Patents

Literature

125results about How to "Reduce sintering cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-loss MnZn ferrite material sintering method

The invention discloses a low-loss MnZn ferrite material sintering method. The method includes four temperature change stages which mainly induce: a, the first temperature rising stage, b, the second temperature rising stage, c, the temperature maintaining stage and d, the temperature falling stage. According to the method, due to the fact that temperature and oxygen partial pressure are controlled in the whole sintering process of temperature rising, temperature maintaining and temperature falling, loss of MnZn power ferrite can be reduced. The method has the advantages of being low in sintering temperature and low in loss when applied to preparing the MnZn ferrite, and the efficiency of MnZn ferrite elements is greatly improved.

Owner:苏州天源磁业股份有限公司

Inert electrode material in nanocrystalline powder form

InactiveUS20040045402A1Improved thermal shockImproved corrosion resistance propertyTransportation and packagingMetal-working apparatusAlloyNanocrystal

The invention relates to an inert electrode material in powder form comprising particles having an average particle size of 0.11 to 100 mum and each formed of an agglomerate of grains of a ceramic material and grains of a metal or alloy with each grain of ceramic material comprising a nanocrystal of the ceramic material and each grain of metal or alloy comprising a nanocrystal of the metal or alloy. Alternatively, each particle can be formed of an agglomerate of grains with each grain comprising a nanocrystal of a single phase ceramic material, a metal or an alloy. The electrode material in powder form according to the invention is useful for the manufacture of inert electrodes having improved thermal shock and corrosion resistance properties.

Owner:GROUPE MINUTIA

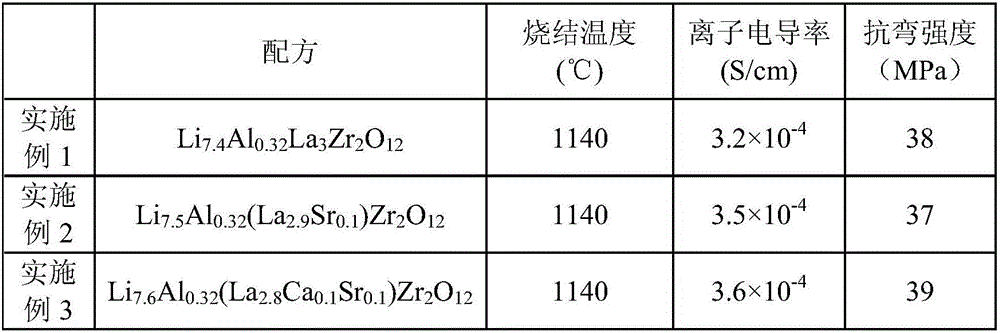

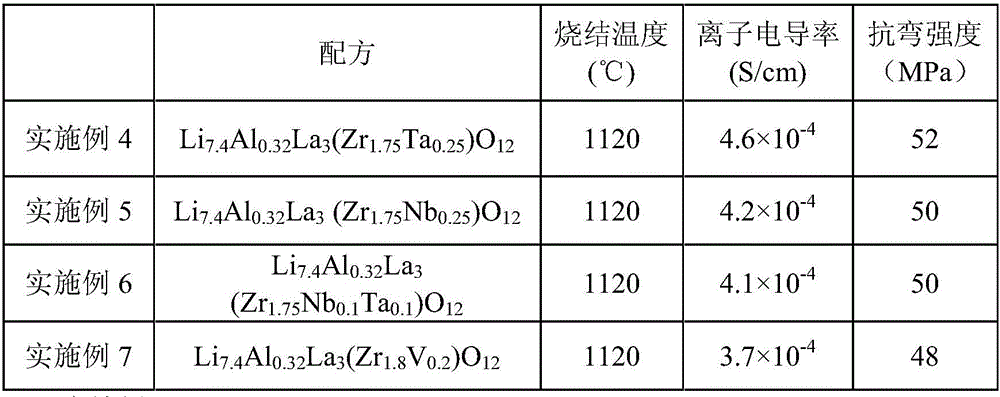

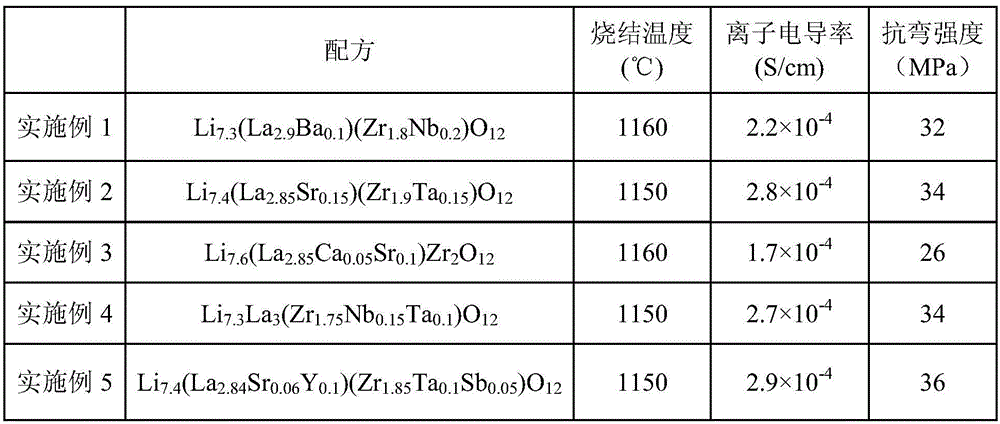

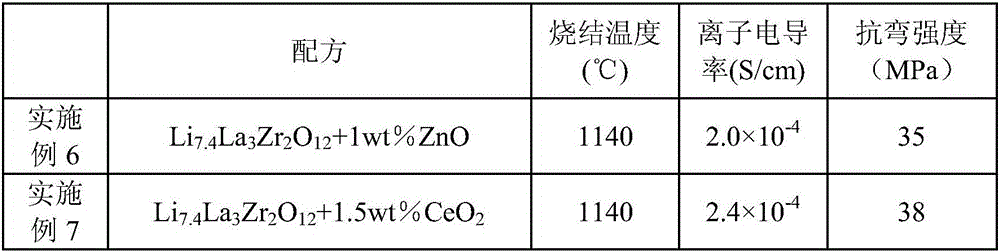

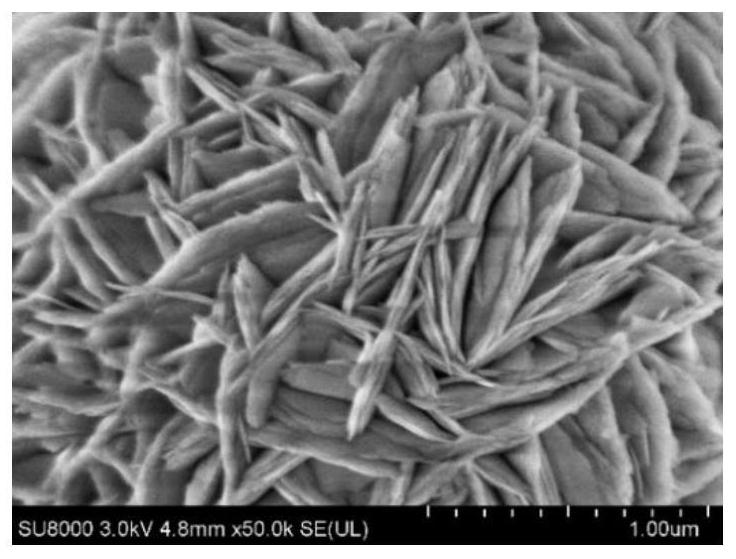

Solid electrolyte material and preparation method thereof

ActiveCN106129463AImprove machinabilityReduce volatilitySolid electrolytesSecondary cellsLithiumChemical composition

The invention relates to a solid electrolyte material and a preparation method thereof. The chemical composition is Li<6+x>Al<y>(La<z>A<3-z>)(Zr<n>G<2-n>)O<12+alpha>wt% D, wherein A is selected from at least one of Ca, Sr, Y and Ba; G is selected from at least one of Ti, Nb, Ta, Sb and V; D is selected from at least one of SiO2, Bi2O3, B2O3, CeO2, ZnO, CuO, MnO2, Co2O3 and SnO2; x is smaller than or equal to 2 and greater than or equal to 0; y is smaller than or equal to 1 and greater than or equal to 0; z is smaller than or equal to 3 and greater than or equal to 2; n is smaller than or equal to 2 and greater than or equal to 1; and alpha is smaller than or equal to 3 and greater than or equal to 0. The safety problems that a lithium-ion liquid battery leaks liquid and is flammable, explosive and the like are solved; battery miniaturization and product shape diversification are facilitated; the process route is simple; massive production is easily to implement; a sample is low in sintering temperature and short in heat preservation time; volatilization of lithium ions is reduced; and the sintering cost is greatly reduced.

Owner:淄博佳润纺织有限公司

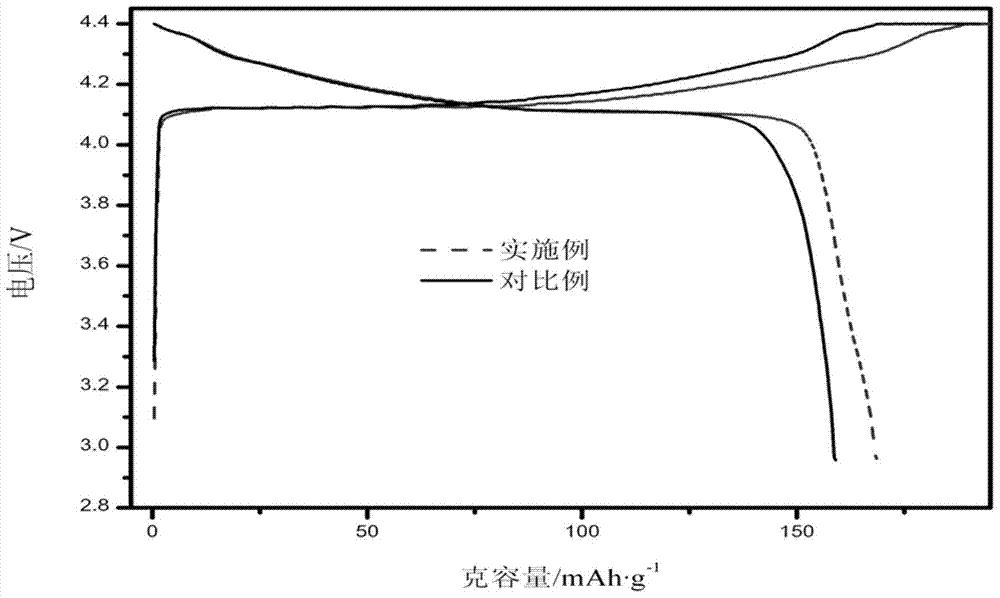

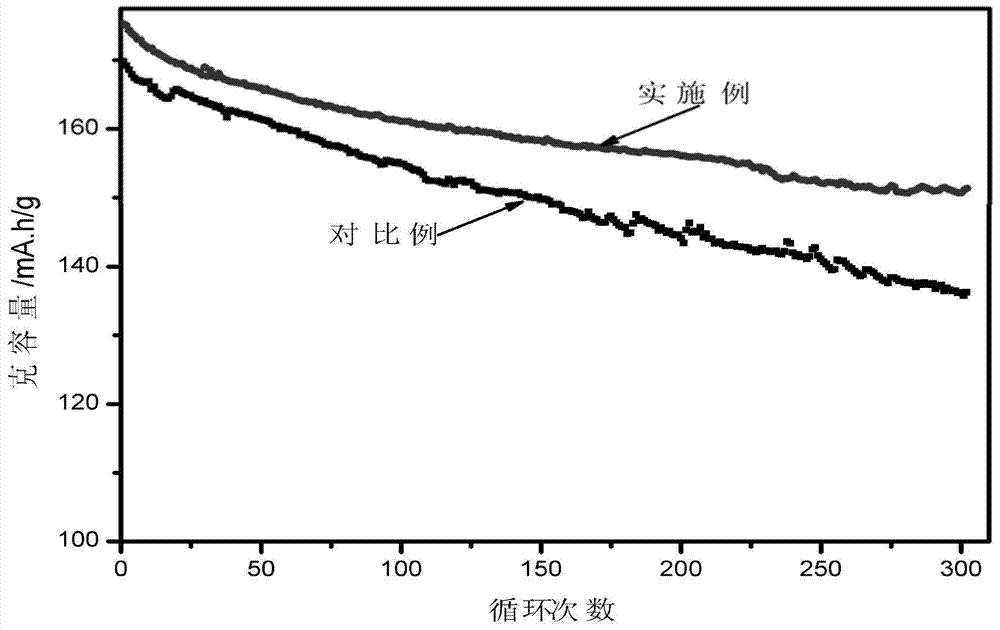

High-voltage high-compaction composite positive electrode material of lithium ion battery and preparation method

ActiveCN103794776AImprove cycle performanceIncrease capacityCell electrodesLithium-ion batteryHigh voltage

The invention relates to a high-voltage high-compaction composite positive electrode material of a lithium ion battery. The composite positive electrode material comprises LiCo<1-x>NxMyO<2-y>, wherein the x is more than or equal to 0.002 and is less than or equal to 0.1, the y is more than or equal to 0 and is less than or equal to 0.05, the M is at least one of F<-1>,S<2->, Cl<-> and PO4<3->,and the N is at least one of Ti<4+>, Zr<4+>, Mn<3+>, Sn<4+>, Ce<4+>, Ir<4+>, Mg<2+>, Al<3+>, V<5+>, Nb<3+> and La<3+>; the composite positive electrode material also comprises LiNimConMn<1-m-n>O2 and a coating compound coating the surfaces of the LiCo<1-x>NxMyO<2-y> and the LiNimConMn<1-m-n>O2, wherein the m is more than or equal to 0.2 and is less than or equal to 0.8, the n is more than or equal to 0.1 and less than or equal to 0.4, the 1-m-n is more than or equal to 0 and is less than or equal to 0.7, the coating compound is at least one of an oxide compound of Mc and Li2MdO3, and the Mc and the Md are independent from each other and are respectively selected from one of Al, Ti, Mn, Zr and Sn. The high-voltage high-compaction composite positive electrode material provided by the invention has the advantages that the security is high, the cost is low, the compacted density is greater than or equal to 4.10g / cm<3>, the charging cut-off voltage of the lithium ion battery prepared from the material is greater than or equal to 4.3V, the first reversible capacity at the cut-off voltage of 4.4V is greater than or equal to 180mA.h / g, and the composite positive electrode material is applied to a high voltage condition and has excellent electrochemical properties.

