Patents

Literature

314 results about "Pentaerythritol triacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pentaerythritol triacrylate technical grade Synonym: PETA CAS Number 3524-68-3. Linear Formula (H 2 C=CHCO 2 CH 2) 3 CCH 2 OH . Molecular Weight 298.29 . Beilstein Registry Number 6598752 . EC Number 222-540-8. MDL number MFCD00009607. PubChem Substance ID 24854825

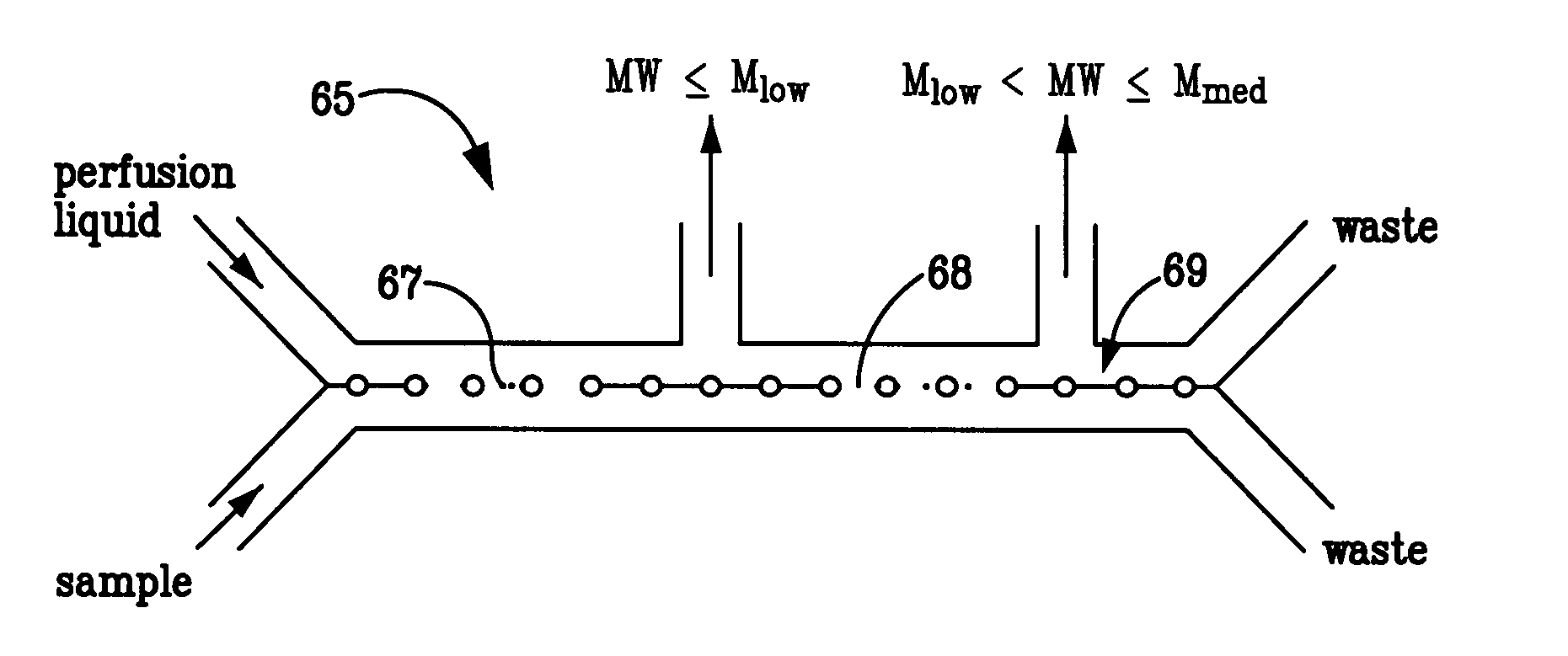

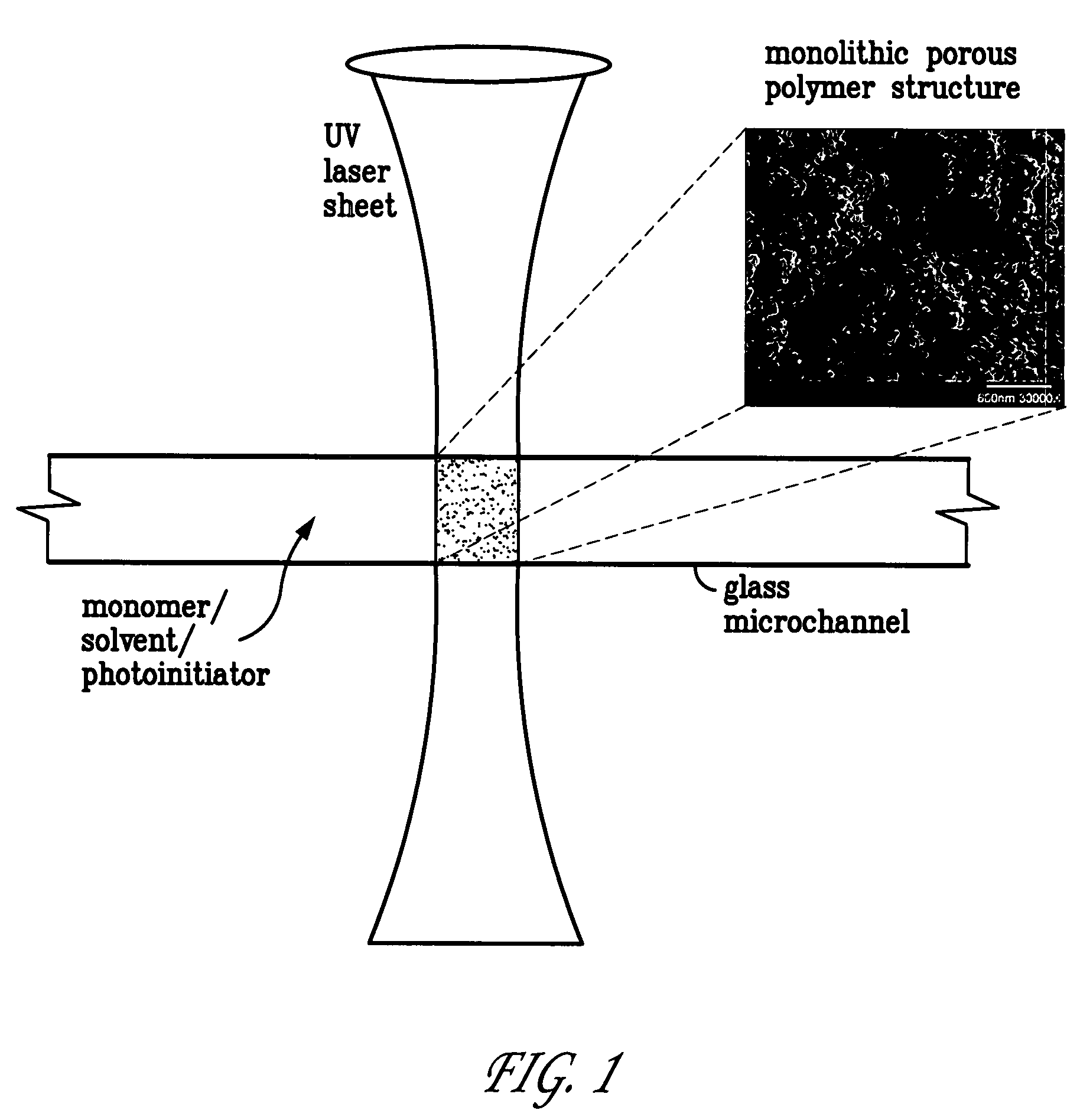

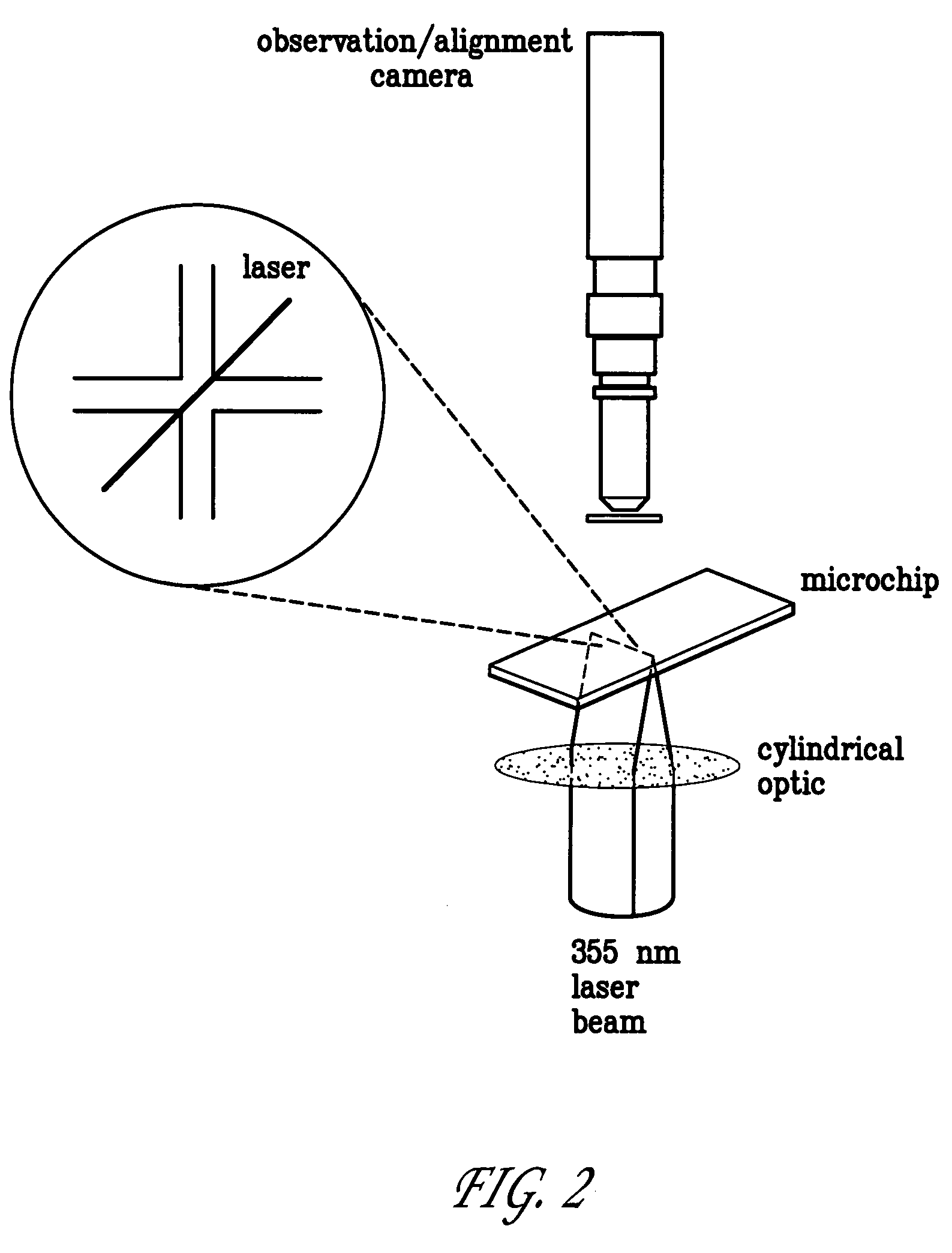

Dialysis on microchips using thin porous polymer membranes

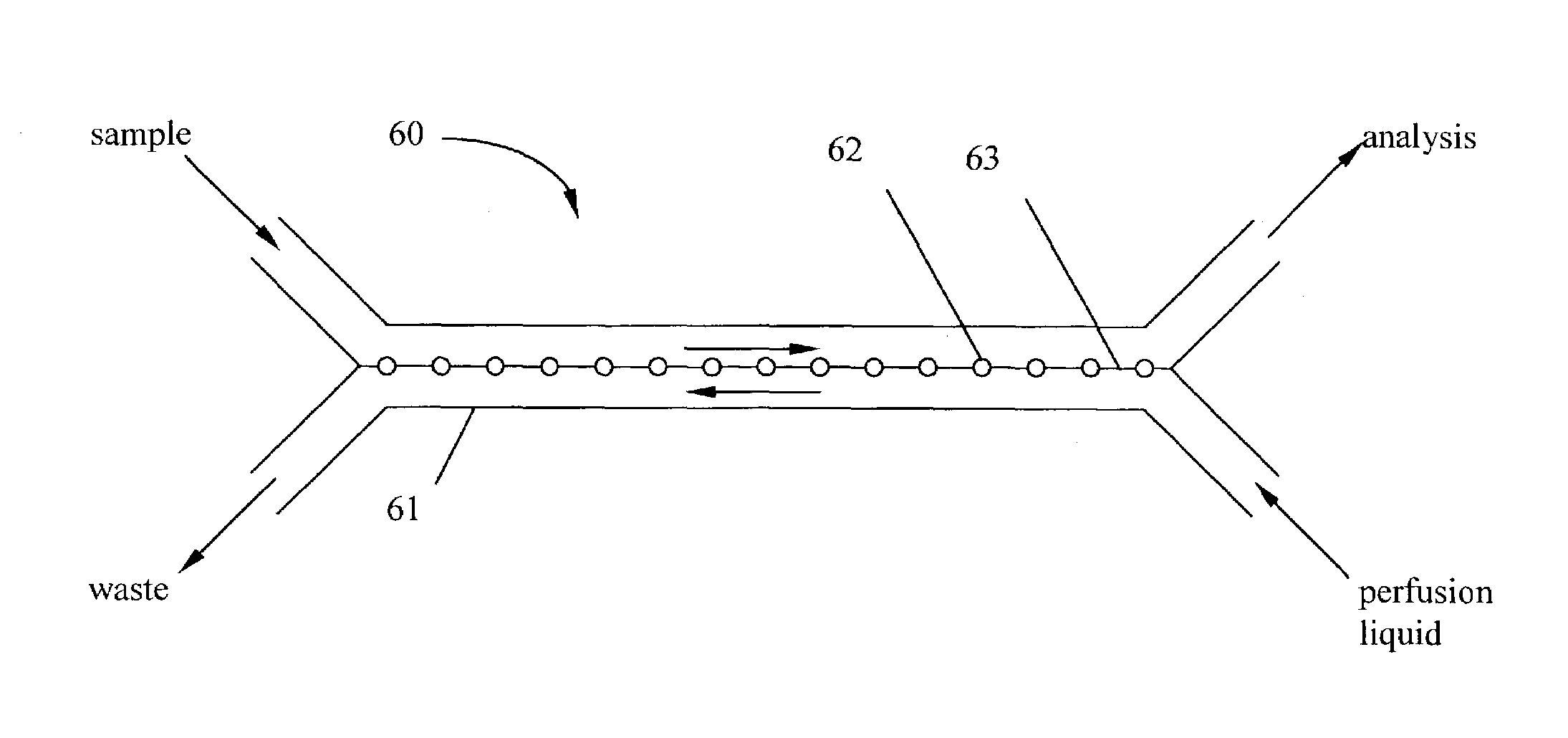

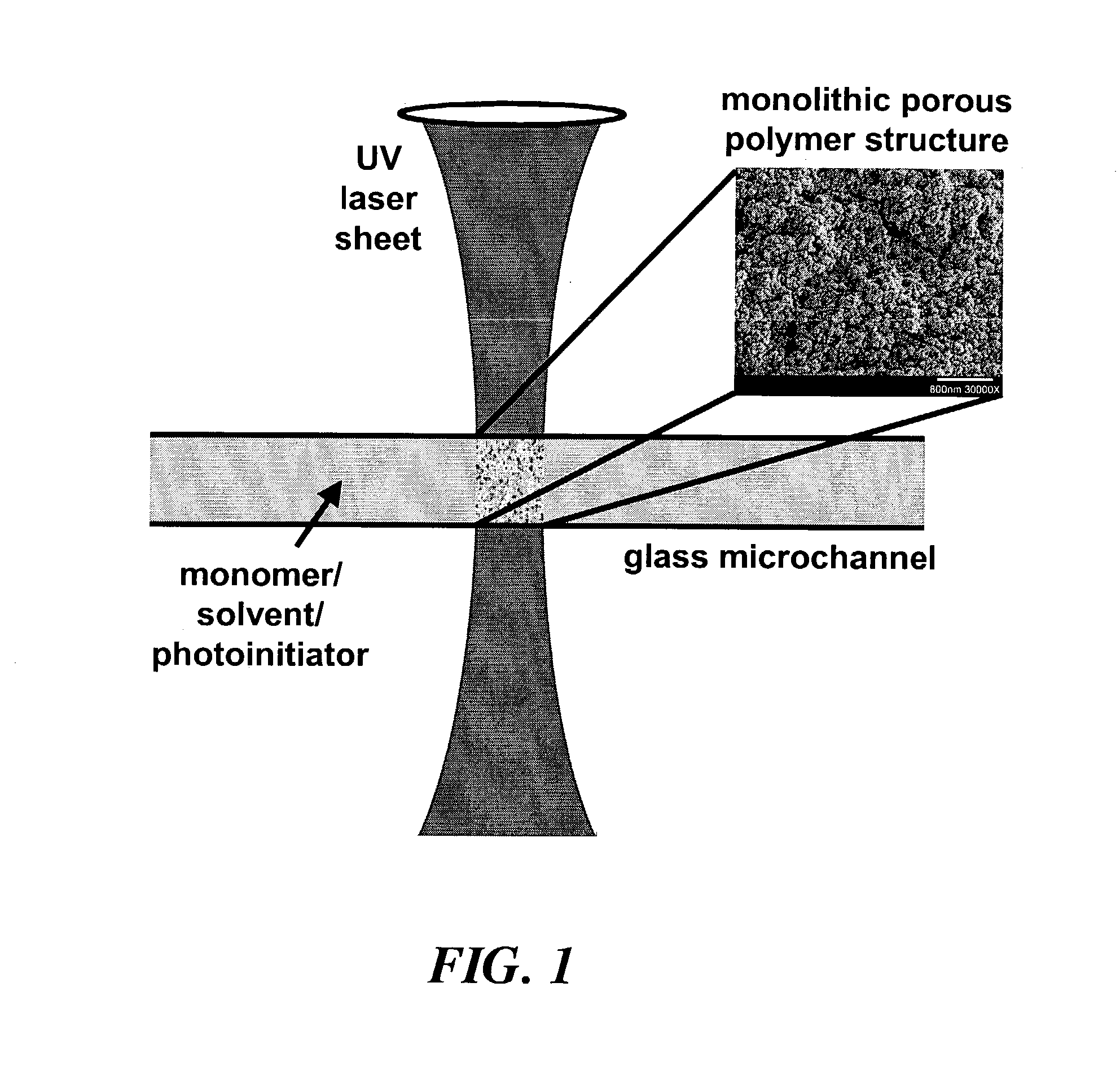

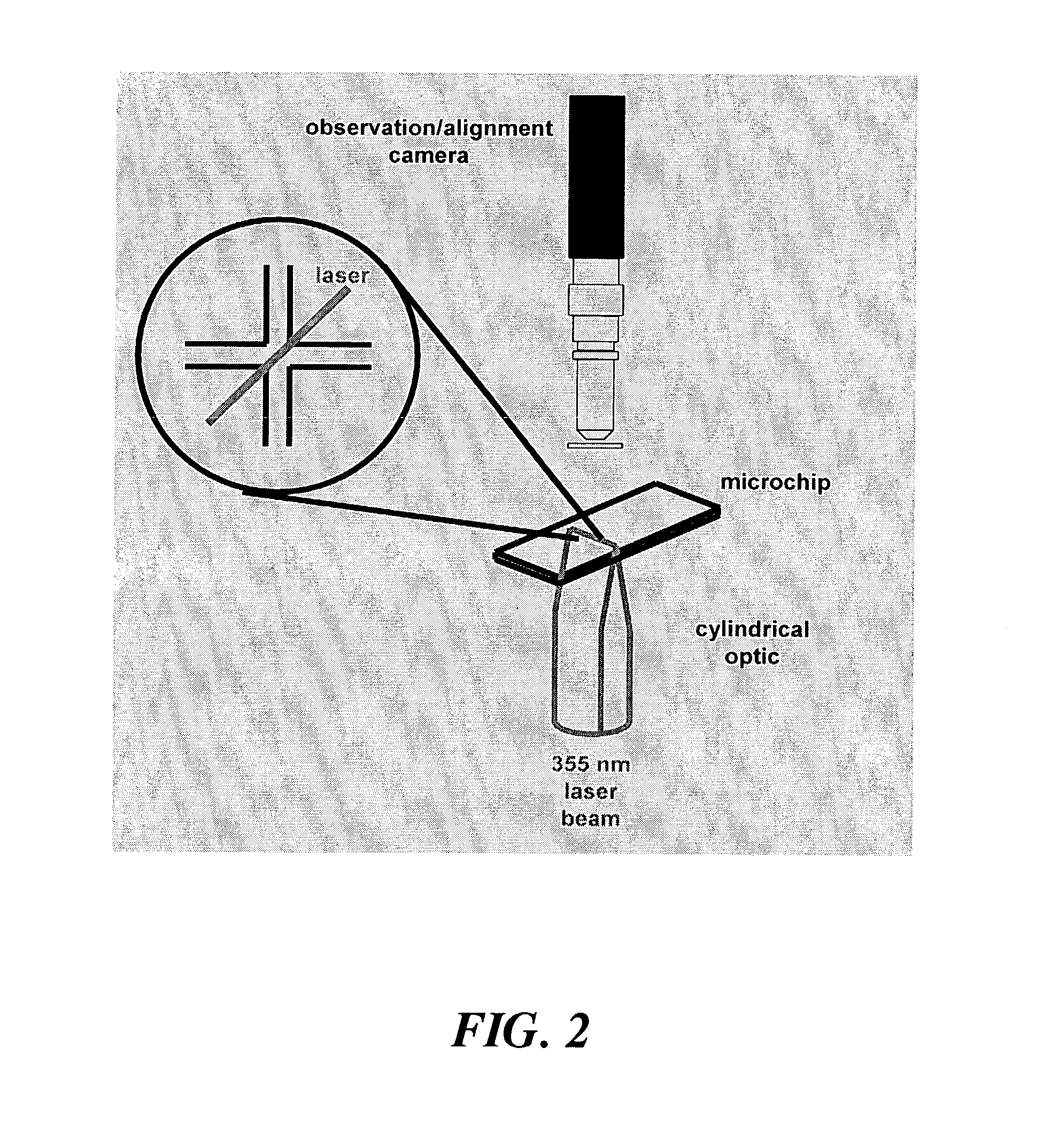

ActiveUS7264723B2Minimize handlingComplicated operationSolvent extractionTransportation and packagingDialysis membranesMeth-

Laser-induced phase-separation polymerization of a porous acrylate polymer is used for in-situ fabrication of dialysis membranes inside glass microchannels. A shaped 355 nm laser beam is used to produce a porous polymer membrane with a thickness of about 15 μm, which bonds to the glass microchannel and form a semi-permeable membrane. Differential permeation through a membrane formed with pentaerythritol triacrylate was observed and quantified by comparing the response of the membrane to fluorescein and fluorescently tagging 200 nm latex microspheres. Differential permeation was observed and quantified by comparing the response to rhodamine 560 and lactalbumin protein in a membrane formed with SPE-methylene bisacrylamide. The porous membranes illustrate the capability for the present technique to integrate sample cleanup into chip-based analysis systems.

Owner:SANDIA NAT LAB

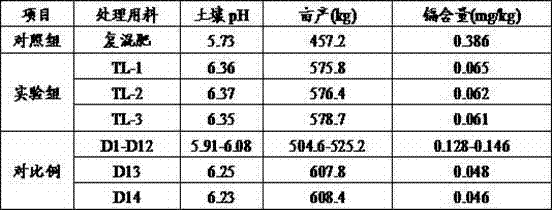

Composite soil conditioner and preparation method and use thereof

ActiveCN104263375APromote repairImprove convenienceAgriculture tools and machinesOther chemical processesTrehaloseIonic liquid

