Patents

Literature

33 results about "Iron increased" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reverse flotation iron increase and silicon removing method for refractory limonite

InactiveCN101234366AImprove mineral processing recovery rateReduce typesFlotationIron increasedRefractory

The invention discloses an reverse flotation iron extracting and desiliconizing method of rebellious limonite. The procedure of the invention is as following: finely grinding, dispersing and desliming ore; adding sulphuric acid to stir the ore power into paste; adding a certain amount of starch or modified starch, lignosulfonate sulphonic acid and their salt and polyacrylamide with the molecular weight about 10,000 or polyacrylamide inhibitory iron-bearing mineral; adopting cation collector quaternary ammonium salt to reverse flotation and separate ore with silicon range or iron ore in a method of adding a little amount of medicine for many times. The reverse flotation iron extracting and desiliconizing method has the advantages of simple process, few medicine agent varieties, able to obtain high grade iron ore concentrate and good effect of raising ore dressing recovery percentage of limonite.

Owner:CENT SOUTH UNIV

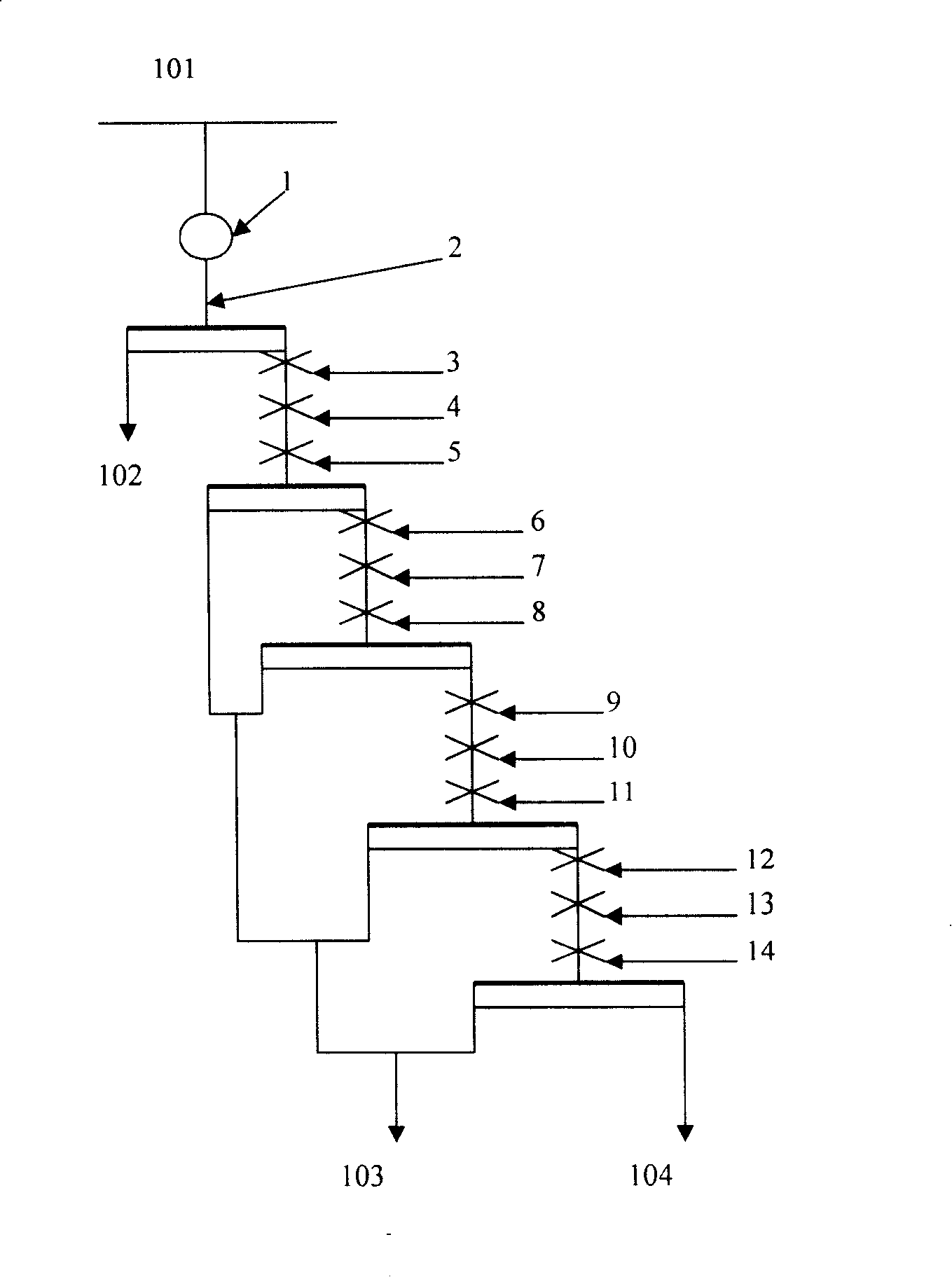

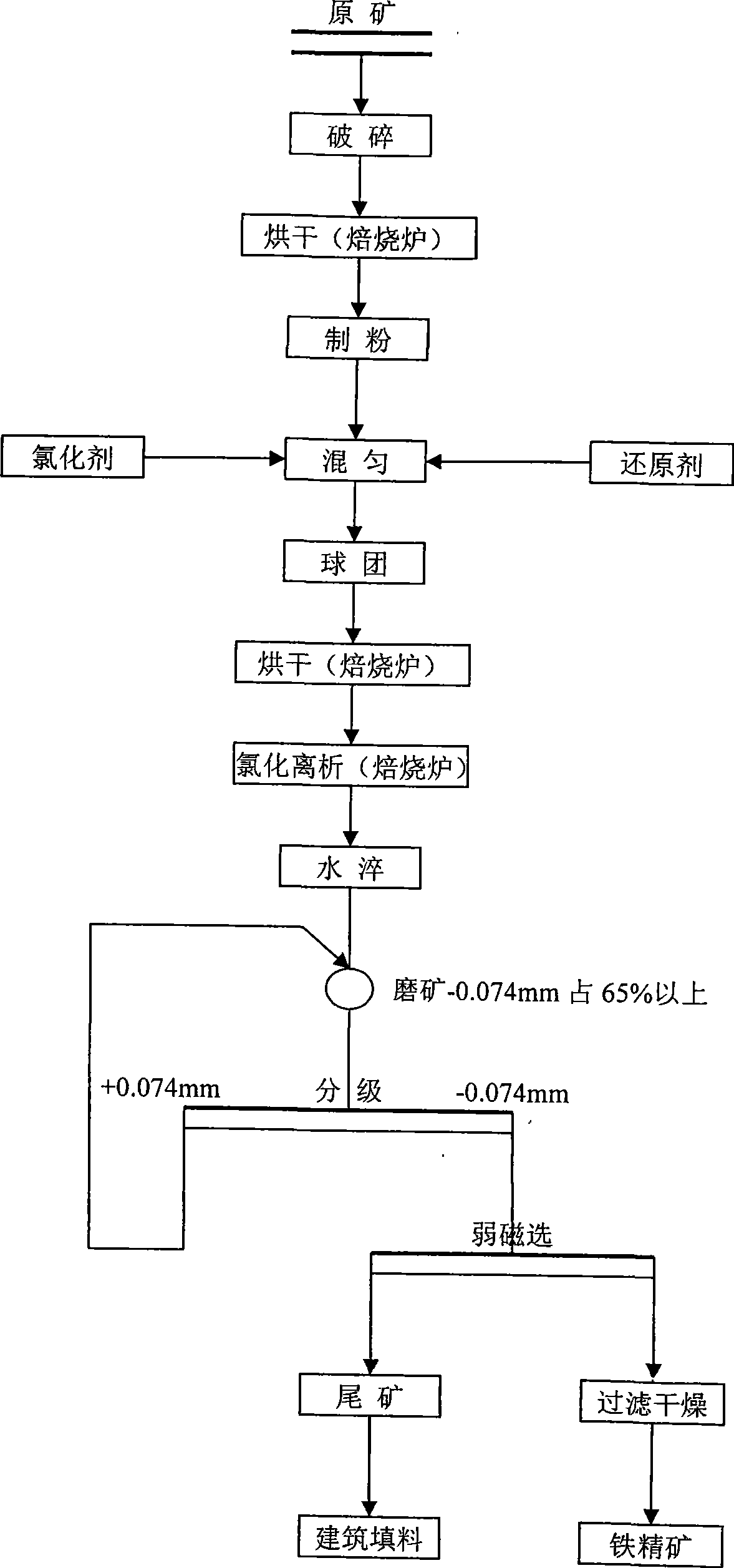

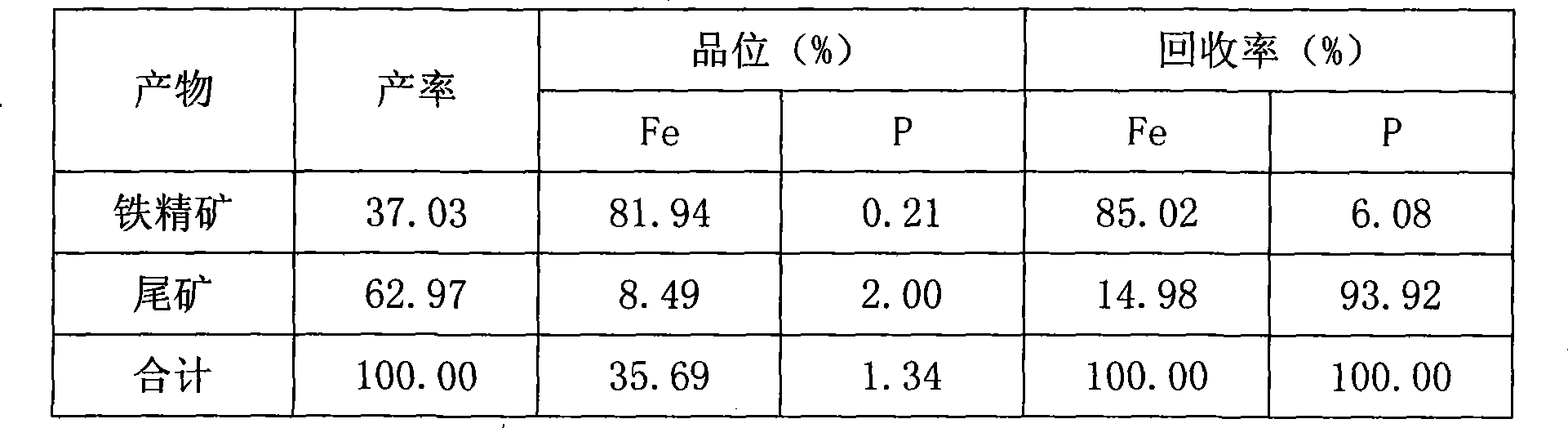

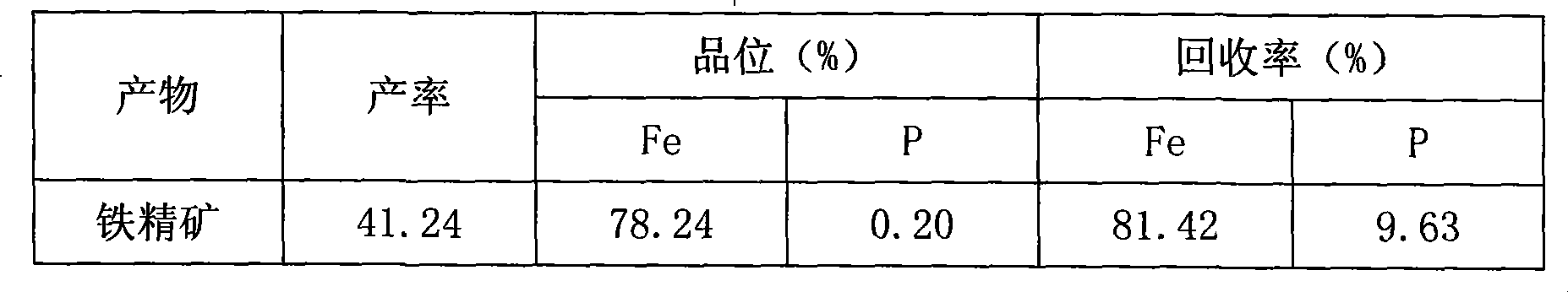

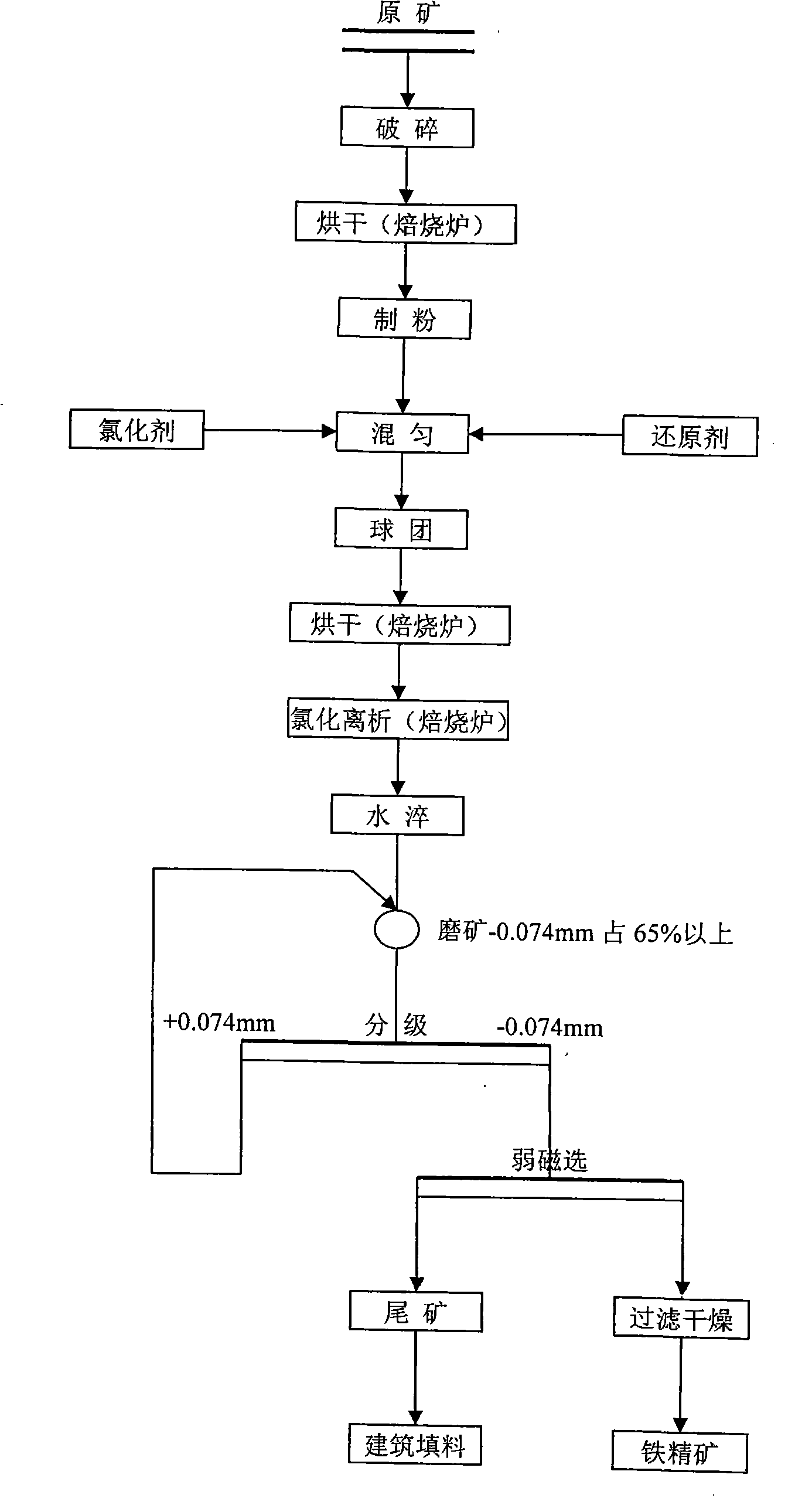

Method for reducing phosphorus by chloridization separation-weak of high phosphor iron ore

InactiveCN101457288AReduce phosphorus contentGood beneficiation indexMagnetic separationWet separationIronstoneIron increased

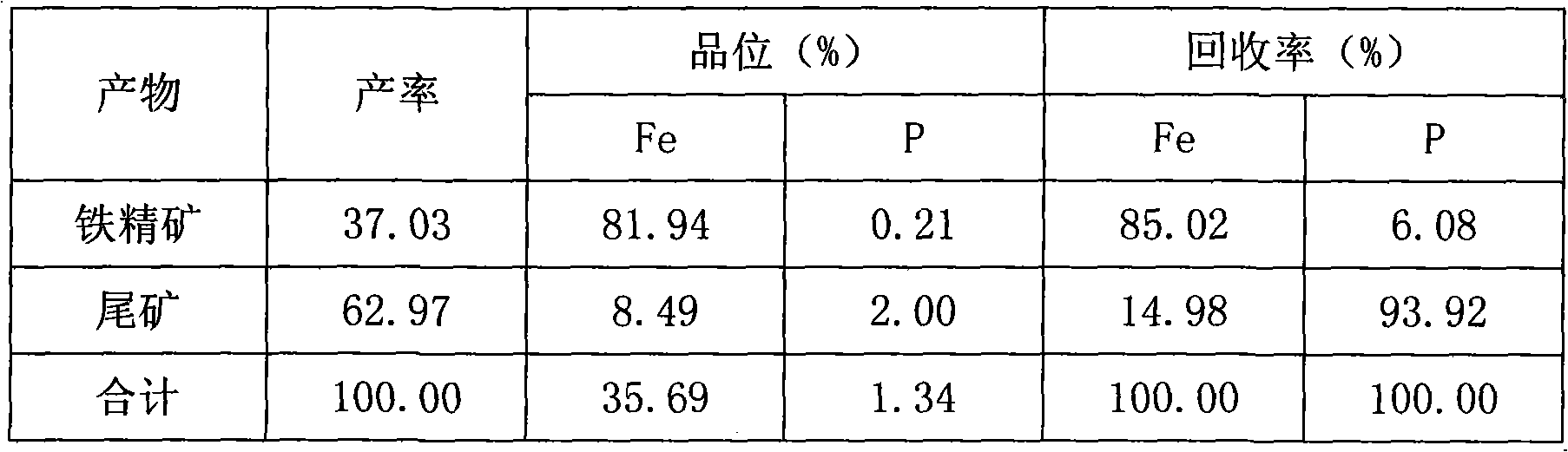

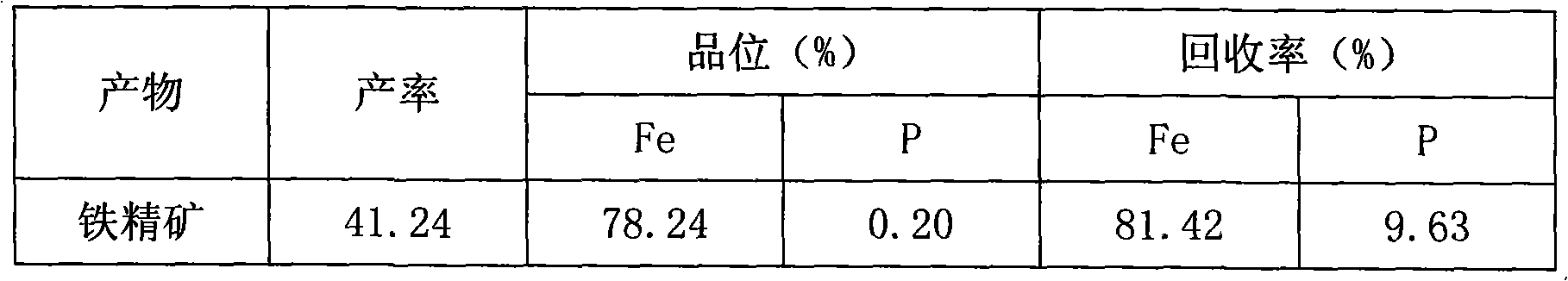

The invention relates to a chloridizing segregation-low-intensity magnetic separation method for reducing phosphorus of a high phosphorus iron ore. A chloridizing segregation-low intensity magnetic separation process is adopted to realize iron increase and phosphorous reduction in the method. A chlorinating agent and a reducing agent coke are added to the high phosphorus iron ore and mixed evenly, then chloridizing segregation roasting is carried out in a roasting furnace; the roasted product is water quenched and ball milled, and then separated by a low-intensity magnetic field magnetic separator, thus being capable of obtaining an iron ore concentrate with the iron grade more than 80%, the iron recovery rate more than 85% and the phosphorous content less than 0.20%. The iron ore concentrate powder can be taken as a raw material for smelting pig iron after being pelletized. Additionally, with regard to high phosphorus iron ores which contain sulfur or contain sulfur and arsenic at the same time, such as hematite, hematite-limonite ore, oolitic hematite-limonite ore, hematite, siderite and the like, the product iron ore concentrate with the sulfur content less than 0.20% and the arsenic content less than 0.04% can also be obtained.

