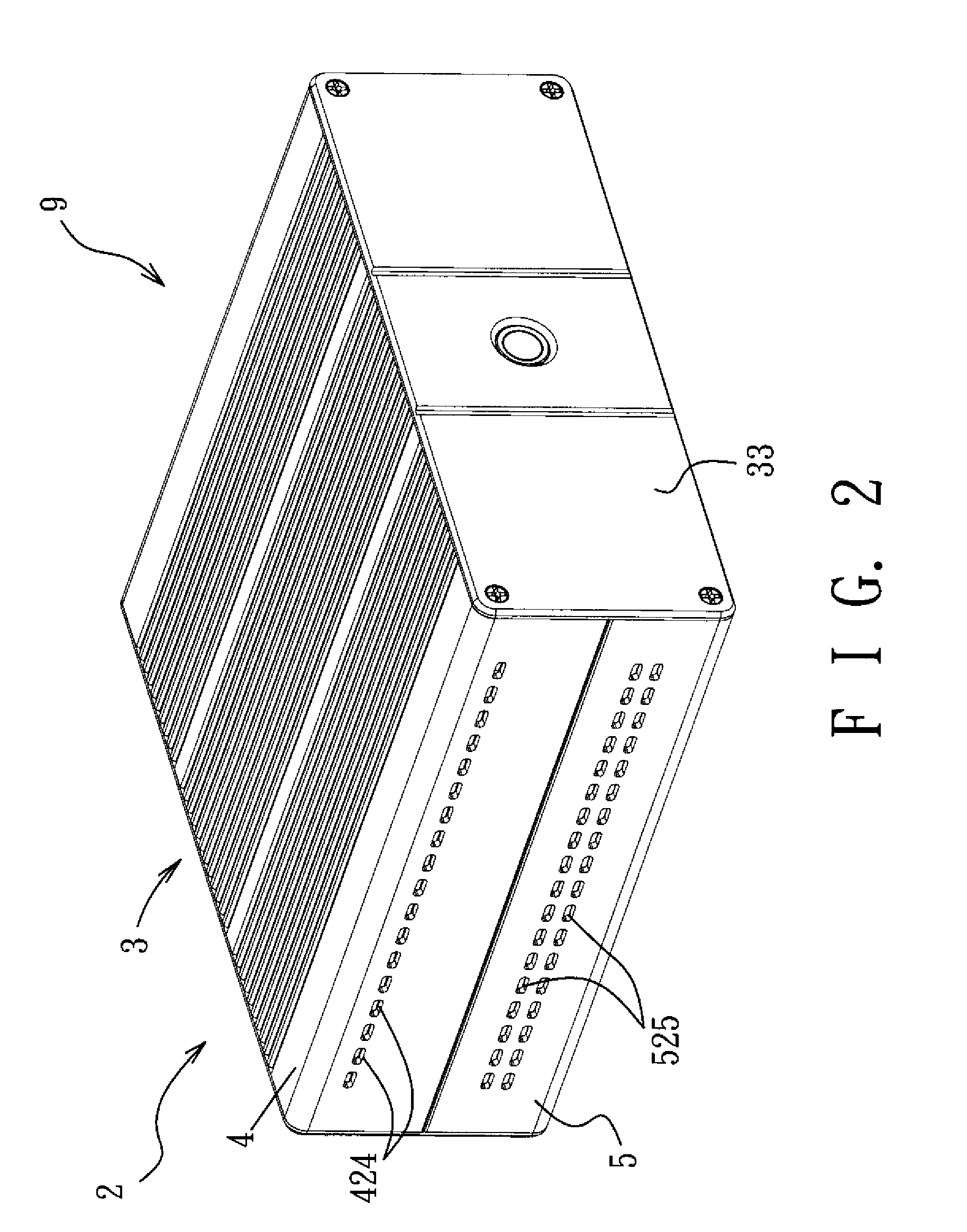

Computer Housing and Computer Including the Same

InactiveUS20100053869A1Quick assemblyResistance to frictionDigital data processing detailsPrinted circuit board receptaclesElectronic componentMotherboard

A computer housing is adapted for receiving a motherboard and at least one electronic component therein, and includes a housing unit and a support board. The housing unit has an opening, and includes at least one first sliding portion that is provided at each of two opposite sides of an inner surface of the housing unit, that extends along a sliding direction, and that is connected to the opening. The support board is adapted for securing the motherboard and the electronic component, and includes a second sliding portion provided at each of two opposite edges of the support board and slidable relative to the first sliding portion in the sliding direction.

Owner:AOPEN

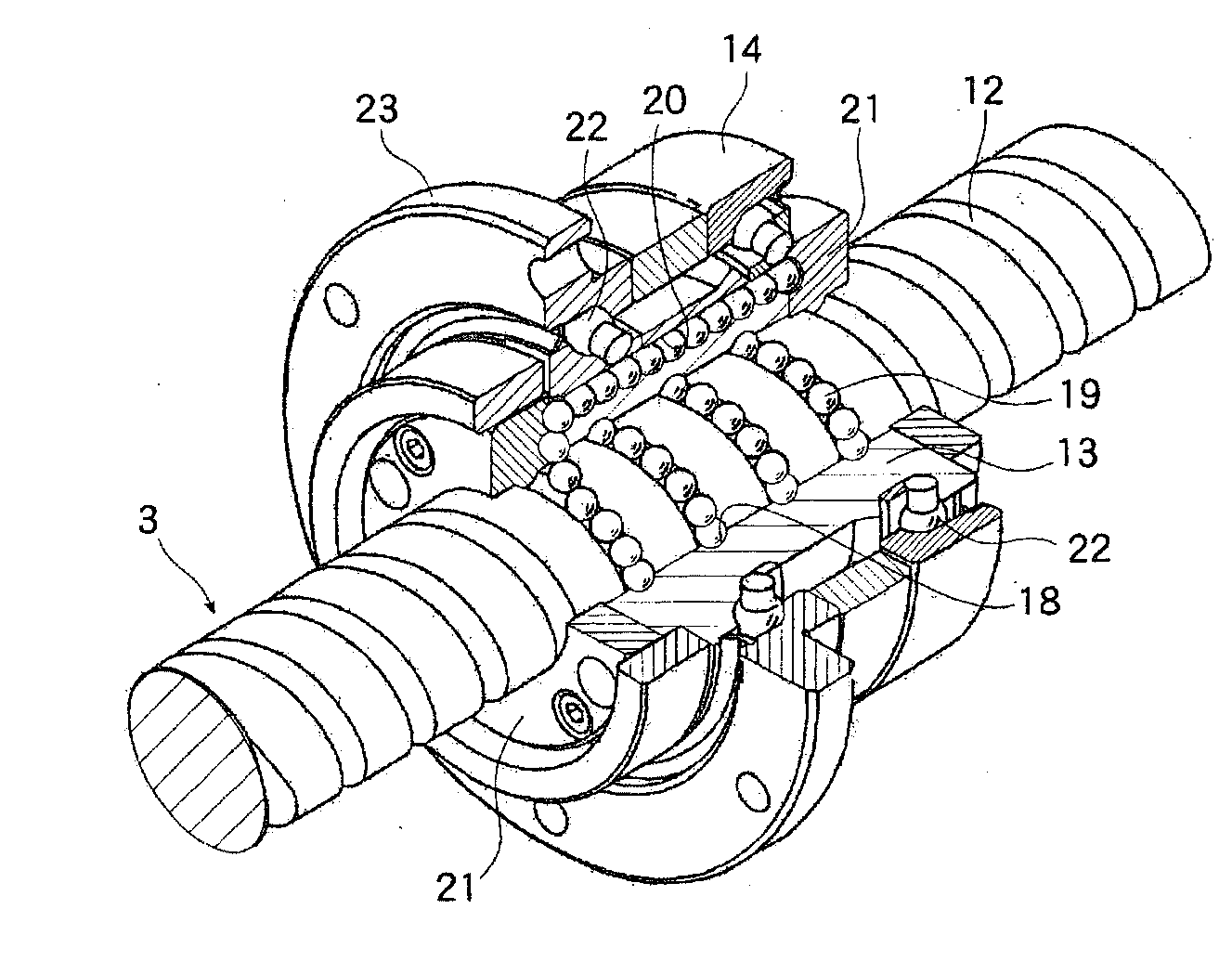

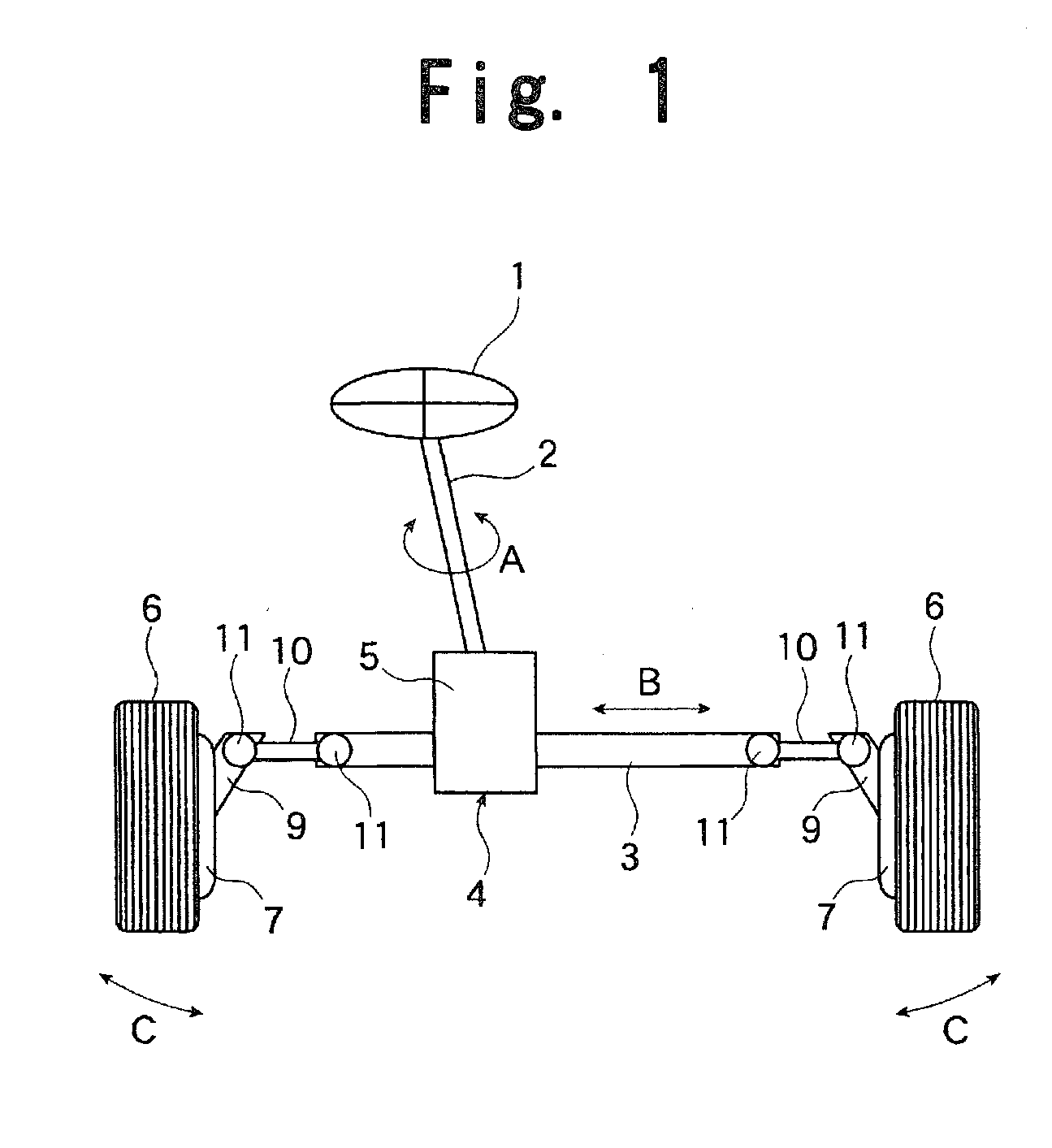

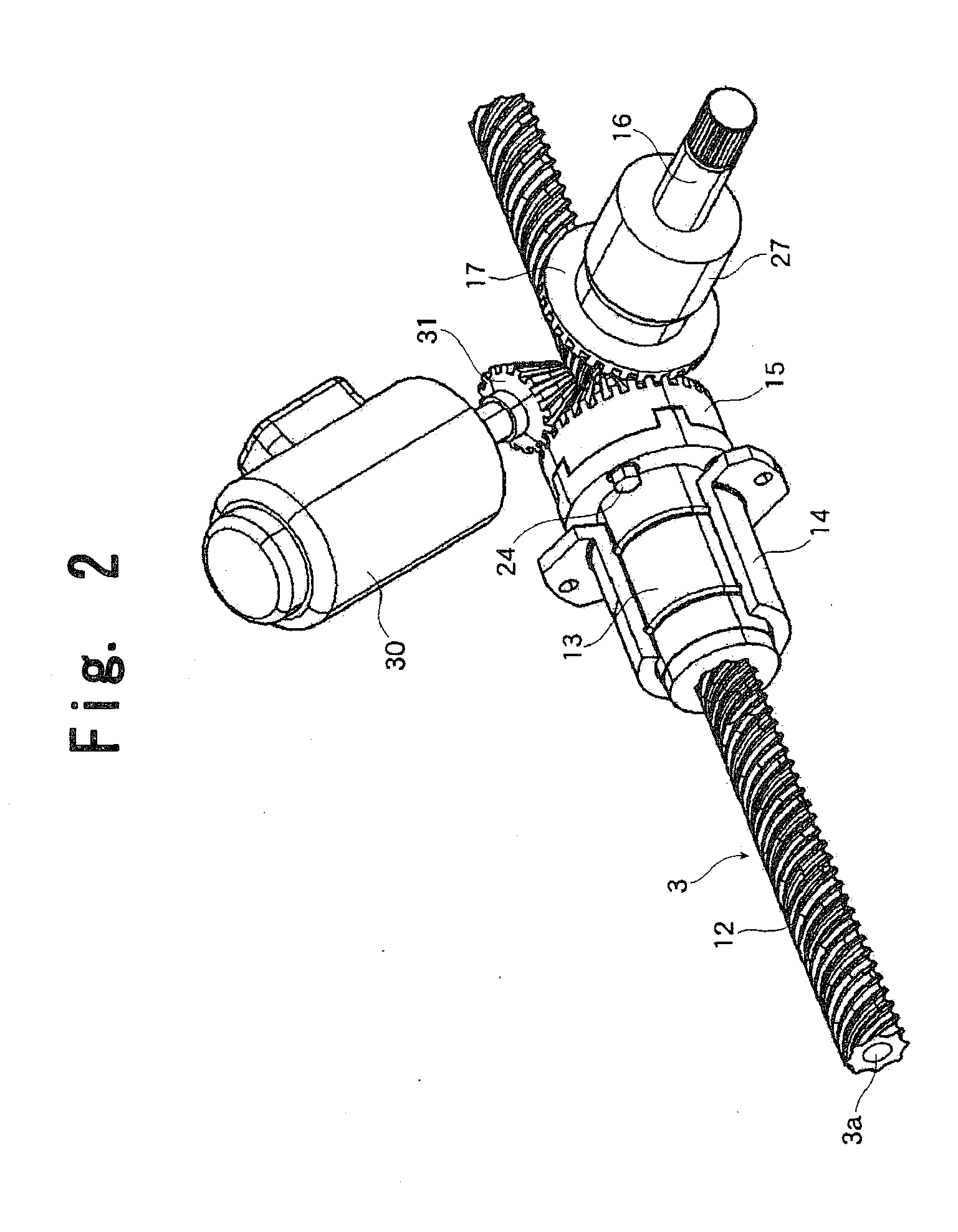

Steering device and movement converting device used therefor

InactiveUS20090260468A1Easy to applySmall sizeToothed gearingsPortable liftingGear wheelControl theory

Provided is a novel steering device which can be formed to be compact, which is easily applicable to a vehicle with a small engine room such as a front-engine / front-drive car, and which is of neither the ball nut type nor the rack and pinion type. The steering device operates steerable wheels by converting rotation of a steering shaft to axial movement of a relay rod, the steering device including: a gear casing through which the relay rod is passed; a spiral ball rolling groove provided in the relay rod within the gear casing so as to exhibit a lead of a magnitude of 1 or more; a nut member threadedly engaged with the ball rolling groove of the relay rod through an intermediation of a large number of balls and supported rotatably with respect to the gear casing; an input shaft to which rotation of the steering shaft is transmitted and which is in an intersecting or offset relationship with the relay rod; and a first transmission gear for transmitting rotation of the input shaft to the nut member.

Owner:THK CO LTD

Computer housing and computer including the same

InactiveUS8009431B2Quick assemblyResistance to frictionDigital data processing detailsPrinted circuit board receptaclesElectronic componentMotherboard

A computer housing is adapted for receiving a motherboard and at least one electronic component therein, and includes a housing unit and a support board. The housing unit has an opening, and includes at least one first sliding portion that is provided at each of two opposite sides of an inner surface of the housing unit, that extends along a sliding direction, and that is connected to the opening. The support board is adapted for securing the motherboard and the electronic component, and includes a second sliding portion provided at each of two opposite edges of the support board and slidable relative to the first sliding portion in the sliding direction.

