High-salt wastewater treatment process system and method thereof

A treatment process and high-salt wastewater technology, which is applied in the direction of gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high cost of softening agents, high requirements for operation and maintenance, and achieve saving wastewater investment and The effect of running and processing costs, saving investment and operating costs, and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with examples, but the implementation of the present invention is not limited thereto.

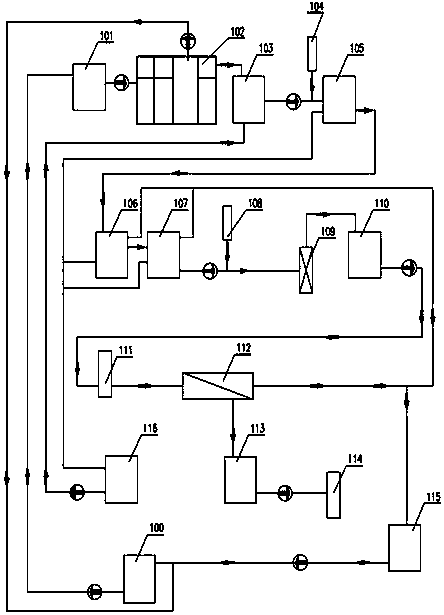

[0035] figure 1 Shows a high-salt wastewater treatment process system and method according to an embodiment of the present invention, including

[0036] (100) Desulfurization treatment system, (101) Raw water conditioning tank, (102) Super softening sedimentation tank, (103) Clean water tank, (104) Super ozone device, (105) Multi-media filter, (106) Weak acid cation bed, (107) sodium bed, (108) ultraviolet device, (109) tubular membrane, (110) security filter, (111) SCRO, (112) special separation membrane, (113) high pressure reverse osmosis, (114) flue Evaporative crystal dryer, (115) waste water tank, (116) reuse water tank.

[0037] In order to achieve zero discharge of high-salt industrial wastewater, this system connects each device through pipelines and pumps. The high-salt industrial wastewater is colle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com