Owner:昆明晶石矿冶有限公司

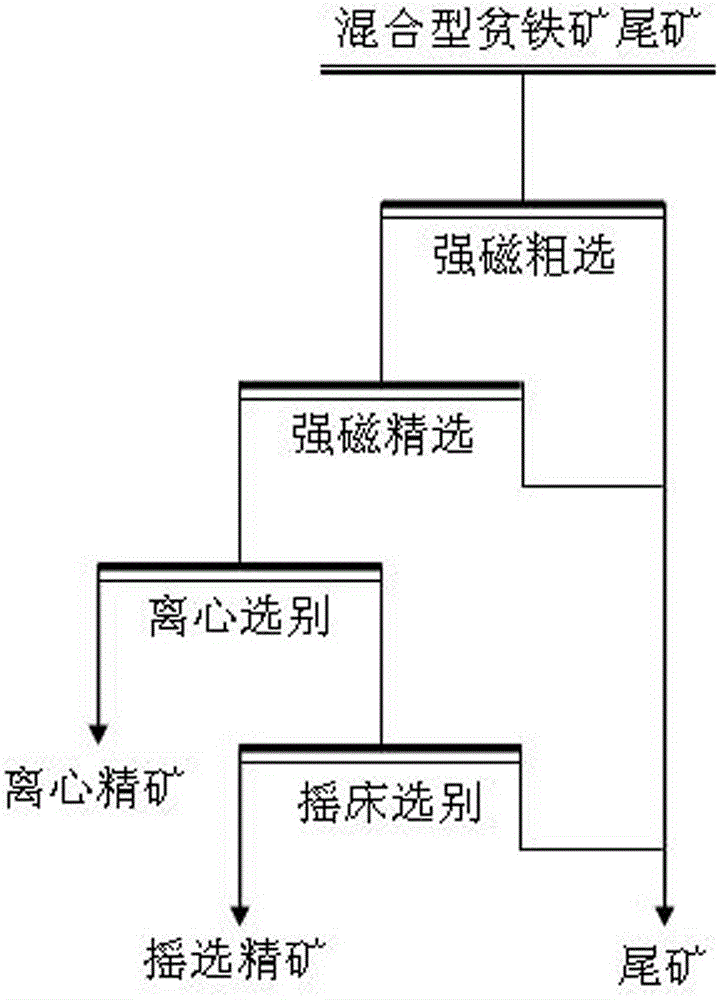

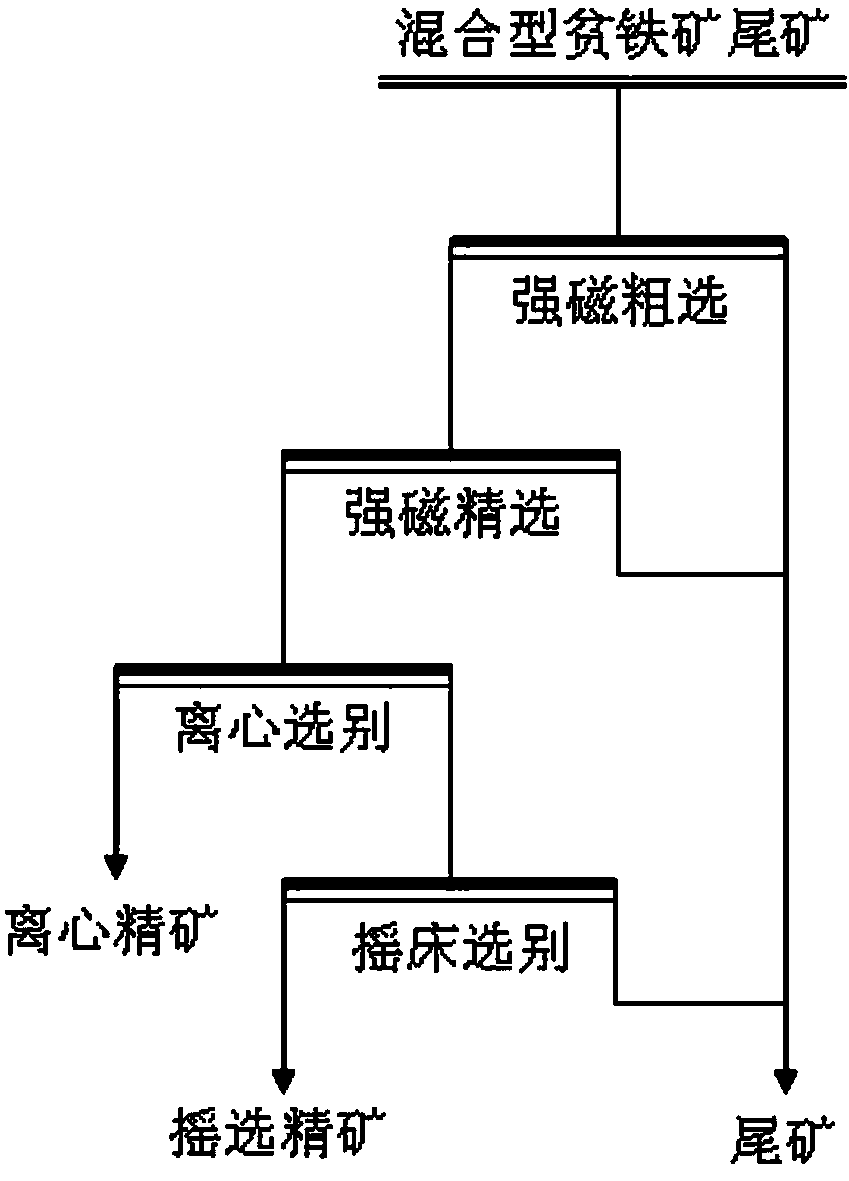

Iron-increasing and silicon-reducing reselection technique for mixed-type lean iron ore tailings

ActiveCN102909124AAchieve recyclingAchieve quality improvement and silicon reductionSolid separationMechanical material recoveryIron increasedRisk stroke

The invention discloses an iron-increasing and silicon-reducing reselection technique for mixed-type lean iron ore tailings, comprising the following steps of: strong magnetic roughing: putting mixed-type lean iron ore tailings through a strong magnetic separator with the magnetic field intensity of [U1] Oersteds to obtain roughed concentrate and roughed tailings; strong magnetic cleaning: selecting the roughed concentrate in the strong magnetic separator with the magnetic field intensity of 10000-20000 Oersteds to obtain magnetic concentrate and magnetic tailings; centrifugal selecting: putting the magnetic concentrate in a centrifugal concentrating machine with the rotating speed of 150-250r / min to obtain centrifugal concentrate and centrifugal tailings; and table selecting: selecting the centrifugal tailings through a table with the stroke of 8-10mm and the frequency of stroke of 250-300 times / min to obtain table concentrate and table tailings. According to the iron-increasing and silicon-reducing reselection technique, a great quantity of tailings is dropped through rough and concentrate double magnetic selection; the magnetic concentrate is selected by using the centrifugal machine so that irons are increased and silicon is reduced; and then the centrifugal tailings are selected by using the table so that the productivity is increased. The iron-increasing and silicon-reducing reselection technique has the effects of realizing iron increment and silicon reduction of the mixed-type lean iron ore tailings, incrasing the productivity of the iron ore to a great extent at the same time and providing an effective approach to iron increment and silicon reduction of the reselected concentrate for the mixed-type lean iron ore tailings.

Owner:YUXI DAHONGSHAN MINING

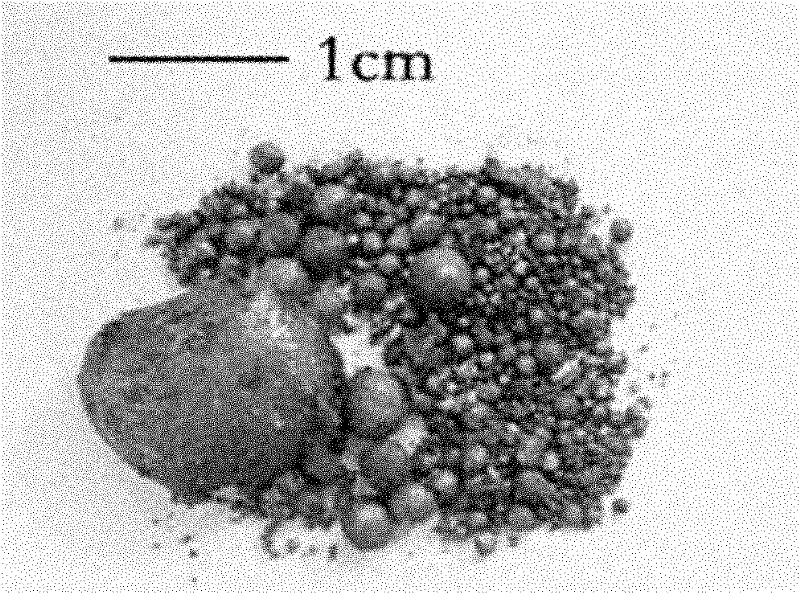

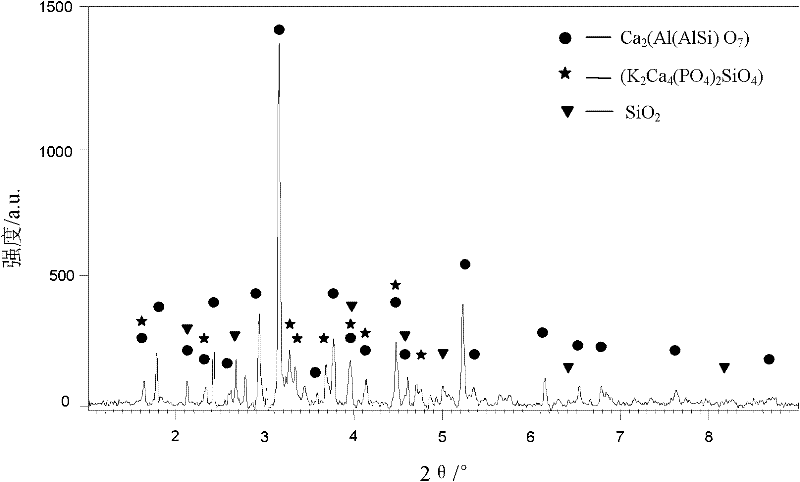

Dephosphorization and iron-increasing method of high phosphorus hematite by direct reduction

InactiveCN101984079ATo achieve the purpose of dephosphorization and ironSimple processProcess efficiency improvementIron increasedPotassium carbonate

The invention particularly relates to a dephosphorization and iron-increasing method of high phosphorus hematite by direct reduction, and the technical scheme comprises the following steps: mixing 60-83wt% of high phosphorus hematite powder, 10-15wt% of carbonaceous reducing agent, 6-15wt% of quicklime and 1-10wt% of additive uniformly, pressing the mixture into blocks, drying, reducing in a high temperature furnace under 1250-1350 DEG C, and keeping the temperature for 15-30 minutes; carrying out furnace cooling until the temperature is 600-800 DEG C, taking the reduction product out, naturally cooling, grinding and performing the magnetic separation to obtain pig iron particles. The additive is sodium carbonate, or potassium carbonate, or the mixture of the sodium carbonate and the potassium carbonate; drying is carried out under the condition of 110-120 DEG C until the weight of the mixture of raw materials is constant; and the high temperature furnace is a resistance furnace, or a rotary kiln, or a rotary hearth furnace, and the atmosphere in the high temperature furnace is neutral or weak-reductive. The invention has the advantages of short reduction time, simple process, high dephosphorization rate, high iron yield, less environmental pollution, recyclable residue and the like.

