Method for controlling ferrous oxide content in sintering ore

A technology of ferrous oxide and sintered ore, which is applied in the field of ironmaking sintered ore preparation, can solve the problems of complex operation, many steps, and unfavorable stable production of blast furnace smelting, and achieve the goals of reducing consumption, saving sintering costs, and reducing solid fuel consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

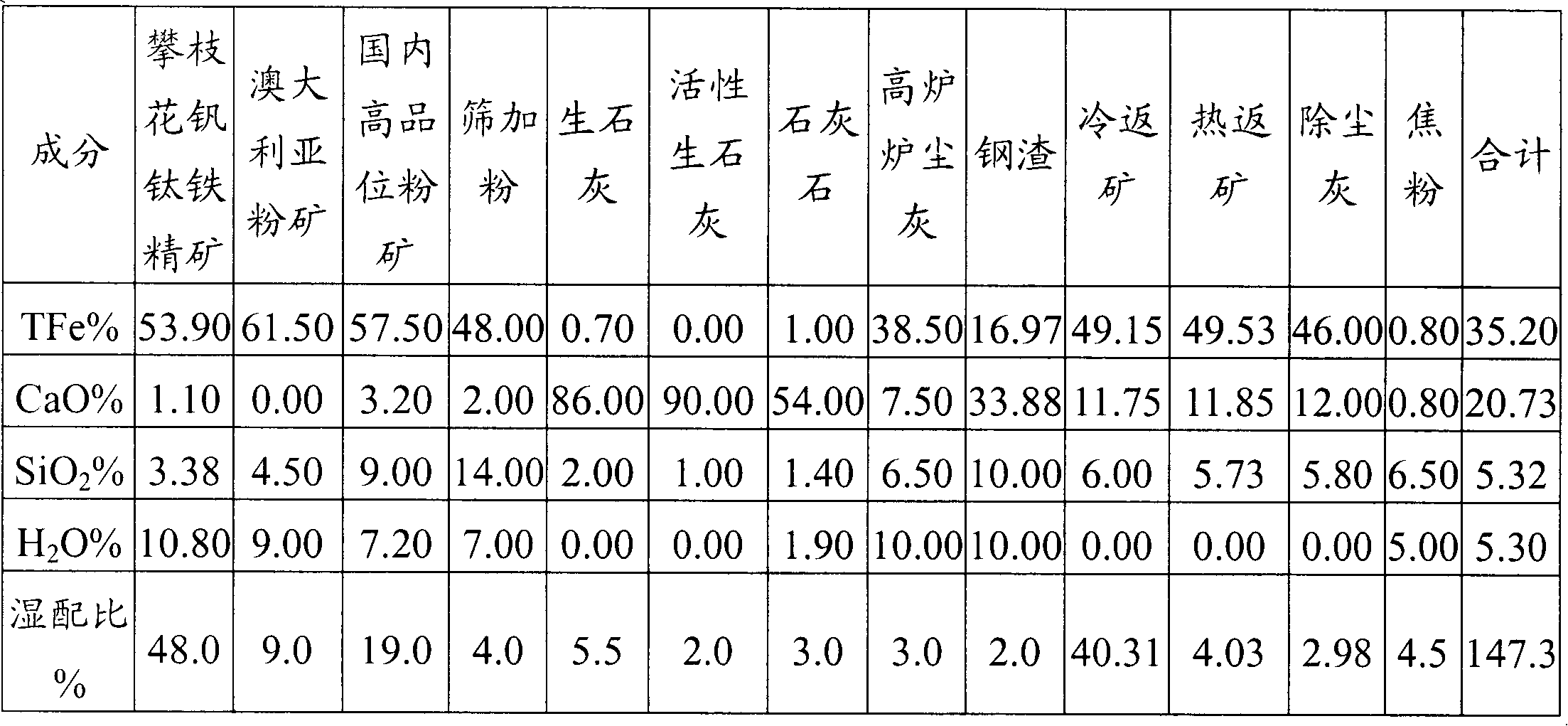

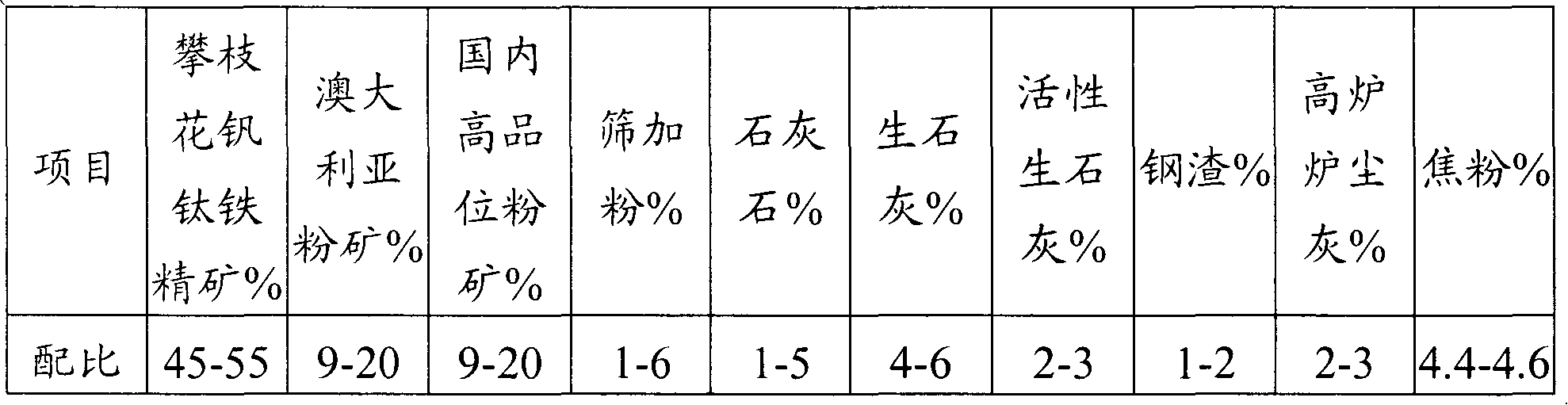

Method used

Image

Examples

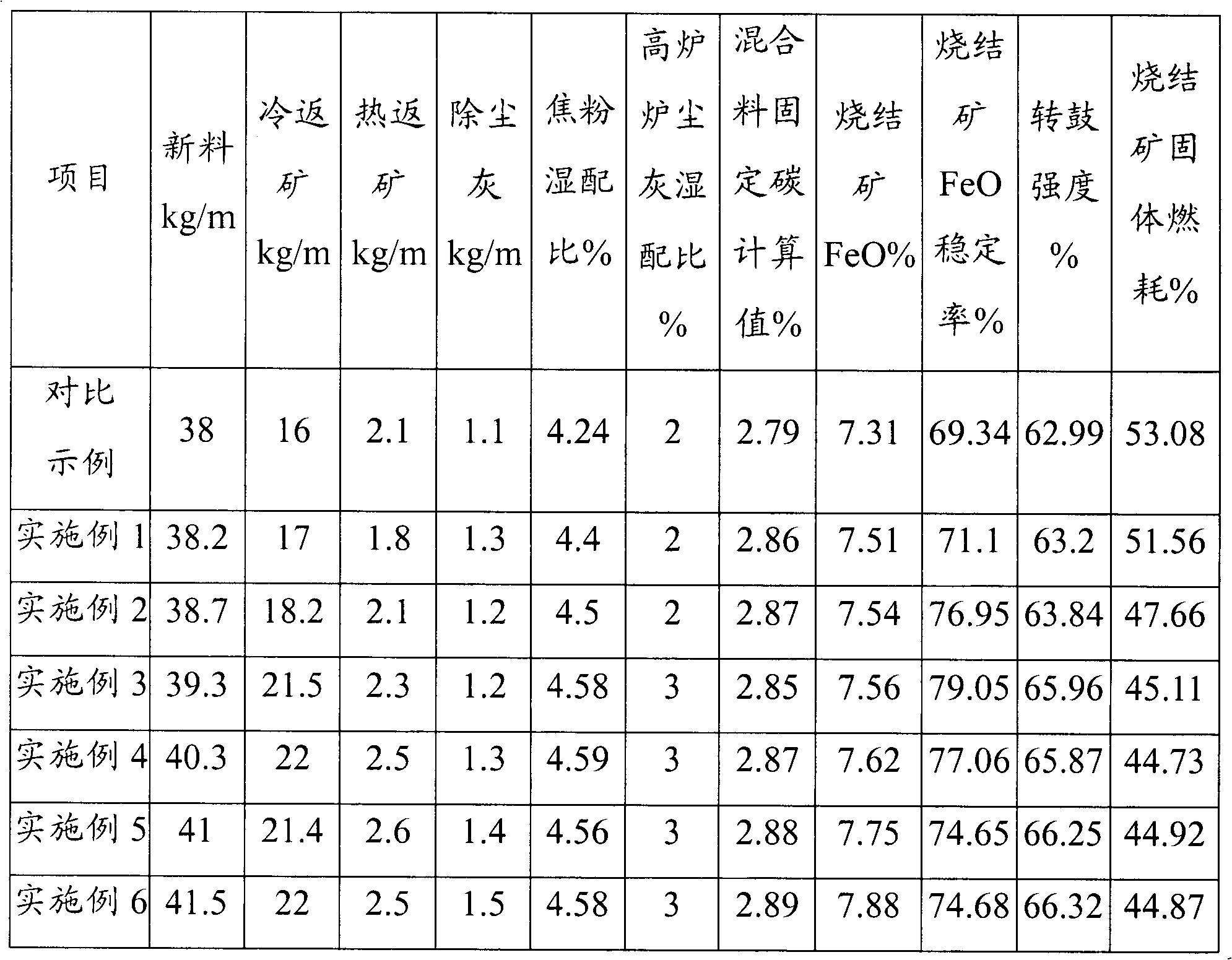

Embodiment 1

[0045] The material structure and operation of the sintering machine are as follows: new material 38.2kg / m, cold return ore 17kg / m, hot return ore control at 1.8kg / m, dust removal ash 1.3kg / m, blast furnace dust ash wet ratio 2%, coke The powder-to-wet ratio is 4.4%, the calculated value of fixed carbon in the mixture is 