Owner:湖南美特新材料科技有限公司

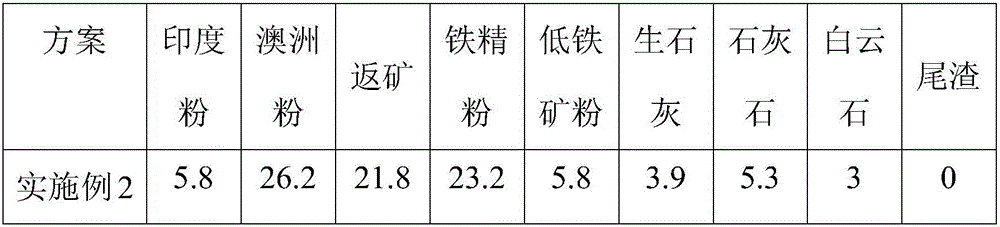

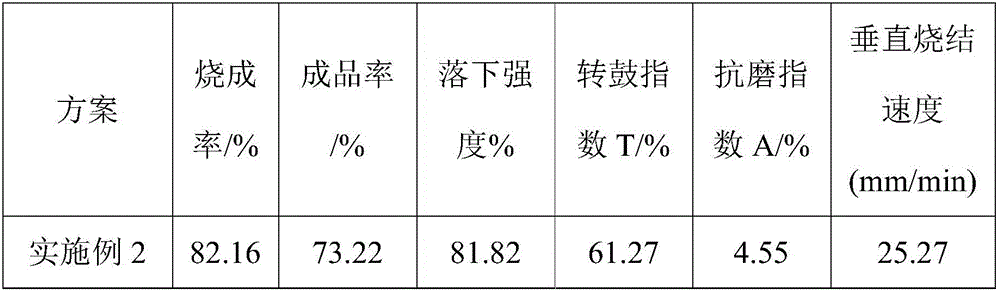

Process for producing sintered ore for ironmaking through blast furnace from high-aluminum limonite

The invention discloses a process for producing sintered ore for ironmaking through a blast furnace from high-aluminum limonite. The high-aluminum limonite accounts for 60%-70% of the weight of iron-containing raw material, and fine particle magnetite concentrate accounting for 25%-35% of the weight of the iron-containing raw material is mixed into the iron-containing raw material. The process comprises the following steps of: performing blending, mixing and pelletizing treatment on the iron-containing raw material, a solvent and coke powder; performing sintering, material distribution, ignition, sintering, cooling and particle adjustment on a pelletized mixture to get a finished product of the sintered ore, determining the alkalinity of a sintered mixture according to the requirement of smelting of the blast furnace on the alkalinity, wherein the ordinary range of the alkalinity is 1.7-2.1; and mixing limestone, dolomite and quicklime into the mixture for regulating the alkalinity, wherein the mixing weight of the quicklime is 1-4%. The adding of the fine particle magnetite concentrate can effectively improve the pelletizing effect of the high-aluminum limonite, significantly improve the sintering air permeability, greatly reduce the using quantity of the coke powder, improve the metallogenic conditions during the sintering process of the high-aluminum limonite, effectively improve the quality indexes of the sintered ore and realize the application of the high-aluminum limonite in sintering production.

Owner:CENT SOUTH UNIV

Preparation method of special-shaped boron carbide ceramic sandblast nozzle

The invention discloses a preparation method of a special-shaped boron carbide ceramic sandblast nozzle. The preparation method comprises the following steps: (1) proportioning all the raw materials in percentage by weight as follows: 50-70wt% of boron carbide powder, 20-40wt% of a sintering aid, 1-8wt% of a carbon source, 0.5-6wt% of an adhesive and 0.6-6wt% of a dispersing agent; (2) carrying out a spray drying granulation process on the obtained slurry into granules; (3) putting the granules into a manufactured soft mould sleeve and moulding by using a dry bag type granules method, thus obtaining a sandblast nozzle biscuit; (4) putting the sandblast nozzle biscuit into a debonding furnace, vacuumizing, heating for removing water and organics, then processing in a vacuum sintering furnace to obtain a finished boron carbide ceramic sandblast nozzle product. The method is suitable for volume production and the prepared boron carbide sandblast nozzle has the advantages of high hardness, good toughness, good wear resistance, long service life, low cost, and high performance cost ratio. The method can be used for preparing sandblast nozzle products with complicated hole structures.

Owner:NINGBO VULCAN TECH CO LTD

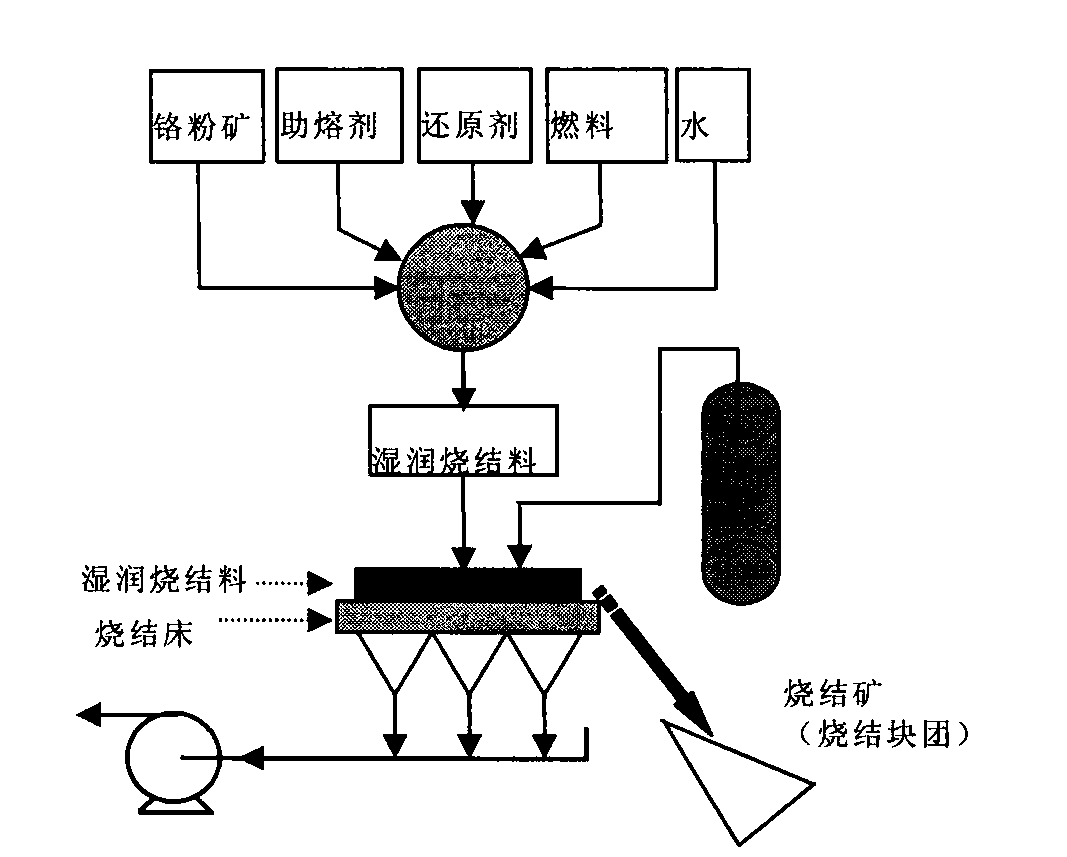

Pretreatment method for chromium powder ore used for smelting production of ferrochrome alloy

The invention provides a pretreatment method for a chromium powder ore used for smelting production of a ferrochrome alloy. The method comprises the steps of 1) mixing the chromium powder ore with a fluxing agent, a reducing agent and a fuel to obtain a mixture; and 2) sintering the mixture to obtain a sintered material. The method is short in process flow and low in sintering cost and is simple and practicable, and production of powder ore pollutions is not easy, so that relatively cheap powder chromium ore can be fully used, smelting consumption can be decreased greatly, and further smelting cost of the ferrochrome is reduced. The sintered material obtained by the sintering treatment method can be directly introduced into an ore smelting electric arc furnace for smelting after smashing. The method can enhance reducibility of furnace charging materials, reduce energy consumption and decrease usage proportion of other auxiliary materials such as coke, silica and the like in the smelting furnace charging materials. At the same time, possibility of reversing materials is greatly decreased, production security is increased and probability of production accidents is reduced greatly.