Owner:WUHAN UNIV OF SCI & TECH

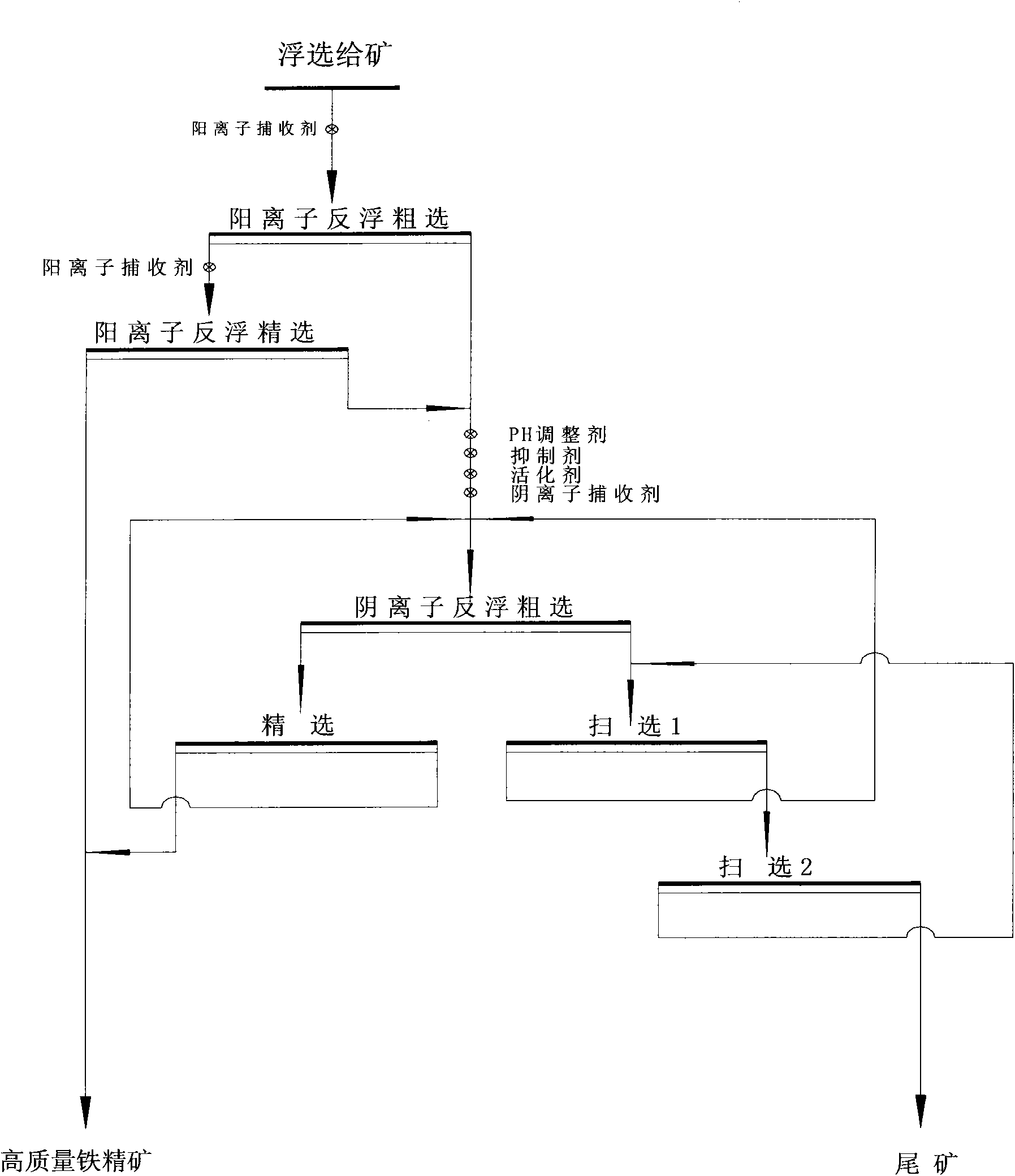

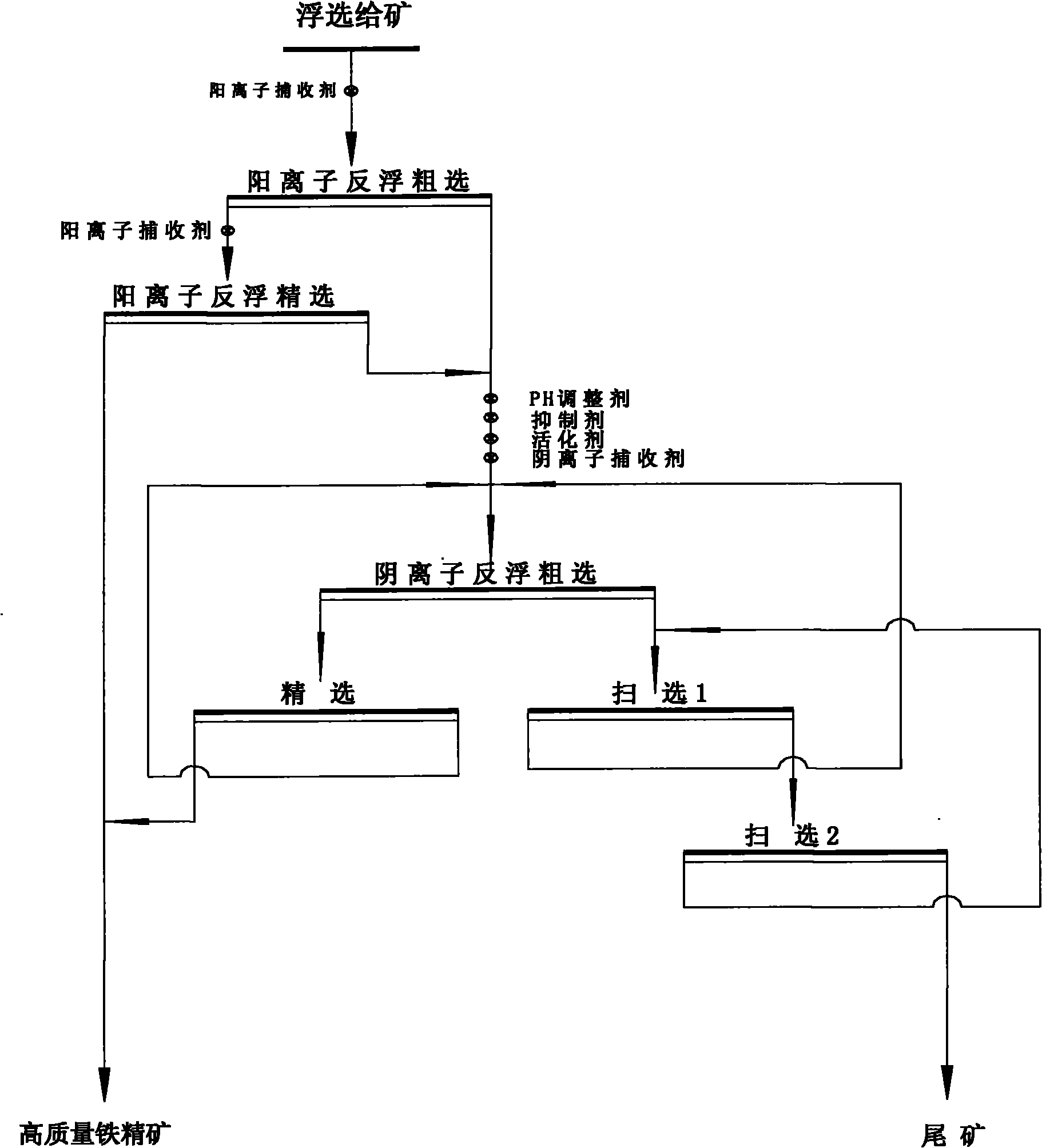

Iron-increasing and silicon-reduction mineral separation method for iron ores

The invention discloses an iron-increasing and silicon-reduction mineral separation method for iron ores, which comprises the following steps of: producing TFe60 to 66 percent iron ore concentrate by the conventional mineral separation method; executing a cationic collector reverse-flotation process on the TFe60 to 66 percent iron ore concentrate to obtain cationic collector reversely-floated iron ore concentrate and middling; executing an anionic collector reverse-flotation process on the middling obtained by the cationic collector reverse-flotation to obtain anionic collector reversely-floated iron ore concentrate, and discharging tailings; and combining the cationic collector reversely-floated iron ore concentrate and the anionic collector reversely-floated iron ore concentrate to obtain final high-quality iron ore concentrate. The method has the advantages of high iron ore concentrate grade, high iron recovery rate, low fine iron mineral loss, low mineral separation energy consumption, low medicament consumption, and the capacity of solving the industrial problem of the difficult filtration of fine-grained concentrate caused by the addition of starch and greatly optimizing concentrate filtration, and can be used for the separation of magnetic iron ores as well as weakly-magnetic iron minerals, such as hematite and the like.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

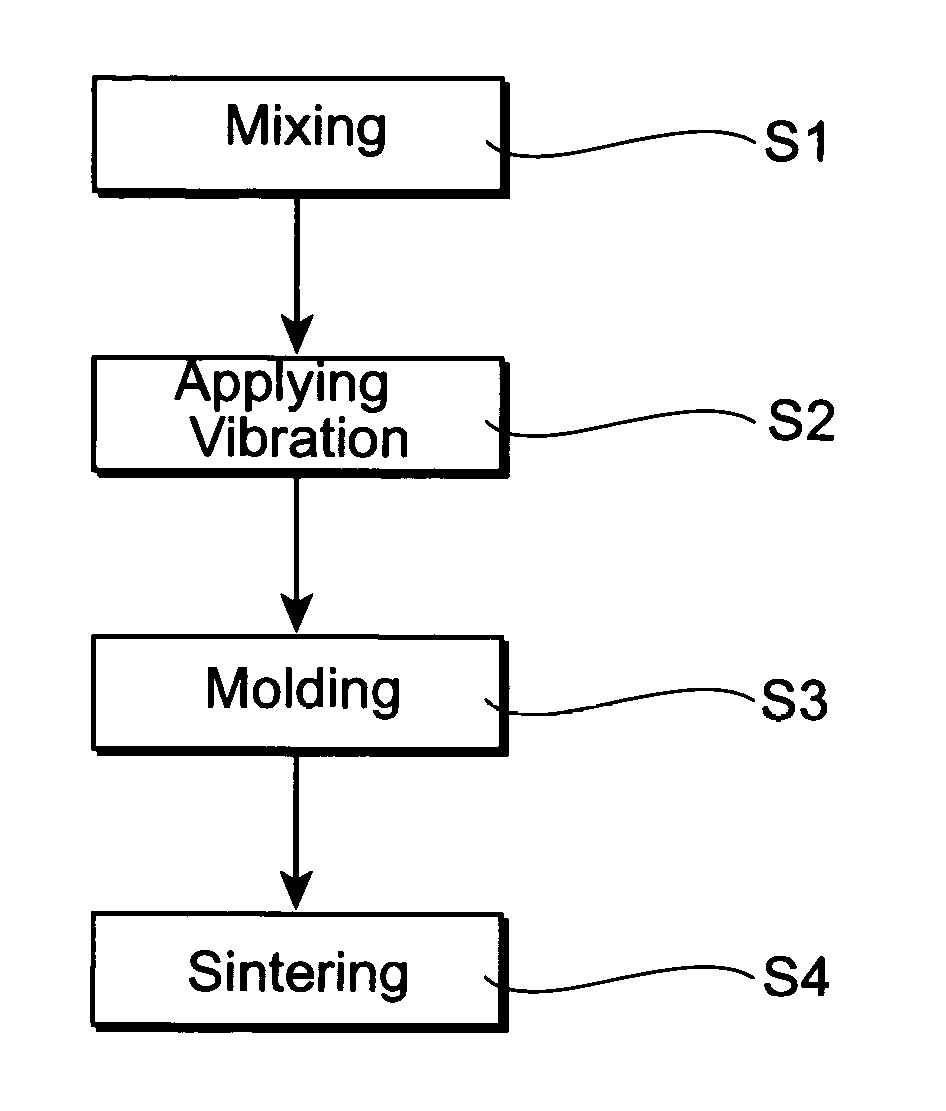

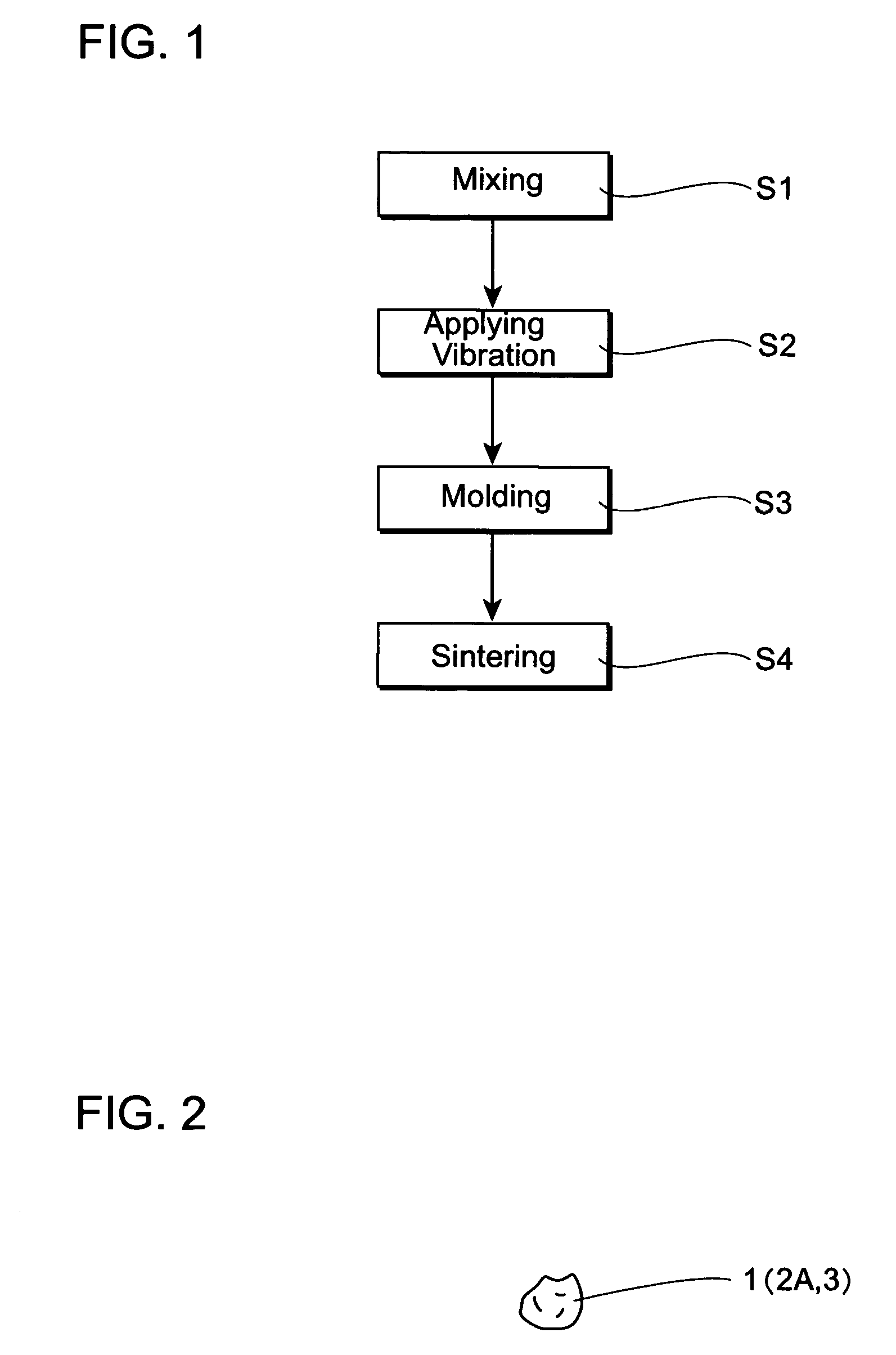

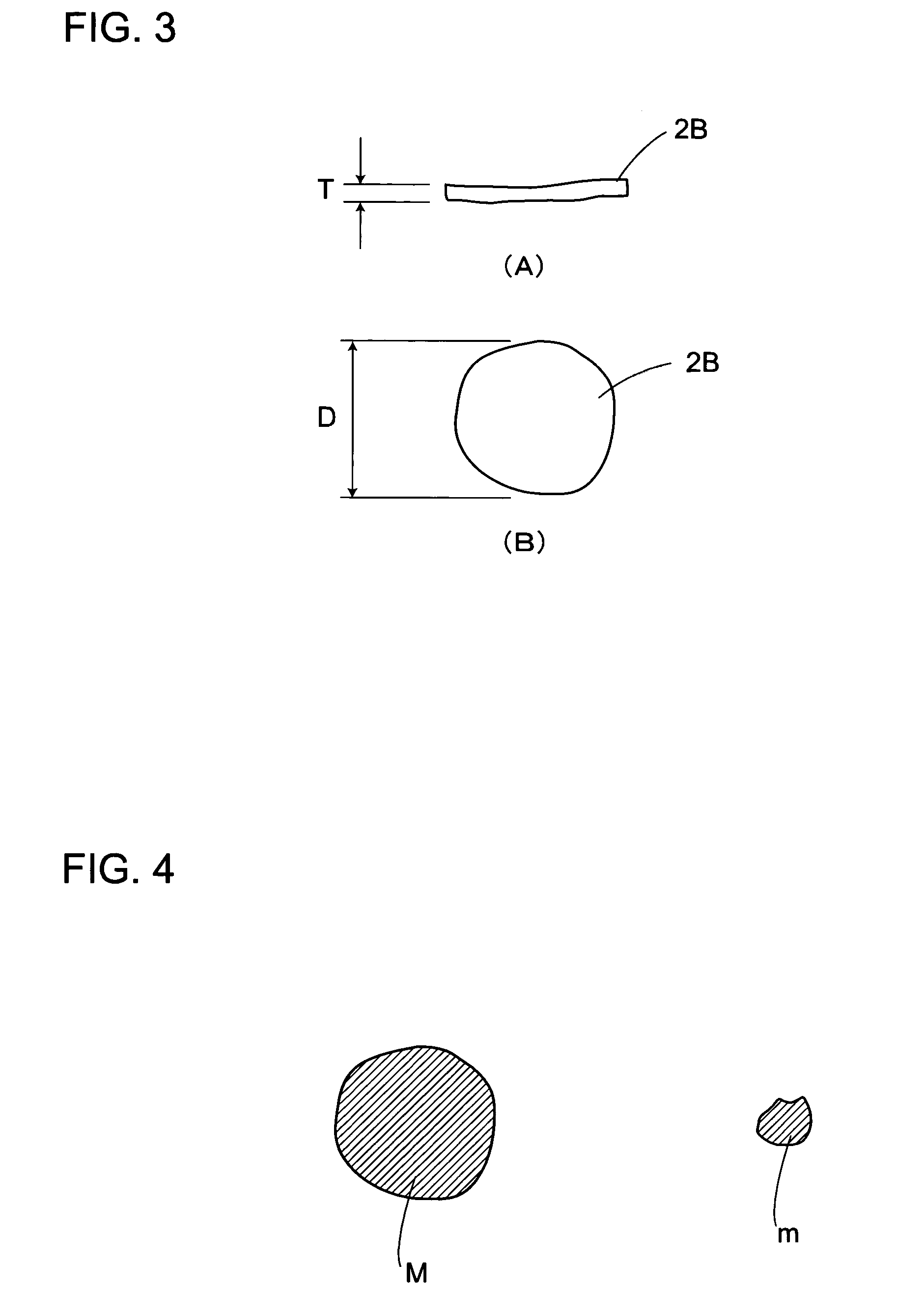

Sliding part and method of manufacturing the sliding part

ActiveUS20050265884A1Reduce frictional resistanceHigh strengthShaftsMetal-working apparatusFrictional coefficientIron increased

A bearing is manufactured by filling iron-based material powder and copper-based material powder in a filling portion of a mold, compacting those material powder so as to for a green compact, and then sintering the green compact. The copper-based material powder contains flat powder particles, the flat powder particles having a large aspect ratio than particles of the iron-based material powder. The coppers-based powder particles segregate on a sliding surface by vibration. The sliding surface of a bearing is covered with copper, and a ratio of iron increases from the sliding surface toward the inside. Since a rotation shaft slides on the sliding surface covered with copper, a frictional coefficient between the rotation shaft and the sliding surface is reduced, thus enabling a smooth rotation thereof. Simultaneously the usage of iron imparts predetermined strength and durability.

Owner:DIAMET CORP

Iron increase and phosphorous reduction method for oolitic high phosphorus hematite

InactiveCN101440416AIncrease profitTo achieve the purpose of increasing iron and reducing phosphorusMagnetic separationPhosphoric acidIron increased

The invention discloses an iron-increasing phosphorous-reducing method for oolitic high-phosphorus hematite. The method comprises the following steps: (1) phosphorus-containing oolitic hematite is crushed till the particle size is not more than 0.25 millimeter, and then is added to a roaster; (2) a reduction chamber of the roaster is supplied with reduction gas, and crushed material is reduced for 10 to 60 minutes at a temperature between 700 and 1,450 DEG C in the roaster; (3) reduced mineral is isolated from oxygen, cooled to not higher than 100 DEG C and then magnetically separated; obtained coarse iron powder per ton is added with 1 to 1.5 kilograms of sodium silicate; the obtained coarse iron powder is ball-milled till the particle size is not more than 0.055 millimeter; obtained fine iron powder is immersed in acid solution with the concentration between 0.5 and 18 percent at normal temperature for 30 to 300 minutes; and the proportion of the acid solution to the fine iron powder is not less than 1:1; and (4) the fine iron powder is poured into a hydroextractor so as to reduce phosphoric acid. The method has the advantages of simple process, low requirement on the quality of raw material and the particle size of ore, no consumption of electric energy and high-quality coke, low energy consumption, high phosphorous reducing rate and high metal yield.

