Patents

Literature

41results about How to "Long flame retardant time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional coatings and preparation method thereof

ActiveCN101386719AGood film formingImprove impermeabilityFireproof paintsLuminescent paintsFire retardantStorage garage

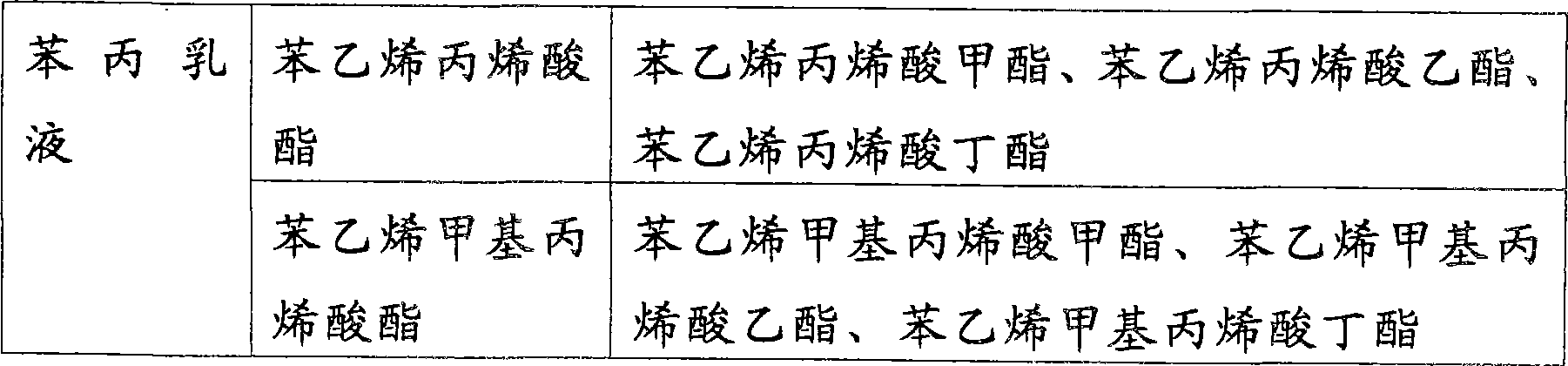

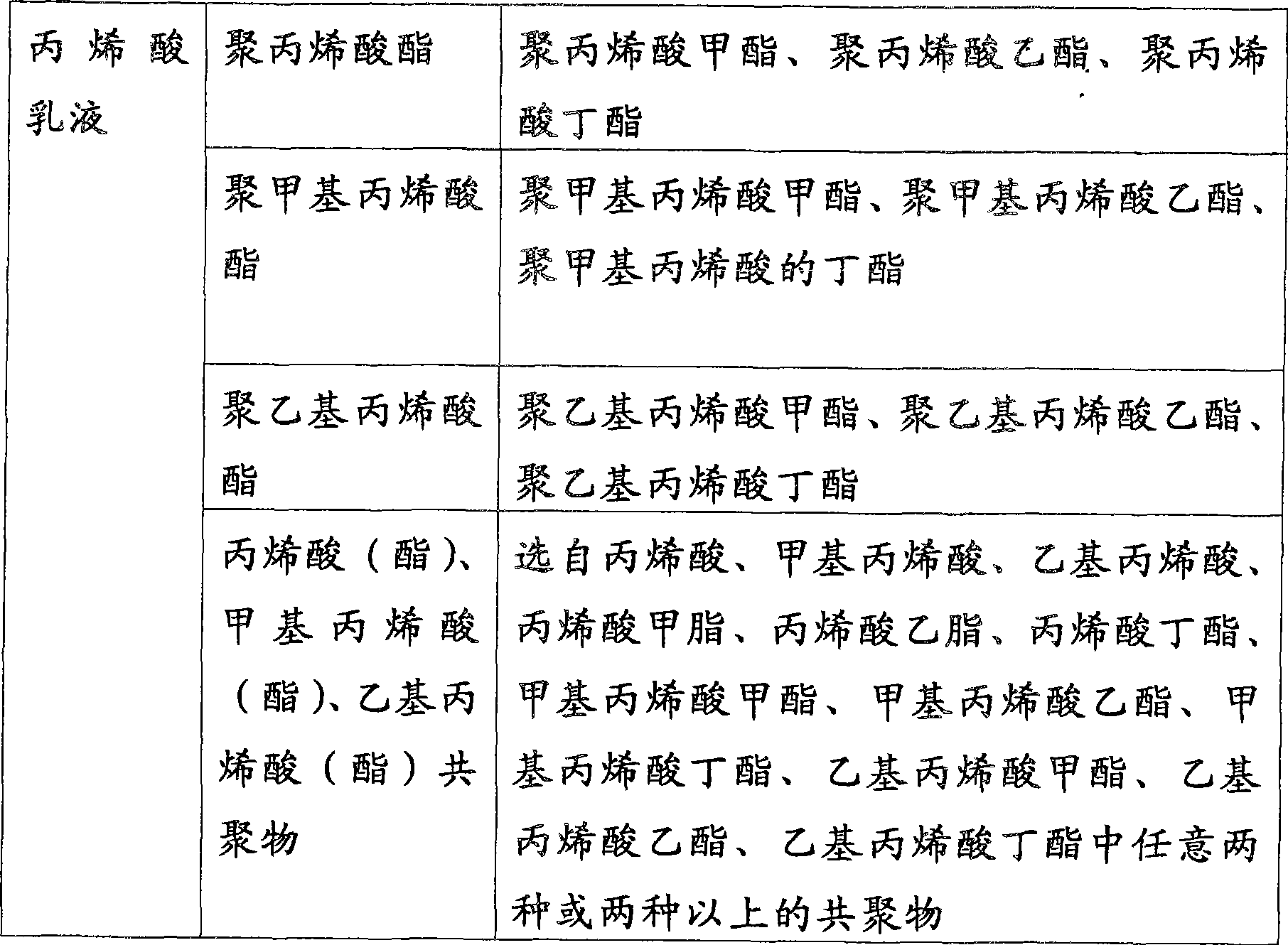

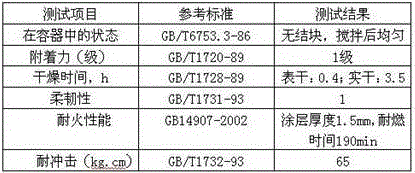

The invention relates to multifunctional paint with the functions of water and fire prevention, lighting, noise reduction, safe escape and decoration and a preparation method thereof. The multifunctional paint comprises a polymer emulsion, a filler, a flame retardant, a long afterglow luminescent material, an addition agent and water, and the paint comprises raw materials in weight percentage: 10 to 50 percent of the polymer emulsion, 5 to 30 percent of the filler, 10 to 30 percent of the flame retardant, 10 to 60 percent of the long afterglow luminescent material, 0.1 to 5 percent of the addition agent and 1 to 50 percent of the water. The multifunctional paint is applied to a highway tunnel, an underground garage, an underground urban traffic passage, a civil defence engineering, an underground fortification, an underground warehouse, an underground production workshop and other underground buildings, can well meet the requirements of waterproof and fireproof functions and has obvious energy-saving effect; and with the characteristic of the long afterglow of the luminescent paint, the multifunctional paint exerts the function of illumination after power failure and is used to guide personnel to safely evacuate the scene of an accident. In addition, the multifunctional paint also has certain functions of noise absorption and noise reduction.

Owner:ANHUI ZHONGYI NEW MATERIAL TECH CO LTD

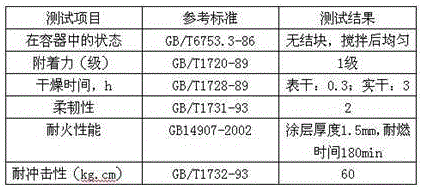

Waterborne fireproof coating for steel structure and preparation method of waterborne fireproof coating

ActiveCN105694627AEasy to prepareLong flame retardant timeFireproof paintsEpoxy resin coatingsAmmonium polyphosphateEmulsion

The invention discloses waterborne fireproof coating for a steel structure and a preparation method of the waterborne fireproof coating. The waterborne fireproof coating is mainly prepared from, by weight, 15-23 parts of ammonium polyphosphate, 11-13 parts of melamine, 6-12 parts of pentaerythritol, 7-13 parts of waterborne epoxy resin, 11-15 parts of hydroxyl acrylic acid emulsion, 6-10 parts of phenolic resin, 2-6 parts of montmorillonite, 19-25 parts of deionized water, 1.0-1.8 parts of thickener, 2-4 parts of dispersion agent and 0.14-0.22 part of defoaming agent. The waterborne fireproof coating is long in flame retardance time, high in adhesive strength, less prone to seasoning crack, excellent in fire resistance, nontoxic, safe, environmental friendly, and the like.

