Patents

Literature

83results about How to "Not prone to pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

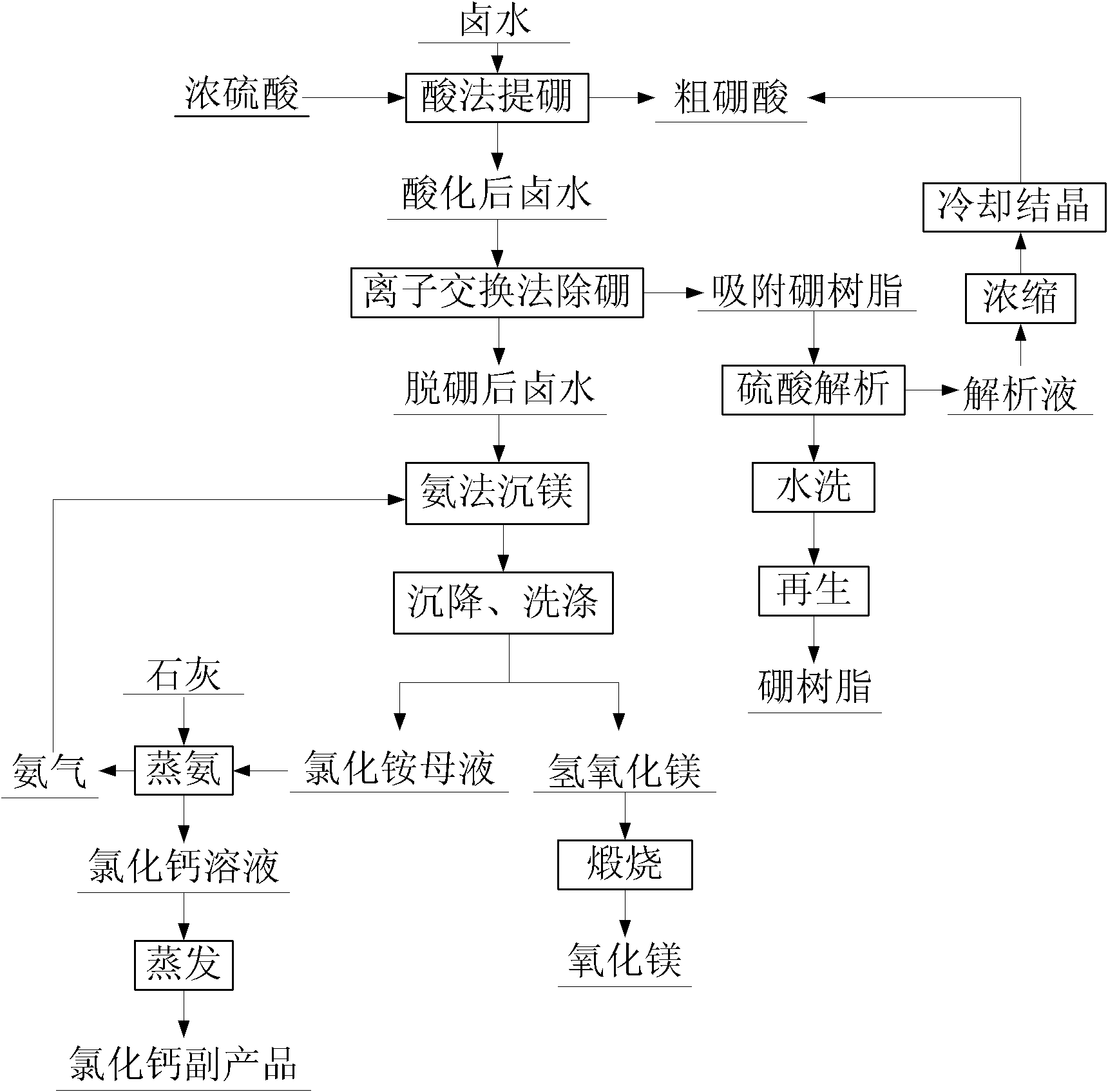

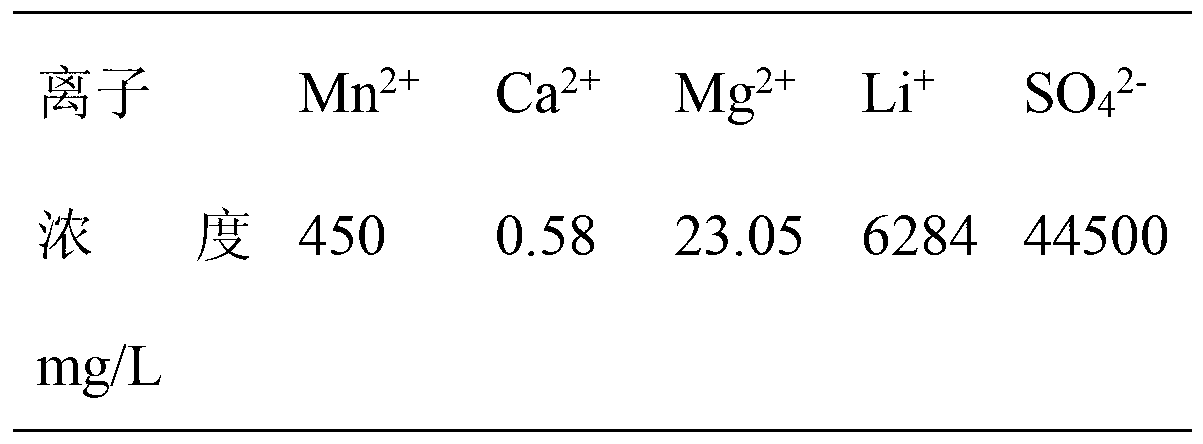

Method for preparing high-purity magnesium oxide with high boron salt lake brine

InactiveCN102491379ALarge particlesReduce extraction costsBoron-oxygen compoundsMagnesiaReaction temperatureIon-exchange resin

Provided is a method for preparing high-purity magnesium oxide with high boron salt lake brine. Salt lake brine is evaporated through a salt pan, concentrated to crystallize potassium sulfate, sodium chloride and potassium chloride and is drawn with lithium in adsorption mode so as to obtain master sauce brine containing magnesium and boron. Concentrated sulfuric acid is added into master sauce brine for reacting, and coarse boracic acid and acidized brine are obtained after cooling and filtering. Potential of hydrogen (pH) value of acidized brine is adjusted to be 5.5-6.5, and acidized brine passes through ion exchange resin adsorbing boron. When boron concentration in effluent liquid is higher than 5 mg / L, brine is not injected, boron-removed brine is obtained, then boron-removed brine and ammonium chloride solution are filled with ammonia for stirring and to produce magnesium sedimentation reaction, reaction temperature ranges from 60 DEG C to 80 DEG C, pH ranges from 7.5 to 8.0, the reaction is stopped when concentration of free ammonia reaches 1.8-2.2 mol / L, and magnesium hydroxide and magnesium sedimentation mother solution are obtained. Magnesium oxide is obtained by calcining magnesium hydroxide, content of magnesium oxide is larger than 99.8%, and magnesium extraction ratio is larger than 90%. Sedimentation mother solution adopts lime to steam ammonia, and generated ammonia circulates to magnesium sedimentation reaction. Mother solution after ammonia steaming is evaporated, concentrated and crystallized to obtain calcium chloride. Ion exchange resin adsorbing boron is washed, analyzed and regeneratively cycled for use. Boron-containing analysis solution is concentrated and cooled to pick up coarse boracic acid, and coarse boracic acid is recrystallized to obtain refined boracic acid with purity larger than 99%. High-purity magnesium oxide prepared by the method is high in purity, good in economic benefit, free of environment pollution, strong in operability and favorable for industrial production.

Owner:CENT SOUTH UNIV

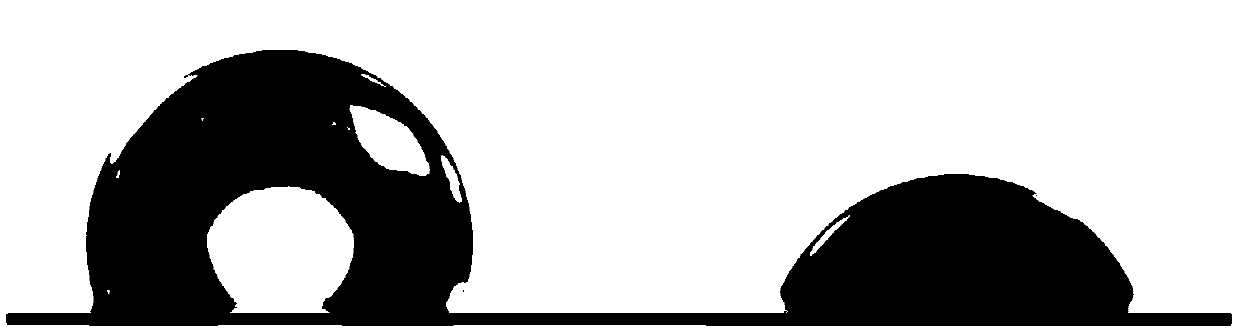

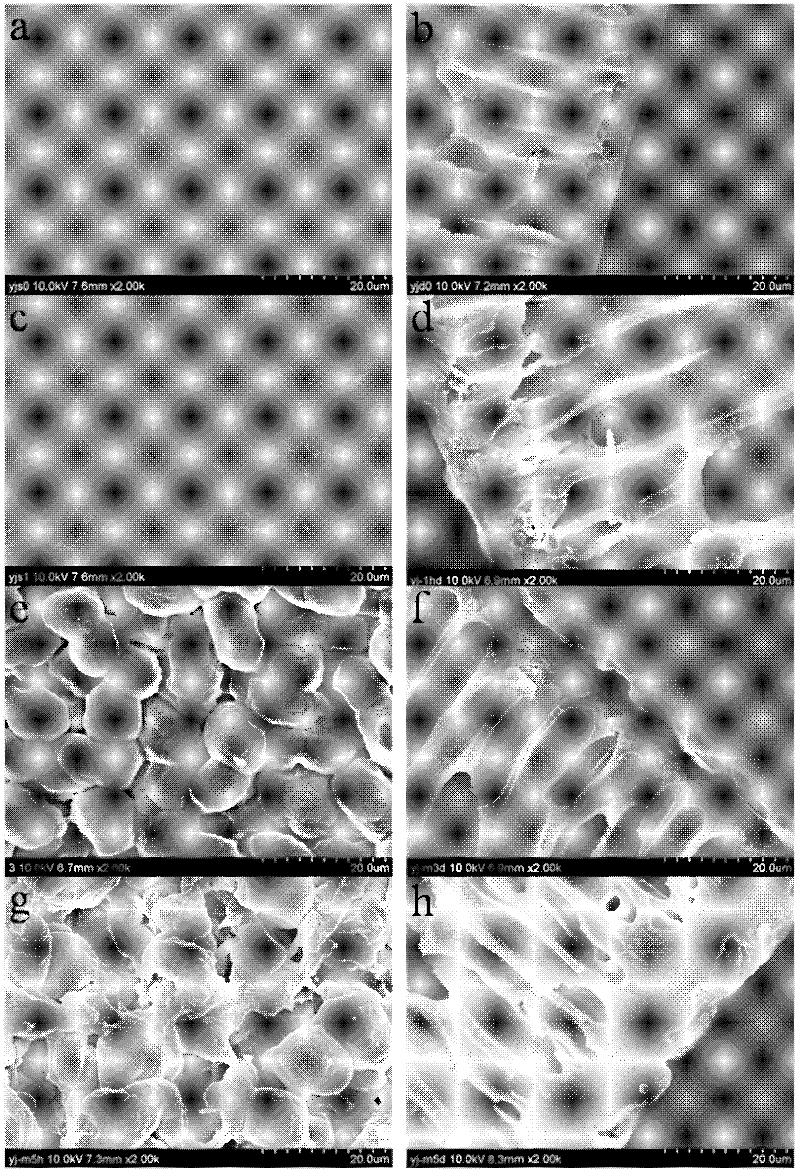

Preparation method of high-throughput hydrophilic modified polypropylene hollow fiber membrane

ActiveCN103933880AImprove hydrophilicityHigh retention rateSemi-permeable membranesFiberHollow fibre membrane

The invention discloses a high-throughput hydrophilic modified polypropylene hollow fiber membrane. The preparation method comprises the following steps: grafting a hydrophilic grafting monomer silane coupling agent to a polypropylene molecular chain through a reaction extrusion method; mixing two esters with different polarities and a high boiling point and an additive according to a certain ratio, heating and blending the mixture in a reactor so as to obtain a uniform membrane casting liquid; spinning, cooling, thermally extracting, and reeling the membrane casting liquid by a double-screw extruder and a spinning machine so as to obtain membrane wires; finally extracting esters with ethanol, and subjecting the membrane wires to thermal setting so as to obtain the polypropylene hollow fiber membrane. The preparation method is simple. The prepared polypropylene hollow fiber membrane has the advantages of high strength, stable hydrophilic property, and high water throughput, and can be used to produce membrane devices or membrane biological reactors (MBR).