The invention relates to a composite soil conditioner, comprising biogas residues, pyroligneous acid, mineral powder, soluble chitosan, diethylene triaminepentaacetic acid pentasodium, a surfactant, tobacco powder, trehalose, di-rhamnolipid, a flocculating component, a penetrating agent, enteromorpha powder, modified zeolite, boron-zinc-magnesium-containing fungicide, a nano additive, an accelerant, pentaerythritol triacrylate and ionic liquid, preferably also comprising 4-methyl phenyl valerate which is equal to the ionic liquid in weight. The novel composite soil conditioner has excellent soil improvement and recovery performance, the utilization rate of the fertilizer by the crop is greatly increased, and the composite soil conditioner can significantly increase the yield, simultaneously also can improve the permeability of the soil and avoids side effects of heavy metals such as cadmium; thus, the composite soil conditioner is beneficial to crop growth and has a wide industrial application prospect.

Owner:山东乐美生物科技有限公司

Vegetable oil based polyurethane acrylic ester, preparing process and use thereof

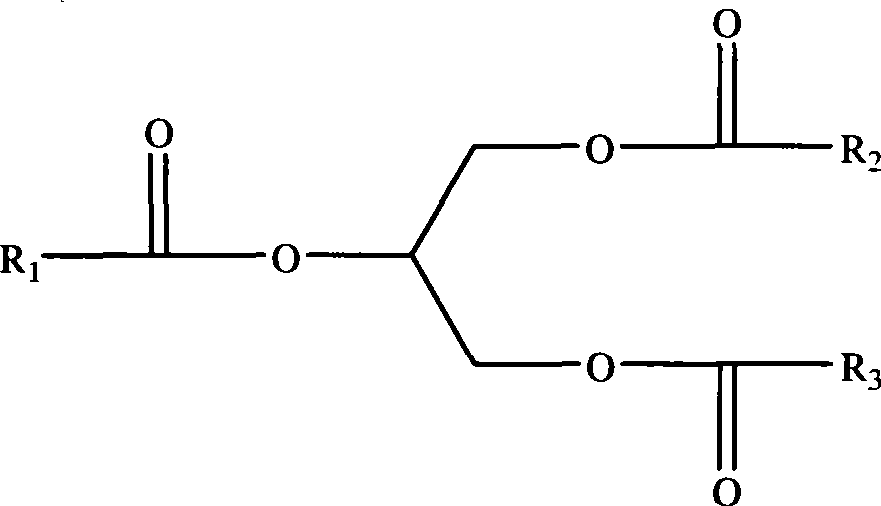

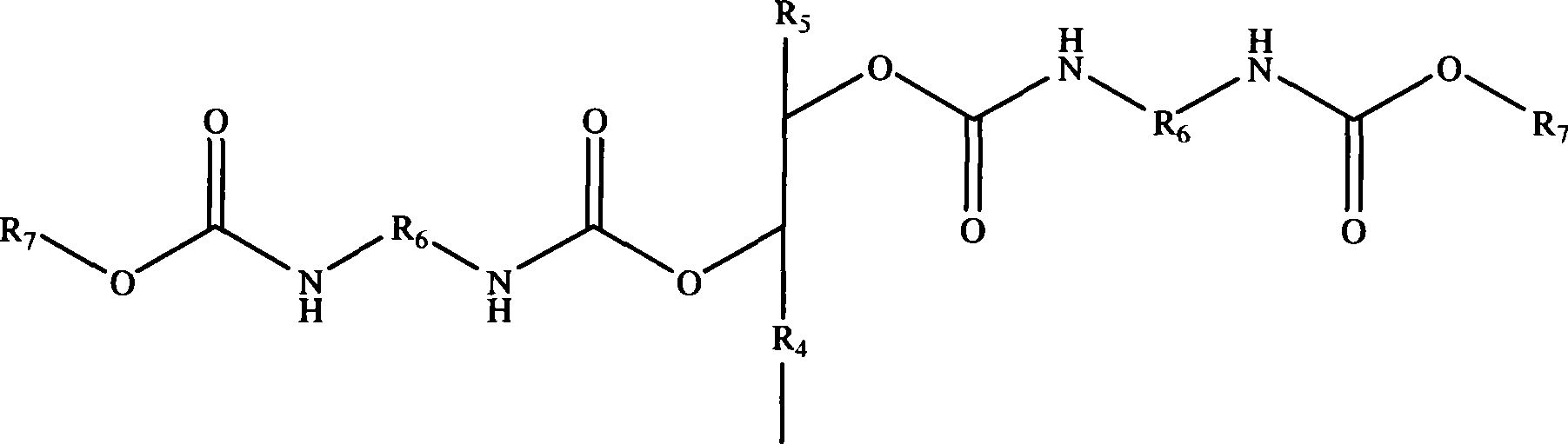

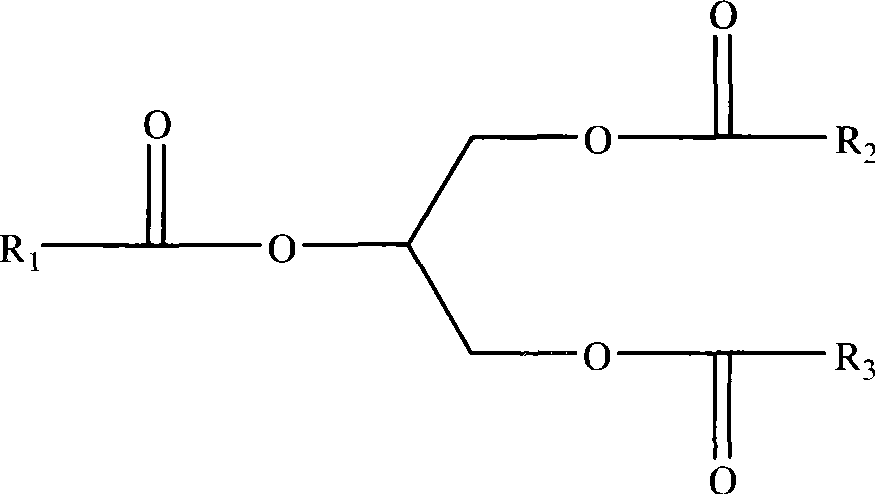

InactiveCN101497684AWide variety of sourcesEasy to makePolyurea/polyurethane coatingsSurface treatment compositionsAlkaneVegetable oil

The invention relates to vegetable oil based polyurethane acrylic ester, belonging to the field of photosensitive polymer material. The vegetable oil based polyurethane acrylic ester is characterized in that the general chemical formula is Formula I, wherein R1, R2 and R3 are respectively chosen from alkane of C1-C18, at least one of the alkane is chosen from Formula II, R4 and R5 are respectively chosen from alkane of C1-C16, R6 is diphenyl methane-4,4'-diisocyanate, or hexamethylene diisocyanate, or isophorone diisocyanate or residue of 2,4-toluene diisocyanate with two isocyanate functional group removed, and R7 is 2-hydroxyethyl acrylate, or hydroxypropyl acrylate, or residue of pentaerythritol triacrylate with hydroxy functional group removed.