Owner:山西永津集团有限公司

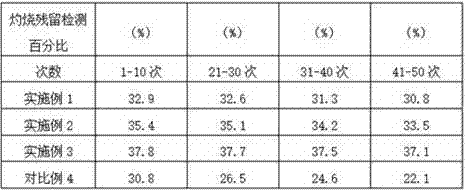

Inhibitor with sustained release property and preparation method thereof

ActiveCN101608553AReduce the number of spraysPlay a slow-release effectDust removalFire preventionInorganic saltsPolymer science

The invention discloses an inhibitor with sustained release property and a preparation method thereof, and the inhibitor is characterized by comprising the following steps of preparing a polymer emulsion by evenly mixing 10-20% of polymer, 79-89% of solvent and 1% of surfactant according to the percentage of the total weight of the prepared emulsion, further adding 4-9 times of the weight of the polymer emulsion of an inorganic salt type inhibitor, stirring for 2-3 hours at the temperature of 40-50 DEG C, drying an obtained product for 6-8 hours at the temperature of 60-80 DEG C, smashing and then obtaining the inhibitor product with the sustained release property. The preparation method is simple and easy to operate, the obtained product can be sustainedly released during the prevention and control process of coal spontaneous combustion of a mine, thereby prolonging the time of flame retardance; the residual polymer is covered on a coal layer, thereby also playing the roles of oxygen isolation and inhibitation; furthermore, the polymer can utilize waste plastics, and the preparation and the using process can not cause harm to environment, thereby having great application prospect.

Owner:UNIV OF SCI & TECH OF CHINA

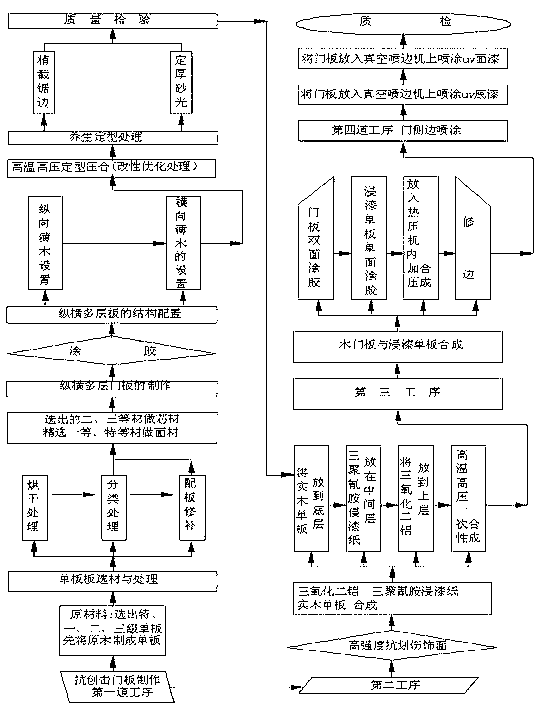

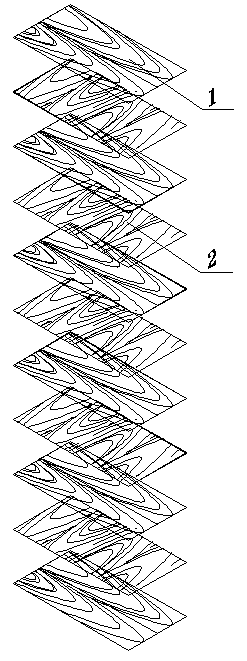

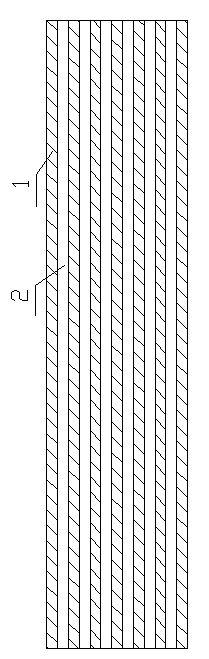

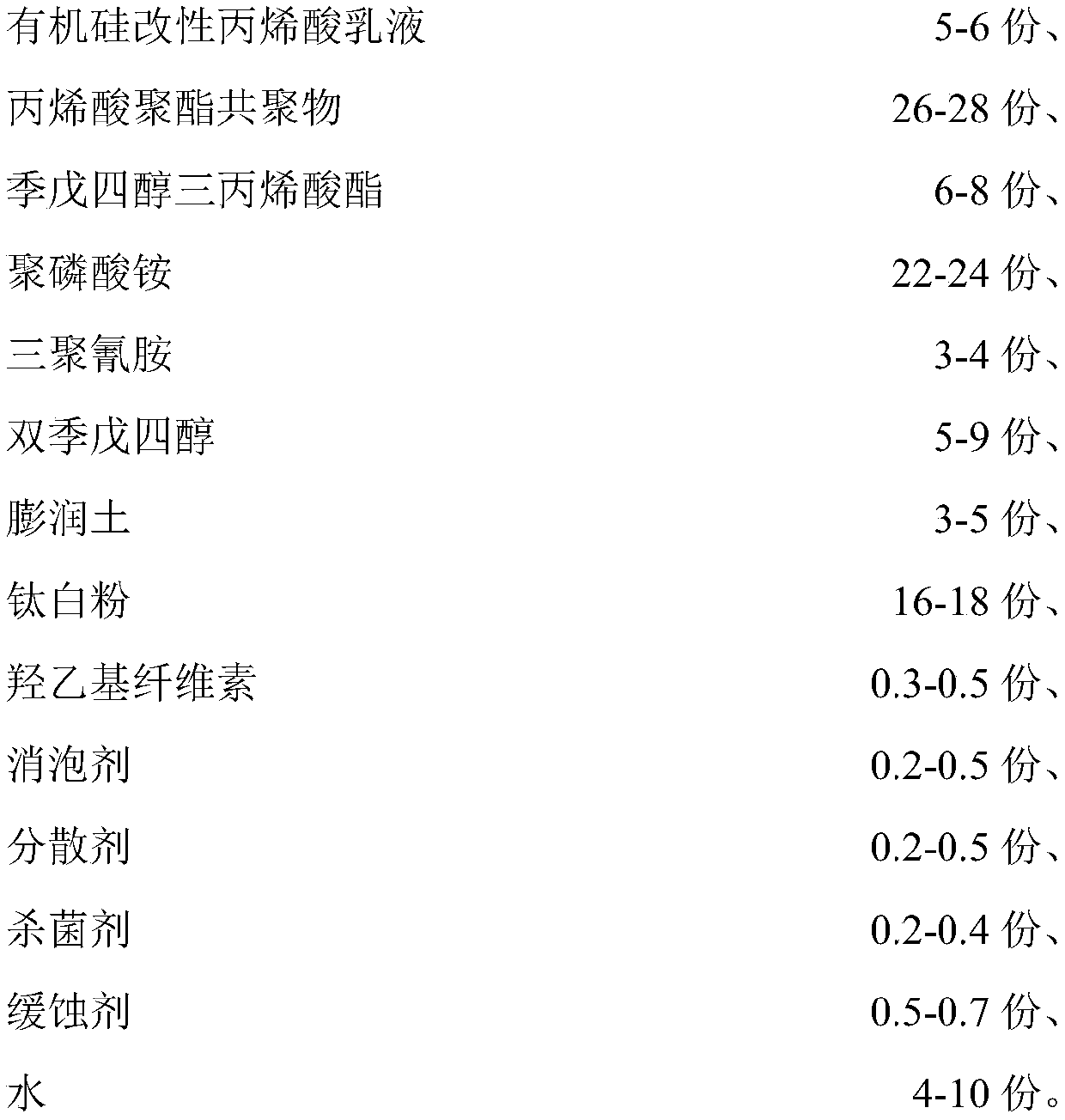

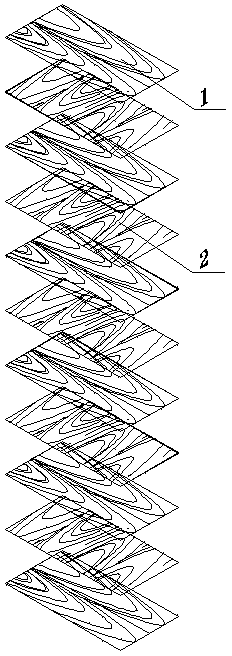

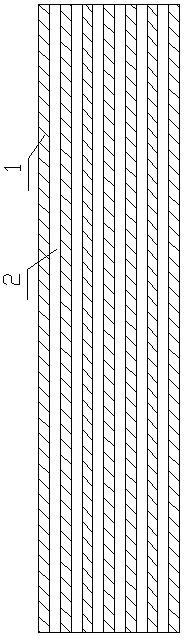

Door manufactured by environment-friendly, energy-saving and fireproof composite board and manufacture method of composite board

InactiveCN103174371ASolve the problem of environmental protectionSolve the problem of not being waterproofFireproof doorsWood veneer joiningSolid woodSingle plate

The invention discloses a door manufactured by an environment-friendly, energy-saving and fireproof composite board and a manufacture method of the composite board. At present, fireproof doors on the market include two kinds including steel fireproof doors and wood fireproof doors, wherein the steel fireproof doors are manufactured by steel plates outside, and the interiors of the steel fireproof doors are filled with rock wool or expanded perlite. The manufacture method of the composite board comprises the following two steps. Firstly, pure solid wood is adopted to manufacture inflaming retarding veneers. Secondly, the inflaming retarding veneers are manufactured to be the fireproof composite board according to a manner that one layer of longitudinal texture veneers and one layer of transverse texture veneers are stacked in an intersected mode. The manufacture method is used for manufacturing the environment-friendly, energy-saving and fireproof composite board.

