Oxazolidinone structure-containing photocuring thermocuring resin and preparation method thereof, and photosensitive solder resisting material containing resin

A technology containing oxazolidinone and cured resin, which is applied in the field of photosensitive solder resist materials, can solve problems affecting the quality of circuit boards, easy foaming and peeling, etc., and achieve excellent heat resistance, increase cross-linking density, and excellent heat resistance and the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

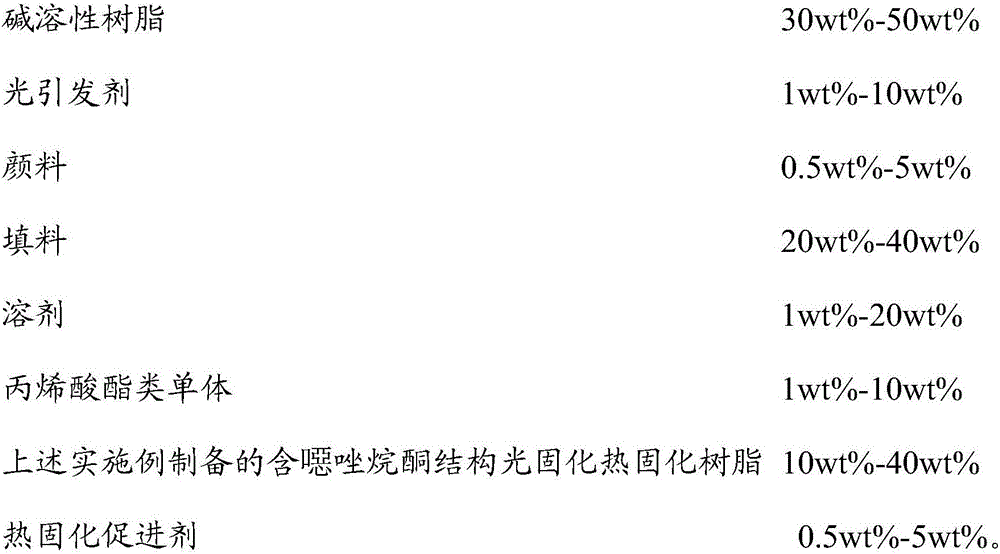

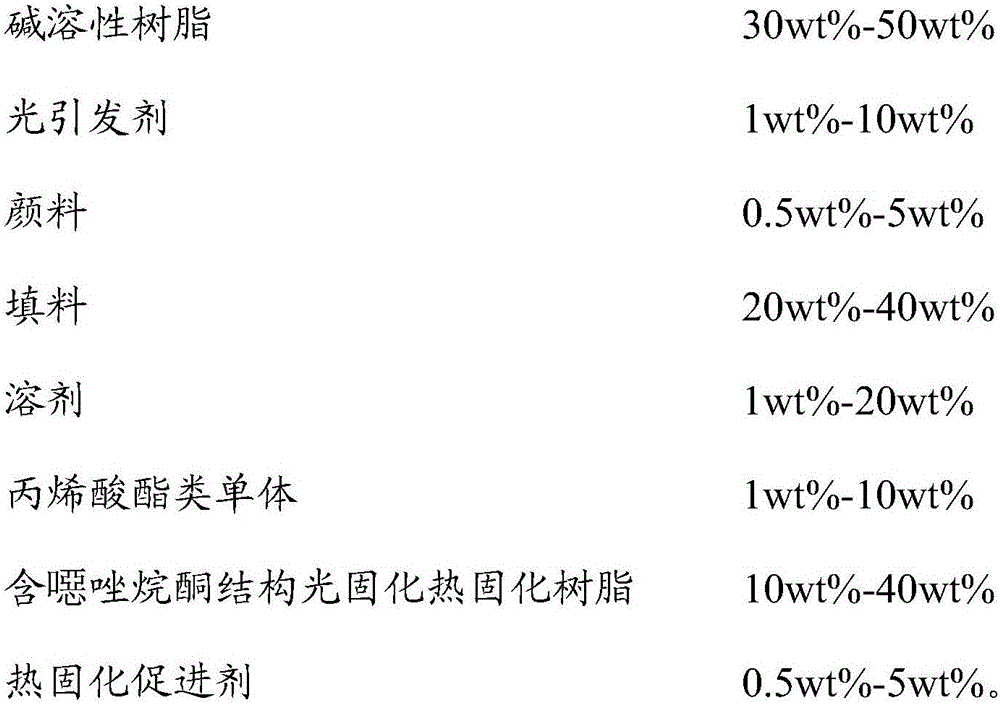

[0028] In one embodiment, the preparation method of the photocurable thermosetting resin containing oxazolidinone ring structure comprises the following steps:

[0029] Add diisocyanate, dibutyltin dilaurate and pentaerythritol triacrylate into the dibasic ester solvent respectively, keep the reaction temperature at 40°C-70°C, and react for a period of time. When the content of -NCO group in the reaction system is monitored to be When the initial content is 48%-50%, the reaction is stopped to obtain diisocyanic acid semi-adducts;

[0030] Add epoxy resin, catalyst and 2,6-di-tert-butyl-4-methylphenol to the diisocyanic acid semi-adduct respectively, keep the reaction temperature at 110°C-140°C, and react for a period of time. Stop the reaction when the -NCO group in the system disappears, and the 1750cm carbonyl in the oxazolidinone ring structure appears in the infrared spectrum -1 The absorption peak at the place, that is to obtain the oxazolidinone-containing structure lig...

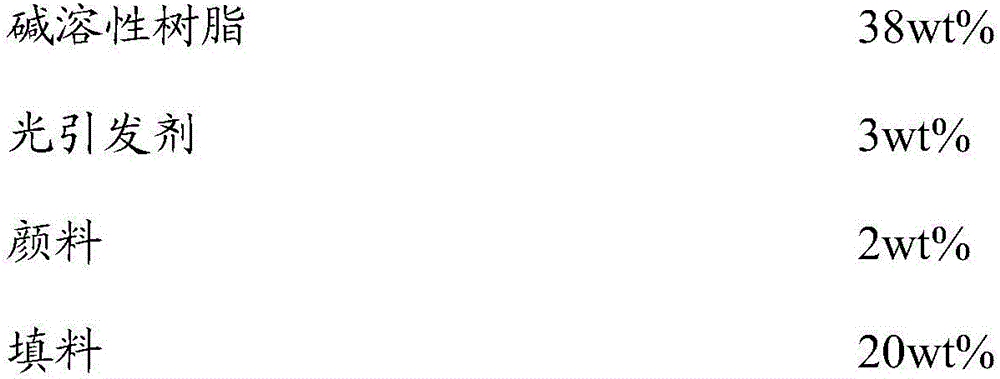

Embodiment 1

[0056] Example 1: Preparation of oxazolidinone-containing structured light-curable heat-curable resin A

[0057] Add 257.8g of diphenylmethane diisocyanate and 0.8g of dibutyltin dilaurate to 36g of S150 aromatic hydrocarbon solvent respectively, add 298.3g of pentaerythritol triacrylate dropwise, keep the reaction temperature at 40-70°C, and react for 2-4h. When the content of -NCO group in the system is monitored to be 50% of the initial content, the reaction is stopped to obtain a diisocyanic acid semi-adduct, which is cooled to room temperature. Add 360 g of novolac epoxy resin (NPPN-638S), 0.7 g of N,N-dimethylbenzylamine, and 0.5 g of 2,6-di-tert-butyl-4-methylphenol into the resulting diisocyanate hemi-adduct , heated to 130°C, stopped the reaction when the -NCO group in the system disappeared, and carried out IR measurement on the product after the reaction, and the absorption peak at 1750cm-1 of the carbonyl in the oxazolidinone ring structure appeared in the infrared...

Embodiment 2

[0058] Example 2: Preparation of oxazolidinone-containing structured light-curable heat-curable resin B

[0059] Add 257.8g of diphenylmethane diisocyanate and 0.8g of dibutyltin dilaurate to 36g of S150 aromatic hydrocarbon solvent respectively, add 298.3g of pentaerythritol triacrylate dropwise, keep the reaction temperature at 40-70°C, and react for 2-4h. When the content of -NCO group in the system is monitored to be 50% of the initial content, the reaction is stopped to obtain a diisocyanic acid semi-adduct, which is cooled to room temperature. Add 276.9g of epoxy novolac resin (NPPN-638S), 0.7g of N,N-dimethylbenzylamine, and 0.5g of 2,6-di-tert-butyl-4-methylphenol to the resulting diisocyanate hemi-adduct , heated to 130°C, stopped the reaction when the -NCO group in the system disappeared, and carried out IR measurement on the product after the reaction, and the absorption peak at 1750cm-1 of the carbonyl in the oxazolidinone ring structure appeared in the infrared sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com