Owner:贵州益华膜科技有限公司

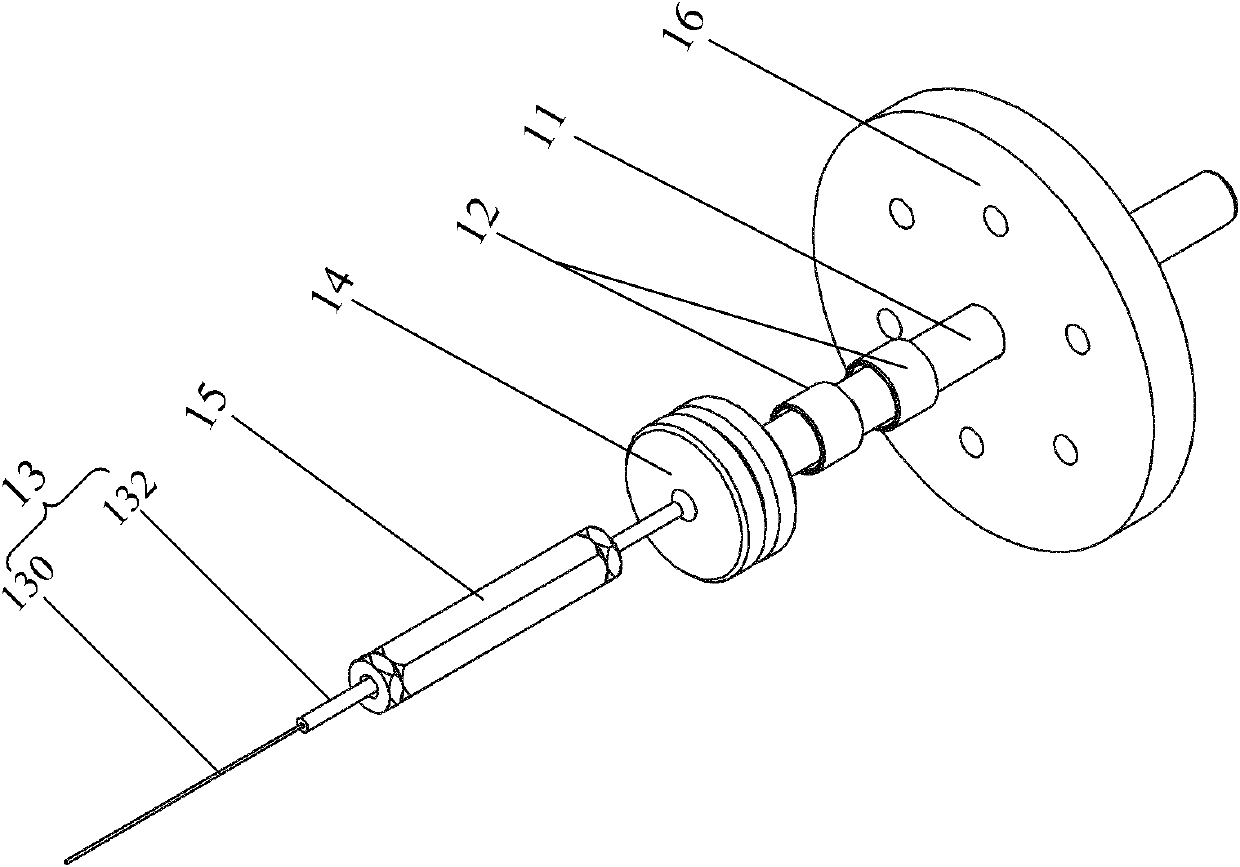

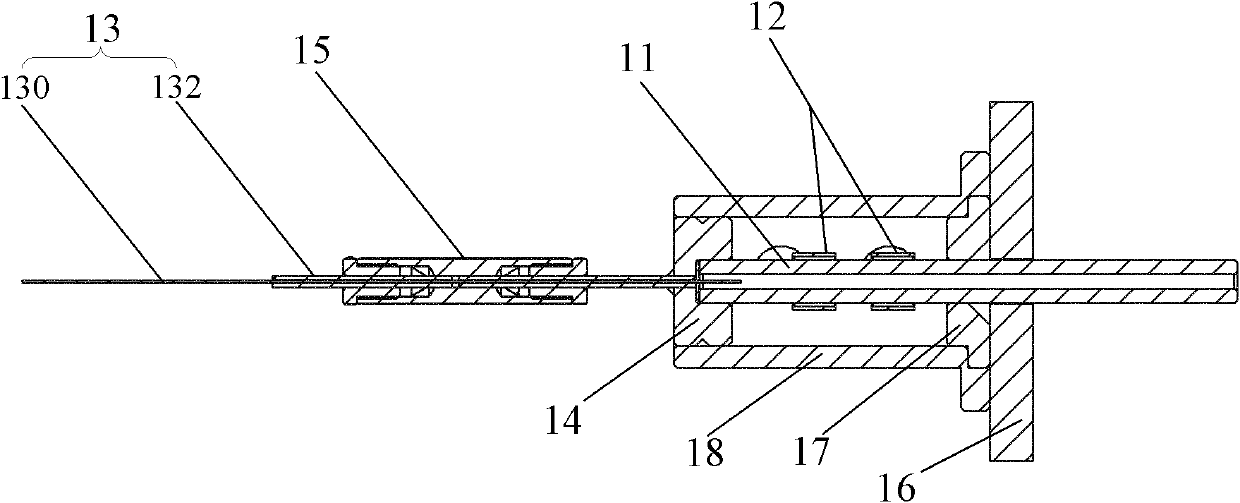

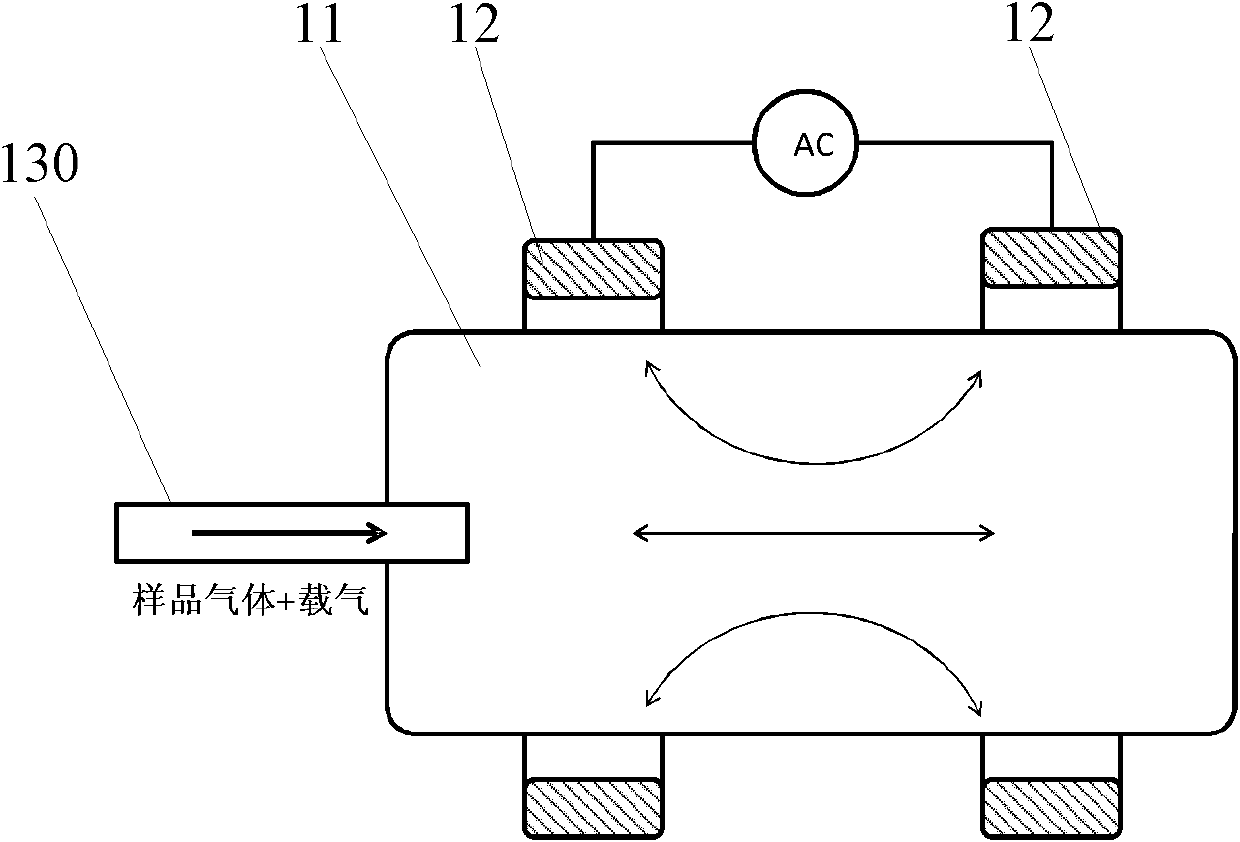

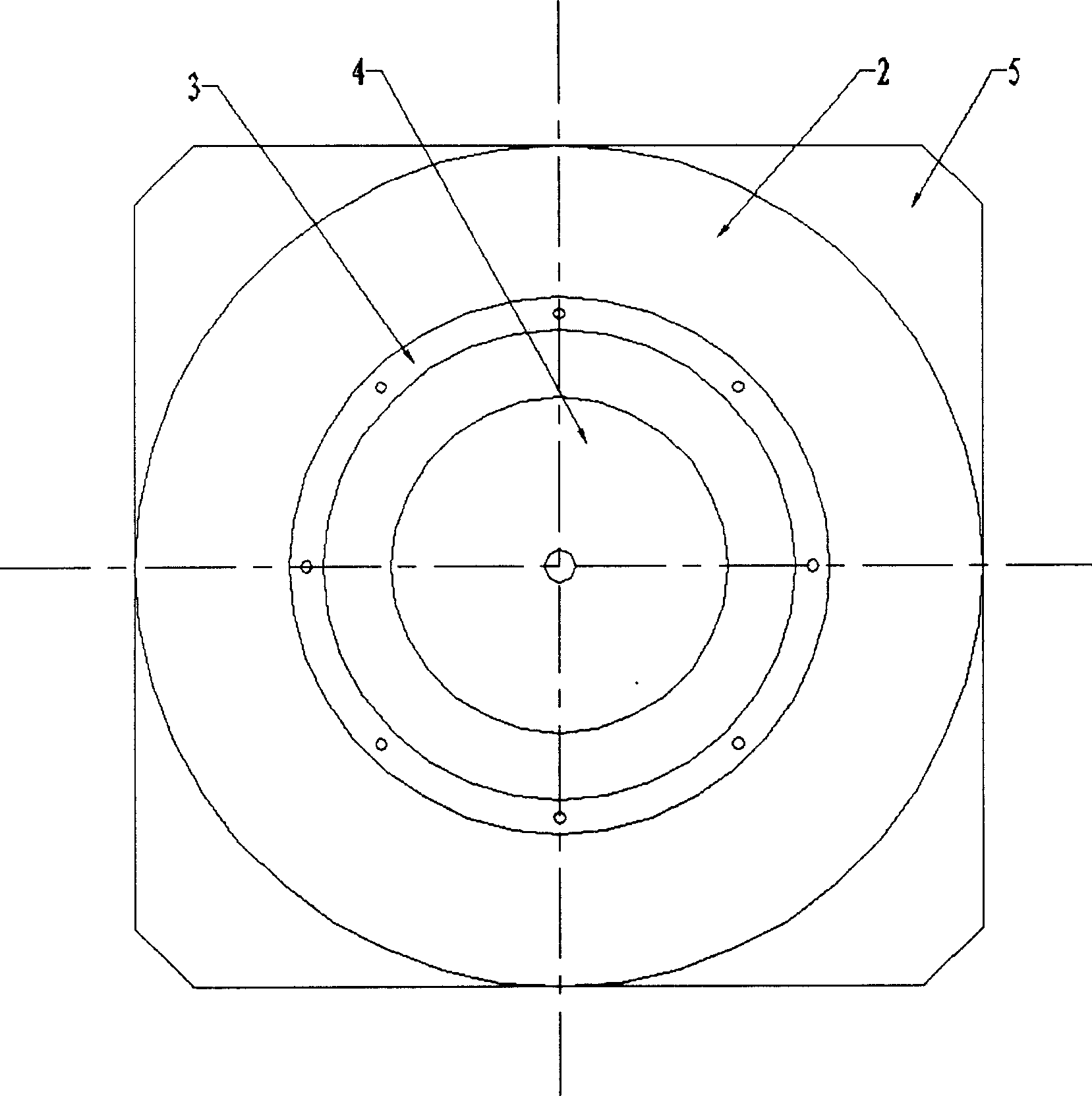

Generating device of plasma ion source

InactiveCN102573260AHigh densityExtend your lifeIon sources/gunsPlasma techniqueHigh densityLow vacuum

The invention relates to a generating device of a plasma ion source, wherein the generating device is applied to a mass spectrometer. The generating device comprises: a plasma generation cavity, which includes a cavity chamber used as a plasma generation zone; a high voltage radio frequency source, which includes a power supply and a radio frequency electrode arranged at an outer surface of the plasma generation cavity; a transmission structure, which is communicated with the plasma generation cavity and is used for introducing sample gas and carrier gas into the plasma generation cavity; and a sealing element, which is used for sealing communication space between the transmission structure and the plasma generation cavity so as to provide a vacuum environment for the plasma generation cavity. Compared with the prior art, the technology employed in the invention enables the generating device of a plasma ion source to have the following beneficial effects: the plasma generation cavity is utilized, so that a plasma ion source with high density can be generated in a low vacuum environment.

Owner:浙江复华质芯生物科技有限公司

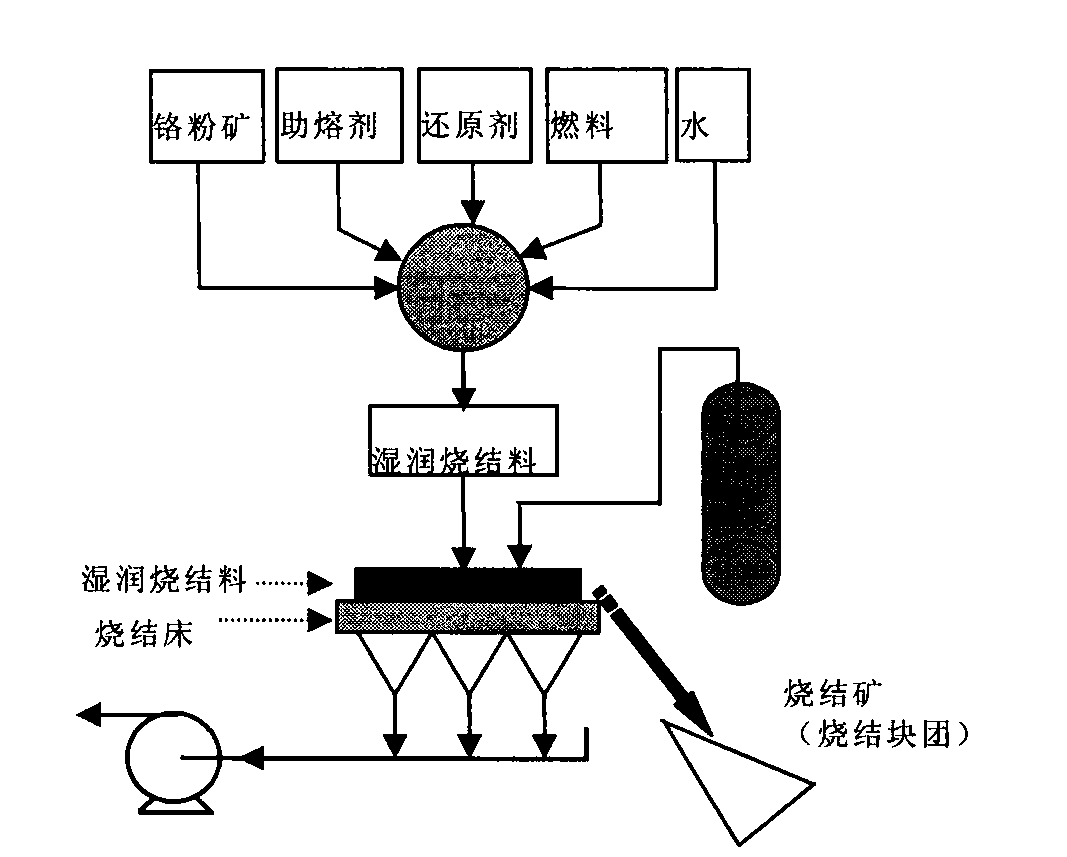

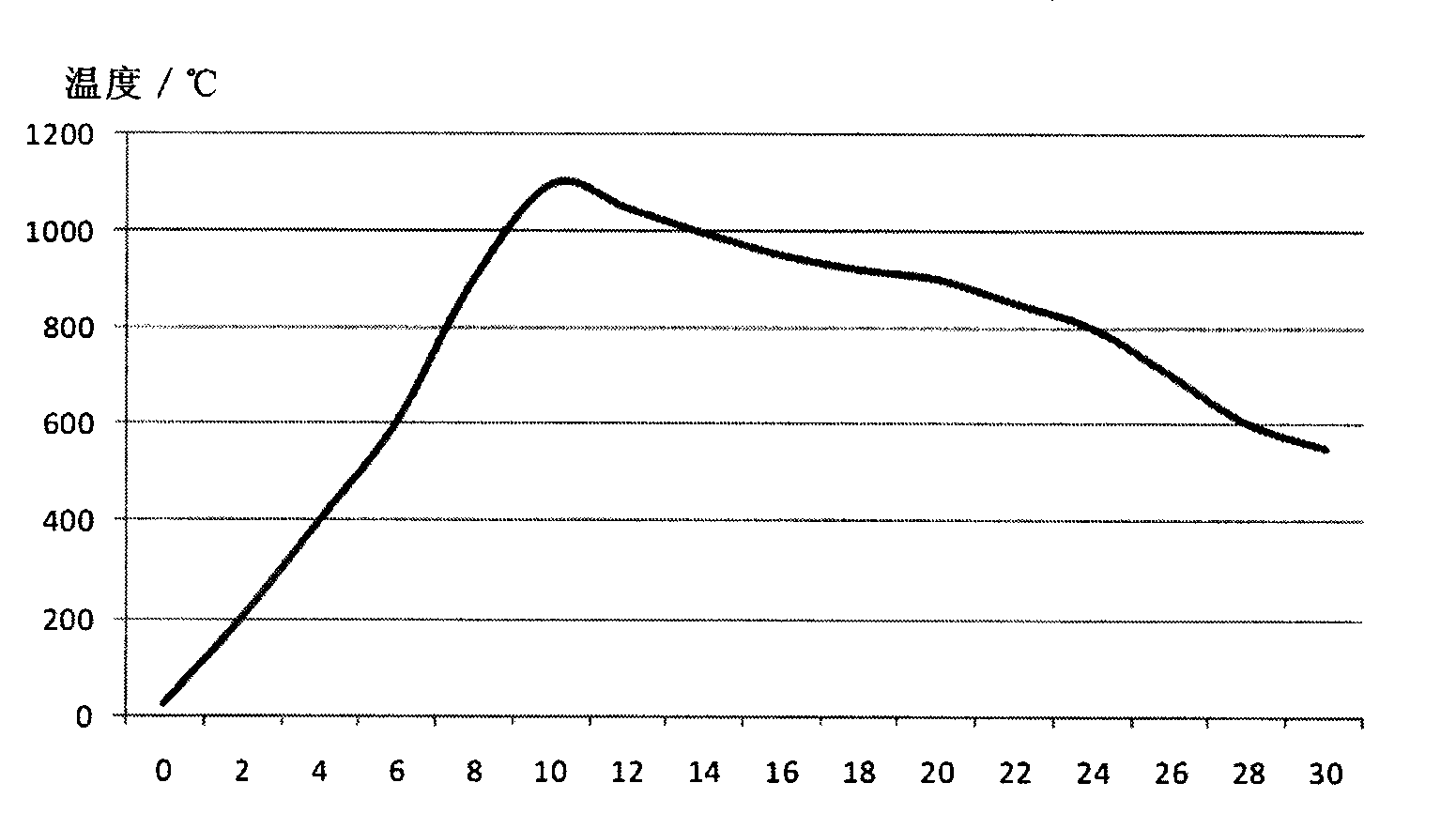

Pretreatment method for chromium powder ore used for smelting production of ferrochrome alloy

The invention provides a pretreatment method for a chromium powder ore used for smelting production of a ferrochrome alloy. The method comprises the steps of 1) mixing the chromium powder ore with a fluxing agent, a reducing agent and a fuel to obtain a mixture; and 2) sintering the mixture to obtain a sintered material. The method is short in process flow and low in sintering cost and is simple and practicable, and production of powder ore pollutions is not easy, so that relatively cheap powder chromium ore can be fully used, smelting consumption can be decreased greatly, and further smelting cost of the ferrochrome is reduced. The sintered material obtained by the sintering treatment method can be directly introduced into an ore smelting electric arc furnace for smelting after smashing. The method can enhance reducibility of furnace charging materials, reduce energy consumption and decrease usage proportion of other auxiliary materials such as coke, silica and the like in the smelting furnace charging materials. At the same time, possibility of reversing materials is greatly decreased, production security is increased and probability of production accidents is reduced greatly.