Owner:中国中化股份有限公司 +1

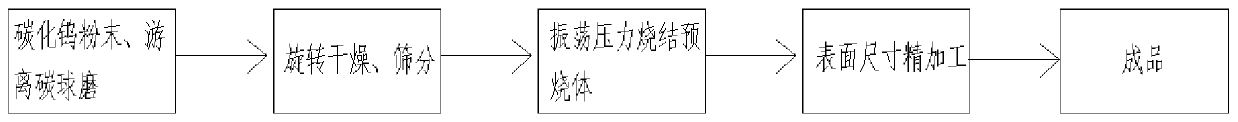

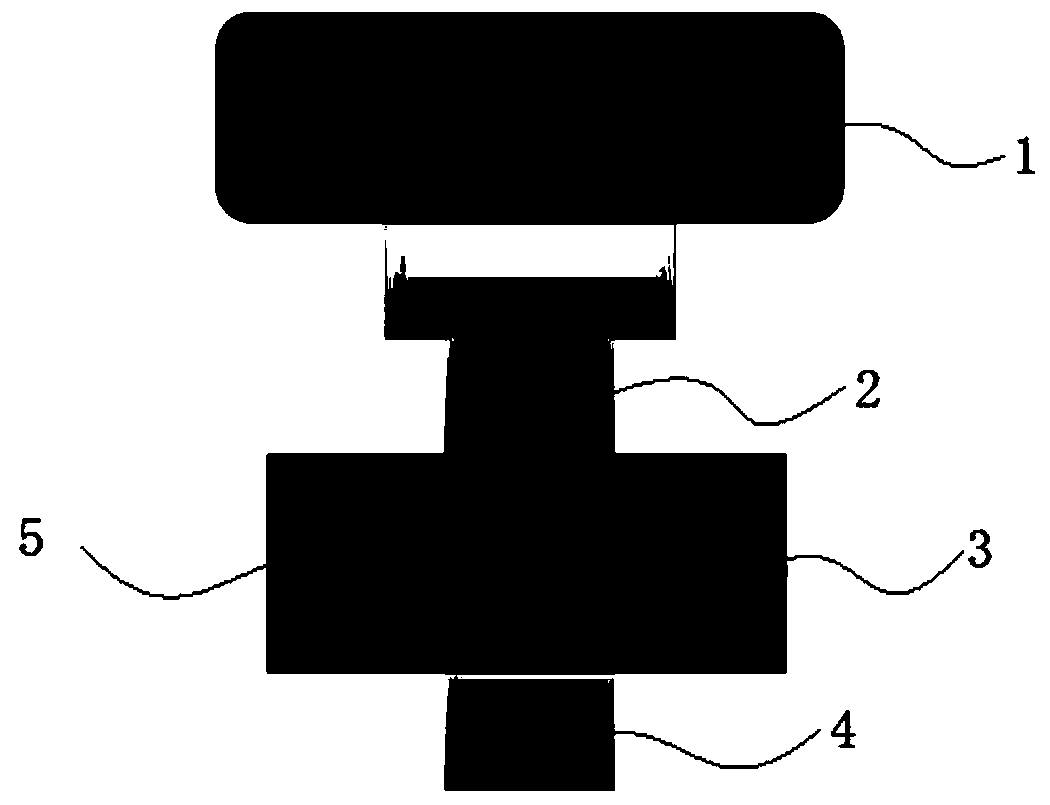

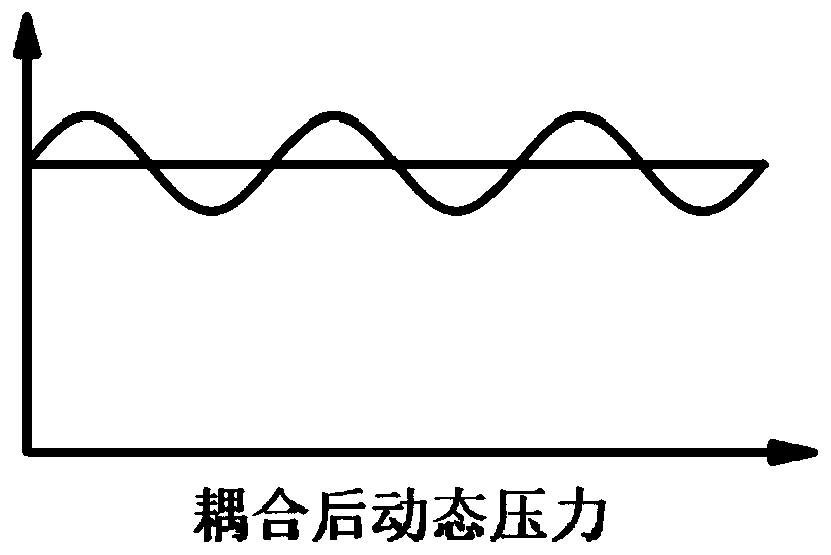

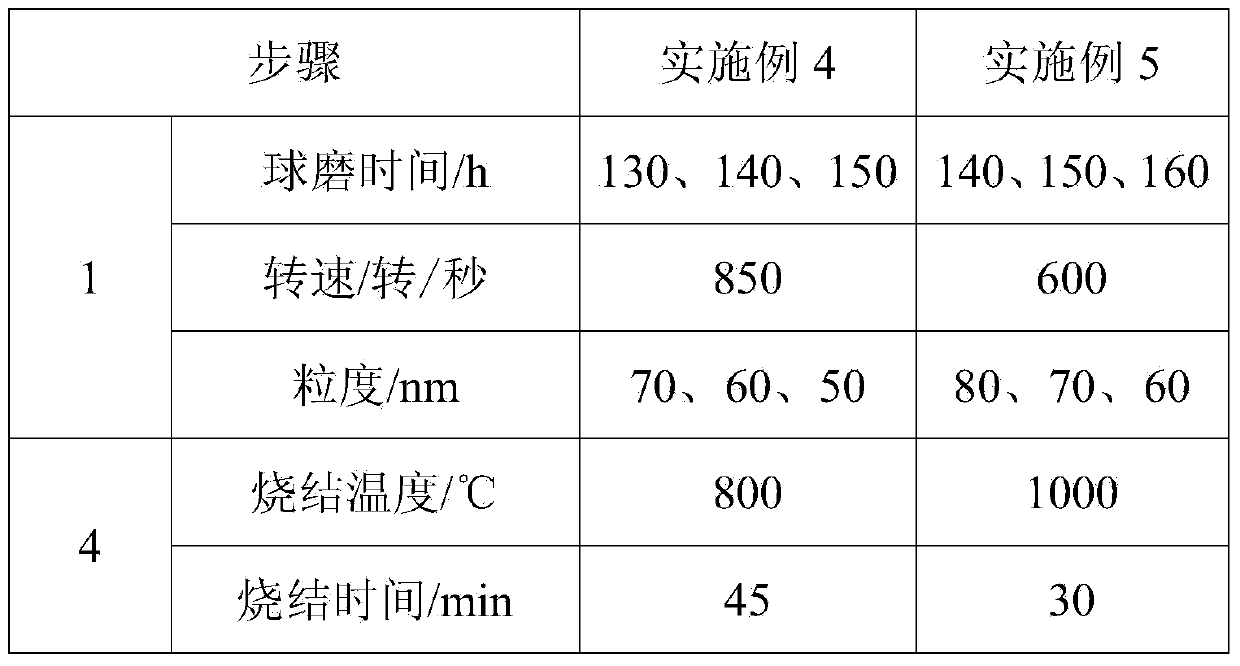

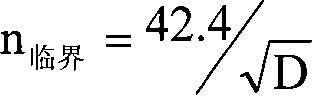

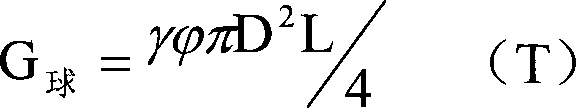

Large-size high-density non-binding-phase tungsten carbide target material and preparing method thereof

ActiveCN110171975AGuaranteed purityQuality improvementVacuum evaporation coatingSputtering coatingHigh pressureMaterials science

The invention provides a preparing method of a large-size high-density non-binding-phase tungsten carbide target material. The method includes the following steps of S1, preparing materials; S2, conducting ball-milling and screening treatment; S3, conducting sintering treatment; S4, conducting after-treatment. The raw materials include tungsten carbide powder and free carbon. The dynamic vibrationpressure is exerted in the sintering treatment process. By introducing the free carbon into the pure tungsten carbide powder, traditional medical binding phases are abandoned, the purity of the target material is ensured, and the quality of a magnetron sputtering coating can be easily improved. The dynamic vibration pressure is introduced in the sintering process, particle rearrangement is promoted in the early sintering stage of the tungsten carbide powder, the removal of residual pores is promoted in the later sintering stage, and the grain is refined when the sintering density is improved;by means of the high-pressure vibration assisted sintering, the sintering temperature is lowered by 50-200 DEG C on the basis of a traditional hot pressing process, the tungsten carbide target material with high density and fine grain is prepared, and the film coating quality is improved.

Owner:株洲万融新材科技有限公司 +1

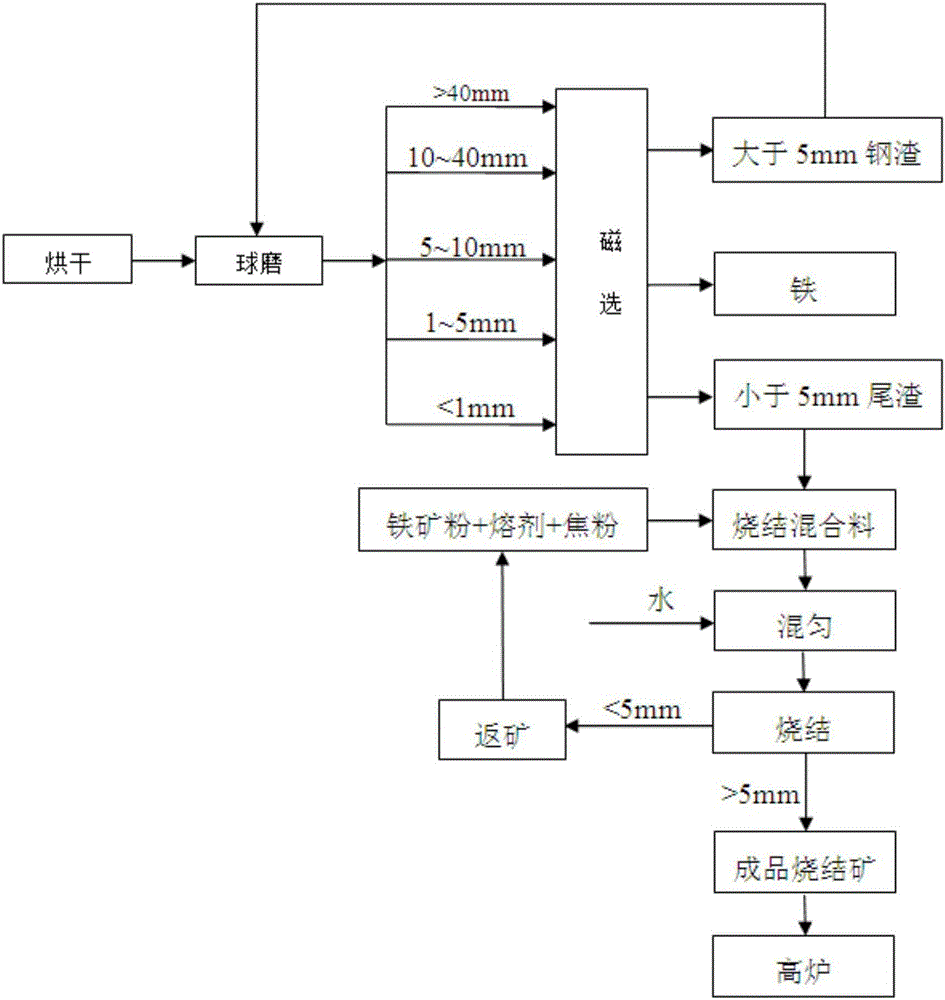

Method for recovering iron in steel slag and using tailing thereof

The invention discloses a method for recovering iron in steel slag and using tailing thereof. The method is characterized by comprising the flows of: 1) drying of the steel slag; 2) ball milling of the steel slag; 3) classification and magnetic separation; 4) returning of crude slag to ball milling; and 5) magnetic separation of the tailing as a sintering flux. The method, provided by the invention, uses the methods of ball milling, classification and magnetic separation for recovering the iron in the steel slag, and uses the magnetically separated tailing as the sintering flux for further recovering non-selected iron and other useful metal elements in the magnetically separated tailing, so that 100% recovery of the iron in the steel slag is realized, the sintering cost is reduced, and the comprehensive recycling of the steel slag resource is realized.

Owner:CHONGQING UNIV

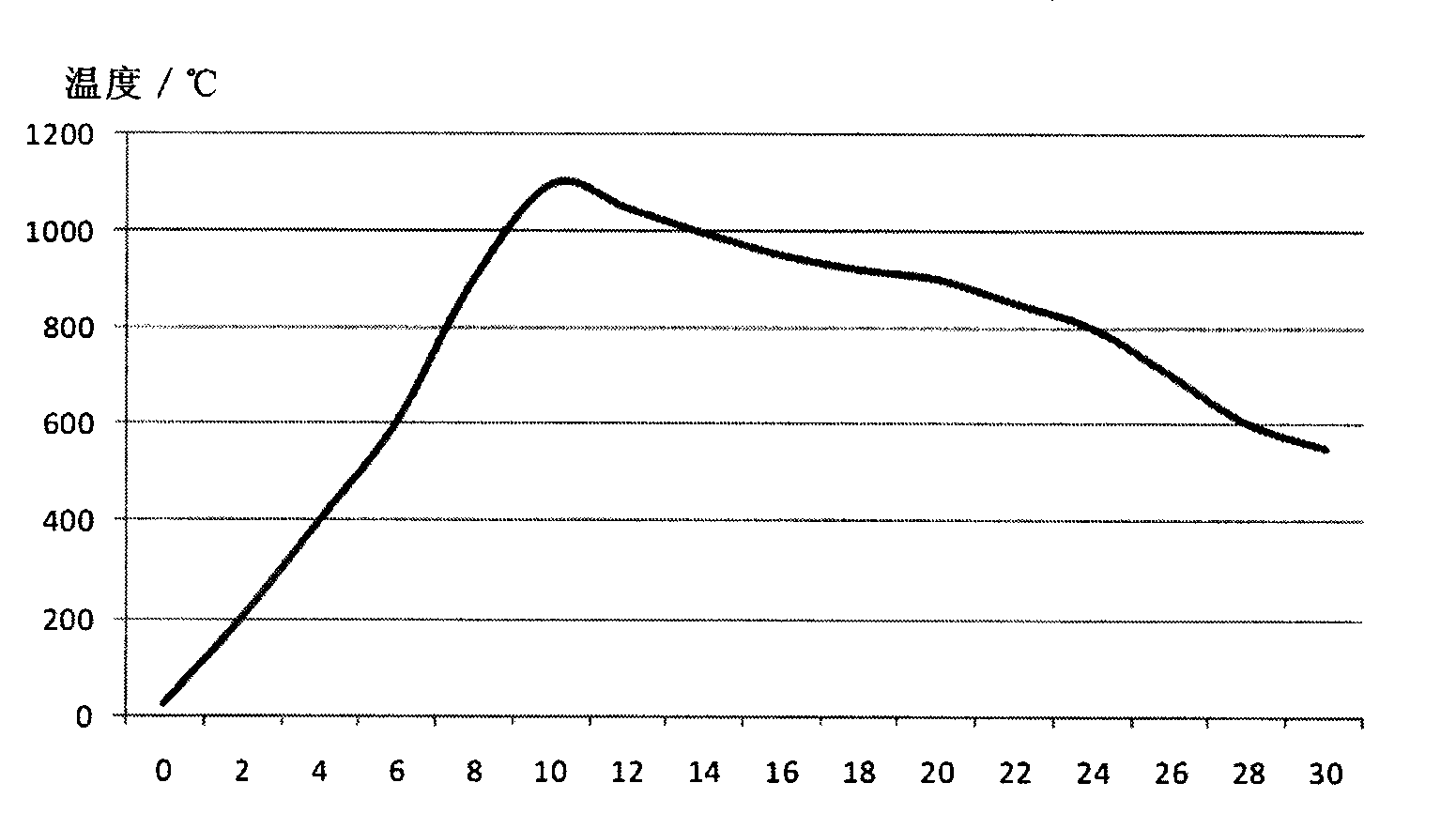

Method for preparing building block sintered from oil field mud

InactiveCN1528530ALarge amount of processingEffective consumptionSolid waste disposalCeramic shaping apparatusSludgeMetallurgy

The invention relates to a method to sinter building block by mud in oil field, including the steps: 1), batching: according to weight ratio, clay 20-80, mud 20-80, and additional auxiliary material 0.1-30% of the total weight of the clay and mud, where the content of the soluble salt is below 0.5% of the total weight; 2) mixing: two modes: one, dry or wet mixing; two, wet mixing; 3), ageing: 1-7 days; 4), molding: adopting half-dry pressing or dry pressing, where the molding pressure is greater than 4.0MPa; 5), drying; 6), sintering: placing the dried preparation into the high temperature furnace for baking, wherein the sintering temperature 800-1200 deg.C, preserving heat for 1-3 hours in the high temperature region and then cooling with the furnace to obtain the products.

Owner:WUHAN UNIV OF TECH

Solid electrolyte material with high ion conductivity and strong mechanical properties and preparation method thereof

ActiveCN105977530AImprove ionic conductivityImprove machinabilitySecondary cellsElectrolytesMiniaturizationLithium-ion battery

The invention relates to a solid electrolyte material with high ion conductivity and strong mechanical properties and a preparation method thereof. The solid electrolyte material has a chemical formula Li6+xAly(LazA3-z)(ZrnG2-n)O12+alphawt%D, wherein A is selected from at least one of Ca, Sr, Y and Ba; G is selected from at least one of Ti, Nb, Ta, Sb and V; D is selected from at least one of SiO2, Bi2O3, B2O3, CeO2, ZnO, CuO, MnO2, Co2O3 and SnO2; x is more than or equal to 0 and smaller than or equal to 2, y is more than or equal to 0 and smaller than or equal to 1, z is more than or equal to 2 and smaller than or equal to 3, n is more than or equal to 1 and smaller than or equal to 2, and alpha is more than or equal to 0 and smaller than or equal to 3. The safety problems of liquid leakage and explosive and flammable properties and the like of a lithium ion liquid battery are solved; miniaturization of the battery and shape diversification of products are facilitated; a process route is simple, and large-batch production is easy to realize; a sample sintering temperature is low, and heat-preservation time is short; the volatilization of lithium ions is reduced, and the sintering cost is greatly reduced.