Owner:HEILONGJIANG HUAXIN FURNITURE

Fireproof coating

The invention discloses a fireproof coating which is prepared from the following components in parts by weight: 10-15 parts of expanded perlite, 8-12 parts of aluminum silicate fiber, 15-20 parts of flexible emulsion, 3-5 parts of pentaerythritol, 8-16 parts of fluorocarbon resin, 2-4 parts of thickening agent, 10-18 parts of an additive and 2-6 parts of an antibacterial agent. By adopting the mode, the fireproof coating is simple in component, low in cost, good in fire resistance, long in flame retardancy time, high in tension viscosity and good in fireproof property.

Owner:SUZHOU MINGXUAN FLOORING COATINGS

Si-N flame retardance high wet modulus viscose fiber and preparation method thereof

ActiveCN107475794AGood physical and mechanical propertiesHigh dry and wet strengthFlame-proof filament manufactureArtificial filaments from cellulose derivativesCelluloseBreaking strength

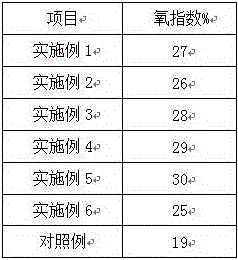

The invention provides a Si-N flame retardance high wet modulus viscose fiber. The dry breaking strength of the fiber is more than or equal to 2.6CN / dtex, the wet breaking strength of the fiber is more than or equal to 1.5CN / dtex, the limit oxygen index of the fiber is more than or equal to 30%, and the wet breaking modulus of the fiber is more than or equal to 0.35CN / dtex. The invention also provides a preparation method of the Si-N inflame retardance high wet modulus viscose fiber. The method comprises the following steps: a step of preparation of cellulose sulfonate: performing a xanthation reaction on cotton with the degree of polymerization of 800-1,400 and / or wood pulp, so as to generate cellulose sulfonate; a step of preparation of spinning liquid: dissolving cellulose sulfonate into alkaline solution, adding a denaturing agent into the mixed solution to obtain stock spinning solution and preparing the spinning solution with the stock spinning solution; a step of intermediate injection before spinning. The high wet modulus viscose fiber prepared by the invention has the characteristics of physical and mechanical properties and high wet modulus and can be applied to the fields of high-end textile and garment fabric with flame retardance requirements and the like.

Owner:山东银鹰化纤有限公司

Water-based fireproof coating and preparing method thereof

ActiveCN105566968ALong flame retardant timeImprove adhesion strengthFireproof paintsWater basedFire resistance

The invention discloses a water-based fireproof coating and a preparing method thereof. The water-based fireproof coating is prepared from, by weight, 16-23 parts of ammonium polyphosphate, 8-14 parts of melamine, 7-10 parts of pentaerythritol triacrylate, 10-16 parts of high-chlorinated polyethylene resin, 6-9 parts of polyurethane resin, 4-8 parts of methyl silicone resin, 2-5 parts of sodium carbonate, 17-21 parts of deionized water, 1.5-2.1 parts of a thickening agent, 1.5-4.5 parts of a dispersing agent, 0.22-0.32 part of an antifoaming agent and an appropriate amount of color paste. The water-based fireproof coating has the advantages of being long in flame-retarding time, high in adhesive strength, not prone to cracking, excellent in fire resistance and the like, and is free of toxicity, safe and environmentally friendly.

Owner:QINGDAO TIANDICAI PAINT

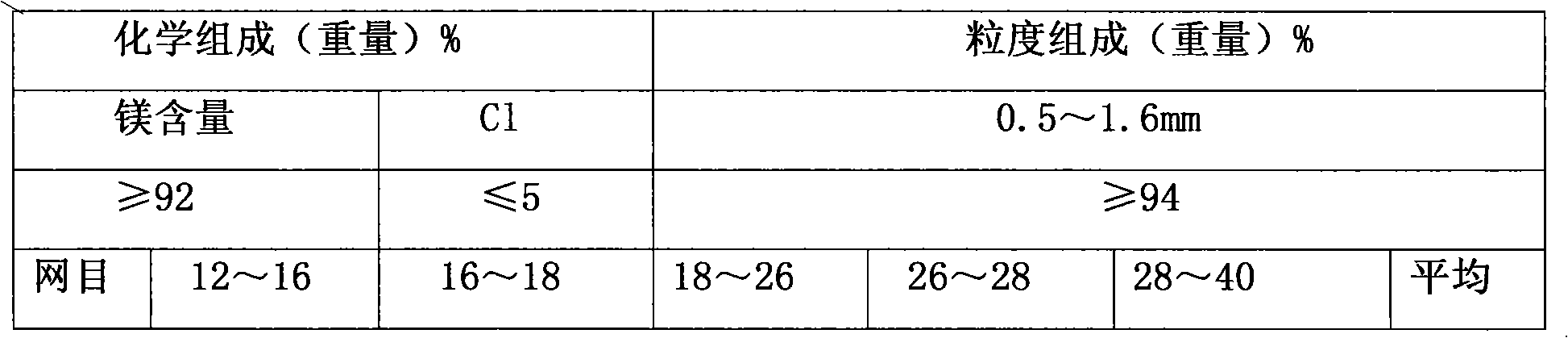

Passivating metal magnesium particles and passivating method thereof

ActiveCN103695884AEvenly wrappedPrecise active magnesium contentLiquid surface applicatorsMetallic material coating processesGraphiteOrganosilicon

The invention discloses passivating metal magnesium particles and a passivating method thereof. The passivating metal magnesium particles comprise the following components in percentage by weight: less than or equal to 99% and greater than or equal to 92% of Mg, less than or equal to 0.002% of S, less than or equal to 0.01% of Cu, less than or equal to 0.001% of P and less than or equal to 1.2% and greater than or equal to 0.1% of H2O. The passivating method comprises the following steps: (I), preparing a metal magnesium particle passivator, placing metal magnesium particles in the passivator, and then naturally cooling to room temperature; (II), coating a coating on the surface of the magnesium particles: firstly, coating an organic silicon compound on the surface of the metal magnesium particles, coating magnesium oxide on the surface of the metal magnesium particles, then, coating compound rare earth on the on the surface of the metal magnesium particles, and finally coating graphite powder on the surface of the metal magnesium particles; and (III), sieving the metal magnesium particles cooled to room temperature. The metal magnesium particle passivating layer is uniform in coating, and the storage and use safety is ensured.

Owner:JIANGSU ZHENGDA FURNACE CHARGE

Organic/inorganic compound flame-retardant rigid polyurethane foam and preparation method thereof

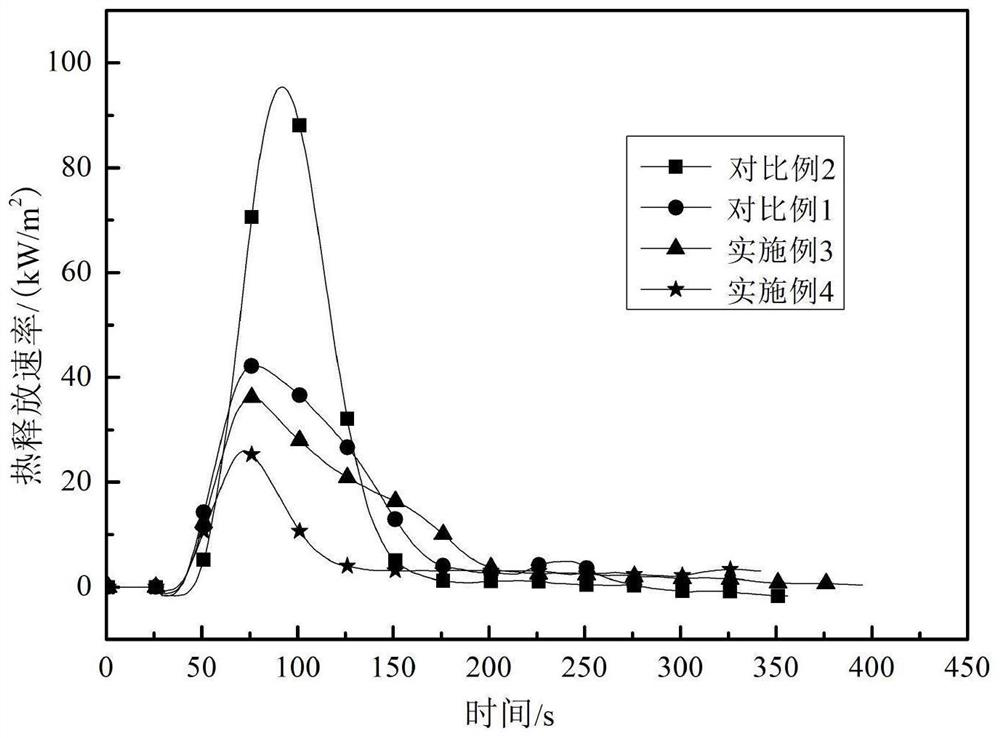

The invention discloses organic / inorganic compound flame-retardant rigid polyurethane foam and a preparation method thereof. The organic / inorganic compound flame-retardant rigid polyurethane foam is composed of a component A, a component B and a component C, wherein the component A is composed of polyether polyol, phosphorus-containing polyol, n-pentane and auxiliaries, the component B is polyisocyanate, and the component C is an organic metal framework material (MOF). The invention also provides a preparation method of the organic / inorganic compound flame-retardant rigid polyurethane foam. The organic / inorganic compound flame-retardant rigid polyurethane foam material can remarkably improve the flame retardance of a pipe, prolong the flame-retardant time, guarantee the quality of the pipeand reduce the construction difficulty, the raw materials are green and environmentally friendly, adverse effects on the environment are avoided, and the organic / inorganic compound flame-retardant rigid polyurethane foam material has good industrial production prospects.

