Water-based fireproof coating and preparing method thereof

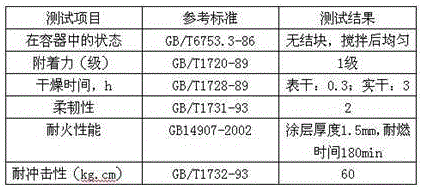

A fire retardant coating and water-based technology, applied in the field of coatings, can solve the problems of easy drying and cracking, low adhesion strength and fire resistance, and achieve the effects of long flame retardant time, high adhesion strength and excellent fire resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 A water-based fireproof coating prepared from the following main raw materials in parts by weight (each part is 2kg): 16 parts of ammonium polyphosphate, 8 parts of melamine, 7 parts of pentaerythritol triacrylate, high chlorinated polyethylene resin 10 parts, 6 parts of polyurethane resin, 4 parts of methyl silicone resin, 2 parts of sodium carbonate, 17 parts of deionized water, 1.5 parts of thickener, 1.5 parts of dispersant, 0.22 parts of defoamer, appropriate amount of color paste.

[0032] The preparation method of above-mentioned water-based fireproof coating is:

[0033] (1) Mix pentaerythritol triacrylate, high chlorinated polyethylene resin, polyurethane resin and methyl silicone resin, add deionized water, stir for 30 minutes, add film-forming aid, the amount of film-forming aid is pentaerythritol triacrylic acid 0.3% of the total weight of ester, high chlorinated polyethylene resin, polyurethane resin and methyl silicone resin, and then ultrasonica...

Embodiment 2

[0036] Example 2 A water-based fireproof coating prepared from the following main raw materials in parts by weight (each part is 2 kg): 23 parts of ammonium polyphosphate, 14 parts of melamine, 10 parts of pentaerythritol triacrylate, and high chlorinated polyethylene resin 16 parts, 9 parts of polyurethane resin, 8 parts of methyl silicone resin, 5 parts of sodium carbonate, 21 parts of deionized water, 2.1 parts of thickener, 4.5 parts of dispersant, 0.32 parts of defoamer, appropriate amount of color paste.

[0037] The preparation method of above-mentioned water-based fireproof coating is:

[0038] (1) Mix pentaerythritol triacrylate, high chlorinated polyethylene resin, polyurethane resin and methyl silicone resin, add deionized water, stir for 70 minutes, add film-forming aid, the amount of film-forming aid is pentaerythritol triacrylate 0.8% of the total weight of ester, high chlorinated polyethylene resin, polyurethane resin and methyl silicone resin, and then ultrason...

Embodiment 3

[0041]Example 3 A water-based fireproof coating prepared from the following main raw materials in parts by weight (each part is 2 kg): 18 parts of ammonium polyphosphate, 10 parts of melamine, 8 parts of pentaerythritol triacrylate, and high chlorinated polyethylene resin 13 parts, 7 parts of polyurethane resin, 5 parts of methyl silicone resin, 3 parts of sodium carbonate, 18 parts of deionized water, 1.7 parts of thickener, 2.3 parts of dispersant, 0.25 parts of defoamer, appropriate amount of color paste.

[0042] The preparation method of above-mentioned water-based fireproof coating is:

[0043] (1) Mix pentaerythritol triacrylate, high chlorinated polyethylene resin, polyurethane resin and methyl silicone resin, add deionized water, stir for 35 minutes, add film-forming aid, the amount of film-forming aid is pentaerythritol triacrylate 0.4% of the total weight of ester, high chlorinated polyethylene resin, polyurethane resin and methyl silicone resin, and then ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com