Owner:淄博佳润纺织有限公司

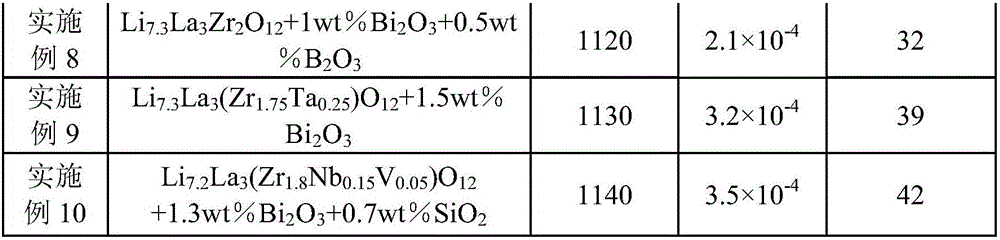

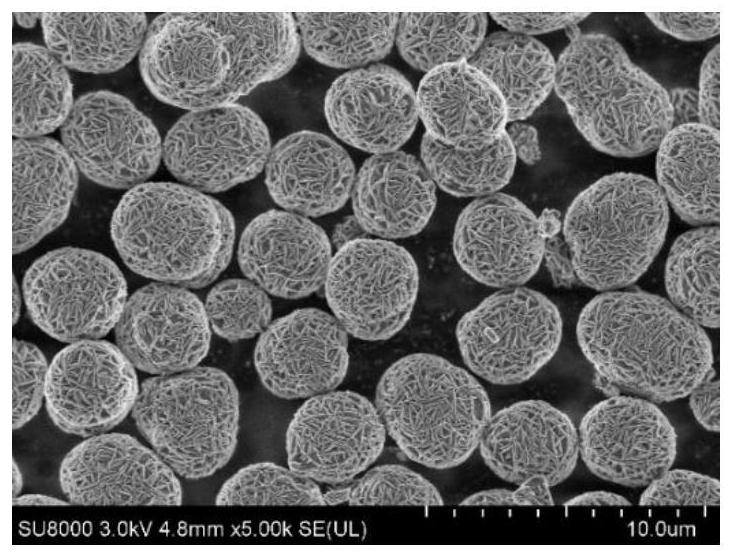

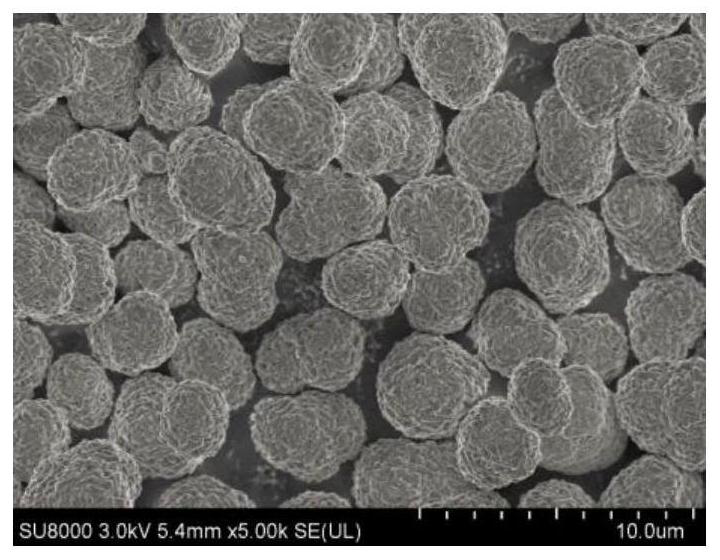

Spherical high-nickel cobalt-free single crystal precursor and preparation method thereof

ActiveCN112939095AGood dispersionReduce DC resistanceCell electrodesSecondary cellsPhysical chemistryReaction temperature

The invention discloses a spherical high-nickel cobalt-free single crystal precursor and a preparation method thereof, a low coprecipitation reaction temperature of 20-40 DEG C is adopted, the crystallinity of the precursor is effectively reduced and the specific surface of the precursor is improved by increasing the feeding speed section by section, changing the pH value and the like, in addition, a long-diameter paddle is adopted, the paddle diameter / kettle diameter is 0.50-0.65, the stirring strength is improved, and the dispersity and sphericity of the single crystal precursor are improved. The process is simple, the process is easy to control, the method is suitable for large-scale production, the prepared high-nickel cobalt-free single crystal precursor is good in dispersity and sphericity, the specific surface area is larger than or equal to 20 m < 2 > / g, the crystallinity is low, the half-peak width FWHM101 of the precursor obtained through XRD testing is larger than or equal to 0.8, and sintering single crystallization is obvious.

Owner:SHAANXI COAL & CHEM TECH INST

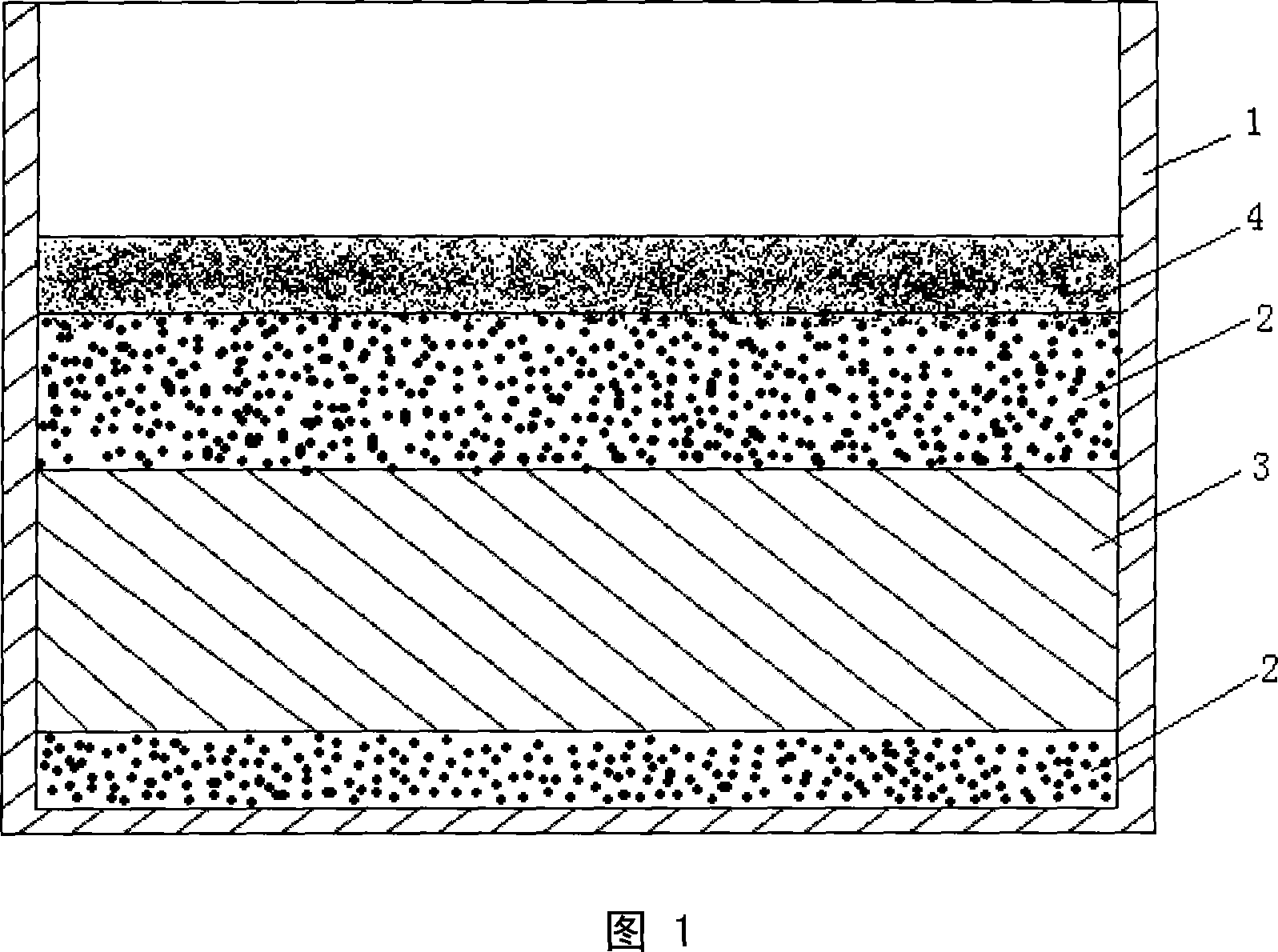

Super-thick material layer sintering method for dual-alkalinity complex sintered ore

The invention discloses a super-thick material layer sintering method for dual-alkalinity complex sintered ore. Two times of material distribution and two times of ignition are conducted, and a sintering mixture at the upper layer is different from a sintering mixture at a lower layer; the sintering mixture A is firstly added into a sintering trolley, the distribution thickness of the sintering mixture A is 600-800 mm, and the sintering mixture A with the alkalinity being 1.8-2.4 is subjected to down draft sintering through ignition of a first igniter; when the sintering trolley travels to the position where the distance between the sintering trolley and a first ignition system is one fifth to one half of the total length of a sintering machine, the sintering mixture B is added and distributed with the distribution thickness of 400-600 mm, and the sintering mixture B with the alkalinity being not higher than 0.5 is subjected to down draft sintering through ignition of a second igniter; and sintered ore at the upper layer and sintered ore at the lower layer are subjected to cooling uniform-mixing and screening uniform-mixing to form the complex sintered ore with the alkalinity being 1-1.4. By means of the super-thick material layer sintering method, the dual-alkalinity sintered ore can be produced through one-time sintering, the mixed sintered ore with the proper comprehensive alkalinity is formed after uniform mixing, and the sintering cost is lowered; and the number of pellets used for a blast furnace is reduced, and the ironmaking cost is lowered.

Owner:ANGANG STEEL CO LTD

Sintering method of super-thick material layer sinter

The invention provides a sintering method of super-thick material layer sinter. The thickness of a sintering material layer is 920-950mm, the sintering moisture is 6.2-6.4%, and the sintering negativepressure is 14.5-15.5kPa. The sintering method comprises the specific steps of (1) burdening, (2) mixing and pelletizing, (3) mixture preheating, (4) micro-negative pressure ignition, and (5) material loosening. According to the sintering method, through development and application of a low-moisture pelletizing technology, low-pressure steam efficient preheating of a mixture is conducted to increase the material temperature, development and application of a micro-negative pressure ignition technology and transformation and application of three rows of material loosening devices, the thicknessof the material layer is increased, the machine speed of a sintering machine is decreased, the sintering crystallization reaction is promoted, the internal return mine rate is decreased, and the quality and yield of the sinter are improved; the thickness of the material layer is increased to 930mm or above from 730mm, the sintering negative pressure is decreased to 14.5kPa-15.5kPa from 16.0kPa-17.0kPa, low-power-consumption and low-fuel-consumption sintering under the super-thick material layer condition is achieved, and the sintering cost is reduced; and NOx emission of sintering raw flue gas is reduced by about 37%, and efficient process emission reduction of the sintering flue gas NOx is achieved.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

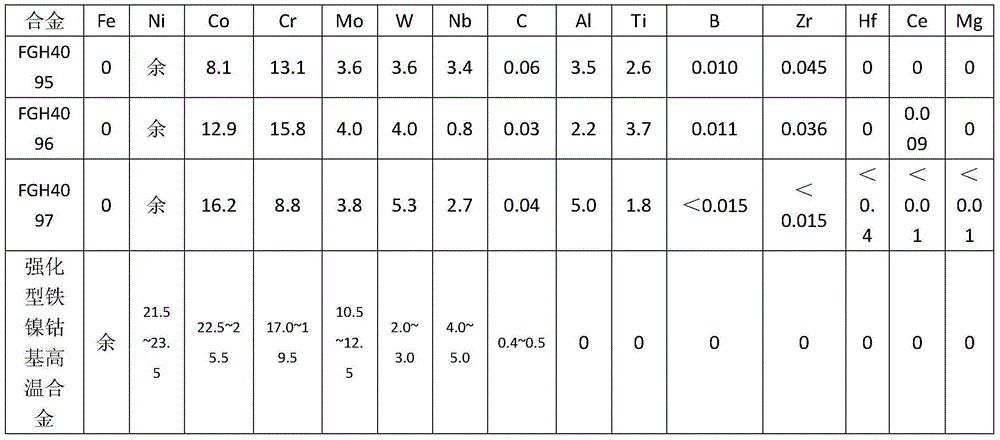

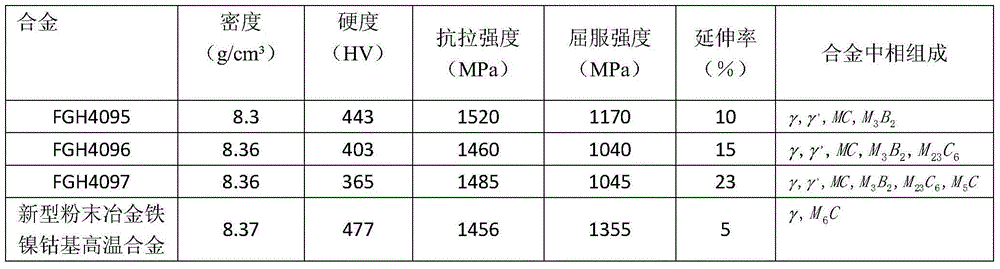

Preparation method of enhanced type Fe-Ni-Co-based high temperature alloy through precipitation

The invention discloses a preparation method of an enhanced type Fe-Ni-Co-based high temperature alloy through precipitation and belongs to the technical field of alloy material preparation. The preparation method of the enhanced type Fe-Ni-Co-based high temperature alloy through precipitation comprises the following steps: firstly selecting pure element powder as a raw material, preparing supersaturated nanocrystalline and non-crystal mixed pre-alloyed powder by adopting a mechanical alloying technique, then putting the pre-alloyed powder into a stainless steel sheath, carrying out vacuum seal welding, then carrying out hot pressed sintering on the stainless steel sheath after vacuum seal welding is finished, and finally cooling a sintered sample, releasing pressure and breaking vacuum, so that the enhanced type Fe-Ni-Co-based high temperature alloy is obtained through precipitation. The preparation method of the enhanced type Fe-Ni-Co-based high temperature alloy through precipitation has the advantages that the stainless steel sheath is adopted for carrying out hot pressed sintering, the traditional female mould is not used any longer, and a large part can be conveniently sintered, powder flowability during sintering is improved, powder can be purified, and bulk alloy with large volume and high compactness can be prepared on the basis; and meanwhile, the preparation method of the enhanced type Fe-Ni-Co-based high temperature alloy through precipitation is easy to operate, and requirement on equipment is low.

