Heat-insulation ceramic coating material as well as preparation method and application thereof

A technology of ceramic particles and composite ceramics, which is applied in the direction of anti-corrosion coatings, cellulose coatings, coatings, etc., can solve the problems of thermal insulation coatings that need to be improved, single thermal insulation fillers, poor compatibility, etc., to improve the interior of the car Environmental quality, long service life, and the effect of improving the thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

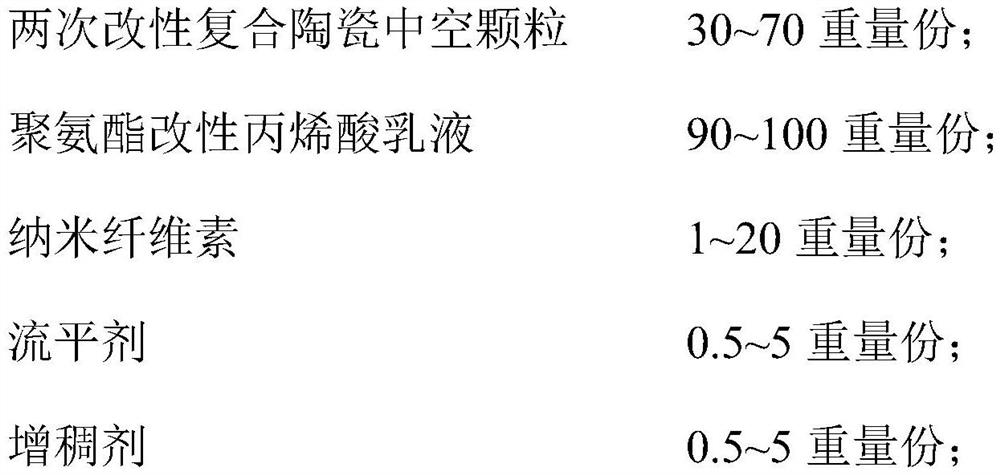

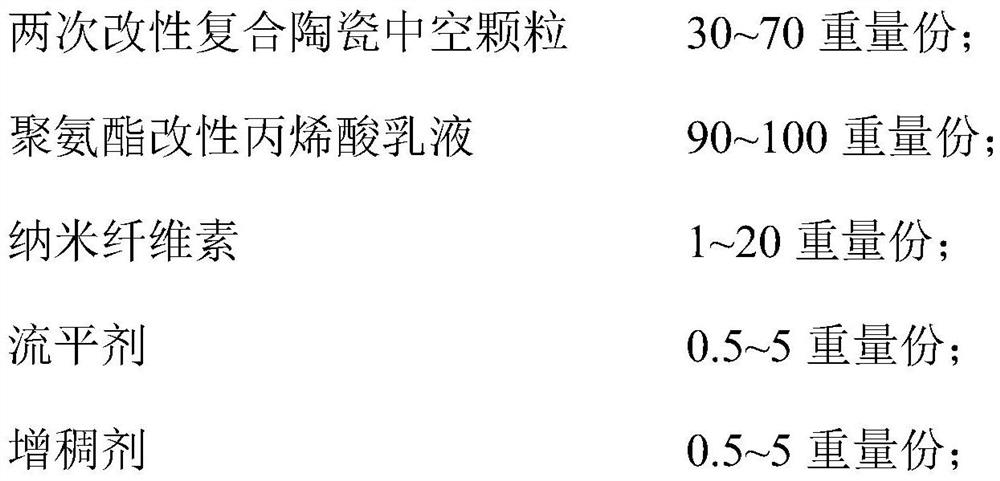

Method used

Image

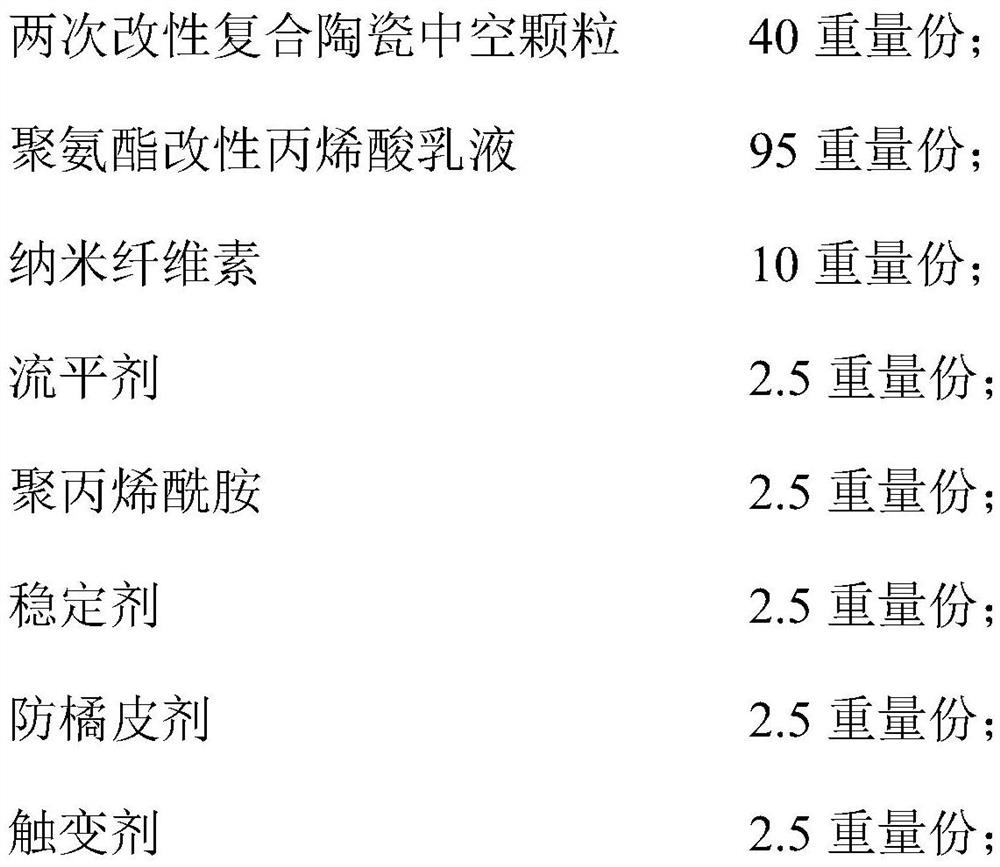

Examples

preparation example 1

[0073] A kind of twice modified composite ceramic hollow particle, its preparation method comprises the following steps:

[0074] (1) Mix composite ceramic hollow particles (with particle sizes of 120 μm, 80 μm, 60 μm and 30 μm, mass ratio of 2:4:7:1) and silane coupling agent 570 in ethanol solution for 3 hours under vacuum and 50°C, Dry at 100°C for 4 hours to obtain primary modified composite ceramic hollow particles;

[0075] (2) Mix the primary modified composite ceramic hollow particles obtained in step (1), epoxy-modified polycarbonate (Covestro Polymer Co., Ltd., model 1803) and chloroform solution at 40 ° C for 1 h, 100 and drying at °C for 3 hours to obtain the twice-modified composite ceramic hollow particles.

preparation example 2

