Patents

Literature

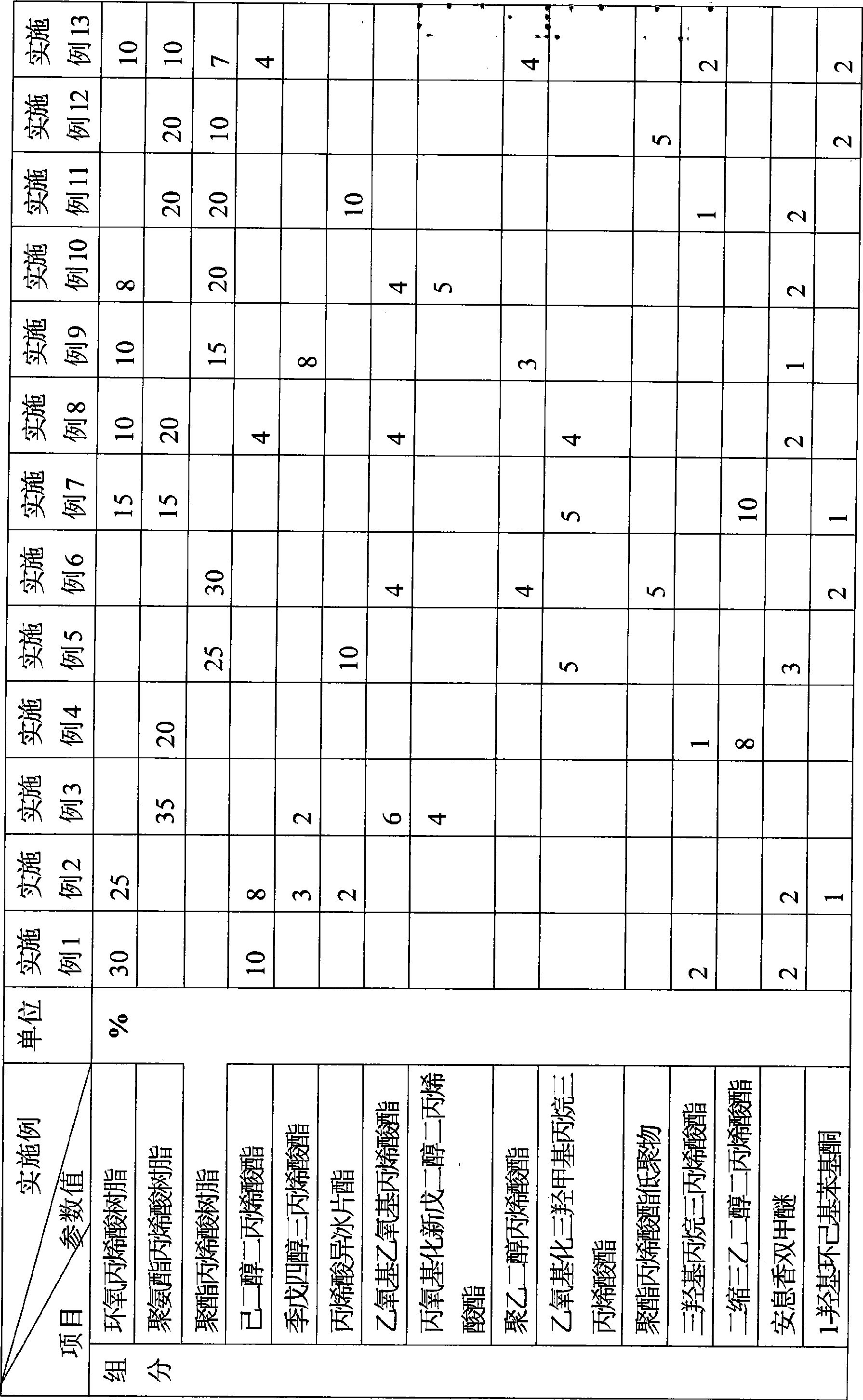

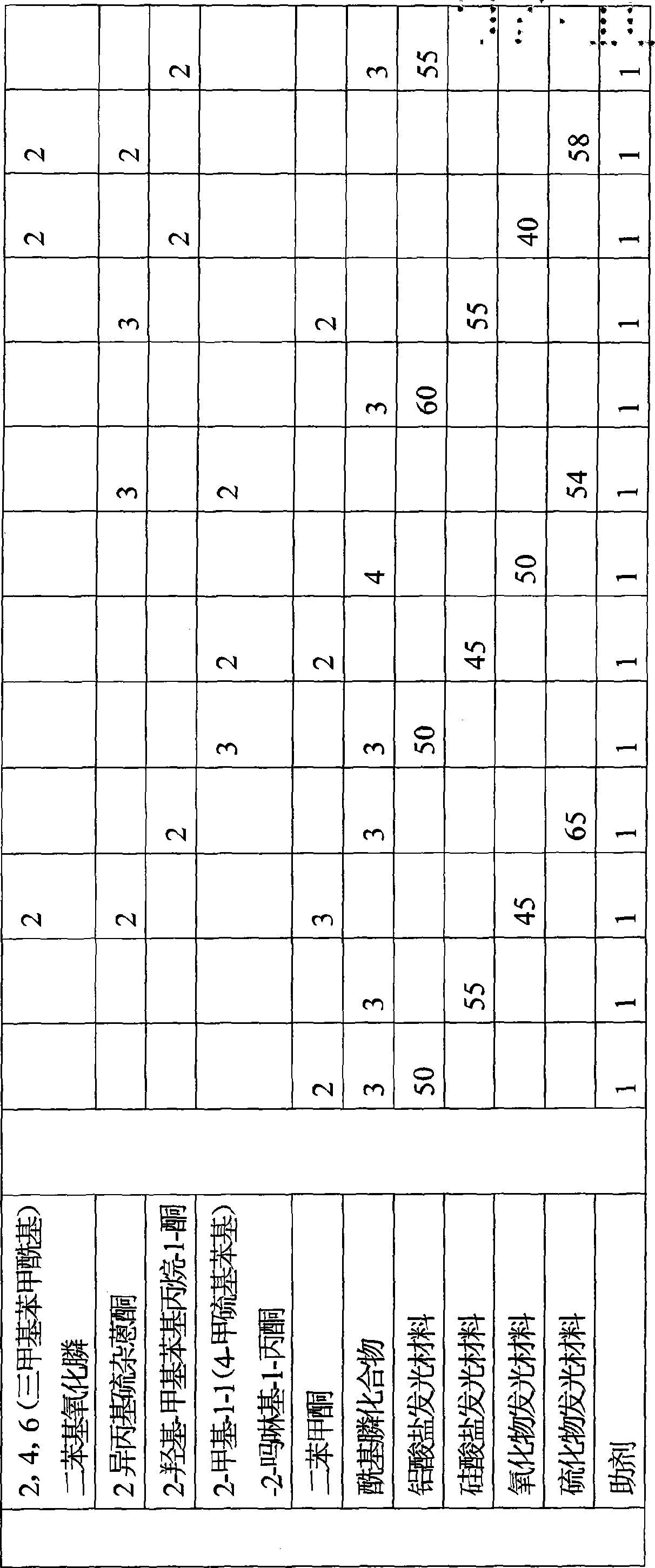

951 results about "Triacrylate ester" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