Owner:周玉平

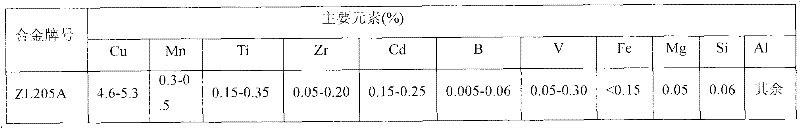

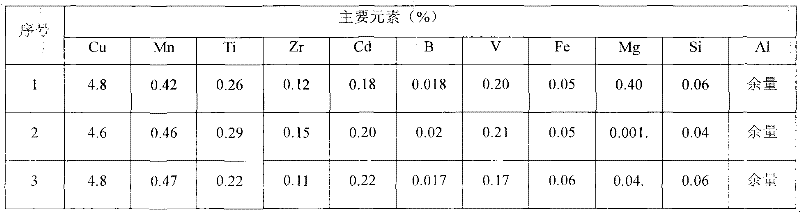

Method for preventing iron increase in ZL205A alloy melting process

The invention relates to a method for preventing the iron increase in a ZL205A alloy melting process. The method comprises the following steps: 1, selecting and preparing a coating: selecting a composite coating of an HGS-1 coating and an aluminum alloy T-1 coating as a coating for a crucible and a melting tool; and 2, coating a protection layer: a, removing an oxidization layer on the surface of the crucible and the melting tool; b, preheating the crucible and the melting tool in a resistor furnace to 120-150DEG C, and starting to coat the protection layer; c, coating with a first layer of the HGS-1 coating with the thickness of 1-2mm, and coating with a second layer the HGS-1 coating of 1-2mm after the first layer is completely dried; and d, coating with a layer of the aluminum alloy T-1 coating with the thickness of 0.5-1.0mm after the second layer is completely dried. According to the invention, control requirements of a harmful element iron by the ZL205A casting aluminum alloy are realized, indexes of the ZL205A casting aluminum alloy can reach GB requirements, and mechanical performances of the ZL205A casting alloy subjected to thermal treatment can satisfy the GB requirements.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

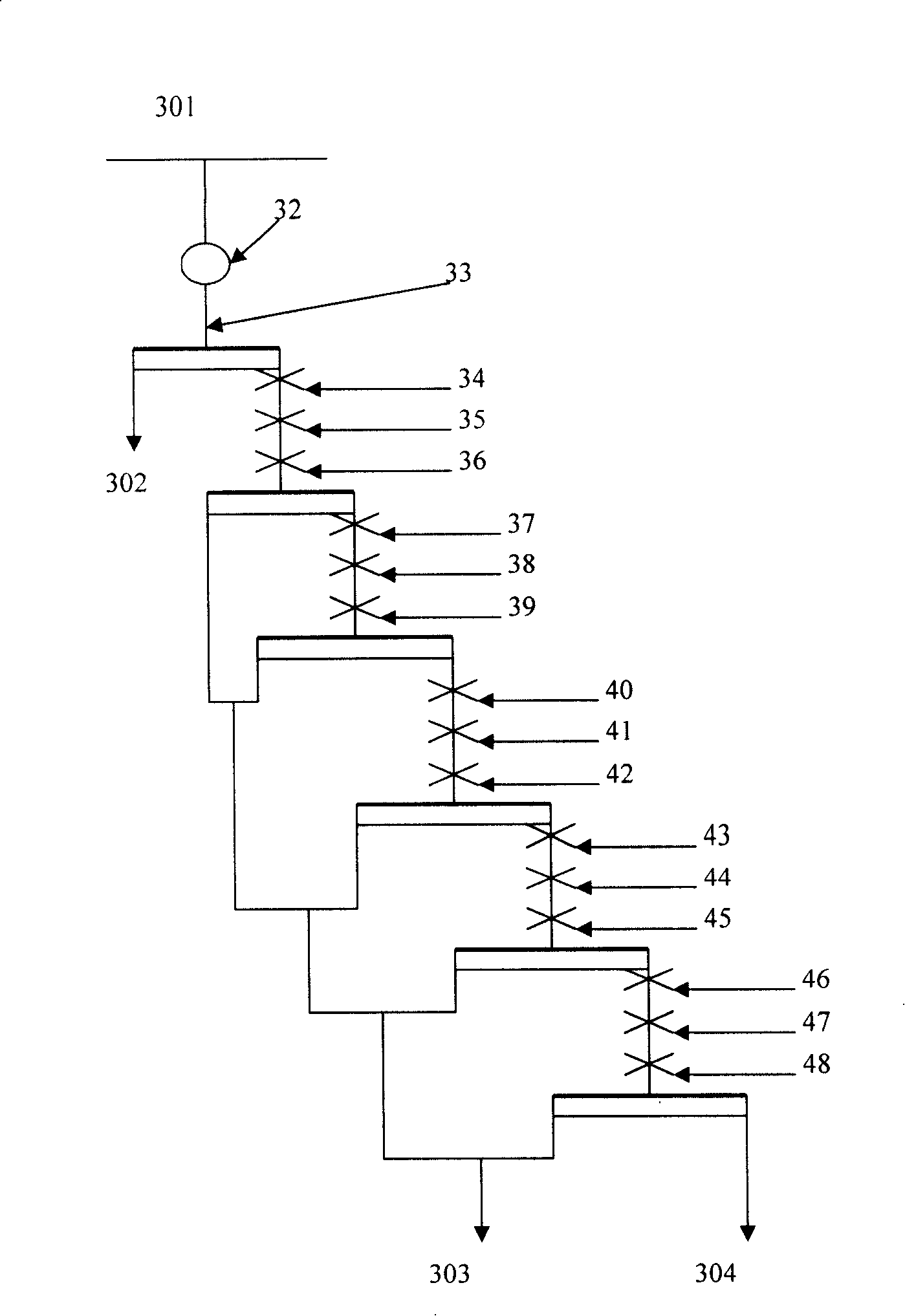

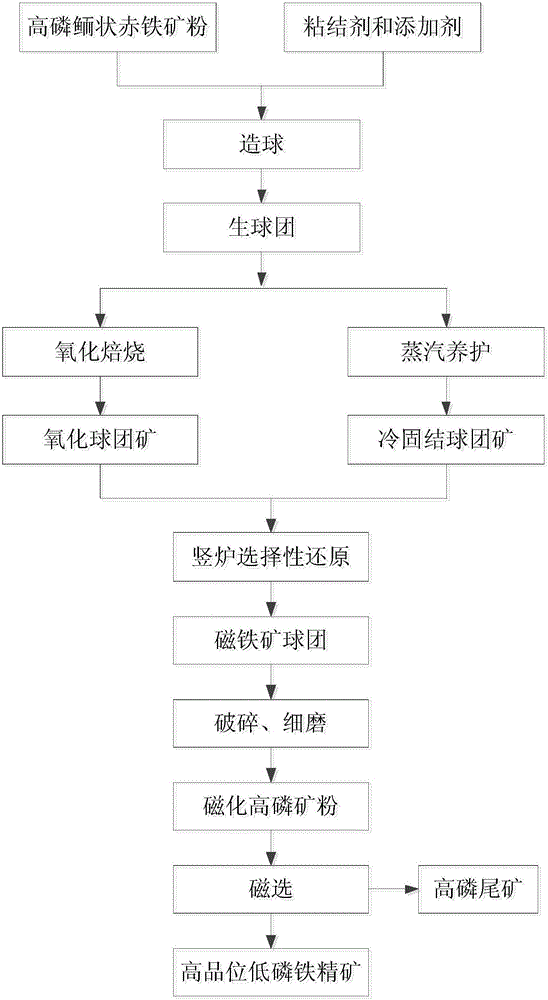

Industrial production method for conducting iron increase and phosphorous reduction on high-phosphorus oolitic hematite

InactiveCN105695734AExpand production scaleRealize large-scale industrial applicationShaft furnaceMagnetic separationIron increasedMagnetite

The invention relates to an industrial production method for conducting iron increase and phosphorous reduction on high-phosphorus oolitic hematite. The method comprises the steps that high-phosphorus oolitic hematite powder, bonding agents and dephosphorization agents are mixed uniformly and prepared into green pellets, and the green pellets are subjected to oxidizing roasting, so that pellets are obtained; oxide pellets or cold bonded pellets are placed in a two-section shaft furnace and induced into magnetite pellets containing gangue through a selective direct-reduction method; high-temperature CO-CO2 mixed gas is introduced into the bottom of a reduction section of the shaft furnace, and normal-temperature CO-CO2 mixed gas is introduced into the bottom of a cooling section; and the reduced magnetite pellets are crushed and fine ground, magnetized high-phosphorus ore powder is obtained and conveyed into a magnetic separator to be subjected to magnetic separation, and finally high-grade low-phosphorus iron ore concentrate and high-phosphorus tailings are produced. The industrial production method has the remarkable advantages of being suitable for large-scale industrial production, environmentally friendly, low in energy consumption, good in economic benefit and the like.

Owner:WUHAN UNIV OF SCI & TECH

Comprehensive utilization technology of blast furnace gas ash

InactiveCN108559852ARealize comprehensive utilizationSolve puzzlesProcess efficiency improvementMagnetic separationIron increasedAlkali metal

The invention discloses a comprehensive utilization technology of blast furnace gas ash and belongs to the technical field of mineral processing. The invention aims at solving the problems of zinc enrichment caused by higher content of alkali metal such as zinc oxide of the blast furnace gas ash and direct returning during sintering influences normal operation of a blast furnace and the like. Thecomprehensive utilization technology comprises the steps of iron increase by weak magnetism and strong magnetism, combustion reduction of a power generating boiler, cooling and zinc recovery of a bagdust collector, iron increase by fly ash and the like, so that elements such as Fe, Zn and C in the gas ash are effectively recycled; the remaining material doped with pulverized coal is burdened intothe fly ash; a mixture is completely used for cement ingredients, so that full comprehensive utilization of the blast furnace gas ash is achieved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Sliding component and method for manufacturing the same

ActiveUS7361203B2Reduce coefficient of frictionSmooth rotationShaftsBearing componentsFrictional coefficientIron increased

A bearing is manufactured by filling iron-based material powder and copper-based material powder in a filling portion of a mold, compacting those material powder so as to form a green compact, and then sintering the green compact. The copper-based material powder contains flat powder particles, the flat powder particles having a large aspect ratio than particles of the iron-based material powder. The coppers-based powder particles segregate on a sliding surface by vibration. The sliding surface of a bearing is covered with copper, and a ratio of iron increases from the sliding surface toward the inside. Since a rotation shaft slides on the sliding surface covered with copper, a frictional coefficient between the rotation shaft and the sliding surface is reduced, thus enabling a smooth rotation thereof. Simultaneously the usage of iron imparts predetermined strength and durability.

Owner:DIAMET CORP

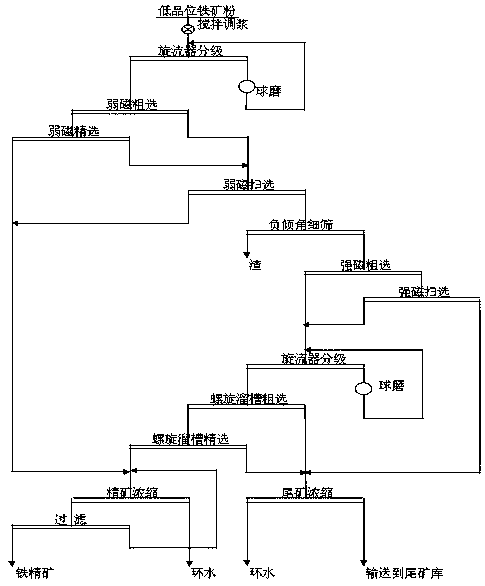

Beneficiation method for iron increase and impurity reduction of low-grade iron ore powder

ActiveCN109894256AReduce the amount of gangueIncrease monomer dissociationMagnetic separationWet separationSlagIron increased

The invention relates to a beneficiation method for iron increase and impurity reduction of low-grade iron ore powder. The method comprises the following steps that firstly, water is added into iron ore powder to be subjected to stirring and slurry mixing, suspension ore slurry is achieved, and flowing is facilitated; secondly, a hydrocyclone is adopted for carrying out grading and concentrating in advance, sand setting is carried out for ore grinding, overflowing is carried out, and the sorting procedure is executed; thirdly, the hydrocyclone carries out overflow to carry out weak magnetic roughing, weak magnetic selection and weak magnetic scavenging, and high-grade weak magnetic concentrates are obtained; fourthly, weak magnetic scavenging tailings are subjected to screening and slag separating, and impurities are removed; fifthly, minus sieve ore slurry after slag separating is subjected to strong magnetic roughing and strong magnetic scavenging, and a strong magnetic separation concentrate is obtained; sixthly, the strong magnetic separation concentrate is subjected to grading and concentrating through the hydrocyclone, sand setting is carried out for ore grinding, overflowingis carried out, and the sorting procedure is executed; and seventhly, hydrocyclone carries out overflow, a spiral chute is adopted for roughing and selection, and the spiral chute concentrate can beobtained.

Owner:NANJING MEISHAN METALLURGY DEV

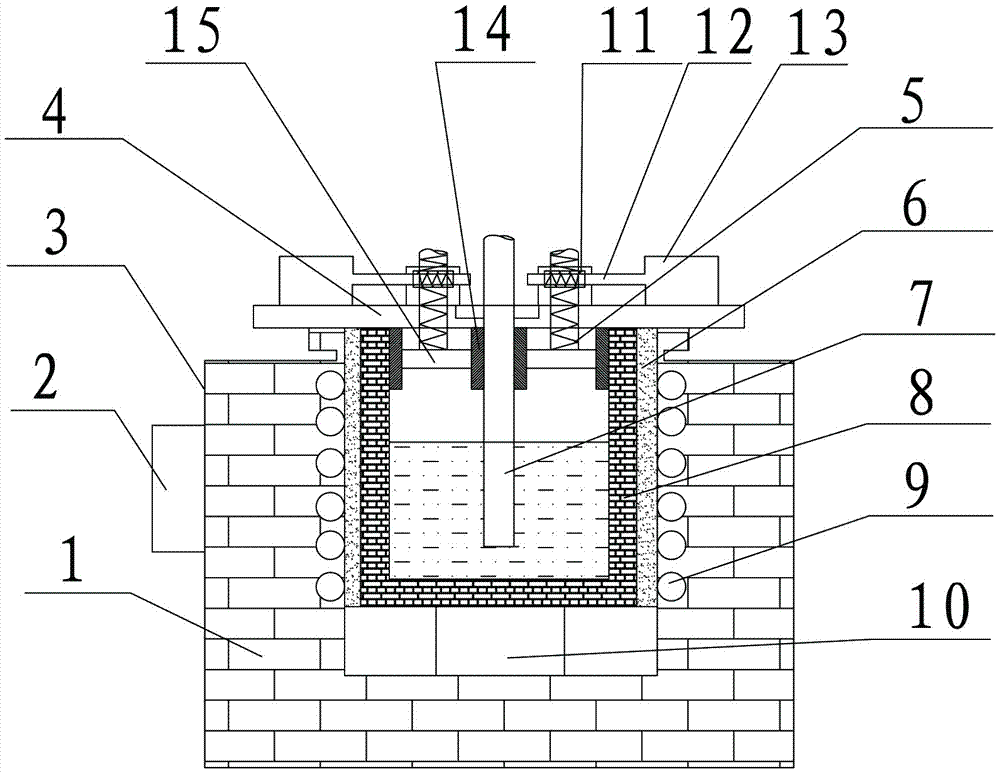

Low pressure casting integrally-sealed boiler with pressurization structure

InactiveCN106925755AAvoid mixingPressurization speed is smooth and uniformThermal insulationCrucible

The invention discloses a low-pressure casting integrally sealed furnace with a pressurized structure, which includes a boiler body, a base structure is installed at the bottom of the inner recess of the boiler body, a crucible is installed on the base, the crucible and the inner wall of the boiler body recess The interlayer is filled with heat-insulating material, and the riser pipe penetrates into the crucible through the middle part of the boiler cover. Lifting screw rods are arranged on both sides of the mouth of the riser pipe, and gears are installed on the lifting screw rods. A threaded structure is provided to connect with the threaded structure on the horizontal screw rod, one end of the horizontal screw rod is connected to the motor, and the outer wall of the boiler body is equipped with a metal shell structure. In this low-pressure casting integral sealed furnace with a pressurized structure, the inner wall of the crucible is made of graphite structure, which effectively solves the phenomenon of iron increase in molten metal, and the outer wall has a stainless steel metal reinforcement structure, which enhances the strength of the crucible and improves its compression resistance. The pressing speed is fast, the production efficiency is improved, the structure is simple, and the cost is low.