Owner:中国中化股份有限公司 +1

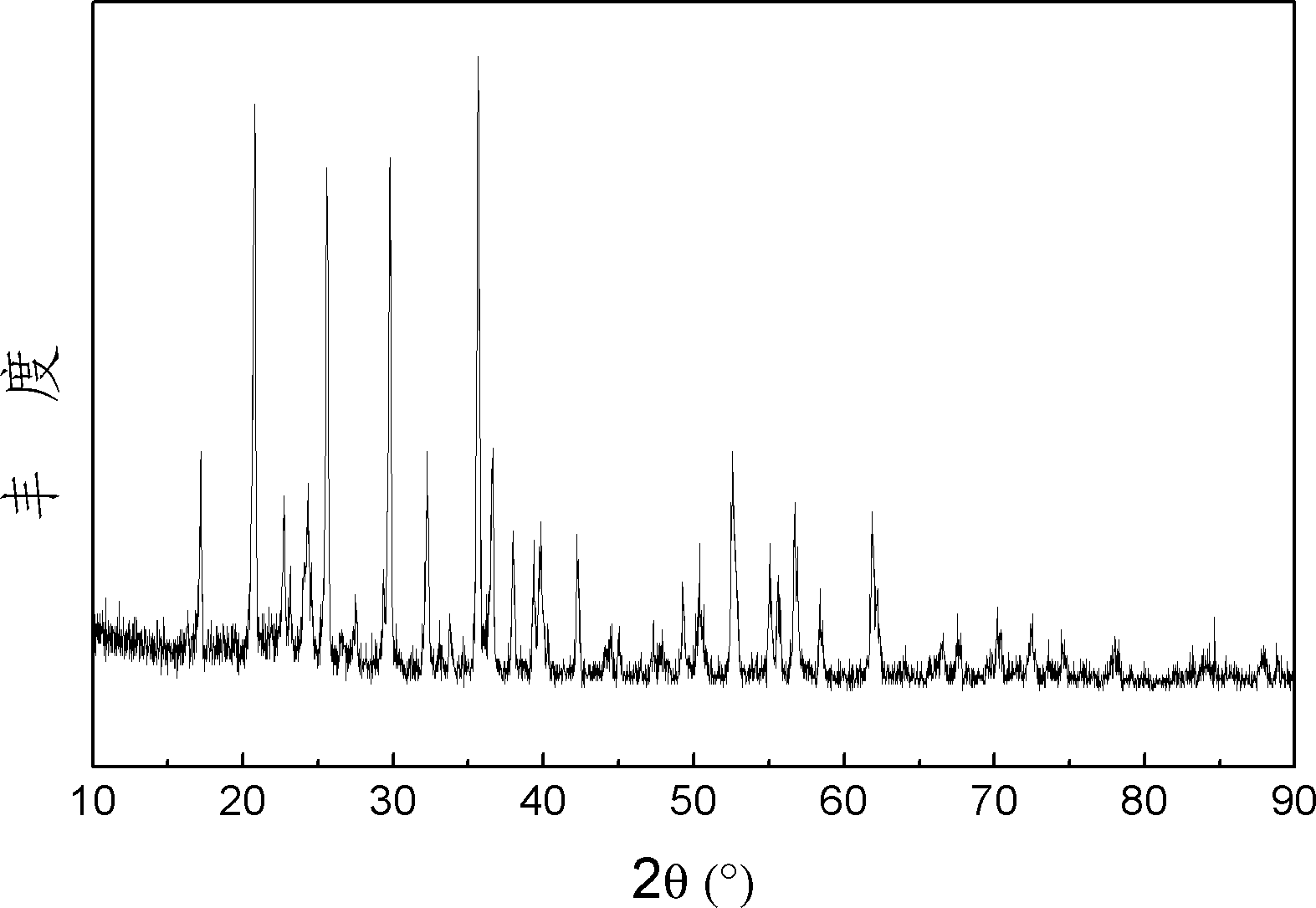

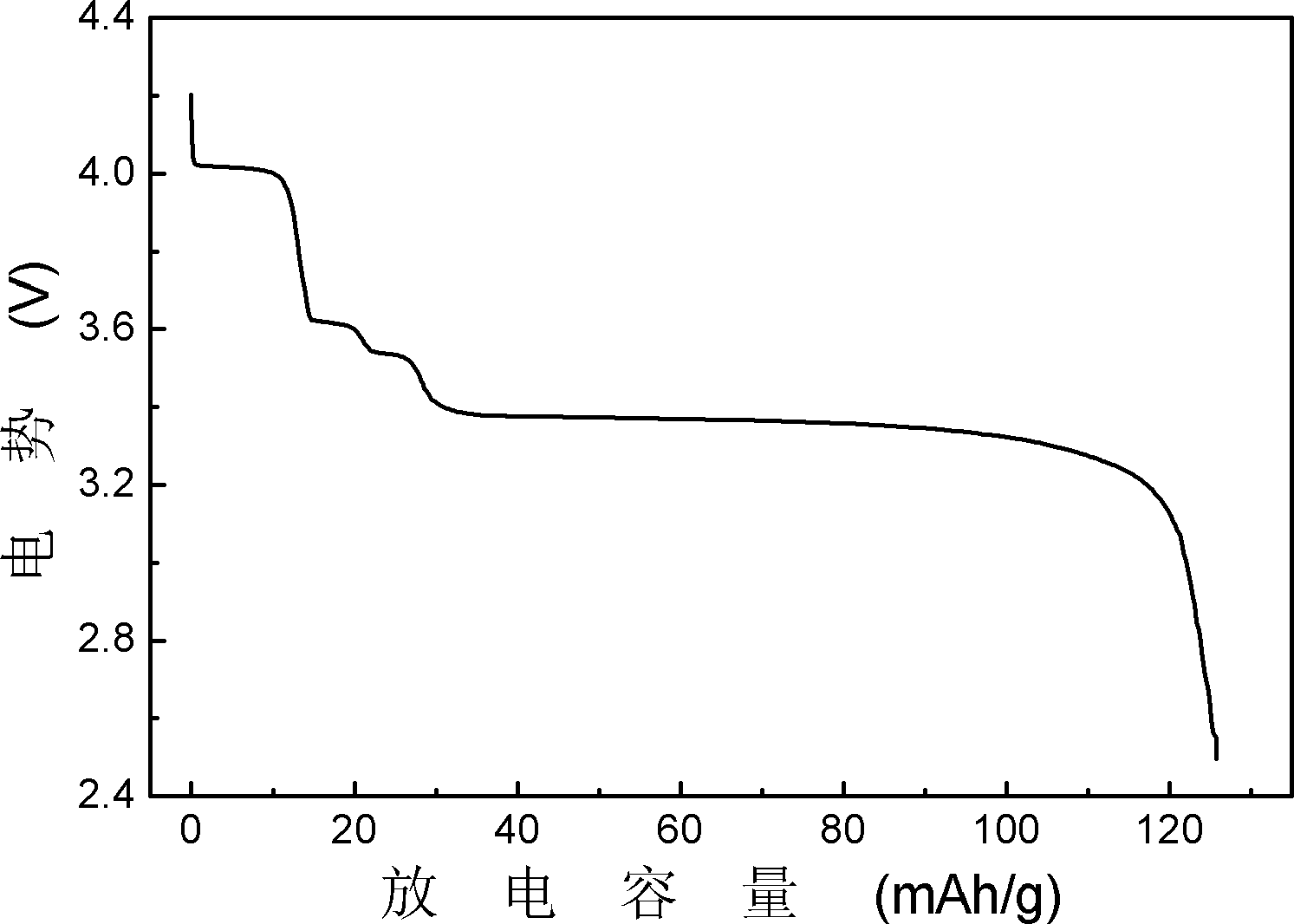

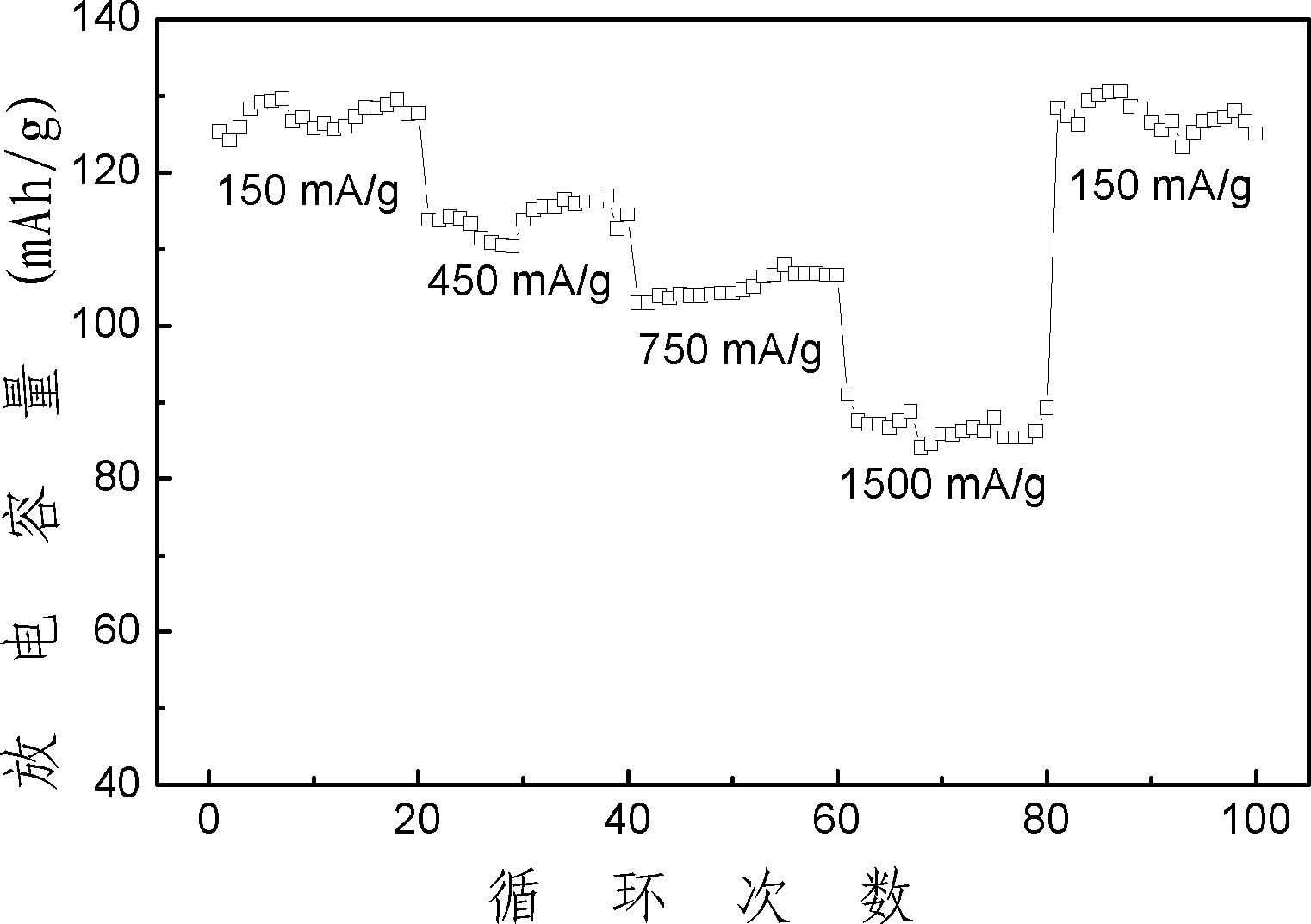

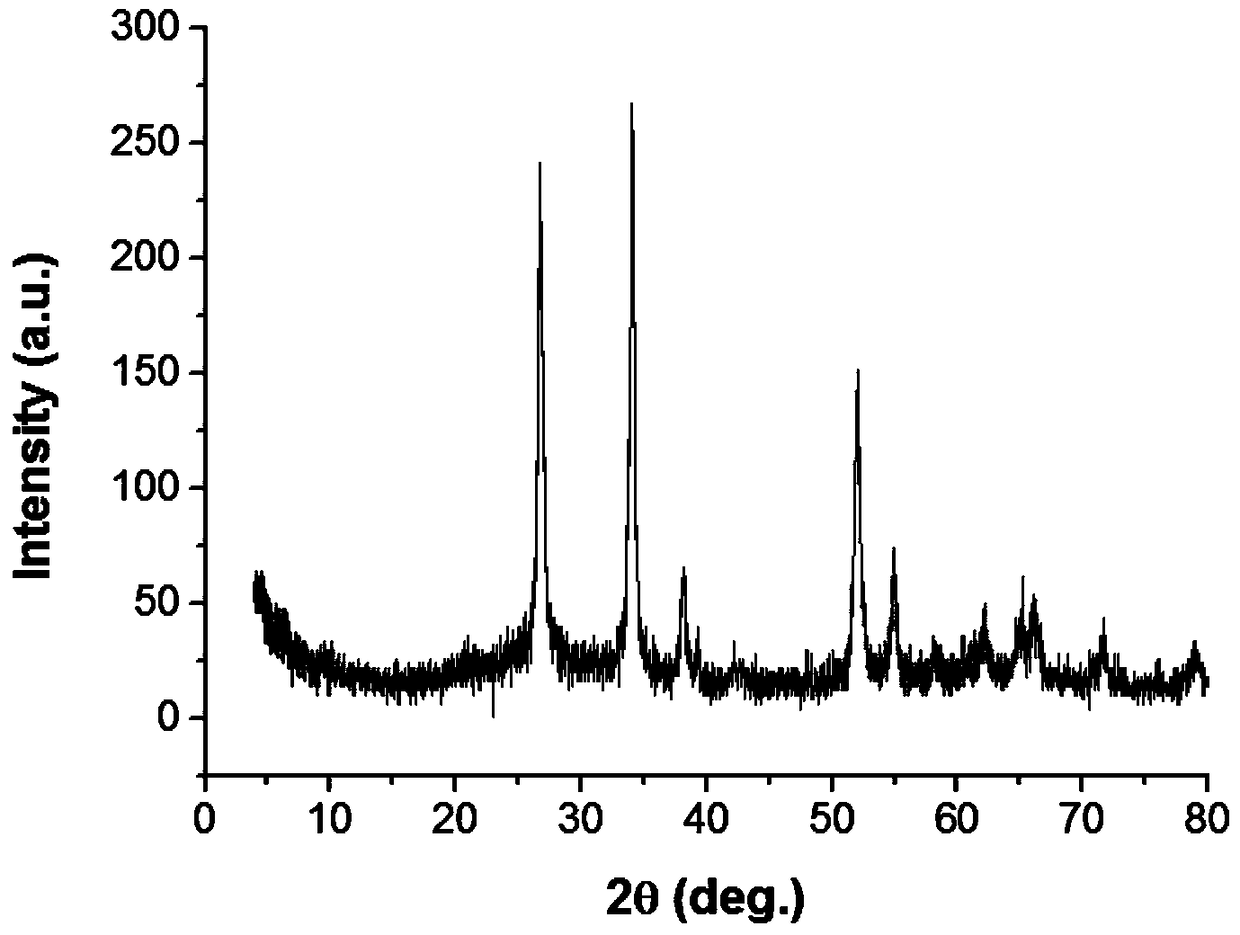

Method for preparing lithium ion battery anode material xLiFePO4.yLi3V2(PO4)3

InactiveCN102208620AImprove rate discharge performanceThe synthesis process is simpleCell electrodesLithiumPhosphate

The invention discloses a method for preparing a lithium ion battery anode material xLiFePO4.yLi3V2(PO4)3, and relates to a method for preparing a lithium ion battery anode material. The method solves the technical problems of poor magnification performance and complex synthesis process in the conventional method for synthesizing the xLiFePO4.yLi3V2(PO4)3. The method comprises the following steps of: weighing lithium source, iron source, vanadium salt, phosphate and carbon source, mixing, and performing wet milling, pre-sintering and calcination to obtain the xLiFePO4.yLi3V2(PO4)3. The process is simple, and environmental pollution easily caused in a liquid phase method is not caused. The anode material prepared by the method has good magnification discharge performance; and during 10C discharge, the discharge specific capacity is 90mAh / g, and the capacity is nearly not attenuated after 20 times of cycles.

Owner:HARBIN INST OF TECH

High-salt industrial wastewater treatment process system

ActiveCN104211204ASave HClPrevent scalingMultistage water/sewage treatmentProcess systemsSoftened water

The invention discloses a high-salt industrial wastewater treatment process system. The system includes a raw water equalizing pool, a mechanical accelerated clarification pool, a clear water pool, a multi-medium filter, a weak acid cation bed, a softened water pool, a self-cleaning filter, an ultrafilter, an ultrafilted water pool, a primary RO security filter, a primary RO instrument, a concentrated water pool, a secondary RO security filter, a secondary RO instrument, a tertiary RO instrument, a pre-desalted water tank, a lime device, a FeCl3 device, a PAM device, a MgO device, a soda ash device, a HCl device, a NaOH device, a scale inhibitor device and a reducing agent device; and the process system also comprises, related supporting, a cleaning system, an adding medicine storage system, a compressed air system, a wastewater neutralization system, an electrical system and an instrument control system in order to ensure the long-term stable operation of the process system. The high-salt industrial wastewater treatment process system has the advantages of operation at a high pH value all the time, effective avoiding of the pollution plugging of the RO instrument, and realization of investment and operation cost saving by utilizing the regeneration characteristic of weak acid cation resin.

Owner:国能朗新明环保科技有限公司

Method for hydrophilic modification on surface of polyurethane carrier

The invention discloses a method for hydrophilic modification on the surface of a polyurethane carrier. The method comprises the following steps: S1, performing plasma surface treatment on a polyurethane carrier so as to obtain a polyurethane carrier after plasma surface treatment; S2, enabling the polyurethane carrier after plasma surface treatment in the step S1 to contact with a polycation solution to be subjected to polycation solution treatment so as to obtain a polycation modified polyurethane carrier; and S3, enabling the polycation modified polyurethane carrier obtained in the step S2to contact with a polyanion solution to be subjected to polyanion solution treatment, so as to obtain a polyanion modified polyurethane carrier. As the polyurethane carrier is subjected to plasma surface treatment, layer-layer self assembling is performed alternatively by enabling the polyurethane carrier to contact with the polycation solution and the polyanion solution in sequence, surface modification on the polyurethane carrier is achieved, and the modified polyurethane carrier has good hydrophilcity and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