Owner:AOPEN

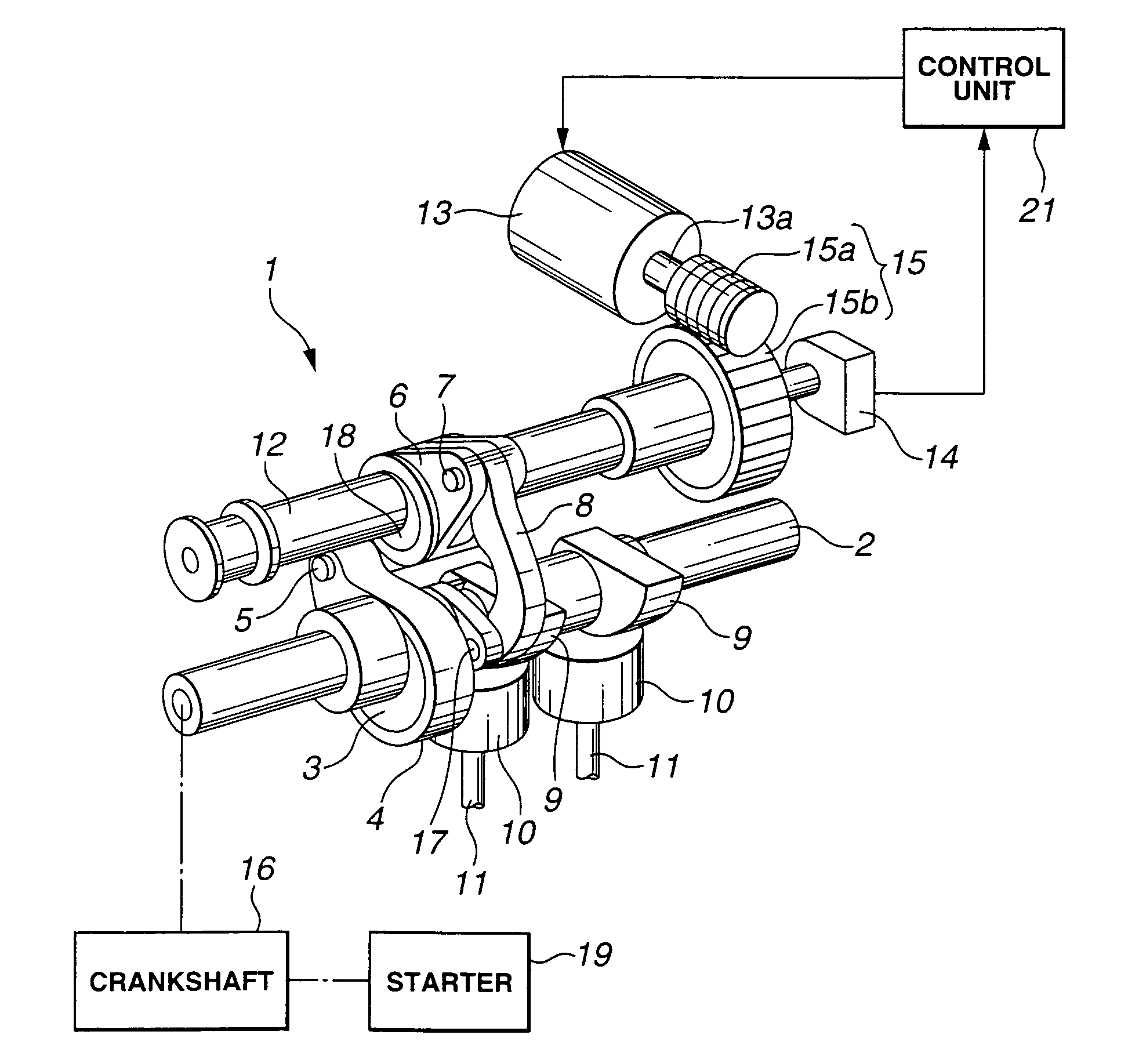

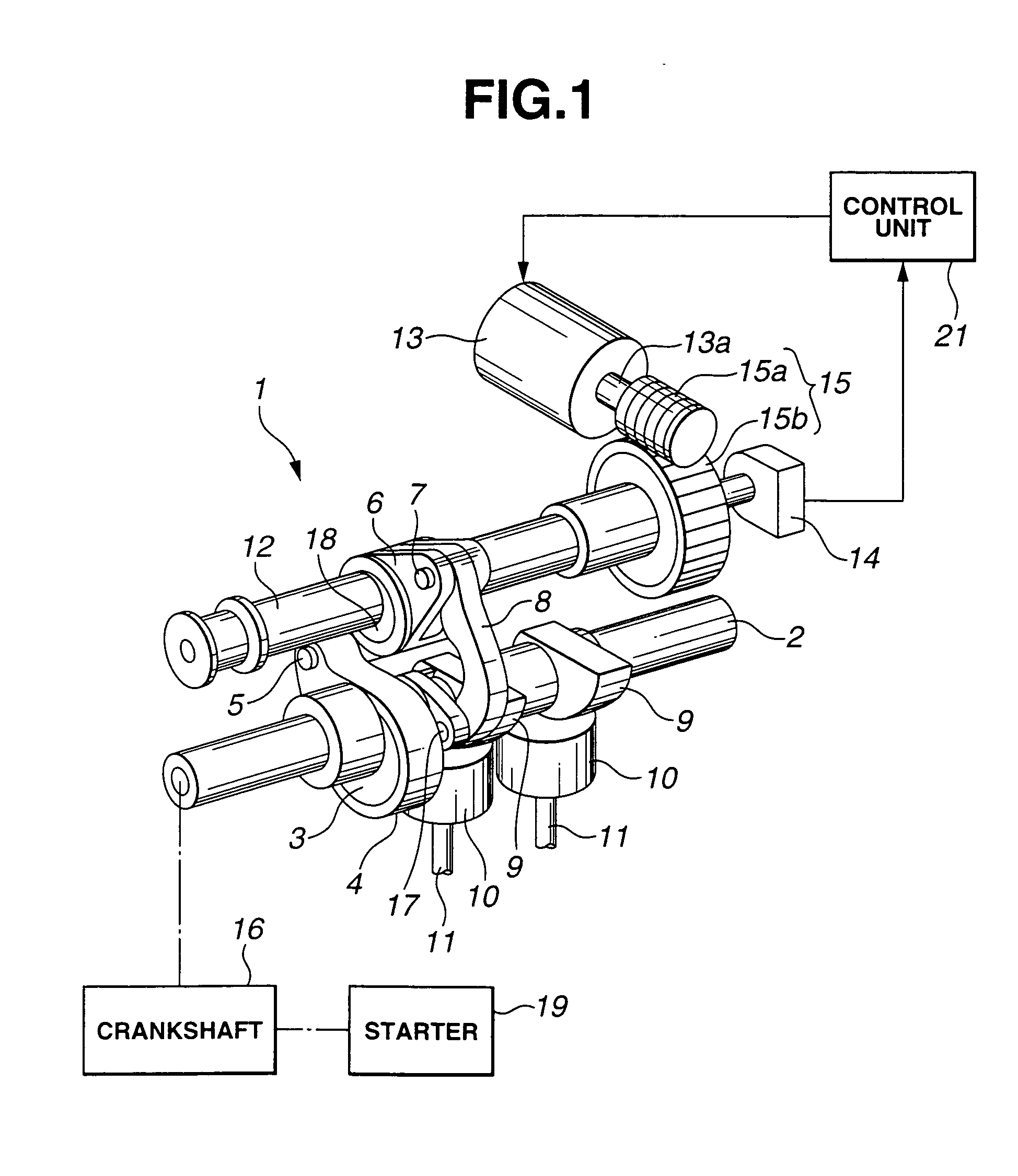

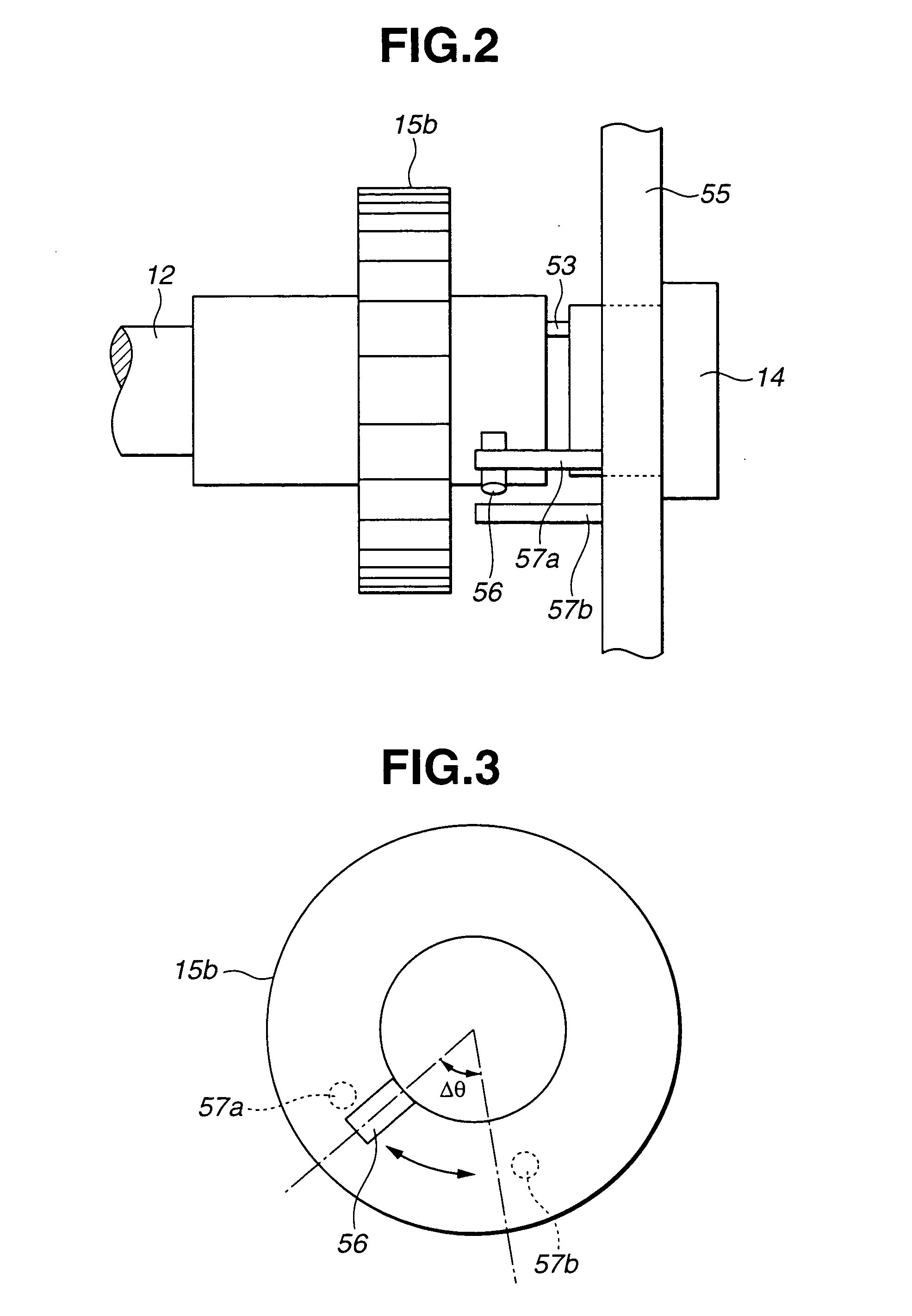

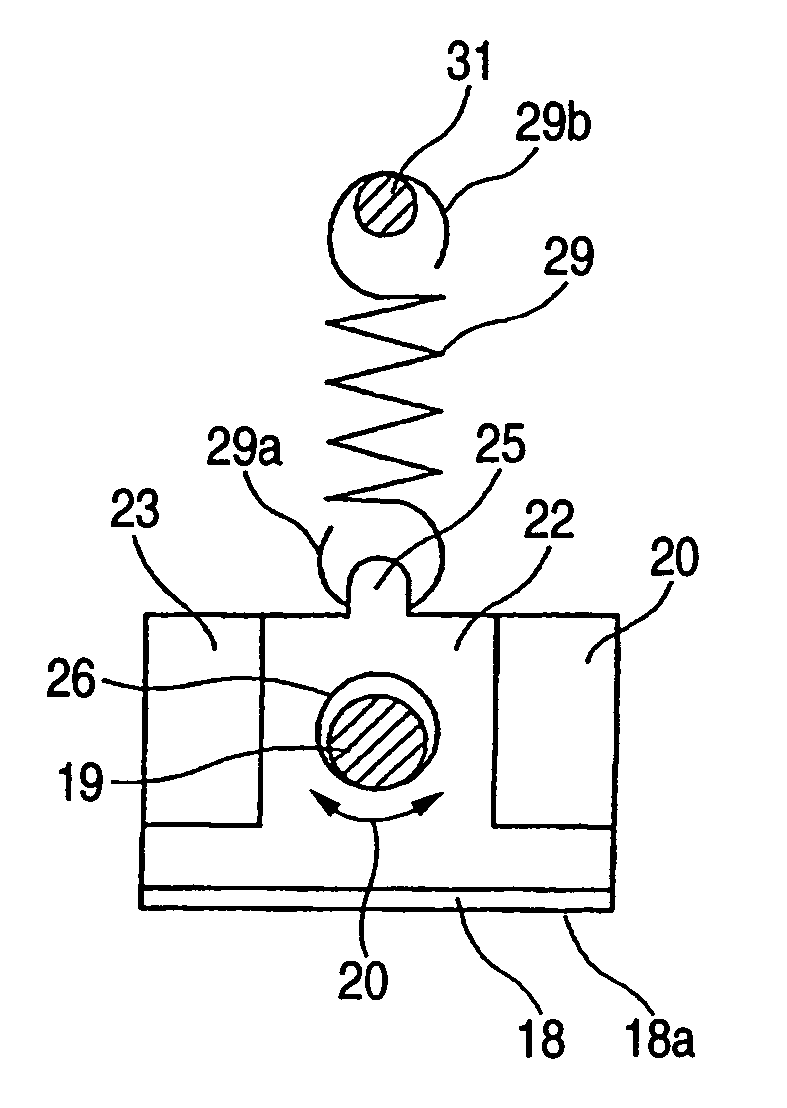

Learning apparatus and method for variable valve control of internal combustion engine

ActiveUS20050193968A1Learning time is longResistance to frictionCam-followersInternal combustion piston enginesEngineeringActuator

A learning apparatus for a variable valve control of an internal combustion engine includes a variable valve operating mechanism, an actuator that rotationally drives the control shaft, a control shaft sensor that detects an angular position of the control shaft, a reference position determining section that determines whether or not the control shaft has reached a predetermined reference position under the drive from the actuator, a learning section that learns an output value of the control shaft sensor when it is determined that the control shaft has reached the reference position and stores the learned output value as a sensor output reference value, and a learning preparing section that causes the control shaft to be driven by the actuator toward the reference position when a crankshaft of the engine is rotating and supply of fuel to the engine is stopped. A learning method is also provided,

Owner:NISSAN MOTOR CO LTD

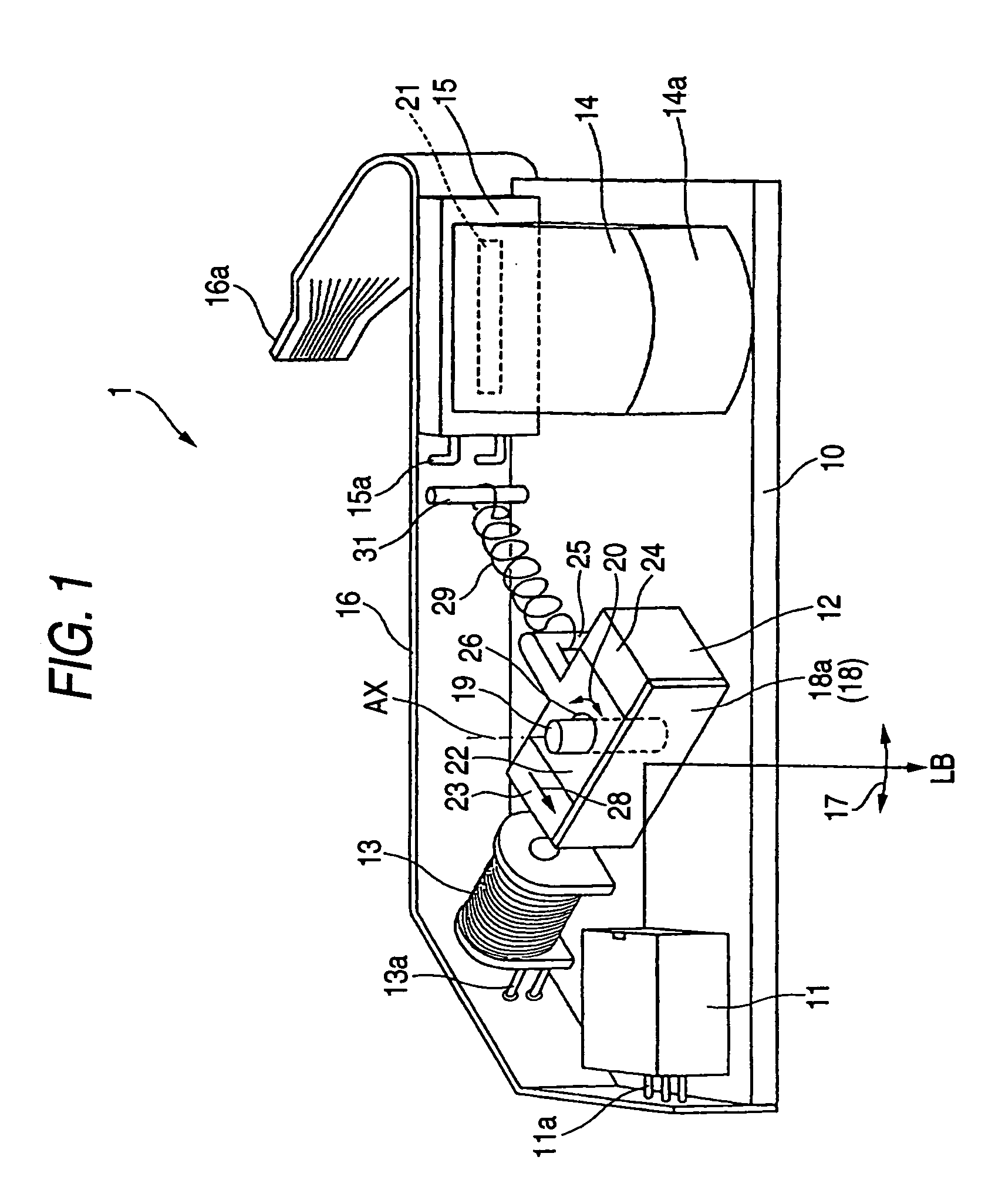

Optical unit for optical symbol reader

InactiveUS6969005B2Optical unitReduce areaTelevision system scanning detailsCharacter and pattern recognitionOptical scannersCoil spring

An optical unit for an optical symbol reader comprises an optical scanner for scanning an optical symbol with the laser beam emitted by a light source, by angularly oscillating a reflection face for reflecting the laser beam owing to an electromagnetic force. The optical scanner comprises a loose bearing structure having a shaft and a bearing bore and supporting a rotor having the reflection face to angularly oscillate freely with respect to a base. A certain bearing gap is formed between an outer diameter of the shaft and an inner diameter of the bearing bore. The optical scanner further comprises a coil spring resiliently for urging the rotor in a predetermined direction so that a part of an outer circumferential face of the shaft may be contacted with an inner circumferential face of a bearing bore.

Owner:KEYENCE

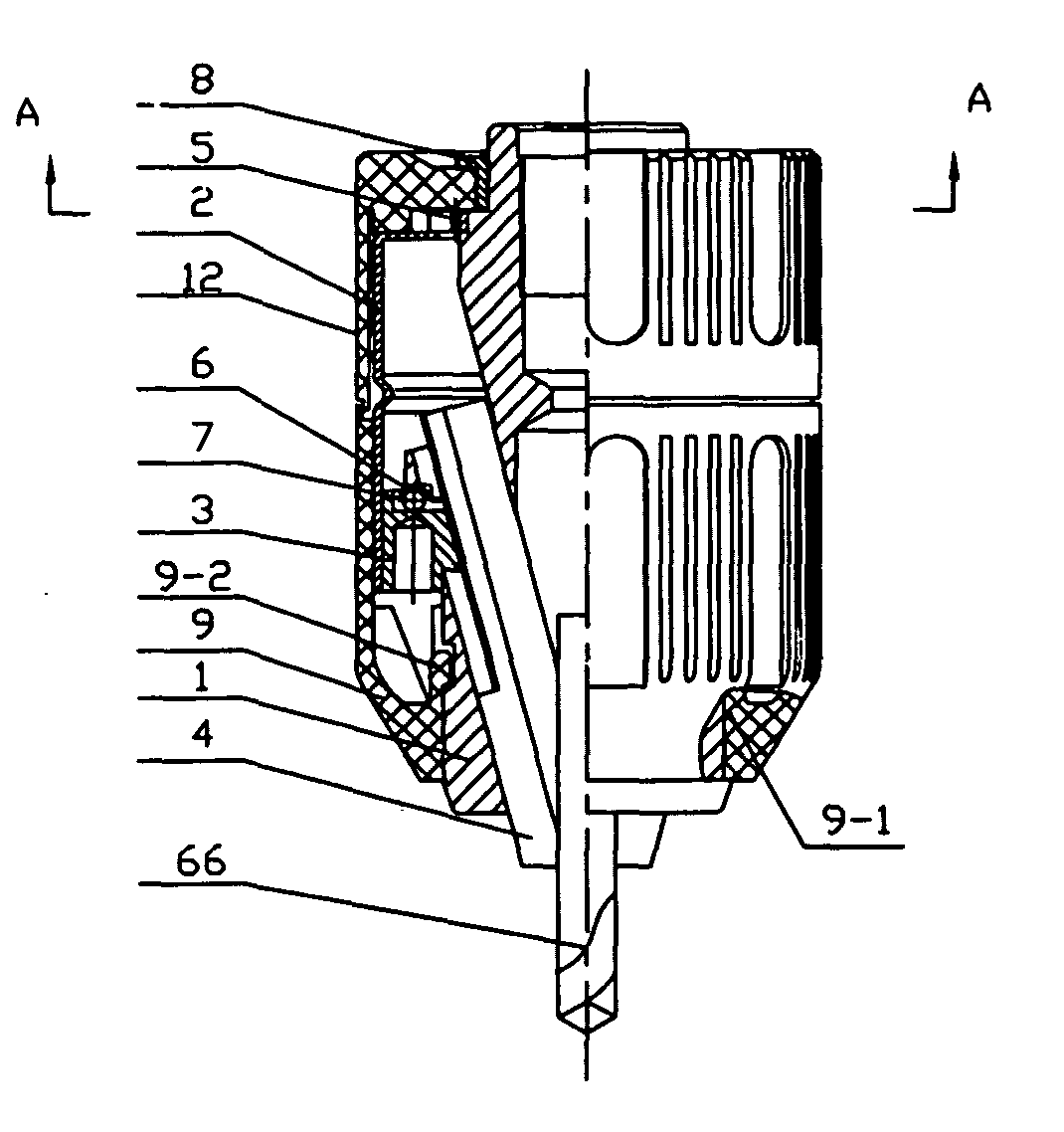

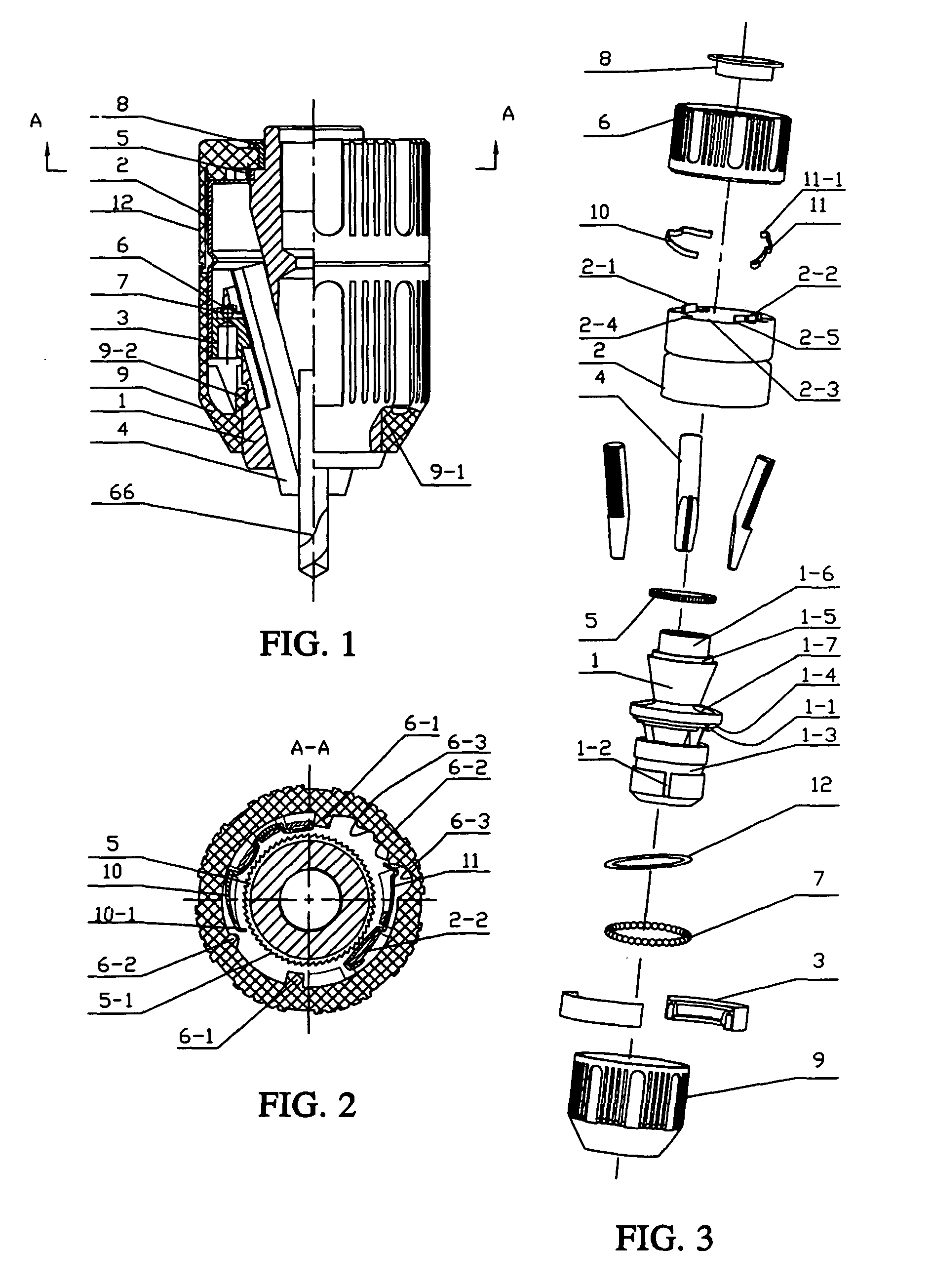

Self-locking drill chuck

ActiveUS20050258605A1Simple structureHigh working reliabilitySleeve/socket jointsChucksEngineeringSelf locking

A self-locking drill chuck device, comprising a body, a nut, jaws, a front sleeve, a rear sleeve, a nut jacket and a rolling member, wherein three jaws are respectively and operatively inserted into three angled bores uniformly distributed around the body, the threads of the nut engages with that of the jaws to form a thread driving mechanism, wherein a ratchet wheel is fixedly mounted at a rear portion of the body, a disk spring is provided between the rolling member and a load carrying shoulder of the body, the front portion of the body has key slots and an annular connecting groove, the rear end of the nut jacket has a plurality of driving grooves and keys on which a locking elastic element and a driving elastic element are respectively fixed, A control ring fixedly fitted in the rear sleeve has an internal surface thereof formed with a plurality of driving keys and a cam face including a plurality of bulged portions and curved teeth. The front sleeve has positioning keys and connecting clips formed in an internal surface thereof. The drill chuck of the present invention has a simple structure, convenience of operation and high working stability and reliability of self-locking capacity.

