Pretreatment method for chromium powder ore used for smelting production of ferrochrome alloy

A ferrochromium alloy and a smelting method technology are applied in the field of pretreatment of chromium fine ore, which can solve the problems of unfavorable industrial production, secondary pollution of dust and high production cost, and achieve less pollution from fine ore, lower smelting cost, and lower smelting energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Main raw material: Turkish chrome powder ore, the particle size is 0-10mm, and the content (by weight %) of all raw materials is 88%;

[0063] Auxiliary raw materials:

[0064] Flux: common stone powder, content (by weight %) of all raw materials is 4%;

[0065] Reducing agent: pulverized coal (by weight %) of all raw materials is 4%;

[0066] Fuel: blue charcoal powder, content (by weight %) of all raw materials is 4%.

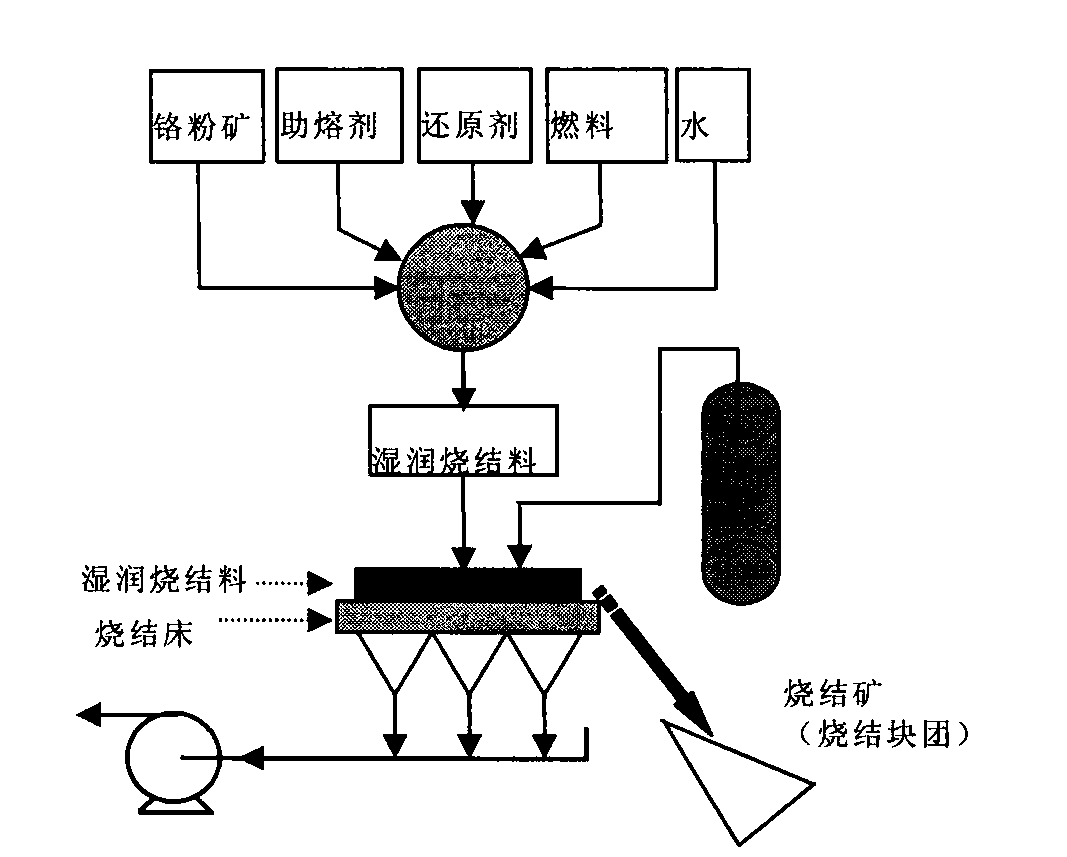

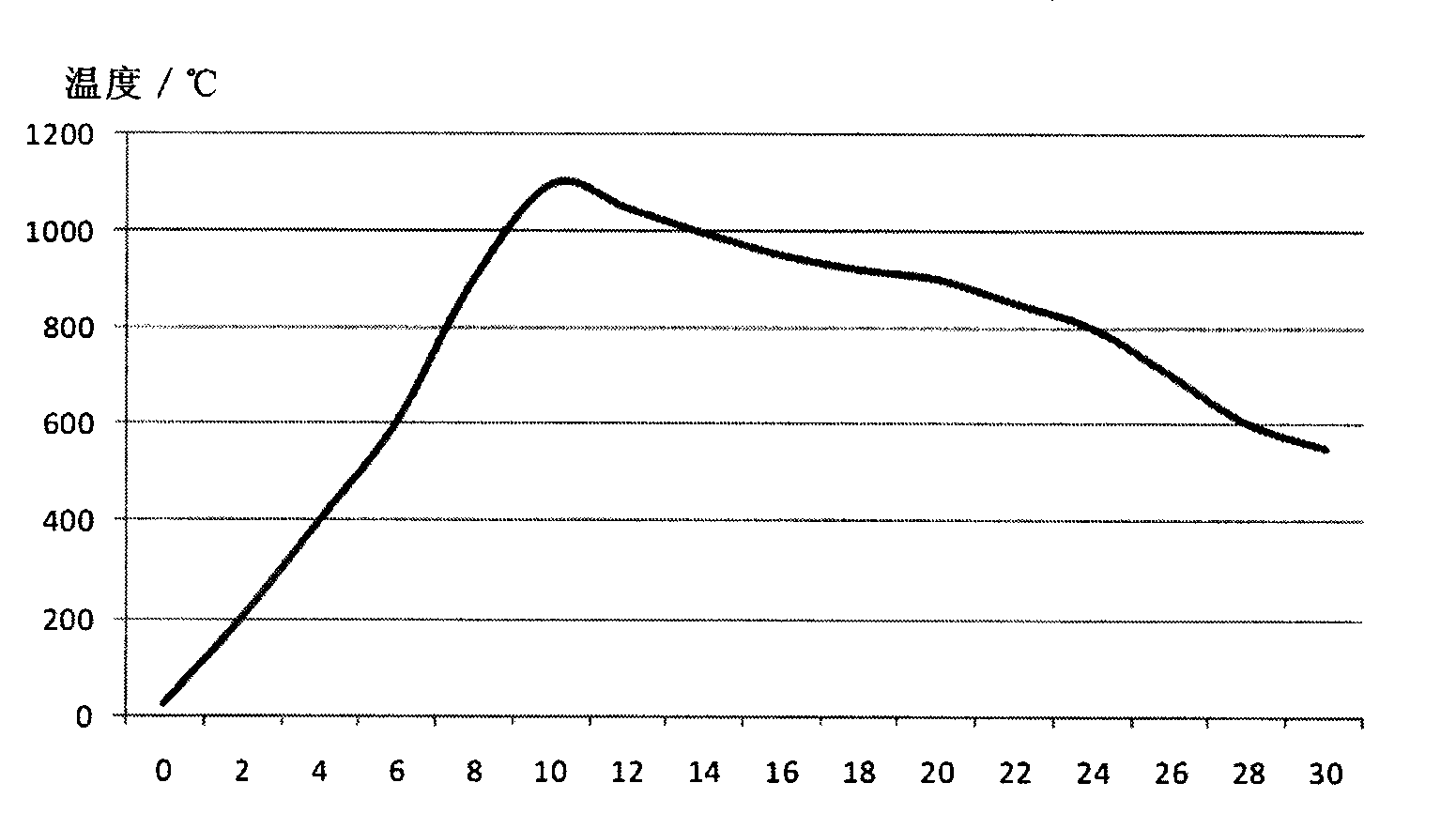

[0067] Such as figure 1 As shown, the main raw materials and auxiliary raw materials are mixed, and water is sprayed during the mixing process of the main and auxiliary materials, so that the humidity of the mixed material reaches 10% after mixing evenly, and then the mixture is arranged in a ring sintering machine (thickness is 50cm ). The fuel in the sinter bed is ignited and burned by coal gas, and the upper part of the sinter layer reaches 1100°C, and then gradually burns downward under the negative pressure of the induced draft fan. The intern...

Embodiment 2

[0071] Main raw material: South African chrome powder ore, the content (by weight %) of all raw materials is 83%;

[0072] Auxiliary raw materials:

[0073] Flux: silica powder, content (by weight %) of all raw materials is 5%;

[0074] Reductant: coke powder, content (by weight %) of all raw materials is 6%;

[0075] Fuel: pulverized coal, the content (by weight %) of all raw materials is 6%.

[0076] Such as figure 1As shown, the main raw materials and auxiliary raw materials are mixed, and water is sprayed during the mixing process of the main and auxiliary materials, so that the humidity of the mixed material reaches 11% after mixing evenly, and then the mixture is arranged in a ring sintering machine (thickness is 35cm ). The fuel in the sinter bed is ignited and burned by coal gas, and the upper part of the sinter layer reaches 1100°C, and then gradually burns downward under the negative pressure of the induced draft fan. The internal temperature of the sinter bed is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com