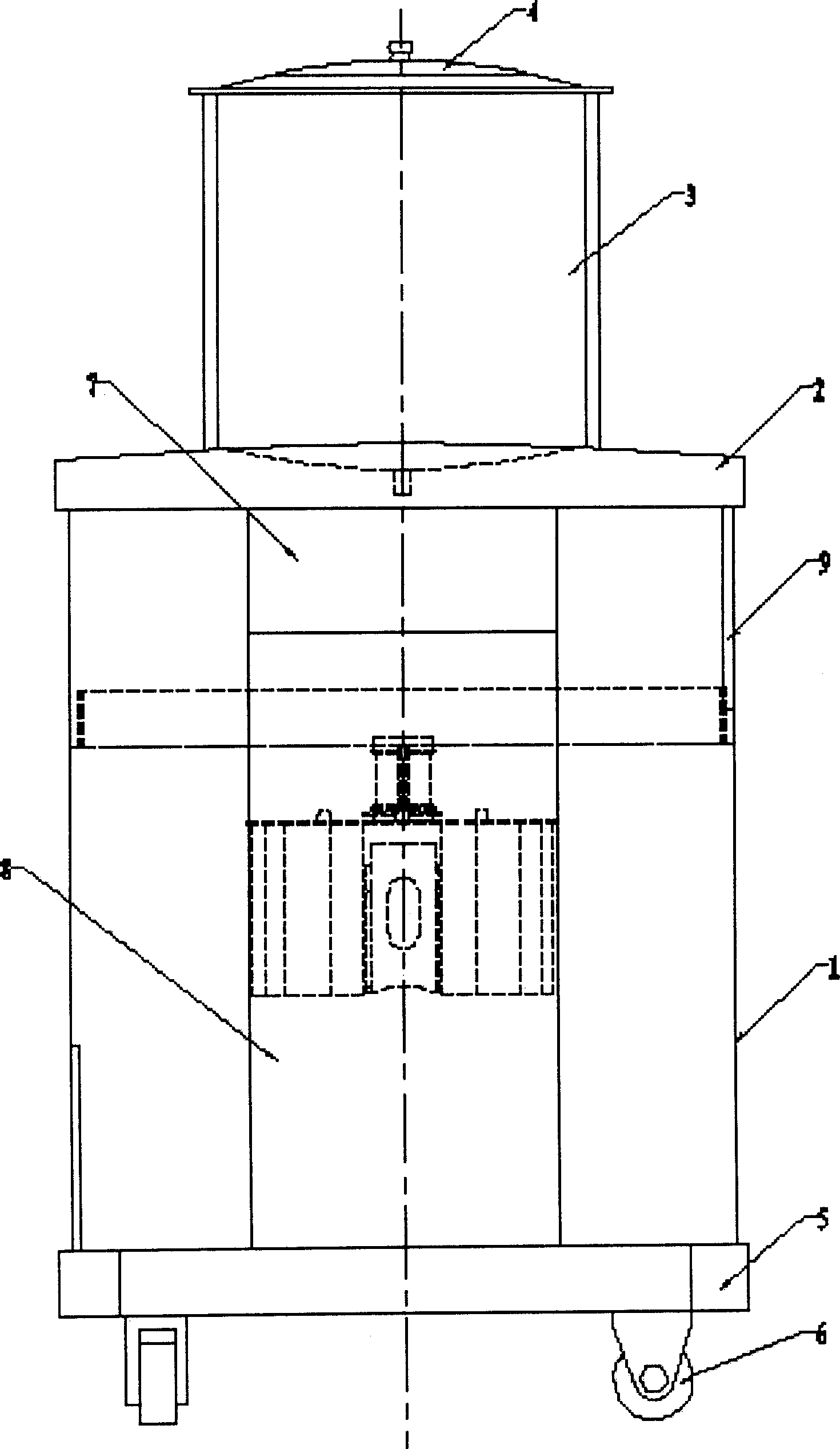

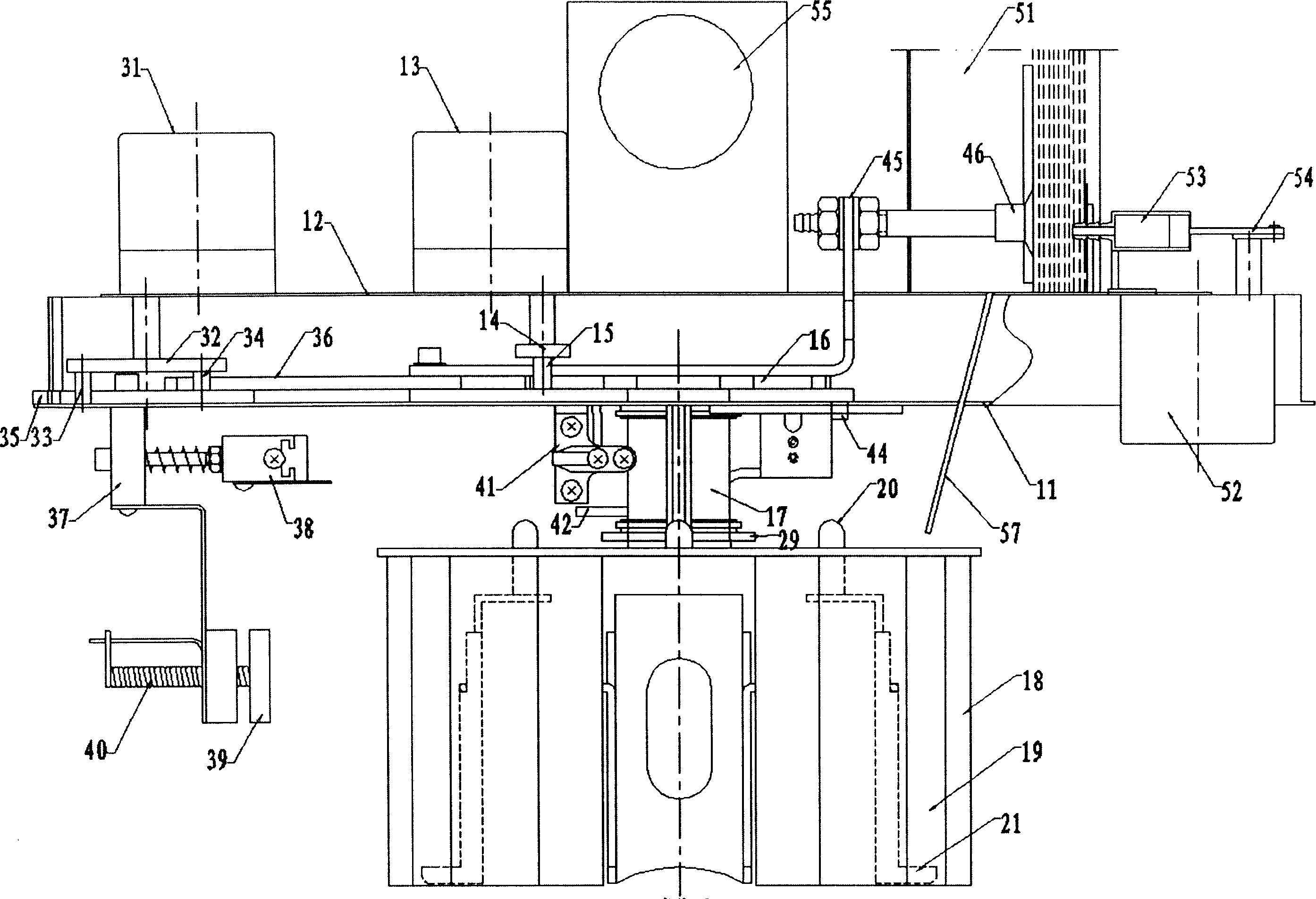

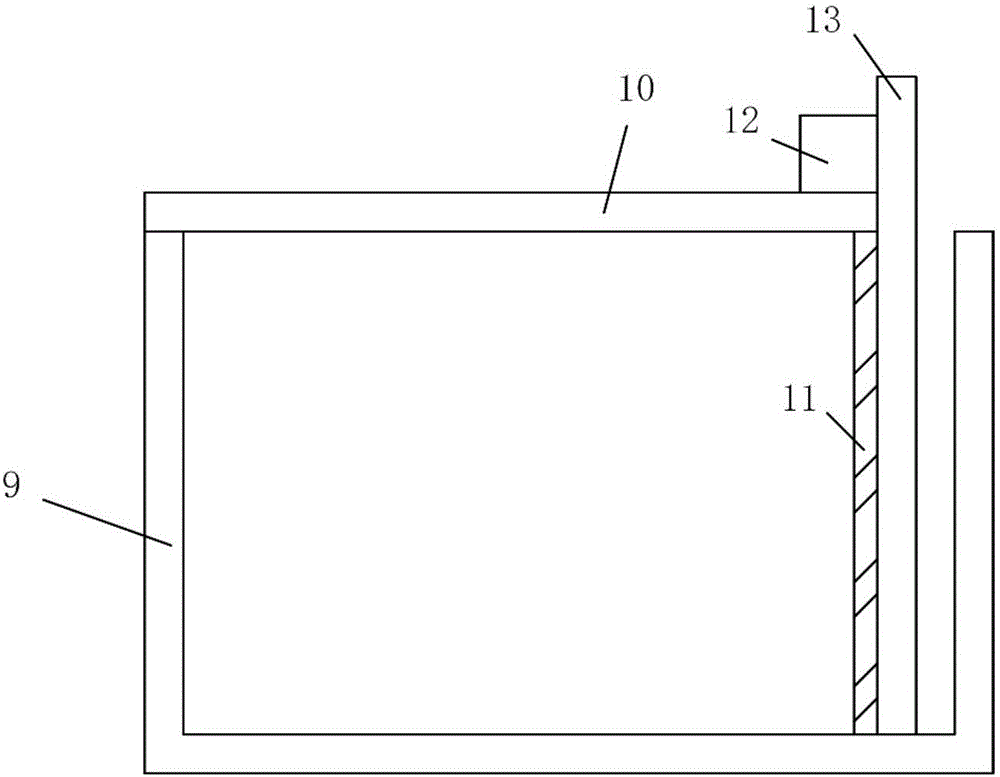

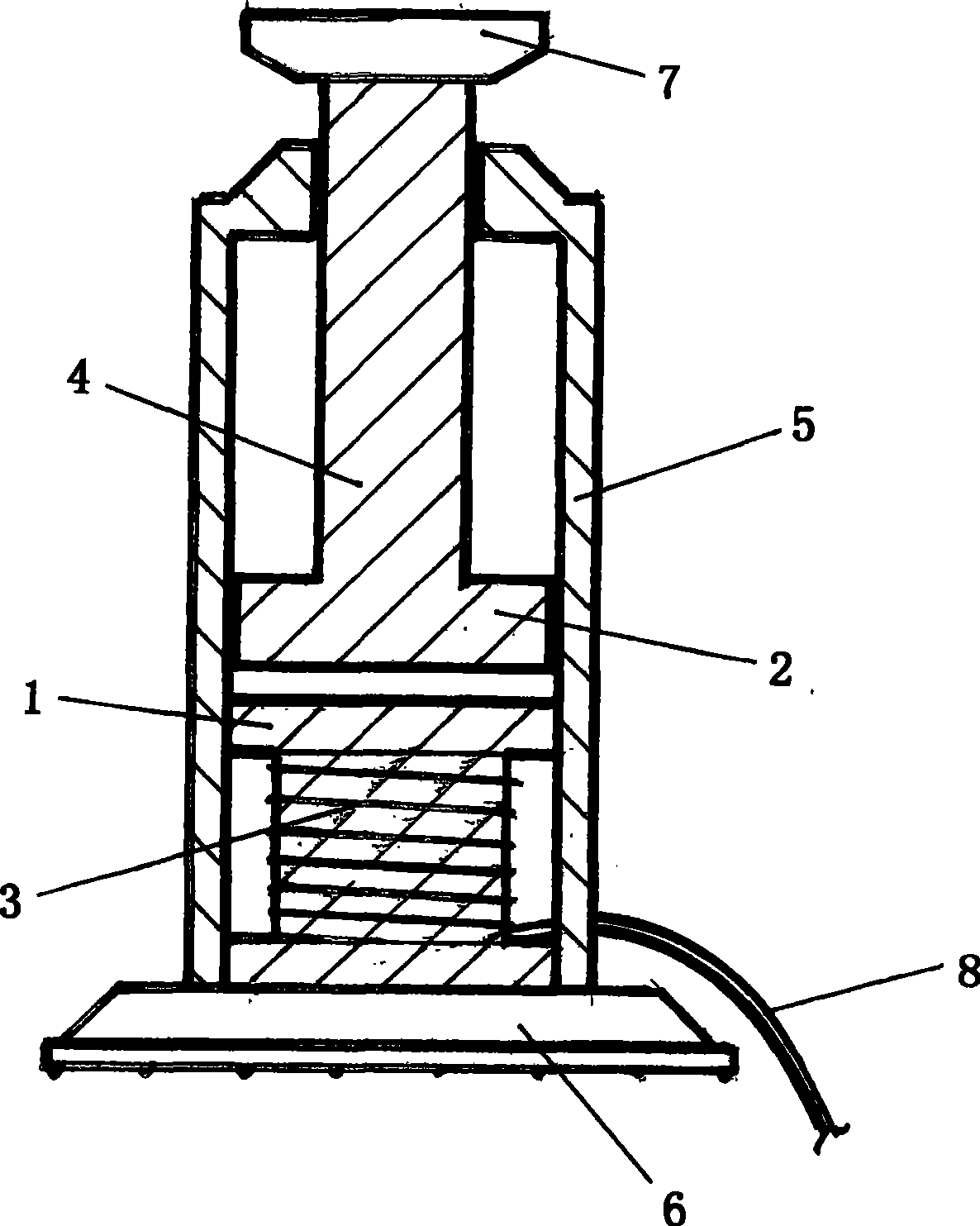

Minitype vertical liquid packing machine

InactiveCN1907810ALess flow pathNot prone to pollutionWrapper twisting/gatheringPackaging automatic controlPulp and paper industrySlide plate

The invention relates to a small upright liquid packing machine, which is formed by cylinder frame, liquid pot, and packing integration, wherein the packing integration comprises rotator, main controller, bag feeder, filler, and sealing device; the rotator is formed by rotational motor, dial fork disc, mume wheel, and the rotational wheel with several bag grooves; the main controller is formed by main control motor, main control dial fork disc, upper sliding plate, and lower sliding plate; the bag feeder is formed by bag chamber, adsorption disc, adsorption motor, and plug pump; the filler is formed by blower, micro switch, filling motor and filing ejector; the sealing device is formed by sealing block, sealing compressor and sealing heater. The invention can pack liquid in small patch, with high automatic degree, stable operation, better sealing property, and wider application, without liquid pollution.

Owner:南浩俊

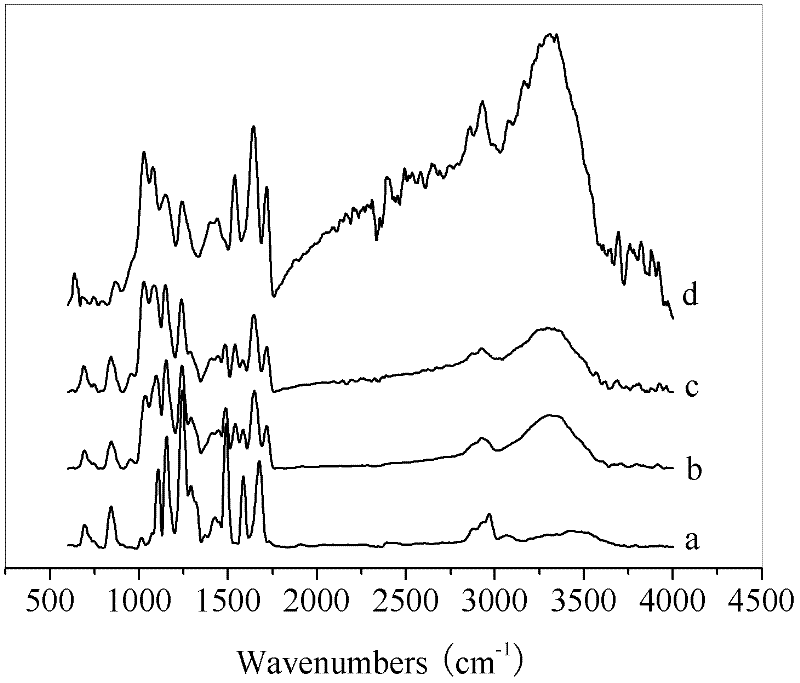

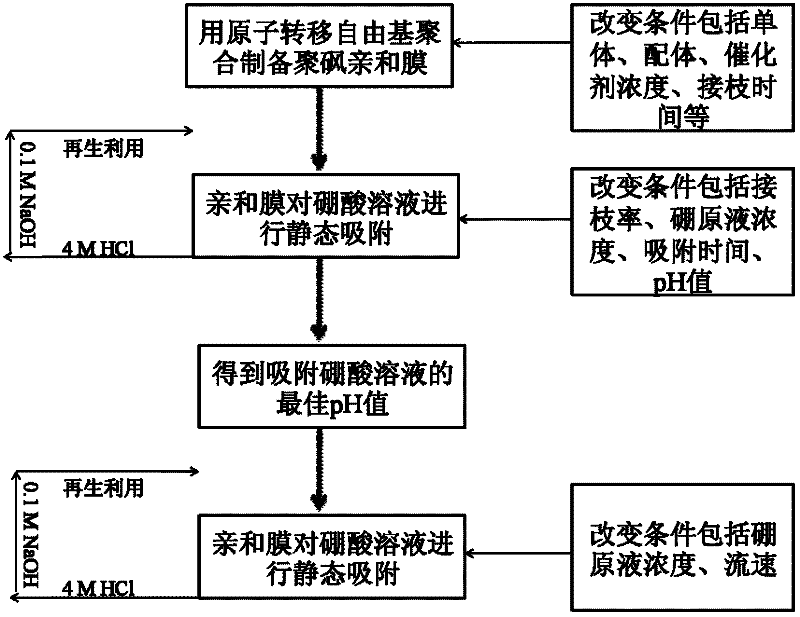

Boron-removed polysulphone modified affinitive membrane as well as preparation method and application

InactiveCN102512993AReduce mass transfer resistanceNot prone to pollutionSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisNitrogen gasCuprous chloride

The invention relates to a boron-removed polysulphone modified affinitive membrane as well as a preparation method and application. The preparation method of the affinitive membrane comprises the following steps of: (1) adding a chloromethylation polysulphone membrane prepared by adopting a phase inversion method, a water solution of methacrylic acid-2-putoutangxiananyizhi, copper chloride and N, N, N', N', N'-pentamethyl diethylene triamine into a container and adding deionized water; and (2) introducing nitrogen gas, adding cuprous chloride, introducing the nitrogen gas continuously, sealing, reacting, taking out the membrane, placing into anhydrous alcohol, washing, washing by using the deionized water, taking out and airing so as to prepare the boron-removed polysulphone modified affinitive membrane. The original physical property of polysulphone is retained by the membrane disclosed by the invention, and the effectiveness of resin affinity and membrane separation is integrated by the membrane after being modified; moreover, the boron-removed polysulphone modified affinitive membrane has smaller mass transfer resistance in comparison with resin because of a porous structure, any phase change does not occur in the boron removing process of the affinitive membrane, and the pollution is not easy to generate; and moreover, the operation of equipment is simple, and the amplification is easy.

Owner:TIANJIN POLYTECHNIC UNIV

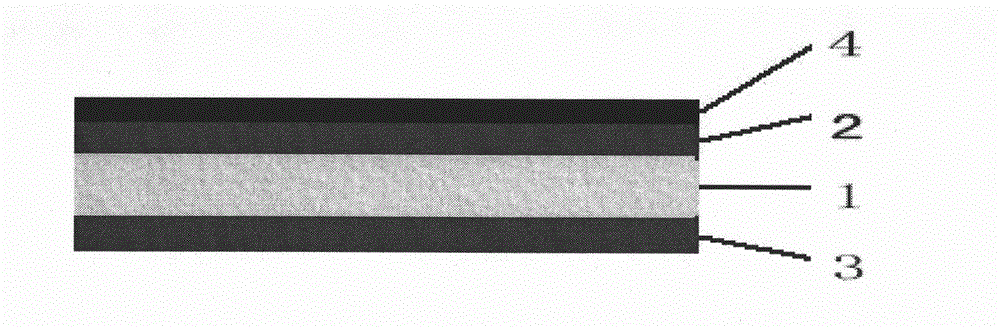

Polypropylene textile environment-friendly advertising cloth

InactiveCN102744938AReduce weightSimple and quick installation and disassemblySynthetic resin layered productsEnvironmental resistancePolyvinyl chloride

The invention relates to a polypropylene textile environment-friendly advertising cloth. Polypropylene is adopted as the main raw material for preparing the novel environment-friendly advertising cloth with a plurality of characteristics and with a polypropylene cloth as the base cloth. The advertising cloth can include a polypropylene base cloth layer, a waterproof coloring layer, and a macromolecular ink absorption layer. Compared with the currently widely used polyvinyl chloride coated mesh sandwiched cloth, the advertising cloth provided in the invention has the advantages of good inkjet printing effect, light weight, cost saving, and more environment-friendly use and treatment after use.

Owner:TAYA CANVAS SHANGHAI CO LTD

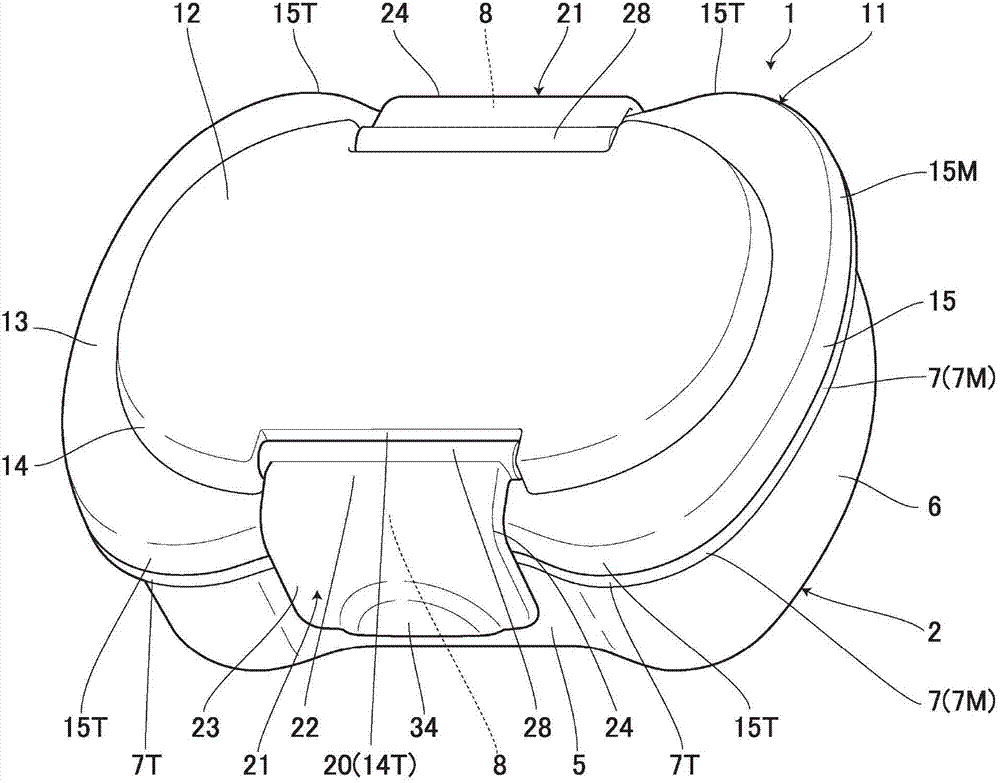

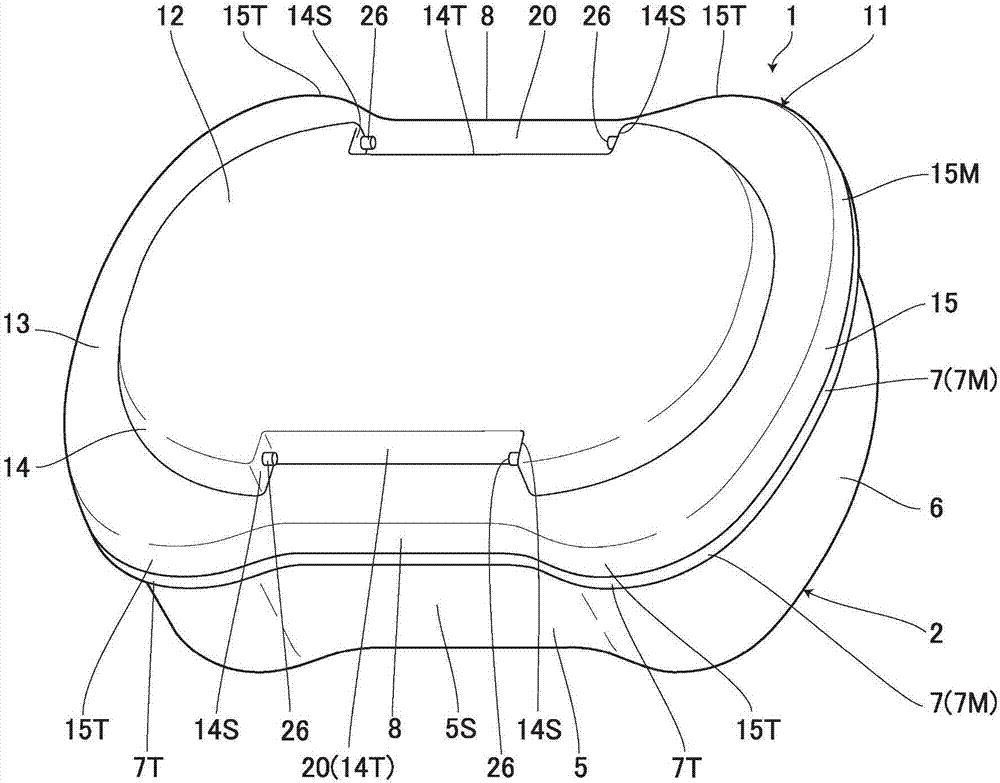

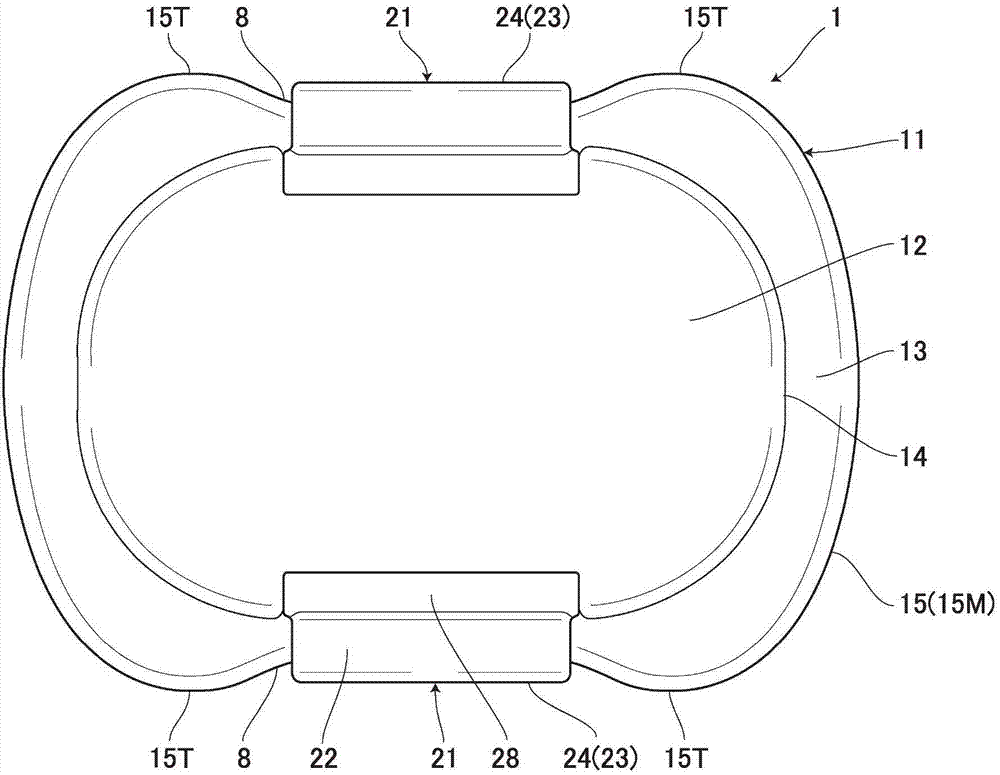

Food container

The present invention provides a food container having a structure where a hinge part is difficult to damage. The food container comprises a container main body (2); a cover body (11) covering an upper opening of the container main body; and a hinge part (21) arranged at the cover body in a free manner and clamped on the container main body. The hinge part at the clamping state is disposed at the outer side in relative to outmost protrusions 5T and 7T of the container main body or the cover body, so the hinge part is not impacted by the outside when the hinge part is clamped in the cover body. In particular, the hinge part is not impacted by the outside, the joint part of the cover body and the hinge part, where damages often occur, is not damaged. In addition, under the conditions where the food container falls down to the ground, the hinge part does not contact with the ground because only the container main body and the cover body contact the ground, thus the hinge part (21) is not easy to contaminate when the container is opened and closed, and the food container is sanitary.