Owner:SHANDONG WEIDA MASCH CO LTD

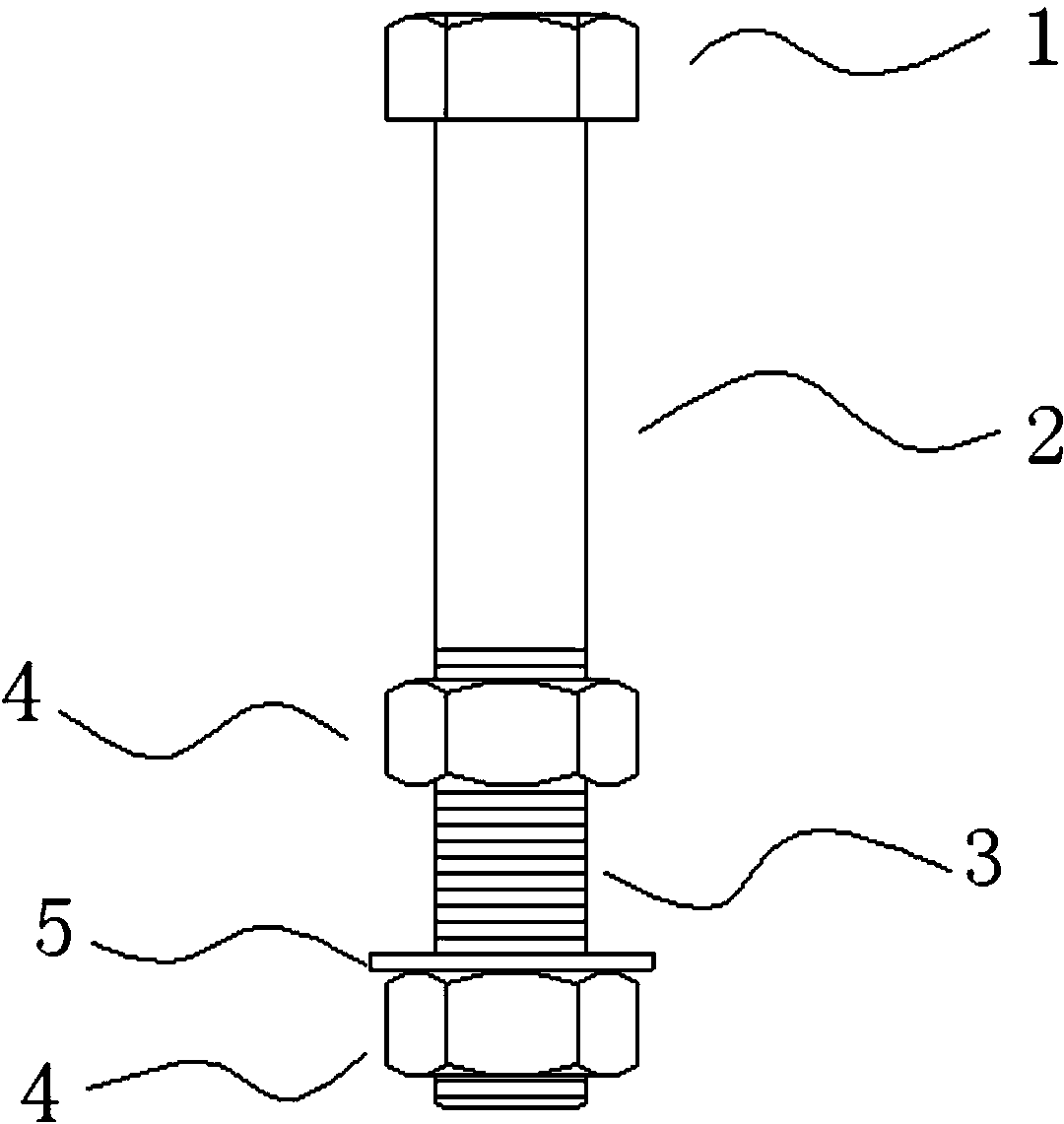

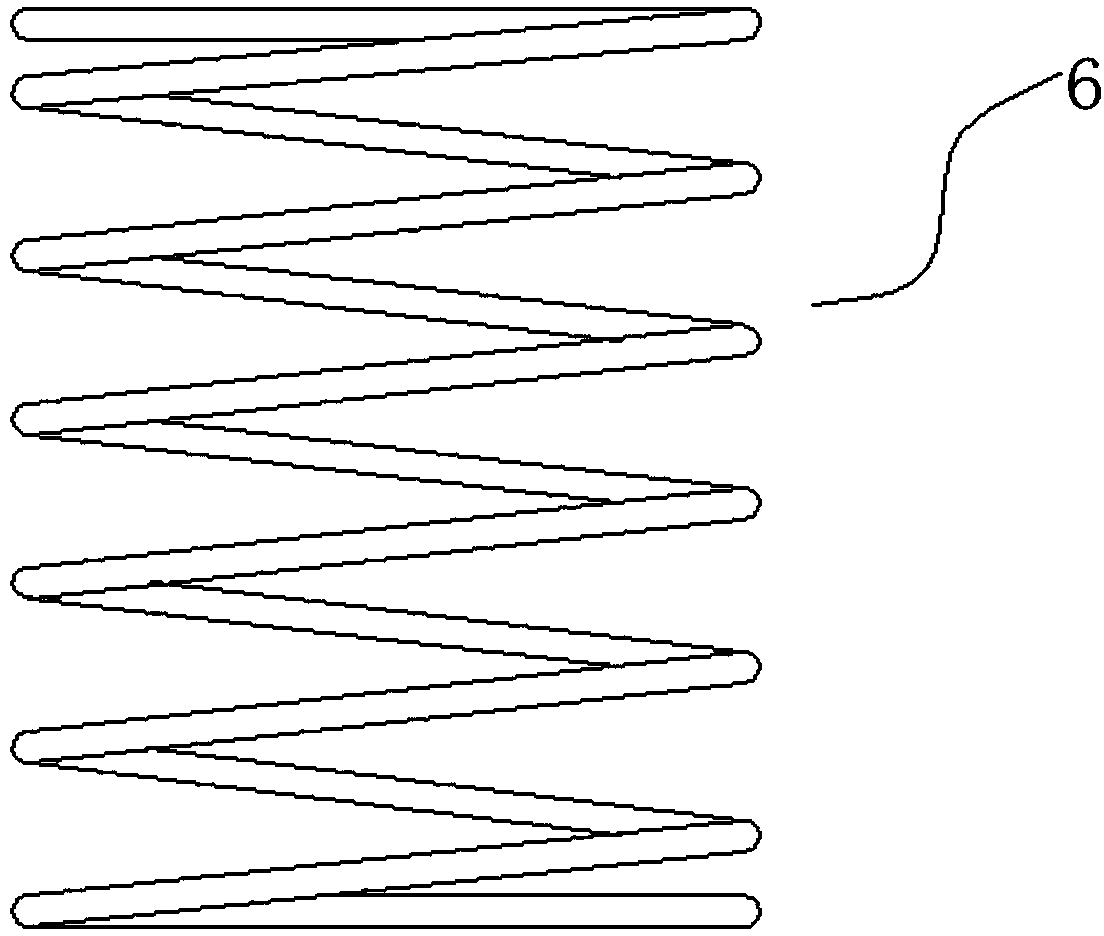

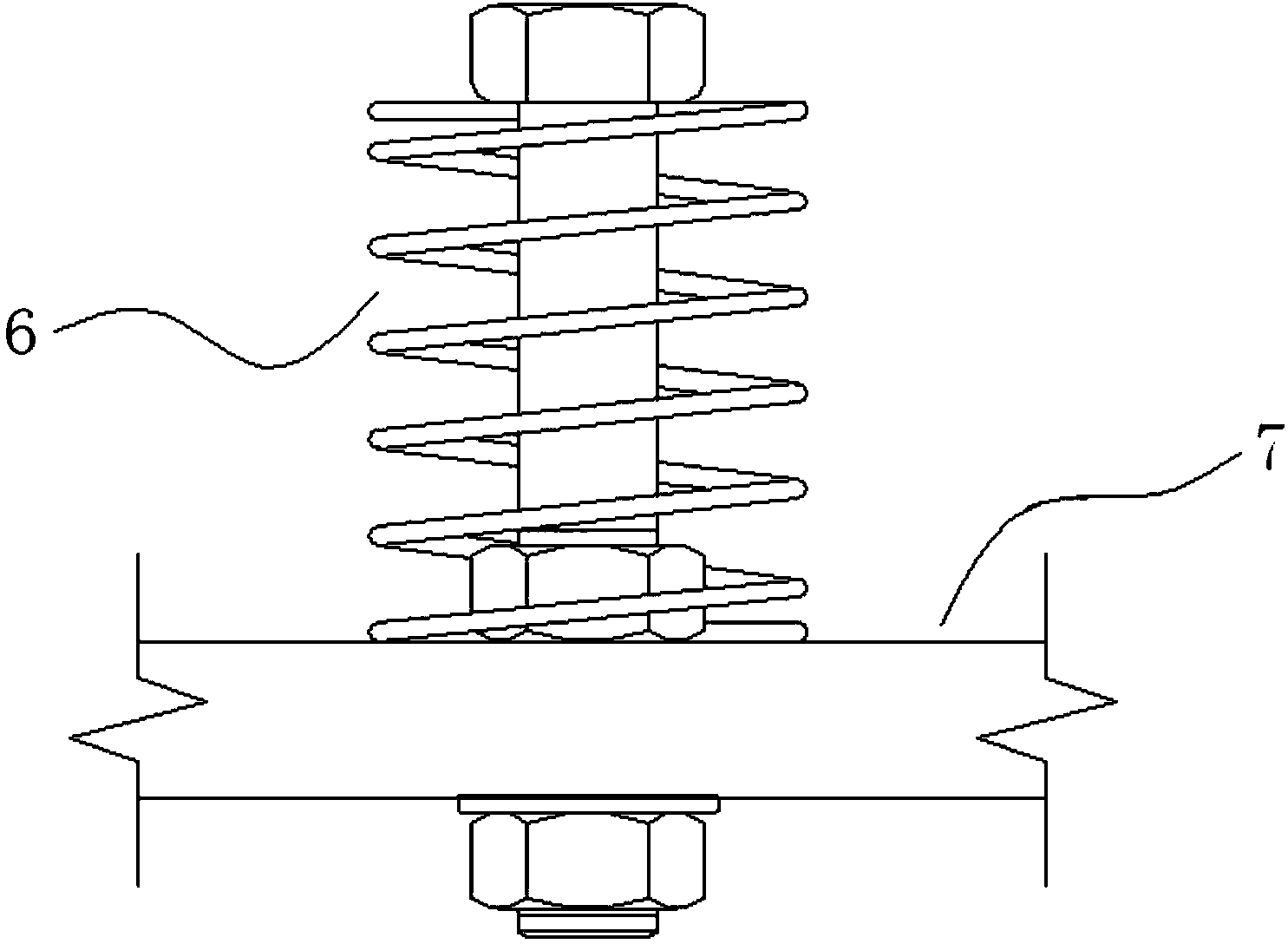

Bolt shear force connecting piece and method for enhancing shear strength by use of spring

InactiveCN103866864AIncrease stiffnessIncreased shear strengthBuilding material handlingMaterial resourcesUltimate tensile strength

Owner:NANJING UNIV OF TECH

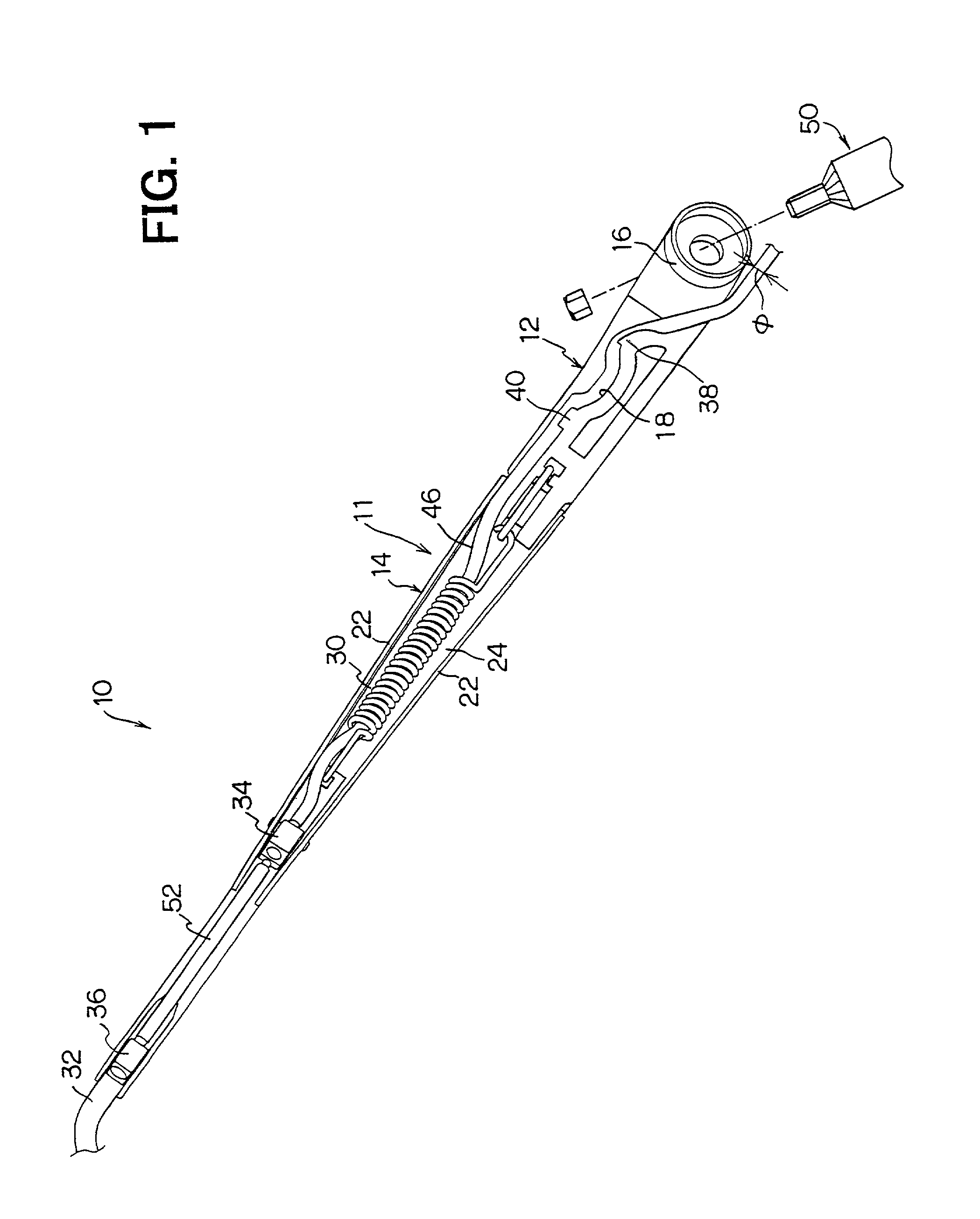

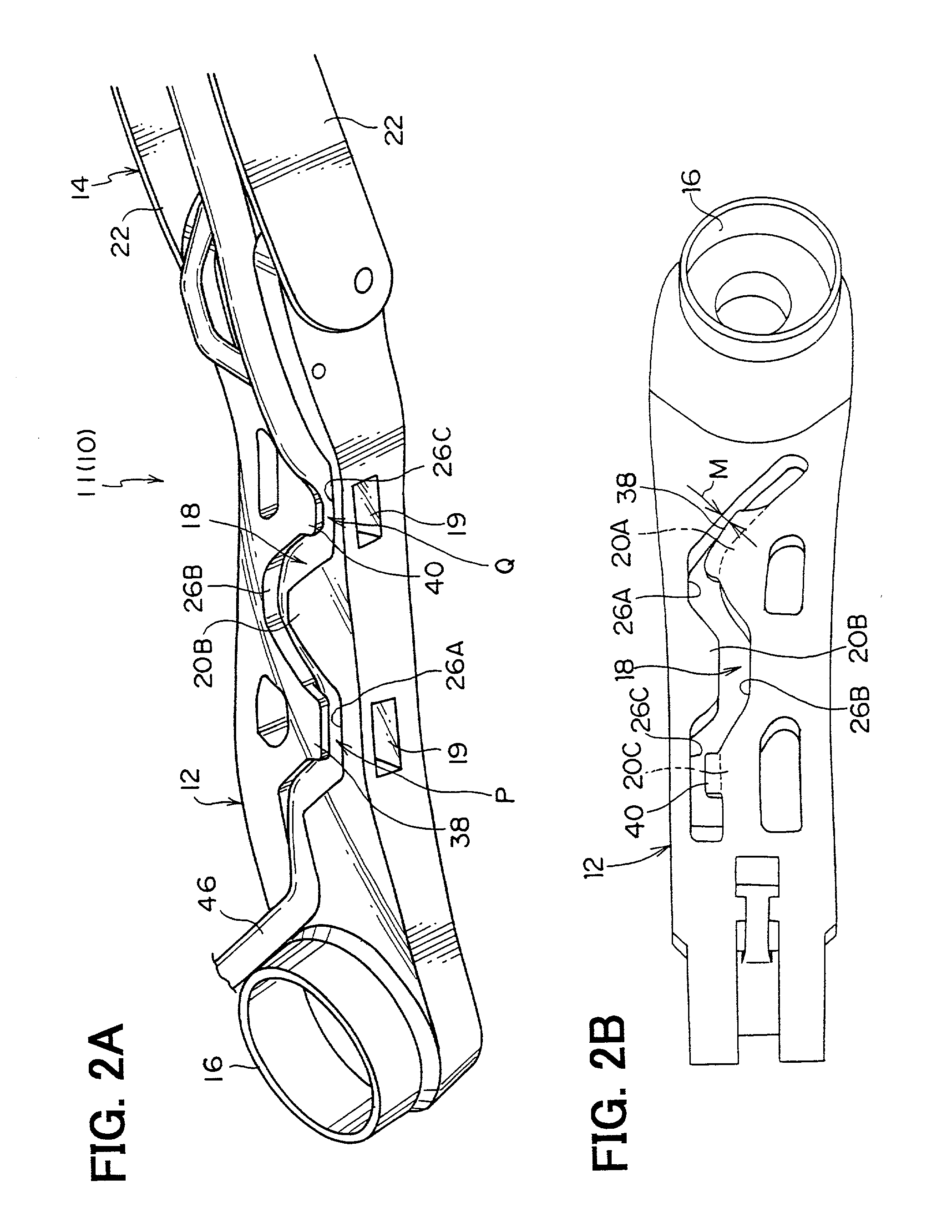

Windshield wiper device mounting washer nozzle and hose

InactiveUS20020133893A1Less timeManufacturing costSpray nozzlesWindow cleanersEngineeringDepth direction

An arm head of a windshield wiper device is provided on a backside thereof with an undulated groove formed by sidewalls. The sidewalls have plural hill portions protruding in opposite directions alternately in a width direction of the arm head so as to be opposed to one another in a longitudinal direction thereof. Tops of the hill portions on one width side of the arm head are integrally provided at upper surfaces thereof with projections extending perpendicularly to a depth direction of the groove to overhang the groove. A hose for delivering washer liquid to a washer nozzle is accommodated in the groove and firmly held by the hill portions and the projections without using an extra part such as a clip.

