Bolt shear force connecting piece and method for enhancing shear strength by use of spring

A technology of connectors and bolts, which is applied in the field of new structures, can solve the problems that are difficult to be guaranteed, affect the safety and reliability of composite beams, and the quality of welds is greatly affected by human factors, so as to achieve quality assurance, increase safety and reliability, and improve construction operations. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

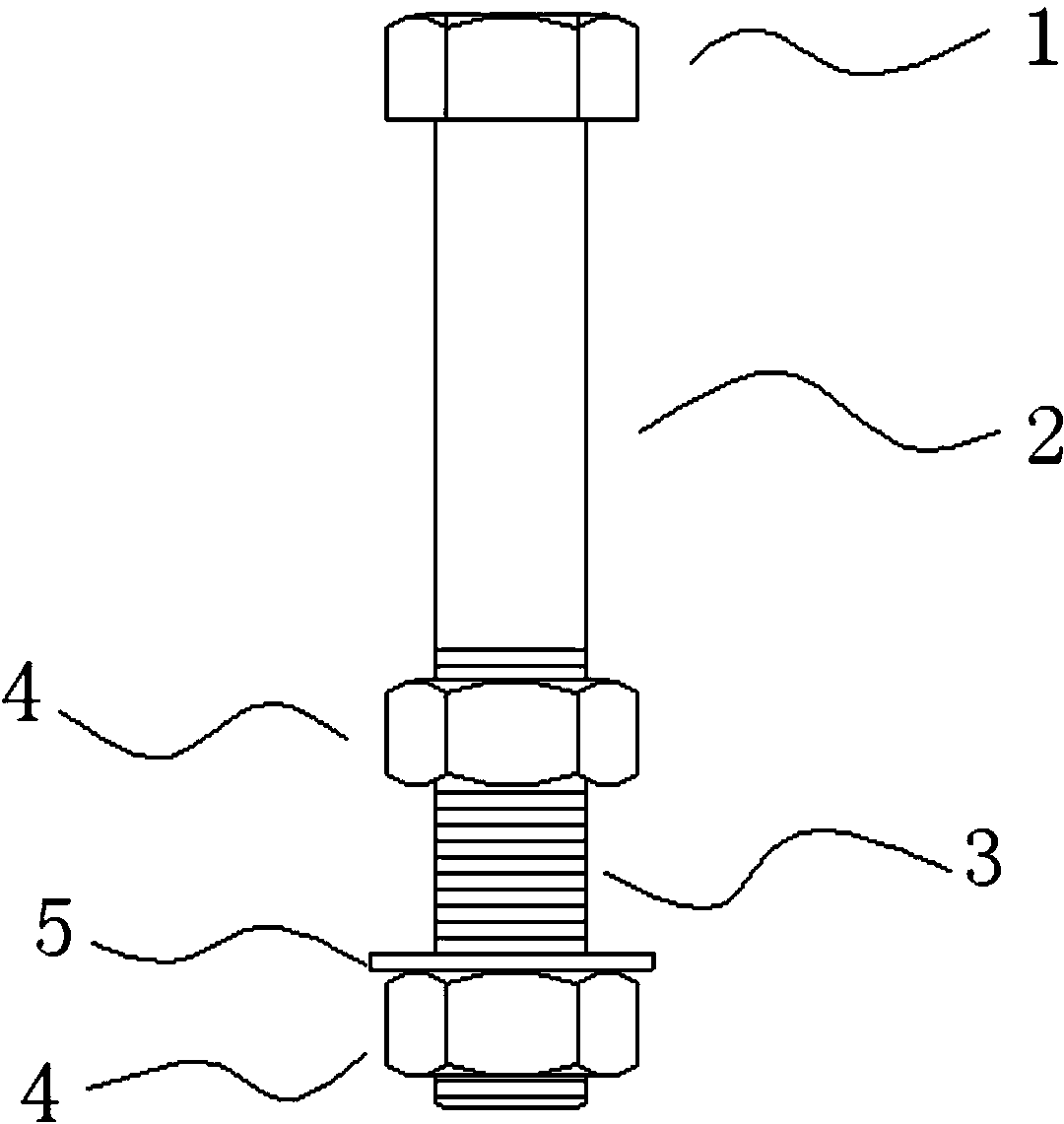

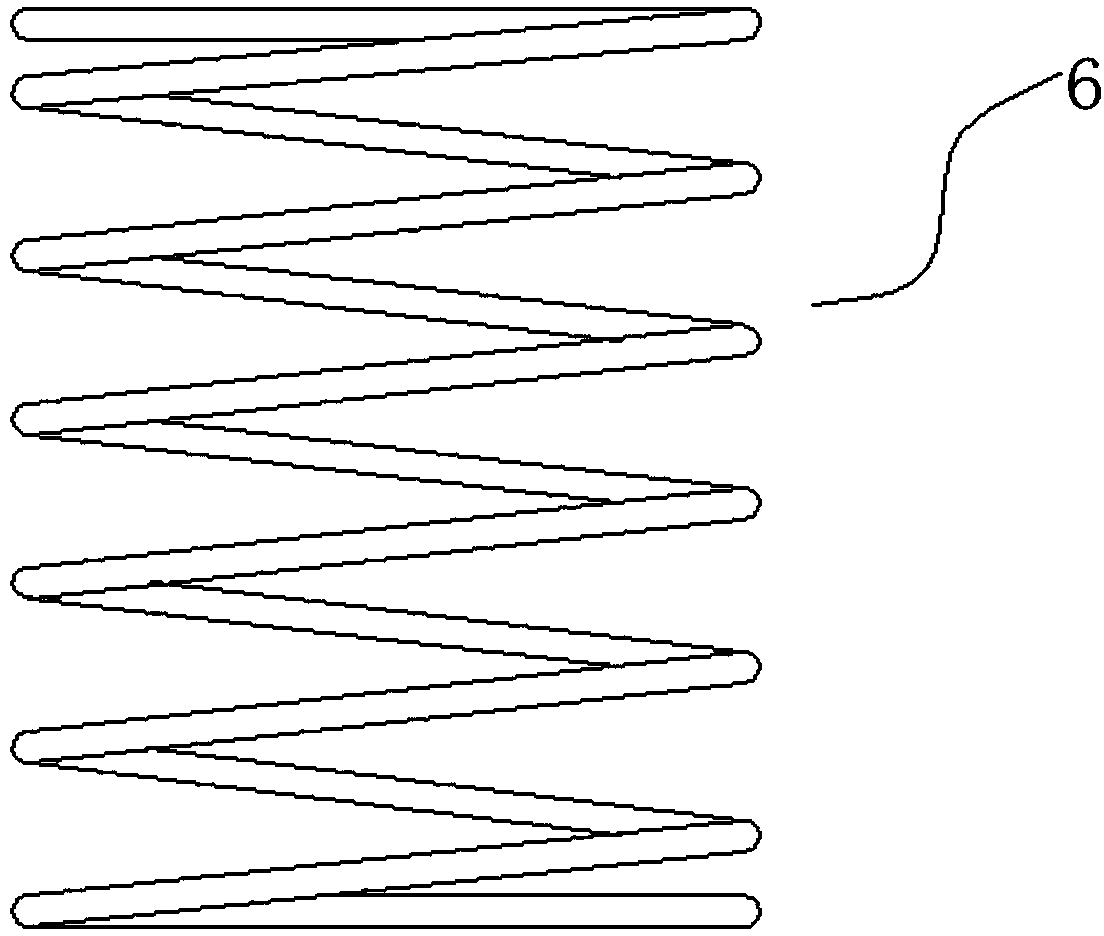

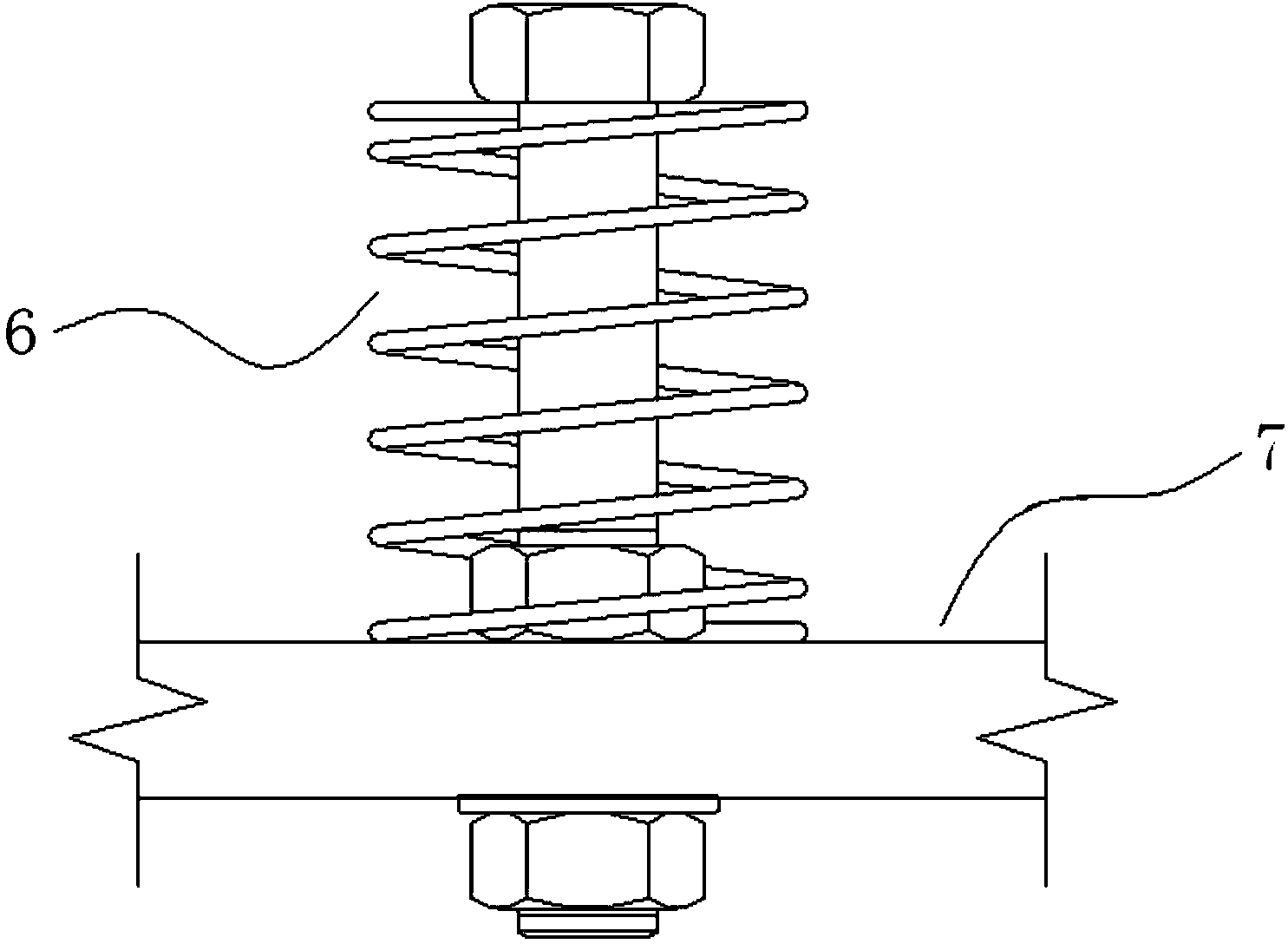

[0043] Such as figure 1 , 2, 3 and 4: a bolt shear connection, including a nut 1, a screw 2, a thread 3, a nut 4, a nut 5 and a spring 6, the screw 2 passes through a preset hole on the flange of the steel beam, And fasten on the steel beam flange 7 by upper and lower two nuts 4, there is a nut 5 between the steel beam flange 7 and the nut 4, the top of the screw 2 is provided with a nut 1, and the spring 6 surrounds the screw 2 is set, the spring at the bottom of the spring 6 is welded to the surface of the steel beam flange 7, the height of the top surface of the spring 6 is flush with the top surface of the screw rod 2, and the screw rod 2 is at the center of the spring 6.

[0044] The screw rod 2 uses high-strength bolts above grade 8.8. The height of the screw rod 2 protruding from the surface of the flange 7 of the steel beam is greate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com