Owner:THERMOS LLC +1

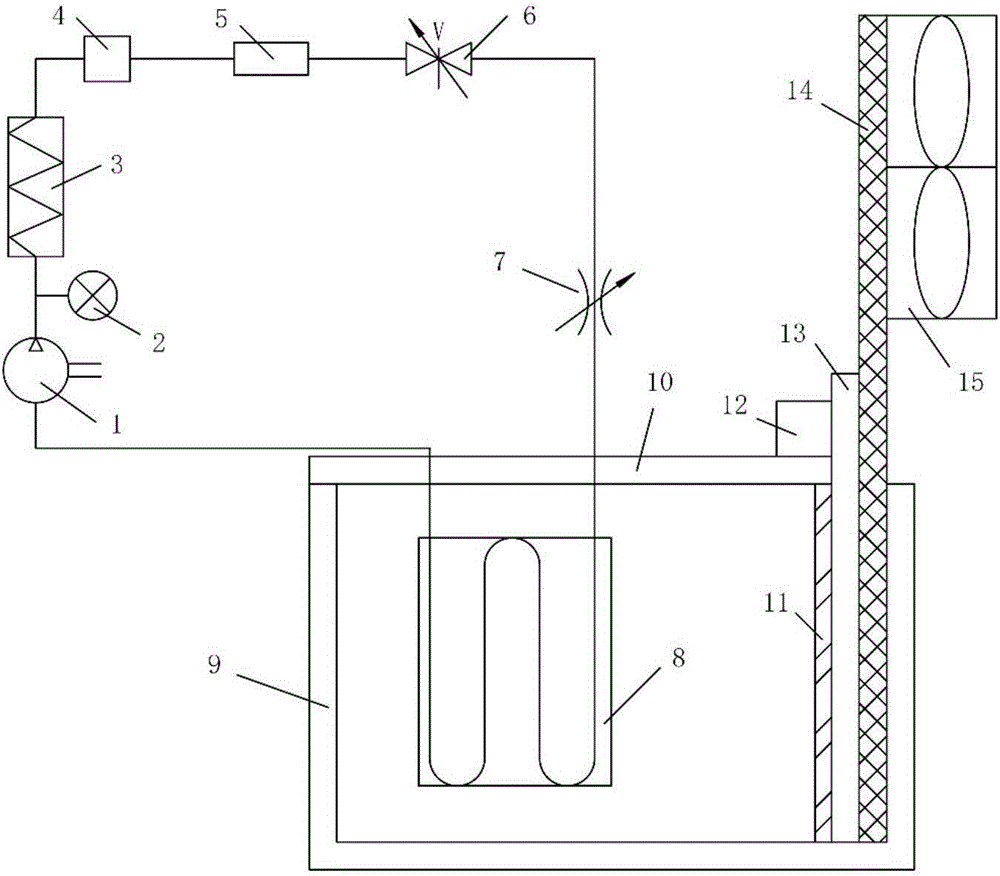

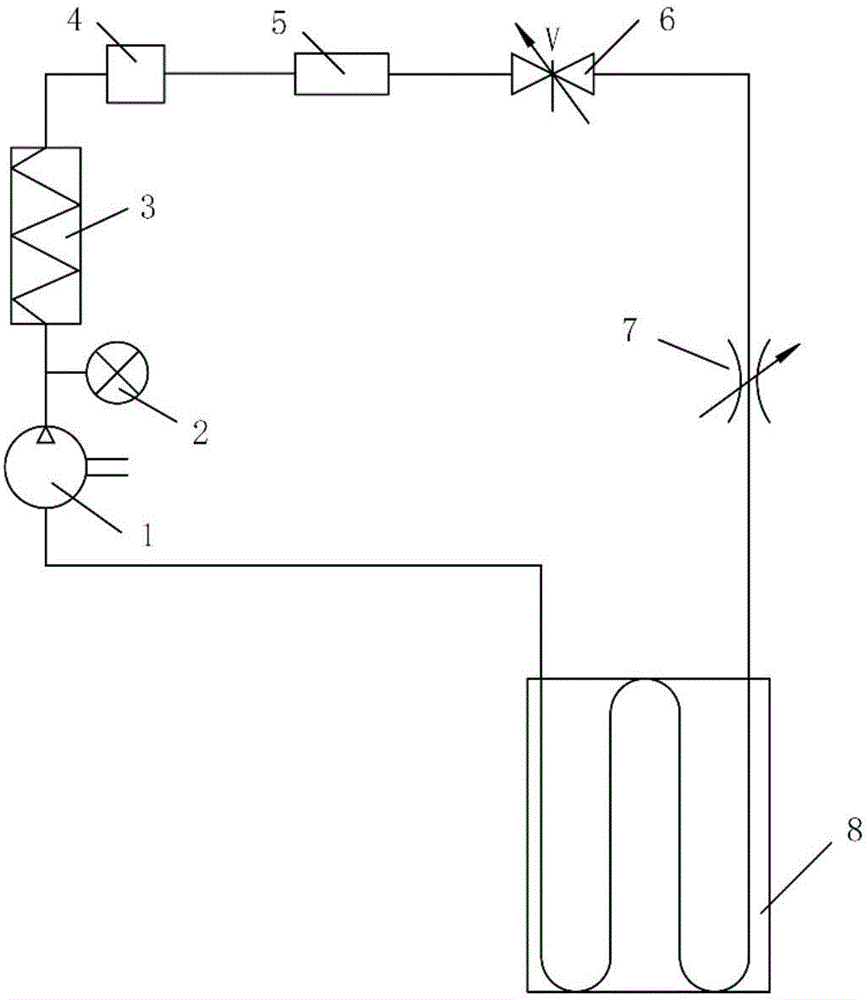

Small ice storage temperature adjusting fan system

InactiveCN106225127ANot easy to polluteNot prone to pollutionLighting and heating apparatusAir conditioning systemsCircular loopIce storage

The invention discloses an ice storage temperature adjusting fan system. The ice storage temperature adjusting fan system is composed of a refrigeration subsystem, an ice storage subsystem and a cold releasing subsystem; a closing area is defined by an ice storage groove, a cover plate and a copper plate in the ice storage subsystem, and is filled with an ice storage agent, the cover plate can be detached, a heat isolation plate is arranged between the copper plate and a heat pipe, and vertical movement is controlled through a motor; combination of the heat pipe and a fan is used in the cold releasing subsystem, and therefore the ice storage agent and the external air are subject to efficient heat exchange, and the air temperature is rapidly reduced. Compared with an existing ice storage air conditioner technology, a cold releasing circular loop is simplified, and miniaturization of the system is facilitated; compared with an existing air conditioner fan device, the system saves the electric charges, and the ice storage agent can be repeatedly used.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

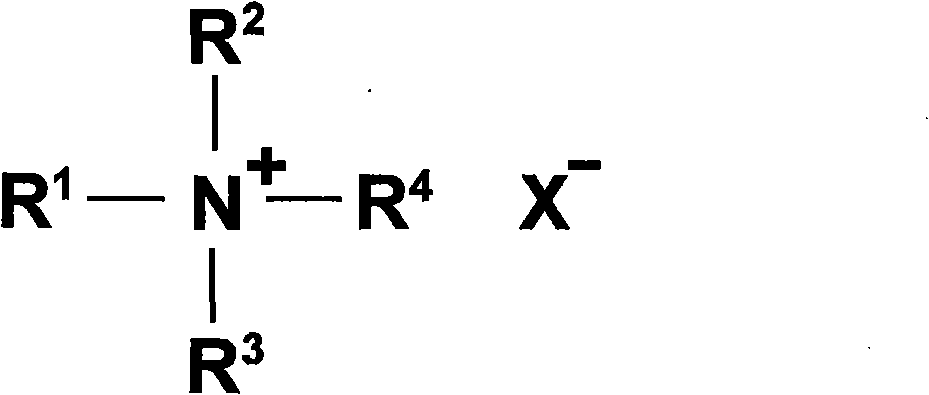

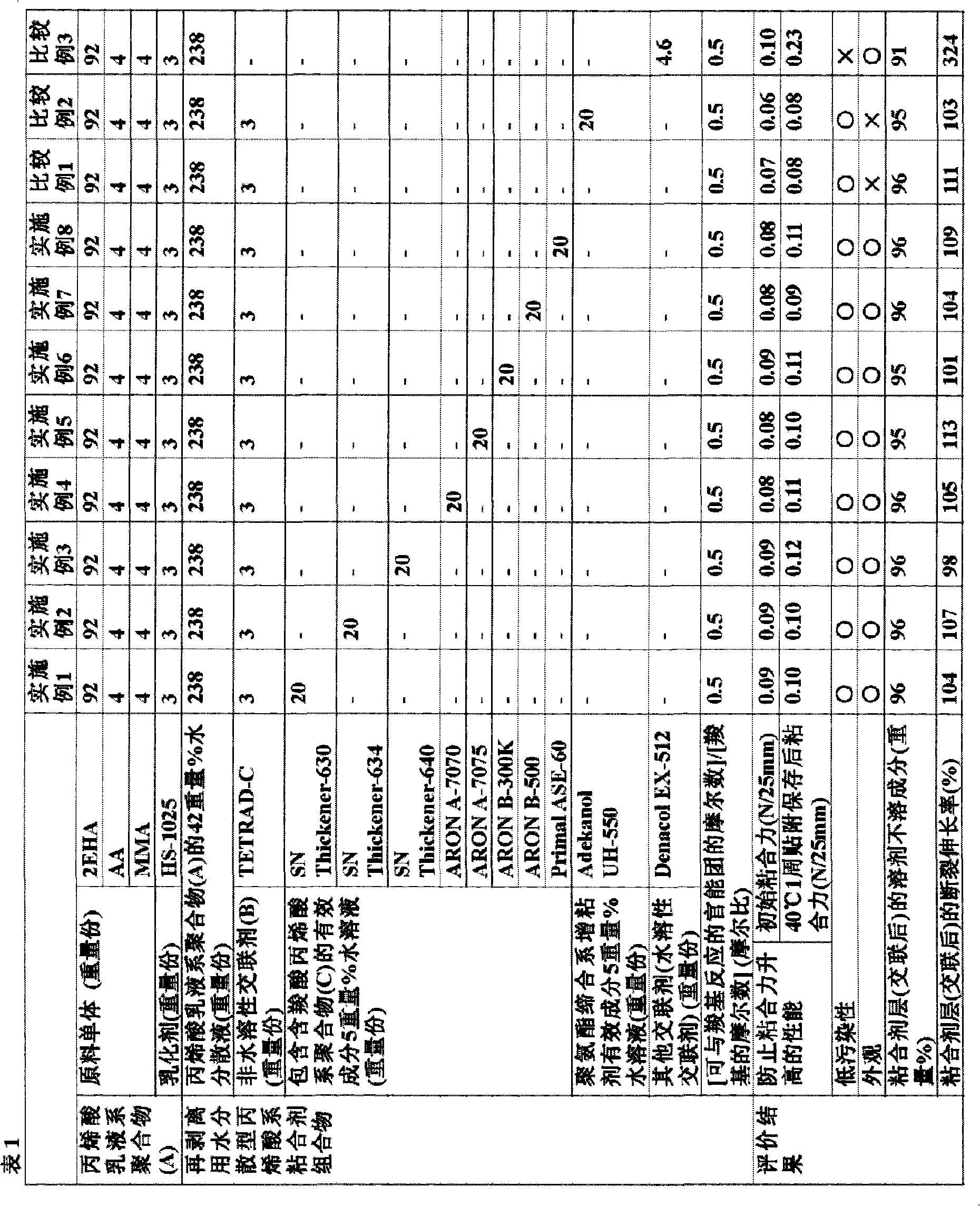

Removable water-dispersible acrylic pressure-sensitive adhesive composition and pressure-sensitive adhesive sheet

ActiveCN102676094AExcellent peelabilityGood adhesionAcid polymer adhesivesEster polymer adhesivesPolymer scienceWater dispersible

A removable water-dispersible acrylic pressure-sensitive adhesive composition according to the present invention includes an acrylic emulsion polymer (A), a water-insoluble crosslinking agent (B), and a carboxylic-acid-containing acrylic polymer (C). The polymer (A) includes a (meth)acrylic alkyl ester and a carboxyl-containing unsaturated monomer as essential constitutive monomers and has a content of the (meth)acrylic alkyl ester of 70 to 99.5 percent by weight and a content of the carboxyl-containing unsaturated monomer of 0.5 to 10 percent by weight, each based on the total amount of constitutive monomers. The polymer (C) includes (meth)acrylic acid as an essential constitutive monomer and has a total content of acrylic acid and methacrylic acid of 11 percent by weight or more based on the total amount of constitutive monomers.

Owner:NITTO DENKO CORP

Hydrophilic polypropylene-nylon composite hollow fiber membrane and preparation method thereof

The invention discloses a hydrophilic polypropylene-nylon composite hollow fiber membrane and a preparation method thereof. The hydrophilic polypropylene-nylon composite hollow fiber membrane comprises the following components in parts by mass: 10-35 parts of a polypropylene-nylon composite material, 45-70 parts of a nonpolar ester thinning agent, 1-25 parts of a polar ester thinning agent and 0.1-0.5 part of an antioxidant, wherein the polypropylene-nylon composite material contains polypropylene, a compatilizer and nylon, and the mass ratio of polypropylene to the compatilizer to the nylon is (90-60):(0-10):(5-30). According to the hydrophilic polypropylene-nylon composite hollow fiber membrane, the proper compatilizer is utilized for carrying out capacity expansion and modification on polypropylene and the nylon so as to prepare the polypropylene-nylon composite material, hydrophobic polypropylene is subjected to hydrophilic blending modification, and meanwhile, the nylon is added, so that the polarity of a membrane material is increased, the hydrophilicity of the composite material can be remained for a long time, the efficiency of a preparation process is high, and a method is simple and is suitable for industrial production; a thermally induced phase separation method is utilized for spinning so as to prepare the hollow fiber membrane, so that the process is simple, a pore structure of the membrane is easy to regulate and control, and the stability of a membrane yarn is good.

Owner:贵州益华膜科技有限公司

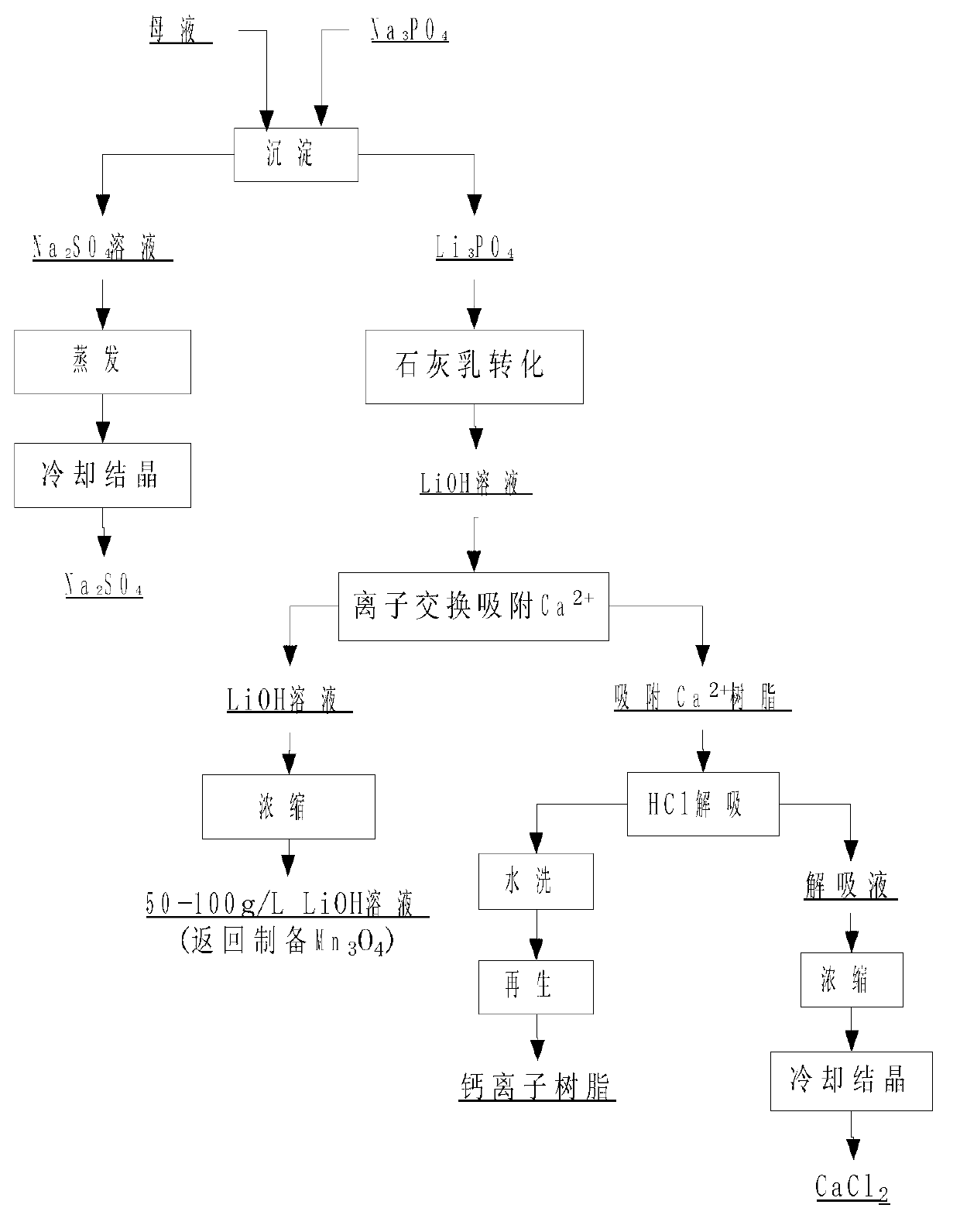

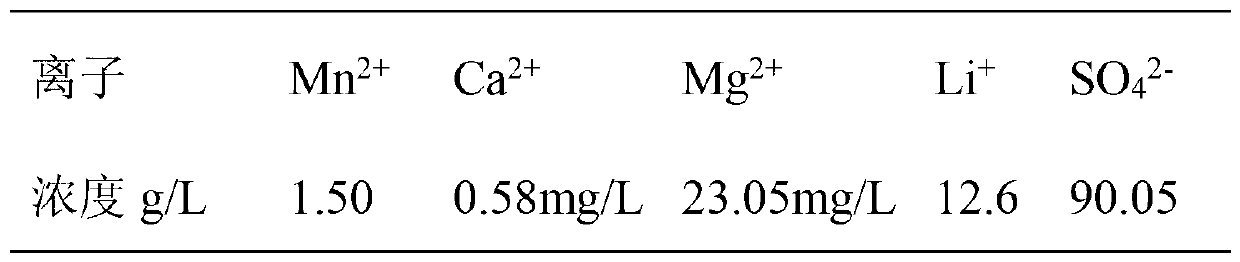

Cyclic and comprehensive utilization method of sodium-free mangano-manganic oxide production mother solution

InactiveCN103122411AImprove conversion rateNot prone to pollutionProcess efficiency improvementSodium phosphatesLithium hydroxide

The invention relates to a cyclic and comprehensive utilization method of a sodium-free mangano-manganic oxide production mother solution, which comprises the following steps: 1, adding a sodium phosphate solution into a sodium-free mangano-manganic oxide production mother solution, controlling the mol ratio of the sodium phosphate to lithium sulfate at (2.0-2.4):3, and filtering after reaction is finished, wherein the filter residues are lithium phosphate and manganese phosphate solids; and 2, washing the obtained filter residues, drying, grinding, screening, adding the lithium phosphate and manganese phosphate powder and calcium hydroxide into hot water according to a lithium phosphate / calcium hydroxide mol ratio of 1:(2.25-3), and reacting to obtain a lithium hydroxide solution; and treating the obtained solution through an ion exchange resin to obtain a lithium hydroxide solution of which the calcium ion concentration is lower than 1 ppm, and using the lithium hydroxide solution as a precipitating agent in the sodium-free mangano-manganic oxide preparation process. According to the invention, the cyclic utilization rate of lithium is up to 96% or above, the byproducts of sodium sulfate and calcium chloride are generated simultaneously, the economic benefits are favorable, the production process is less prone to cause environmental pollution, the equipment investment is low, and industrial production can be easily realized.

Owner:CENT SOUTH UNIV

Novel glass adhesive and preparation method therefor

InactiveCN107353846AImprove adhesionNot easy to fall offNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEpoxyAdhesive

The invention discloses a novel glass adhesive. The novel glass adhesive is prepared from the following raw materials in parts by weight: 20-40 parts of styrene-butadiene rubber, 13-22 parts of polyacrylic acid, 15-27 parts of epoxy resin, 7-14 parts of methyl methacrylate, 8-17 parts of starch, 11-18 parts of polyurethane, 15-26 parts of acetone, 2-5 parts of Chinese herbal medicine mixture, 17-28 parts of filler, 3-6 parts of modifier, 1-3 parts of oxide additives and 4-7 parts of curing agent. The novel glass adhesive is good in adhesiveness and long in service life, is not prone to spalling and is not prone to chemical residue generation and environmental pollution causing.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

Magnetic force hoisting roof

The invention provides a magnetic raising-power elevator. An electromagnet is arranged under a casing connected with a seat. An outer-wound coiled power-supply wire is threaded through the casing; a magnet block provided with the same magnetism as the electromagnet is oppositely arranged on the lower part of the electromagnet and the connected top part is threaded through the top of the casing to be connected with a flat top part. The invention adopts the like-pole repulsion theory to oppositely arrange the electromagnet and magnetic block which are provided with the same magnetism, after the electromagnet is switched on power and generates magnetic power the upper magnet block is driven to rise to generate the raising power used for elevating common objects.

Owner:郑强

Hydroponics liquid for herba menthae

InactiveCN106631294AImprove germination rateIncrease productionCalcareous fertilisersMagnesium fertilisersPropolisSucrose

The invention relates to hydroponics liquid for herba menthae. The hydroponics liquid comprises water, inorganic nutrients, carbon sources, vitamins, growth regulation substrates, algae inhibitors and antibacterial agents. The inorganic nutrients comprise potassium nitrate, potassium sulfate, calcium chloride, magnesium chloride, boric acid, ammonium molybdate and manganese sulfate, the carbon sources comprise sucrose and amino acid, the vitamins include vitamins A5, B1, B5 and B6, the growth regulation substrates comprise beta-indoleacetic acid, cytokinin and gibberellin, the algae inhibitors comprise straw bio-oil and activated carbon, and the antibacterial agents comprise flos caryophylli oil and natural propolis extract liquid. The hydroponics liquid has the advantages that the hydroponics liquid is used for carrying out hydroponics on the herba menthae and contains abundant mineral ions and the vitamins required by growth of the herba menthae, and accordingly sufficient nutrition can be provided for growth of the herba menthae; sufficient illumination is required by the herba menthae but can easily drive algae to excessively grow, and accordingly the algae inhibitors need to be added into the hydroponics liquid; bacteria are easy to breed in the hydroponics liquid and can affect growth of the herba menthae, and accordingly the antibacterial agents are added into the hydroponics liquid.