Owner:赵群英

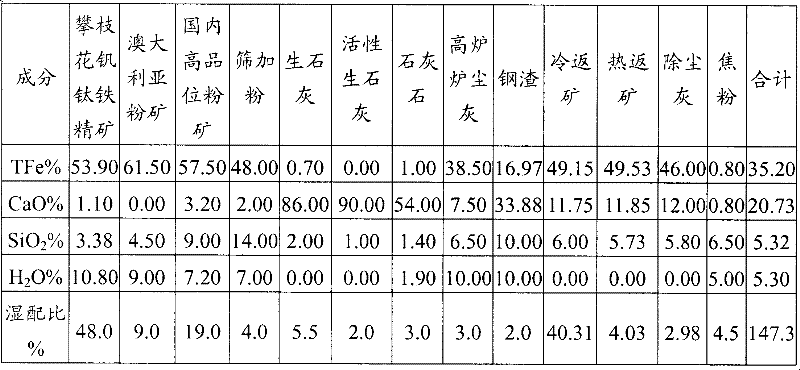

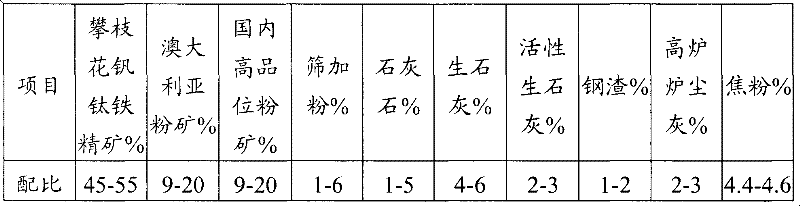

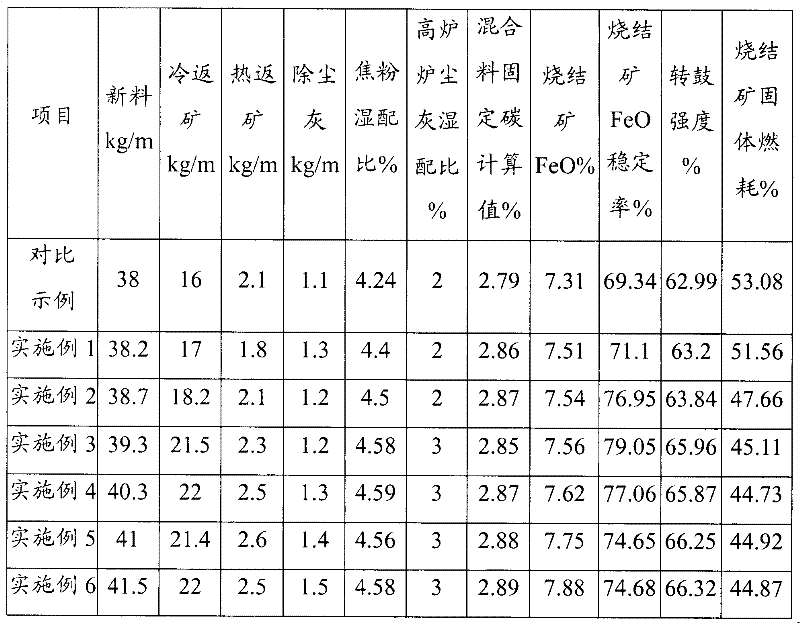

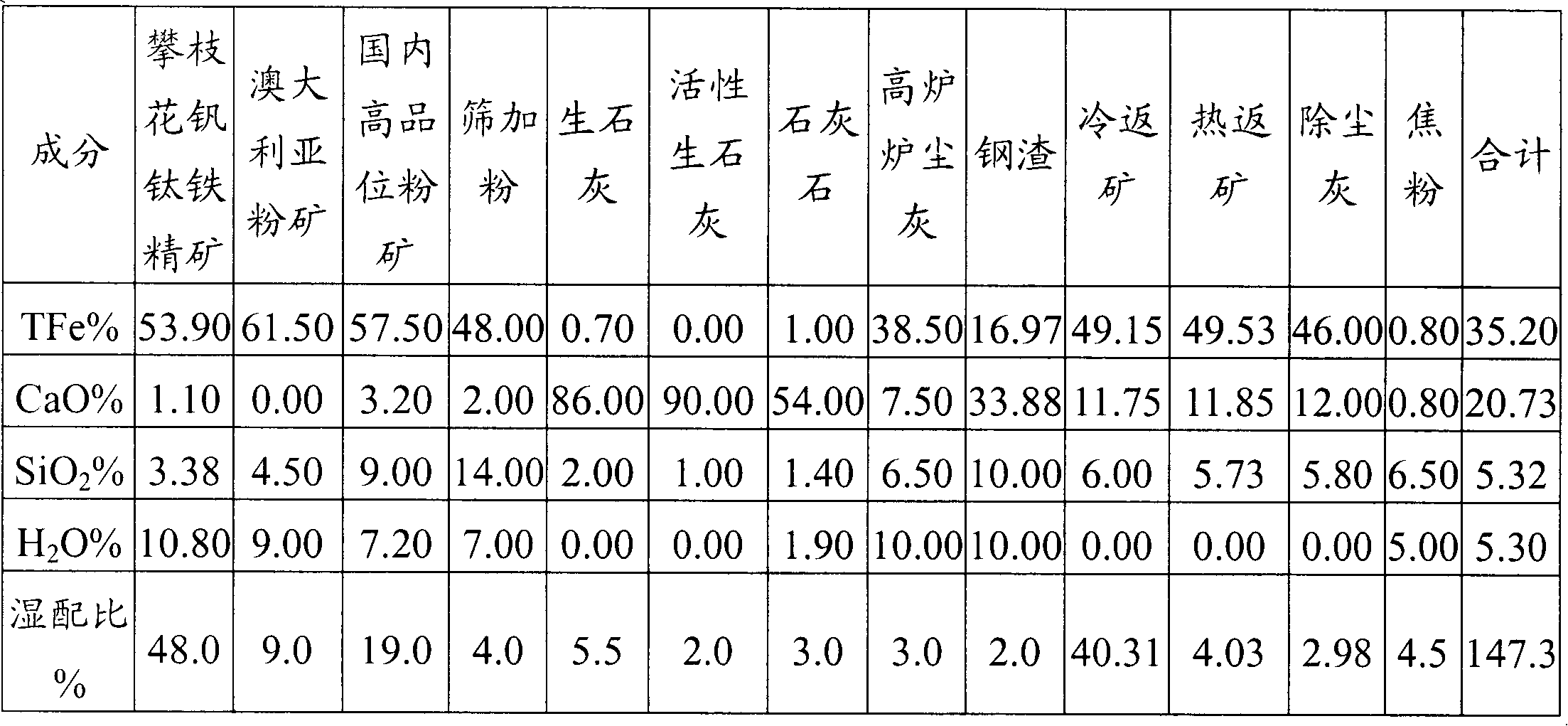

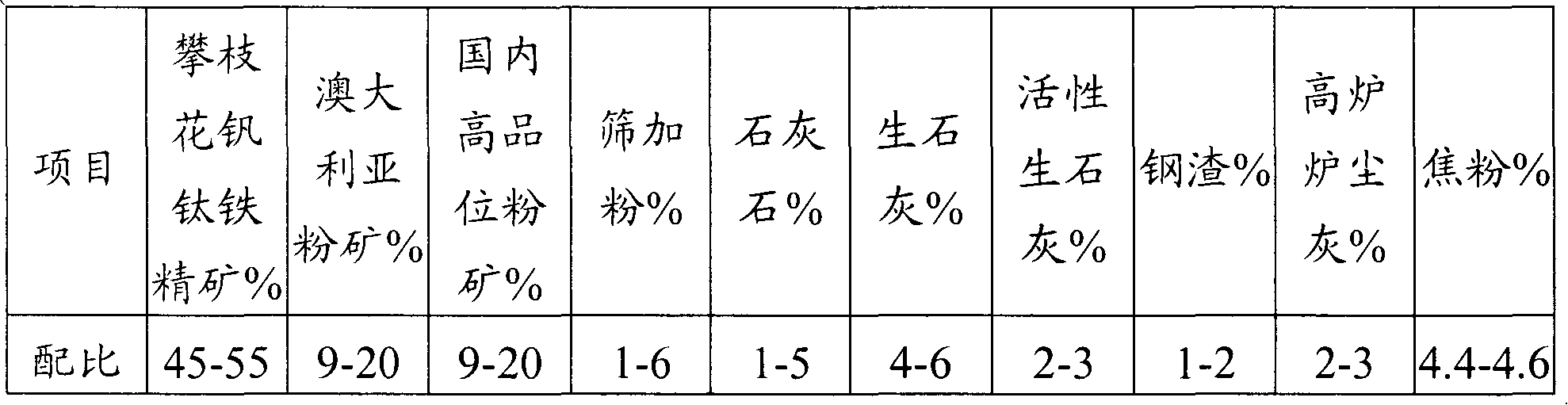

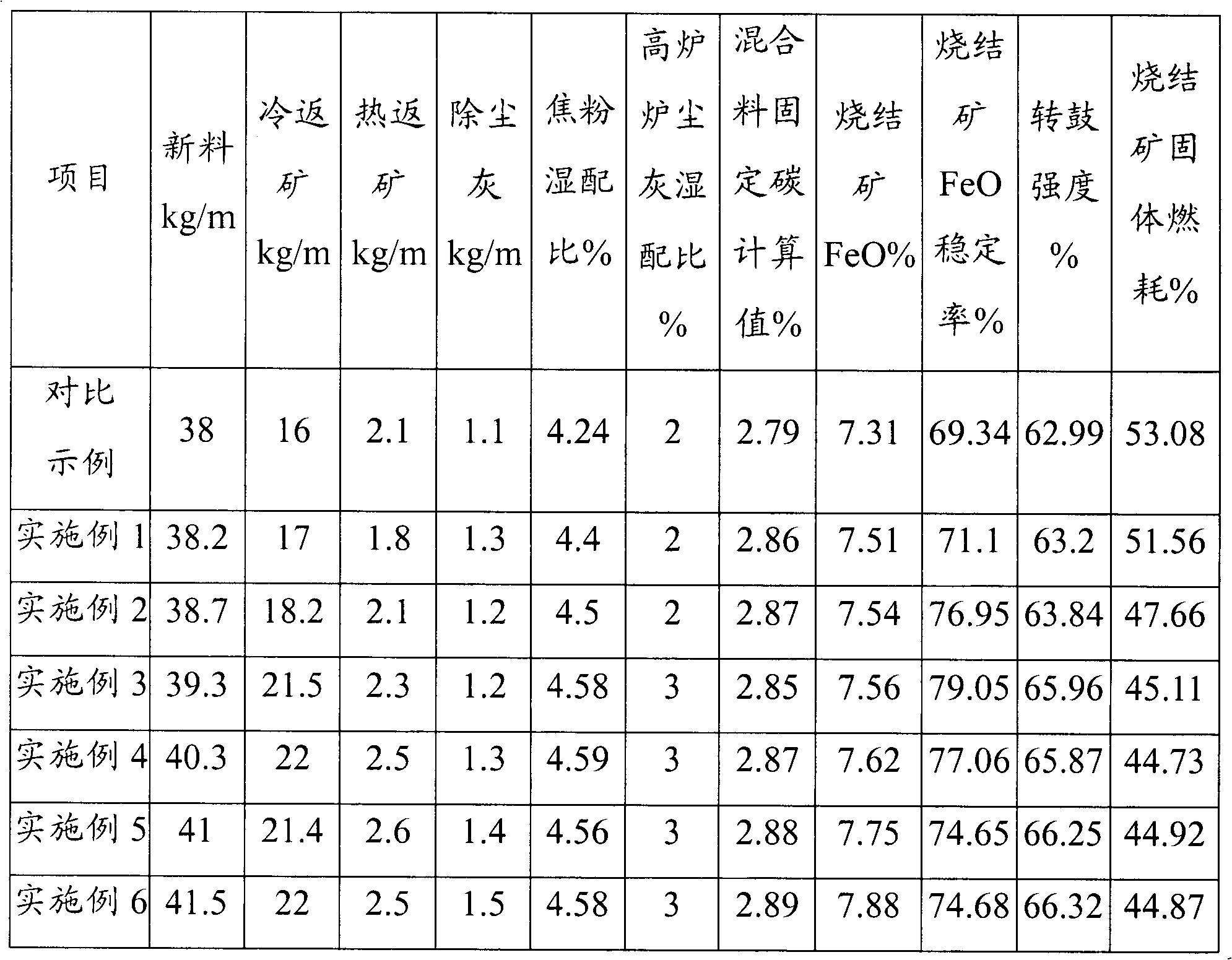

Method for controlling ferrous oxide content in sintering ore

The invention provides a method for controlling the ferrous oxide (FeO) content in a sintering ore. In the method, the sintering ore comprises the following raw materials: titanium-containing iron ore powder, fuel, a flux and blast furnace dust; and a value in formula 1 is controlled within 2.8wt%-2.9wt% so as to control the ferrous oxide content in the sintering ore within 7.2wt%-8.2wt%, wherein, the formula 1 is as follows: (FC) mixture=[Wfuel*(1-Afuel-Vfuel-Sfuel-Hfuel)+R(blast furnace dust)*Wnew material*C(blast furnace dust)] / Wmixture*100%. The method of the invention can control the FeOcontent in the sintering ore accurately and stably to obtain the sintering ore with excellent reducibility and intensity, thus further promoting iron increase and coke reduction during the blast-furnace smelting process, lowering the iron-making cost, reducing the coke powder usage during the sintering process, lowering the solid fuel consumption and saving the cost while realizing recovery and reuse of the blast furnace dust.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

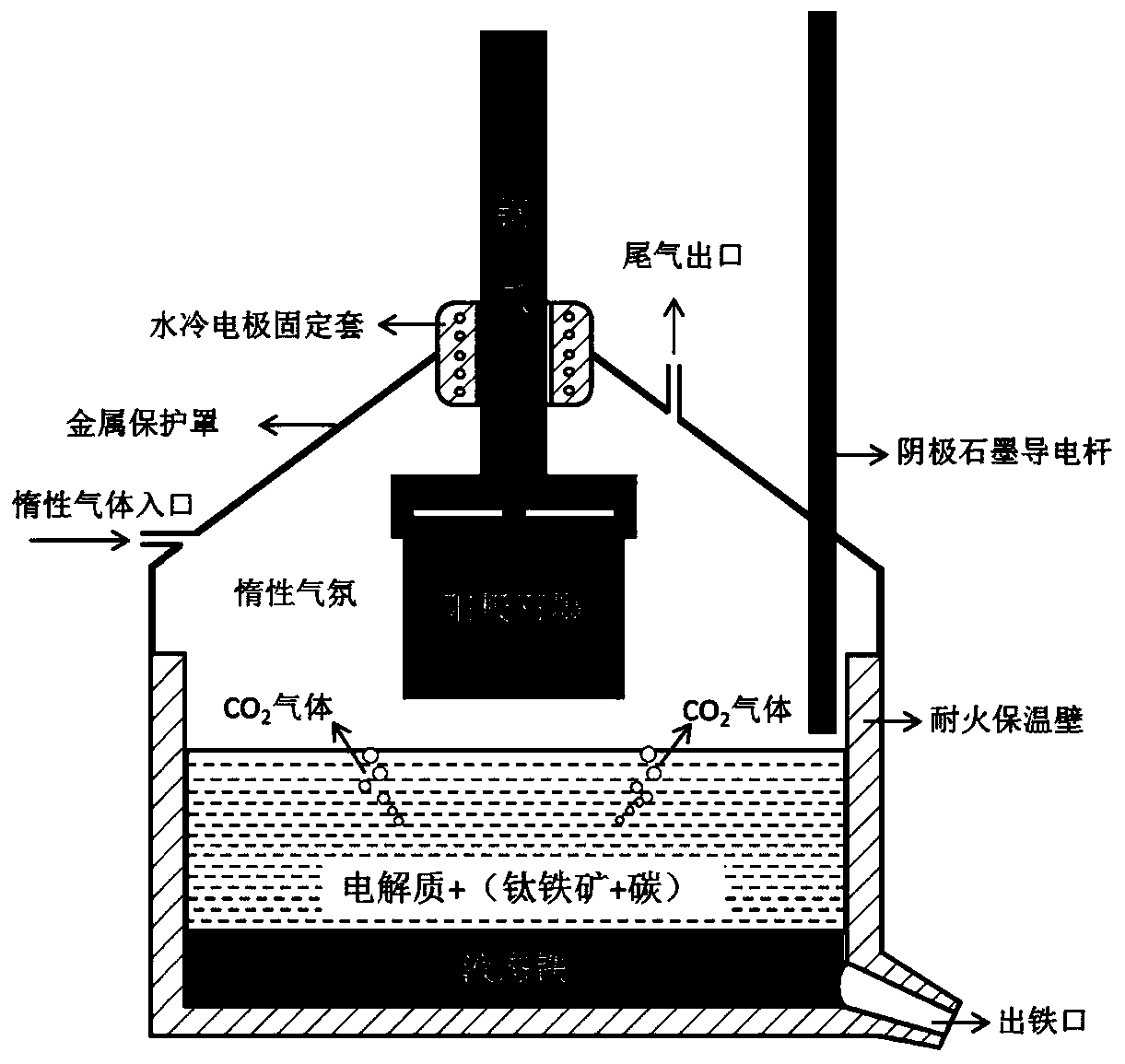

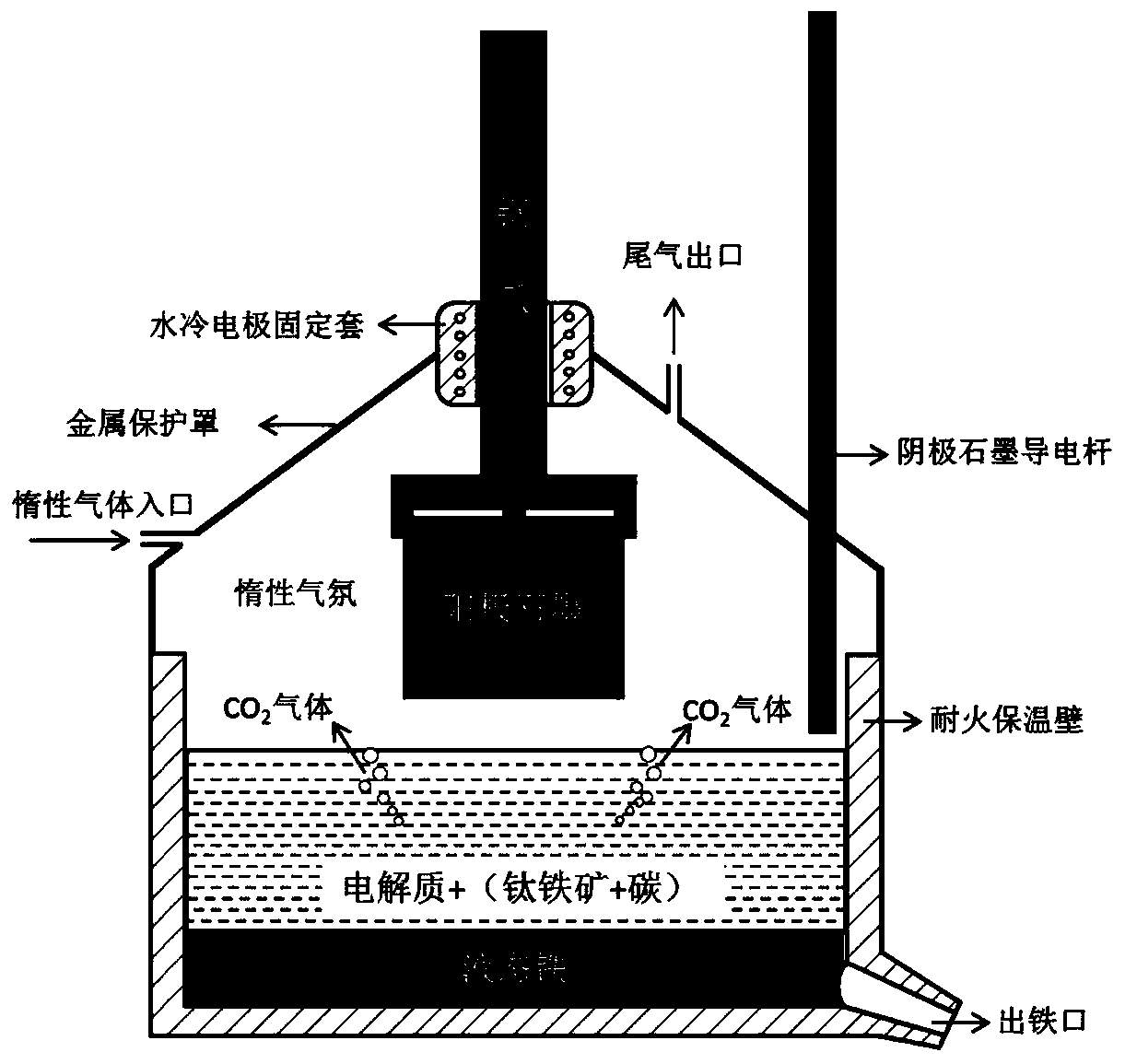

Method for preparing ilmenite by ilmenite carbothermic-electrolysis

The invention discloses a method for preparing ilmenite by ilmenite carbothermic-electrolysis, and belongs to the field of electrochemical metallurgy. The method for preparing ilmenite by the ilmenitecarbothermic-electrolysis comprises the steps that ilmenite and reducing agent carbon are evenly mixed in proportion, and then the mixture is placed into molten oxide electrolyte; carbothermic reduction is carried out on the ilmenite in the electrolyte to obtain molten iron; graphite or inert electrode is used as anode, a graphite rod or an inert metal rod is inserted into the molten iron as cathode, and a constant potential or constant current method is adopted for electrolysis; electrochemical deposition is carried out on the cathode molten iron after electrolysis to obtain ferrotitanium alloy products; after the content of iron and titanium in the electrolyte is reduced to a certain value, a mixture of the ilmenite and the reducing agent carbon is added to the electrolyte again for thenext cycle; and when the titanium content in the molten iron increases to a certain amount or reaches the required ferrotitanium alloy ratio, the liquid ferrotitanium alloy products are discharged through a tapping hole in the bottom of a crucible, and the next cycle is continued. The method for preparing the ilmenite by the ilmenite carbothermic-electrolysis has the characteristics of short flow, simple operation, low equipment requirement, high titanium element recovery rate in the ilmenite, no waste residue and waste water, green and cleanness.

Owner:UNIV OF SCI & TECH BEIJING +1

Composite force field sorting machine for magnetite sorting and sorting method thereof

ActiveCN109046743ARaise the gradeGuaranteed RecoveryMagnetic separationWet separationMagnetiteIron increased

The invention discloses a composite force field sorting machine for magnetite sorting and a sorting method thereof. The sorting machine comprises a housing, wherein the housing is of a hollow verticalcolumn type cylindrical structure; a guide plate, a dispersing cylinder and a sorting cylinder are sequentially arranged in the housing from top to bottom; the axes of the dispersing cylinder, the sorting cylinder and the housing are on the same line; and a hollow coil capable of generating a magnetic field is arranged outside the housing. By using the device and the method provided by the invention, all that is needed is to adjust the feeding amount, the amount of flushing water, the height of the sorting cylinder, the magnetic field strength and the magnetic field position of the sorting machine according to the sorting process requirements, the adjustment and control of a particle distribution rule can be realized, thereby realizing sorting optimization. The composite force field sorting machine provided by the invention integrates the advantages of multiple sorting methods such as re-election, flotation and magnetic separation, not only can improve the concentrate grade of magnetite, but also ensure the recovery rate of magnetite; and the reverse flotation process of magnetite is effectively shortened, and thus the composite force field sorting machine is suitable for the process of reverse flotation iron increase and silicon reduction of magnetite.