Owner:DENSO CORP +1

Cleaning unit and image forming apparatus

This invention relates to a cleaning unit including a cleaning blade that keeps a front end of rubber material in contact with the surface with a pressure so as to scrape residual toner left on the surface of the photoreceptor and a fiber body having multiple fibers in contact with the surface of the photoreceptor in the upstream in the cyclic moving direction of the surface of the photoreceptor with respect to the cleaning blade, the cleaning blade satisfying A≧−2.5×B+102 and 6.3≦B≦19.6, where A designates a contact angle (°) with pure water under 23° C., 55% RH and B designates 100% modulus (MPa) at 23° C.

Owner:FUJIFILM BUSINESS INNOVATION CORP

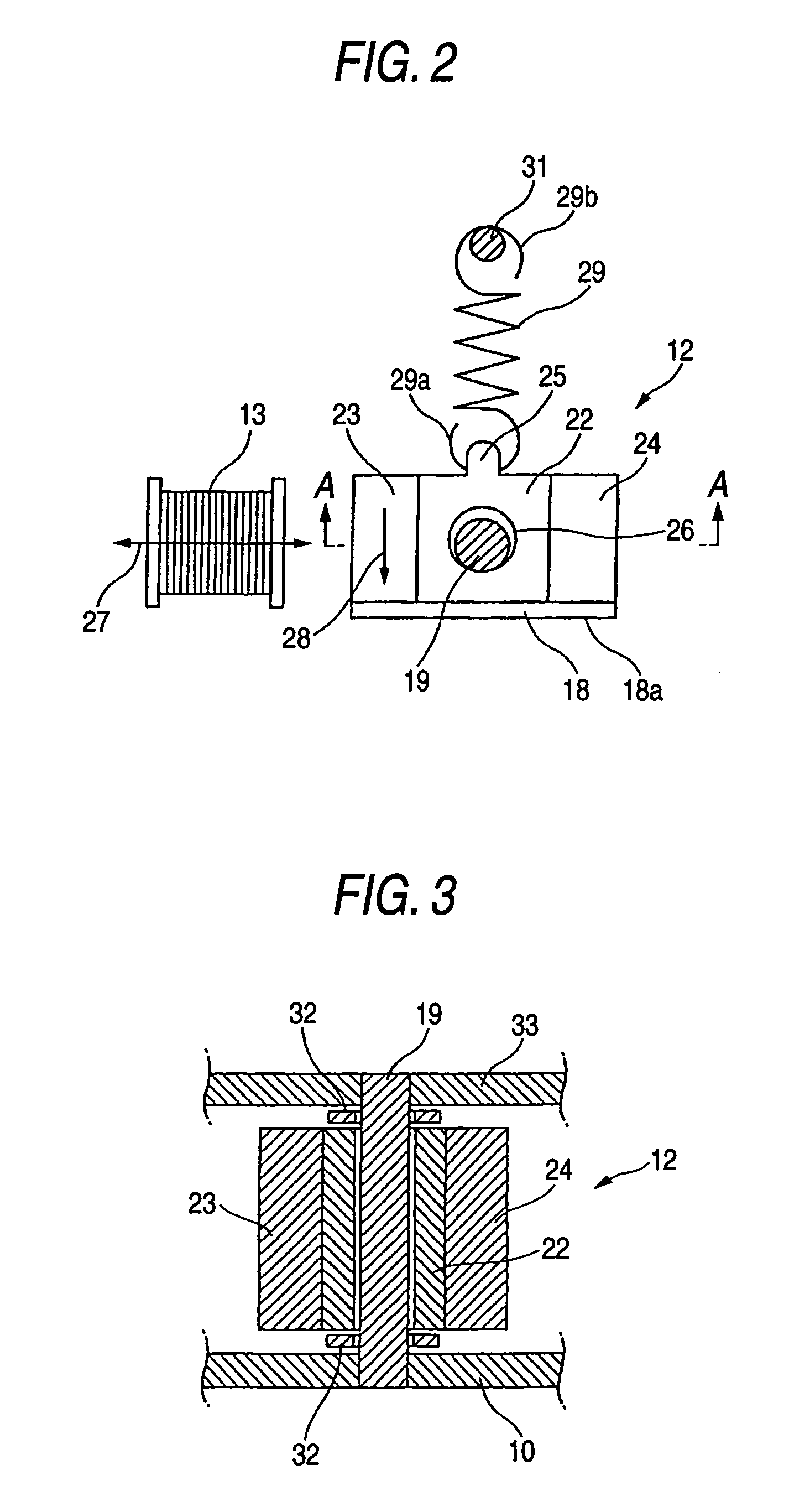

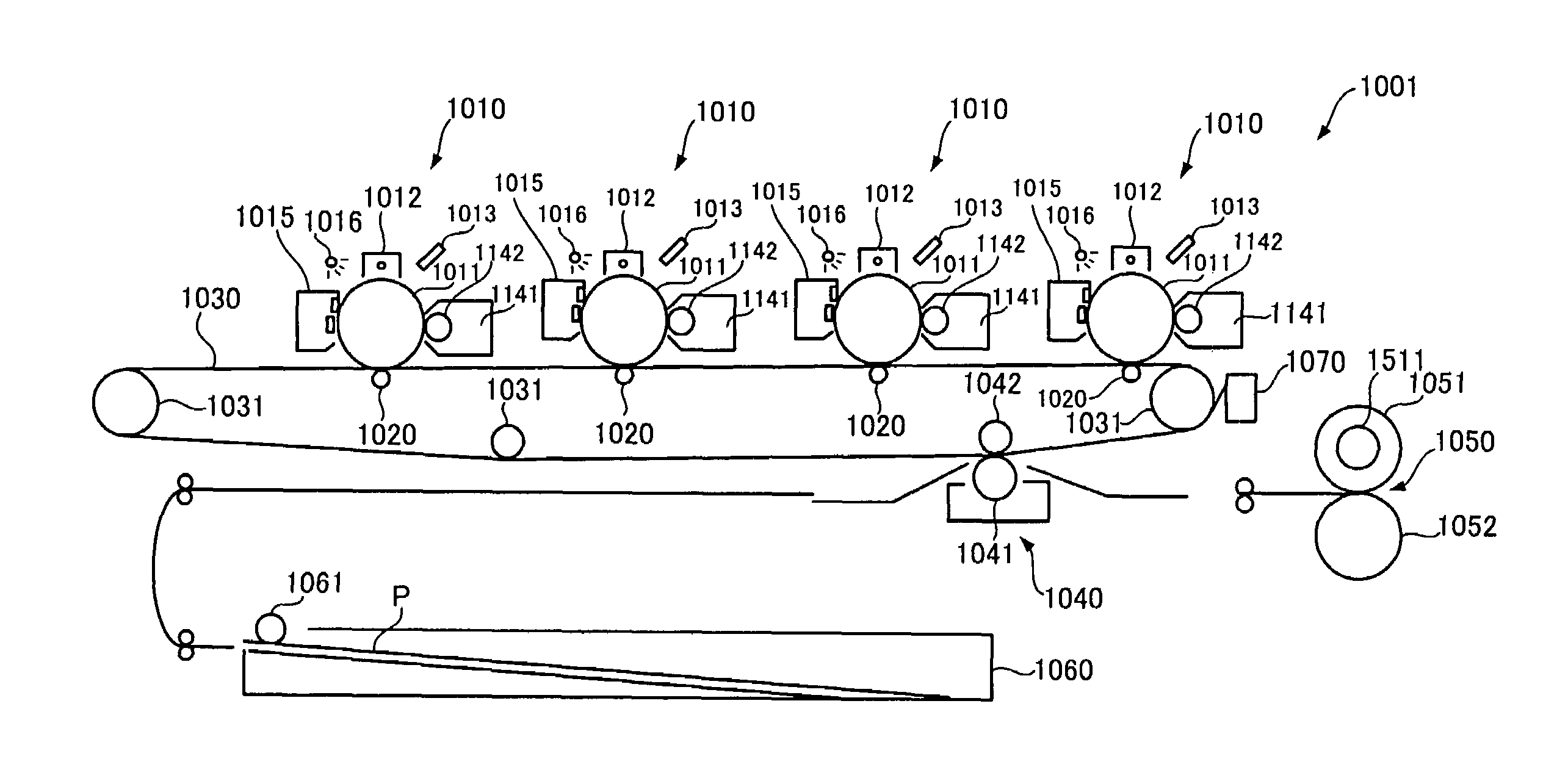

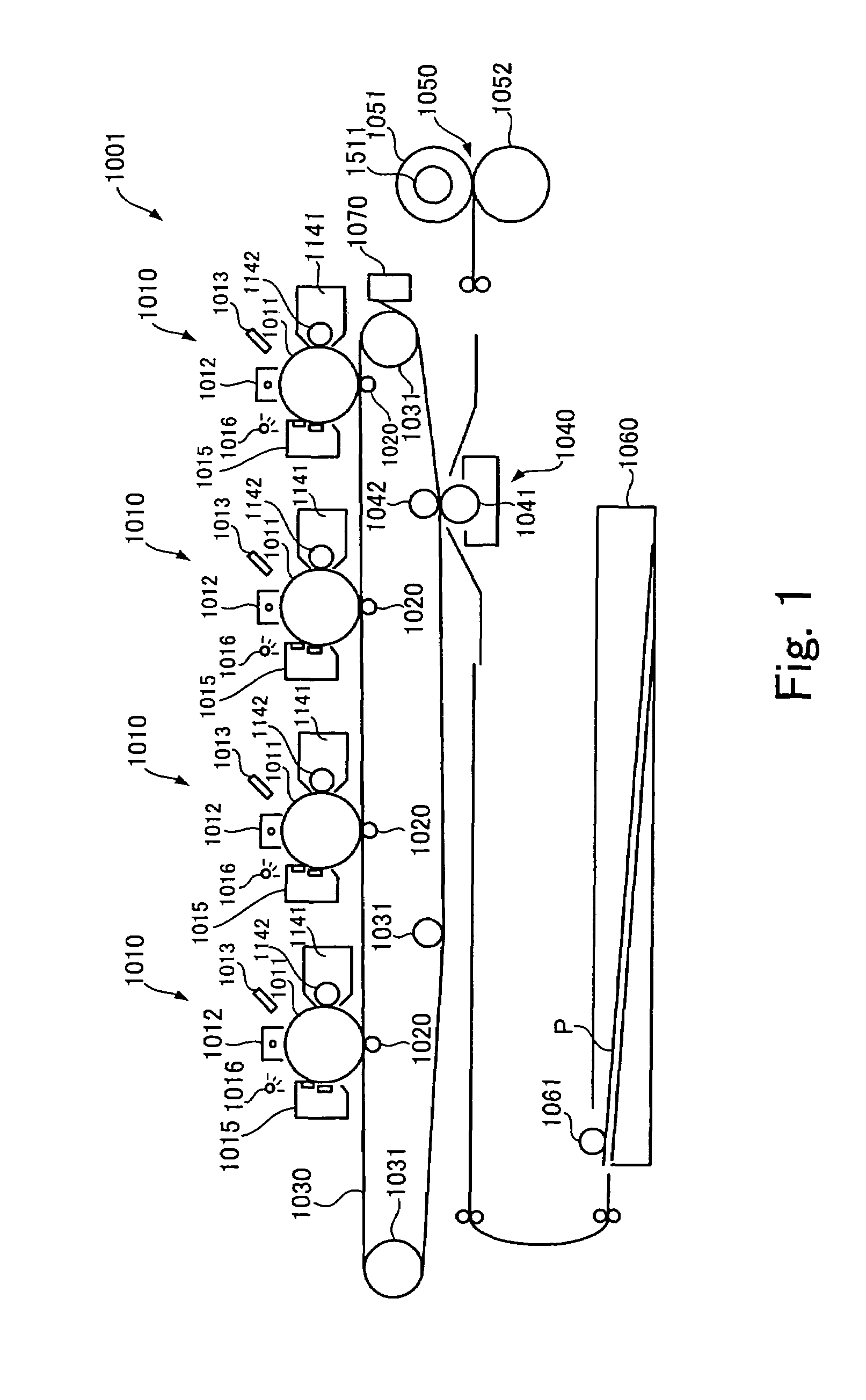

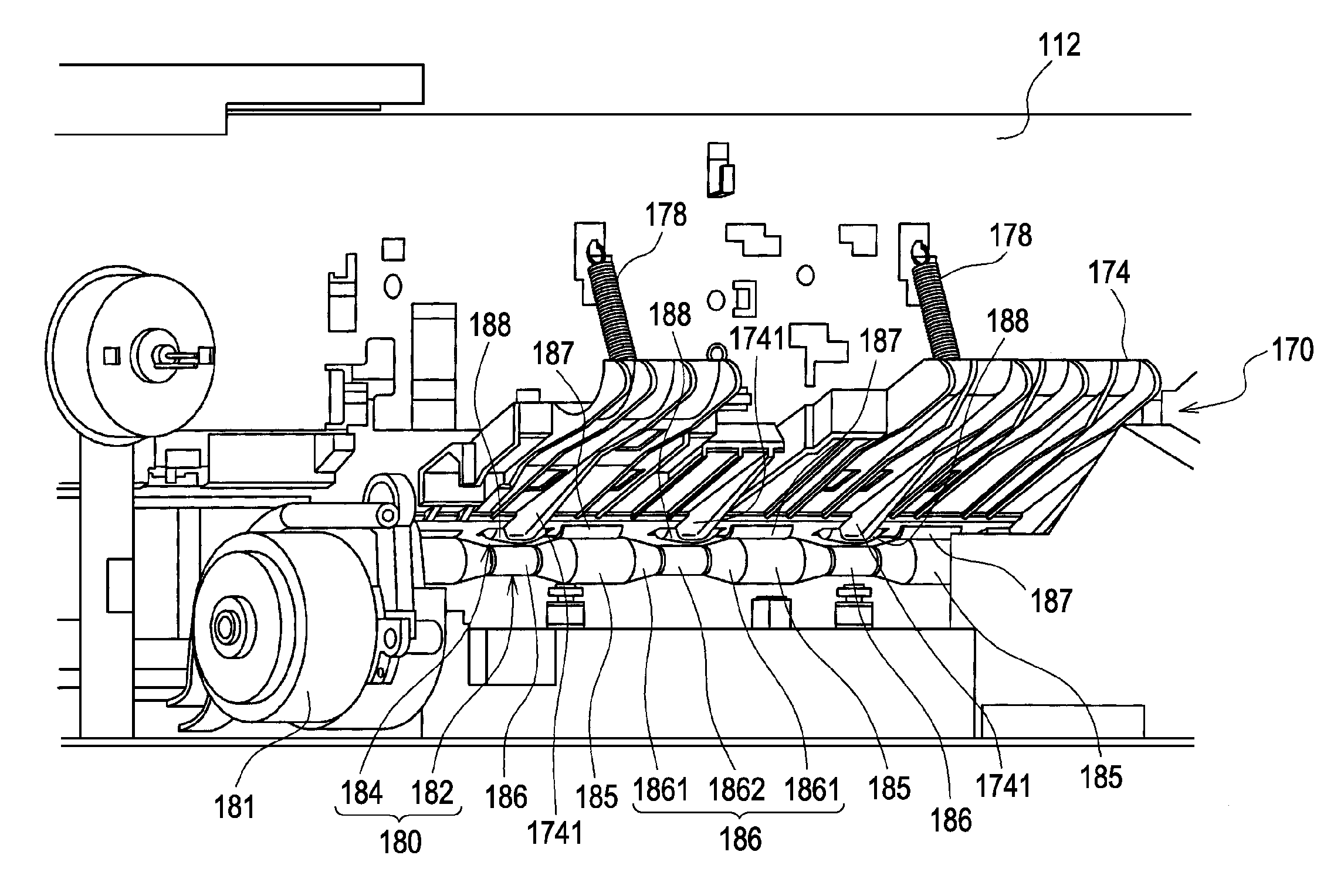

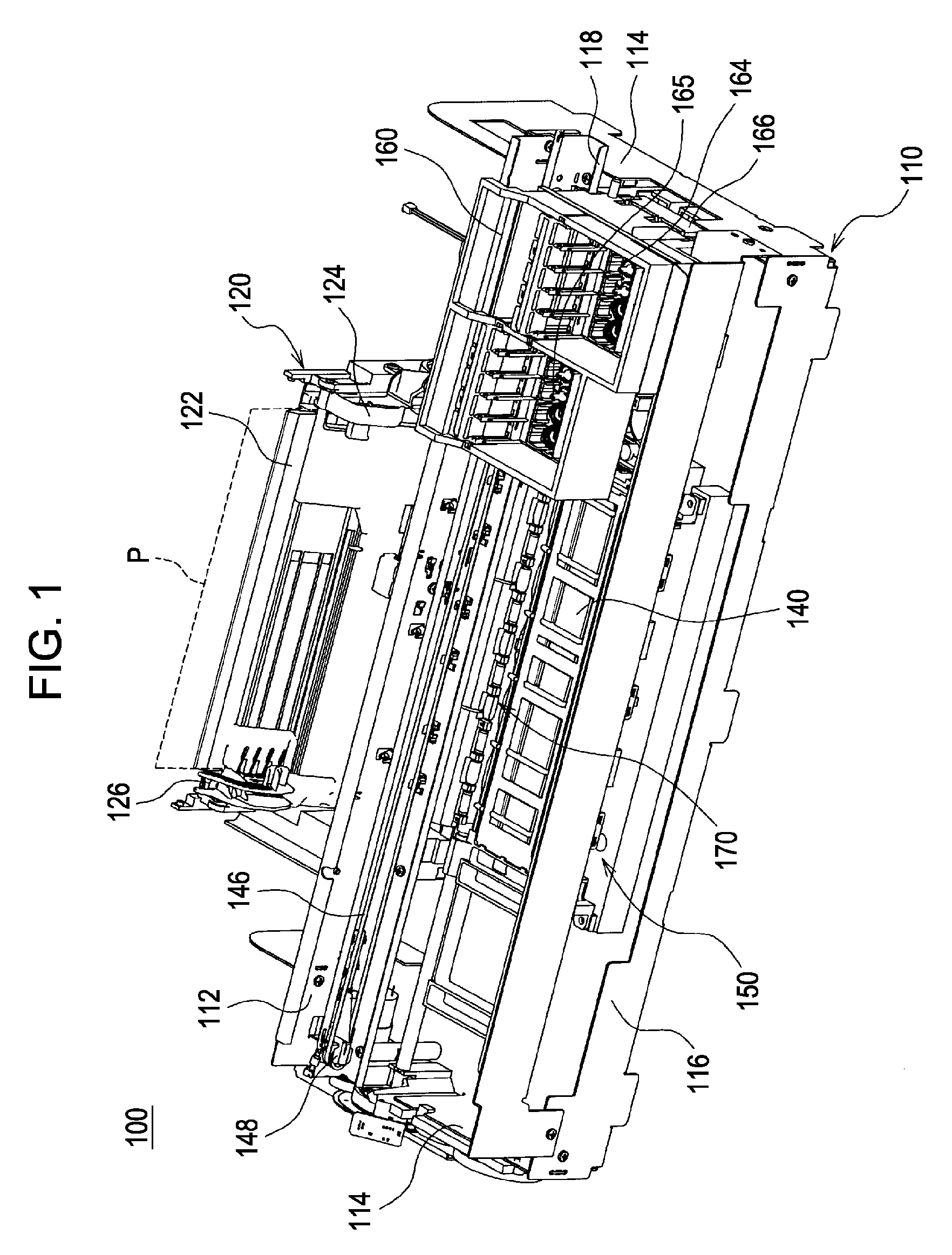

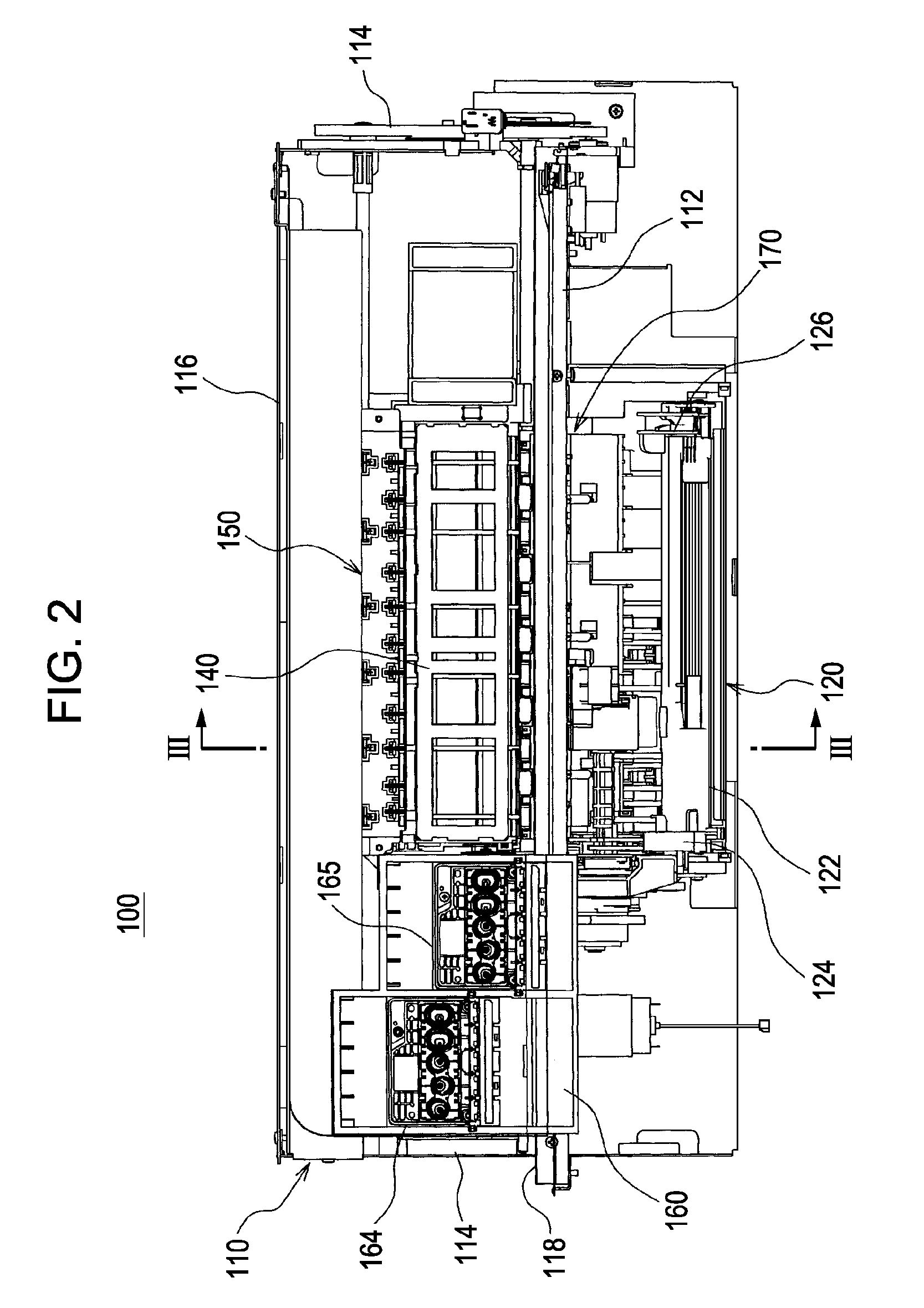

Recording apparatus

InactiveUS20090212495A1Large caliberSuppress rapid changesElectrographic process apparatusOther printing apparatusMechanical engineeringRecording media

A recording apparatus includes a recording head, a transport driving roller, and a transport driven roller. The recording head discharges ink onto a transported recording medium, thereby performing recording. The transport driving roller is provided on the upstream side of the recording head in the transport direction and includes driving side roller portions and depressed portions. The driving side roller portions are rotationally driven, thereby transporting the recording medium. The diameter of the depressed portions is smaller than that of the driving side roller portions. The driving side roller portions and the depressed portions are arranged in a direction perpendicular to the transport direction of the recording medium in such a manner that at least one driving side roller portion alternates with at least one depressed portion. The transport driven roller is provided opposite the transport driving roller and includes driven side roller portions and presser rollers.