Owner:天津市天骄辐射固化材料有限公司

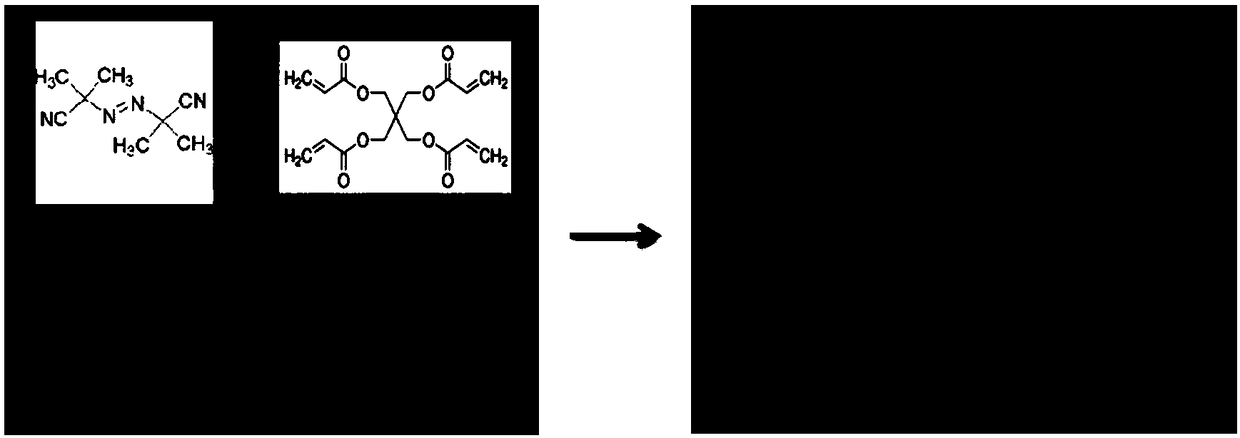

Preparation method of in-situ polymerization solid-state battery

ActiveCN108493486AImprove securityCurb churnFinal product manufactureElectrolyte accumulators manufacturePolymer scienceOrganic solvent

The invention relates to a preparation method of an in-situ polymerization solid-state battery. The preparation method comprises the following steps: step S1, mixing electrolyte salt, an organic solvent, 1-10 percent of acrylic ester and 0.1-1 percent of an initiating agent AIBN to prepare a mixture I, wherein the acrylic ester is one of or more of isopentyl tetraacrylate, pentaerythritol triacrylate and allyl hydroxyethyl ether; step 2, weighing an active substance, acetylene black and positive pole piece made by PVDF according to the mass ratio of 6:3:1, taking a lithium sheet as a negativeelectrode, taking the mixture I as an electrolyte and taking a polypropylene thin film as a diaphragm assembly battery; step S3, putting the battery in a drying box and maintaining for 1-30 minutes after the battery is heated to 40-80 DEG C. The preparation method provided by the invention has the benefit that by adopting an in-situ heat curing technology, the interface problem between the electrolyte and a battery anode and cathode can be better solved.

Owner:武汉新能源研究院有限公司

Method for dialysis on microchips using thin porous polymer membrane

InactiveUS7534315B1Minimize handlingComplicated operationGlovesPretreated surfacesDialysis membranesMicrosphere

Laser-induced phase-separation polymerization of a porous acrylate polymer is used for in-situ fabrication of dialysis membranes inside glass microchannels. A shaped 355 nm laser beam is used to produce a porous polymer membrane with a thickness of about 15 μm, which bonds to the glass microchannel and forms a semi-permeable membrane. Differential permeation through a membrane formed with pentaerythritol triacrylate was observed and quantified by comparing the response of the membrane to fluorescein and fluorescently tagging 200 nm latex microspheres. Differential permeation was observed and quantified by comparing the response to rhodamine 560 and lactalbumin protein in a membrane formed with SPE-methylene bisacrylamide. The porous membranes illustrate the capability for the present technique to integrate sample cleanup into chip-based analysis systems.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

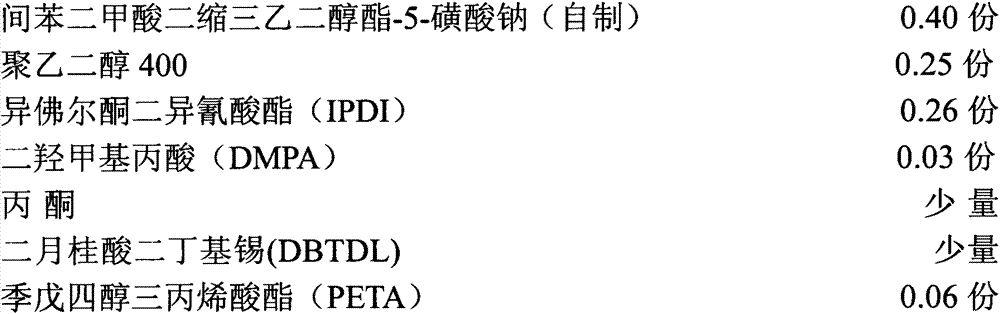

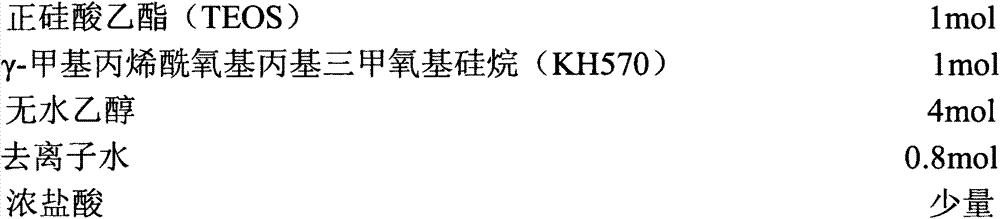

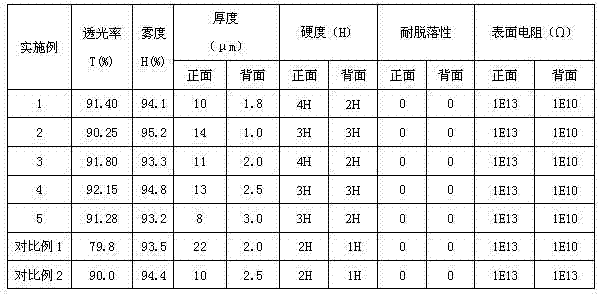

Preparation method for antifogging thin film coating with high light transmission

ActiveCN103709927APolyurea/polyurethane coatingsPigment treatment with organosilicon compoundsSolventDibutyltin dilaurate

Provided is a preparation method for an antifogging thin film coating with high light transmission. M-phthalic acid triethylene glycol ester-5-sodium sulfonate (self made), polyethylene glycol 400, isophorone diisocyanate and pentaerythritol triacrylate are employed as main raw materials, dibutyltin dilaurate is employed as a catalyst, dimethylolpropionic acid is employed as a chain extender, acetone is employed as a solvent, and hydrophilic UV prepolymers are prepared; ethyl orthosilicate is employed as a precursor, gamma-methacryloxy propyl trimethoxysilane is employed as a modifier, a sol-gel method is employed, and uniform and stable modified SiO2 sol is prepared; the hydrophilic UV prepolymers and the modified SiO2 sol are subjected to hybridization through a UV curing way, and a thin film coating is obtained. The prepared thin film coating has good hardness and adhesive force, water resistance and high light transmission and good antifogging effects, and can be used for antifog of surfaces of glass and eyeglass. The preparation technology of the thin film coating accords with green environmental protection concepts, curing and film forming are fast, and comprehensive performances are good. The antifogging thin film coating has good market prospect and is suitable for popularization and application.

Owner:JIANGNAN UNIV

Radiant energy curable polyester resin composition

InactiveUS6037385APolyurea/polyurethane coatingsGlass/slag layered productsPolymer chemistryPhysical property

An acrylic urethane prepolymer composition and an unsaturated polyester resin composition to which the prepolymer has been added. The prepolymer composition includes an acrylic urethane prepolymer prepared by the reaction of diisocyanate, such as MDI, with an hydroxyl-containing acrylate monomer, such as a pentaerythritol triacrylate. The prepolymer composition contains a styrene monomer and an inhibitor, such as benzoquinone, to retard the reaction of the prepolymer and styrene monomer prior to the addition of the prepolymer composition into the polyester resin composition and a photoinitiator to promote the polymerization of the resin by exposure to radiant energy. The employment of the urethane prepolymer composition provides for the reduction in the amount of styrene monomer used in the unsaturated resin composition and also provides for improved chemical and physical properties of the photocured, unsaturated resin composition.

Owner:HEHR INT

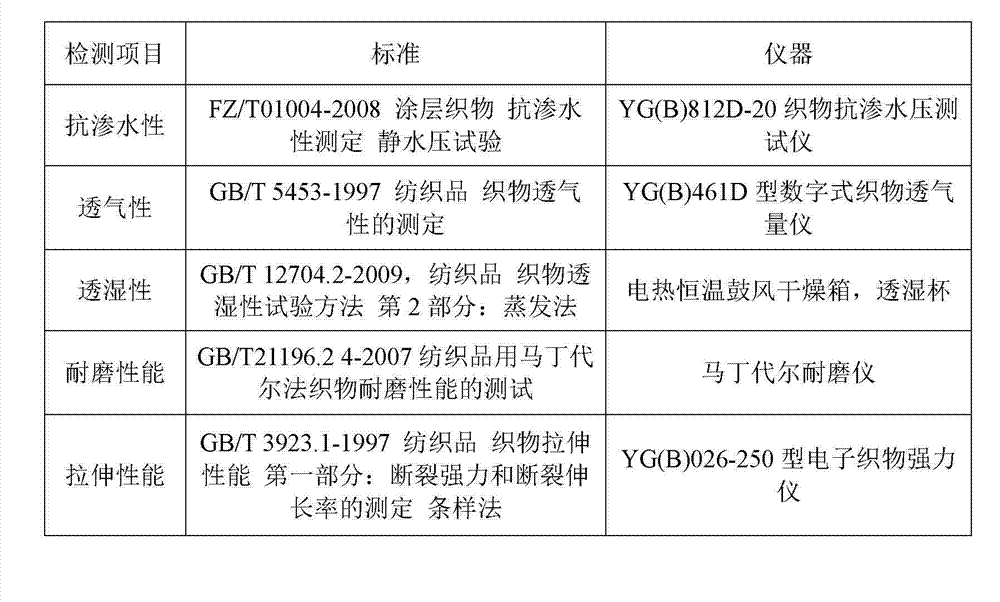

Method for producing textile coated with coating adhesive

InactiveCN102965907AImprove thermal stabilityGood weather resistancePhysical treatmentAdhesiveWater resistant

The invention relates to a method for producing textile coated with coating adhesive, comprising the following steps of: sheering double-stop end vinyl silicone oil, hydrogen-containing silicone oil, oily polyurethane resin, silane coupling agent, pentaerythritol triacrylate and nano-stage white carbon black by a high-shear homomixer at high efficiency under room temperature to prepare coating adhesive; and hot pressing a base cloth by a hot-press roller of a planishing mill, coating the coating adhesive onto the base cloth, putting the base cloth provided with the coating adhesive on a bundle transferring frame of a 200 KeV low-energy electron accelcrator through a driving roller to be cured in a radiation way to obtain the textile coated with the coating adhesive. The water permeability resistance of the textile is 17084-36483 Pa, the mean air permeability of the textile is 10.97-25.1L / M<2>.s, the moisture permeability rate of the textile is 5799-7832 g / m<2>.24h, the coating layer starts to be broken after being ground at 116-140 circles, the radial breaking strength of the textile reaches 802.7N, and the latitudinal breaking strength of the textile reaches 456.7N. The textile produced by the method can increase the humidity management, is free from wrinkle, easy to iron and press, good in tensile property and recovery property, elastic, flexible, smooth, comfortable in hand feel, nontoxic, sunshine-resistant, wind-resistant, water-resistant, and suitable for the clothes, the outdoors, the fashion fabric and the like.

Owner:JIHUA 3509 TEXTILE

Method for preparing pentaerythritol triacrylate

InactiveCN101462953AReduce pollutionReduce by-productsOrganic compound preparationCarboxylic acid esters preparationPentaerythritolColor intensity

The invention belongs to a method for preparing pentaerythritol trimethylacrylate, comprising the steps as follows: (1) pentaerythritol, acrylic acid, catalyst, solvent and polymerization inhibitor are put into a reaction kettle to be fully mixed and stirred so as to form a miscible liquid; (2) a steam valve of the reaction kettle is opened to slowly heat the miscible liquid, and the temperature is controlled and maintained at 70-90 DEG C for a 20-40min reaction; (3) the mixture is continued to be heated, when the temperature is increased to 80-115 DEG C, reflow is carried out for 3-5h and then the reaction is finished; (4) soda water solution and sodium chloride water solution are added into the mixture and after washing the upper organic phase is extracted; (5) the upper organic phase is separated from the solvent; (6) and filter pressing is carried out to obtain the end product. The method has simple process, good quality, activity and flexibility, low shrinking percentage and color intensity and high yield coefficient, and produces few by-products or little waste water.

Owner:TIANJIN CHEM REAGENT RES INST

Optical diffusion barrier

ActiveCN102778712AHigh hardnessThin coatingDiffusing elementsSynthetic resin layered productsDisplay deviceFlat panel display

The invention relates to an optical diffusion barrier which comprises a substrate, a diffusion layer and a back layer, wherein the diffusion layer is ultraviolet-cured on any one of the surfaces of the substrate by coating solution comprising optical diffusion particles A, resin A and photo-initiator, wherein the resin A consists of epoxy acrylate resin and urethane acrylate with 8 degrees of functionality in the weight ratio of 1:9-9:1; the back layer is ultraviolet-cured on the other surface of the substrate by coating solution comprising optical diffusion particles B, resin B, photo-initiator and antistatic agent, wherein the resin B consists of pentaerythritol triacrylate and caprolactone modified dipentaerythritol penta / hexa-acrylate in the weight ratio of 1:9-9:1; the optical diffusion particles A consist of high polymer micro-spheres in particle sizes of 10-25 microns and inorganic particles in the particle sizes of 1-4 microns, in the weight ratio of 2:1-4:1; the optical diffusion particles B are inorganic particles in the particle sizes of 2-4 microns; and the diffusion barrier has high hardness, thin coating layer and high transmittance, full diffusion performance and good antistatic property and can meet the development direction of a flat panel display in large size, thinning, light weight and low cost.

Owner:昆山乐凯锦富光电科技有限公司

High-water-resistance quick-photocuring pearlescent water-based UV paint, and preparation method and application method thereof

ActiveCN105969161AHigh hardnessImprove wear resistancePretreated surfacesPolyurea/polyurethane coatingsEpoxyWater based

The invention relates to a water-based UV paint, particularly a high-water-resistance quick-photocuring pearlescent water-based UV paint, and a preparation method and application method thereof. The paint is prepared from a water-based polyurethane acrylate resin, a water-based epoxy acrylic resin, a functional monomer, a photoinitiator, a leveling agent, an anti-settling agent, pearl powder and a solvent, wherein the functional monomer comprises at least one of dipentaerythritol hexaacrylate, pentaerythritol triacrylate and trimethylolpropane triacrylate. The number of the functional groups of the dipentaerythritol hexaacrylate, pentaerythritol triacrylate and trimethylolpropane triacrylate is 3 or above. The photocured paint film has the advantages of high crosslinking density, excellent hardness, excellent tensile strength and excellent mechanical properties. The water-based epoxy acrylic resin is introduced on the basis of the water-based polyurethane acrylic resin, thereby enhancing the water resistance of the paint film. By introducing the pearl powder and anti-settling agent, the paint film has gorgeous pearl effects.

