Method for preparing lithium ion battery anode material xLiFePO4.yLi3V2(PO4)3

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of complex synthesis process and poor rate performance, and achieve simple synthesis process, good rate discharge performance, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

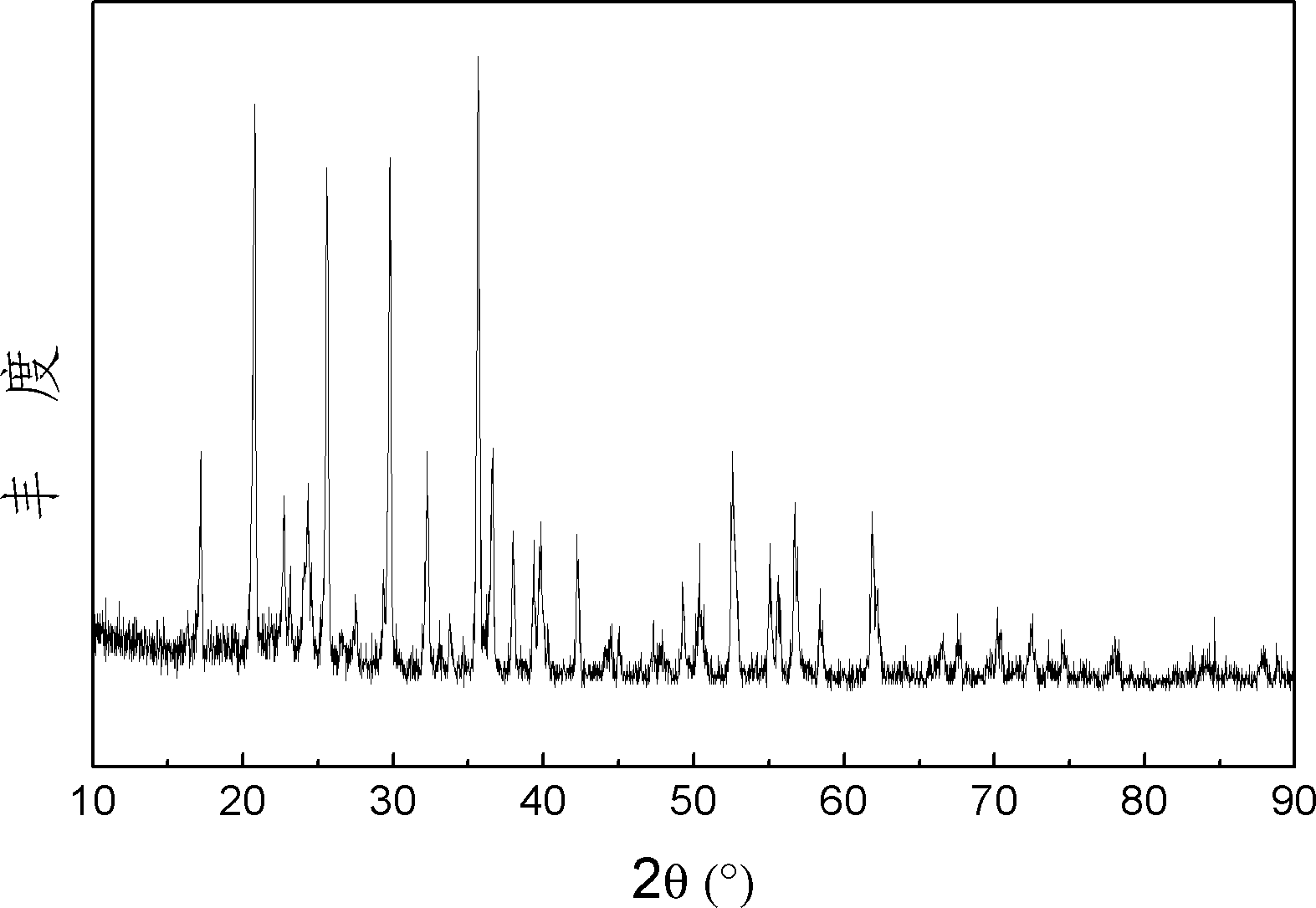

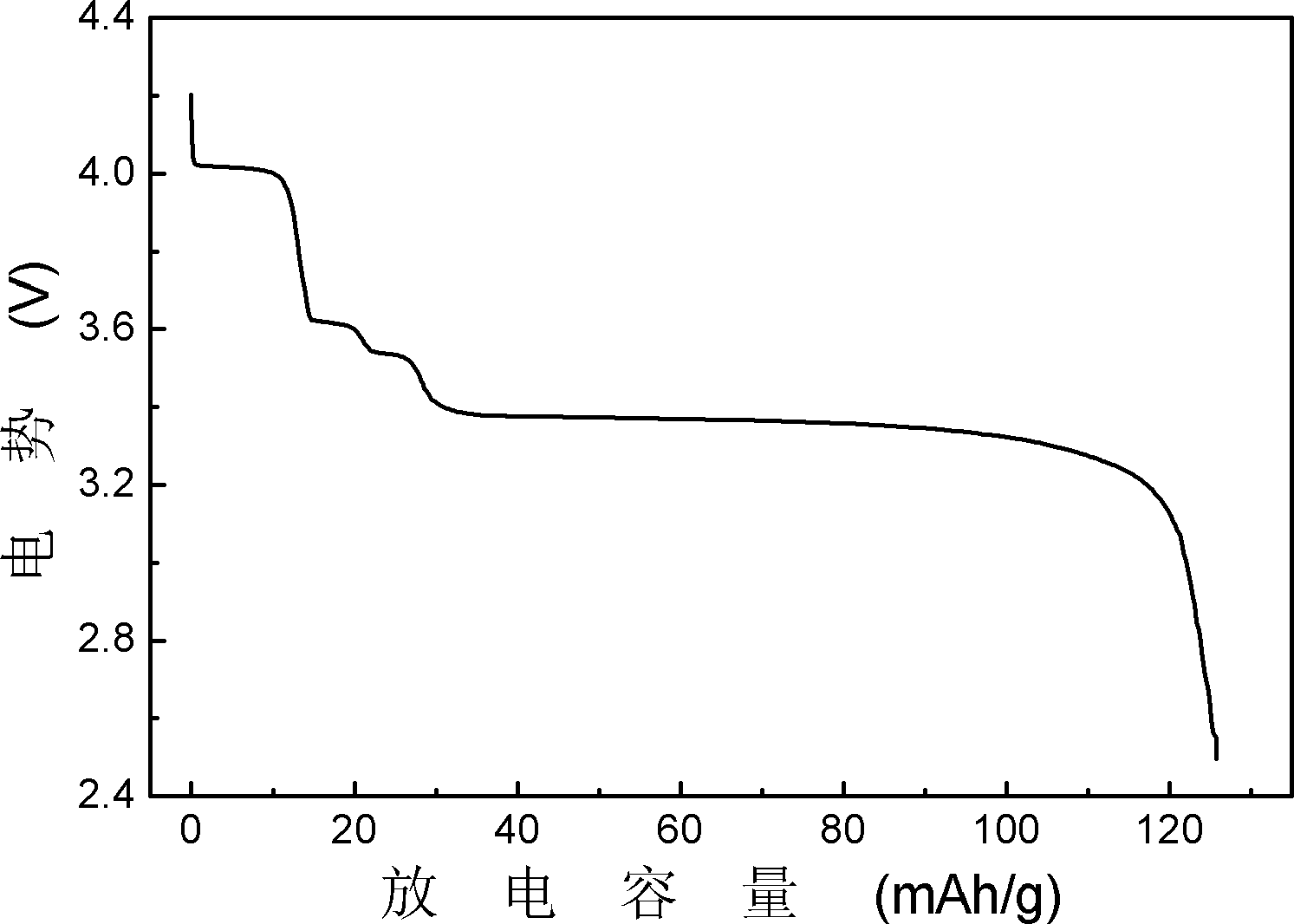

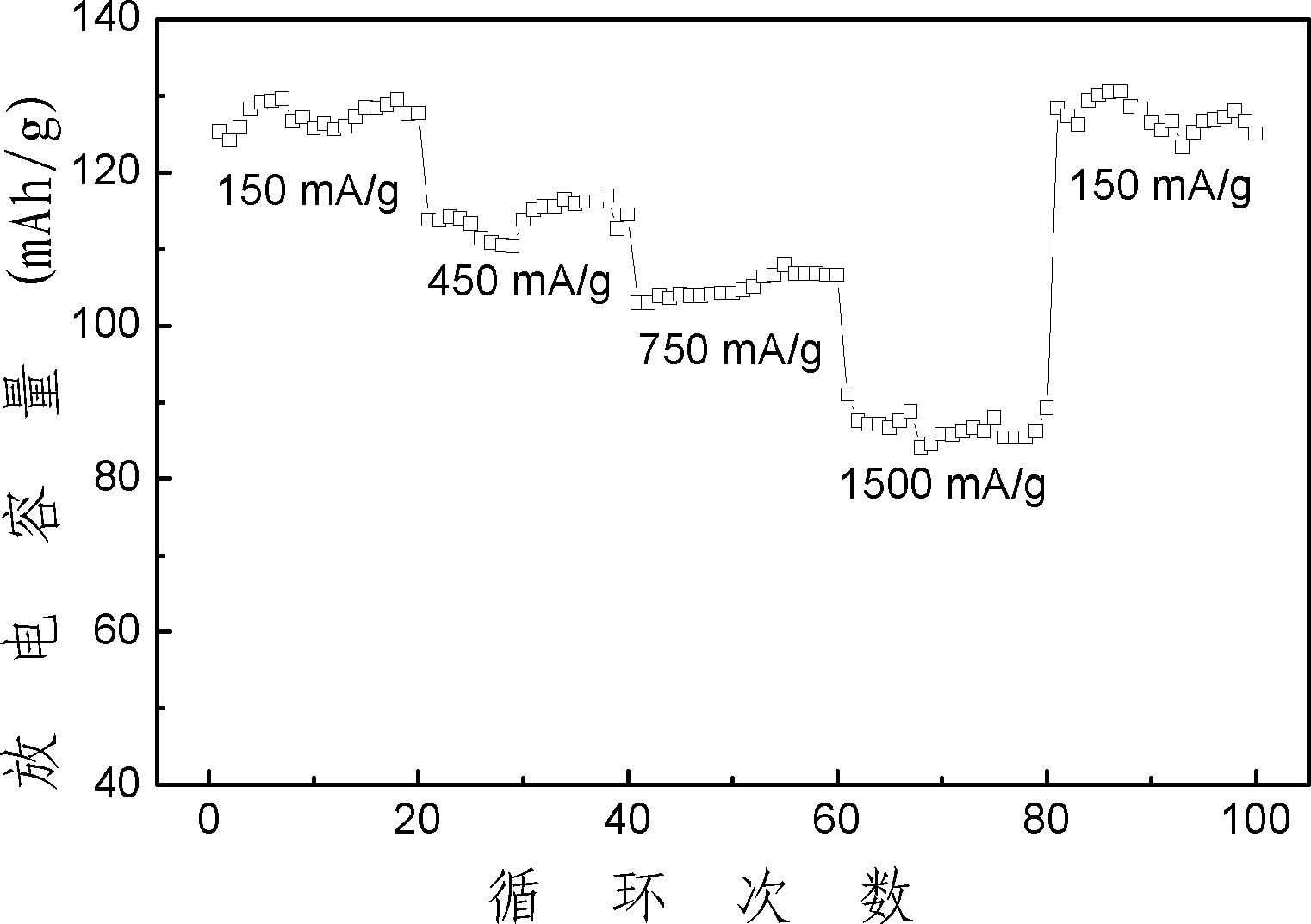

[0011] Specific implementation mode 1: In this implementation mode, the positive electrode material of lithium ion battery xLiFePO 4 ·yLi 3 V 2 (PO 4 ) 3 The preparation method is carried out according to the following steps: one, according to the molar