Owner:SEIKO EPSON CORP

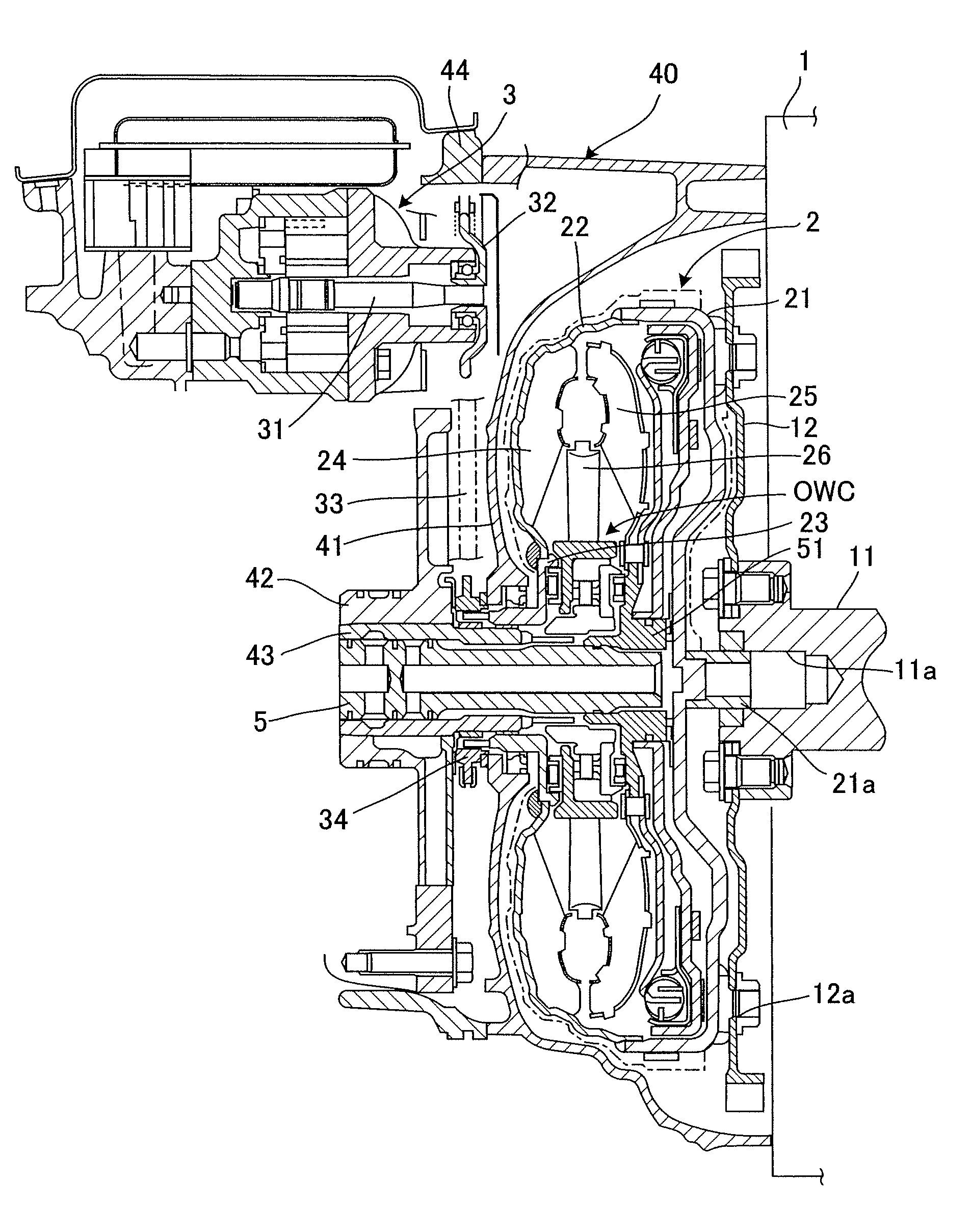

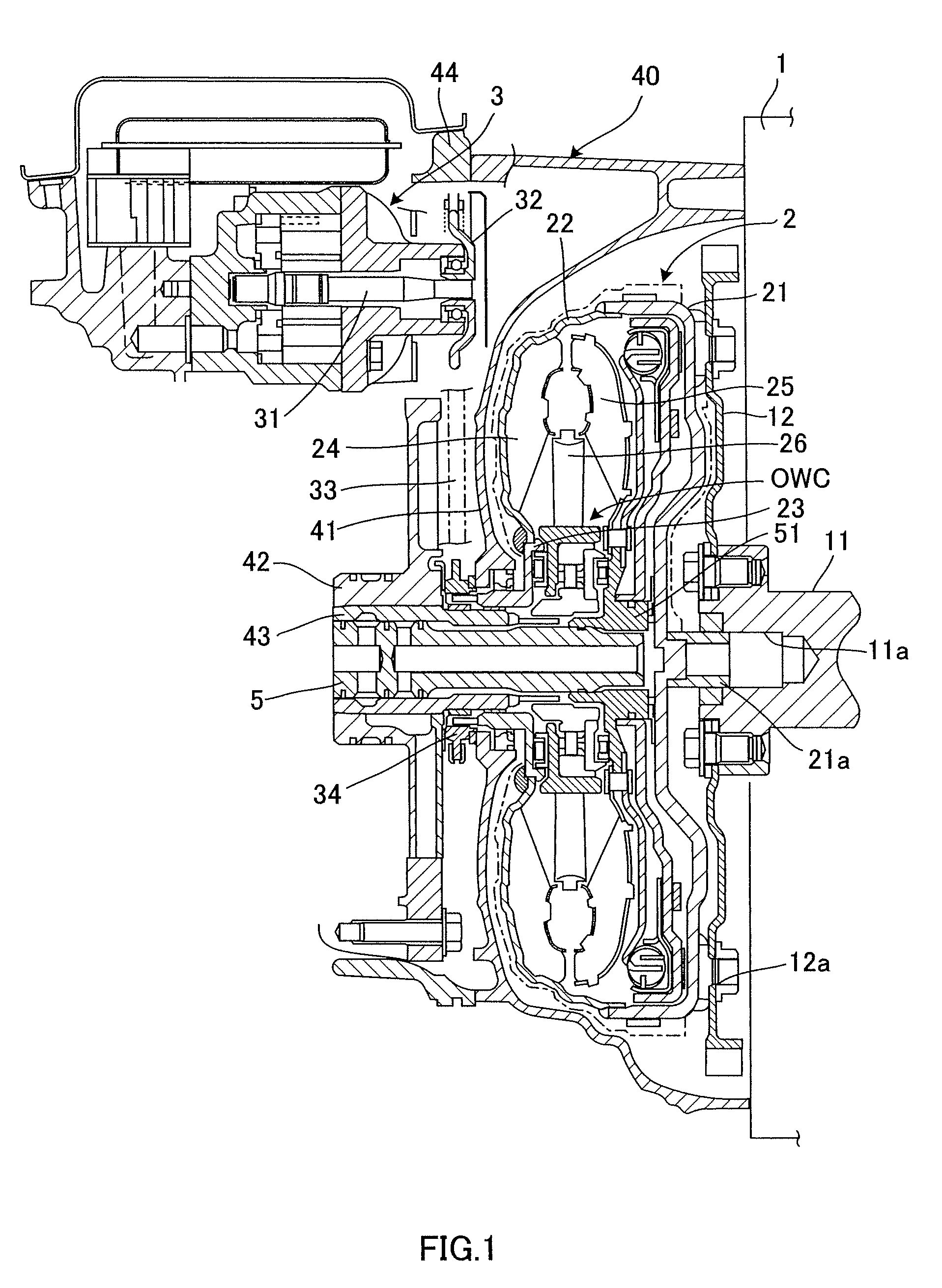

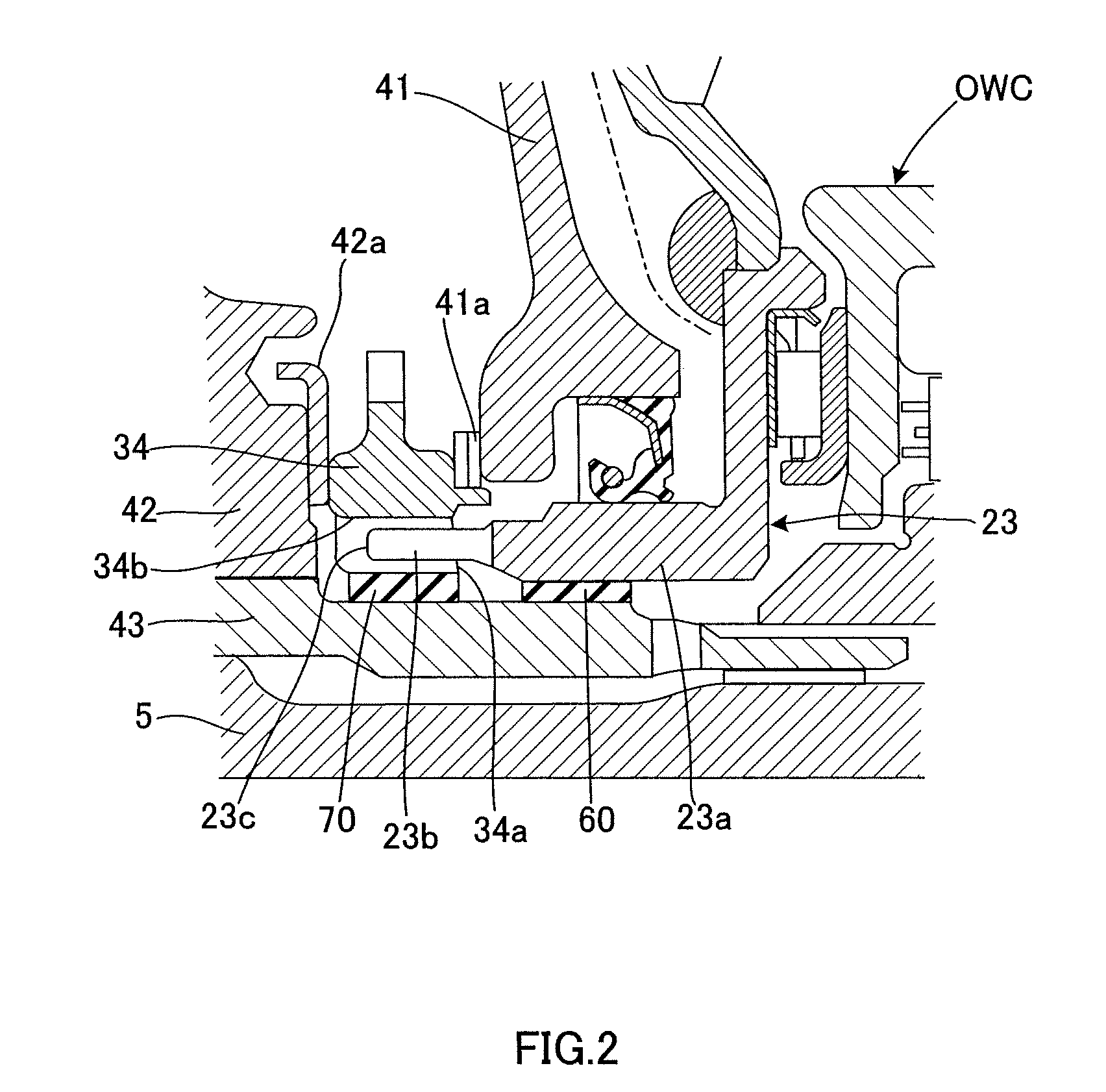

Oil pump driving mechanism

ActiveUS20080293530A1Resistance to frictionEasy to installGear lubrication/coolingPortable liftingSprocketEngineering

When an engaging pawl 23b is fitted into a recessed portion 34b of a first sprocket 34, which is linked by a chain 33 to a second sprocket 32 that drives an oil pump 3 disposed at a radial detached from a torque converter 2, frictional resistance between a side face 34a of the first sprocket 34 and an end face 23c of the engaging pawl 23b is reduced by tapering the side face 34a of the first sprocket 34.