Owner:XI AN JIAOTONG UNIV

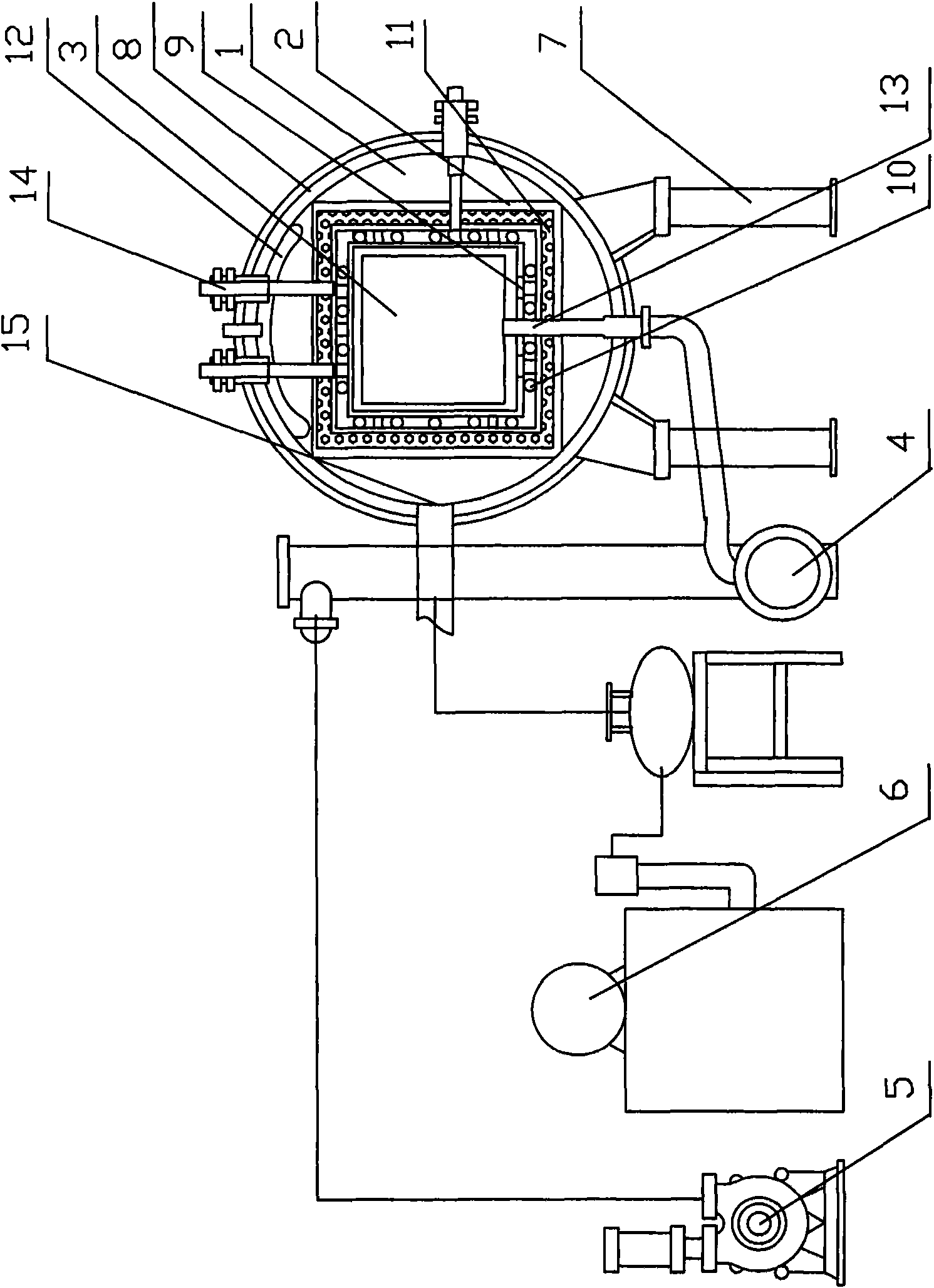

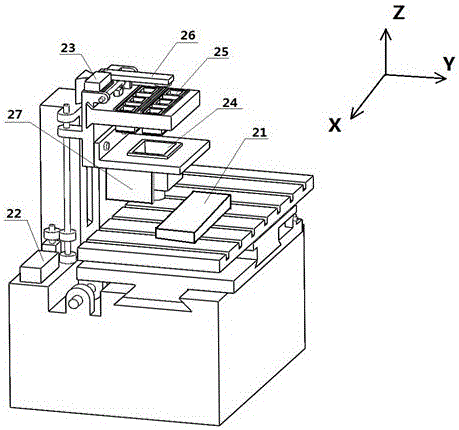

Hard alloy sintering process and degumming and vacuum sintering integrated furnace

InactiveCN101596596AAvoid the disadvantage of easy oxidationImprove sintering qualityMuffle furnacesRetort furnacesProduct gasVacuum pump

A hard alloy sintering process comprises the following steps: filling moulded workpiece in a sintering chamber, starting vacuum pump to vacuumize and starting glue pump, raising temperature to 330 to 350 DEG C, making adhesive gasify, at the same time, pumping the gasified adhesive gas from sintering chamber by glue pump, and then, continuously raising temperature to 630 to 660 DEG C, making furnace-residual adhesive gas crack, after finishing degumming, continuously vacuumizing to 140 to 160 Pa and raising temperature to 1410 to 1480 DEG C, at last finishing sintering. The degumming and vacuum sintering integrated furnace of the invention comprises: a furnace, a heat preservation box, a sintering chamber, an adhesive tank, a glue pump and a vacuum pump. The invention has rational design, simple device structure, convenient operation and integration of degumming and vacuum sintering for effectively improving the product sintering quality, shortening sintering period, saving energy resource and reducing product sintering cost. The furnace is a novel product fit for replacing the current hard alloy sintering device because of wide sintering product range, low device cost and safe production process.

Owner:株洲楚天硬质合金股份有限公司

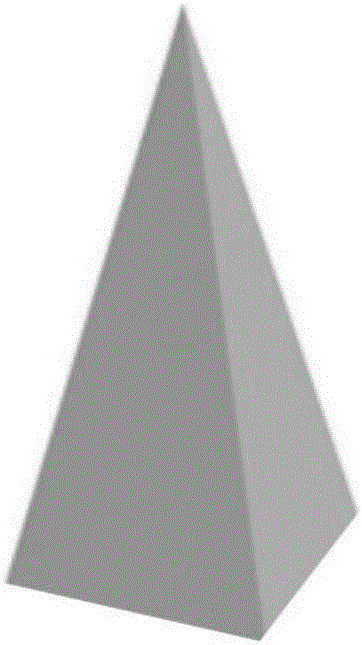

Pyramidal silicon carbide ceramic absorber and preparation method thereof

The invention discloses a pyramidal silicon carbide ceramic absorber and a preparation method thereof. Particularly, the pyramidal silicon carbide ceramic absorber is prepared from the following components in percentage by weight: 40-60% of SiC, 5-15% of SiO2, 15-20% of MgO, 0-10% of BaCO3, 0-3% of MnO2, 0-2% of CoO, 0-2% of V2O5, 0-2% of Al2O3, 5-10% of semi-refined paraffin wax and 1-5% of PE (polyethylene) plasticizer. The preparation method comprises the following components: carrying out high-temperature compounding, carrying out injection molding to obtain pyramids, degreasing and sintering to obtain the final product. The pyramidal ceramic absorber with broadband absorption property prepared by the injection molding process has the characteristics of simple technique, stable properties, favorable heat conductivity coefficient, high hemispherical emittance, high vacuum applicability and the like.

Owner:NANJING LUOPU TECH CO LTD

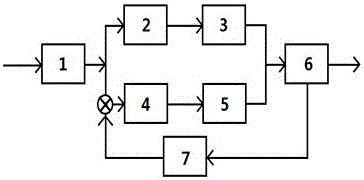

A 3D printing method based on self-propagating reaction

InactiveCN104923781BIncrease print speedIncrease speedAdditive manufacturing apparatusCombustionChemical reaction

The invention relates to a self-propagating reaction and a 3D printing technology, in particular to a 3D printing method based on a self-propagating reaction. The self-propagating chemical reaction is used in the whole printing process for heat releasing, and an outer heat source is completely or partly not needed. In the printing process, products with needed components and structures are obtained through a self-sustained reaction of fast automatic wave combustion. The printing controllability is good, the speed, the temperature, the conversion rate and the components and the structures of the products in the process are controlled by changing the releasing and transmitting speed of heat. The self-propagating reaction and the traditional 3D printing technology are combined to increase the overall printing speed, the printing period is shortened, a large quality of printed products can be obtained rapidly, and various metal powder materials can be applied. Energy does not need to be supplied continuously once ignition is conducted, compared with laser sintering, cost is lower, efficiency is higher, and equipment is simple and easy to manufacture.

Owner:WUHAN UNIV

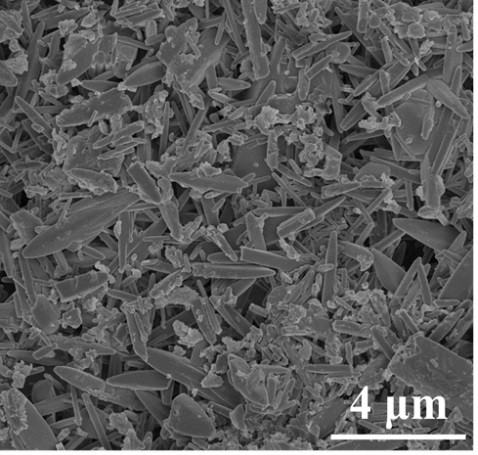

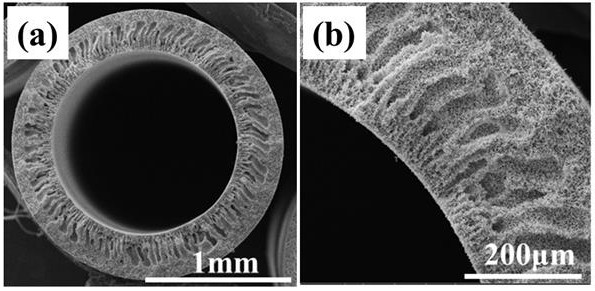

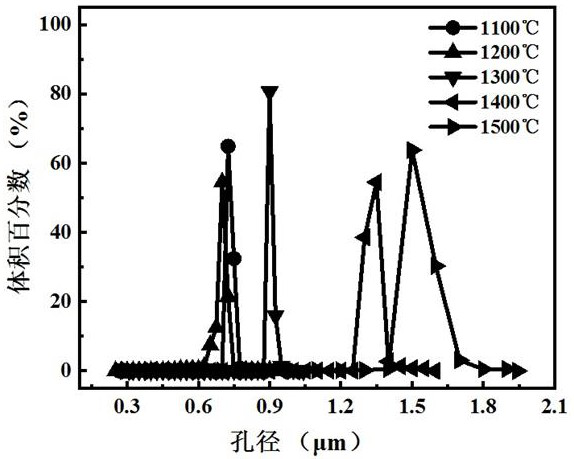

Preparation and application of whisker-shaped ceramic membrane with low cost and high permeability

ActiveCN113105223ALow costImprove permeabilitySemi-permeable membranesHigh concentrationOil retention

The invention discloses preparation and application of a whisker-shaped ceramic membrane with low cost and high permeability, and belongs to the technical field of preparation of high-permeability membranes. According to the method, tungsten oxide is added to form thewhisker-shaped ceramic membrane; the ceramic membranehas lower mullite forming temperature, and the sintering cost is greatly reduced; higher porosity, higher mechanical strength and better mechanical strength are achieved, and the permeability is improved; and the surface is rougher, so that the wettability of the membrane is effectively enhanced, and the membrane has higher oil pollution resistance in the oil-water separation process. In the preparation process, a phase inversion method or an extrusion molding method is adopted, so that hollow fibrous, tubular or hollow flat-plate-shaped and large-size tubular or flat-plate-shaped whisker structure mullite ceramic membranes can be respectively obtained, and can be used for large-scale industrial application. The whisker-shaped mullite ceramic membrane shows stable high permeation flux and high oil retention rate for oil-water separation (such as high-concentration and high-acid-base environments and complex oily wastewater), and has a wide application prospect.

Owner:DALIAN UNIV OF TECH

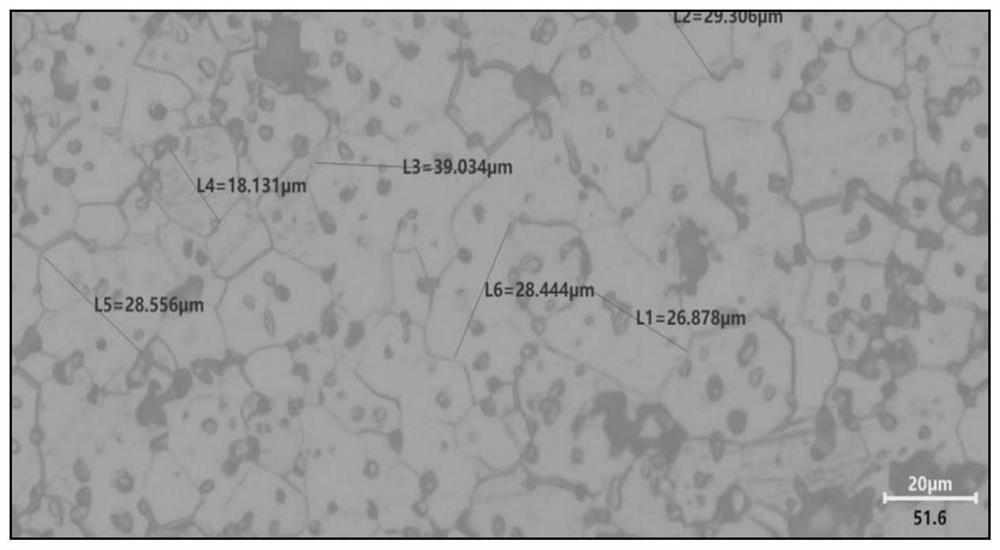

Method for preparing nanocrystalline soft magnetic material employing microwave sintering

The invention discloses a method for preparing a nanocrystalline soft magnetic material employing microwave sintering. The Mn-Zn ferrite powder or nickel-zinc ferrite powder which is prepared from pure iron powder by a sol-gel method is pressed and molded after by annealed, and then subjected to surface treatment after microwave sintering, so as to obtain the nanocrystalline soft magnetic material. By adopting the method for preparing the nanocrystalline soft magnetic material employing microwave sintering, which is disclosed by the invention, the mean grain size of the obtained nanocrystalline soft magnetic material achieves nanoscale by adopting microwave sintering, the prepared nanocrystalline soft magnetic material is uniform in powder particle, small in crystal particle, excellent in magnetic property, safe and environment-friendly, the sintering time is shortened, and energy sources are saved. The method disclosed by the invention is simple and convenient to operate, simple in preparation technology, and low in fabrication and sintering costs.

