Water-based steel structure fireproof coating and preparation method thereof

A technology for fire-resistant coatings and steel structures, applied in fire-resistant coatings, epoxy resin coatings, coatings, etc., can solve the problems of easy drying and cracking, low adhesion strength and fire resistance, and achieve the characteristics of not easy drying and cracking, high adhesion strength, and excellent fire resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

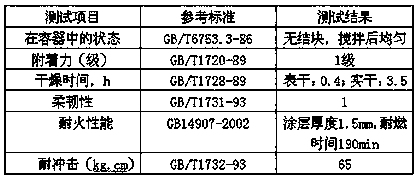

Examples

Embodiment 1

[0032] Example 1 The water-based steel structure fireproof coating is prepared from the following main raw materials in parts by weight (each part is 3kg): 15 parts of ammonium polyphosphate, 11 parts of melamine, 6 parts of pentaerythritol, 7 parts of water-based epoxy resin, hydroxyacrylic acid 11 parts of emulsion, 6 parts of phenolic resin, 2 parts of montmorillonite, 19 parts of deionized water, 1.0 part of thickener, 2 parts of dispersant, and 0.14 part of defoamer.

[0033] The preparation method of above-mentioned waterborne steel structure fireproof coating is:

[0034] (1) Mix the hydroxyacrylic acid emulsion, defoamer and film-forming aid, the weight of the film-forming aid is 2% of the weight of the hydroxyacrylic acid emulsion, stir at a speed of 180r / min, stir for 10 minutes, and set aside;

[0035] (2) Mix water-based epoxy resin and phenolic resin with the result of step (1), stir for 30 minutes, and then ultrasonically disperse for 25 minutes;

[0036] (3) Mi...

Embodiment 2

[0037] Example 2 The water-based steel structure fireproof coating is prepared from the following main raw materials in parts by weight (each part is 3kg): 23 parts of ammonium polyphosphate, 13 parts of melamine, 12 parts of pentaerythritol, 13 parts of water-based epoxy resin, hydroxyacrylic acid 15 parts of emulsion, 10 parts of phenolic resin, 6 parts of montmorillonite, 25 parts of deionized water, 1.8 parts of thickener, 4 parts of dispersant, and 0.22 parts of defoamer.

[0038] (1) Mix the hydroxyacrylic acid emulsion, defoamer and film-forming aid, the weight of the film-forming aid is 7% of the weight of the hydroxyacrylic acid emulsion, stir at a speed of 240r / min, stir for 24 minutes, and set aside;

[0039] (2) Mix water-based epoxy resin and phenolic resin with the result of step (1), stir for 45 minutes, and then ultrasonically disperse for 35 minutes;

[0040] (3) Mix ammonium polyphosphate, melamine, pentaerythritol, montmorillonite and the result of step (2),...

Embodiment 3

[0041] Example 3 The water-based steel structure fireproof coating is prepared from the following main raw materials in parts by weight (each part is 3kg): 17 parts of ammonium polyphosphate, 11.5 parts of melamine, 8 parts of pentaerythritol, 9 parts of water-based epoxy resin, and hydroxyacrylic acid 12 parts of emulsion, 7 parts of phenolic resin, 3 parts of montmorillonite, 21 parts of deionized water, 1.3 parts of thickener, 2.5 parts of dispersant, and 0.16 parts of defoamer.

[0042] (1) Mix the hydroxyacrylic acid emulsion, defoamer and film-forming aid, the weight of the film-forming aid is 3% of the weight of the hydroxyacrylic acid emulsion, stir at a speed of 200r / min, stir for 14 minutes, and set aside;

[0043] (2) Mix water-based epoxy resin and phenolic resin with the result of step (1), stir for 33 minutes, and then ultrasonically disperse for 28 minutes;

[0044] (3) Mix ammonium polyphosphate, melamine, pentaerythritol, montmorillonite and the result of step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com