Owner:JATCO LTD +1

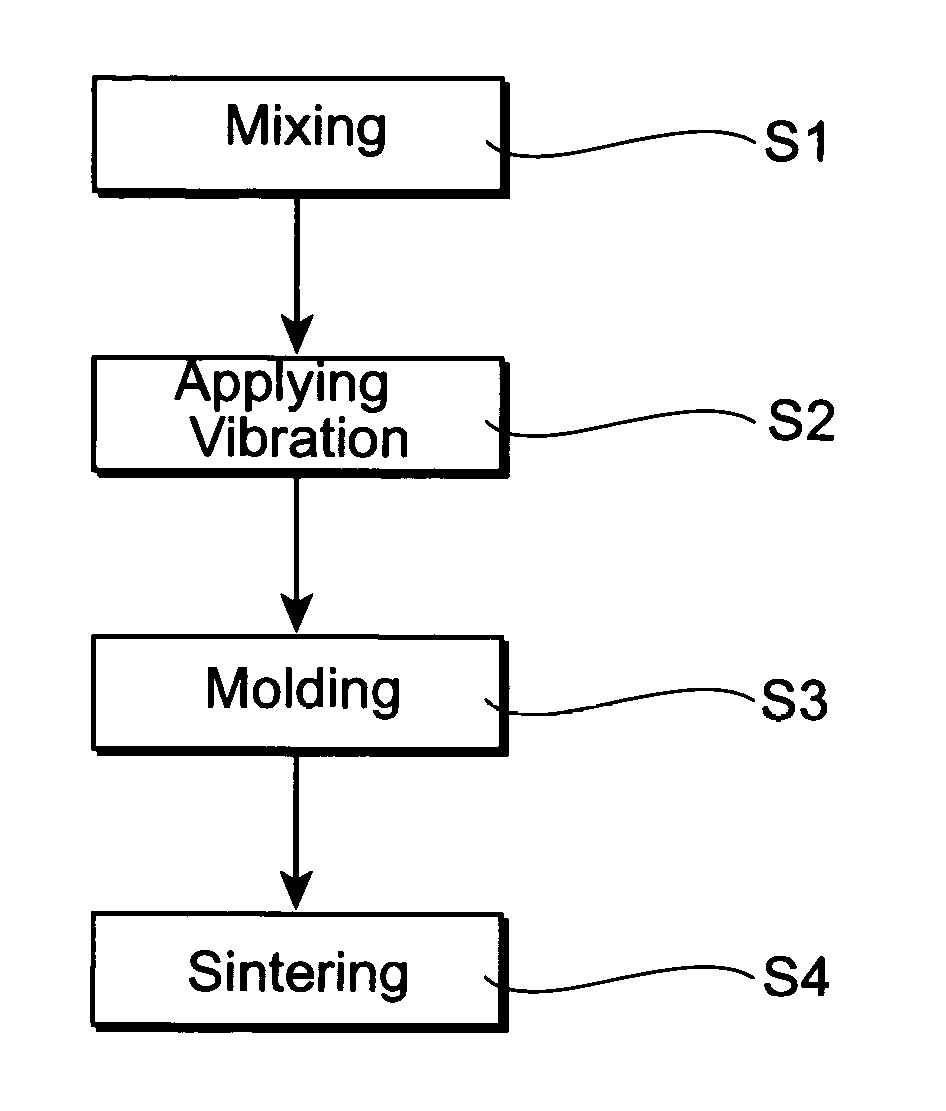

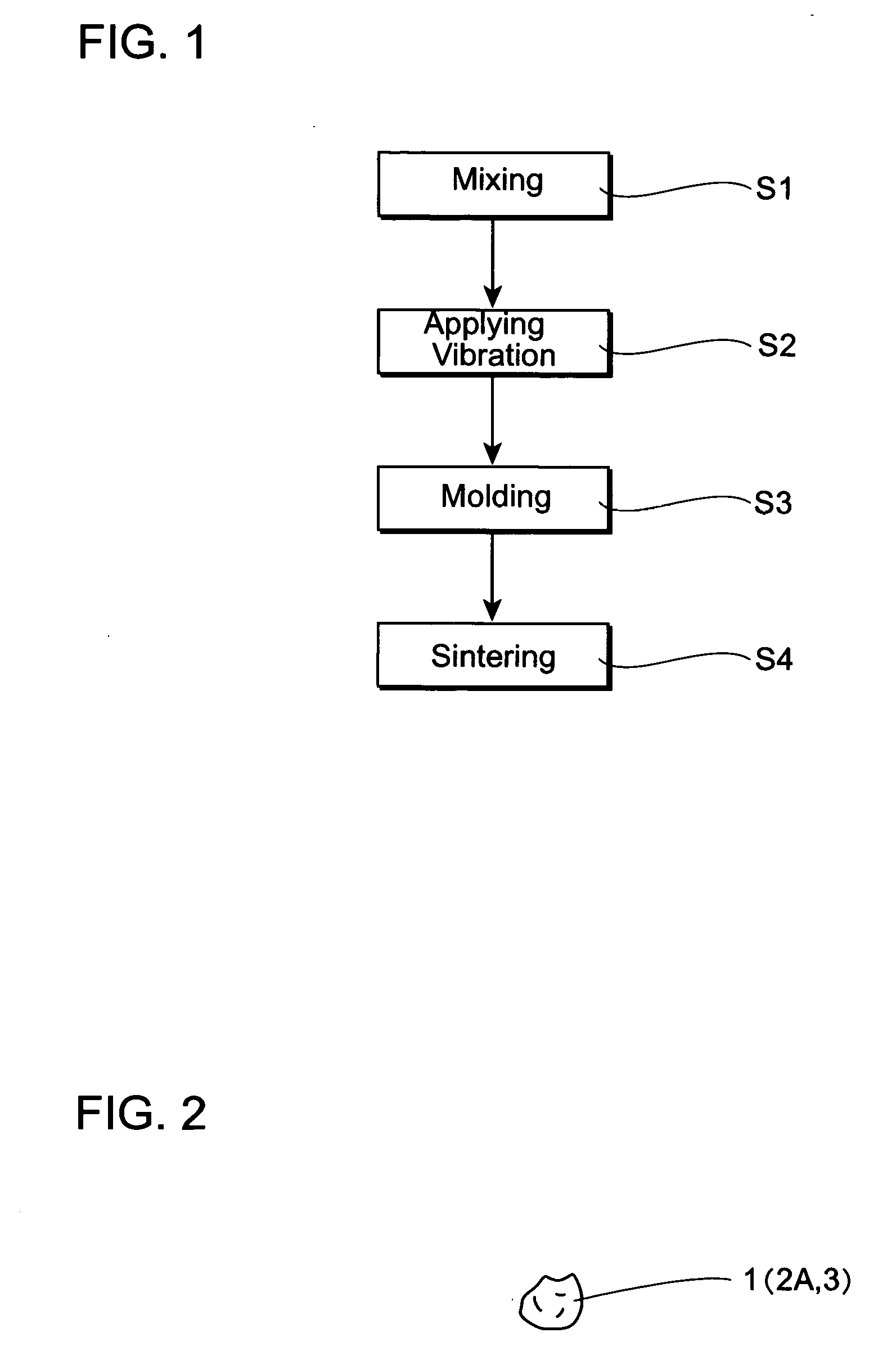

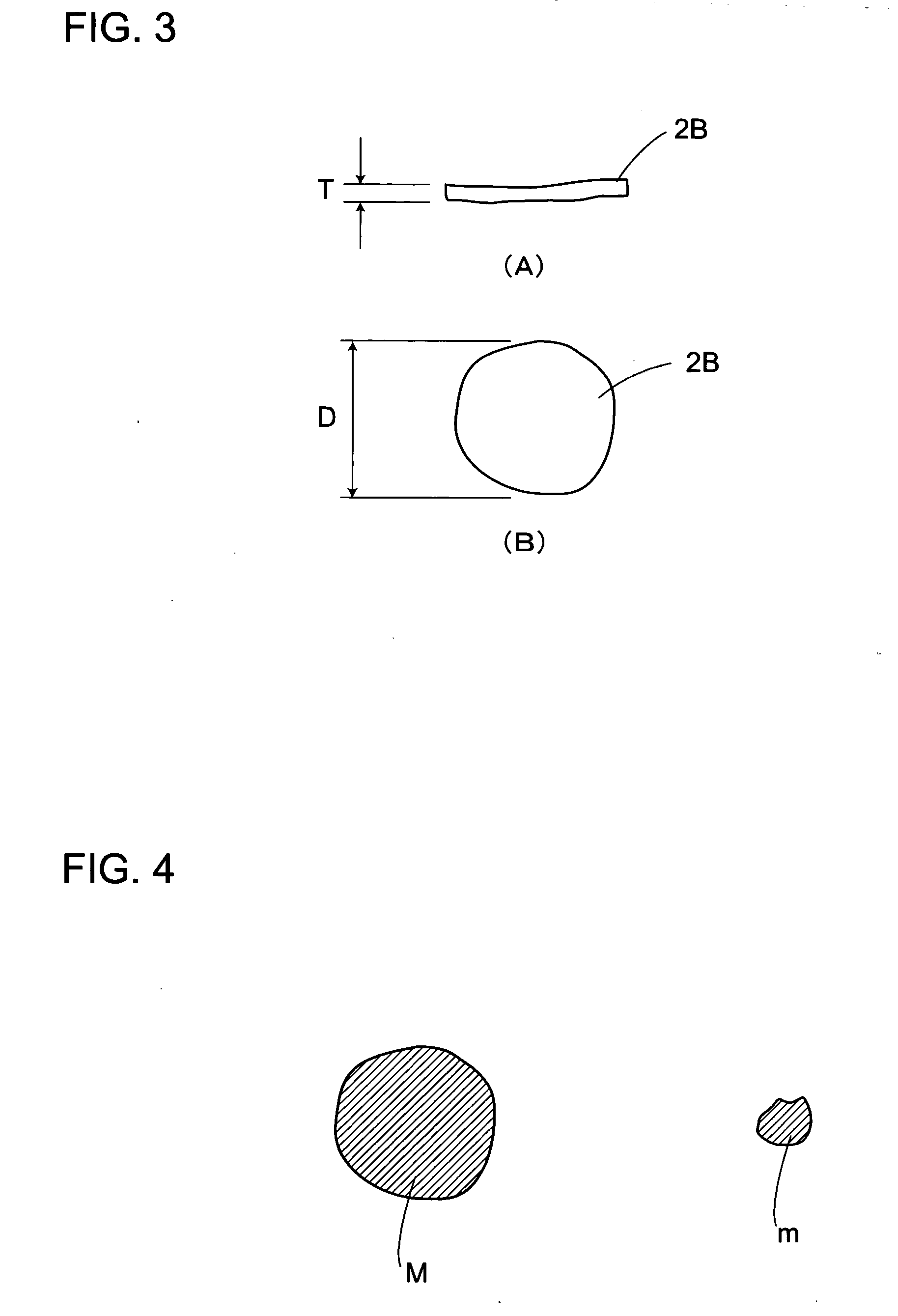

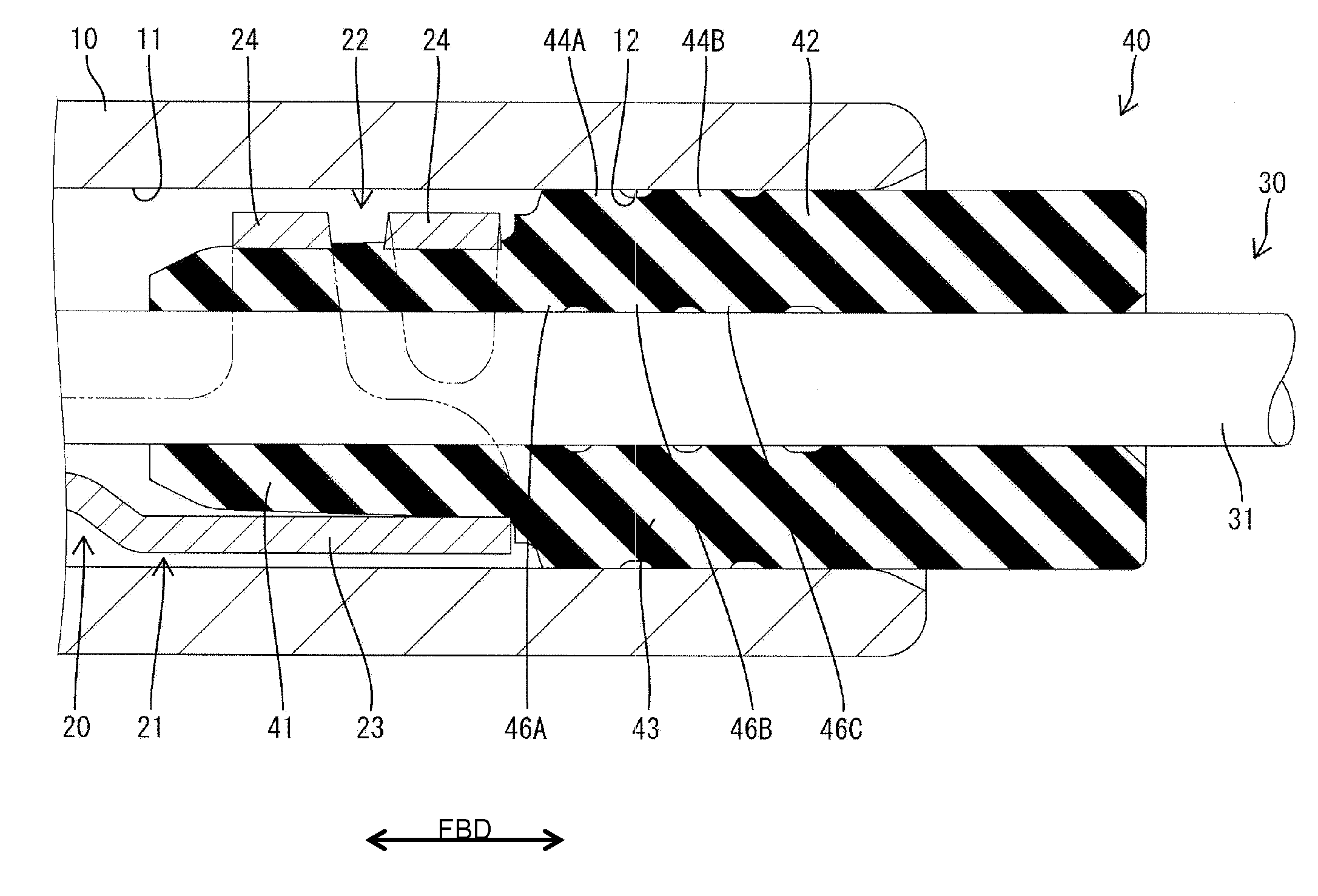

Sliding part and method of manufacturing the sliding part

ActiveUS20050265884A1Reduce frictional resistanceHigh strengthShaftsMetal-working apparatusFrictional coefficientIron increased

A bearing is manufactured by filling iron-based material powder and copper-based material powder in a filling portion of a mold, compacting those material powder so as to for a green compact, and then sintering the green compact. The copper-based material powder contains flat powder particles, the flat powder particles having a large aspect ratio than particles of the iron-based material powder. The coppers-based powder particles segregate on a sliding surface by vibration. The sliding surface of a bearing is covered with copper, and a ratio of iron increases from the sliding surface toward the inside. Since a rotation shaft slides on the sliding surface covered with copper, a frictional coefficient between the rotation shaft and the sliding surface is reduced, thus enabling a smooth rotation thereof. Simultaneously the usage of iron imparts predetermined strength and durability.