Owner:河北君业科技股份有限公司

Heat-insulation and fireproof paint

InactiveCN106010261ALong flame retardant timeHigh extensional viscosityFireproof paintsAnti-corrosive paintsToxic gasEmulsion

The invention discloses a heat-insulating fireproof coating, which comprises 14-16 parts of titanium nanopolymer; 33-37 parts of flexible emulsion; 23-27 parts of fluorocarbon resin; 12-14 parts of hydroxyethyl cellulose; and 34-16 parts of CrO ; 8~12 parts of expanded perlite; 3~8 parts of antibacterial agent; 4~6 parts of dispersant; 2~4 parts of thickener. Through the above method, the heat-insulating fire-proof coating of the present invention has the advantages of long flame-retardant time, high elongational viscosity, good fire resistance, good high-temperature resistance, remarkable anti-corrosion effect, and is not easy to produce toxic gas in high-temperature environment. advantage.

Owner:SUZHOU MINGXUAN FLOORING COATINGS

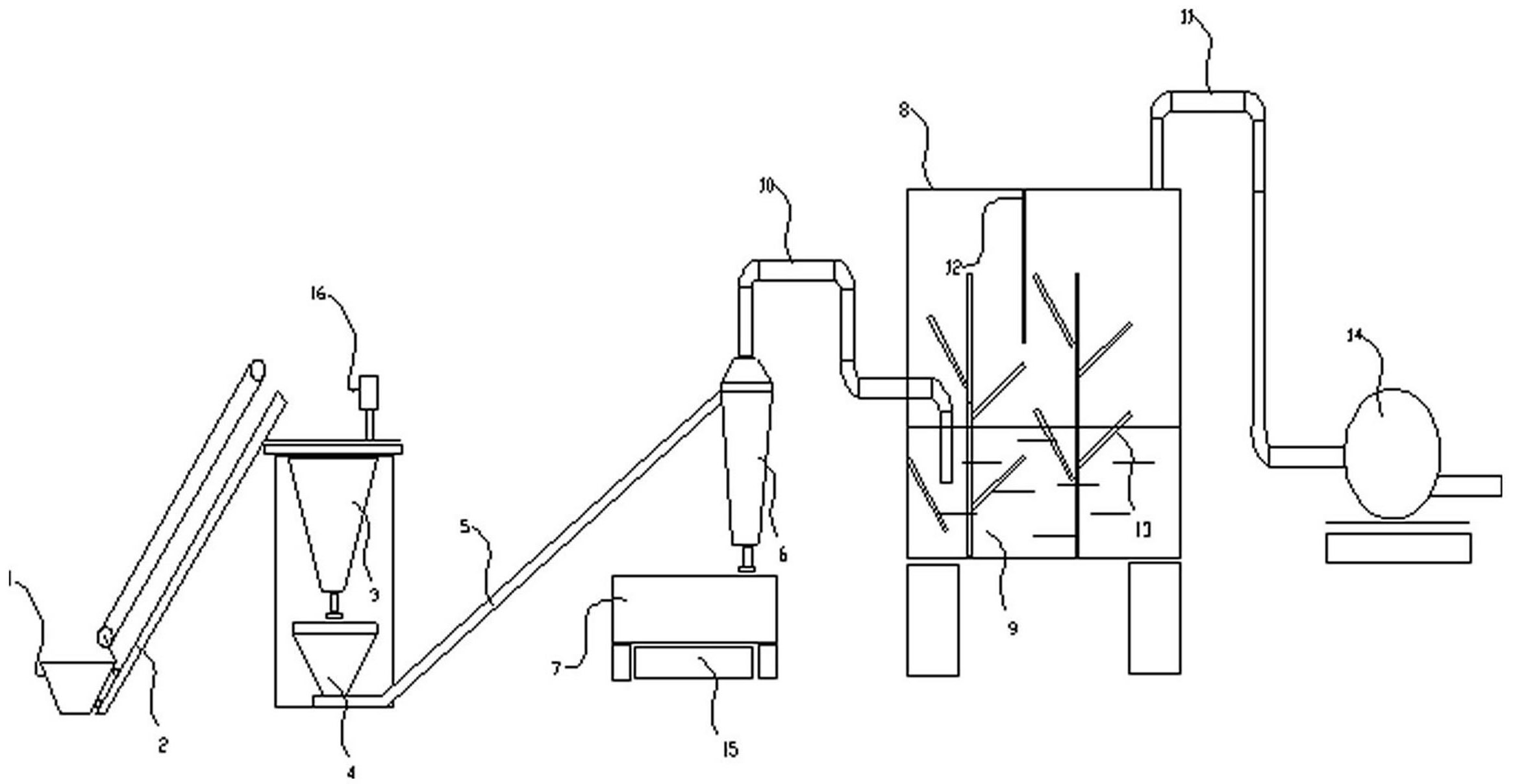

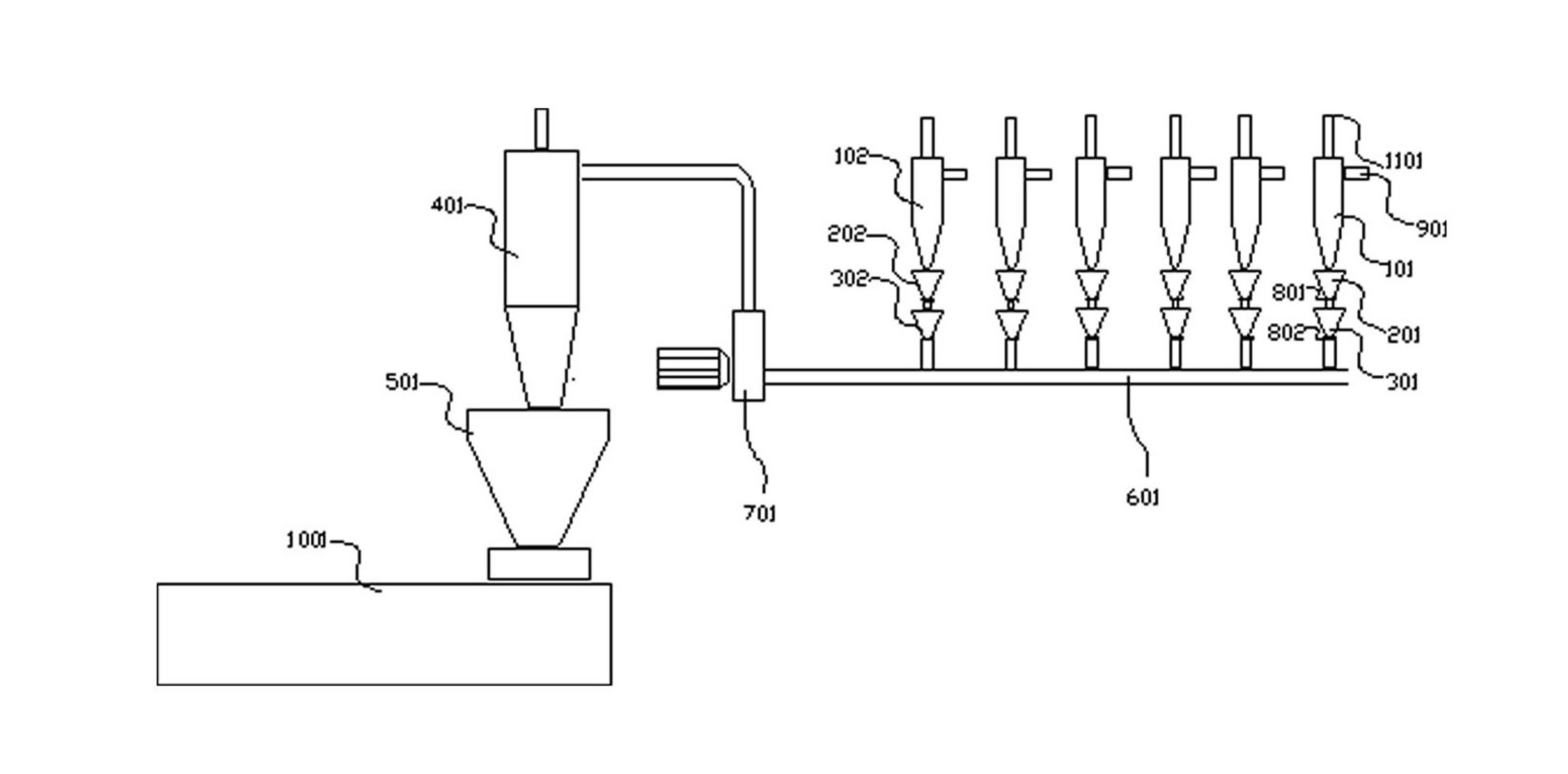

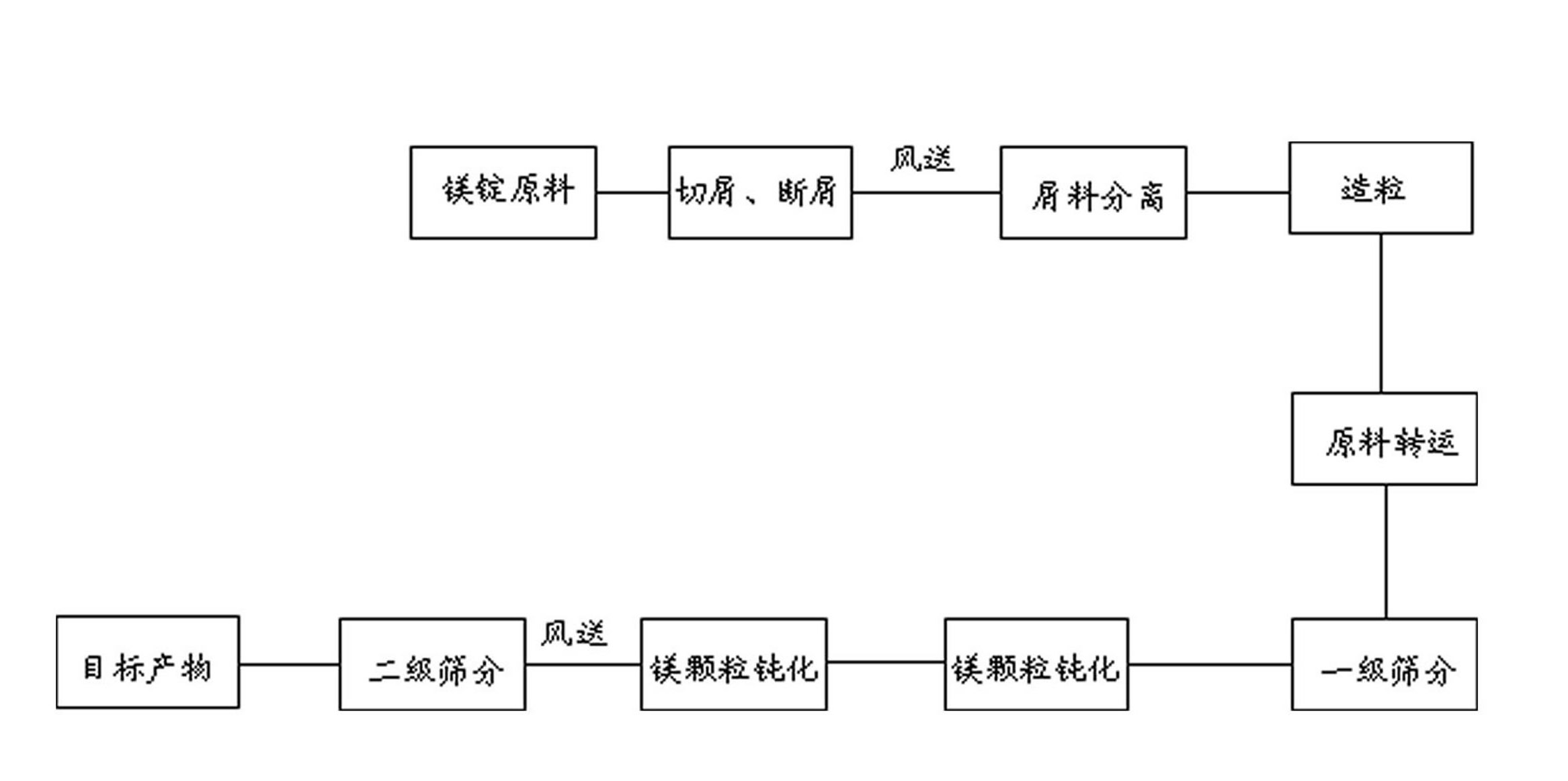

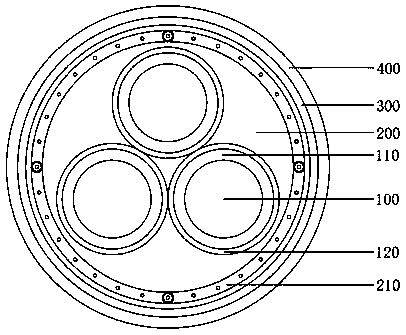

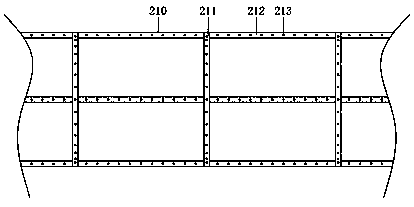

Preparation method of magnesium-based desulfurizing agent

The invention belongs to the technical field of desulfurization of metallurgical molten iron and particularly relates to a preparation method of a magnesium-based desulfurizing agent. The preparation method comprises the following steps of: (1) processing a magnesium ingot raw material and feeding the processed magnesium ingot raw material into a pelletizer for pelletizing; (2) feeding a product obtained in the step (1) into the inlet of a first group of cyclone tanks (101), feeding the product into a first group of one-stage blanking bins (201) from the discharge hole of the first group of cyclone tanks (101), feeding the product into a first group of two-stage blanking bins (301) from the discharge hole of the first group of one-stage blanking bins (201), blowing the product into a final stage cyclone tank (401) and finally feeding the product into a final stage storage tank (501) and a one-stage vibrating screen (1001) for screening; (3) passivating raw material particles and charging a heated and stirred passivated magnesium material into a passivated magnesium storage bin; and (4) feeding passivated magnesium into a cyclone separator by using a radiating conveying mechanism so as to select the passivated magnesium material. The preparation method has high safety performance, remarkable environmental protection efficiency and appropriate flame retarding time; and a granularity range value meets the structural demand of a spray gun.

Owner:营口东邦环保科技股份有限公司

Water-based steel structure fireproof coating and preparation method thereof

