Ultraviolet curable coating for low energy curing and preparation method of ultraviolet curable coating

A technology of curing coatings and ultraviolet light, which is applied in the direction of polyester coatings, epoxy resin coatings, coatings, etc., can solve the problems of not being well applied, and achieve excellent wettability, good sanding performance, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

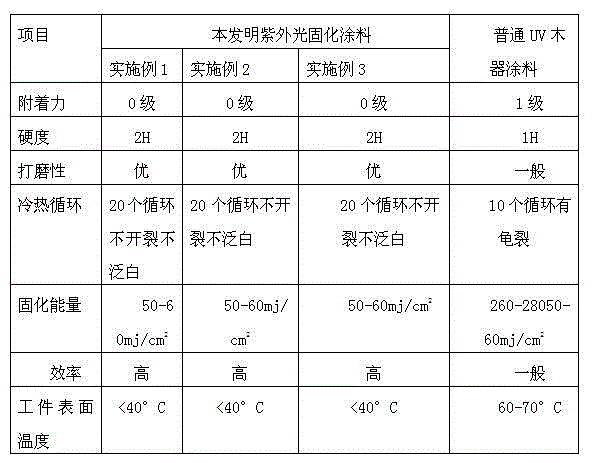

Embodiment 1

[0041] The low-energy curing UV-curable coating of the present embodiment, the raw material weight percent in its formula is as follows:

[0042] Modified multifunctional polyester acrylate: 35%

[0043] Modified Epoxy Acrylate 10%

[0044] Modified Pentaerythritol Acrylate 20%

[0045] TPGDA10%

[0046] Wetting and dispersing agent 0.5%

[0047] Clear Talc 15%

[0048] Photoinitiator 14%

[0049] Photoinitiator 21%

[0050] Photoinitiator 34%

[0051] Leveling agent 0.5%.

[0052] The above-mentioned modified polyester acrylate adopts HY-218 sold by our company;

[0053] The above-mentioned modified epoxy acrylate resin adopts Jiangsu Sanmu SM-6109D;

[0054] The above-mentioned modified pentaerythritol triacrylate adopts Wuxi Huihong L-300;

[0055] The above wetting and dispersing agent uses BYK 164;

[0056] Above-mentioned transparent talcum powder is the 1250# talcum powder of Longsheng;

[0057] Above-mentioned photoinitiator 1 is 2-hydroxyl-2-methyl-1-pheny...

Embodiment 2

[0060] The low-energy curing UV-curable coating of the present embodiment, the raw material weight percent in its formula is as follows:

[0061] Modified multifunctional polyester acrylate: 30%

[0062] Modified Epoxy Acrylate 14%

[0063] Modified Pentaerythritol Triacrylate 22%

[0064] TPGDA12%

[0065] Wetting and dispersing agent 0.5%

[0066] Clear Talc 12%

[0067] Photoinitiator 14%

[0068] Photoinitiator 21%

[0069] Photoinitiator 34%

[0070] Leveling agent 0.5%.

[0071] The above-mentioned modified polyester acrylate adopts HY-218 sold by our company;

[0072] The above-mentioned modified epoxy acrylate resin adopts Jiangsu Sanmu SM-6109D;

[0073] The above-mentioned modified pentaerythritol triacrylate adopts Wuxi Huihong L-300;

[0074] The above wetting and dispersing agent uses BYK 164;

[0075] Above-mentioned transparent talcum powder is the 1250# talcum powder of Longsheng;

[0076] Above-mentioned photoinitiator 1 is 2-hydroxyl-2-methyl-1-ph...

Embodiment 3

[0079] The low-energy curing UV-curable coating of the present embodiment, the raw material weight percent in its formula is as follows:

[0080] Modified multifunctional polyester acrylate: 25%

[0081] Modified Epoxy Acrylate 15%

[0082] Modified Pentaerythritol Triacrylate 25%

[0083] TPGDA15%

[0084] Wetting and dispersing agent 0.5%

[0085] Clear Talc 10%

[0086] Photoinitiator 14%

[0087] Photoinitiator 21%

[0088] Photoinitiator 34%

[0089] Leveling agent 0.5%.

[0090] The above-mentioned modified polyester acrylate adopts HY-218 sold by our company;

[0091] The above-mentioned modified epoxy acrylate resin adopts Jiangsu Sanmu SM-6109D;

[0092] The above-mentioned modified pentaerythritol triacrylate adopts Wuxi Huihong L-300;

[0093] The above wetting and dispersing agent uses BYK 164;

[0094] Above-mentioned transparent talcum powder is the 1250# talcum powder of Longsheng;

[0095] Above-mentioned photoinitiator 1 is 2-hydroxyl-2-methyl-1-ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com