Owner:TAIYUAN UNIV OF TECH

Method for controlling ferrous oxide content in sintering ore

The invention provides a method for controlling the ferrous oxide (FeO) content in a sintering ore. In the method, the sintering ore comprises the following raw materials: titanium-containing iron ore powder, fuel, a flux and blast furnace dust; and a value in formula 1 is controlled within 2.8wt%-2.9wt% so as to control the ferrous oxide content in the sintering ore within 7.2wt%-8.2wt%, wherein, the formula 1 is as follows: (FC) mixture=[Wfuel*(1-Afuel-Vfuel-Sfuel-Hfuel)+R(blast furnace dust)*Wnew material*C(blast furnace dust)] / Wmixture*100%. The method of the invention can control the FeO content in the sintering ore accurately and stably to obtain the sintering ore with excellent reducibility and intensity, thus further promoting iron increase and coke reduction during the blast-furnace smelting process, lowering the iron-making cost, reducing the coke powder usage during the sintering process, lowering the solid fuel consumption and saving the cost while realizing recovery and reuse of the blast furnace dust.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

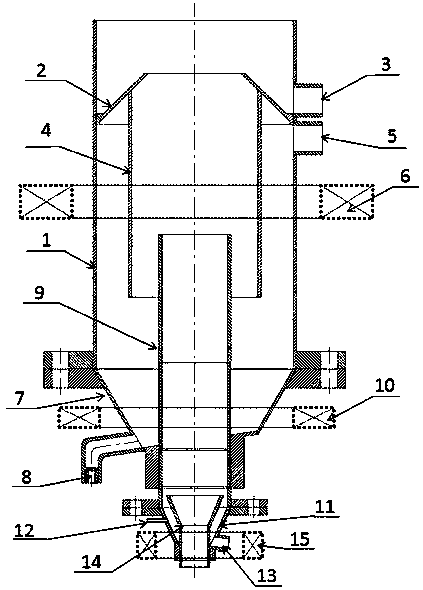

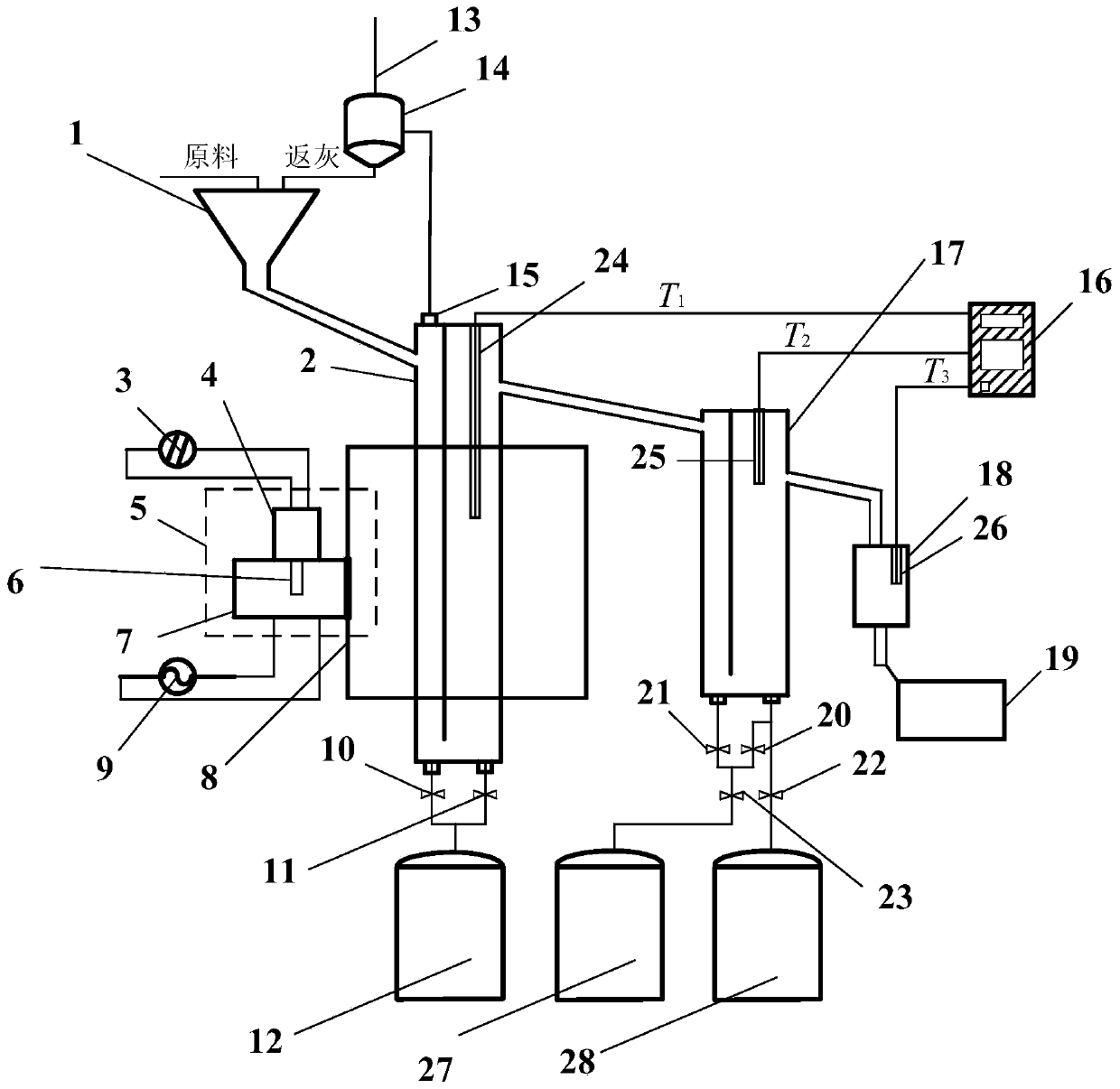

Microwave continuous suspension roasting method of enhancing high-phosphorus oolitic hematite for iron increase and phosphorus reduction

The invention discloses a microwave continuous suspension roasting method of enhancing high-phosphorus oolitic hematite foriron increase and phosphorus reduction. The microwave continuous suspension roasting method adopts a microwave continuous suspension roasting system and comprises the following steps that (1) the high-phosphorus oolitic hematite is crushed and finely ground into iron ore powder, and then the iron ore powder is poured into a feeding bin and is conveyed to a pretreatment fluidization device; (2) protective gas is introduced into a pretreatment feeding chamber and a pretreatment discharging chamber; (3) the iron ore powder is heated througha microwave cavity and then enters a reduction fluidization chamber; (4) the protective gas is introduced into a reduction feeding chamber and a reduction discharging chamber, and when thetemperature is lowered to 450-700 DEG C, reducing mixed gas is introduced into the reduction discharging chamber for reduction magnetization roasting, and a reduction material enters a cooler; and (5) the reduction material is cooled to thetemperature below 100 DEG C and enters a collection tank. By adopting the method disclosed by the invention, efficient and comprehensive utilization of high-phosphorus iron ores is realized, the iron grade and the recovery rate are high, and the phosphorus removal effect is remarkable; and resource and efficient development and utilization of the high-phosphorus oolitic hematite are realized.

Owner:NORTHEASTERN UNIV

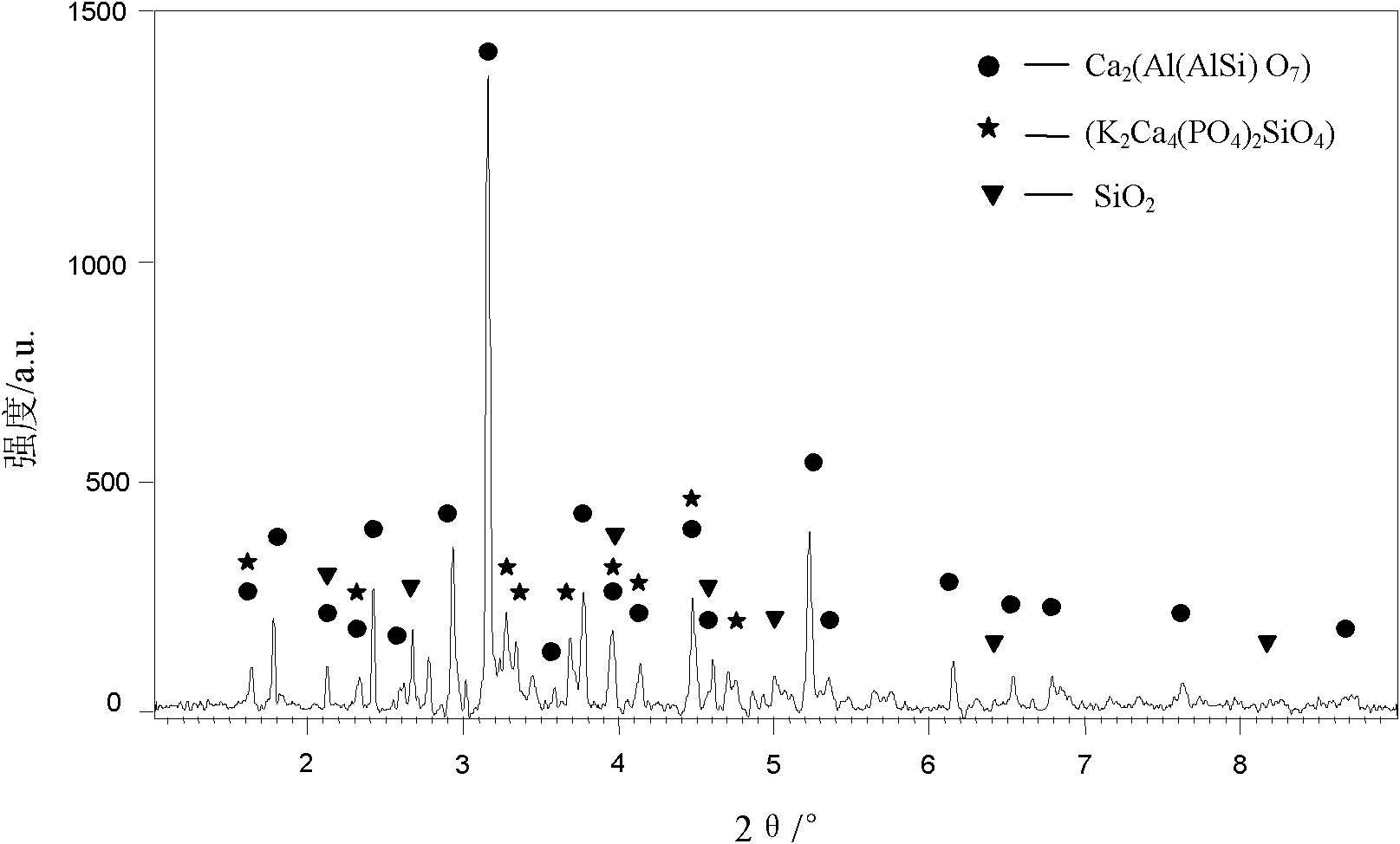

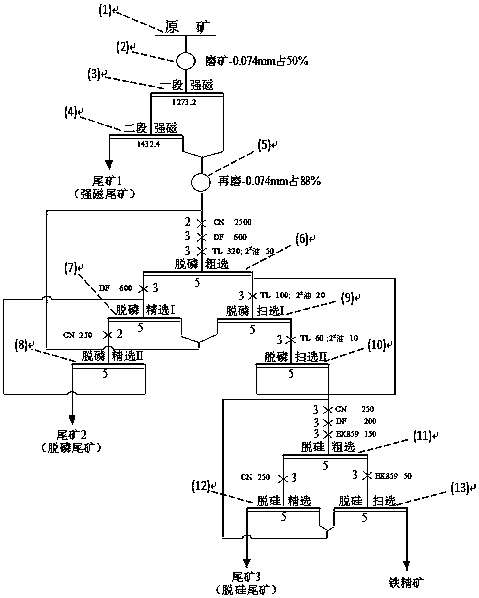

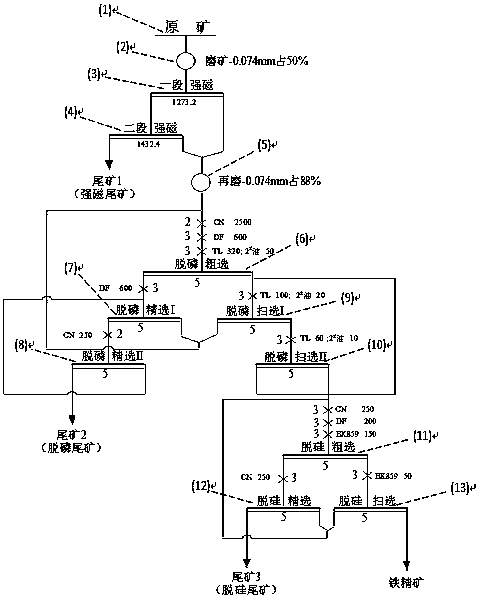

High-phosphorus oolitic hematite high-magnetic reverse-flotation dephosphorization and desilicication mineral processing technology

The invention relates to a high-phosphorus oolitic hematite high-magnetic reverse-flotation dephosphorization and desilicication mineral processing technology used in the field of mineral processing. The technological processes include (1) mineral feeding, (2) mineral grinding, (3) first-stage high magnetic separation, (4) second-stage high magnetic separation, (5) regrinding, (6) dephosphorization roughing, (7) dephosphorization selection, (8) dephosphorization selection, (9) dephosphorization scavenging, dephosphorization scavenging, desilicication roughing, desilicication selection and selection scavenging. According to the technology, the high-magnetic tailing discarding-reverse flotation dephosphorization-reverse flotation desilicication double reverse flotation beneficiation combined method technology is adopted, dephosphorization and desilicication efficient composite collecting agents TL and BK-859 are adopted, the separation efficiency of high-phosphorus oolitic hematite is obviously improved, the problems of iron increase and phosphorous reduction of this kind of iron mine are successfully solved, and exploitation of the kind of resource becomes possible. By means of the high-phosphorus oolitic hematite high-magnetic reverse-flotation dephosphorization and desilicication mineral processing technology, high-phosphorus oolitic hematite beneficiation technical indexes reach the conditions that the iron ore concentrate grade is higher than 55.74%, contained phosphorus is lower than 0.12%, the iron recovery rate is higher than 62%, and the phosphorus removal rate is higher than 94%.