The invention discloses waterborne fireproof coating for a steel structure and a preparation method of the waterborne fireproof coating. The waterborne fireproof coating is mainly prepared from, by weight, 15-23 parts of ammonium polyphosphate, 11-13 parts of melamine, 6-12 parts of pentaerythritol, 7-13 parts of waterborne epoxy resin, 11-15 parts of hydroxyl acrylic acid emulsion, 6-10 parts of phenolic resin, 2-6 parts of montmorillonite, 19-25 parts of deionized water, 1.0-1.8 parts of thickener, 2-4 parts of dispersion agent and 0.14-0.22 part of defoaming agent. The waterborne fireproof coating is long in flame retardance time, high in adhesive strength, less prone to seasoning crack, excellent in fire resistance, nontoxic, safe, environmental friendly, and the like.

Owner:山西永津集团有限公司

Fire-resistant elastic coating

InactiveCN104449142AStrong three-dimensional senseGood flexibilityFireproof paintsPolyester coatingsExtensional viscosityEmulsion

The invention discloses a fire-resistant elastic coating. The fire-resistant elastic coating comprises the following components in parts by weight: 2-5 parts of polyester resin, 3.2-6.2 parts of methyl isobutyl ketone, 2.5-3.6 parts of an acrylic emulsion, 3-5 parts of propylene glycol, 5-8 parts of elastic powder, 8-10 parts of quartz sand, 10-12 parts of bentonite and 4-6 parts of talc powder. In such a manner, the fire-resistant elastic coating disclosed by the invention has strong three-dimensional sense, good flexibility, simplicity in components and low cost as well as long flame-retardant time, high tensile viscosity and good fire resistance.

Owner:SUZHOU MINGXUAN FLOORING COATINGS

Fire retardant coating for steel structure

The invention belongs to the technical field of fire retardant coating, and relates to a fire retardant coating for a steel structure; the fire retardant coating is composed of the following raw materials in parts by weight: 300-400 parts of 325 cement, 100-150 parts of a gypsum powder, 40-80 parts of bentonite, 100-150 parts of a heavy calcium carbonate powder, 30-50 parts of high-temperature aluminum silicate fibers, and 400-500 parts of water. During preparation, the high-temperature aluminum silicate fibers are dissolved in water to prepare a glue liquid, then the 325 cement, the gypsum powder, the bentonite and the heavy calcium carbonate powder are mixed evenly and then are mixed with the glue liquid, and stirring is carried out to obtain the coating. The coating is prepared by adopting all the inorganic, non-toxic, odorless and harmless substances, is safe and environmentally friendly, is excellent in fire resistance, has no generation of harmful gas after being heated, and is low in production cost, simple in preparation process, and suitable for wide promotion and application.