[0077] A kind of twice modified composite ceramic hollow particle, its preparation method comprises the following steps:

[0078] (1) Mix composite ceramic hollow particles (with particle sizes of 115 μm, 75 μm, 55 μm and 25 μm, mass ratio of 2:4:7:1) and silane coupling agent 550 in ethanol solution for 1 h under vacuum and 50°C, Dry at 100°C for 2 hours to obtain primary modified composite ceramic hollow particles;

[0079] (2) Mix the primary modified composite ceramic hollow particles obtained in step (1), epoxy-modified polycarbonate (SABIC, 945A-116) and chloroform solution at 40°C for 4h, and then mix them at 100°C Dry for 4 hours to obtain the twice-modified composite ceramic hollow particles.

preparation example 3

[0081] A kind of twice modified composite ceramic hollow particle, its preparation method comprises the following steps:

[0082] (1) Mix composite ceramic hollow particles (with particle sizes of 125 μm, 85 μm, 65 μm and 35 μm, mass ratio of 2:4:7:1) and silane coupling agent 550 in ethanol solution for 3 hours under vacuum and 60°C, Dry at 100°C for 4 hours to obtain primary modified composite ceramic hollow particles;

[0083] (2) Mix the primary modified composite ceramic hollow particles obtained in step (1), epoxy-modified polycarbonate (SABIC, 945A-116) and chloroform solution at 40°C for 4h, and then mix them at 100°C Dry for 3 hours to obtain the twice-modified composite ceramic hollow particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com