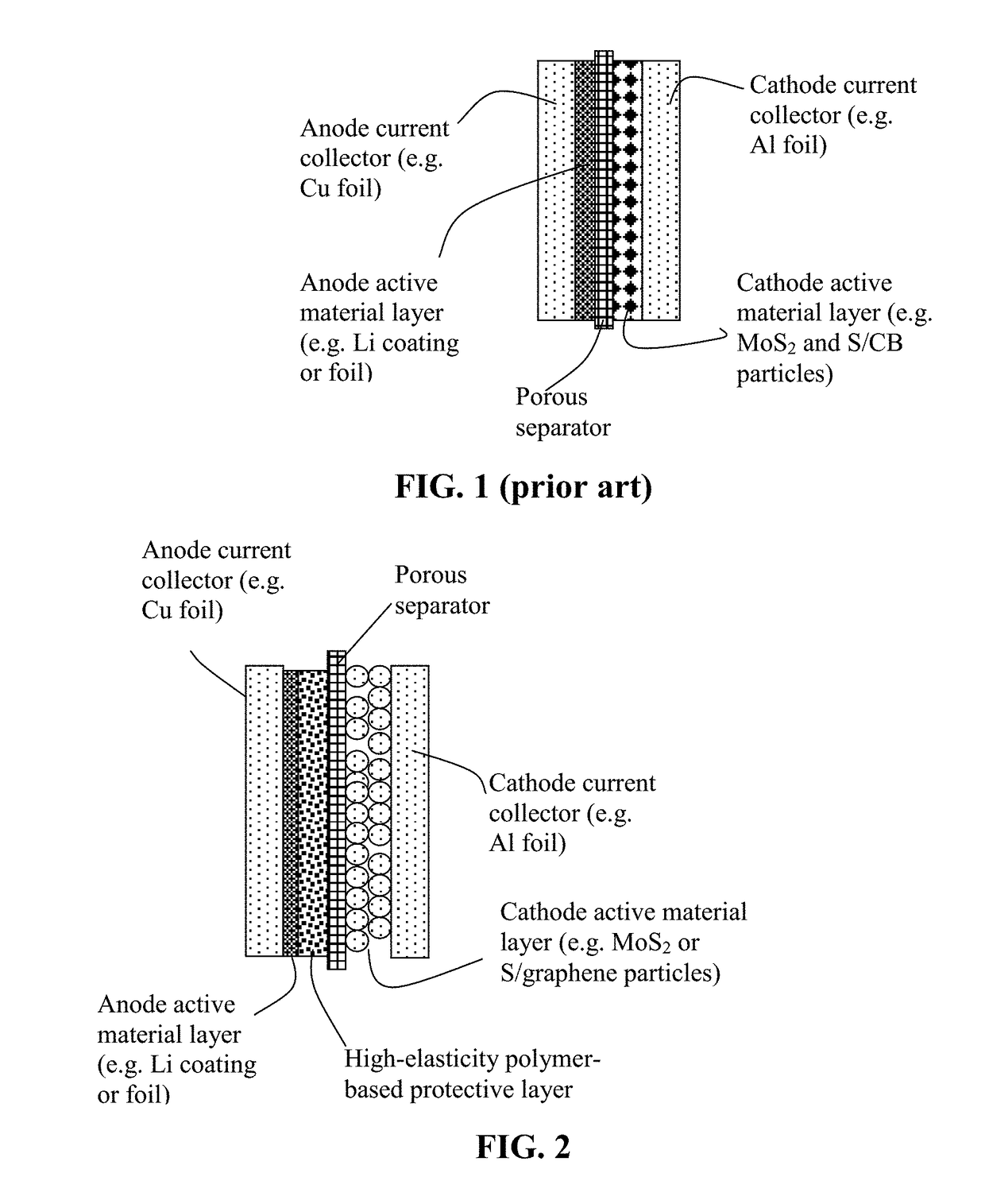

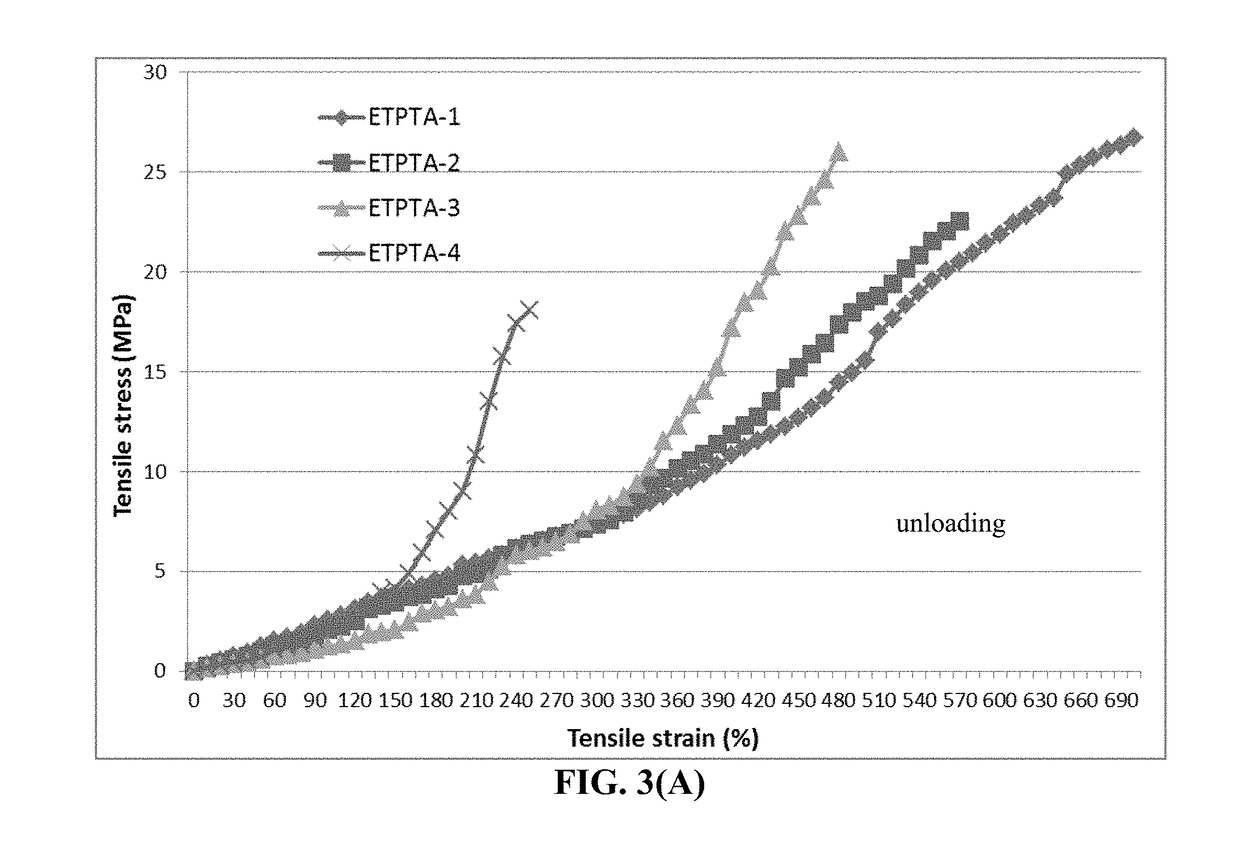