Owner:谈钢华

Preparation method of flame-retardant foam tape substrate

InactiveCN110437522AImprove crosslink strengthHigh foaming rateFilm/foil adhesivesLow-density polyethylenePolymer science

The invention belongs to the technical field of polymer materials, and particularly relates to a preparation method of a flame-retardant foam tape substrate. The effect of effectively preparing the flame-retardant foam tape substrate is achieved through the modes of adding a foaming agent, a flexibilizer, an antioxidant, a lubricant and a flame retardant into low-density polyethylene, and combining with step-by-step extrusion, irradiation crosslinking and step-by-step foaming processes. The preparation method has the advantages that the preparation method of the flame-retardant substrate is reasonable and effective, the prepared foam tape substrate is good in flame-retardant performance and long in effective flame-retardant time, and the whole preparation method is efficient and economical.

Owner:ZHEJIANG RUNYANG NEW MATERIAL TECH

Fireproof coating with superior fireproof performance

InactiveCN104845457AFlame retardantImprove non-combustibilityFireproof paintsChloropene polymer coatingsPentaerythritolEmulsion

The invention discloses a fireproof coating with a superior fireproof performance. The fireproof coating with a superior fireproof performance is prepared from, by weight, 400-600 parts of water, 250-350 parts of a flexible emulsion, 100-200 parts of melamine, 50-100 parts of pentaerythritol, 100-200 parts of a fire retardant and a proper amount of an aqueous thickening agent. The fire retardant is prepared from ammonium sulfate and water by uniformly stirring and dissolving ammonium sulfate and water in a container according to a weight ratio of 1:2. The fireproof coating with a superior fireproof performance is prepared by adopting the flexible emulsion as a base material and melamine and pentaerythritol as the fire retardant, so the coating has the characteristics of long fire retardation time, high stretching and bonding strength, and good fireproof performance; and a solvent formed by dissolving ammonium sulfate in water has a fire retardation performance, so the fire retardation performance of products coated with the solvent is obviously improved.

Owner:TONGLING XIANGYUN FIRE FIGHTING TECH

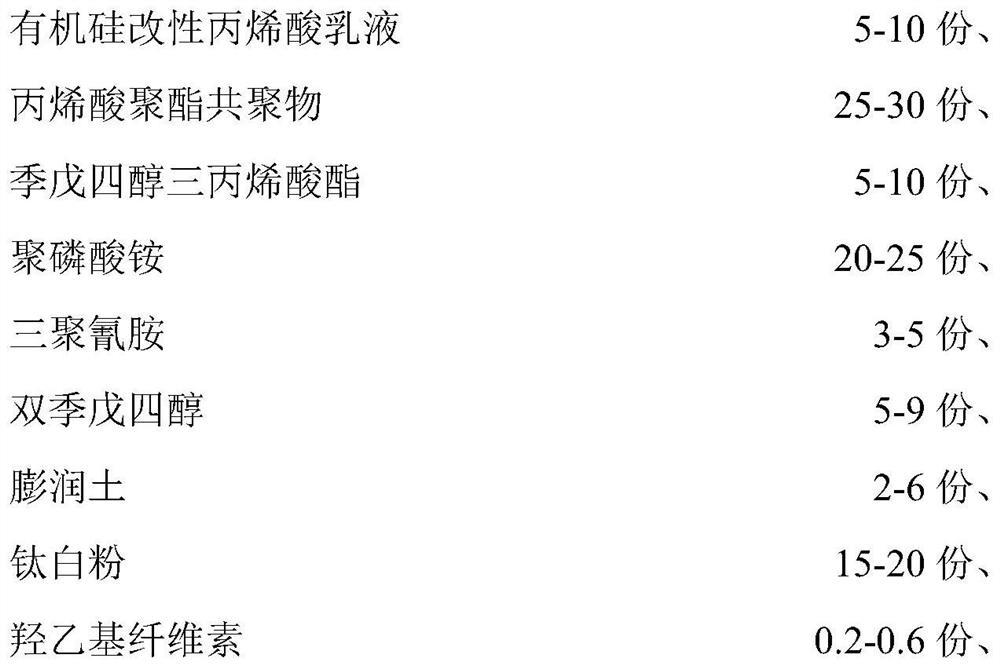

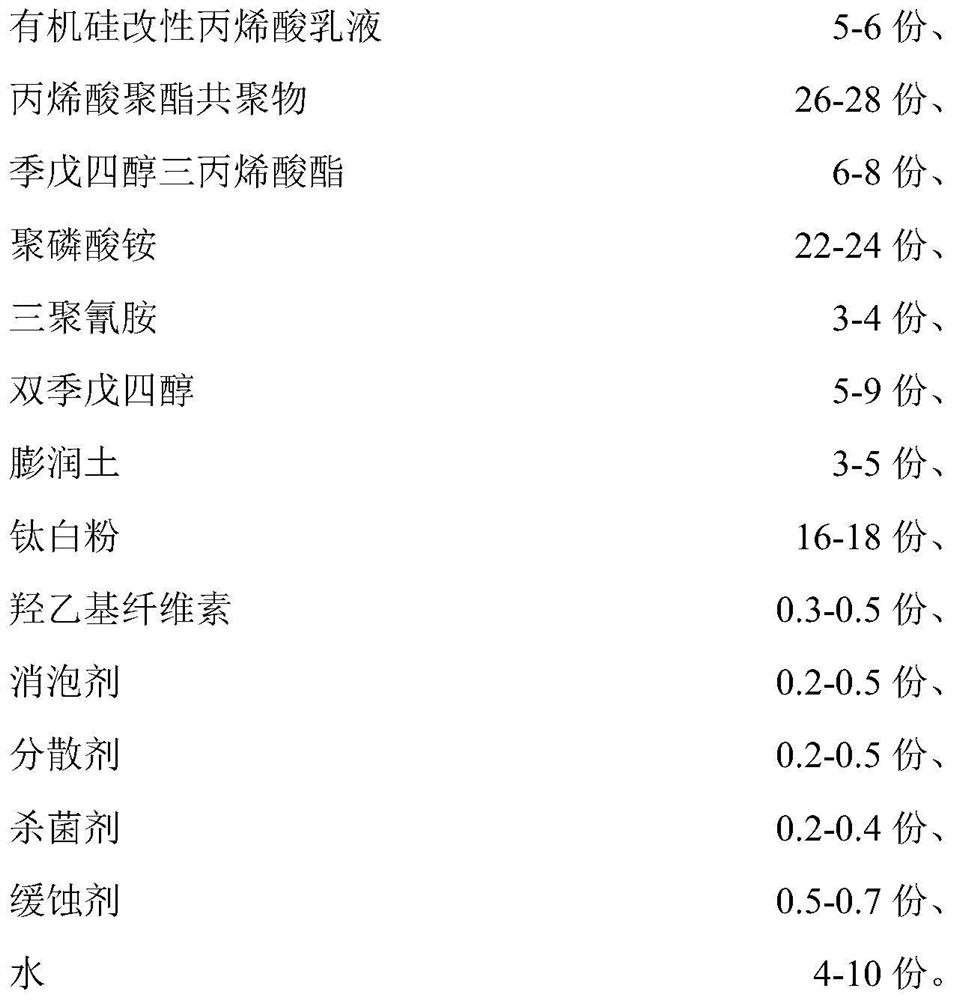

Aqueous thin coating type aluminum alloy fireproof coating material and preparation method thereof