Owner:北京中矿东方矿业有限公司

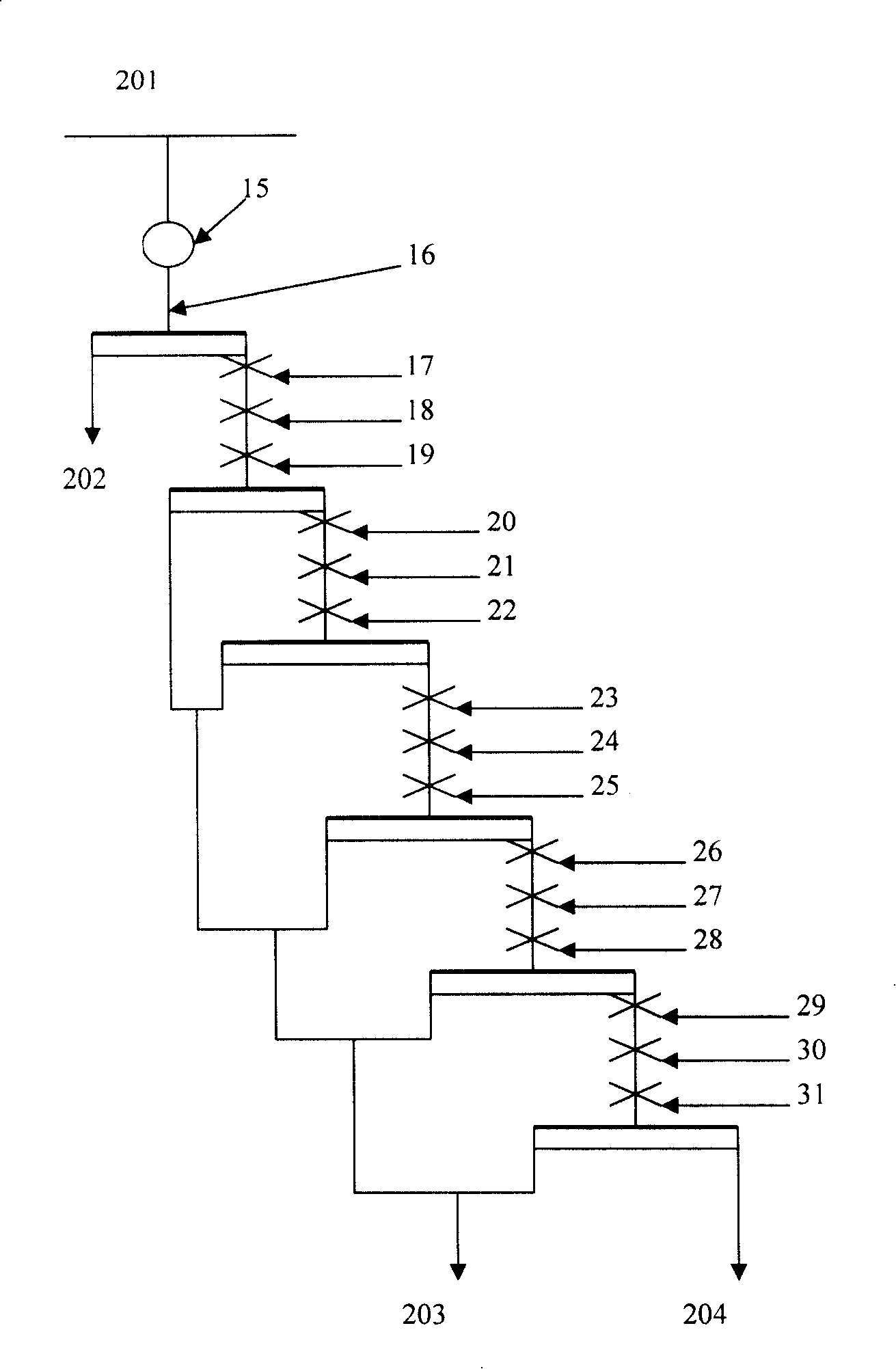

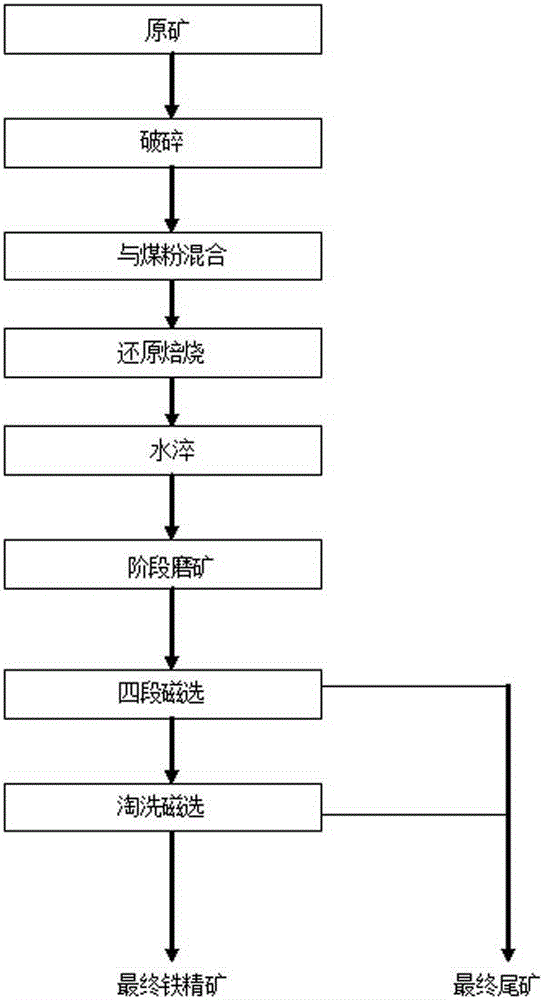

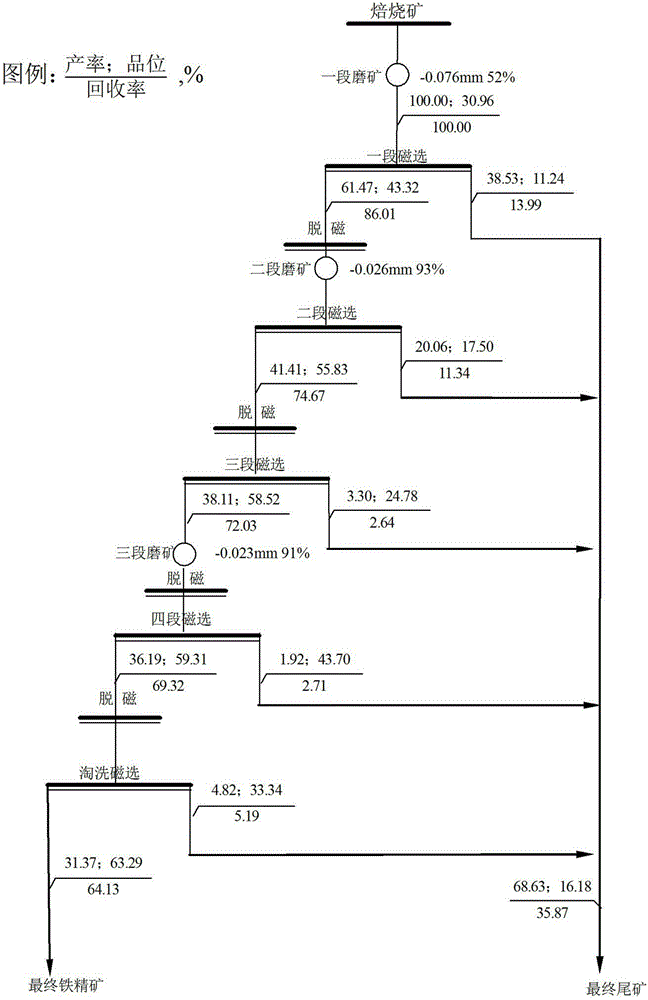

Beneficiation process for reducing roasting, iron increase and impurity reduction of amphibole type oxidized ore

ActiveCN105170285ARaise the gradeHigh recovery rateMagnetic separationGrain treatmentsIron increasedElutriation

The invention belongs to the technical field of beneficiation, and relates to a beneficiation process for reducing roasting, iron increase and impurity reduction of amphibole type oxidized ore. The beneficiation process comprises the following steps that 1, broken amphibole type oxidized ore and pulverized coal are mixed; 2, water quenching is carried out after reducing roasting; 3, primary grinding is carried out; 4, primary magnetic separation is carried out, and secondary grinding is carried out on obtained concentrates; 5, secondary magnetic separation is carried out, and third-stage grinding is carried out on obtained concentrates; and 6, third-stage magnetic separation is carried out, fourth-stage magnetic separation is carried out on obtained concentrates, fifth-stage elutriation magnetic separation is carried out on concentrates obtained again through an elutriation magnetic separator, and the iron grade of obtained final iron ore concentrates ranges from 63% to 64%. The final iron ore concentrates produced through the method are high in grade and recycling rate, the grade and the recycling rate of the final iron ore concentrates are greatly increased, economic benefits are remarkable, and the flowage structure is simple and feasible.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

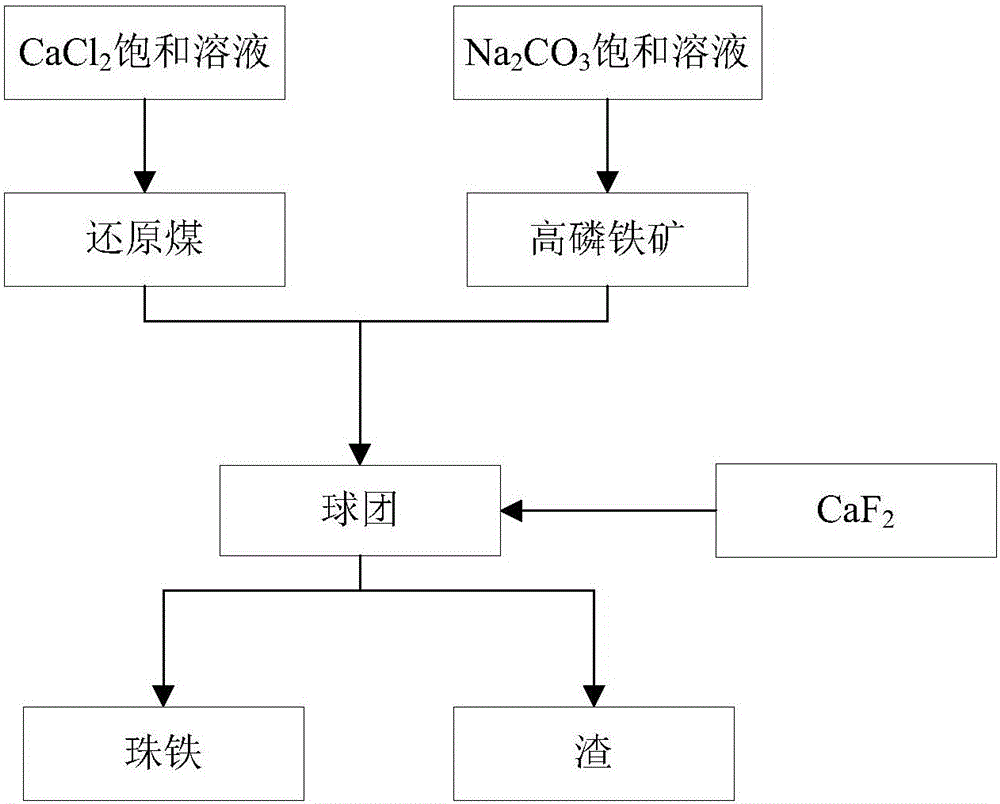

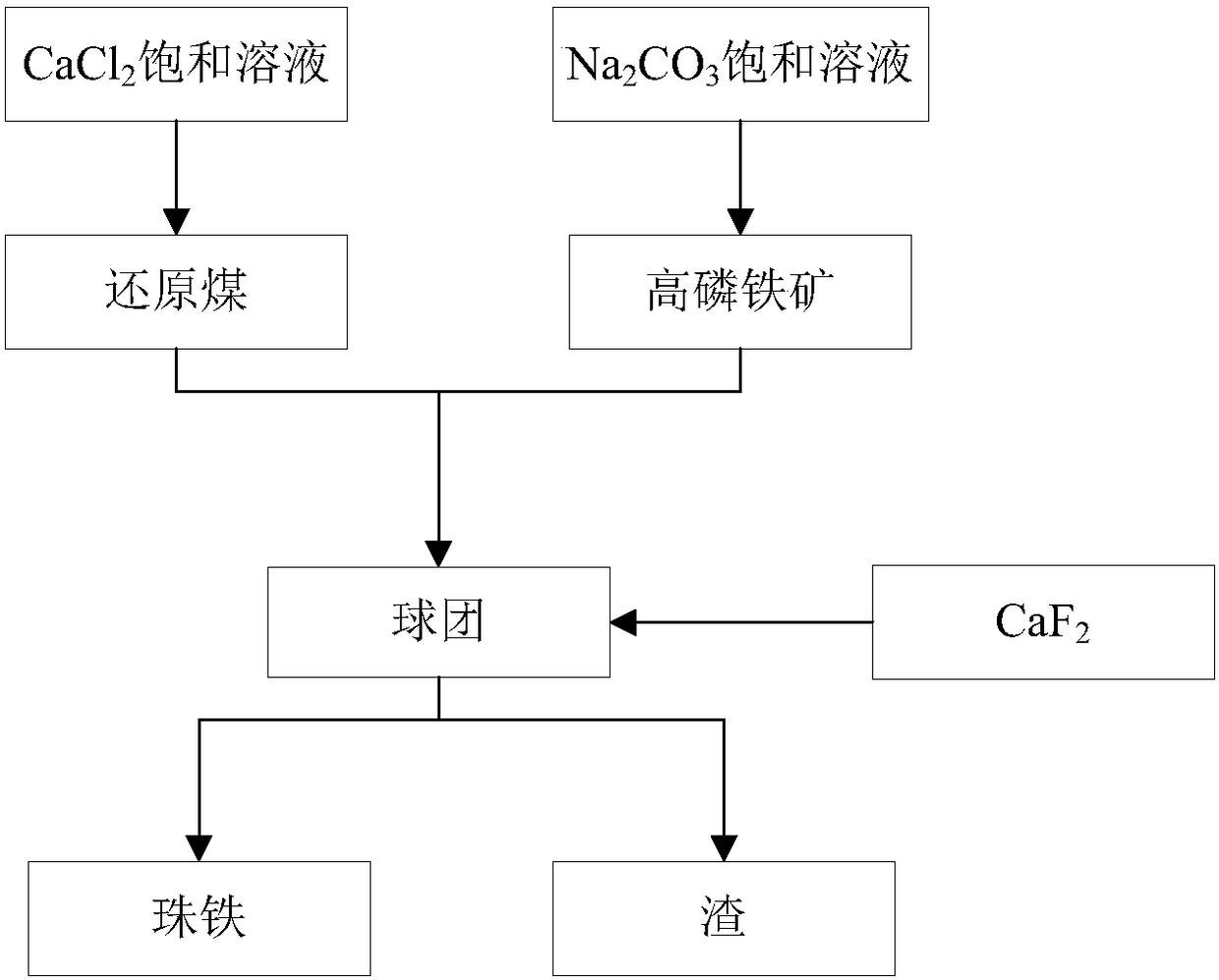

Dephosphorization iron-increasing method for high-phosphorus iron ore

The invention discloses a dephosphorization iron-increasing method for high-phosphorus iron ore. The method comprises the following steps that 1, reduction coal is treated to be modified reduction coal powder, wherein a CaCl2 saturate water solution is sprayed to the surface of the reduction coal, the reduction coal is dried and ground, and the modified reduction coal powder is obtained; 2, high-phosphorous iron ore is treated to be modified high-phosphorous iron ore powder, wherein a NaCO3 saturate water solution is sprayed to the surface of the high-phosphorous iron ore, the high-phosphorous iron ore is dried and ground, and modified high-phosphorous iron ore powder is obtained; 3, the modified reduction coal powder and the modified high-phosphorous iron ore powder are mixed to be uniform to be prepared into pellets and dried; 4, the dried pellets are cooled after being roasted to obtain iron beads. The dephosphorization iron-increasing method for the high-phosphorus iron ore has the advantages of being short in flow and good in dephosphorization effect, and is of great significance in effectively improving high-phosphorus iron ore and solving the problem of lack of ore resources.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

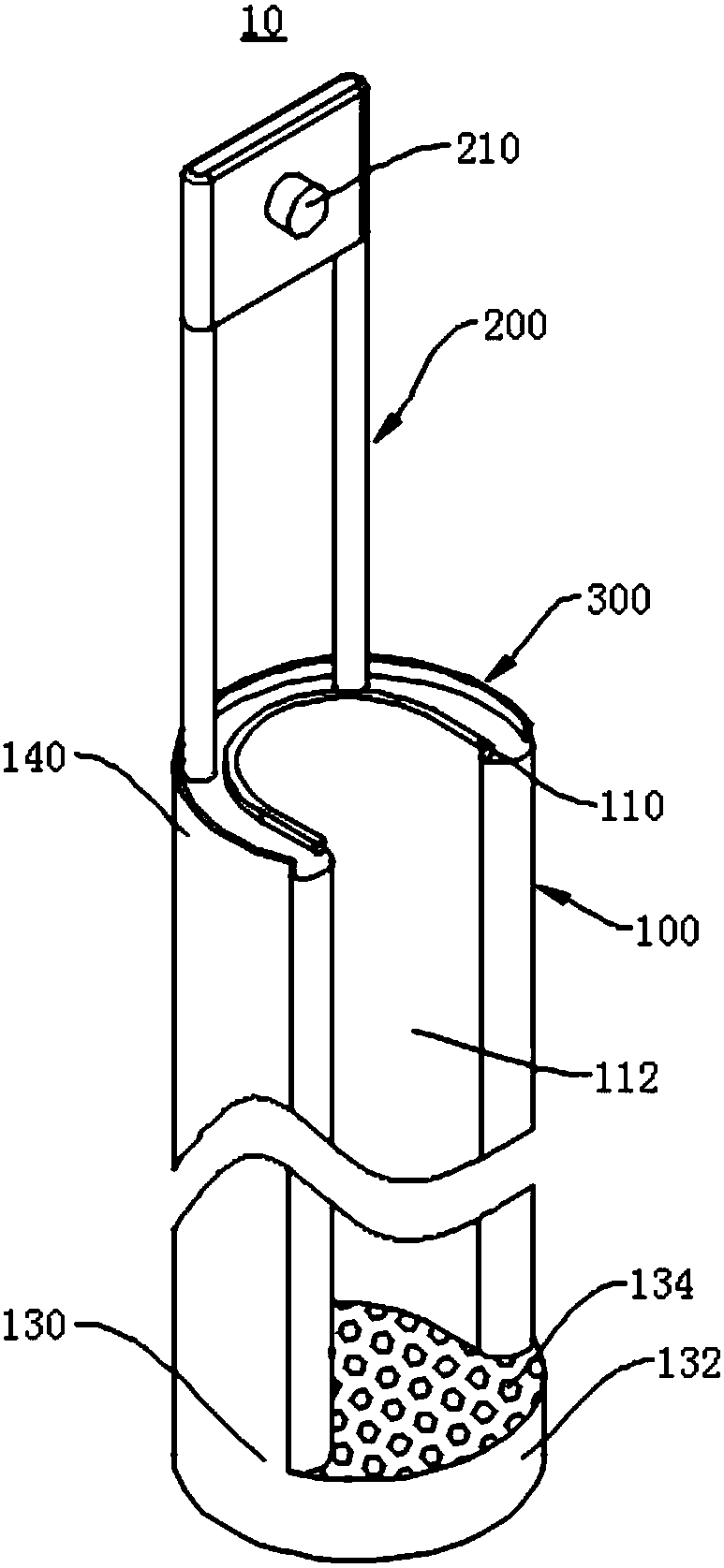

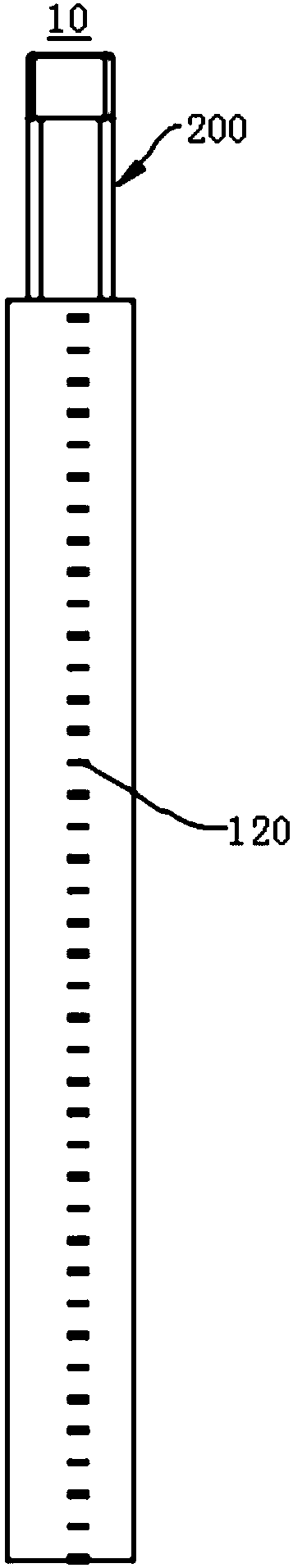

Engine oil dip stick and oil pan

PendingCN107816374AAvoid problems such as clogged filtersOilsumpsMachines/enginesIron increasedDipstick

The invention discloses an engine oil dip stick and an oil pan, and relates to the technical field of engines. According to the engine oil dip stick provided by the invention, when the engine oil dipstick is stretched into the oil pan to measure the oil quantity, iron scraps mixed in engine oil are adsorbed in an accommodating space of a magnetic part due to attractive force of the magnetic part,and the problems that the outer diameter of the outer wall of a stick body is increased and the stick body is hardly stretched into a dip stick hole of the oil pan due to the fact that the outer wallof the stick body magnetically adsorbs the iron scraps, the iron scraps adsorbed on the peripheral wall of the stick body are scraped and fall into engine oil again when the dip stick is stretched out of the dip stick hole of the oil pan, and a filter is blocked are solved. The oil pan provided by the invention comprises the engine oil dip stick and has the beneficial effects.

Owner:SHAANXI JUZHEN POWER TECH CO LTD

Dephosphorization and iron-increasing method of high phosphorus hematite by direct reduction

InactiveCN101984079BTo achieve the purpose of dephosphorization and ironSimple processProcess efficiency improvementIron increasedPotassium carbonate

The invention particularly relates to a dephosphorization and iron-increasing method of high phosphorus hematite by direct reduction, and the technical scheme comprises the following steps: mixing 60-83wt% of high phosphorus hematite powder, 10-15wt% of carbonaceous reducing agent, 6-15wt% of quicklime and 1-10wt% of additive uniformly, pressing the mixture into blocks, drying, reducing in a hightemperature furnace under 1250-1350 DEG C, and keeping the temperature for 15-30 minutes; carrying out furnace cooling until the temperature is 600-800 DEG C, taking the reduction product out, naturally cooling, grinding and performing the magnetic separation to obtain pig iron particles. The additive is sodium carbonate, or potassium carbonate, or the mixture of the sodium carbonate and the potassium carbonate; drying is carried out under the condition of 110-120 DEG C until the weight of the mixture of raw materials is constant; and the high temperature furnace is a resistance furnace, or arotary kiln, or a rotary hearth furnace, and the atmosphere in the high temperature furnace is neutral or weak-reductive. The invention has the advantages of short reduction time, simple process, high dephosphorization rate, high iron yield, less environmental pollution, recyclable residue and the like.