Owner:DANYANG HUADU GARDENING

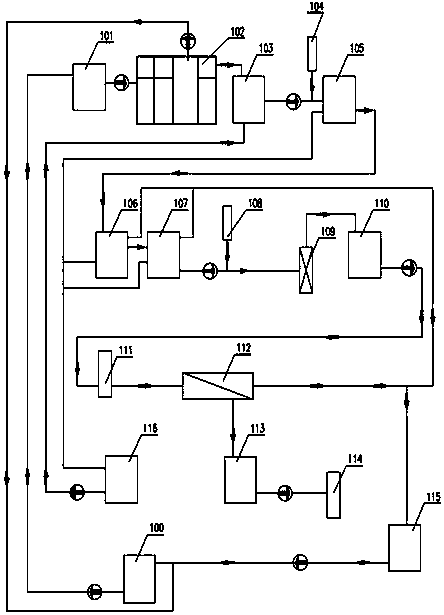

High-salt wastewater treatment process system and method thereof

PendingCN109205895AEasy to adjustShort processWater treatment parameter controlWater/sewage treatment by irradiationProcess systemsEvaporation

The invention discloses a high-salt wastewater treatment process system and a method thereof. the system comprises a desulphurization treatment system, a raw water regulating tank, a super softening sedimentation basin, a super ozone device, a clean water basin, a multi-media filter, a weak acid cation bed, a sodium bed, a ultraviolet device, a tubular membrane, a security filter, a SCRO, a special separating membrane, a high pressure reverse osmosis device, a flue evaporation crystallization drier, a wastewater tank and a recycled water tank. In order to ensure the long-term stable operationof the process system, the related matched cleaning device, a chemical dosing device, an electrical system and instrument control are also included. The system has the following advantages: chemical dosage is less; wastewater is reutilized, and investment and operation treatment costs of part of wastewater are saved. The problems in zero emission of high-salt wastewater in the prior art are solved.

Owner:国能朗新明环保科技有限公司

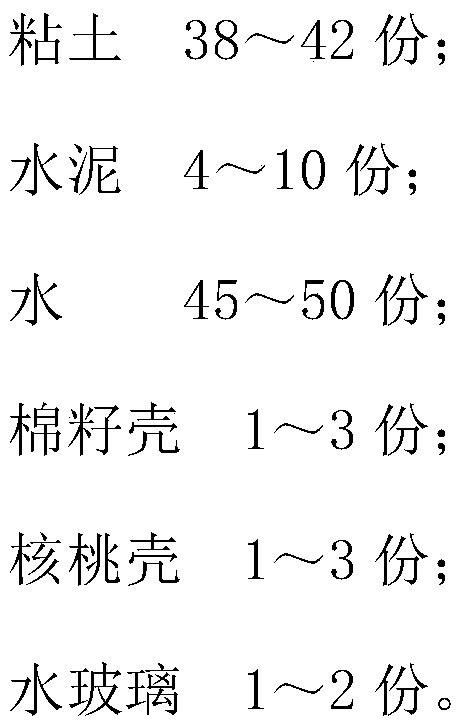

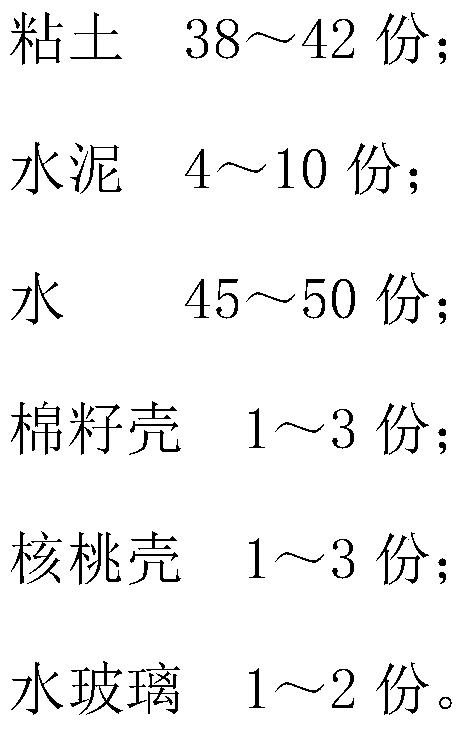

Clay cement-aggregate mixed grouting material and preparation method thereof

The invention discloses a clay cement and aggregate mixed grouting material.The material is prepared from 38-42 parts of clay, 4-10 parts of cement, 45-50 parts of water, 1-3 parts of cottonseed hulls, 1-3 parts of walnut hulls and 1-2 parts of water glass. The invention further discloses a preparation method of theclay cement-aggregate mixed grouting material.The preparation method comprises thesteps that 1, 38-42 parts of clay is uniformly added in 45-50 parts of water, and stirring is conducted at room temperature to form mixed slurry; 2, 4-10 parts of cement is added in the mixed slurry,and stirring is conducted to form mixed slurry; 3, 1-3 parts of cottonseed hulls and 1-3 parts of walnut hulls are added in the mixed slurry, and stirring is conducted to form mixed slurry; 4, 1-2 parts of water glass is uniformly added in the mixed slurry, stirring is conducted to be uniform, and the clay cement-aggregate mixed grouting material is obtained. According to the clay cement-aggregatemixed grouting material and the preparation method thereof, the cost of coal seam floor reinforcement is lowered, and pollution is not likely to be produced.

Owner:北京大地高科地质勘查有限公司

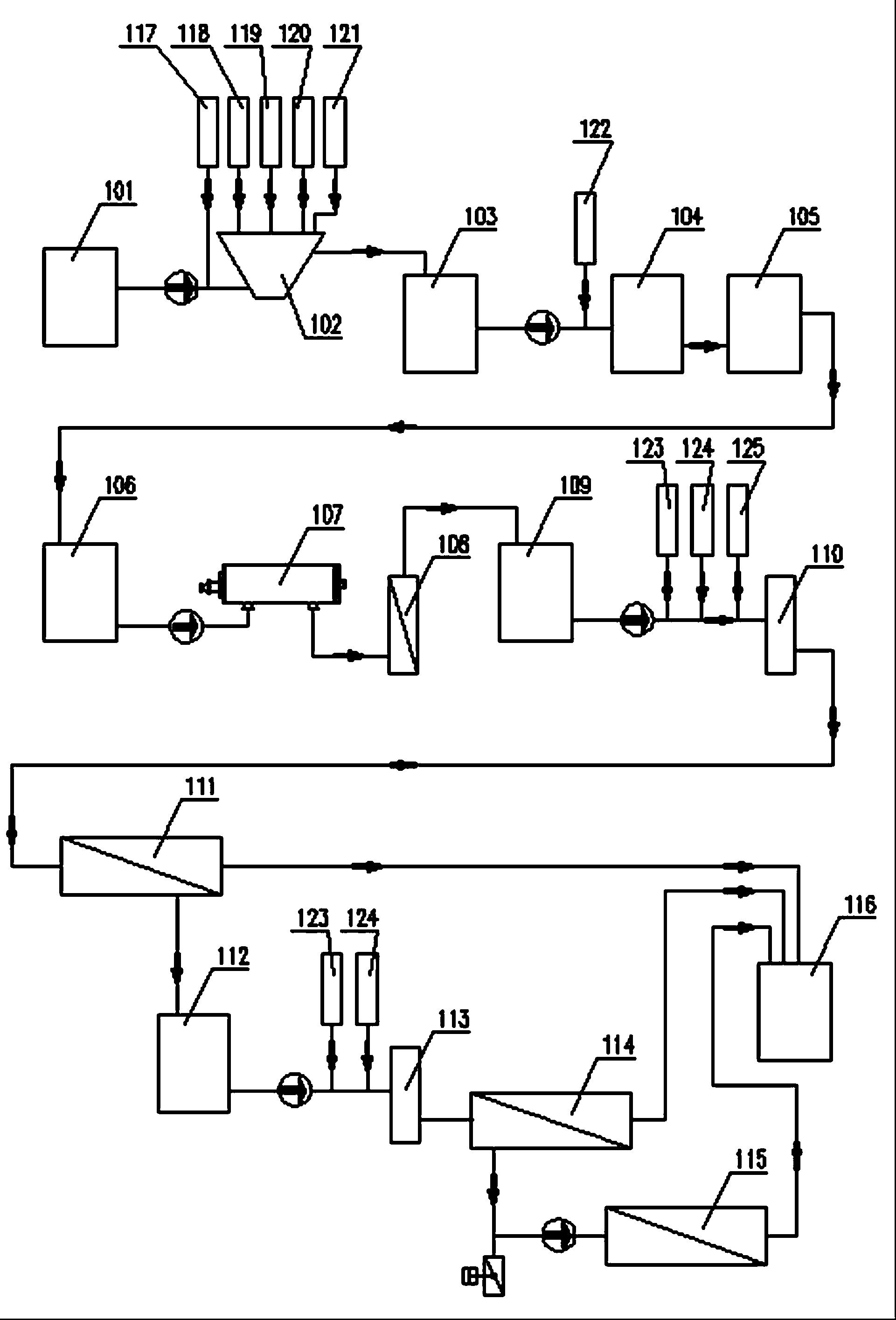

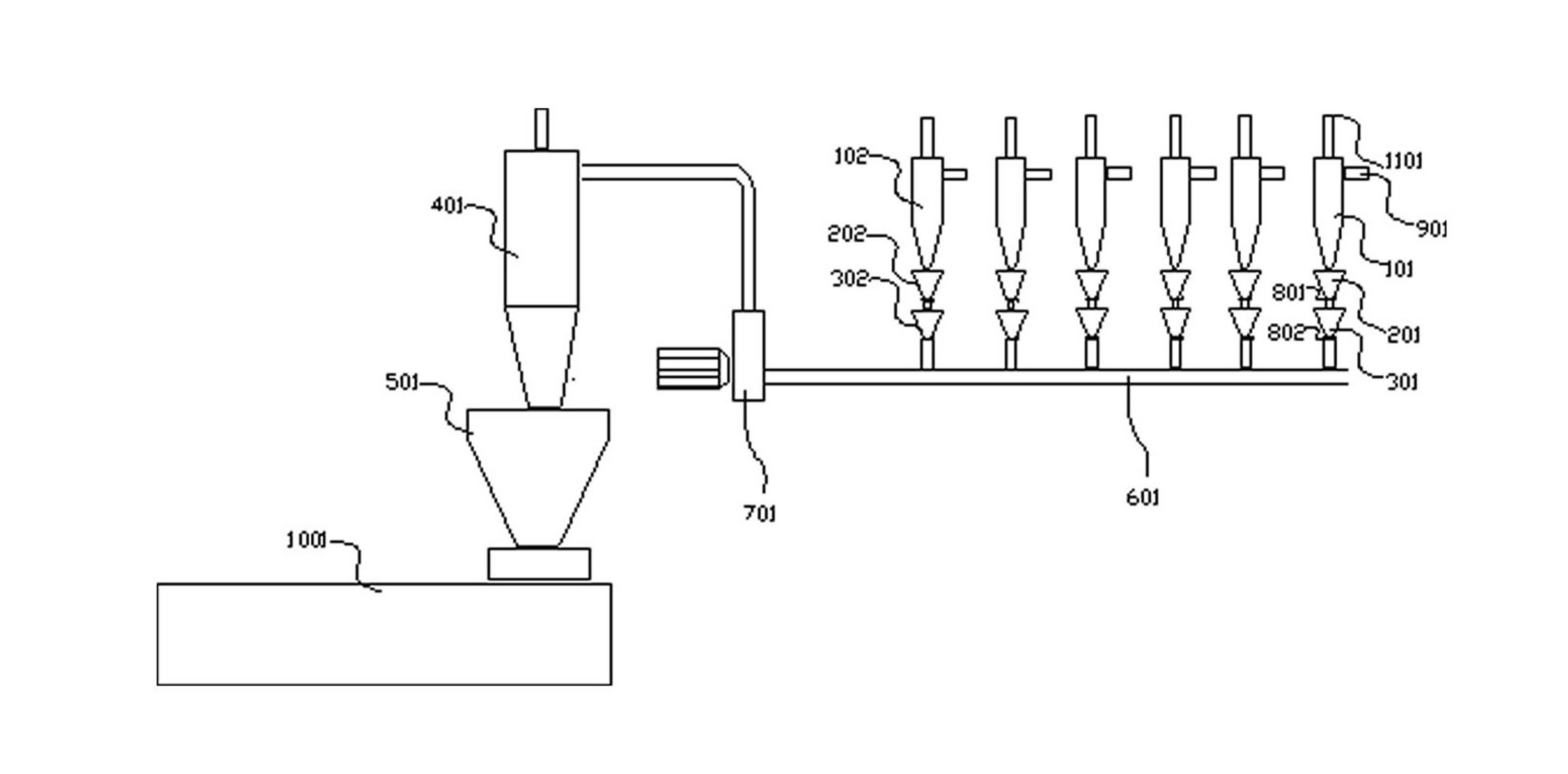

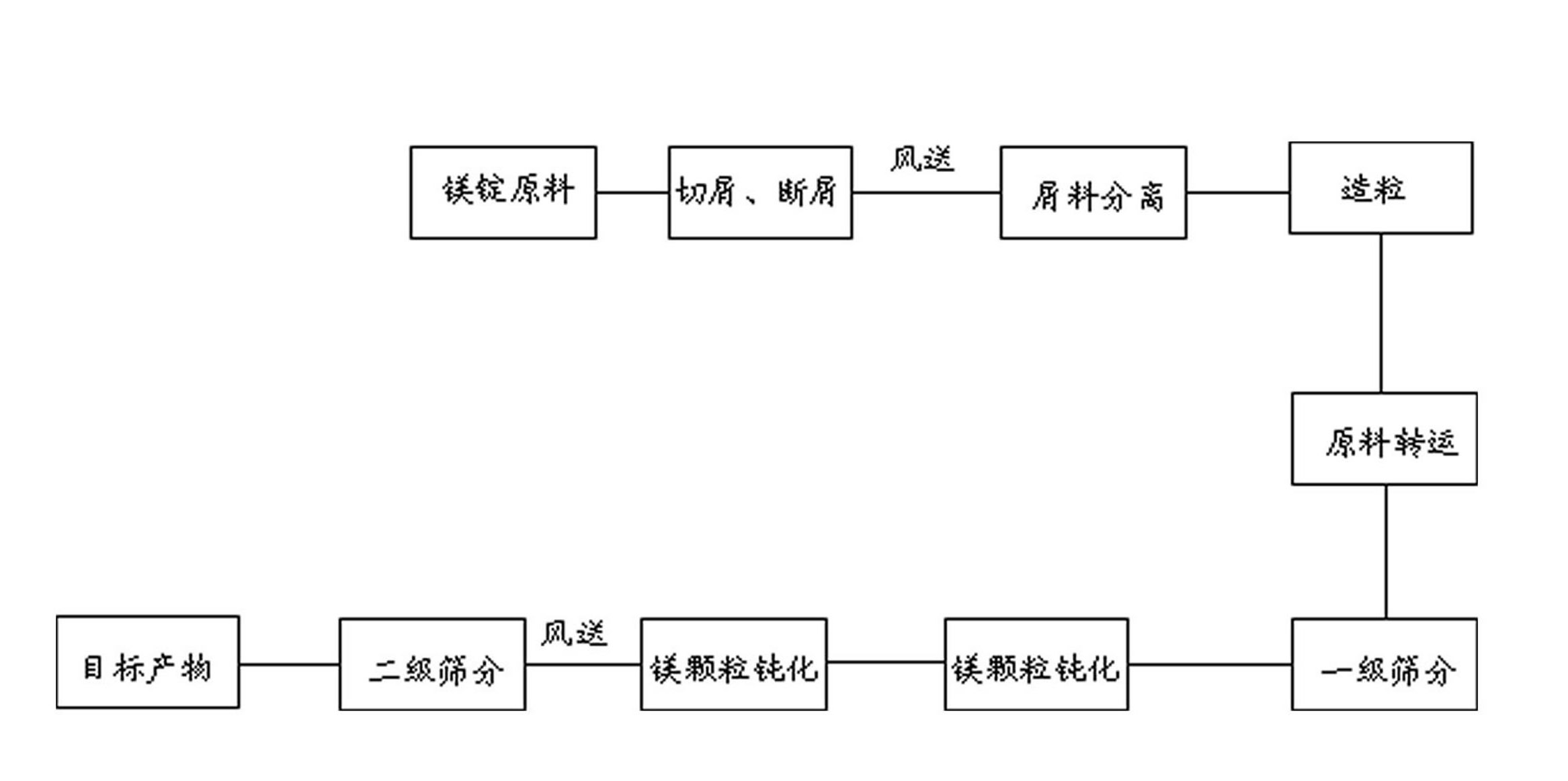

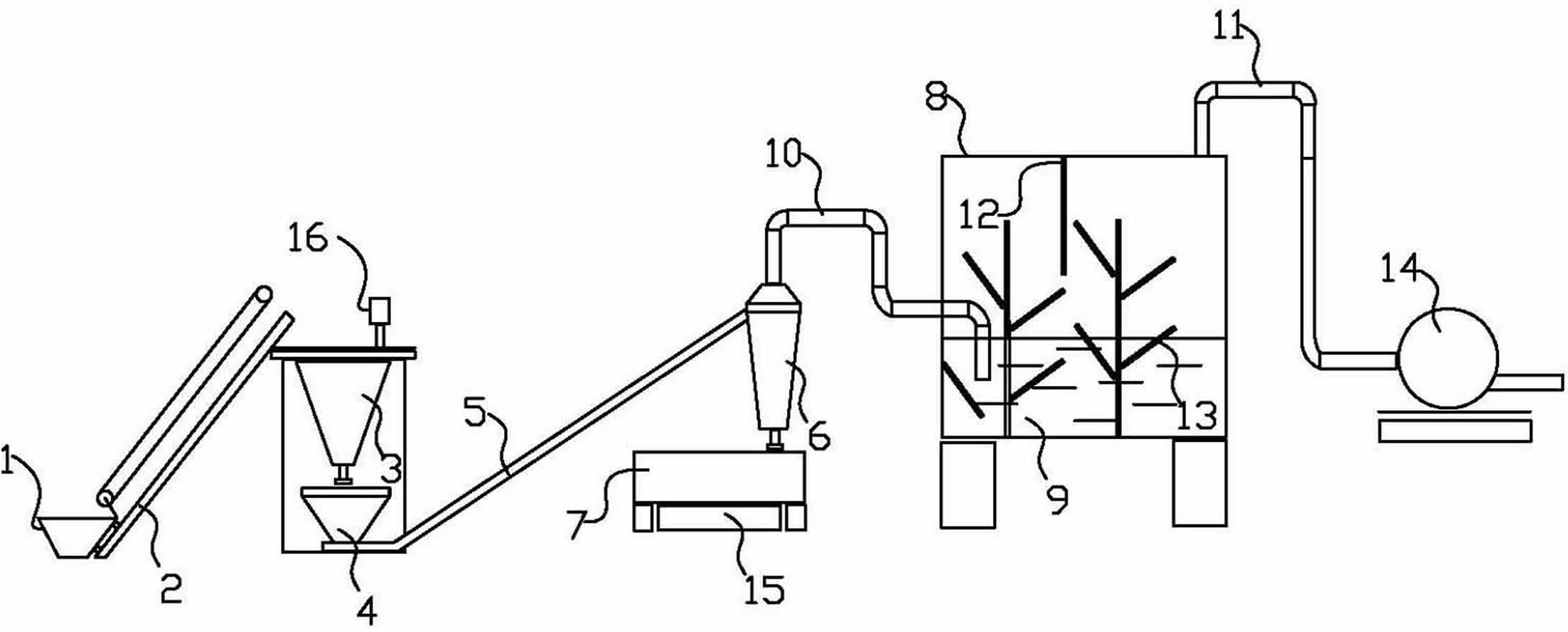

Preparation method of magnesium-based desulfurizing agent

The invention belongs to the technical field of desulfurization of metallurgical molten iron and particularly relates to a preparation method of a magnesium-based desulfurizing agent. The preparation method comprises the following steps of: (1) processing a magnesium ingot raw material and feeding the processed magnesium ingot raw material into a pelletizer for pelletizing; (2) feeding a product obtained in the step (1) into the inlet of a first group of cyclone tanks (101), feeding the product into a first group of one-stage blanking bins (201) from the discharge hole of the first group of cyclone tanks (101), feeding the product into a first group of two-stage blanking bins (301) from the discharge hole of the first group of one-stage blanking bins (201), blowing the product into a final stage cyclone tank (401) and finally feeding the product into a final stage storage tank (501) and a one-stage vibrating screen (1001) for screening; (3) passivating raw material particles and charging a heated and stirred passivated magnesium material into a passivated magnesium storage bin; and (4) feeding passivated magnesium into a cyclone separator by using a radiating conveying mechanism so as to select the passivated magnesium material. The preparation method has high safety performance, remarkable environmental protection efficiency and appropriate flame retarding time; and a granularity range value meets the structural demand of a spray gun.