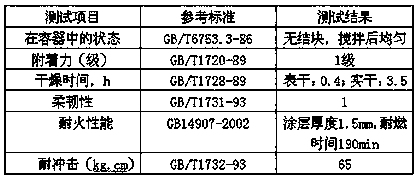

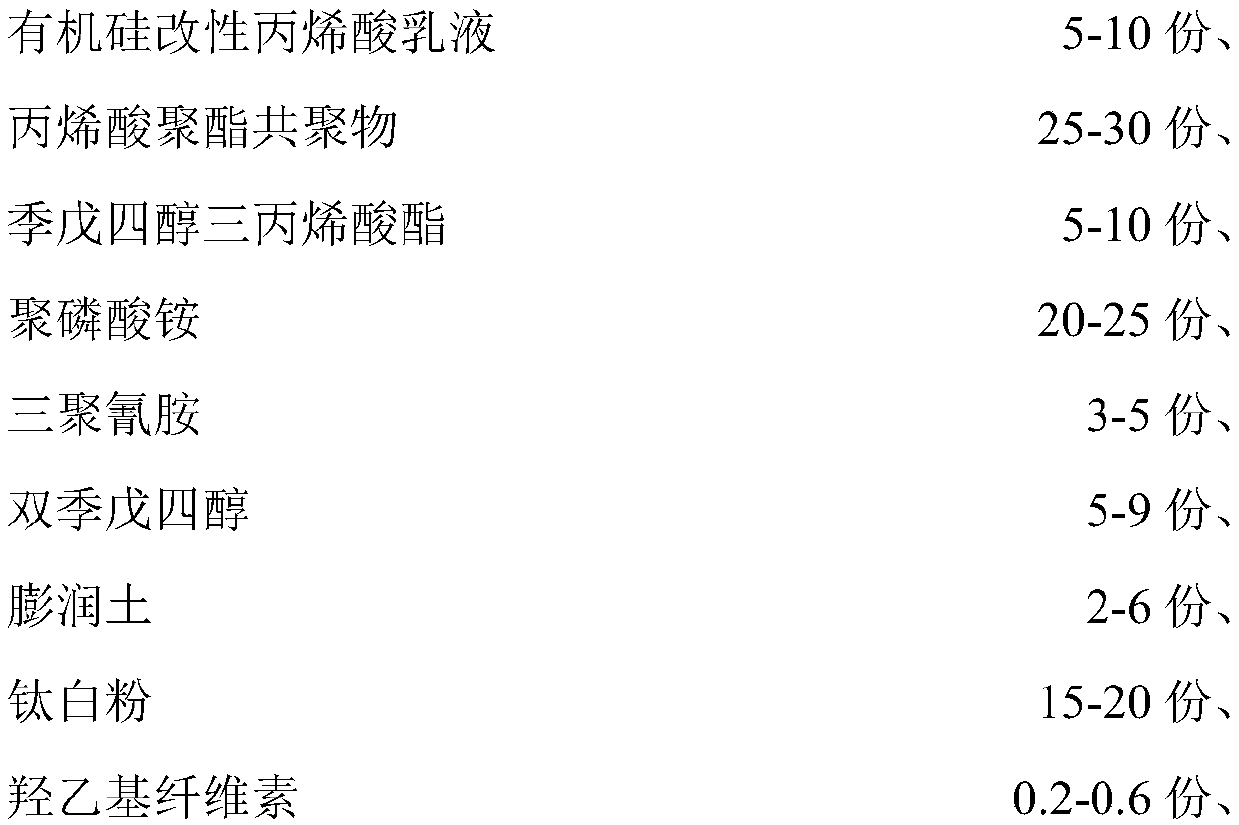

ActiveCN109554081AGood adhesionFilm transparentFireproof paintsAntifouling/underwater paintsAmmonium polyphosphateEmulsion

The invention provides an aqueous thin coating type aluminum alloy fireproof coating material and a preparation method thereof, wherein the aqueous thin coating type aluminum alloy fireproof coating material is prepared by mixing the following raw materials by weight: 5-10 parts of an organosilicon modified acrylic emulsion, 25-30 parts of an acrylic polyester copolymer, 5-10 parts of pentaerythritol triacrylate, 20-25 parts of ammonium polyphosphate, 3-5 parts of melamine, 5-9 parts of dipentaerythritol, 2-6 parts of bentonite, 15-20 parts of titanium dioxide, 0.2-0.6 part of hydroxyethyl cellulose, 0.1-0.5 part of an anti-foaming agent, 0.3-0.5 part of a dispersant, 0.1-0.4 part of a bactericide, 0.2-0.8 part of a corrosion inhibitor, and 4-10 parts of water. According to the present invention, the aqueous thin coating type aluminum alloy fireproof coating material has advantages of uniform fineness, high bonding strength, long flame retardant time, good weather resistance, thin coating, environmental protection and the like; and the preparation method has characteristics of simple process, high production efficiency, stable product quality and environmental friendliness.

Owner:长沙飞鹿高分子新材料有限责任公司

Passivated magnesium desulfurizer containing rare earth oxide and method for preparing same

InactiveCN100475981CReduce lossesAvoid reactionMetallic material coating processesRare earthChloride

Owner:SHANGHAI JIAOTONG UNIV

A kind of flame-retardant simulated tree bark and preparation method thereof

The invention provides a flame-retardant bark of an artificial tree and a making method thereof. The bark is prepared from the following raw materials: epoxy resin, polyaniline, carboxyl polysiloxane, heavy calcium carbonate powder, fumed silica, pigment printing paste, glass fiber, a curing agent, a fire retardant, dibutyl phthalate and a mixed solvent. The making method comprises the following steps: adding epoxy resin into a reaction vessel, then adding the mixed solvent for dissolving, adding polyaniline into the reaction vessel, mixing polyaniline with mixing under high-speed stirring, carrying out a reaction at 20 to 25 DEG C for 1 h with a pH value controlled to be 1 and then adding carboxyl polysiloxane; continuing the reaction at a temperature in a range of room temperature to 50 DEG C for 2 to 5 h; and then adding dibutyl phthalate, heavy calcium carbonate powder, fumed silica, pigment printing paste, glass fiber, the curing agent and the fire retardant, carrying out uniformly mixing under stirring, pouring the obtained mixture into a bark die placed in advance and carrying out micro-pressure standing so as to eventually obtain the flame-retardant bark of the artificial tree. The bark of the artificial tree has lifelike texture and flame retardation effect.

Owner:广西凯威铁塔有限公司

Door made of environmental-protection and energy-saving fireproof composite plates and production method

InactiveCN104533252ASolve the problem of environmental protectionSolve the problem of not being waterproofFireproof doorsWood veneer joiningSolid woodSingle plate

Provided are a door made of environmental-protection and energy-saving fireproof composite plates and a production method. Fireproof doors at the market are steel fireproof doors and wood fireproof doors, wherein the steel fireproof doors are usually made of steel plates with rock wool or expanded perlite filled inside. The production method of environmental-protection and energy-saving fireproof composite plates includes the following two steps: producing flame retardant single plates by aid of pure solid wood; arraying the flame retardant single plates in a way of placing one layer of longitudinal texture single plates and then placing one layer of transverse texture single plates crossly. The production method is used for producing the door made of the environmental-protection and energy-saving fireproof composite plates.

Owner:HEILONGJIANG HUAXIN FURNITURE

Hydrotalcite type water-based facing fireproof coating

PendingCN113969105AImprove water resistanceReduce solubilityFireproof paintsCellulosePentaerythritol

The invention discloses hydrotalcite type water-based facing fireproof coating, which is composed of the following components: 3-7 parts of carbonate hydrotalcite; 1-2 parts of cellulose; 4-6 parts of a dispersant; 0.5 to 2 parts of a defoaming agent; 6 to 11 parts of pentaerythritol; 15 to 20 parts of ammonium polyphosphate; 8 to 12 parts of melamine; 1-3 parts of light calcium carbonate; 2-4 parts of titanium dioxide; 8 to 12 parts of emulsion; 1-3 parts of urea; and 33-42 parts of water. According to the invention, the carbonate hydrotalcite with flame-retardant effect is adopted to replace part of pentaerythritol, ammonium polyphosphate and melamine, part of skeleton, foaming and flame-retardant effects are undertaken, and the cost of the fireproof coating is greatly reduced while the same performance is achieved. In addition, due to the fact that hydrotalcite is heated to generate carbon dioxide and water vapor, flame retardance is achieved, meanwhile, the temperature of a combustion area is reduced, and the flame-retardant time of the fireproof coating is prolonged. Moreover, the hardness of the hardened hydrotalcite is higher, so that the impact resistance of a coating film of the facing fireproof coating is improved. Compared with ammonium polyphosphate, the solubility of the carbonate type hydrotalcite is lower, so that the water resistance of the coating film of the facing fireproof coating containing the carbonate type hydrotalcite is more excellent.

Owner:重庆兴渝新材料研究院有限公司

A kind of cabinet board and its manufacturing method

InactiveCN104802229BLow densityHigh strengthAldehyde/ketone condensation polymer adhesivesWood veneer joiningEngineeringUltimate tensile strength

Owner:广西玉麒木业股份有限公司

A kind of water-based thin coating type aluminum alloy fireproof coating and preparation method thereof

ActiveCN109554081BGood weather resistanceUniform finenessFireproof paintsAntifouling/underwater paintsPolyesterCellulose

The invention provides an aqueous thin coating type aluminum alloy fireproof coating material and a preparation method thereof, wherein the aqueous thin coating type aluminum alloy fireproof coating material is prepared by mixing the following raw materials by weight: 5-10 parts of an organosilicon modified acrylic emulsion, 25-30 parts of an acrylic polyester copolymer, 5-10 parts of pentaerythritol triacrylate, 20-25 parts of ammonium polyphosphate, 3-5 parts of melamine, 5-9 parts of dipentaerythritol, 2-6 parts of bentonite, 15-20 parts of titanium dioxide, 0.2-0.6 part of hydroxyethyl cellulose, 0.1-0.5 part of an anti-foaming agent, 0.3-0.5 part of a dispersant, 0.1-0.4 part of a bactericide, 0.2-0.8 part of a corrosion inhibitor, and 4-10 parts of water. According to the present invention, the aqueous thin coating type aluminum alloy fireproof coating material has advantages of uniform fineness, high bonding strength, long flame retardant time, good weather resistance, thin coating, environmental protection and the like; and the preparation method has characteristics of simple process, high production efficiency, stable product quality and environmental friendliness.