Owner:WUHAN UNIV OF SCI & TECH

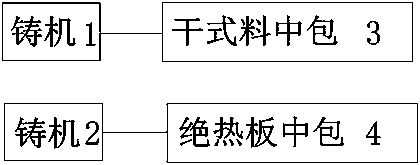

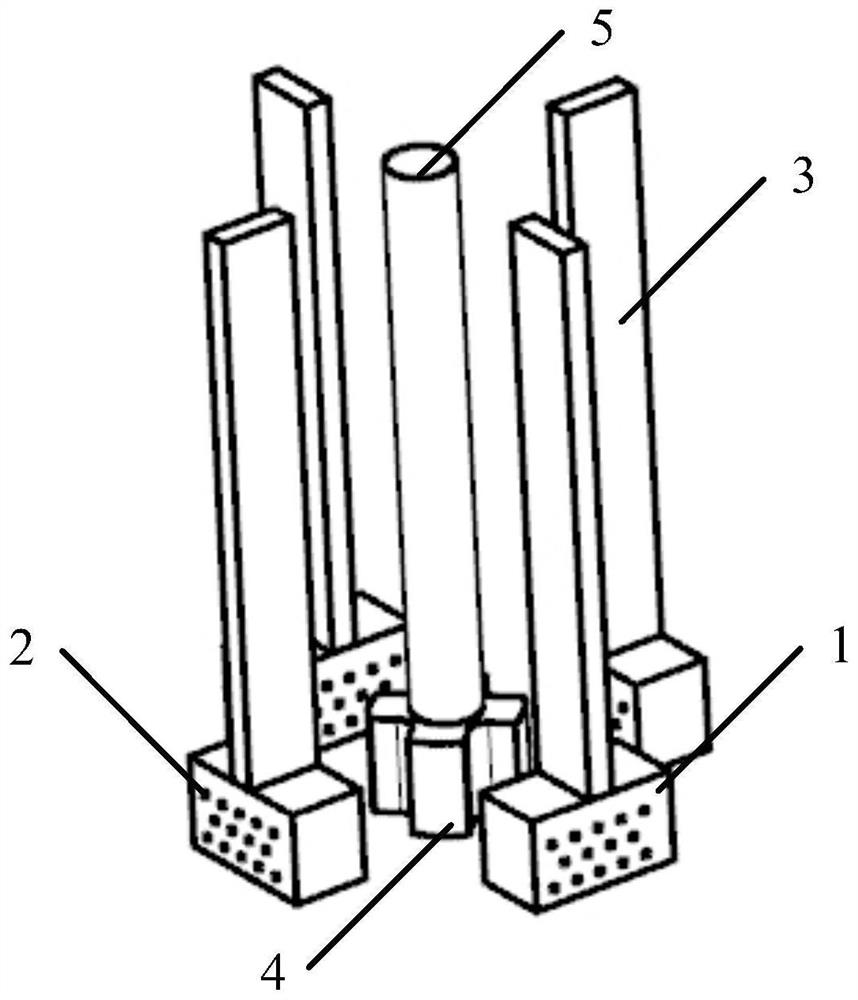

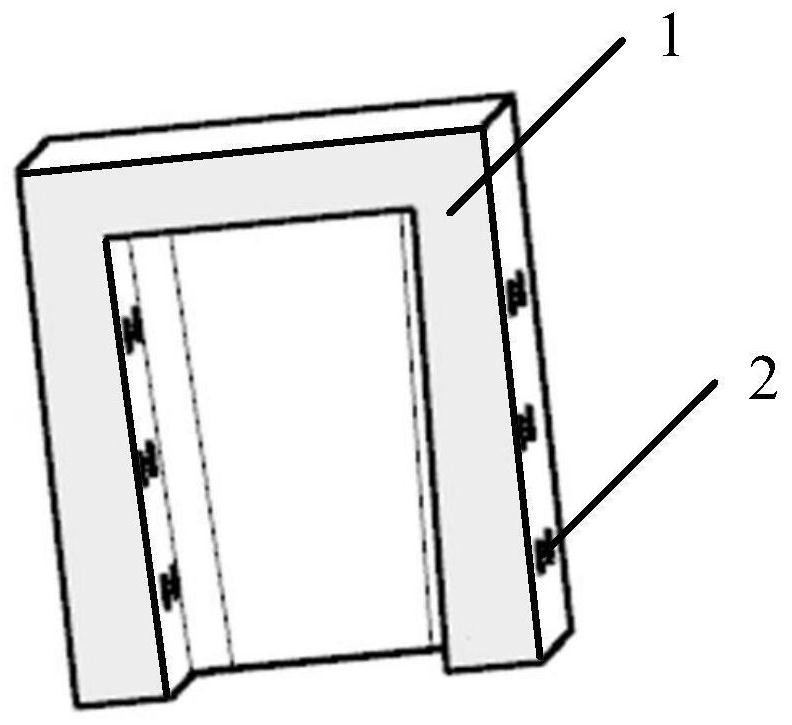

Continuous casting system for steel casting

The invention discloses a continuous casting system for iron and steel casting, which comprises a dry material tundish, a thermal insulation plate tundish and two casting machines, one of which pulls the dry material tundish, and the other casting machine is used in conjunction The heat-insulating tundish; the dry tundish is made of steel plate material, and on its inner surface there are reinforcing ribs arranged in the form of evenly distributed ribs; the dry tundish is provided with three Independent roasting system, each roasting system is equipped with an independent gas pipeline, and the three roasting systems adopt the overall purging pipeline system. Compared with the prior art, the continuous casting system for iron and steel casting provided by the present invention, on the one hand, reduces the number of bag changes, speeds up the production rhythm, improves the operation rate of the casting machine, increases the iron elimination capacity, and thus increases the maintenance time of the equipment; On the one hand, it can also reduce head and tail cutting, increase the yield of molten steel, reduce the consumption of steel materials, and create significant economic benefits.

Owner:QINGDAO RUNCHENG VEHICLE FITTINGS CO LTD

A refining agent adding device and adding method

Owner:BEIJING HANGXING MACHINERY MFG CO LTD

A method for dephosphorizing iron ore and raising iron

The invention discloses a dephosphorization iron-increasing method for high-phosphorus iron ore. The method comprises the following steps that 1, reduction coal is treated to be modified reduction coal powder, wherein a CaCl2 saturate water solution is sprayed to the surface of the reduction coal, the reduction coal is dried and ground, and the modified reduction coal powder is obtained; 2, high-phosphorous iron ore is treated to be modified high-phosphorous iron ore powder, wherein a NaCO3 saturate water solution is sprayed to the surface of the high-phosphorous iron ore, the high-phosphorous iron ore is dried and ground, and modified high-phosphorous iron ore powder is obtained; 3, the modified reduction coal powder and the modified high-phosphorous iron ore powder are mixed to be uniform to be prepared into pellets and dried; 4, the dried pellets are cooled after being roasted to obtain iron beads. The dephosphorization iron-increasing method for the high-phosphorus iron ore has the advantages of being short in flow and good in dephosphorization effect, and is of great significance in effectively improving high-phosphorus iron ore and solving the problem of lack of ore resources.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

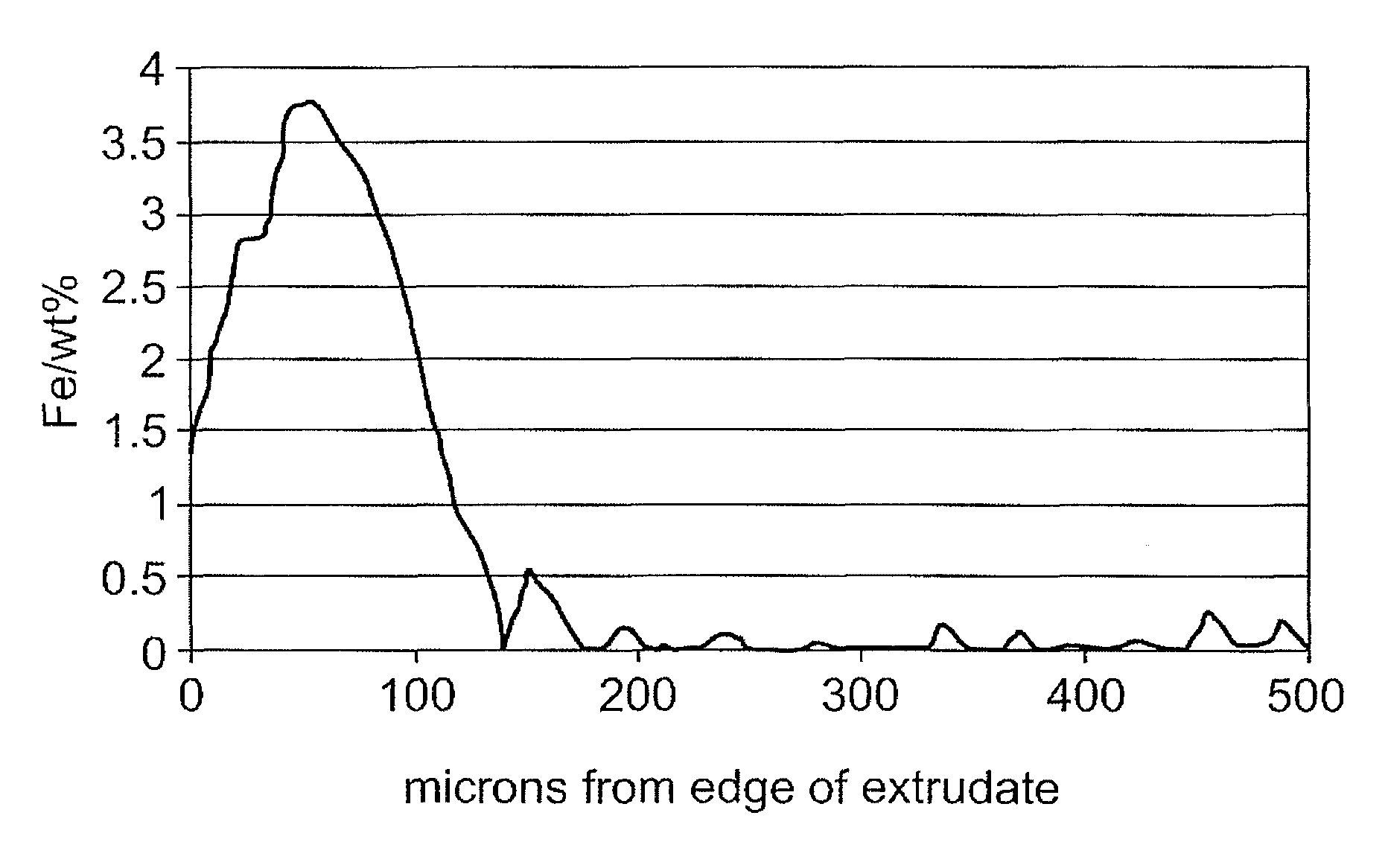

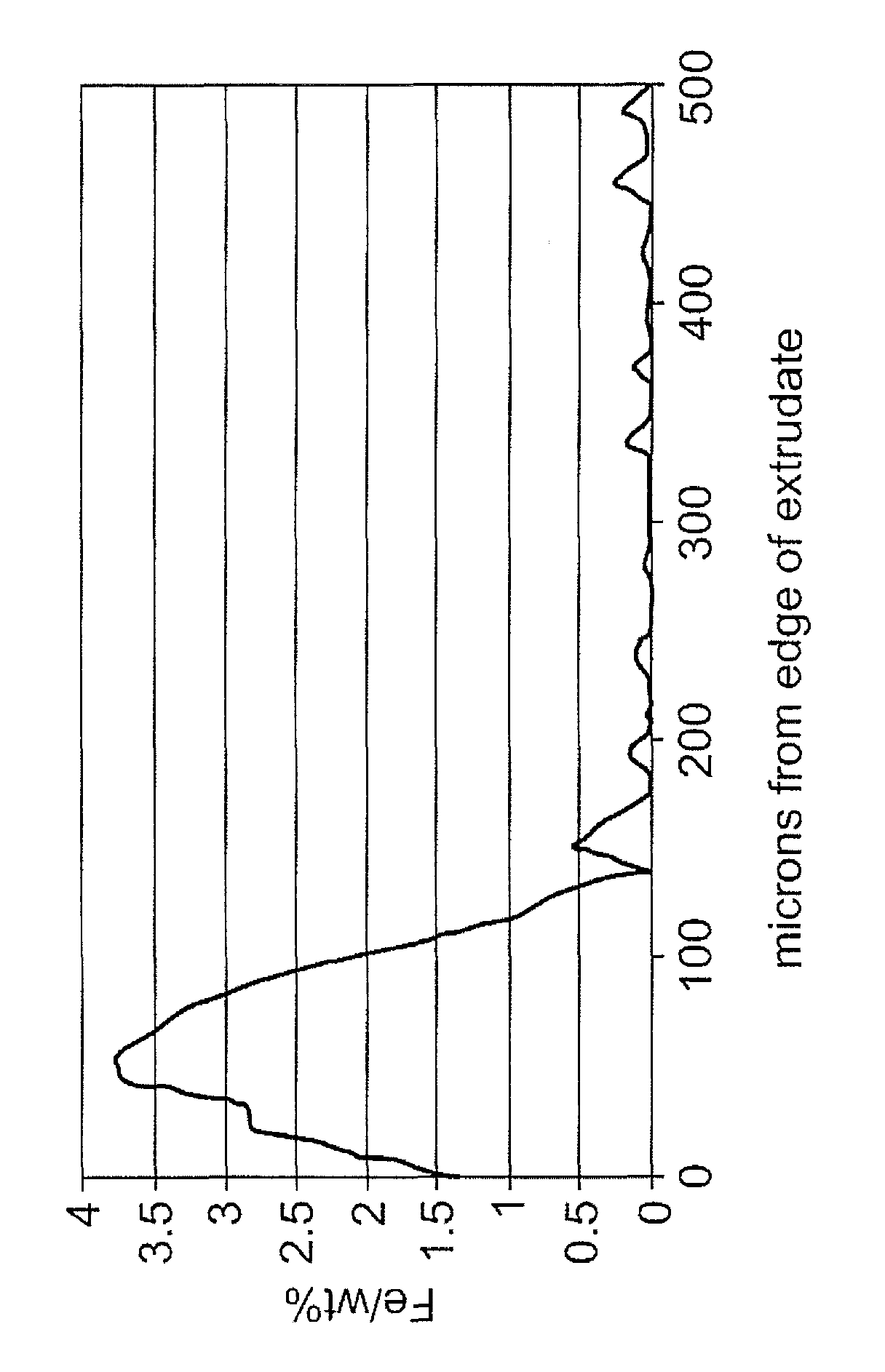

Fischer-Tropsch catalyst

InactiveUS8455556B2Organic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIron increasedMetal

A process for the preparation of a packed bed comprising an iron enriched cobalt catalyst for use in a Fischer-Tropsch reaction, the process comprising the steps of: (a) providing a packed bed with one or more catalyst particles comprising metallic cobalt; (b) contacting a part of the catalyst particle(s) in the packed bed with an iron containing compound. The process is preferably conducted in situ which conveniently results in an iron containing cobalt catalyst with a higher C5+ selectivity. In certain preferred embodiments the concentration of iron increases towards the surface of the resulting catalyst particles whereas the cobalt concentration is constant which further increases the selectivity of the catalyst to producing C5+ hydrocarbons.

Owner:SHELL OIL CO

Iron-increasing and silicon-reducing reselection technique for mixed-type lean iron ore tailings

ActiveCN102909124BAchieve recyclingAchieve quality improvement and silicon reductionSolid separationMechanical material recoveryHybrid typeIron increased

The invention discloses an iron-increasing and silicon-reducing reselection technique for mixed-type lean iron ore tailings, comprising the following steps of: strong magnetic roughing: putting mixed-type lean iron ore tailings through a strong magnetic separator with the magnetic field intensity of 5000-10000 Oersteds to obtain roughed concentrate and roughed tailings; strong magnetic cleaning: selecting the roughed concentrate in the strong magnetic separator with the magnetic field intensity of 10000-20000 Oersteds to obtain magnetic concentrate and magnetic tailings; centrifugal selecting: putting the magnetic concentrate in a centrifugal concentrating machine with the rotating speed of 150-250r / min to obtain centrifugal concentrate and centrifugal tailings; and table selecting: selecting the centrifugal tailings through a table with the stroke of 8-10mm and the frequency of stroke of 250-300 times / min to obtain table concentrate and table tailings. According to the iron-increasing and silicon-reducing reselection technique, a great quantity of tailings is dropped through rough and concentrate double magnetic selection; the magnetic concentrate is selected by using the centrifugal machine so that irons are increased and silicon is reduced; and then the centrifugal tailings are selected by using the table so that the productivity is increased. The iron-increasing and silicon-reducing reselection technique has the effects of realizing iron increment and silicon reduction of the mixed-type lean iron ore tailings, incrasing the productivity of the iron ore to a great extent at the same time and providing an effective approach to iron increment and silicon reduction of the reselected concentrate for the mixed-type lean iron ore tailings.

Owner:YUXI DAHONGSHAN MINING

Combined use method of iron ore anion reverse flotation desulfurizing and silicon reducing agent

The invention discloses a combined use method of an iron ore anion reverse flotation desulfurizing and silicon reducing agent, which comprises the following steps: obtaining iron ore rough concentrates through magnetic selection or magnetogravity combined selection of iron ores achieving base unit dissociation through fine grinding, and adopting anion reverse flotation for the desulfurization andsilicon reduction of the obtained rough concentrates, wherein the agent comprises the components in the following types and dosages (computed according to the flotation feeding dry basis): 80-100g / t of ethyl xanthate, 950-1150g / t of NaOH, 450-600g / t of starch, 320-420g / t of CaO and 600-750g / t of anion reverse flotation collector. The method can remove sulfur as a detrimental impurity in the iron ore concentrates while extracting iron and reducing silicon of the iron ores without considering the influence of numerous foams generated by an oil foamer on an iron separation process, lowers the medicament cost, simplifies the process flow, is easy to implement in production, can be widely used for the iron increase, desulfurization and silicon reduction of magnetite separation plants and hematite separation plants, and can also be used for the desulfurizing and silicon reducing flotation of limonite, martite and semi-martite.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Method for reducing phosphorus by chloridization separation-weak of high phosphor iron ore

InactiveCN101457288BReduce phosphorus contentGood beneficiation indexMagnetic separationWet separationIronstoneIron increased

Owner:昆明晶石矿冶有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com