Owner:深圳市嘉卓成科技发展有限公司 +1

Ultraviolet light-cured coating and preparation method thereof

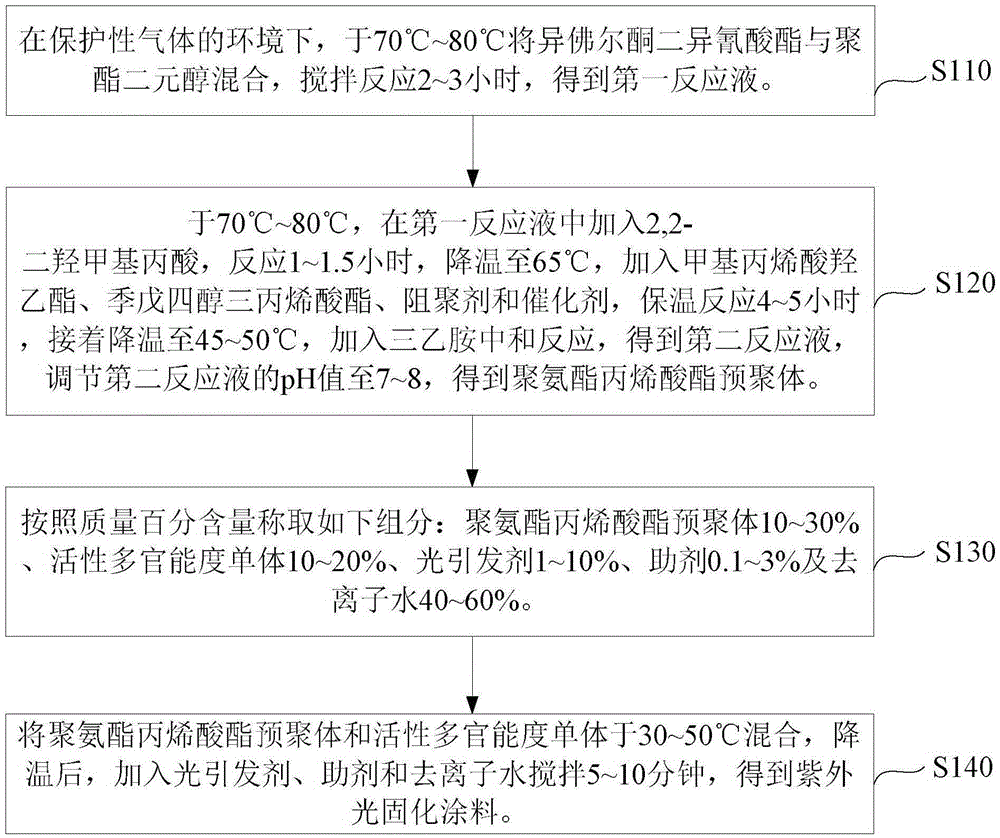

InactiveCN105400415AEasy to operateEase of industrial productionPolyurea/polyurethane coatingsPolyesterFunctional monomer

The invention relates to an ultraviolet light-cured coating and a preparation method thereof. The preparation method for the ultraviolet light-cured coating comprises the following steps: mixing isophorone diisocyanate with polyester dihydric alcohol diol and carrying out a reaction under stirring so as to obtain a first reaction solution; adding 2,2-bis(hydroxymethyl)propionic acid into the first reaction solution at 70 to 80 DEG C, carrying out a reaction for 1 to 1.5 h, then carrying out cooling to 65 DEG C, adding hydroxyl ethyl methacrylate, pentaerythritol triacrylate, a polymerization inhibitor and a catalyst, carrying out a reaction for 4 to 5 h under a heat preservation condition, then carrying out cooling to 45 to 50 DEG C, adding triethylamine, carrying out a neutralization reaction so as to obtain a second reaction solution and adjusting the pH value of the second reaction solution to 7 to 8 so as to obtain polyurethane acrylate prepolymer; and mixing the polyurethane acrylate prepolymer with active multi-functional monomer at 30 to 50 DEG C, adding a photoinitiator, an auxiliary agent and deionized water after cooling and carrying out mixing under stirring so as to obtain the ultraviolet light-cured coating. The ultraviolet light-cured coating prepared by using the method is environment-friendly.

Owner:CHINA ACADEMY OF ENG PHYSICS FUNCTION MATERIAL RES INST

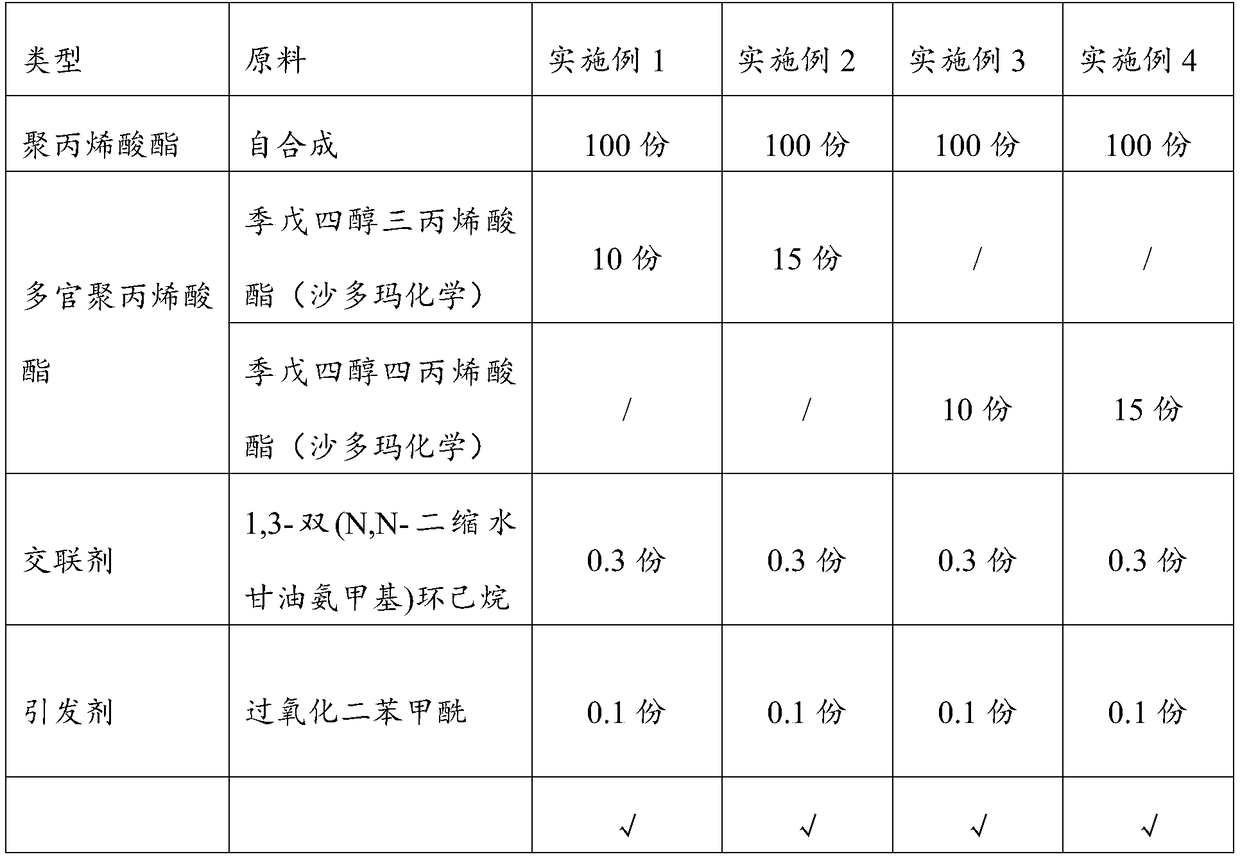

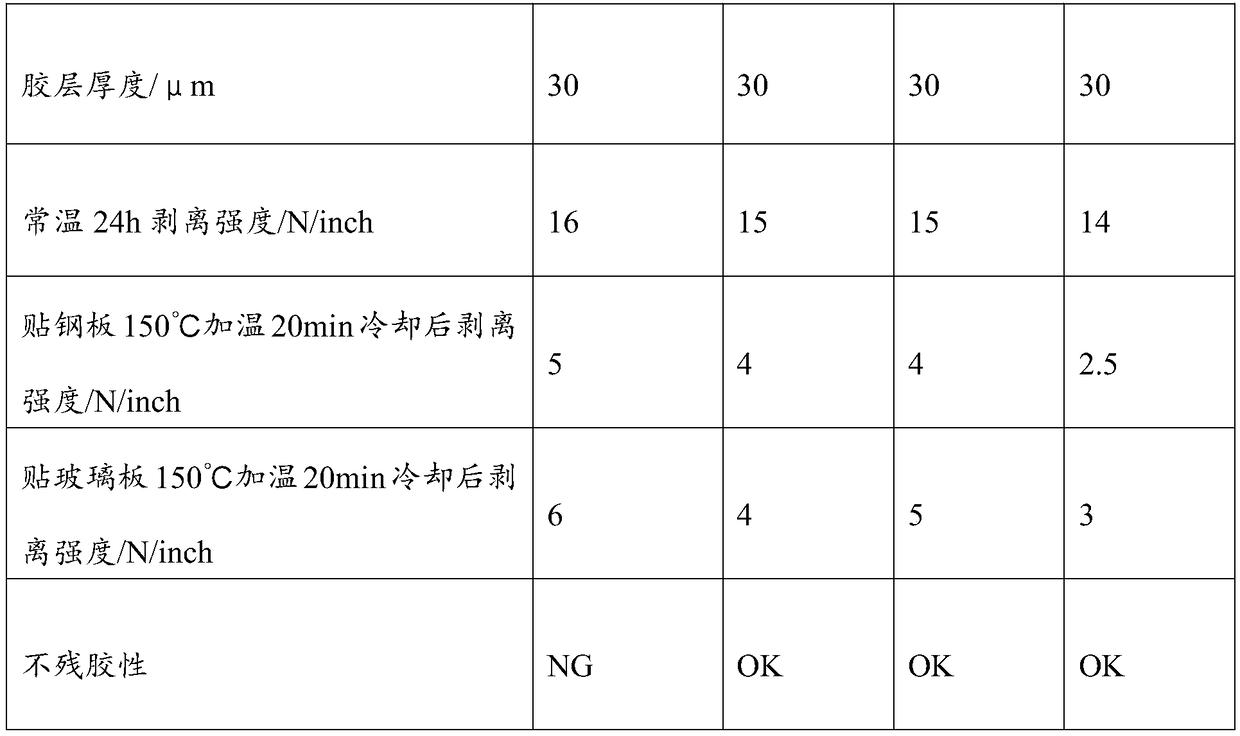

High-temperature-resistence viscosity-reducing adhesive tape and preparation method thereof

ActiveCN109266236ASmall peeling forceEasy to peelOrganic non-macromolecular adhesivePressure sensitive film/foil adhesivesCross-linkPentaerythritol

The invention relates to a high-temperature-resistence viscosity-reducing adhesive tape. The high-temperature-resistence viscosity-reducing adhesive tape comprises a base material membrane and high-temperature-resistence viscosity-reducing polyacrylate pressure sensitive adhesive smeared on the base material membrane; and the high-temperature-resistence viscosity-reducing adhesive tape is preparedfrom 100 parts of polyacrylate, 10 to 15 parts of multi-functional acrylate, 0.3 part of cross-linking agent and 0.1 part of initiator; and the multi-functional acrylate is any one of pentaerythritoltriacrylate or pentaerythritol tetraacrylate. The base material membrane is any one of a PET membrane or PI membrane. The polyacrylate comprising the high-temperature-resistence cross-linked functional group in the high-temperature-resistence viscosity-reducing adhesive tape is further cross-linked with the multi-functional acrylate at a high temperature, so that the stripping force is greatly reduced, and the high-temperature prepared adhesive tape is easier to strip; and the high-temperature-resistence viscosity-reducing adhesive tape disclosed by the invention is heated and used for 20 to30 minutes at 120 to 160 DEG C, the stripping force is apparently reduced, the adhesive tape is easier to strip, the adhesive residue risk is reduced, and the production efficiency is improved.

Owner:YANTAI DARBOND TECH

Response type medical gel as well as preparation method and application thereof

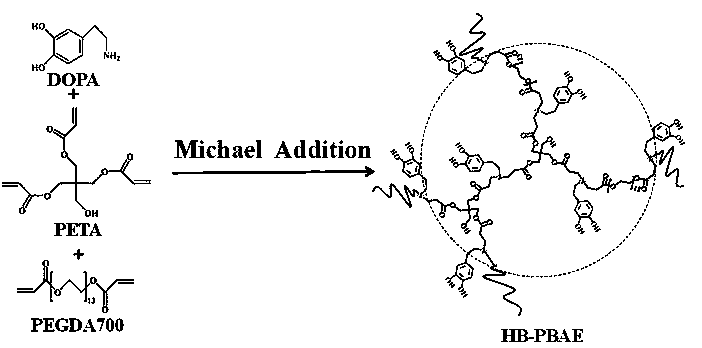

ActiveCN107626002AAdhesion can be regulatedSurgical adhesivesBandagesSurgical operationPolymer science

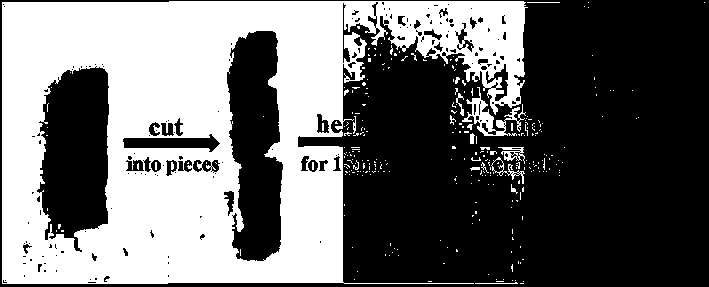

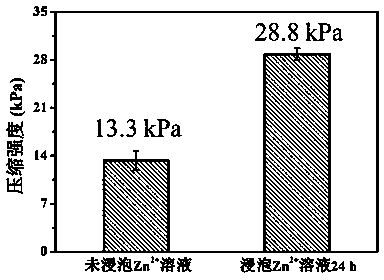

The invention provides response type medical gel. Particularly, a functional hyperbranched polymer monomer (HB-PBAE) is synthesized by virtue of Michael addition reaction of dopamine (DOPA), polyethylene glycol diacrylate (PEGDA700) and pentaerythritol triacrylate (PETA); and gel is formed by virtue of a mixed solution of HB-PBAE, polyvinyl imidazol (PVI) and gelatin (Geln) under the action of aniron ion (Fe<3+> solution). The gel has the properties of softness and viscidity in the primary formation period, and the viscidity is obviously reduced after the gel is soaked in a zinc ion (Zn<2+> solution). Hydrogel provided by the invention has syringeability, can be taken as a sealing agent or a wound surface dressing for surgical operations and is used for smearing the wound surface of a tissue, so that the adverse leakage of liquid or gas is avoided; and the viscidity of the gel has ion responsitivity, so that the secondary injury in a dressing change process can be reduced, and the pain of the wound surface can be alleviated.