Owner:DIAMET CORP

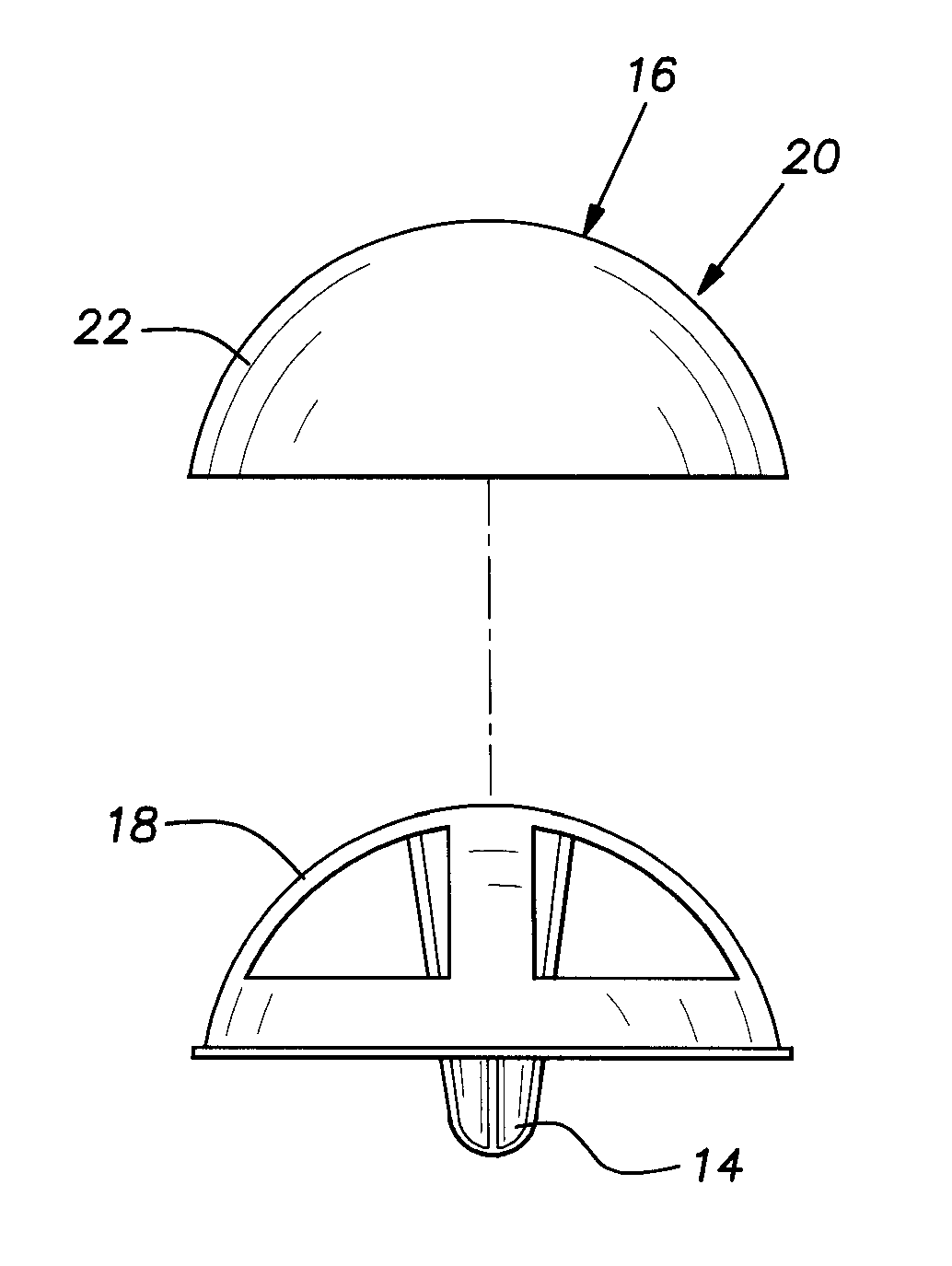

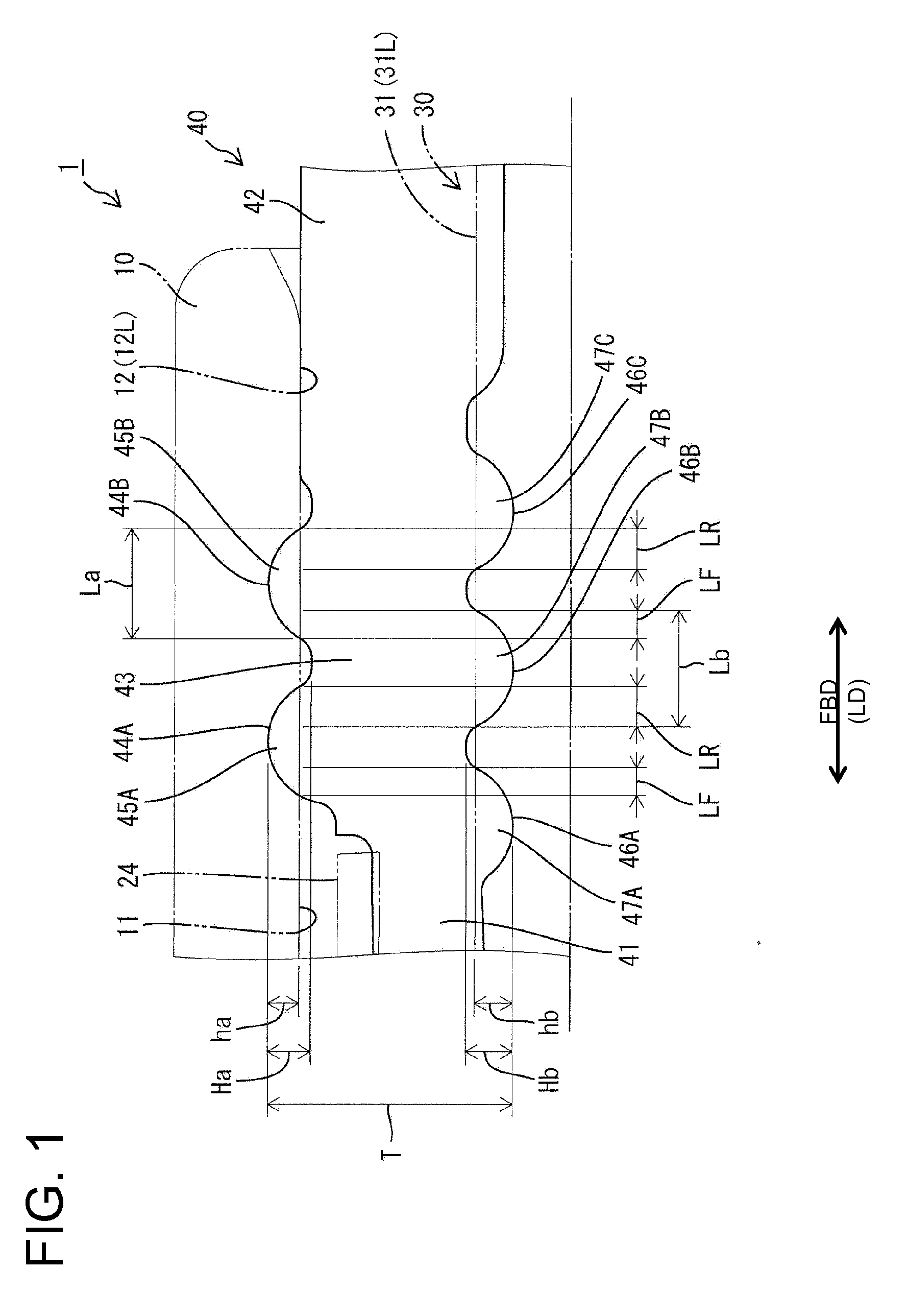

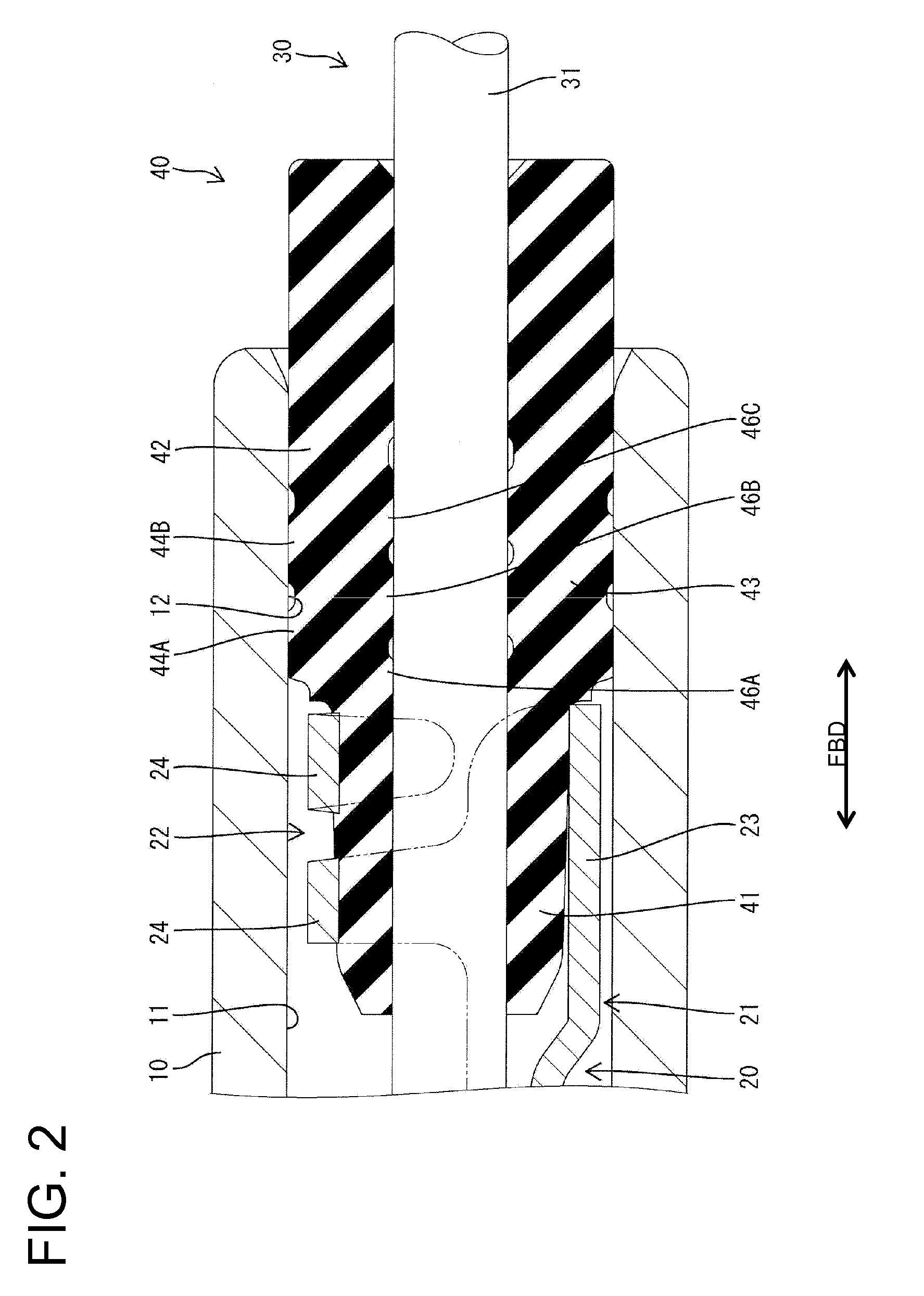

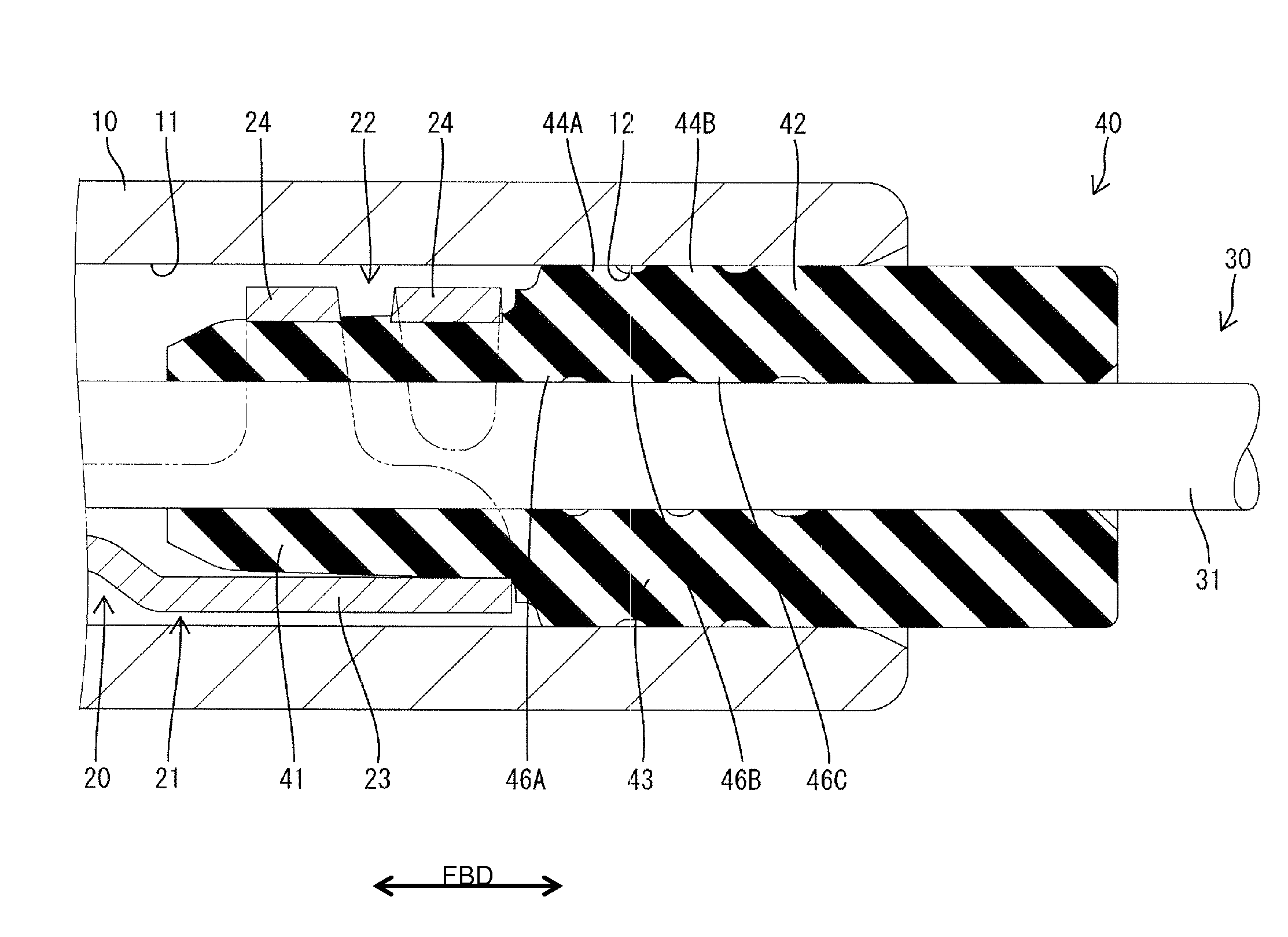

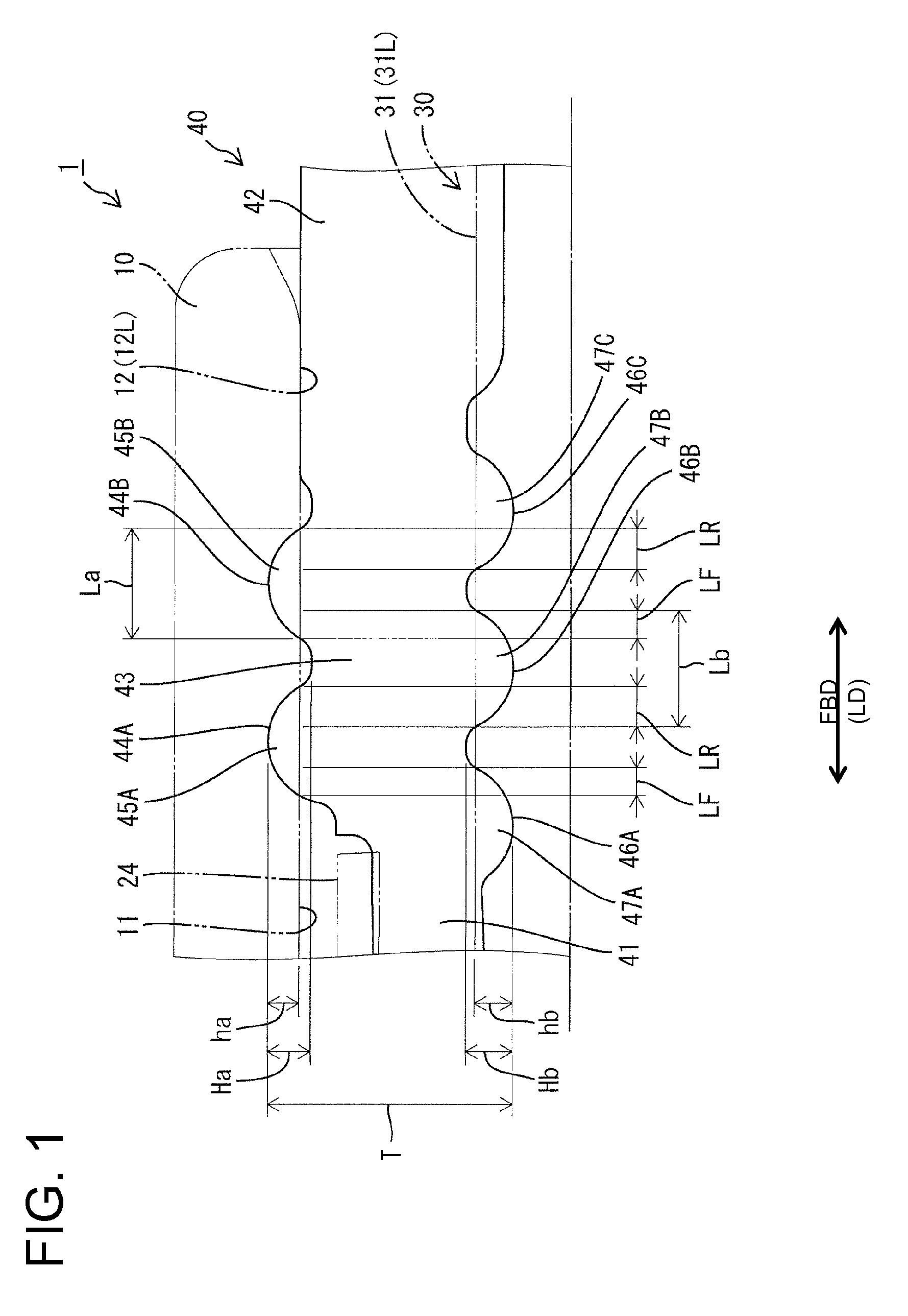

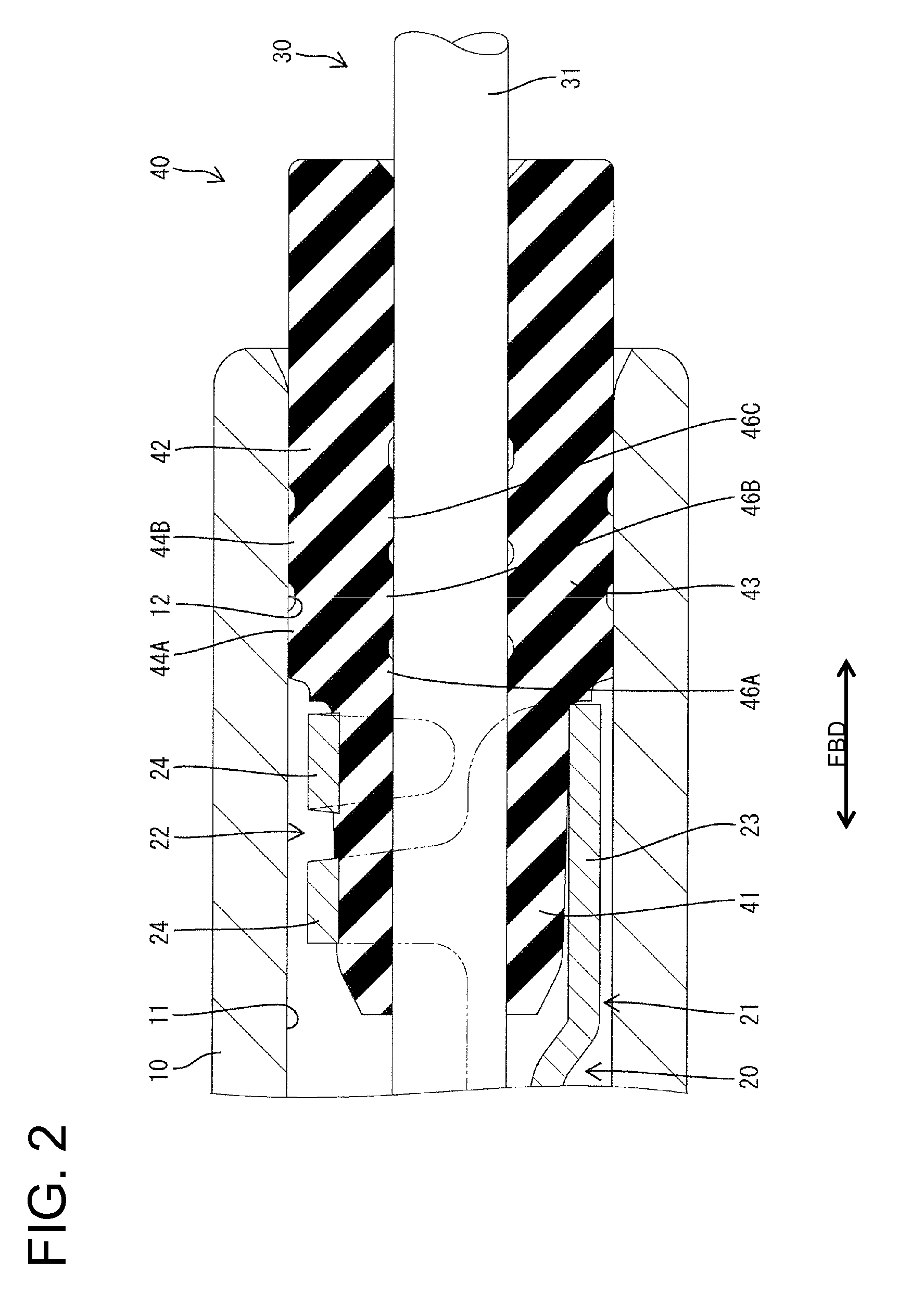

Resilient plug, fluid proof construction and connector

ActiveUS20100255703A1Improve sealingReduce frictional resistanceEngine sealsPipesProof constructionEngineering

A rubber plug (40) is provided with a stable sealing property while reducing frictional resistance when the rubber plug (40) is inserted into a cavity. In a cross section including axis lines of the rubber plug (40), a cavity (11) and a wire (30), areas of outer lips (44A, 44B) not resiliently deformed radially outward of a virtual line (12L) corresponding to the inner circumferential surface of the cavity (11) are specified as outer virtual deforming portions (45A, 45B), areas of inner lips (46A, 46B and 46C) not resiliently deformed radially inward of a virtual line (31L) corresponding to the outer circumferential surface of the wire (30) are specified as inner virtual deforming portions (47A, 47B, and 47C) and at least parts of the inner virtual deforming portions (47A, 47B and 47C) correspond to only parts of the outer virtual deforming portions (45A, 45B).

Owner:SUMITOMO WIRING SYST LTD

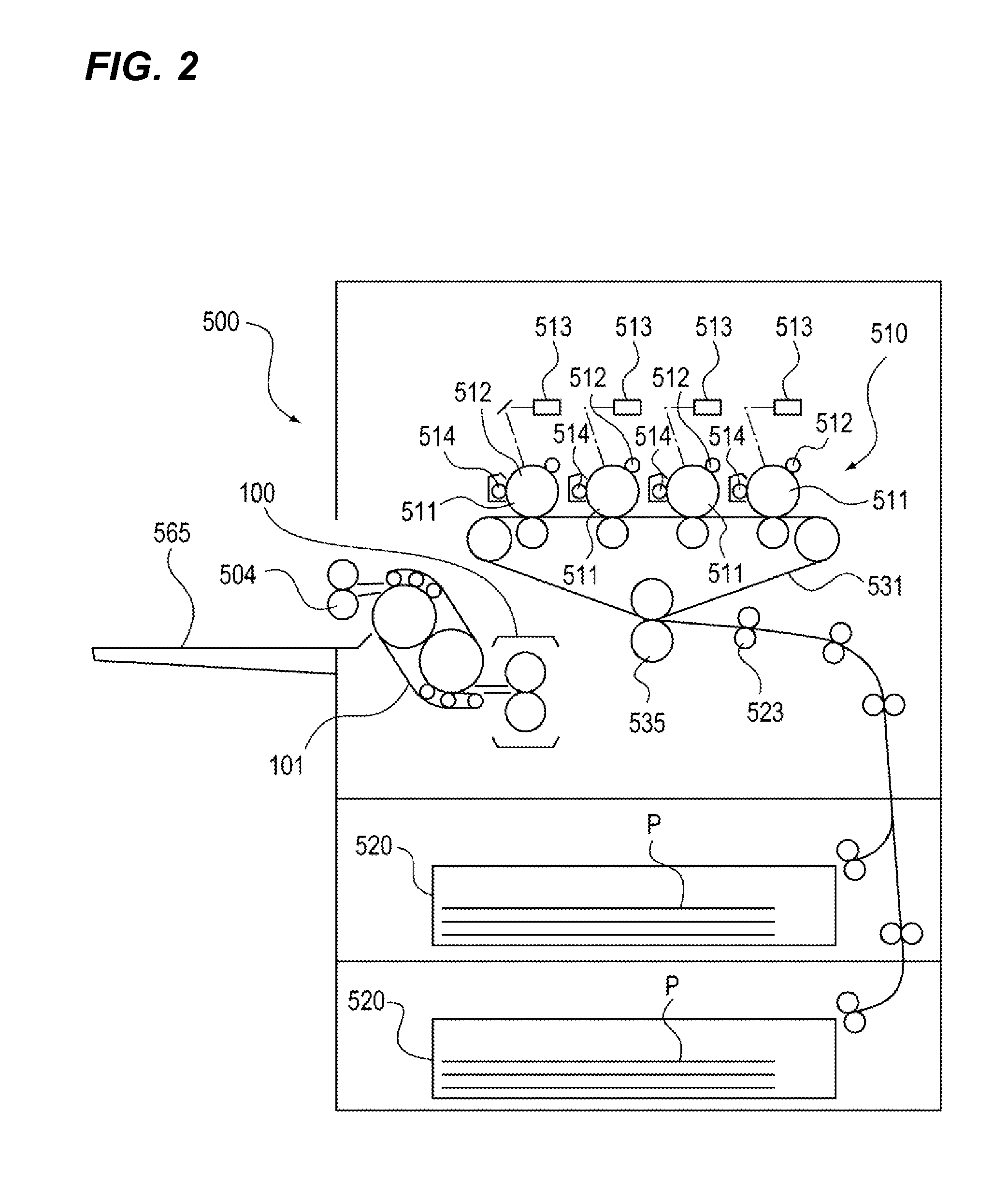

Sheet cooling apparatus and image forming apparatus

InactiveUS20140029995A1Increased durabilityReduce abrasionElectrographic process apparatusSheet materialEngineering

Owner:CANON KK

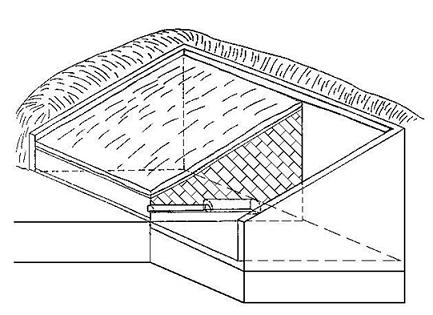

Geotechnical engineering anti-blast structure model test device

InactiveCN102262003AScientific and reasonable shapeHigh strengthEarth material testingStructural/machines measurementLocking mechanismModel test

The invention belongs to the technical field of geotechnical engineering model test equipment. The proposed geotechnical engineering anti-explosion structure model test device is composed of a side-limited box body and an explosion pit at the lower part, and is equipped with a matching wave-eliminating mechanism, a locking mechanism and a sliding Positioning mechanism; wave dissipation mechanism includes aluminum wave dissipation grid (21) and wooden wave dissipation plate (20); sliding positioning mechanism includes two-way jack cylinder (15), guide rail (17) and limit block (19); locking The mechanism is composed of a locking pull rod (3), a side limit connecting block (18) and a nut (2). The invention can simulate different explosion forms in equipment with moderate size; meet the convenient and feasible requirements for excavation of caverns, installation of enclosure structures and measurement equipment; it can be reused, and it is beneficial to observe the damage of structures in the test; The results can provide an important basis for underground explosion-resistant engineering design and scientific research.

Owner:THE THIRD ENG CORPS RES INST OF THE HEADQUARTERS OF GENERAL STAFF PLA

Resilient plug, fluid proof construction and connector

ActiveUS7997916B2Improve sealingReduce frictional resistancePipesCouplings bases/casesProof constructionEngineering

A rubber plug (40) is provided with a stable sealing property while reducing frictional resistance when the rubber plug (40) is inserted into a cavity. In a cross section including axis lines of the rubber plug (40), a cavity (11) and a wire (30), areas of outer lips (44A, 44B) not resiliently deformed radially outward of a virtual line (12L) corresponding to the inner circumferential surface of the cavity (11) are specified as outer virtual deforming portions (45A, 45B), areas of inner lips (46A, 46B and 46C) not resiliently deformed radially inward of a virtual line (31L) corresponding to the outer circumferential surface of the wire (30) are specified as inner virtual deforming portions (47A, 47B, and 47C) and at least parts of the inner virtual deforming portions (47A, 47B and 47C) correspond to only parts of the outer virtual deforming portions (45A, 45B).

Owner:SUMITOMO WIRING SYST LTD

Connector

ActiveUS20150340788A1Fit tightlyResistance to frictionCoupling contact membersTwo-part coupling devicesMechanical engineering

A terminal used in a connector includes a base portion that is retained in a housing, and a front terminal and a rear terminal that extend from the base portion. A front terminal is provided with a front contact portion that comes in contact with a mating terminal through a flat plate surface of the front contact portion, and a rear terminal is provided with a rear contact portion that comes in contact with a terminal of a mating connector through a flat plate surface of the rear contact portion. The front contact portion and the rear contact portion are arranged at the same position in a width direction.