2.86%, the speed of the sintering machine is 1.6m / min, the thickness of the material layer is 668mm, and the sintering end point is 310°C.

[0046] The results show that sinter FeO: 7.51%; compared with the comparative example, the stability rate of sinter FeO increases by 1.76%, the drum strength increases by 2.01%, and the solid fuel consumption of sinter decreases by 1.54kg.

Embodiment 2

[0048] The material structure and operation of the sintering machine are as follows: new material 38.7kg / m, cold return ore 18.2kg / m, hot return ore controlled at 2.1kg / m, dust removal ash 1.2kg / m, blast furnace dust ash wet ratio 2%, The wet ratio of coke powder is 4.5%, the calculated value of fixed carbon in the mixture is 2.87%, the speed of the sintering machine is 1.52m / min, the thickness of the material layer is 695mm, and the sintering end point is 316°C.

[0049] The results show that sinter FeO: 7.54%. Compared with the comparative example, the stability rate of sinter FeO increases by 7.61%, the drum strength increases by 2.85%, and the solid fuel consumption of sinter decreases by 5.42kg.

Embodiment 3

[0051] The material structure and operation of the sintering machine are as follows: new material 39.3kg / m, cold return ore 21.5kg / m, hot return ore controlled at 2.3kg / m, dust removal ash 1.2kg / m, blast furnace dust ash wet ratio 3%, The wet ratio of coke powder is 4.58%, the calculated value of fixed carbon in the mixture is 2.85%, the speed of the sintering machine is 1.61m / min, the thickness of the material layer is 693mm, and the sintering end point is 321°C.

[0052] The results show that sinter FeO: 7.56%; compared with the comparative example, the stability rate of sinter FeO increases by 9.71%, the drum strength increases by 2.97%, and the solid fuel consumption of sinter decreases by 7.97kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com