ratio of Li element, Fe element, V element, P element and C element is (x+3y)~1.1(x+3y): x: 2y: (x +3y): 0.5(x+2y)~2(x+2y) ratio Weigh lithium source, iron source, vanadium salt, phosphoric acid source and carbon source and mix to obtain a mixture, then put the mixture in a ball mill, add dispersant After wet milling for 2 to 12 hours, the mixture is obtained, wherein the volume ratio of the dispersant to the mixture is 1 to 10:1, the dispersant is absolute ethanol, acetone or water, and 0.05≤x / (x+y)≤0.95 ; 2. Under the protection of 250-450 ℃ and protective gas, pre-sinter the mixture obtained in step 1 for 2-6 hours; 3. Then pre-sinter the mixture obtained in step 2 at 570-870 ℃ and under the protection of protective gas ...

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the lithium source described in step one is LiOH·H 2 O, LiF, Li 2 CO 3 、LiCH 3 COO·H 2 O and LiNO 3 one or a combination of several of them. Other steps and parameters are the same as in the first embodiment.

[0014] In this embodiment, when the lithium source is a mixture, various lithium sources are mixed in any ratio.

specific Embodiment approach 3

[0015] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the iron source in Step 1 is ferrous oxalate, ferric phosphate, ferric phosphate hydrate, ferric nitrate or iron oxide. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com