Owner:营口东邦环保科技股份有限公司

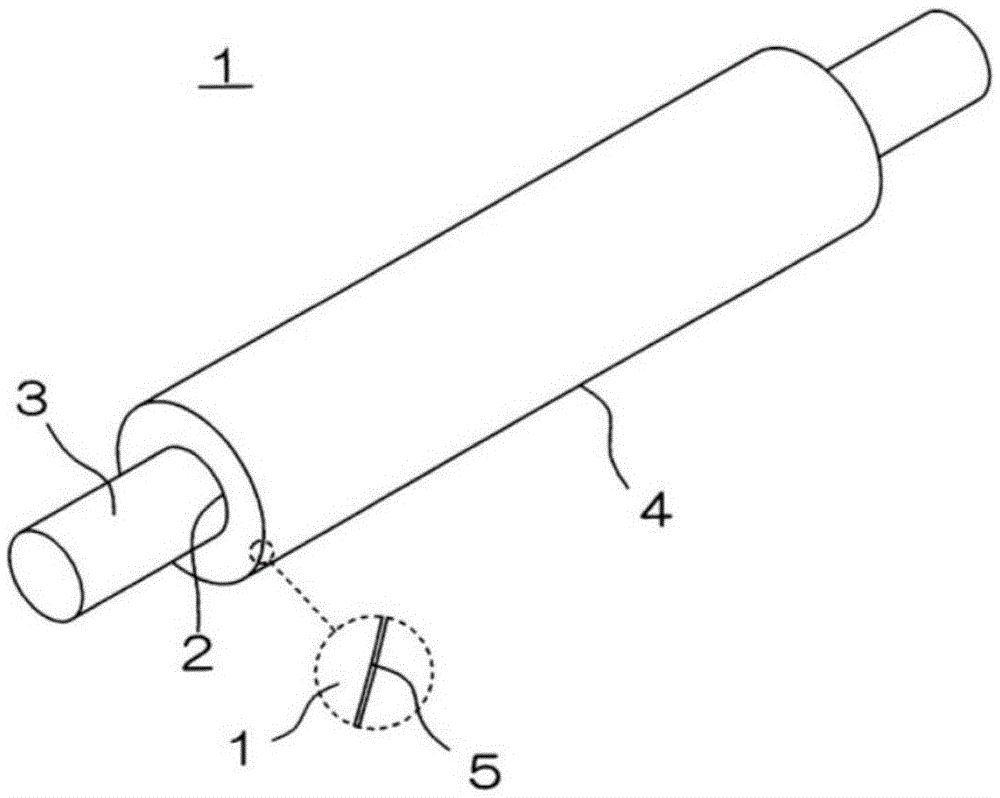

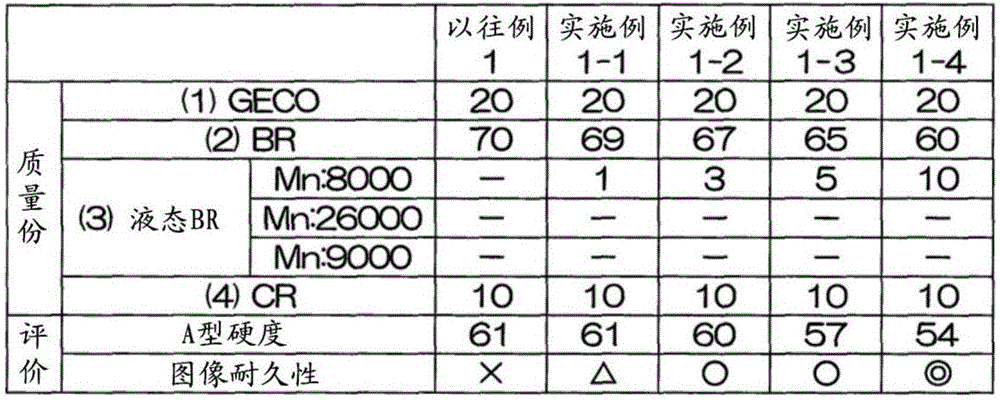

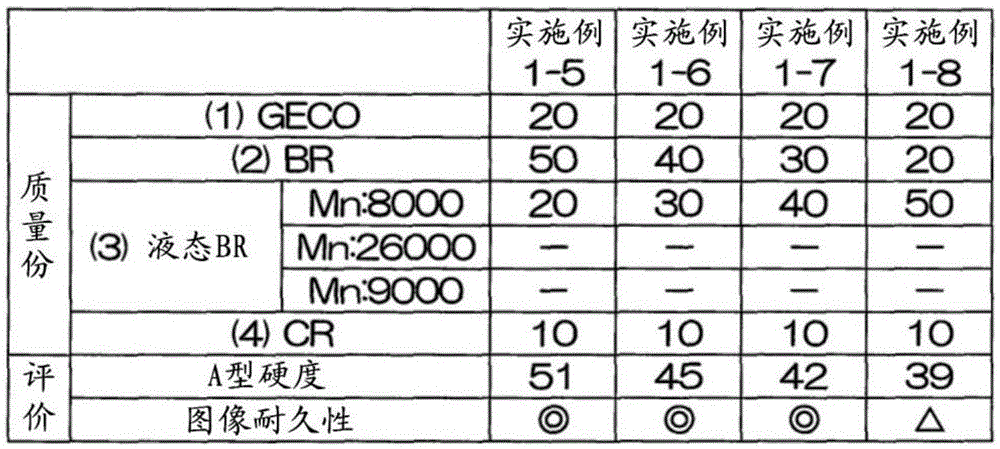

Semiconductive roller

ActiveCN106054560ANot prone to deteriorationNot prone to pollutionElectrographic process apparatusEngineeringEpichlorohydrin

The invention provides a semiconductive roller. The semiconductive roller is soft while serving as a developing roller, can avoid degradation of toner, is excellent in image durability, can avoid photoreceptor pollution, is less in compression permanent deformation, and can avoid deformation. A semiconductive roller (1) is provided, which is formed from a rubber composition containing a rubber component including: (1) an epichlorohydrin rubber; (2) at least one solid rubber selected from the group consisting of a solid BR and a solid SBR; and (3) at least one liquid rubber selected from the group consisting of a liquid BR and a liquid SBR.

Owner:SUMITOMO RUBBER IND LTD

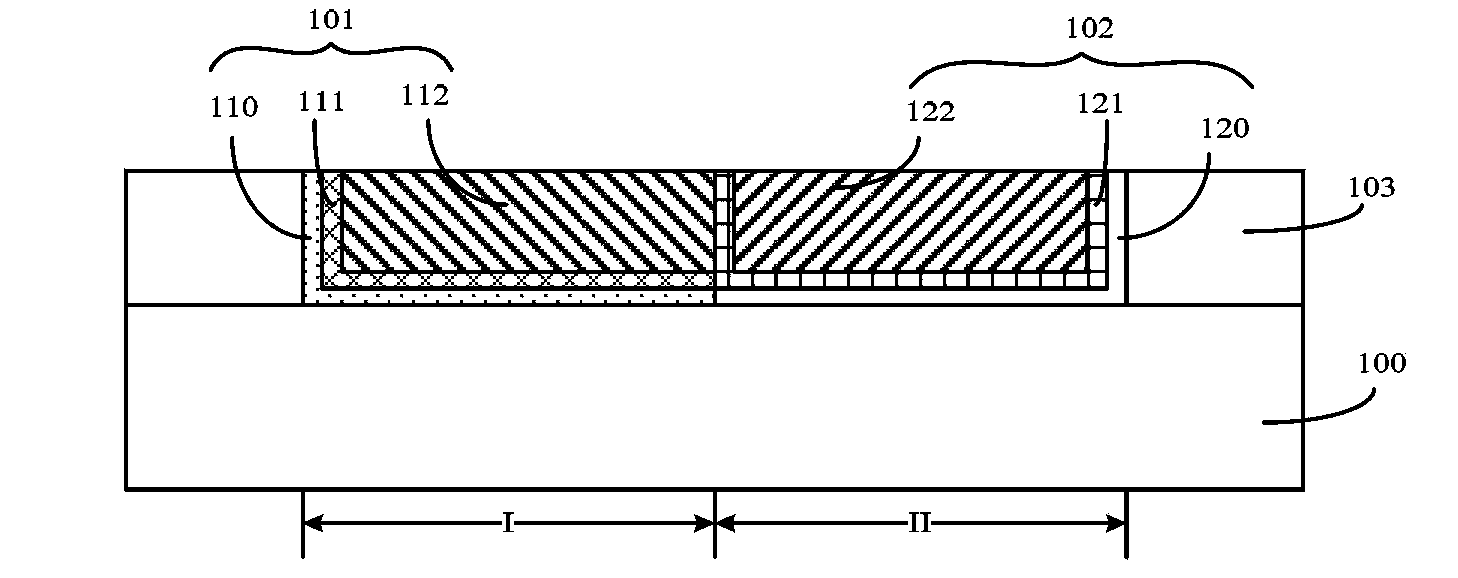

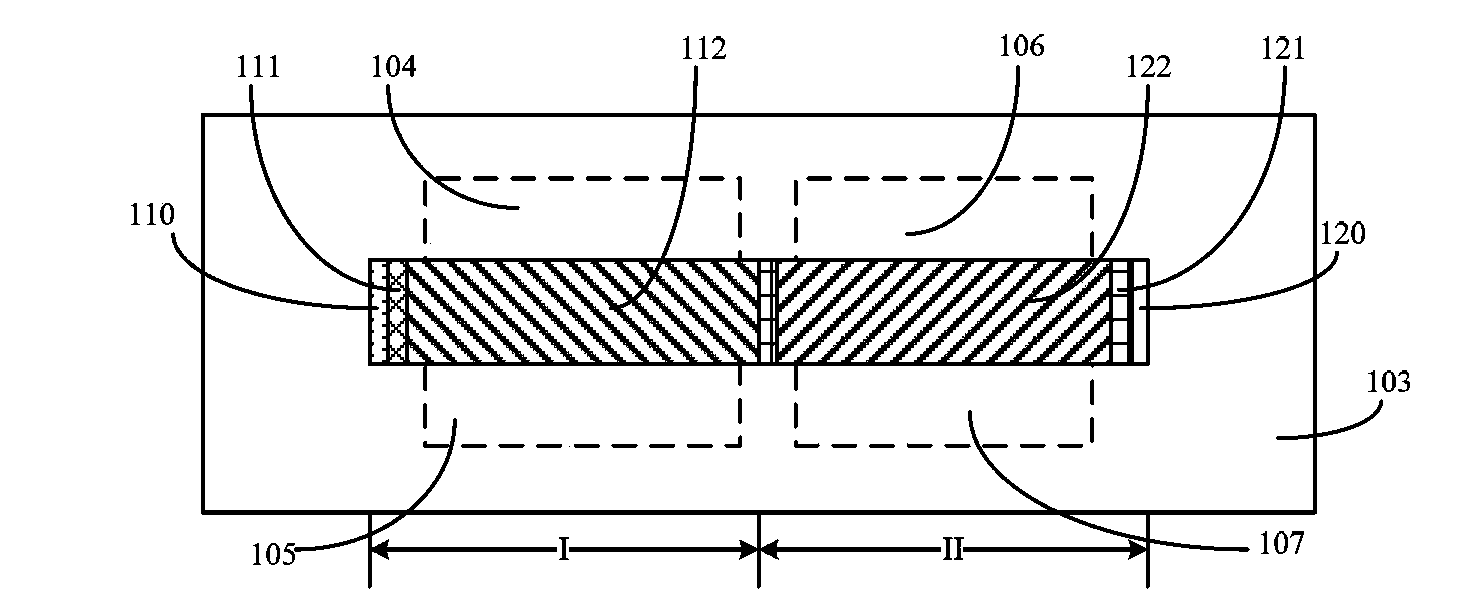

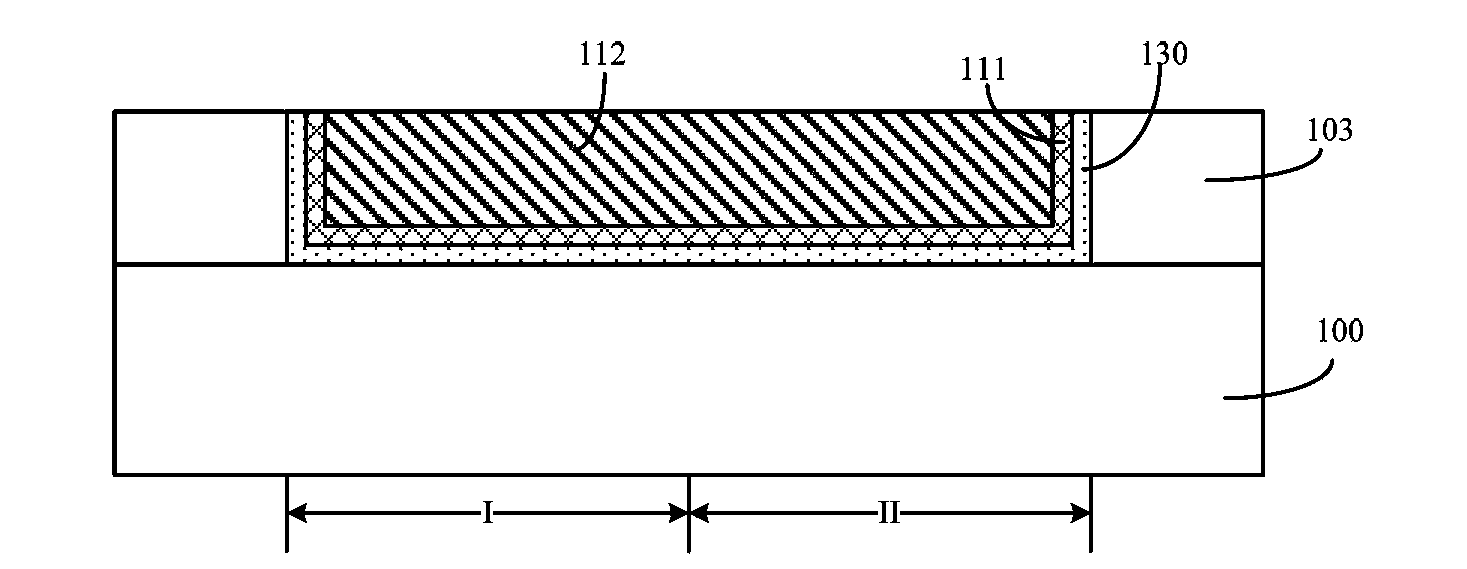

Semiconductor device and forming method thereof

ActiveCN103779198ALower resistanceAvoiding problems with galvanic isolationTransistorSemiconductor/solid-state device manufacturingGate dielectricDevice material

The invention discloses a semiconductor device and a forming method thereof. The semiconductor device comprises a semiconductor substrate, a first gate structure, a second gate structure, a second dielectric layer and a first conductive plug, wherein the semiconductor substrate comprises a first region and a second region near to each other; the first gate structure is located on the surface of the semiconductor substrate in the first region, and the first gate structure comprises a first high K gate dielectric layer, a first work function layer located on the surface of the first high K gate dielectric layer and a first gate electrode layer located on the surface of the first work function layer; the second gate structure is located on the surface of the semiconductor substrate in the second region, and the second gate structure comprises a second high K gate dielectric layer, a second work function layer located on the surface of the second high K gate dielectric layer and a second gate electrode layer located on the surface of the second work function layer; the second dielectric layer is located on the surface of the first gate structure and the second gate structure, and the second dielectric layer is internally provided with a contact through hole exposed out of part of the first gate structure and part of the second gate structure; and the first conductive plug is formed and located in the contact through hole. Performances of the semiconductor device are good.

Owner:SEMICON MFG INT (SHANGHAI) CORP

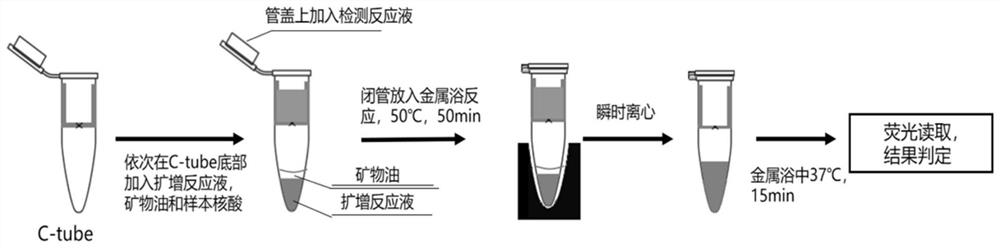

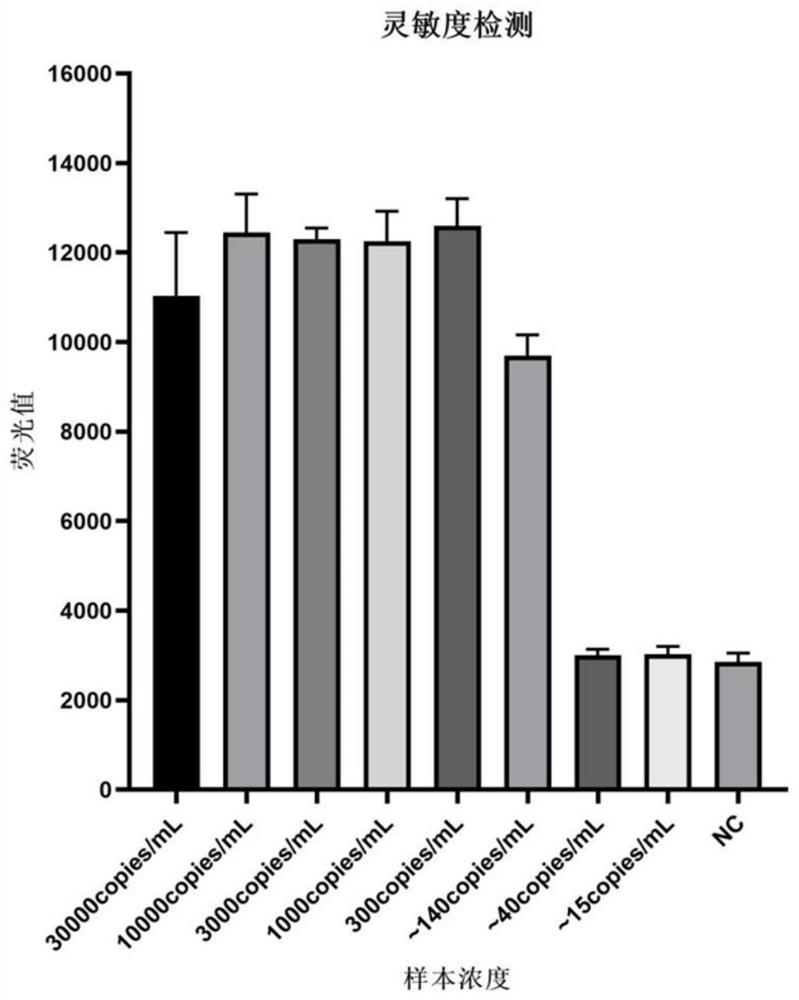

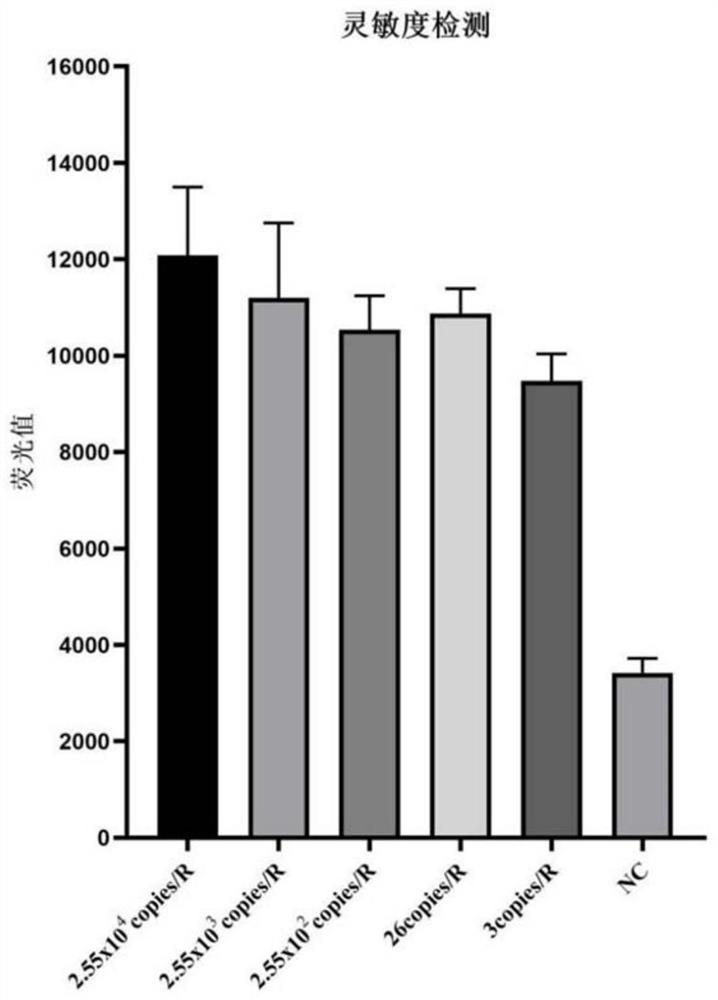

Novel coronavirus nucleic acid detection kit

PendingCN113308569ANot easy to polluteHigh sensitivityMicrobiological testing/measurementMicroorganism based processesEnzymeMineral oil

The invention discloses a novel isothermal amplification CRISPR detection kit for coronavirus nucleic acid. The kit mainly comprises: 1) a high-temperature-resistant amplification enzyme; 2) an amplification buffer solution; 3) a detection enzyme; 4) a detection buffer solution; 5) mineral oil; and 6) C-tube (a reaction tube capable of separating an upper liquid reagent and a lower liquid reagent in one tube). The kit can be used for detecting the RNA of the N gene of the novel coronavirus (SARS-CoV-2) in throat swab, sputum and other samples, and has the characteristics of single tube, one step, rapidness, high specificity, high sensitivity, difficulty in pollution due to the fact that the amplification product is RNA, and the like. The kit can complete a detection reaction within about 1 hour, and the sensitivity can reach up to 3 copies per reaction or 140 copies / mL of a sample. The kit can provide molecular level judgment basis and help for clinical diagnosis of novel coronavirus infection.