Owner:HANGZHOU YAHUI BIOTECH CO LTD

Water-based ultraviolet-curing printing ink and preparation method thereof

The invention discloses a water-based ultraviolet-curing printing ink and a preparation method thereof. The printing ink comprises the following raw materials by weight: 20-30 parts of epoxy acrylic resin, 10-15 parts of polyurethane acrylic resin, 5-10 parts of polyester acrylic resin, 4-6 parts of diphenyl ketone, 2-4 parts of 2,2-diethoxyacetophenone, 10-15 parts of pigments, 2-3 parts of isopropanolamine, 8-12 parts of pentaerythritol triacrylate, 15-20 parts of diacrylic acid-1,6-hexylene glycol ester, 3-5 parts of propylene glycol ethyl ether, 1-2 parts of a fluorocarbon surfactant FC-4430, 0.5-1 part of a defoamer BYK-019, 3-5 parts of a compound filler and 20-25 parts of de-ionized water. The water-based printing ink is excellent in performance, can be instantly cured after being irradiated by ultraviolet rays, is free from evaporation of a petroleum solvent, cannot pollute the environmental and is safe to use; the printing ink can be still kept stable in performance and cannot be mildewed after being stored in the printing process and even an ink fountain for a long term; a printed product is good in color stability and high in brightness, and an ink layer is higher in friction resistance, chemical resistance and adhesiveness; the printing ink has a wide application prospect.

Owner:青岛米品品服装有限公司

High-fire-retardant ultraviolet curing coating

InactiveCN105038569AImprove wear resistanceStrong adhesionFireproof paintsPolyurea/polyurethane coatingsPolyethylene glycolDefoaming Agents

The invention discloses a high-fire-retardant ultraviolet curing coating. The high-fire-retardant ultraviolet curing coating comprises the following raw materials: urethane acrylate, epoxy acrylate, epoxidized soybean oil acrylate, phosphorus-containing acrylate, N-vinyl pyrrolidone, polyethylene glycol acrylate, tri(propylene glycol) diacrylate, pentaerythritol triacrylate, trimethylolpropane triacrylate, benzophenone, 2-methyl-2-hydroxyl-1-phenylacetone, coumarone, nano-silica, nano aluminum hydroxide, ammonium polyphosphate, silica powder, expanded graphite, a flattening agent, a defoaming agent, a wetting agent, a dispersant and a coupling agent. The high-fire-retardant ultraviolet curing coating disclosed by the invention is good in flame retardance property, high in adhesion force, excellent in comprehensive performance and long in service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Long chain branched polylactic acid grafted by free radicals of melt and preparation method thereof

The invention relates to long-chain-branched polylactic acid grafted by free radicals of melt and a preparation method thereof. The long-chain-branched polylactic acid is prepared by the following components in parts by weight: 80-100 parts of polylactic acid (PLA), 0.1-0.5 part of diisopropylamine peroxide (DCP), 6-10 parts of pentaerythritol triacrylate (PETA) and 0.1-0.5 part of antioxidant. The peroxide DCP and PETA are added into PLA, and the obtained PLA is subjected to free-radical reaction of the melt to generate long branch chains, so that the crystallization property of the material is improved and the physical property of the material is also improved. The method has the advantages that the reaction time is short, the processing period can be shortened and more convenience is brought for industrial production of the PLA material.

Owner:HEFEI GENIUS NEW MATERIALS

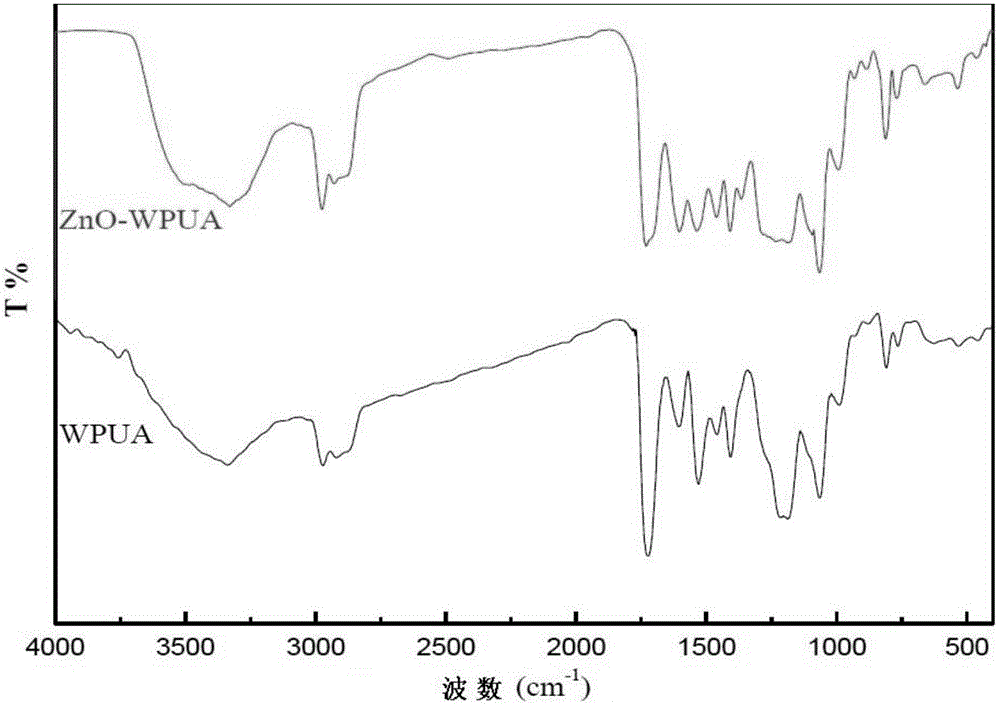

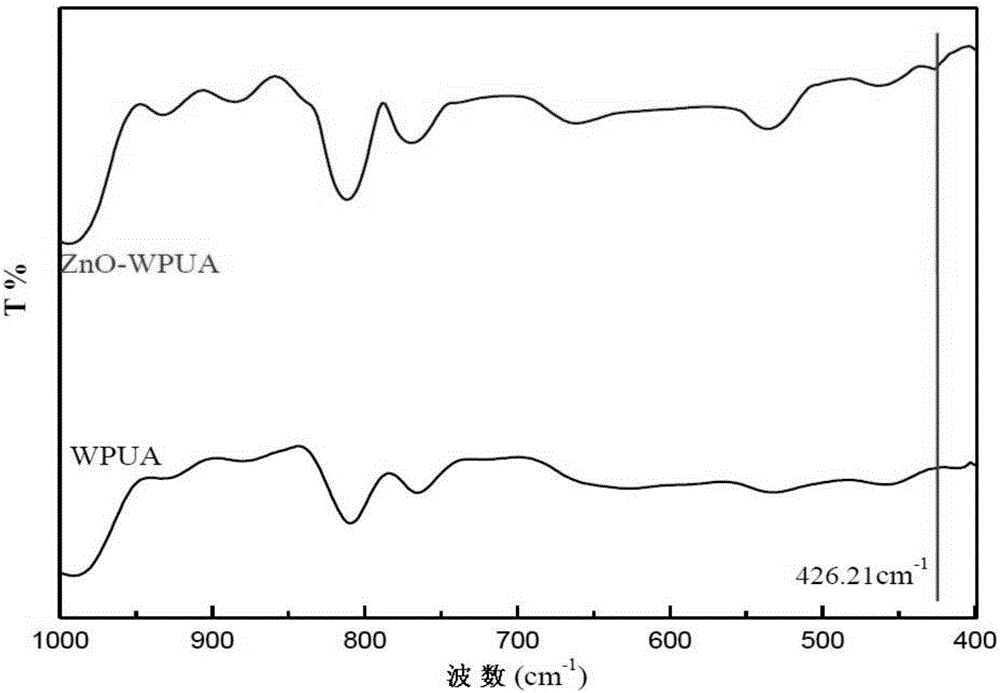

Nano zinc oxide grafted aqueous UV light-cured polyurethane resin and preparation method thereof

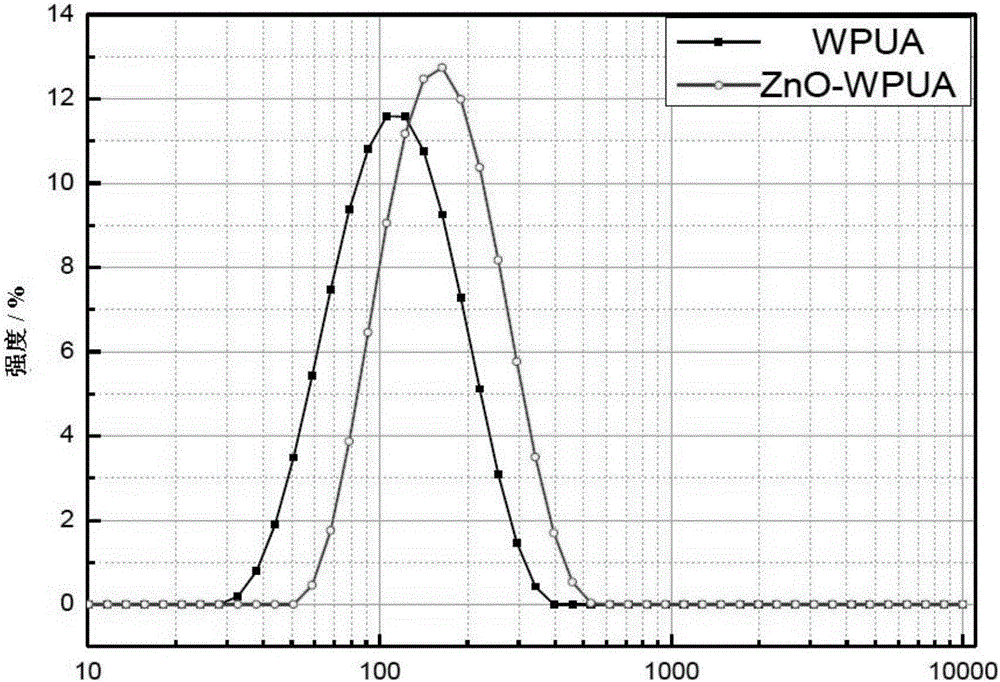

ActiveCN106188482ARegulated contentAdjust light curing ratePolyurea/polyurethane coatingsSolventWater resistant

The invention belongs to the technical field of paints, and discloses a nano zinc oxide grafted aqueous UV light-cured polyurethane resin and a preparation method thereof. The preparation method comprises the following steps: reacting aromatic or aliphatic diisocyanate with polyether glycol at a temperature of 70 to 90 DEG C in the presence of a catalyst to obtain a polyurethane prepolymer (I); controlling the temperature in a range of 60 to 80 DEG C, dropwise adding an acetone solution of dimethylolpropionic acid to carry out reactions to obtain a polyurethane prepolymer (II); then adding hydroxypropyl acrylate, which contains nano ZnO, a catalyst, and a polymerization inhibitor, and a mixed dispersion liquid of pentaerythritol triacrylate to carry out graft copolymerization reactions, cooling the reaction products, then adding a neutralizing agent and water, stirring, evenly mixing, and removing the solvent (acetone) to obtain the nano zinc oxide grafted aqueous UV light-cured polyurethane resin. The provided polyurethane resin has the advantages of high mechanical strength, high light-cured speed, excellent water resistant performance, and good storage stability.

Owner:SOUTH CHINA UNIV OF TECH

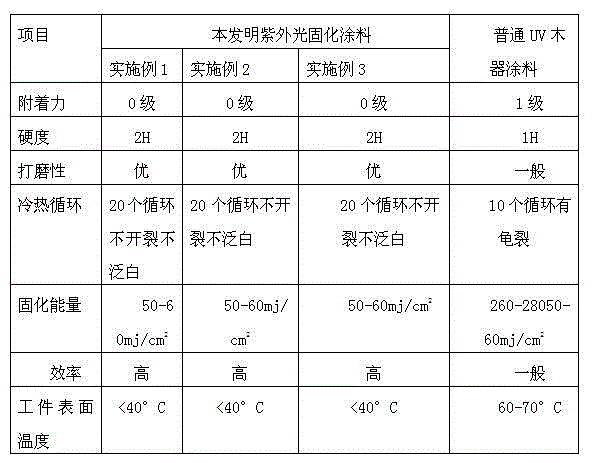

Ultraviolet curable coating for low energy curing and preparation method of ultraviolet curable coating

InactiveCN105567063AHigh solid contentLow viscosityEpoxy resin coatingsPolyester coatingsEpoxyPolyester

The invention discloses an ultraviolet curable coating for low energy curing and a preparation method of the ultraviolet curable coating. The ultraviolet curable coating consists of the following raw materials in percentage by weight: 25-30% of modified polyfunctionality polyester acrylic ester, 10-15% of modified epoxy acrylate, 20-25% of modified pentaerythritol acrylic ester, 15-20% of TPGDA, 0.3-1.0% of a wetting dispersant, 10-15% of transparent talcum powder, 2-4% of a photoinitiator 1, 1-3% of a photoinitiator 2, 2-4% of a photoinitiator 3 and 0.3-0.5% of a leveling agent. The preparation method comprises the following steps: mixing the modified polyfunctionality polyester acrylic ester, modified epoxy acrylate, modified pentaerythritol acrylic ester and TPGDA, stirring to disperse, further adding the photoinitiators 1, 2 and 3 and the wetting dispersant, feeding the transparent talcum powder, and dispersing, thereby obtaining a product coating. An expected curing degree can be achieved for the ultraviolet curable coating disclosed by the invention by virtue of 40-80mj / m<2> of ultraviolet energy, so that the energy for curing a coating is greatly reduced, the construction efficiency can be improved, and the probability of quality defects on the backlight side of an irregular workpiece can be reduced.