Owner:XIAN UNIV OF TECH

Aluminum nitride ceramic low-temperature sintering aid system

The present invention relates to an aluminum nitride ceramic low-temperature sintering aid system, which comprises a component A and a component B, wherein the component A is at least one selected from TiO2, ZrO2 and HfO2, and the component B is at least one selected from V2O5, Nb2O5 and Ta2O5. Compared to the scheme reported in the current literatures, the sintering aid scheme of the present invention has the following advantages that the densification process of the material can be achieved within the short time, the process is simple and reliable, and the high thermal conductivity can be obtained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Indium tin oxide target material and sintering preparation method thereof

The invention discloses an indium tin oxide target material sintering preparation method which comprises the following steps: putting a target biscuit into a sintering furnace, keeping the sintering furnace be in a normal air atmosphere, raising the temperature inside the sintering furnace in a speed of 15-100 DEG C per hour till the temperature achieves a first high temperature, keeping the temperature for 4-10 hours, converting the atmosphere inside the sintering furnace to be in a normal pressure pure oxygen atmosphere, and raising the temperature inside the sintering furnace in a speed of 20-100 DEG C per hour till the temperature achieves a second high temperature; oscillating the temperature inside the sintering furnace for 5-30 hours within an oscillation range between a third high temperature and the second high temperature, specifically, when the temperature achieves the second high temperature, raising the temperature inside the sintering furnace in a speed of 50-300 DEG C per hour till the temperature achieves the third high temperature, and when the temperature achieves the third high temperature, reducing the temperature inside the sintering furnace till the temperature achieves the second high temperature in a speed of 150-300 DEG C per hour; reducing the temperature to be the normal temperature in the speed of 20-200 DEG C per hour, so as to prepare the indium tin oxide target material. The technical scheme is low in application cost and high in product quality.

Owner:广西华锡集团股份有限公司

Making technology for Al2O3/Cu electrical contact material

InactiveCN101034635AThe process method is simple and reliableShorten the timeElectric switchesAl powderMaterials preparation

The invention relates to one kind of Al2O3 / Cu electricity contact material preparation craft, which belongs to the preparation electricity contact material technique. It includes the raw material preparation, interal oxidizing reaction, the suppression shape and agglutinates. Its characteristic is that the used raw material is Cu, Al and the Cu2O powder which can buy from the market, after put Cu and Al powder in the ball mill to ball grinding to achieve the melting, then join the Cu2O powder to continue ball grinding, render the Cu2O even distribution, the granularity to be thin. After puts the ball grinded alloy powder in the vacuum oven and carry on internal oxidation, then uses the mold to suppress shape, finally uses the cover embedding method to agglutinate in the ordinary resistancefurnace. The merit is: (1) the raw material may buy from the market; has omitted the complex atomization craft. (2) Use the ball mill to ball grinding the metal powder, render the metal powder to be thin and also even distribution, achieve to melting, may reduce the oxidized time, reduce the production cost.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

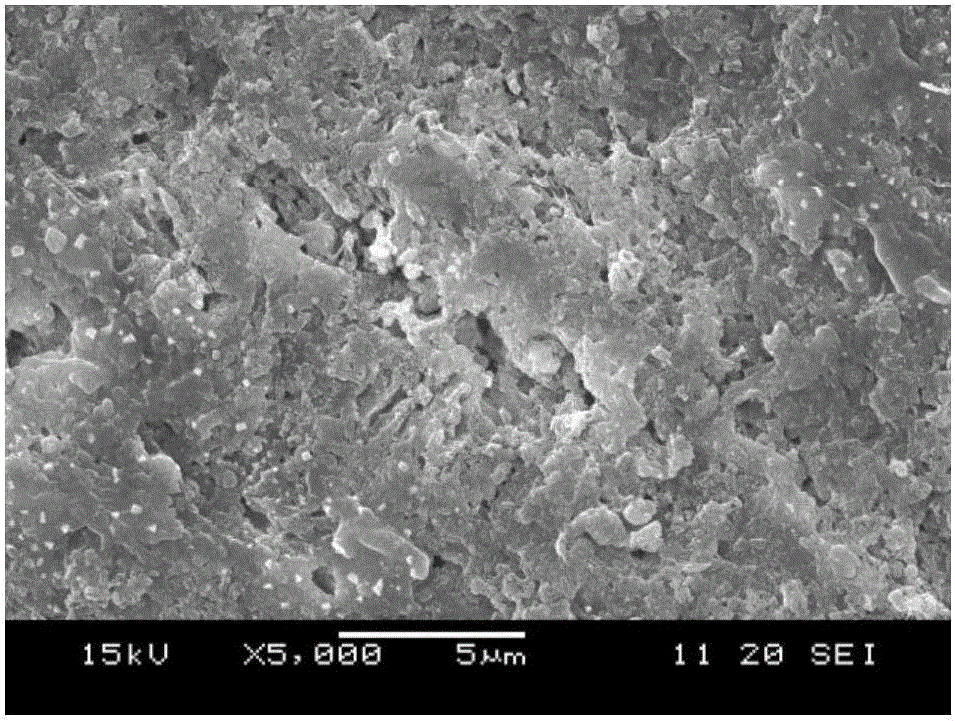

Preparation method of high-density low-free-silicon-content reactively-sintered silicon carbide ceramic material

ActiveCN111574226AEvenly dispersedHomogeneous microstructureFeeding arrangmentsCarbide siliconHigh density

The invention provides a preparation method of a high-density low-free-silicon-content reactively-sintered silicon carbide ceramic material. The method comprises the following steps: mixing, vacuum degassing, slip casting, demolding, drying and sintering. According to the invention, reasonable raw material particle size distribution is selected, and pressure slip casting is adopted to enhance thedensity of a biscuit of a product; an optimized sintering curve is adopted in the sintering process, and organic matter removal and presintering are combined into a whole, so sintering cost is reducedunder the condition that product quality is not affected, and the problem that the silicon carbide ceramic biscuit deforms or cracks in the high-temperature organic matter removal process is solved;and the high-density green body can undergo sufficient reactive sintering at a low temperature to generate a high-density low-free-silicon ceramic product, thereby ensuring the microstructure uniformity of the silicon carbide ceramic biscuit and greatly enhancing the strength and structural stability of the ceramic material.

