High-salt industrial wastewater treatment process system

A technology for industrial waste water and treatment process, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of high operating cost, high risk and high investment, and achieve savings The effect of energy consumption, reduced operational risk, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

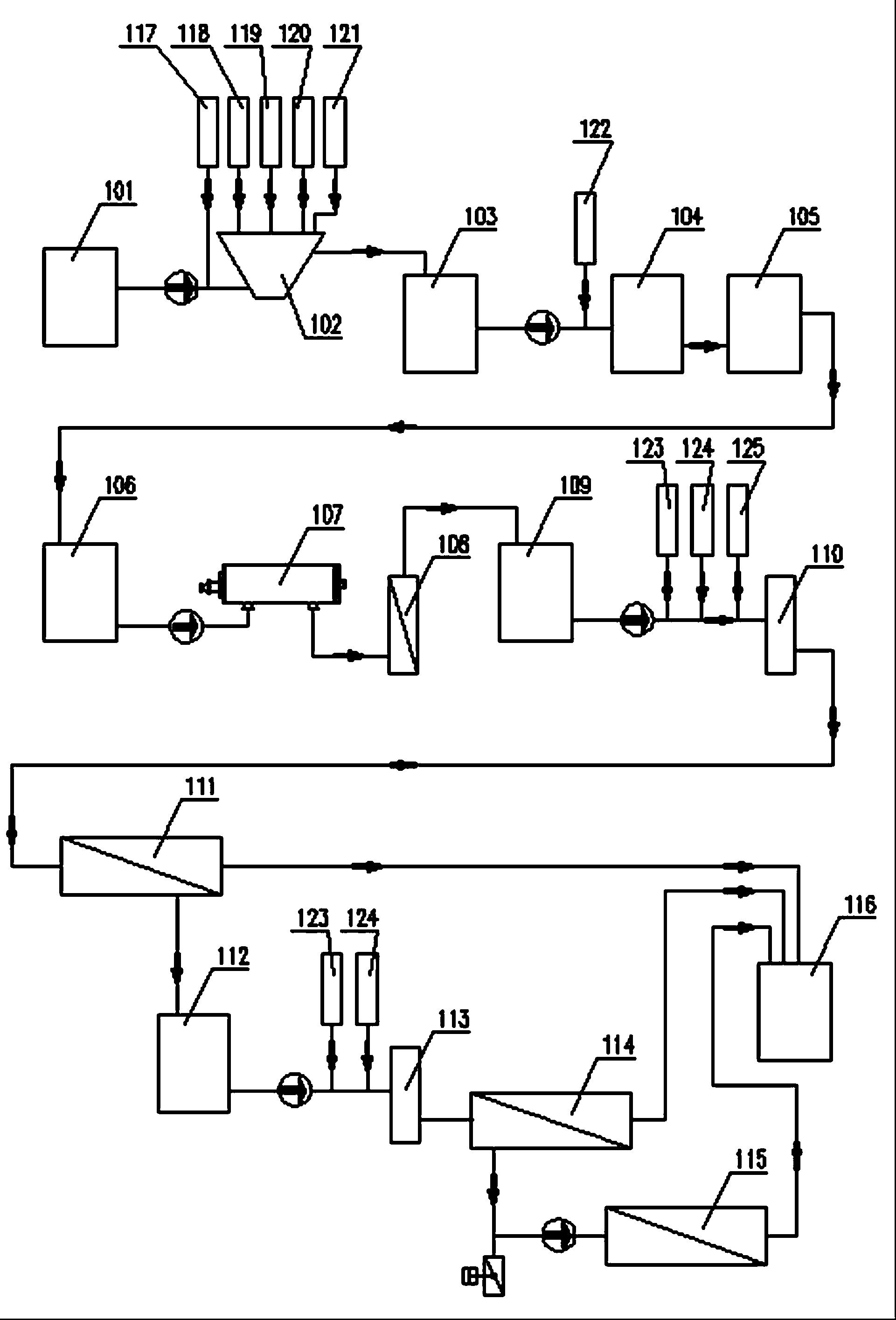

[0022] figure 1 Shows a high-salt industrial wastewater treatment process system diagram according to an embodiment of the present invention, including

[0023] Raw water adjustment tank (101), mechanical acceleration clarification tank (102), clear water tank (103), multi-media filter (104), weak acid cation bed (105), softening water tank (106), self-cleaning filter (107), Ultrafiltration (108), ultrafiltration outlet pool (109), primary RO security filter (110), primary RO (111), concentrated water tank (112), secondary RO security filter (113), secondary RO (114), three-stage RO (115), pre-demineralized water tank (116), lime plant (117), FeCl 3 device (118), PAM device (119), MgO device (120), soda ash device (121), HCl device (122), NaOH (123) device, scale inhibitor device (124), reducing agent dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com