Owner:HUNAN JINHAI SCI & TECH

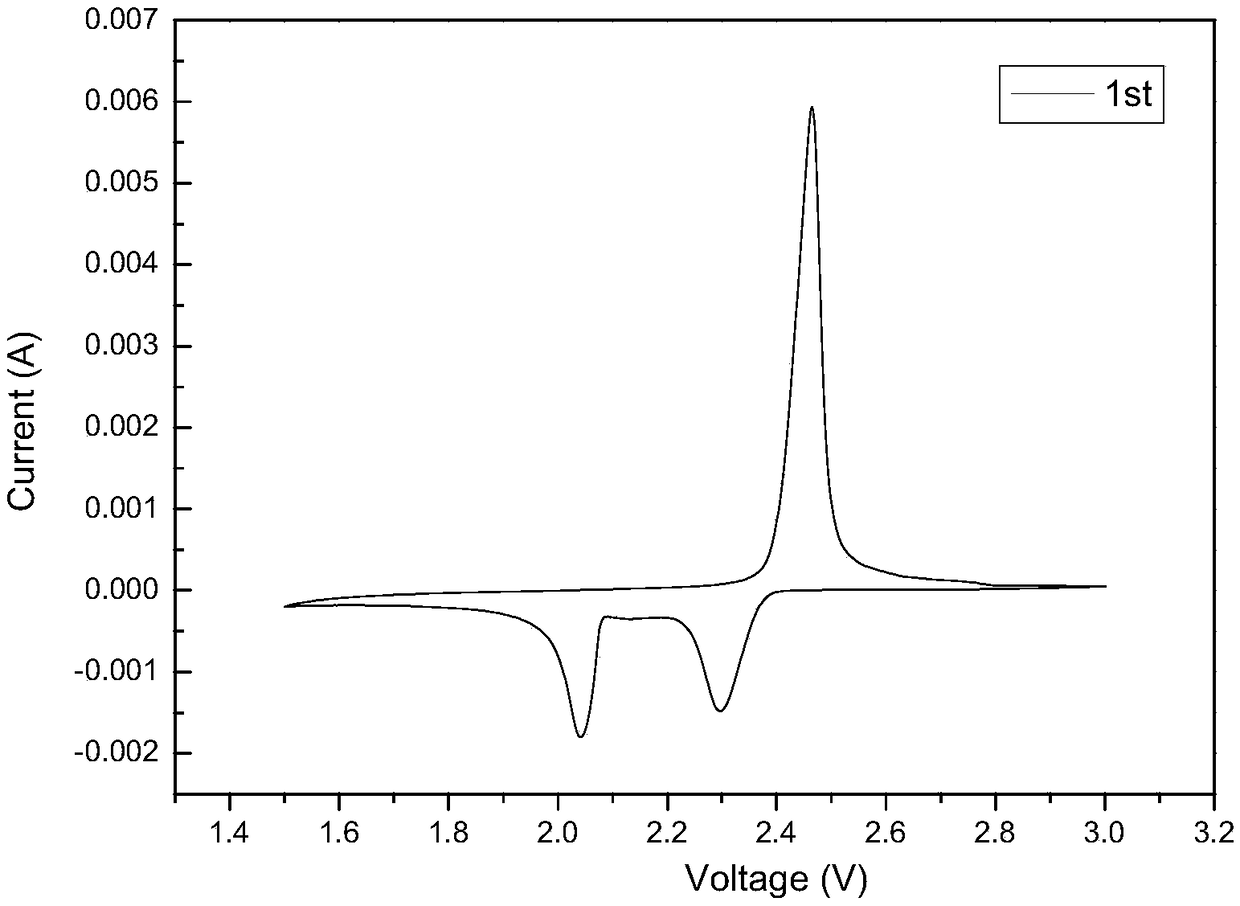

Preparation method of naringenin molecular imprinting electrochemical sensor

InactiveCN107064256AHigh affinityHigh selectivityMaterial electrochemical variablesTetrafluoroborateCarbon nanotube

The invention discloses a preparation method of a naringenin molecular imprinting electrochemical sensor. The preparation method is characterized in that firstly, a glassy carbon electrode is modified with a nano silver / carbon nanotube, and a nano silver / carbon nanotube modified electrode is obtained; 50%-60% of ethanol, 15%-20% of dipentaerythritol triacrylate, 4%-8% of methacrylic acid, 12%-18% of 1-vinyl-3-ethyl imidazole tetrafluoroborate, 1.0%-2.0% of azo-bis-iso-heptonitrile and 3.0%-6.0% of naringenin are added to a reactor, stirred, dissolved and stirred to react at the temperature of 65+ / -2 DEG C for 12-15 h in an oxygen-free atmosphere, template molecules are removed through a methanol and acetic acid mixed solution, and naringenin molecular imprinting polymers are obtained; the naringenin molecular imprinting polymers are dispensed to the nano silver / carbon nanotube modified electrode, and the naringenin molecular imprinting electrochemical sensor is obtained. The sensor has high affinity, selectivity and sensitivity and good specificity, can realize rapid detection and can be repeatedly used.

Owner:UNIV OF JINAN

Wear-resistance and corrosion-resistance polyurethane paint

The present invention discloses a wear-resistance and corrosion-resistance polyurethane paint, which is prepared from the raw materials such as polyurethane, silicon dioxide, titanium dioxide, asphalt, nanometer aluminum oxide, zirconium oxide, silicon nitride, talc powder, a phenolic resin, butyl methacrylate, an epoxy resin and a dispersing auxiliary agent, wherein the dispersing auxiliary agent is prepared from diatomaceous earth, jade powder, a silane coupling agent, acrylate and pentaerythritol triacrylate. According to the present invention, the paint has characteristics of extremely strong corrosion resistance, saline resistance, alkali resistance, good metal protection effect, high hardness, wear resistance, compression resistance, substantially-improved paint protection effect, strong paint stability, easy use, and easy operation.

Owner:天津渤海望亚涂料有限公司

High-strength impact resistance oil paint

InactiveCN105255353AOvercoming impact resistanceOvercome the problem of large shrinkage during curingFireproof paintsPolyurea/polyurethane coatingsAcrylic resinPolyethylene glycol

The invention discloses high-strength impact resistance oil paint. The high-strength impact resistance oil paint is prepared from polyurethane acrylic resin, epoxy-acrylic resin, bisphenol A epoxy resin, ethylene diglycidyl ether, polyethylene glycol, 2-propenoic acid,1,1'-[(1-methyl-1,2-ethanediyl)bis[oxy(methyl-2,1-ethanediyl)]]ester, pentaerythritol triacrylate, azodiisobutyronitrile, 1-hydroxycyclohexylphenylketone, triarylsulfonium hexafluoroantimonate salt, carbon black, graphene oxide, carbon nanotubes, cresyl diphenyl phosphate, a flatting agent, an antifoaming agent, a thickening agent, a silane coupling agent, phenolic epoxy acrylate, solvent and corrosion inhibitor. The high-strength impact resistance oil paint is good in impact resistance, excellent in anti-static property, high in strength, high in adhesive force with a base material and not prone to be disengaged in the using process.

Owner:安徽嘉年华漆业有限公司

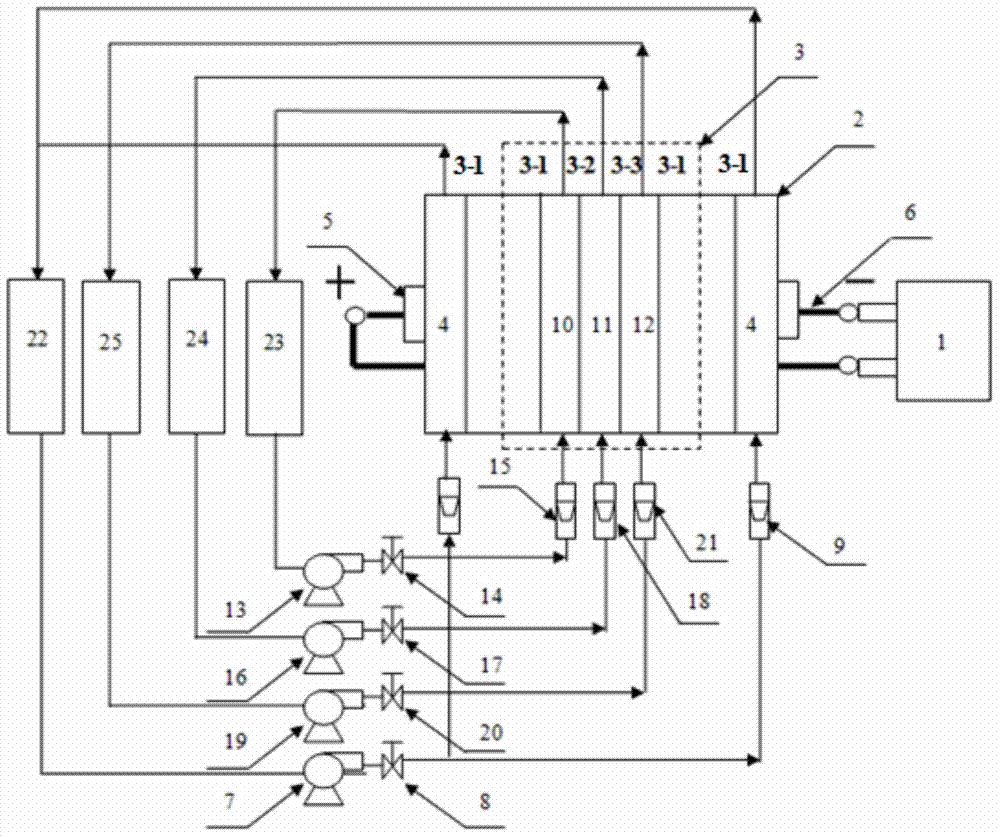

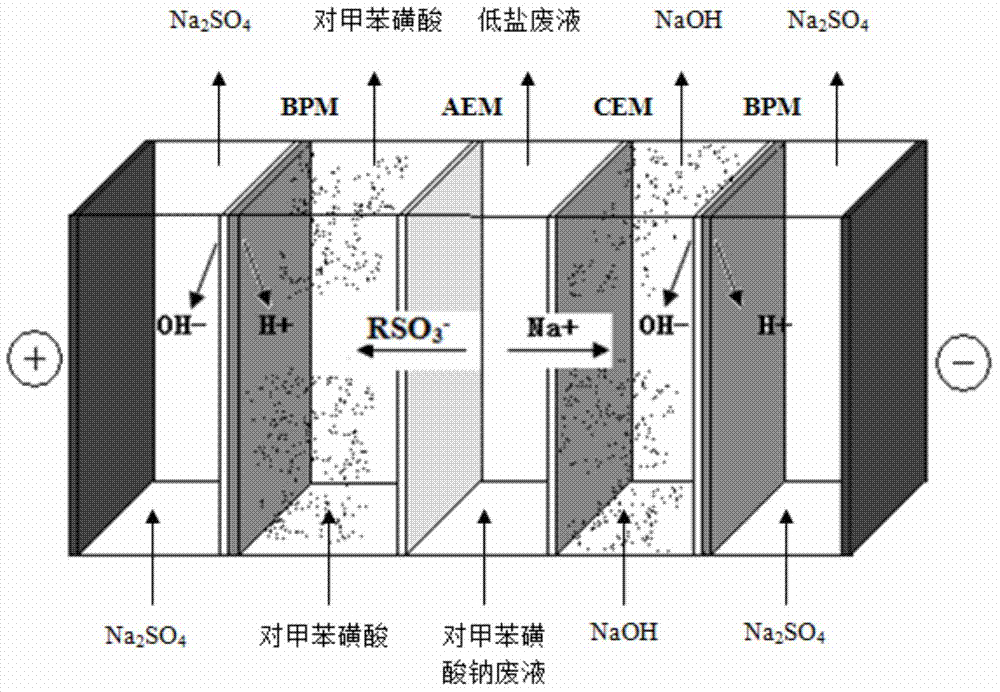

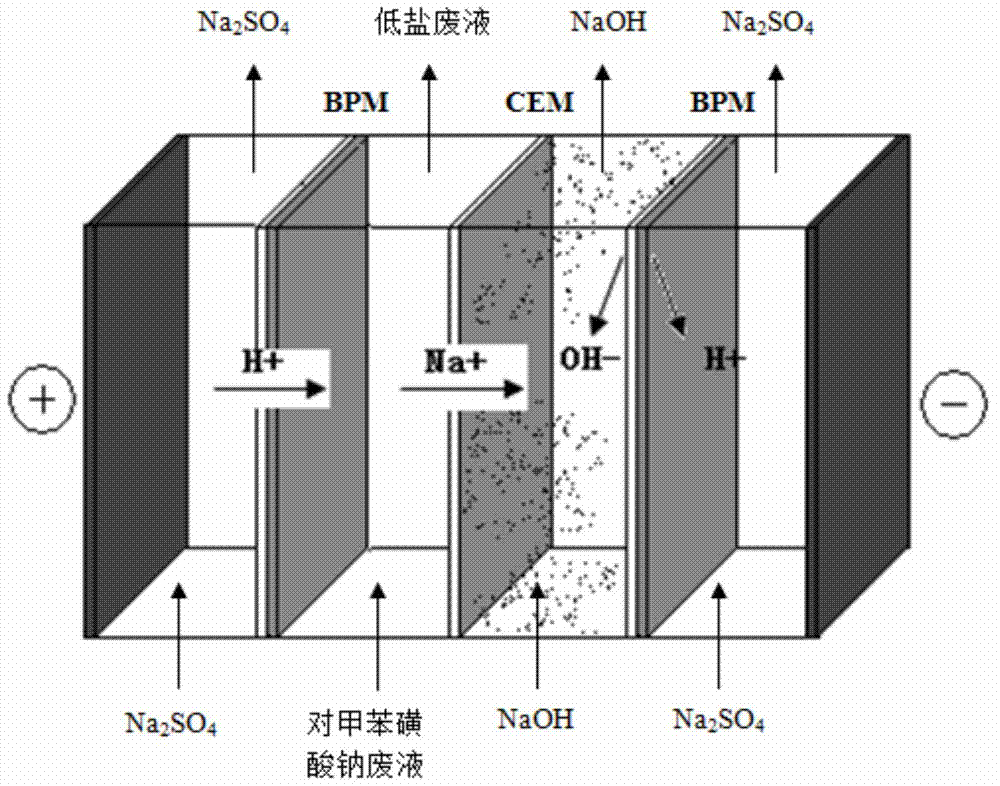

Device and method for processing sodium p-toluenesulfonate waste liquor

ActiveCN103787471ALower resistanceImprove conductivityWater contaminantsDispersed particle separationLiquid wasteHigh concentration

The invention relates to a device and method for processing sodium p-toluenesulfonate waste liquor. The device comprises a direct current power supply, a membrane stack, a clamping device, a carbon fiber felt electrode, an electrode liquor storage tank, an acid chamber storage tank, a waste liquor chamber storage tank, an alkali chamber storage tank, a liquor adjuster, an alkali chamber valve block, a waste liquor chamber valve block, an acid chamber valve block, an electrode chamber valve block, an acid chamber filled with a cation exchange resin, a salt chamber, an alkali chamber filled with an anion exchange resin, an anion exchange membrane, a cation exchange membrane and a bipolar membrane. A PAN (polyacrylonitrile)-based carbon fiber felt electrode used in the device and method has the characteristics of low resistance, good electric conductivity, oxidation resistance and corrosion resistance. The salt chamber is filled with a cation and anion mixed resin, and the acid chamber and the alkali chamber are respectively filled with the cation exchange resin and the anion exchange resin, so as to further improve the conductance of an electrodialysis cell, reduce the polarization and energy consumption, and lighten the membrane pollution. The device and method can be used for processing the production waste liquor of high-concentration hardly-degradable pentaerythritol triacrylate, so as to obtain acid and / or alkali and realize recycling of the waste liquor.