Owner:HANGZHOU MATRIDX BIOTECH CO LTD

Noble metal catalyst and preparation method and application thereof

ActiveCN108636403AHigh activityHigh catalytic activityIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsPtru catalystLattice oxygen

The invention provides a noble metal catalyst, which employs noble metal as a first active component and stannic oxide as a second active component, and a methane combustion catalyst having high catalytic activity and sintering-resistant performance is obtained. The stannic oxide can protect the noble metal component from sintering, contains abundant and active surface oxygen vacancy, the latticeoxygen in a body phase has certain activity, at the same time, the surface of the stannic oxide has Lewis acid center, realizes effective catalysis, and is in favor of a catalytic combustion reactionof methane. A part of the noble metal is introduced into lattice of stannic oxide to substitute the divalent tin ions, and can increase the cavity concentration, so that the free electron concentration is reduced, adsorbed oxygen ions can be formed at the surface of the catalyst, the noble metal catalyst is in favor of generation of an oxidation reaction by the reductibility gas methane at the surface of the catalyst through oxygen ion adsorption, and the activity of the catalyst is increased.

Owner:吉林晟航科技发展有限公司

Heat-insulation ceramic coating material as well as preparation method and application thereof

ActiveCN113429858AImprove insulation effectImprove insulation efficiencyCellulose coatingsAnti-corrosive paintsCeramic coatingComposite ceramic

The invention provides a heat-insulation ceramic coating material and a preparation method and application thereof. The heat-insulation ceramic coating material comprises a combination of twice modified composite ceramic hollow particles, polyurethane modified acrylic emulsion, nano cellulose, a leveling agent and a thickening agent, and by adding a combination of four ceramic particles with different particle size ranges, the heat-insulation ceramic coating material which is good in heat-insulation effect, simple in construction process and excellent in machining performance is obtained; the heat-insulation ceramic coating material can be applied to a passenger car heat insulation plate, has the advantages of being high in heat insulation efficiency, not prone to generating dust and germ pollution, long in service life, excellent in machining performance and easy to clean, and can greatly improve the in-car environment quality and the heat preservation effect of a passenger car.

Owner:GUANGZHOU TONGDA AUTO ELECTRIC +1

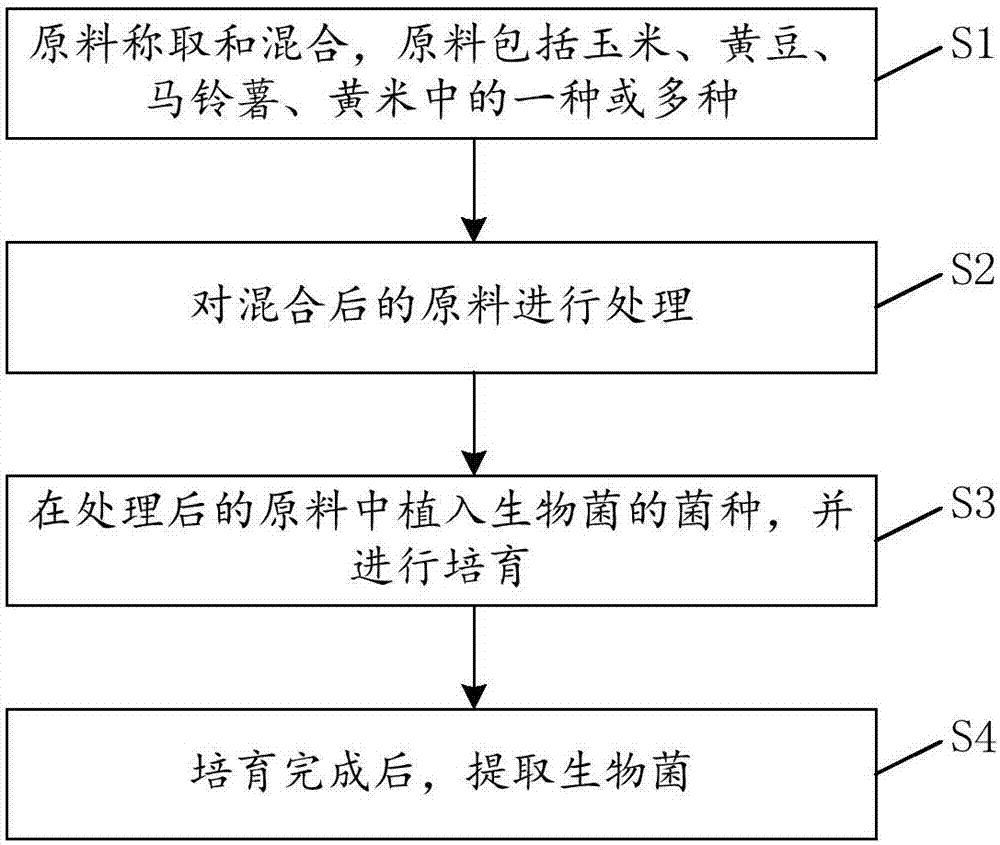

Environment-friendly organic cultivation method of biological bacteria

InactiveCN107267390AReduce cultivation costQuality improvementMicroorganismsMicroorganism based processesBiotechnologyBacteria

The invention discloses an environment-friendly organic cultivation method of biological bacteria and relates to the technical field of biology. The method of the invention comprises the steps of S1, weighing materials, including one or more of corn, soybean, potato and millet, and mixing; S2, treating the mixture of the materials; S3, implanting strains of the biological bacteria in the treated materials, and cultivating; S4, after cultivating, extracting the biological bacteria. The method of the invention is applicable to the cultivation of biological bacteria by plant materials.

Owner:黑龙江九穗谷农业科技发展有限公司

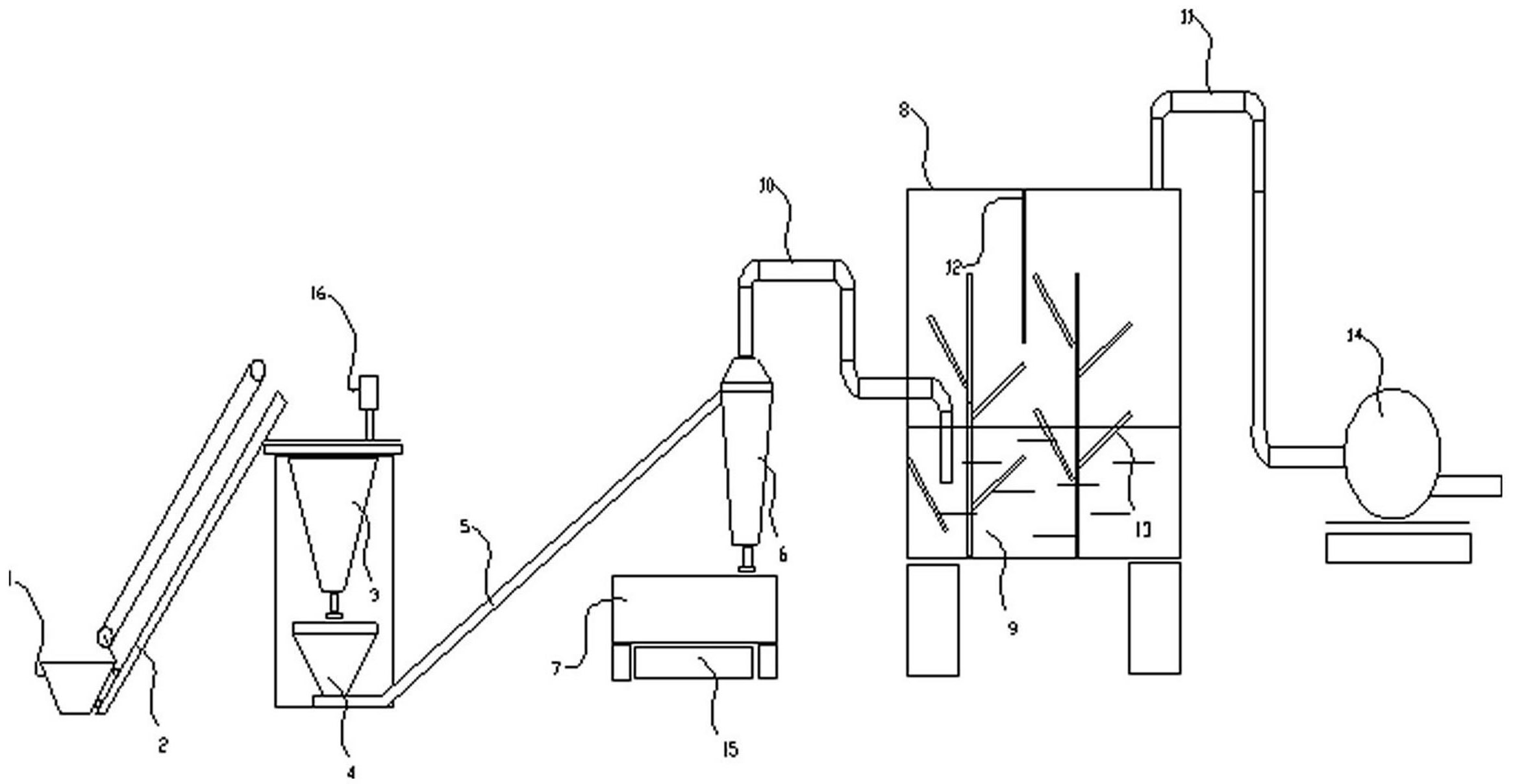

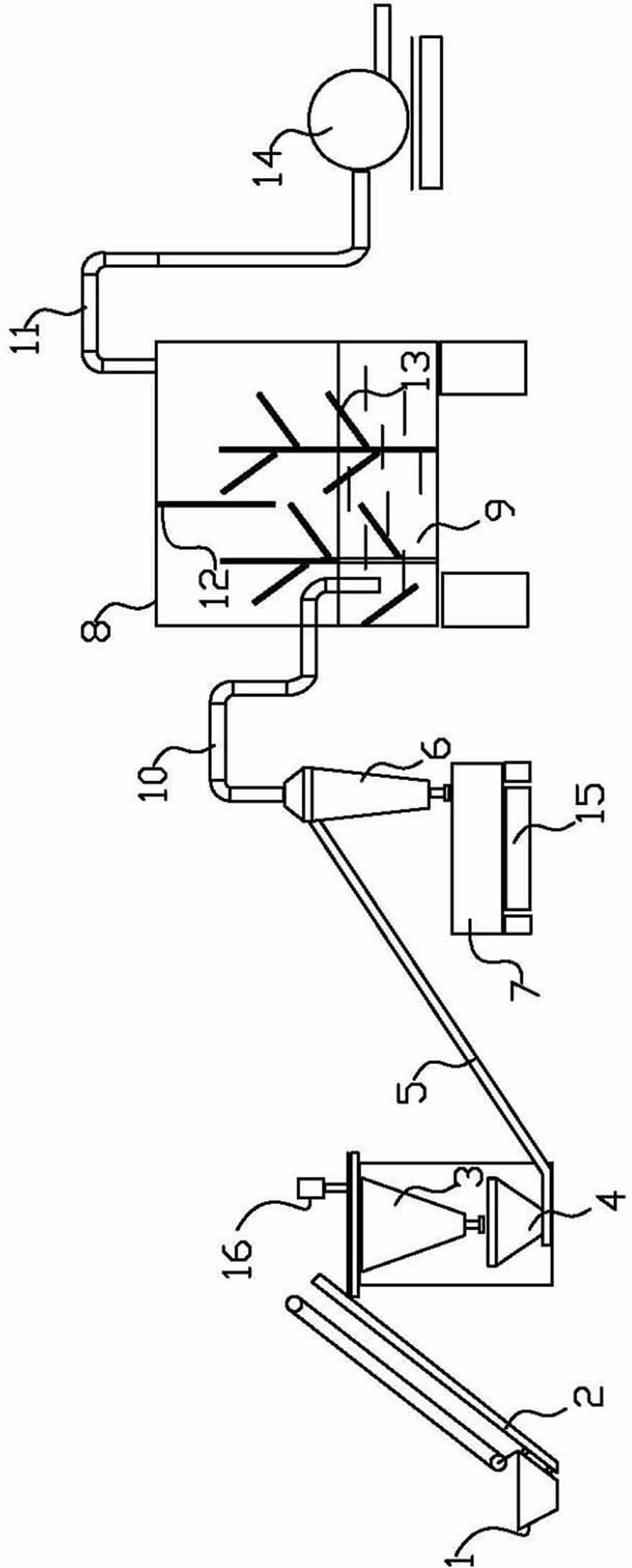

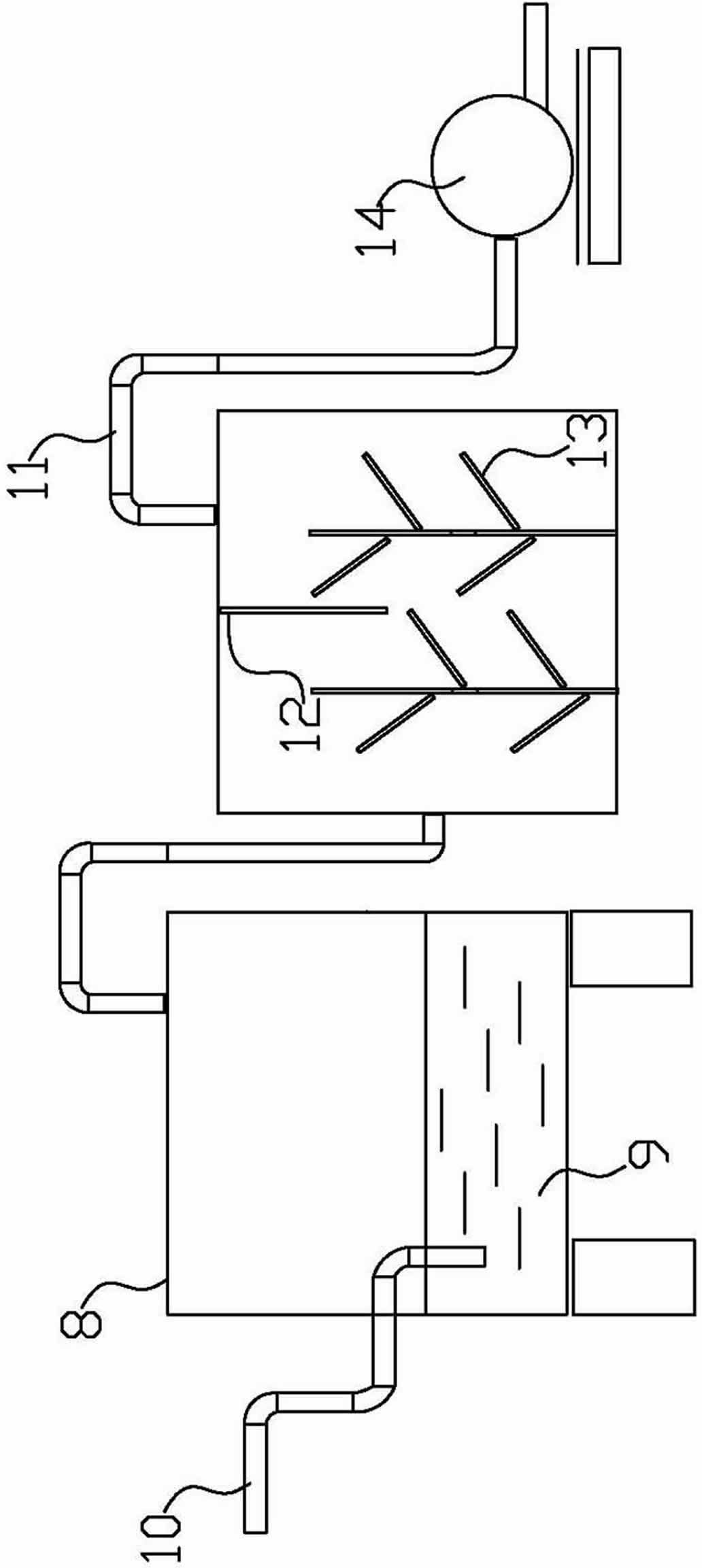

Environment-friendly granular magnesium passivation system

InactiveCN101983803AImprove liquiditySuitable flame retardant timeCharge manipulationEngineeringMetal

The invention belongs to the technical field of molten iron pretreatment and desulfuration, and particularly relates to an environment-friendly granular magnesium passivation system. The system comprises a to-be-passivated magnesium bin (1), a transmission mechanism (2), a heating stirring kettle (3), a passivated magnesium storehouse (4), a separator (6), a vibrating screen (7) and a dust treatment device; the inlet of the heating stirring kettle (3) corresponds to the end of the transmission mechanism (2); the inlet of the passivated magnesium storehouse (4) corresponds to the discharge hole of the heating stirring kettle (3); the discharge hole of the passivated magnesium storehouse (4) is communicated with the feeding hole of the separator (6) through a heat dissipation conveying mechanism (5); the exhaust port on the upper part of the separator (6) is communicated with the inlet of the dust treatment device; and the discharge hole of the separator (6) is communicated with the inlet of the vibrating screen (7). The system has the advantages of high automation degree, good fluidity of a passivated magnesium metal target product and moderate flame retarding time, and is not easy to produce the problems such as environmental pollution and the like during operation.

Owner:营口东邦环保科技股份有限公司

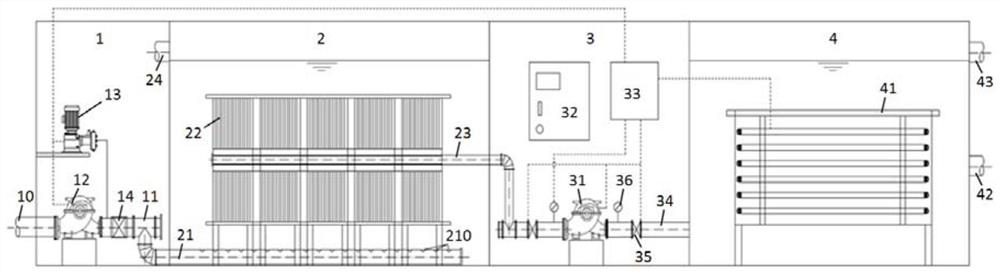

Coagulation ceramic membrane combined rural drinking water treatment device

InactiveCN112266116AIncrease pollutionShorten the lengthWater/sewage treatment by irradiationMultistage water/sewage treatmentWater treatmentMechanical engineering

The invention relates to a coagulation ceramic membrane combined rural drinking water treatment device. The device comprises a coagulation unit (1), a ceramic membrane unit (2), a transfer control unit (3) and a clear water area ultraviolet digestion unit (4) which are sequentially connected in series, wherein the coagulation unit (1) is provided with a water inlet pipe (11), a tubular mixer (14)and a coagulant feeding pump (13), and the water inlet pipe (11) is connected with the ceramic membrane unit (2); the tubular mixer (14) is arranged on the water inlet pipe (11); and the coagulant feeding pump (13) and the water inlet pipe (11) are connected to the front end of the tubular mixer (14). Compared with the prior art, the method has the advantages of improving the water treatment efficiency of short-flow integrated equipment, being suitable for rural drinking water treatment and the like.

Owner:TONGJI UNIV

Grouting material for coal seam floor reinforcement

The invention discloses a grouting material for coal seam floor reinforcement. The grouting material is prepared from cement, loess and water through mixing and is in a form of slurry, wherein the weight ratio of cement to loess is (20-4):1, and the amount of water is 120%-300% of the total weight of cement and loess. The grouting material has the benefits as follows: (1) the cheap loess substitutes for part of cement in pure cement paste (single liquid cement paste), cement-loess mixed slurry is formed, accordingly, the material integrates advantages of good durability and high strength of pure cement slurry, and the cost of coal seam floor reinforcement is reduced; (2) components of the mixed slurry are not prone to pollution generation.

Owner:北京大地高科地质勘查有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com