Owner:IRISO ELECTRONICS CO LTD

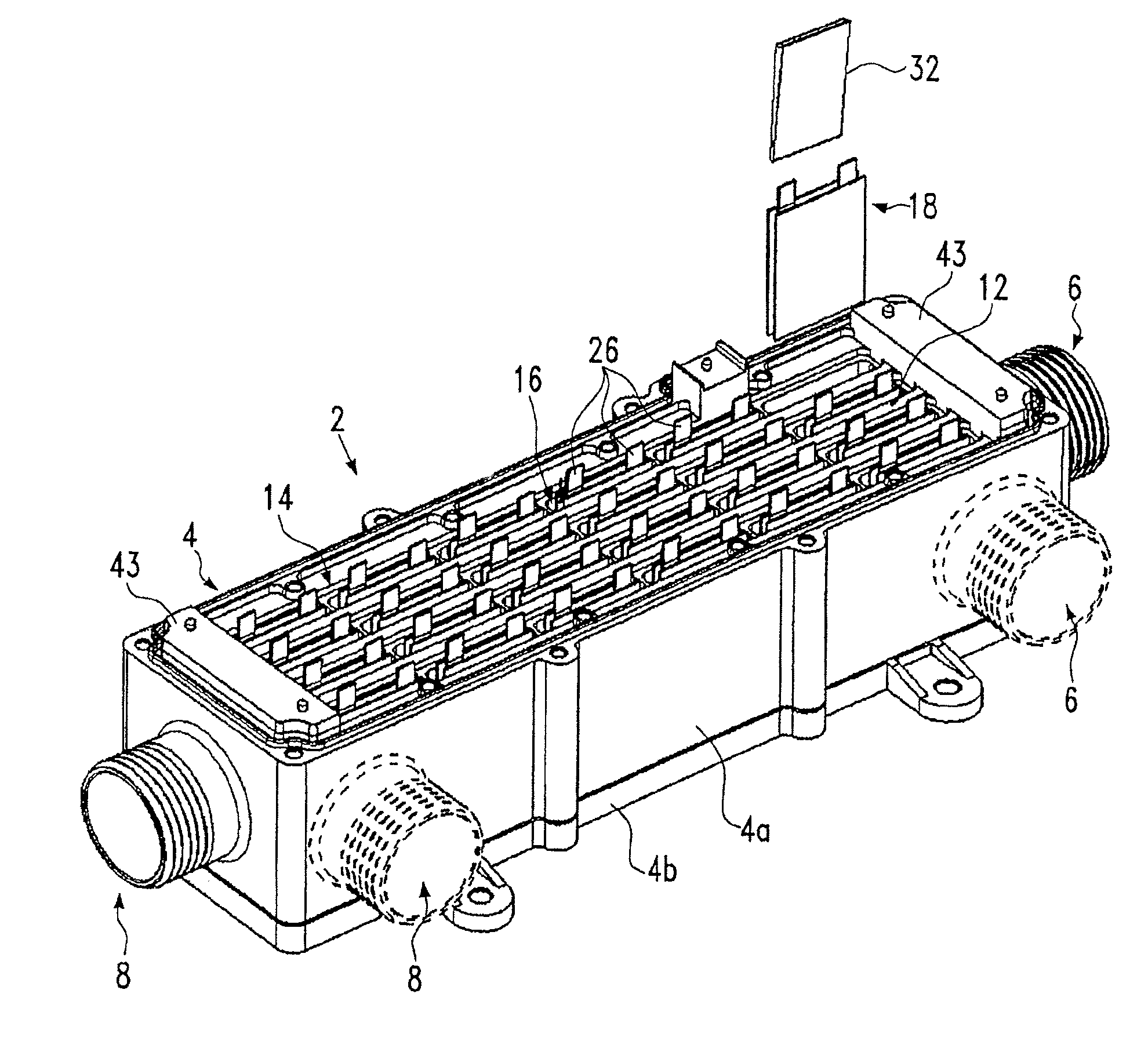

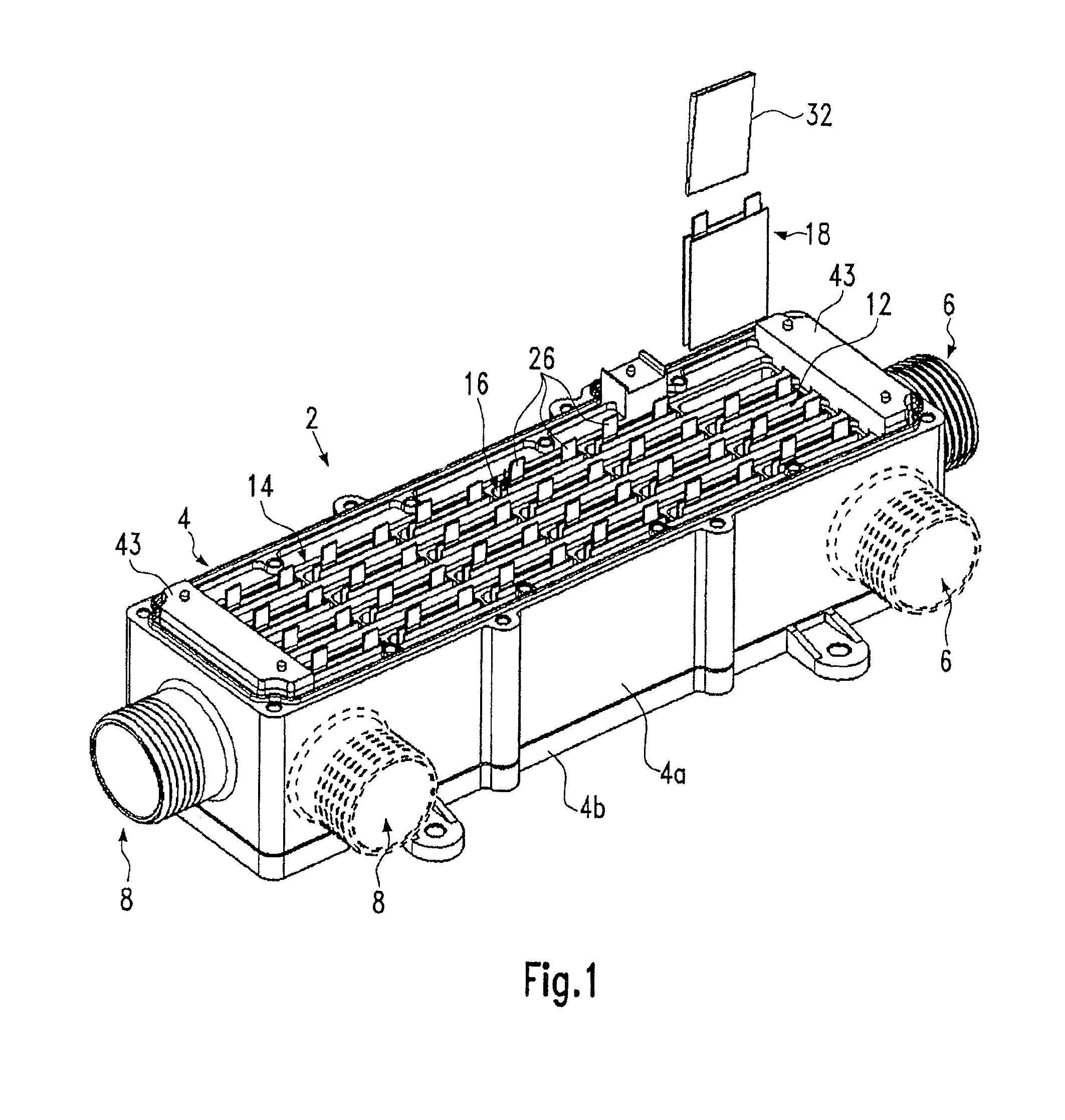

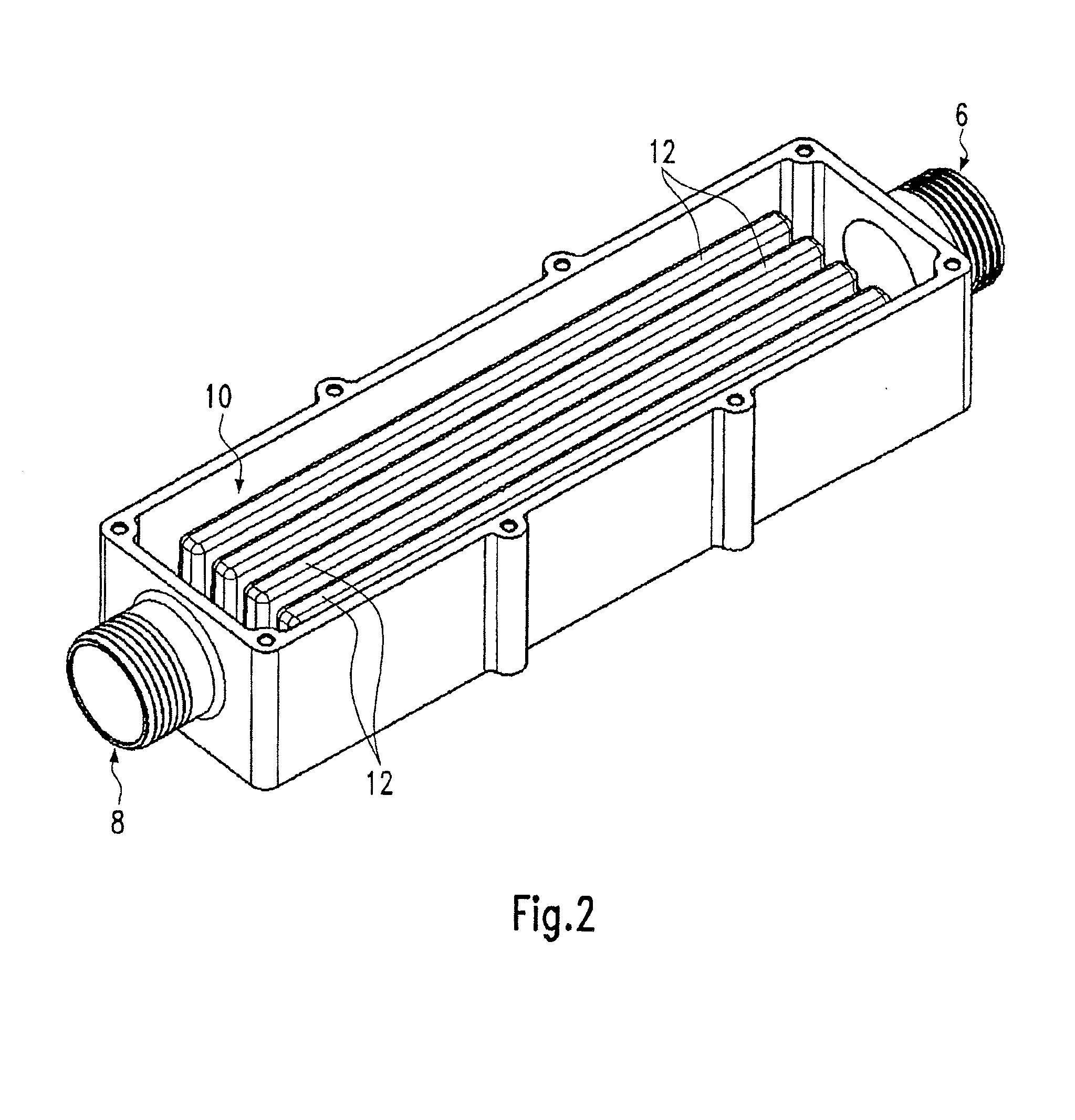

Electric heating device

ActiveUS8946599B2Sufficient securityAvoid problemsAir-treating devicesAir heatersEngineeringElectric drive

The invention under consideration relates to an electric heating device for heating a flowing medium with a housing, in which the at least one electric heating element of the electric heating device is held securely and fully shielded from the medium held in the circulation chamber by a separating wall that divides the housing into a heating chamber and a circulation chamber. The circulation chamber has inlet openings and outlet openings for introducing and removing, respectively, the medium. The heating element is preferably a PTC heating element and is held by means of a clamping force in a recess formed by the separating wall, said recess preferably projecting into the circulation chamber. The invention furthermore relates to a recuperator for converting electrical energy into thermal energy, particularly for an electric drive in a vehicle.

Owner:CATEM

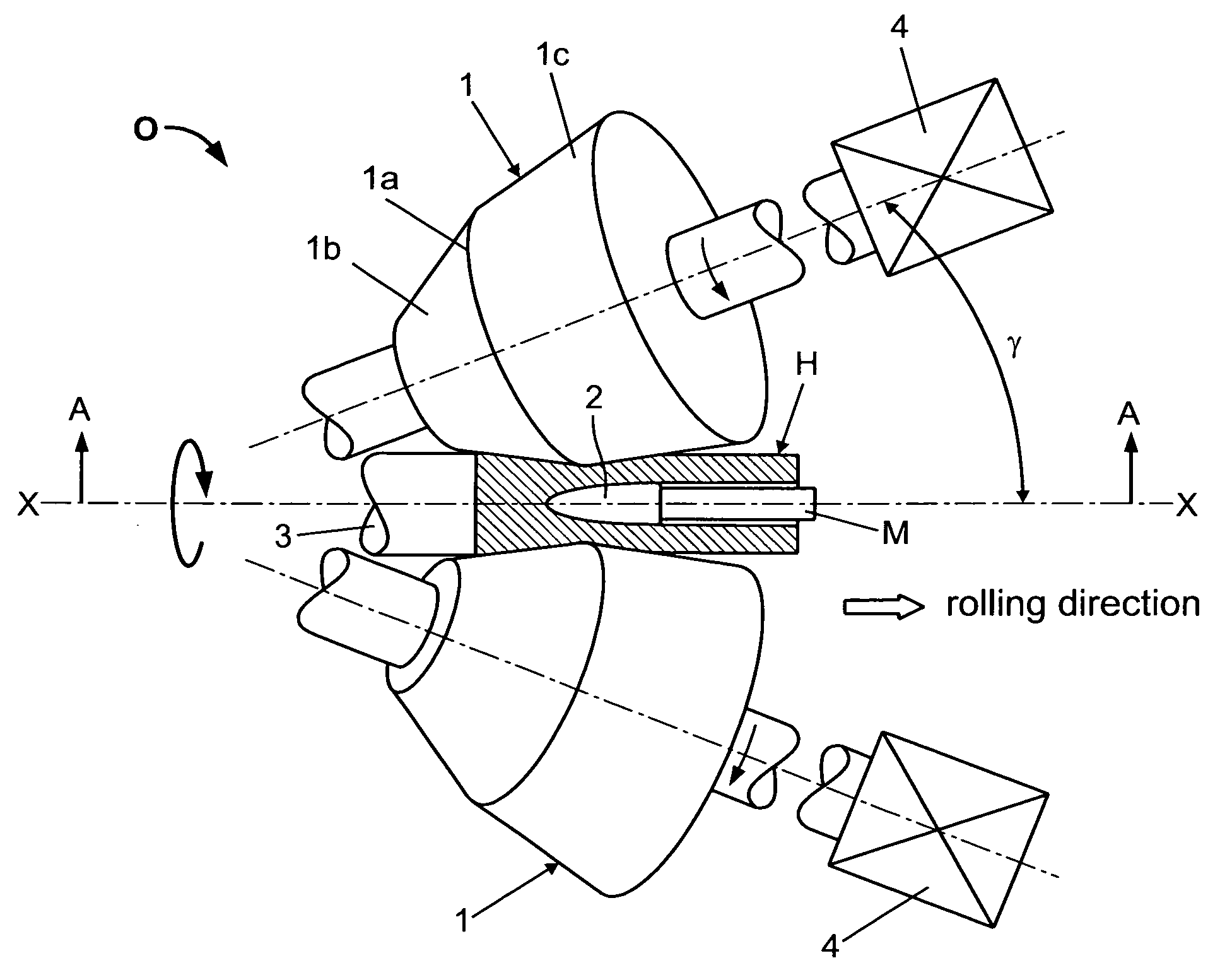

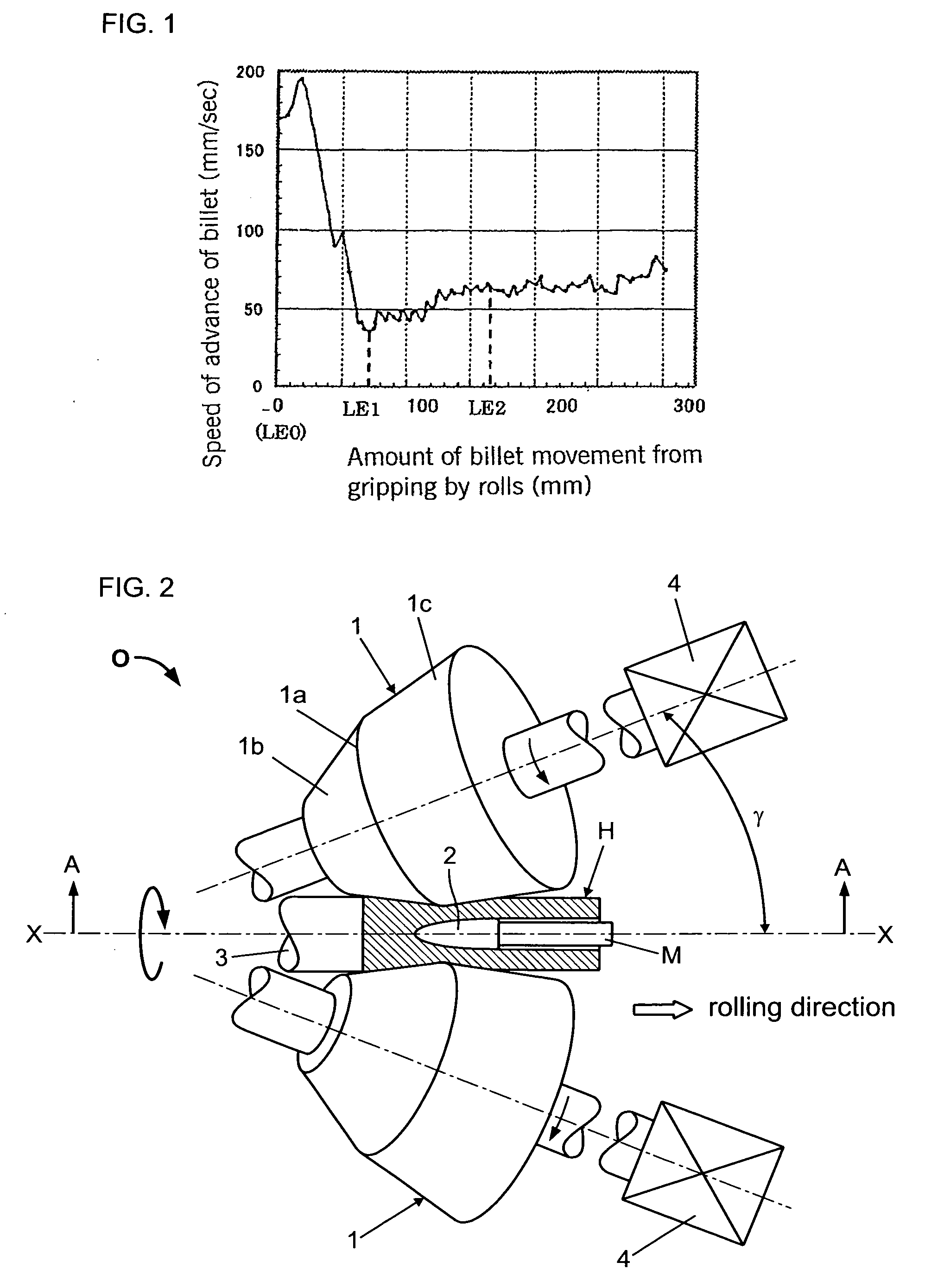

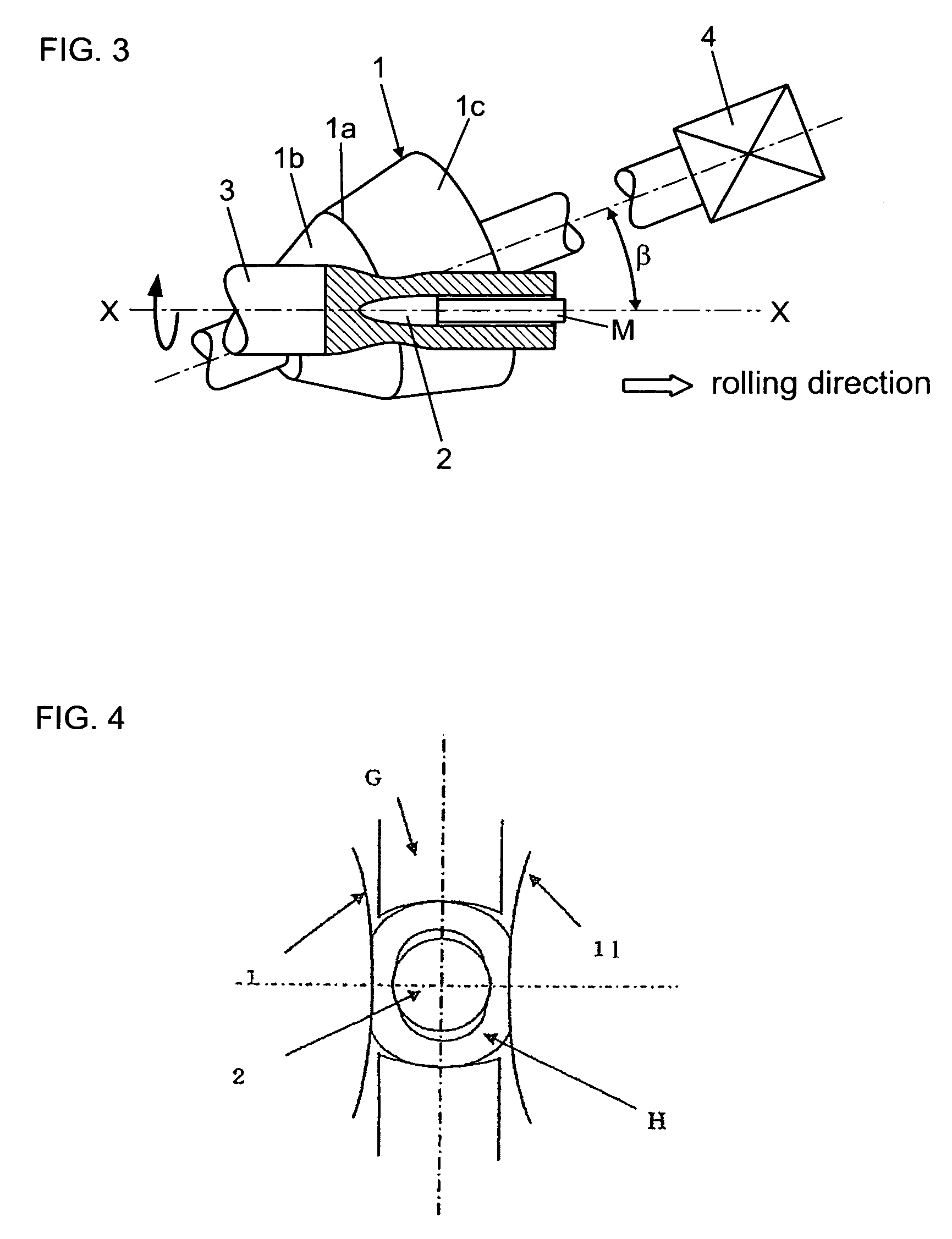

Process for manufacturing a seamless tube

ActiveUS20090064748A1Eliminate the effects ofResistance to frictionRollsRolling mill drivesCircular discEngineering

A high quality hollow shell in which the occurrence of internal surface flaws caused by the rotary forging effect and / or shear deformation is prevented by suppressing the rotary forging frequency and shear deformation in a transient region at the stage of billet gripping and a worsening of thickness deviations in the top portion of the hollow shell is also prevented is reliably produced with preventing miss-rolling such as incomplete billet gripping and troubles in bottom withdrawal and an increase in the outer diameter of the hollow shell in the bottom portion. A billet is pierced while being rotated and advanced to produce a hollow shell, from which a seamless tube is finally manufactured, using a pair of skew rolls, a pair of disk rolls, and a plug under such conditions that each of the ratio (Dg / d) of the diameter Dg of the gorge portion of the skew rolls and the outer diameter d of the billet, the ratio (Dd / d) of the diameter Dd of the groove bottom of the disk rolls and the outer diameter d of the billet, the ratio (Dd / Dg) of the diameter Dg and the diameter Dd, the inlet face angle θ1 of the skew rolls, and the square root of the product (Ns×Df)0.5 of the rotational frequency Ns of the billet in a transient (non-steady state) region when billet gripping and the reduction ratio Df of the outer diameter of the billet satisfies a prescribed equation.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com