Owner:UNIV OF SCI & TECH BEIJING

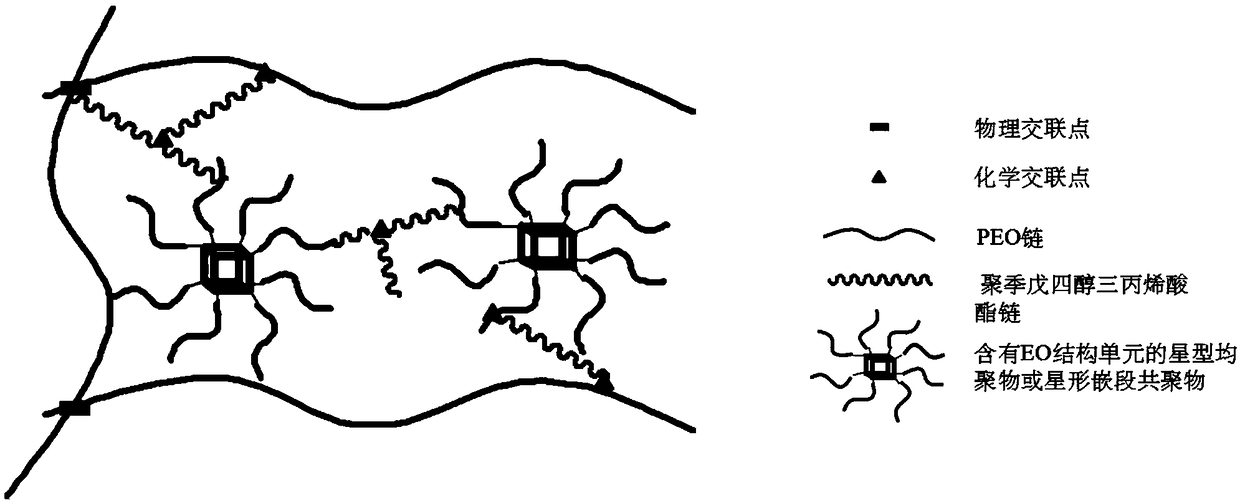

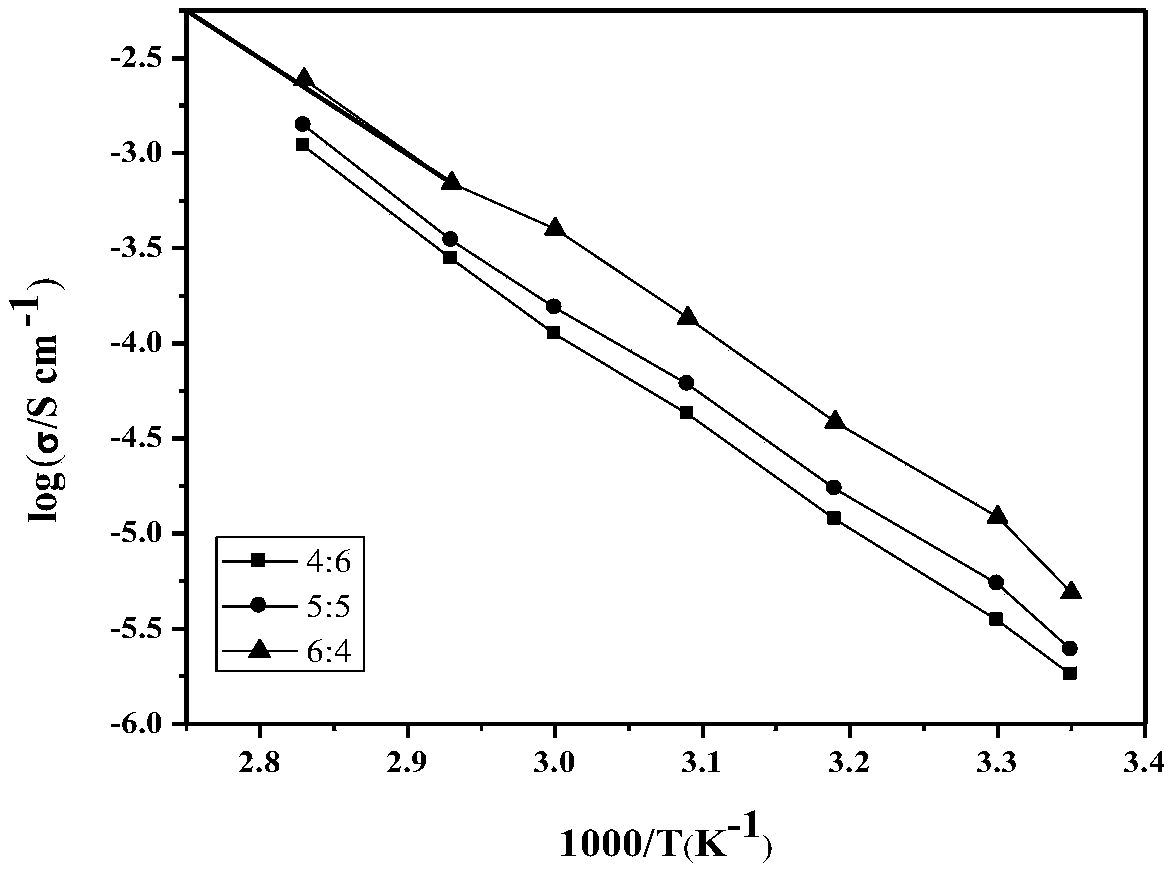

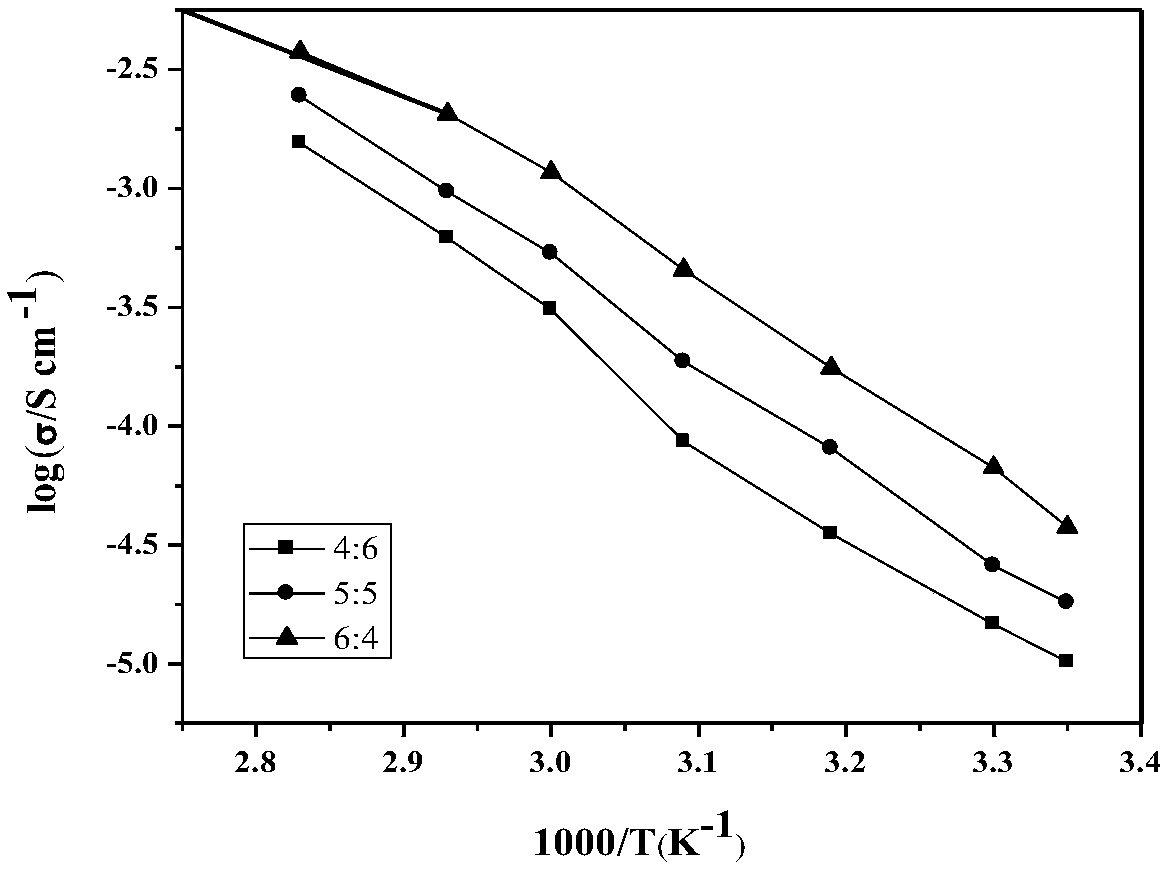

A controllable light-curable PEG solid-state topology polymer electrolyte and preparation method thereof

InactiveCN109065947AImprove ionic conductivityImprove mechanical propertiesSecondary cellsSolid state electrolyteUltraviolet lights

A controllable light-curable PEG solid-state topology polymer electrolyte and a preparation method thereof, A controllable light-curable PEG solid-state topology polymer electrolyte is prepared from PEO, lithium salts and star-shaped homopolymers or star-shaped block copolymers containing EO structural units, Pentaerythritol triacrylate (PETA) was synthesized by radical polymerization of PETA initiated by ultraviolet light with the addition of polyfunctional monomer pentaerythritol triacrylate. The solid electrolyte designed by the invention has good ionic conductivity, mechanical properties,electrochemical stability and thermal stability.

Owner:RES & DEV INST OF NORTHWESTERN POLYTECHNICAL UNIV IN SHENZHEN +1

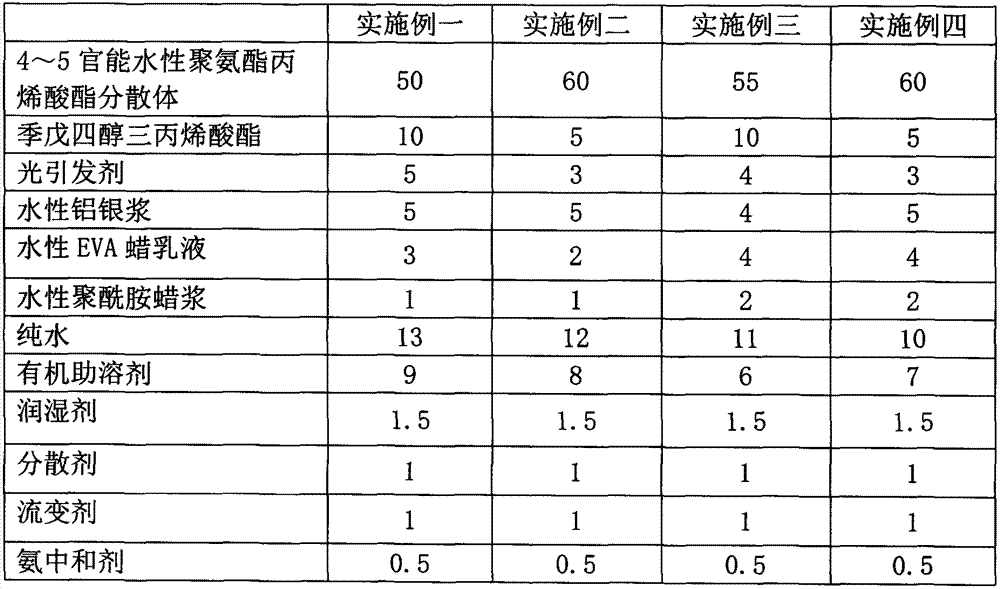

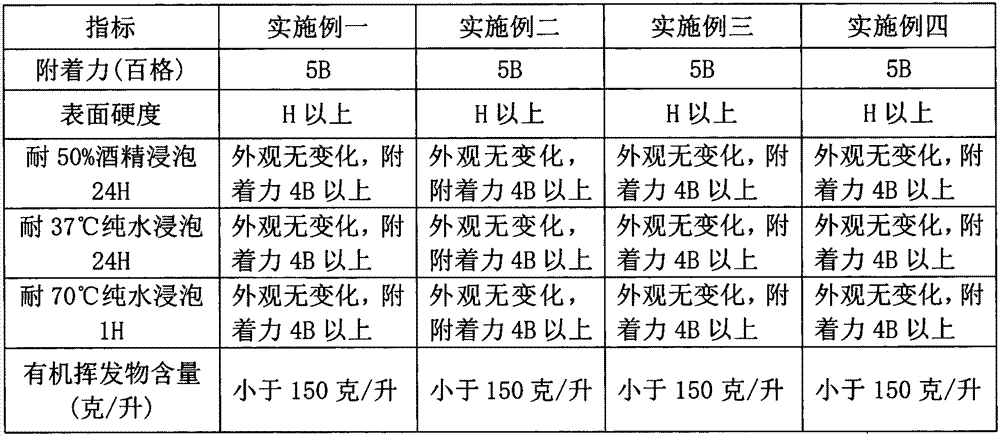

Water-based UV aluminum powder paint and preparation method thereof

InactiveCN107513346AEasy alignmentStrong metal coatingPolyurea/polyurethane coatingsWater basedPolyamide

The invention discloses water-based UV aluminum powder paint and a preparation method thereof. The water-based UV aluminum powder paint contains the following components by weight percent: 50%-60% of a 4-5 functional waterborne polyurethane acrylate dispersion body, 5%-10% of pentaerythritol triacrylate, 4%-5% of water-based aluminum-silver paste, 1%-5% of a photoinitiator, 1%-5% of a water-based EVA wax emulsion, 1%-5% of a water-based polyamide wax, 1%-2% of a wetting agent, 1%-2% of a dispersing agent, 5%-10% of an organic cosolvent, 10%-15% of pure water, 1%-2% of a rheological agent and 0.3%-0.5% of an ammonia neutralizer. According to the water-based UV aluminum powder paint and the preparation method, the disadvantages and deficiencies in the prior art are overcome, the VOC content of the UV aluminum powder paint is 100g / L-150g / L and is decreased by 70%-80% compared with that of the traditional solvent type aluminum powder paint; after a coating film is irradiated by virtue of ultraviolet light (for 10-20 seconds), a film can be formed through drying; after the coating film is dried, the directional alignment property of aluminum powder is good, the coating film has excellent physical and chemical properties, the production efficiency is high, the energy conservation and the emission reduction are realized, and the aluminum powder paint can pass relevant detection standards of cosmetic coatings.

Owner:东周化学工业(昆山)有限公司

Water emulsion type polyester acrylate printing adhesive and preparation method thereof

The invention discloses a water emulsion type polyester acrylate printing adhesive which is prepared from the following raw materials in parts by weight: 35-40 parts of polyester acrylate, 3-4 parts of peregal O, 1-2 parts of sodium dodecyl benzene sulfonate, 10-12 parts of butyl acrylate, 1-2 parts of dimethyl aminopropyl methacrylamide, 18-20 parts of methyl methacrylate, 5-6 parts of acrylic acid, 15-17 parts of dipentaerythritol hexaacrylate, 8-10 parts of propylene glycol monomethyl ether acetate, 10-12 parts of pentaerythritol triacrylate, 1-2 parts of ammonium persulfate, 4-5 parts of auxiliary and 80-90 parts of water. According to the adhesive disclosed by the invention, crosslinking modification is performed by use of the polyester acrylate, dipentaerythritol hexaacrylate, butyl acrylate and the like so that the adhesive has the advantages of strong adhesive force, high peel strength and dust prevention of polyester acrylate resin as well as the characteristics of difficulty in hydrolysis and low shrinkage rate of cured film; and the adhesive is applied to printing and is not easily stuck on a silk screen, realizes stable pattern and good fastness, and is easy to control and simple and convenient to operate.