Owner:潍坊盛润特种陶瓷有限公司

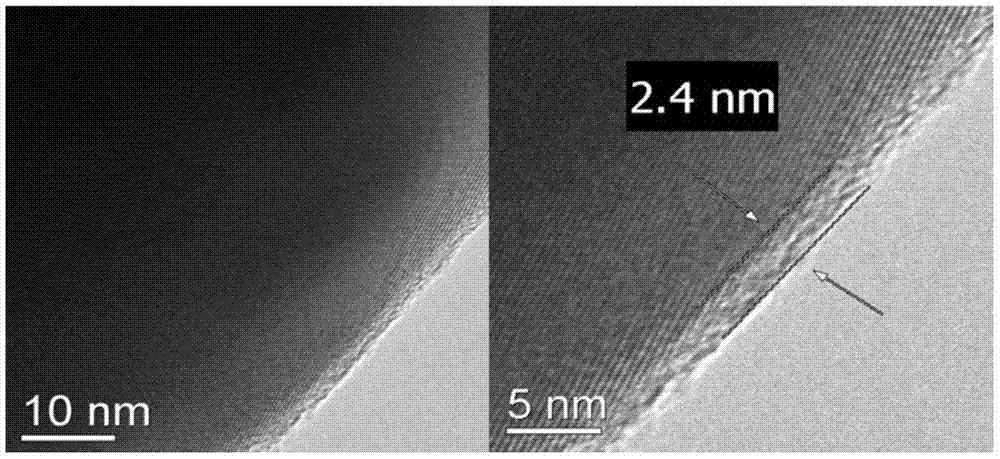

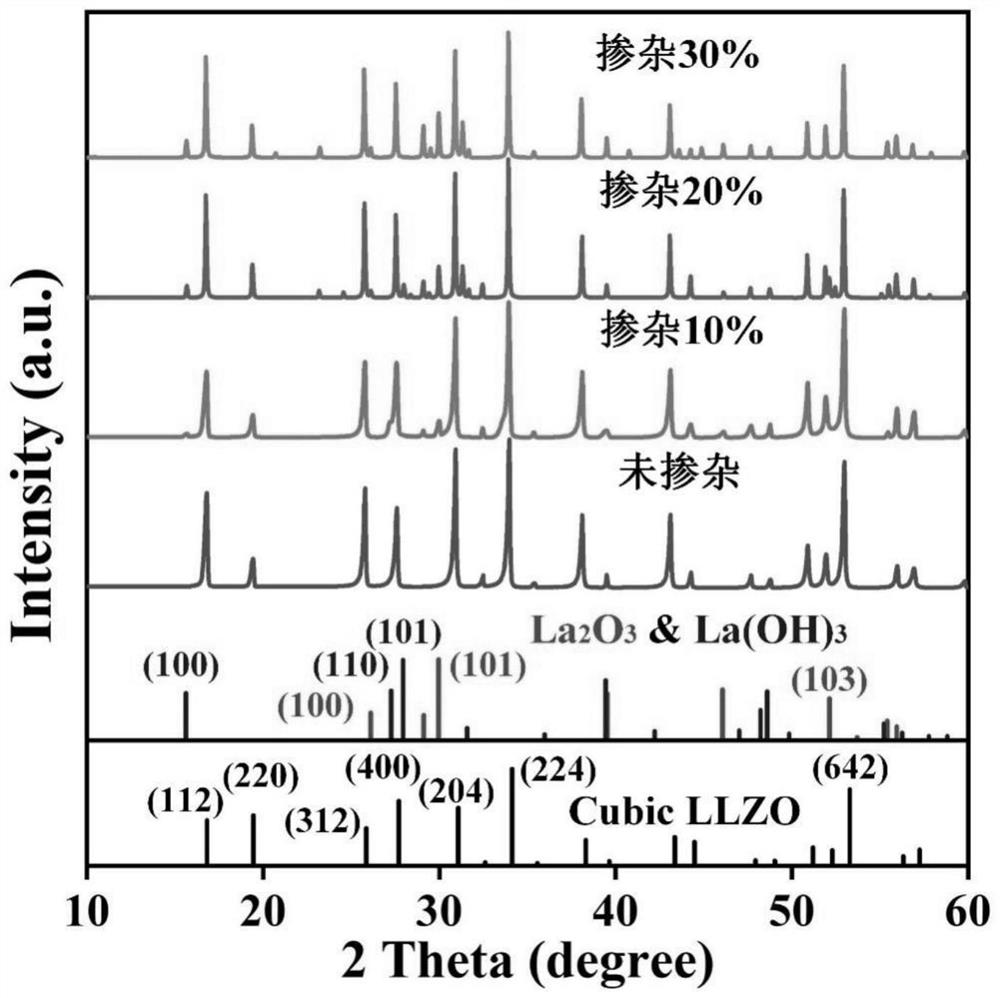

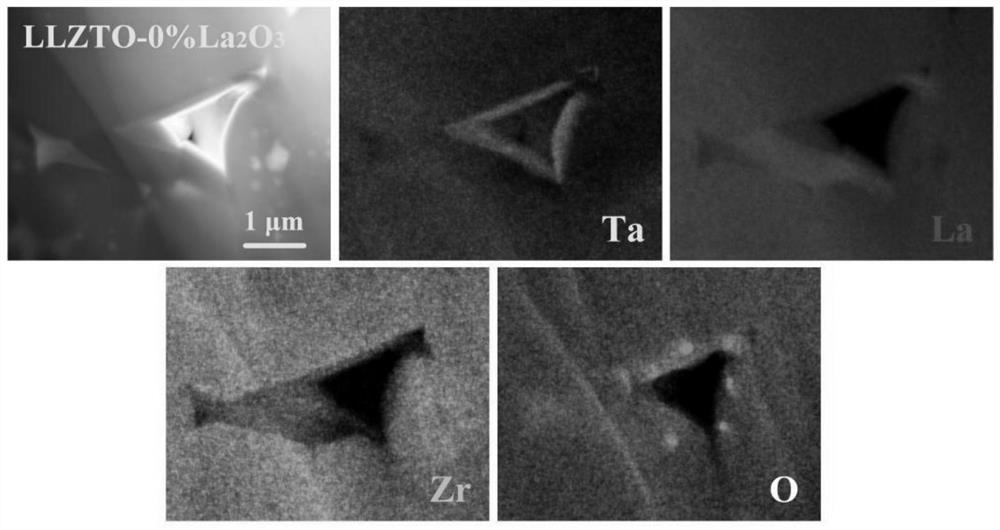

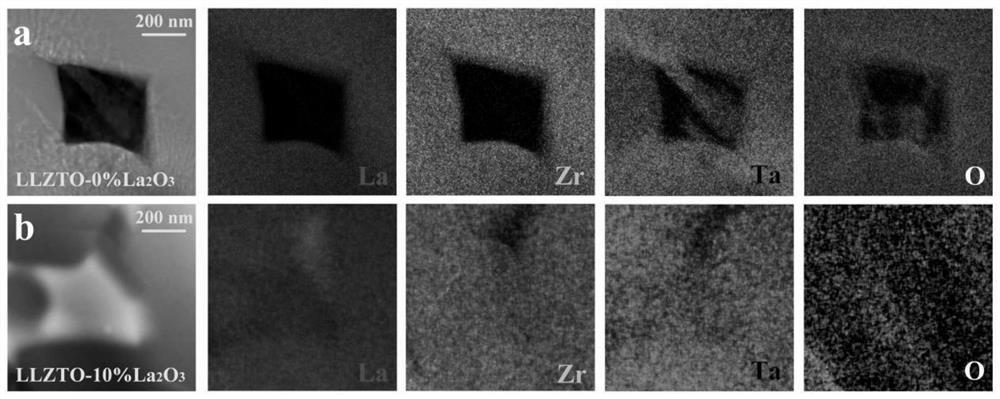

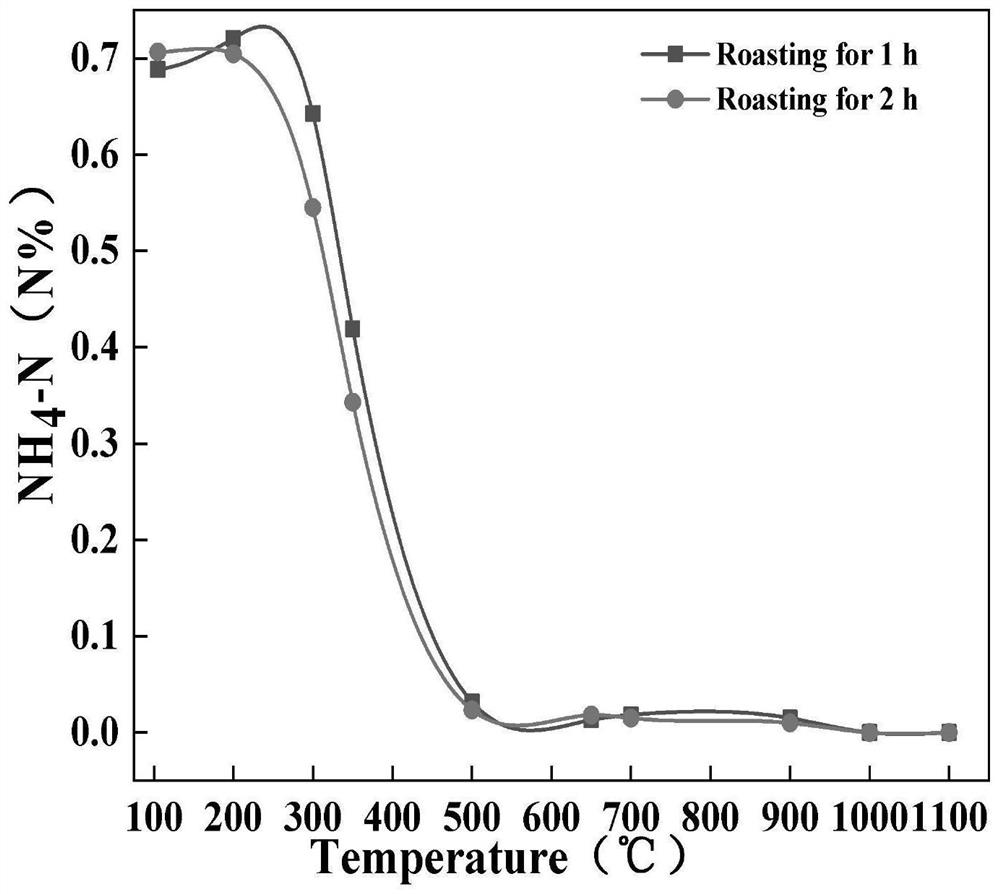

Method for improving compactness and conductivity of tantalum-doped garnet type solid electrolyte

ActiveCN113402271AHigh densityImprove compactnessSecondary cellsElectrolytesSolid state electrolyteAbnormal grain growth

The invention discloses a method for improving compactness and conductivity of tantalum-doped garnet type solid electrolyte, and belongs to the field of electrochemical energy storage. The invention aims to solve the technical problem that the conductivity and compactness of the existing tantalum garnet-doped solid electrolyte are not fully improved. The method comprises the steps of powder mixing, wet ball milling, drying, presintering, wet ball milling, drying, grinding and sieving, glue mixing and tabletting, degumming, and powder burying and sintering. According to the tantalum-doped garnet type solid electrolyte and the preparation method thereof, the element proportion of the La site and the Zr (Ta) site in the tantalum-doped garnet type solid electrolyte LLTZO is adjusted by doping La2O3 nano-particles, then generation of an intermediate phase LaTaO4 is mediated, abnormal grain growth of the LLTZO is effectively inhibited, the sintering homogeneity of the tantalum-doped garnet type solid electrolyte is improved, meanwhile, hole defects are reduced or eliminated to improve the compactness, therefore, the ionic conductivity is improved, and the cycling stability of the solid-state battery is improved. The method is simple, the sintering cost is low, and industrial mass production is easy to realize.

Owner:HARBIN INST OF TECH

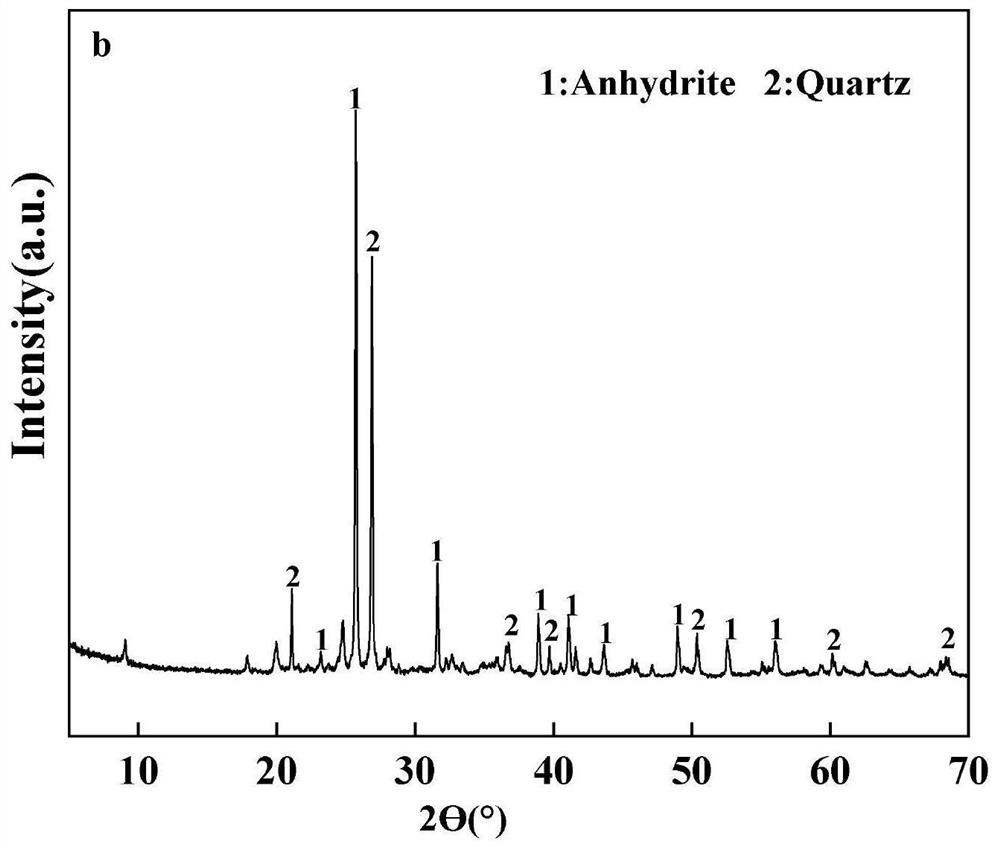

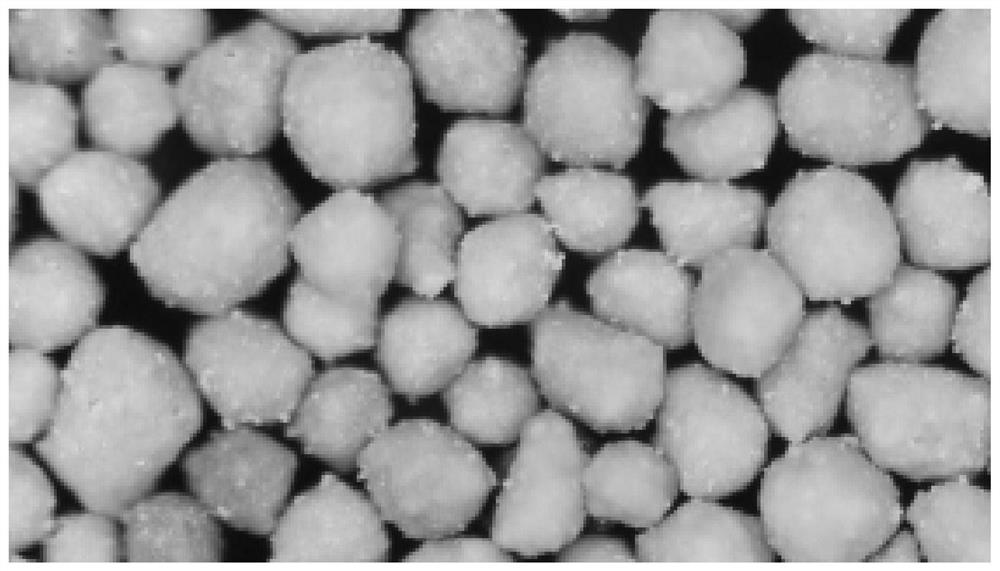

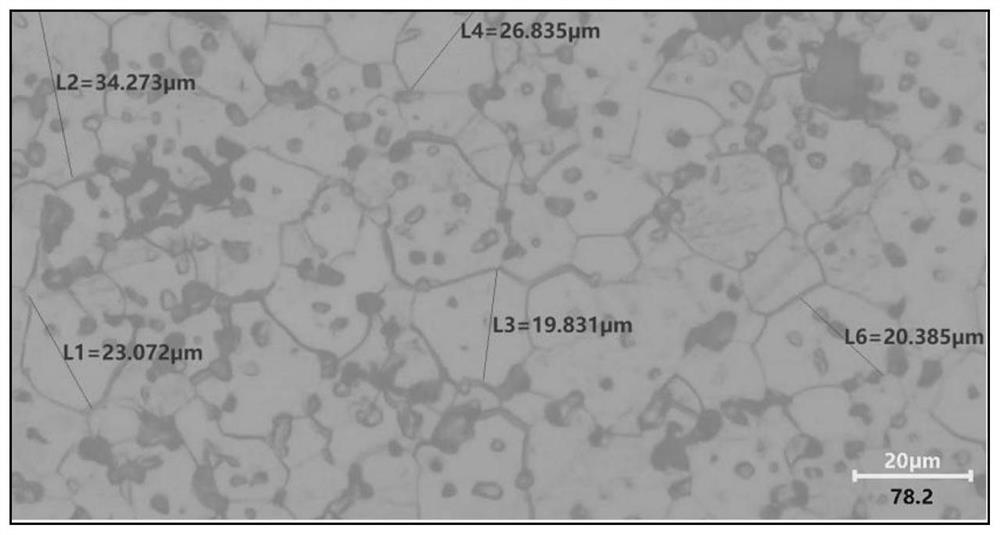

Preparation method and application of low-density ceramsite proppant added with pretreated electrolytic manganese residues

ActiveCN112919889AReduce bulk densitySimple peak shapeFluid removalDrilling compositionElectrolysisPhysical chemistry

The invention discloses a preparation method and application of a low-density ceramsite proppant added with pretreated electrolytic manganese residues. The low-density ceramsite proppant is mainly prepared from the following raw materials: pretreated electrolytic manganese residues and bauxite, wherein the mass fraction of the pretreated electrolytic manganese residues is 15-20%; the pretreated electrolytic manganese residues are obtained by calcining waste residues obtained after a process of extracting manganese metal through wet electrolysis for 2-3 hours at the temperature of 650-750 DEG C. The performance of the prepared low-density ceramsite proppant meets the SY / T5108-2014 industrial standard, the low-density ceramsite proppant can be used for replacing natural quartz sand to be used for fracturing operation under the closing pressure of 52 MPa, and the low-density ceramsite proppant is particularly used for hydraulic fracturing exploitation of shallow petroleum and natural gas. According to the prepared low-density ceramsite proppant, the pretreated electrolytic manganese residues can be added in a large proportion, and the adding proportion can reach 15-20%. In the preparation method, the sintering temperature is further reduced after the ball blank is obtained through treatment, and only the temperature of 1150-1250 DEG C is needed.

Owner:GUIZHOU UNIV

Molybdenum-nickel-based multi-element alloy rotary target material and preparation method thereof

ActiveCN113463053AImprove adhesionImprove antioxidant capacityNuclear energy generationVacuum evaporation coatingIngotTitanium

The invention discloses a molybdenum-nickel-based multi-element alloy rotary target material and a preparation method thereof. The atomic composition of the rotary target material is Mo100-x-y-zNixTiyAlz, X, Y and Z represent the atomic composition percentage, X is larger than or equal to 10 and smaller than or equal to 40, Y is larger than or equal to 1 and smaller than or equal to 20, and Z is larger than or equal to 1 and smaller than or equal to 18. The preparation method comprises the steps of mixing molybdenum powder, electrolytic nickel powder and titanium-aluminum pre-alloy powder in proportion, then carrying out deoxidation and purification treatment, ball milling and mixing, powder filling and compaction treatment, cold isostatic pressing forming, demolding, vacuum horizontal sintering, rotary swaging treatment and annealing treatment to obtain a molybdenum-nickel-titanium-aluminum alloy pipe ingot, and finally slicing the molybdenum-nickel-titanium-aluminum alloy pipe ingot through machining to prepare the molybdenum-nickel-titanium-aluminum alloy target material. According to the preparation method, introduction of impurity elements can be reduced in the preparation process, the produced target material is uniform in component, free of segregation and fine in grain, the density can reach a theoretical value of 99% or above, and the coating requirement of a current large-size sputtering target material can be completely met.