Owner:长沙飞鹿高分子新材料有限责任公司

Composite-coating granular magnesium desulfurizer

The invention belongs to the field of molten iron desulfurizers in steel making industry, and particularly relates to a composite-coating granular magnesium desulfurizer which comprises the following components in percentage by weight: 90-95% of metallic granular magnesium, 1-8% of chloride and 2-10% of filler, wherein the chloride is a mixture of KCl, NaCl and CaCl2; the filler is one of CaF2 and CaOMgO, or the mixture thereof; the weight ratio of KCl to NaCl to CaCl2 is (1-10):(1-8):(1-5); and the granularity of the metallic granular magnesium is 0.5-1.6mm. The composite-coating granular magnesium desulfurizer has the advantages of uniform and compact surface, long flame-retardant time, favorable flowing property and environmental protection, does not stick to or plug the gun and does not splash in the spraying process of the spray gun with a gasification chamber, and is convenient to transport and store.

Owner:营口东邦环保科技股份有限公司

Petroleum or industrial fireproof thermal insulation coating

InactiveCN107163696ASimple preparation processLow costChloropene polymer coatingsEmulsionPentaerythritol

The invention relates to a petroleum or industrial fireproof thermal insulation coating, and belongs to the field of industrial fire-fighting coating. The petroleum or industrial fireproof thermal insulation coating is prepared from, by weight, 400 to 500 parts of water, 280 to 400 parts of a flexible emulsion, 100 to 180 parts of melamine, 60 to 80 parts of pentaerythritol, and an appropriate amount of an aqueous thickening agent. The flexible emulsion in the petroleum or industrial fireproof thermal insulation coating is capable of prolonging flame retardant time of a base material; foaming is adopted so as to improve the flame retardant effect further and achieve thermal insulation performance. A preparation method of the petroleum or industrial fireproof thermal insulation coating is relatively simple; cost is relatively low; the finished product can be used in industrial buildings; and workability is improved further.

Owner:南通市乐佳涂料有限公司

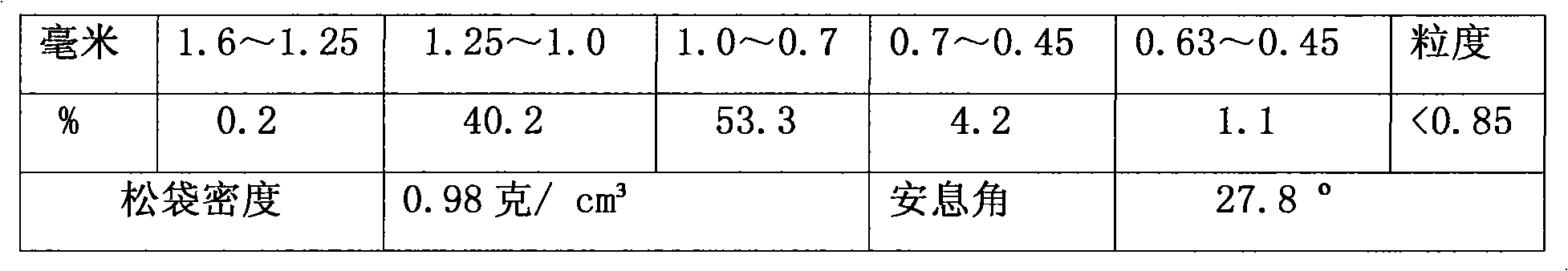

A cross-linked polyethylene insulated fire-resistant and flame-retardant power cable

ActiveCN110148492BLong flame retardant timeLow oxygenPower cables with screens/conductive layersInsulated cablesCopper conductorPower cable

The invention discloses a crosslinked polyethylene insulating fireproof flame-retardant power cable in the technical field of cables. The cable comprises a copper conductor, and the outer wall of thecopper conductor is sleeved by an insulating layer. The outer wall of the insulating layer is sleeved by a shielding layer. The outer wall of the shielding layer is sleeved by a flame-retardant layer,and a heat conduction frame is arranged in the flame retardant layer. The heat conduction frame comprises ferrules, and the ferrules are uniformly arranged in the flame-retardant layer, wherein a connecting rod is welded between the ferrules. Through holes are formed in the outer walls of the ferrules and the connecting rod, and the outer wall of the flame-retardant layer is sleeved by a mineralinsulating layer, wherein the outer wall of the mineral insulating layer is sleeved by an outer protective sleeve. According to the cable, the heat conduction frame is arranged in the flame retardantlayer; when the cable encounters a fire, the local flame-retardant layer is heated to enable the heat conduction frame to be heated to conduct heat, the flame-retardant layer at the heated heat conduction frame is heated to decompose water vapor, the water vapor moves towards the burning damage position of the cable due to pressure, the flame-retardant time of the flame-retardant layer is effectively prolonged, and the normal power-on time of related alarm and safety indication equipment is effectively prolonged.

Owner:JINYUAN ELECTRIC GRP

Coating granule magnesium desulfurizer and preparation method thereof

Owner:HUNAN S R M SCI & TECH

Method for making flame-retardant artificial tree bark cement utility pole

The invention provides a manufacturing method of a flame retardant simulation tree bark cement telegraph pole. The manufacturing method comprises the steps of: (S1) manufacturing of the cement telegraph pole; (S2) preparation of flame retardant simulation tree bark slurry; and (S3) coating of the flame retardant simulation tree bark slurry; and manufacturing of the flame retardant simulation tree bark cement telegraph pole. The cement telegraph pole is simply treated, is coated with one layer of flame retardant simulation tree bark, is beautiful in appearance, is coordinated with surrounding environments, can bring visual enjoyment for tourist attraction environments, and can add beautiful elements for tourist attractions. The flame retardant simulation tree bark slurry is prepared by the following raw materials: epoxy resins, polyaniline, carboxyl polysiloxane, calcium carbonate heavy, fumed silica, pigment printing paste, glass fibers, aliphatics polyamine, microencapsulation red phosphorus, dibutyl phthalate and mixed solvent; the construction is convenient and fast; and the bark formed by coating is natural in vein and excellent in flame retardance, and is used for beautifying the cement telegraph pole to bring visual enjoyment to people.

Owner:广西凯威铁塔有限公司

EPP flame-retardant particles with low energy consumption

PendingCN109666214AImprove flame retardant performanceLong flame retardant timeElastomerWear resistant

The invention discloses EPP flame-retardant particles with low energy consumption. The EPP flame-retardant particles are prepared from the following raw materials in parts by weight: 130 to 150 partsof polypropylene resin, 20 parts to 40 parts of ethylene elastomer, 3 to 5 parts of benzene alkene elastomer, 10 to 15 parts of nylon resin, 1 to 3 parts of cross-linking agent, 0.t to 1 part of co-cross-linking agent, 2 to 4 parts of compatilizer, 1 to 3 parts of light stabilizer, 1 to 3 parts of antioxidant, 3 to 8 parts of reinforcing agent, 1 to 3 parts of wear-resistant agent, 3 to 5 parts offlame retardant, 3 to 5 parts of flame retardant additive, 0.5 to 1.5 parts of polyethylene wax lubricant, 3 to 5 parts of flame retardant synergist, and 3 to 20 parts of carbon black pigments. The EPP flame-retardant particles with low energy consumption provided by the invention are ingenious in design, reasonable in composition and good in flame retardant effect, and suitable for popularization and use.

Owner:安徽康乐机械科技有限公司

Flame-retardant bark of artificial tree and making method thereof

The invention provides a flame-retardant bark of an artificial tree and a making method thereof. The bark is prepared from the following raw materials: epoxy resin, polyaniline, carboxyl polysiloxane, heavy calcium carbonate powder, fumed silica, pigment printing paste, glass fiber, a curing agent, a fire retardant, dibutyl phthalate and a mixed solvent. The making method comprises the following steps: adding epoxy resin into a reaction vessel, then adding the mixed solvent for dissolving, adding polyaniline into the reaction vessel, mixing polyaniline with mixing under high-speed stirring, carrying out a reaction at 20 to 25 DEG C for 1 h with a pH value controlled to be 1 and then adding carboxyl polysiloxane; continuing the reaction at a temperature in a range of room temperature to 50 DEG C for 2 to 5 h; and then adding dibutyl phthalate, heavy calcium carbonate powder, fumed silica, pigment printing paste, glass fiber, the curing agent and the fire retardant, carrying out uniformly mixing under stirring, pouring the obtained mixture into a bark die placed in advance and carrying out micro-pressure standing so as to eventually obtain the flame-retardant bark of the artificial tree. The bark of the artificial tree has lifelike texture and flame retardation effect.

Owner:广西凯威铁塔有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com