Owner:HEFEI JUHE RADIAL CHEM TECH

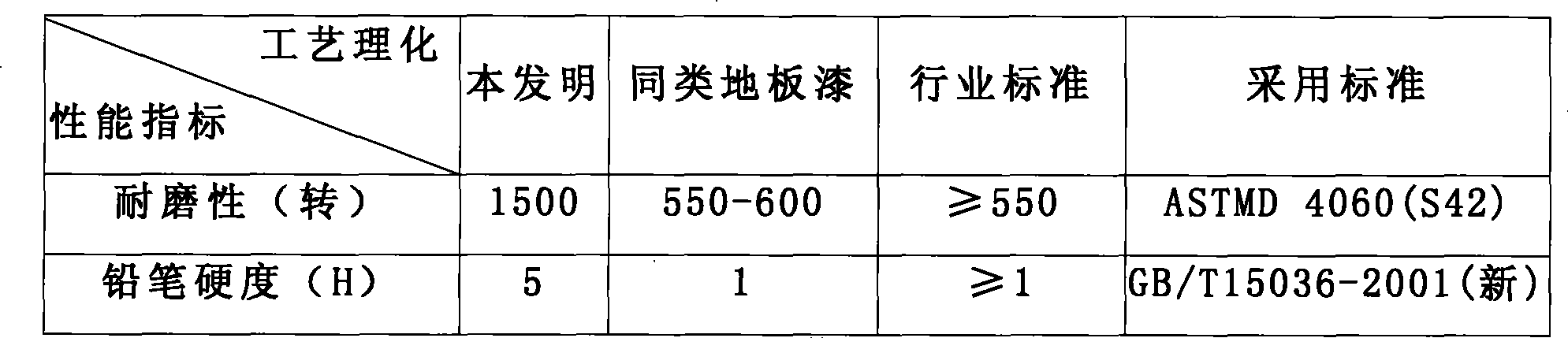

Floor paint

ActiveCN101412887AImprove wear resistanceExcellent abrasion resistance and scratch resistancePolyurea/polyurethane coatingsEpoxy resin coatingsLacquerAcrylic resin

The invention discloses floor paint formed by aqueous primer and UV finishing coat. The solid content of aqueous polyurethane in the primer is between 25 and 45 percent, and is formed by oligomer polylol and isocyanate through hydrophilic chain extender by chain extension, wherein the ligomer polylol has molecular weight of between 500 and 3,000, and is selected from tetrahydrofuran polylol, polybutanediol adipate polylol and polycaprolactone polylol; and the hydrophilic chain extender is ethylenediamine with anionic sulphonate or anionic carboxylate groups. The finishing coat uses butanone as a solvent, and contains epoxy mondified acrylic resin, trifunctional monomer, 1,6-hexanediol diacrylate, silicon dioxide powder, light initiator, active amine assistant initiator, organic fluorine foam suppressor and aluminum oxide powder, wherein a diluent monomer is selected from trimethylolpropane triacrylate, trifunctional extractant acid ester, pentaerythritol triacrylate, and propoxylated propanetriol triacrylate. The floor paint has the advantages of good wear resisting property and scraping resisting property and splitting resisting property.

Owner:SINO MAPLE JIANGSU CO LTD

Preparation of nano silver/carbon nano tube-modified electrode naringin molecular imprinting sensor

InactiveCN107202822AHigh affinityHigh selectivityMaterial nanotechnologyNanosensorsNaringinCarbon nanotube

The invention discloses preparation of a nano silver / carbon nano tube-modified electrode naringin molecular imprinting sensor. The preparation comprises the following steps: firstly preparing a nano silver / carbon nano tube-modified electrode by adopting a nano silver / carbon nano tube-modified glassy carbon electrode; then respectively adding 52-62 percent by weight of ethanol, 8-15 percent by weight of pentaerythritol triacrylate, 5-10 percent by weight of itaconic acid, 10-18 percent by weight of 1-propenyl-3-ethylimidazolium, 1.0-3.0 percent by weight of azodiisobutyronitrile and 4.0-10 percent by weight of naringin into a reactor, stirring at a temperature of 60+ / -2 DEG C under anaerobic atmosphere for reaction for 18-24 hours and removing template molecules by adopting a methanol and acetic acid mixed solution to obtain a naringin molecular imprinting polymer; dispensing the naringin molecular imprinting polymer onto the nano silver / carbon nano tube-modified electrode to obtain the naringin molecular imprinting sensor. The sensor is high in affinity and selectivity, high in sensitivity, good in specificity, quick in detection and capable of being reused.

Owner:UNIV OF JINAN

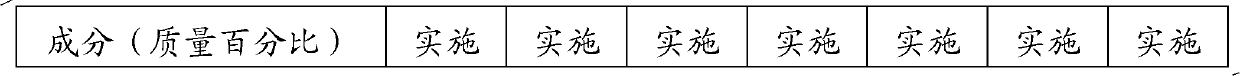

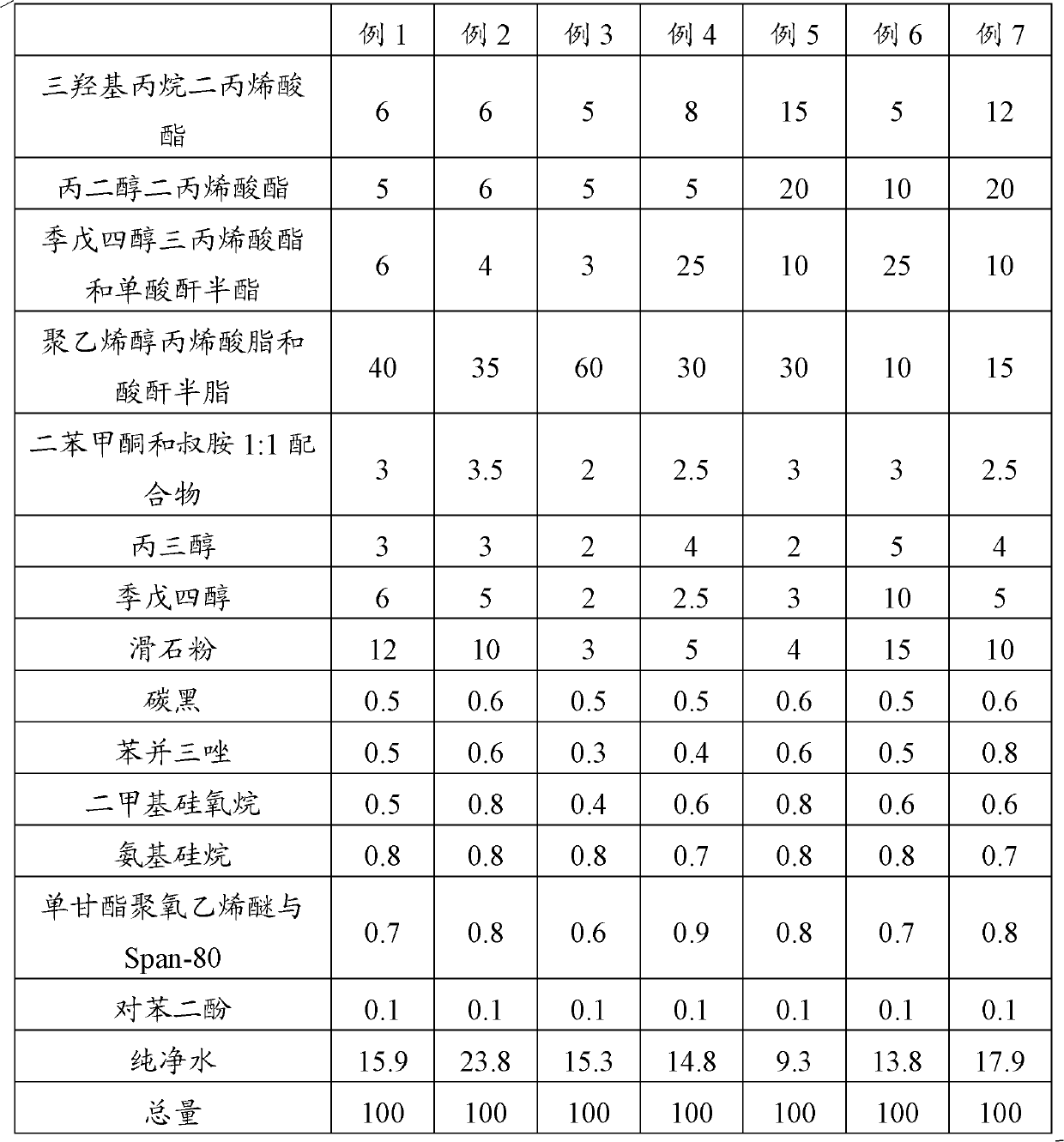

Photosensitive water developing corrosion-resistant composition and photosensitive water developing corrosion-resistant dry film

The invention relates to a photosensitive water developing corrosion-resistant composition and a photosensitive water developing corrosion-resistant dry film. The photosensitive water developing corrosion-resistant composition consists of acrylate, polyvinyl alcohol acrylate-benzoic anhydride half-ester, pentaerythritol triacrylate, monoanhydride half-ester, a photoinitiator, a plasticizer, an inorganic filler, a coloring agent, a tackifier, a leveling defoaming agent, a coupling agent, an emulsifying agent, a polymerization inhibitor and balance of water. As the polyvinyl alcohol acrylate-benzoic anhydride half-ester is used, the photosensitive water developing corrosion-resistant composition can provide water solubility, water developing property, high film-forming property and contact dryness and has high adhesive force when applied to circuit board etching.

Owner:HUIZHOU LIANDA ELECTRONICS MATERIAL

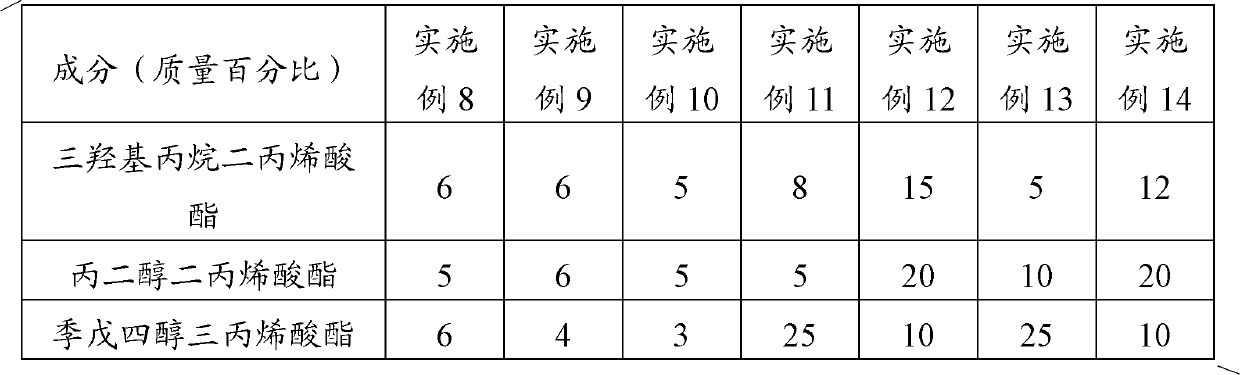

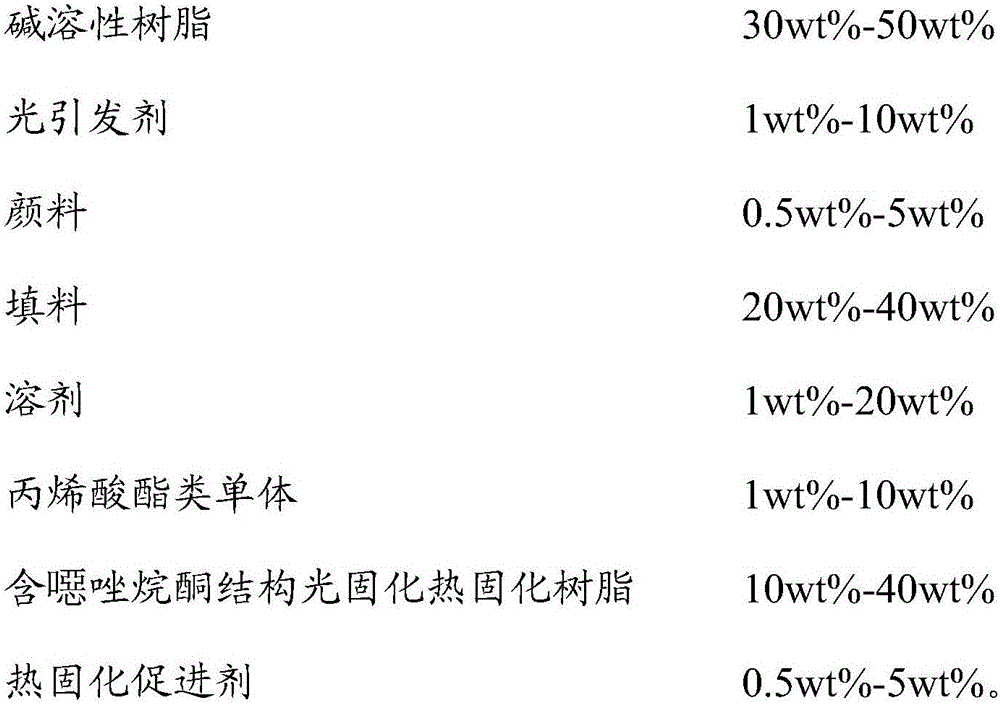

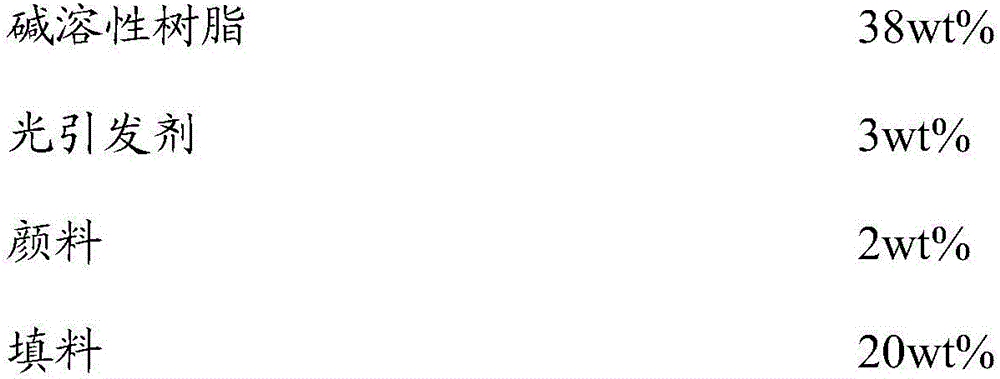

Oxazolidinone structure-containing photocuring thermocuring resin and preparation method thereof, and photosensitive solder resisting material containing resin

ActiveCN106832221AImprove heat resistanceImprove adhesionPhotosensitive materials for photomechanical apparatusEpoxyPolymer science

The invention relates to an oxazolidinone structure-containing photocuring thermocuring resin and a preparation method thereof, and a photosensitive solder resisting material containing the resin. In the preparation process of the oxazolidinone structure-containing photocuring thermocuring resin, diisocyanate, dibutyltin dilaurate and pentaerythritol triacrylate are added into a solvent respectively, a reaction temperature is kept at 40 DEG C-70 DEG C, the concentration change of -NCO groups in the system is monitored, the reaction is stopped when the content of the -NCO groups is 48%-55% of the initial content, and a diisocyanate semi-addition product is obtained; and then epoxy resin, a catalyst and 2,6-di-tert-butyl-4-methyl phenol are added to the diisocyanate semi-addition product respectively, a reaction temperature is kept at 110 DEG C-140 DEG C, the reaction is stopped when the content of the -NCO groups in the system is 0, a 1750 cm<-1> absorption peak of carbonyl in an oxazolidinone ring structure is determined to appear in an infrared spectrogram, and thus the oxazolidinone ring-containing photocuring thermocuring resin is obtained. The photocuring thermocuring resin prepared by the method has excellent heat resistance and good adhesive force.

Owner:FOSHAN 3Q ELECTRONICS MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com