Owner:NANJING DAMAI SCI&TECH IND CO LTD

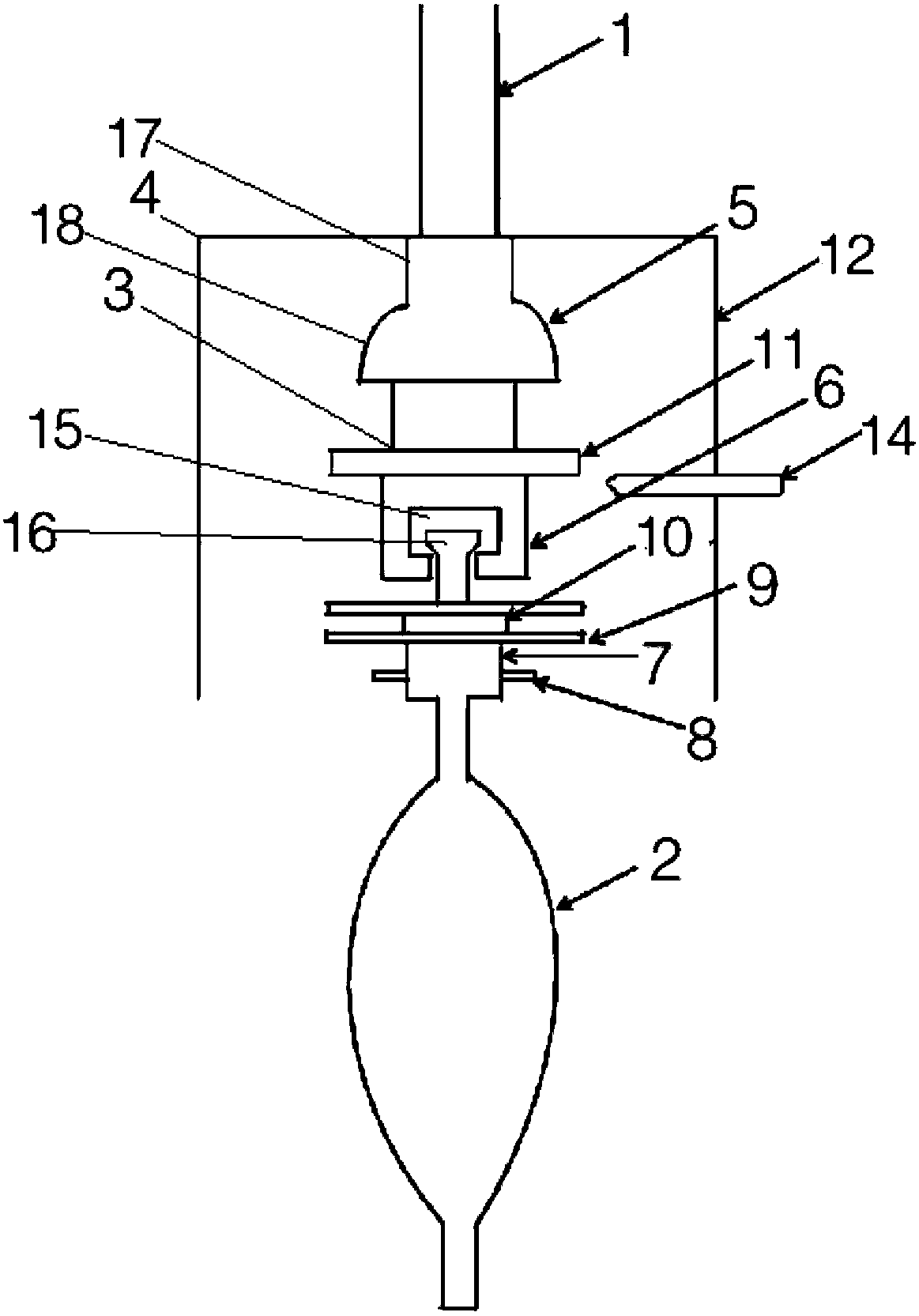

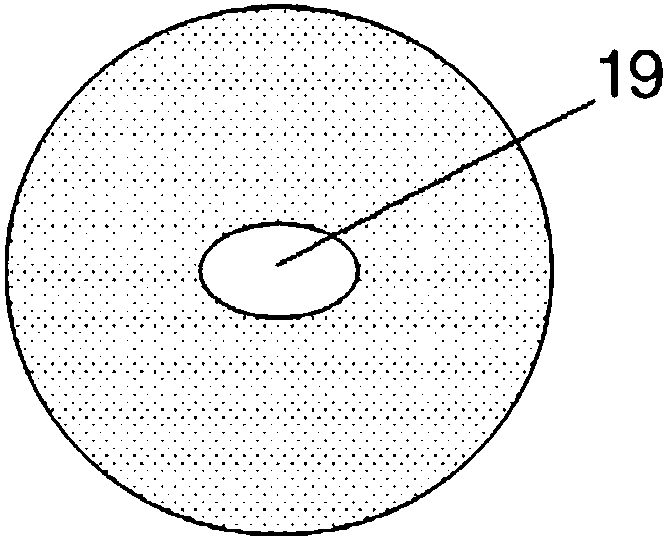

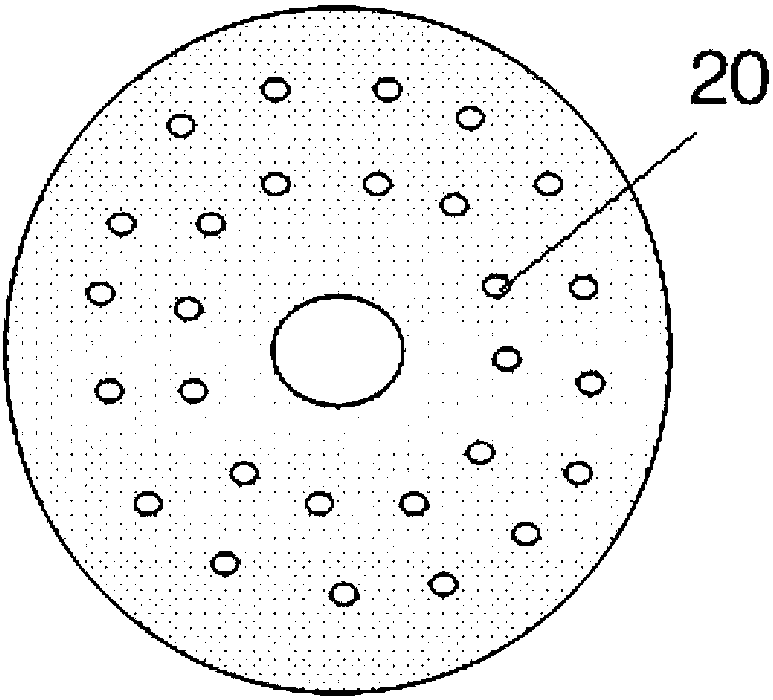

Device for improving OVD sintering efficiency and prolonging service life of lead rod and OVD sintering method

The invention provides a device for improving the OVD sintering efficiency and prolonging the service life of a lead rod. The device comprises a flow-limiting and heat-insulating unit arranged betweenthe lead rod and a prefabricated rod loose body, and an air suction unit arranged by corresponding to the flow-limiting and heat-insulating unit, wherein the flow-limiting and heat-insulating unit comprises a connecting coupler mounted at the lower end of the lead rod; an adapter is connected to a connector at the lower end of the connecting coupler; the prefabricated rod loose body is connectedto the bottom of the adapter through a pin; two layers of flow-limiting plates corresponding to each other up and down are arranged on the adapter; a quartz ring is arranged between the two flow-limiting plates; a heat-insulating plate is arranged on the adapter. In the device, through the two layers of flow-limiting plates and the heat-insulating plate, heat is effectively insulated so as to keepthe lead rod away from a high-temperature zone, so that the lead rod is maximally avoided from being thinned by stretching at high temperature; in addition, the consumption of a raw material gas is effectively reduced, the sintering time is shortened, and the sintering cost of a prefabricated rod is reduced.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD +1

High-thermal-expansion-coefficient thick-film dielectric paste for stainless steel base material and preparation method thereof

InactiveCN110880376ASoftening temperature adjustmentCrystallization temperature adjustmentNon-conductive material with dispersed conductive materialCable/conductor manufactureDielectricActive agent

The invention relates to high-thermal-expansion-coefficient thick-film dielectric paste for a stainless steel base material and a preparation method thereof. The thick-film dielectric paste is characterized by comprising the following components in percentage by weight: 70-80% of lead-free microcrystalline glass powder and 20-30% of an organic bonding phase. The lead-free microcrystalline glass powder is BaO-CaO-Al2O3-SiO2-B2O3-SrO-Sm2O3-ZrO2 series microcrystalline glass powder, and the lead-free microcrystalline glass powder comprises the following components in percentage by weight: 10%-20%of BaO, 10%-15% of CaO, 5%-10% of Al2O3, 20%-30% of SiO2, 5%-20% of B2O3, 5%-10% of SrO, 5%-10% of Sm2O3 and 1%-6% of ZrO2. And the organic bonding phase comprises the following components in percentage by weight: 70%-85% of an organic solvent, 2%-10% of a polymer thickener, 0.5%-5% of a dispersing agent, 0.5%-5% of a leveling agent, 0.5%-5% of a thixotropic agent and 0.5%-5% of a surfactant. Thehigh-thermal-expansion-coefficient thick-film dielectric paste for the stainless steel base material has the characteristics of high uniformity, high stability, high solid content and the like.

Owner:广东顺德弘暻电子有限公司

Environment-friendly microporous brick prepared by comprehensive utilization of solid wastes and preparation method of environment-friendly microporous brick

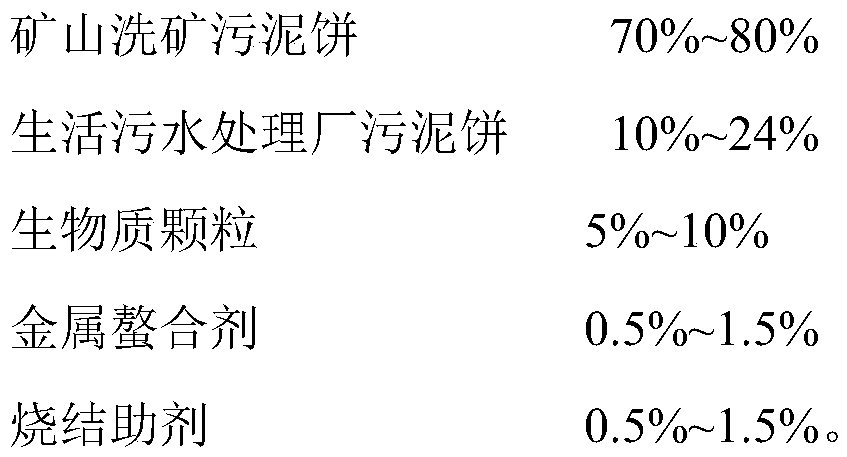

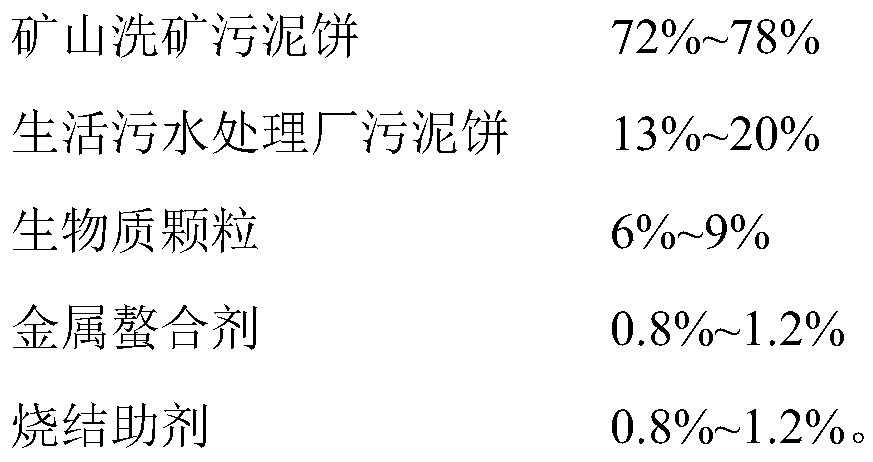

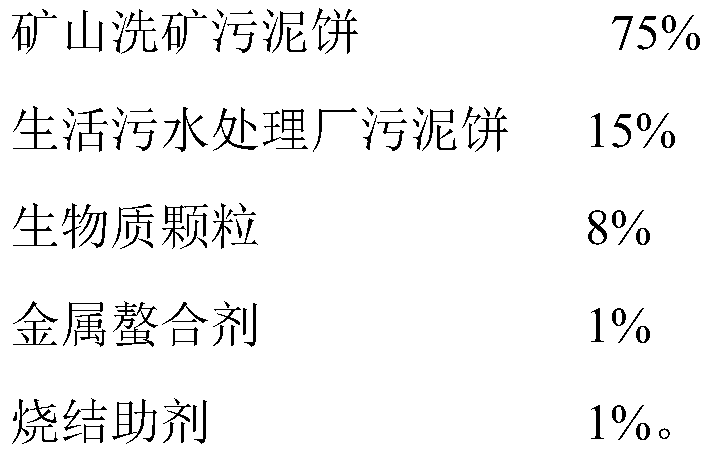

InactiveCN110723961AReduce your weightGuaranteed sintering strengthCeramic materials productionCeramicwareSludge cakeBrick

The invention relates to the technical field of resource utilization of solid wastes and in particular relates to an environment-friendly microporous brick prepared by comprehensive utilization of thesolid wastes and a preparation method of the environment-friendly microporous brick. The environment-friendly microporous brick prepared by comprehensive utilization of the solid wastes comprises mining ore washing sludge cakes, sewage treatment plant sludge cakes, biomass particles, a metal chelating agent and sintering aids. The environment-friendly microporous brick sufficiently utilizes richminerals and inorganic matter in mining ore washing sludge, rich organic matter in sludge of sewage treatment plants and high heat values of the biomass particles, both the self weight of the microporous brick is reduced and the sintering strength of the microporous brick is ensured, and meanwhile, energy consumption of external heat energy is reduced; and meanwhile, the problem of comprehensive utilization of solid wastes such as mining ore washing sludge, sewage treatment plant sludge and crop straws is solved. The preparation method of the environment-friendly microporous brick prepared bycomprehensive utilization of the solid wastes has the characteristics of being simple in process, low in production cost and applicable to large-scale production.

Owner:GUANGREEN ENVIRONMENTAL PROTECTION ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com