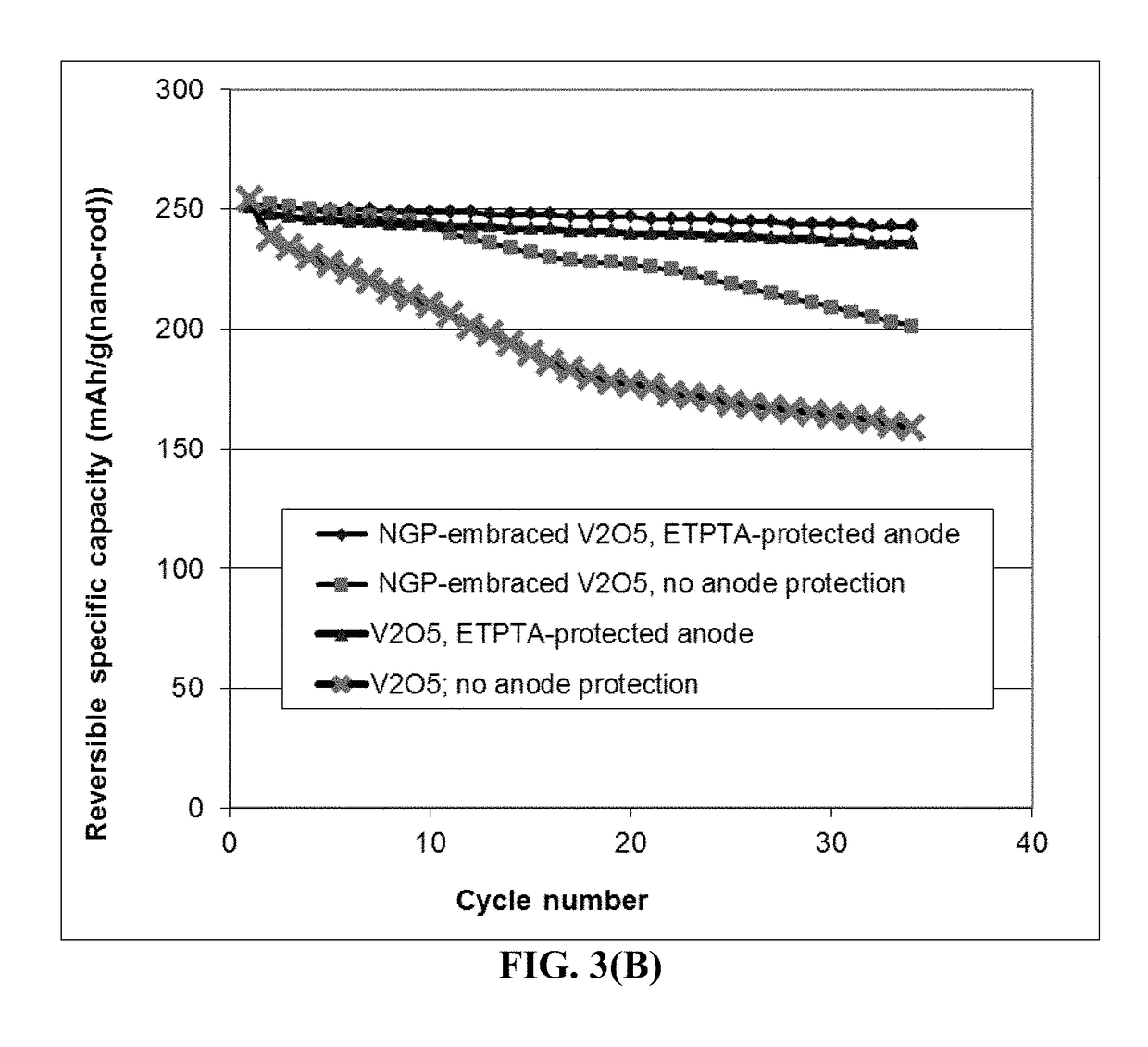

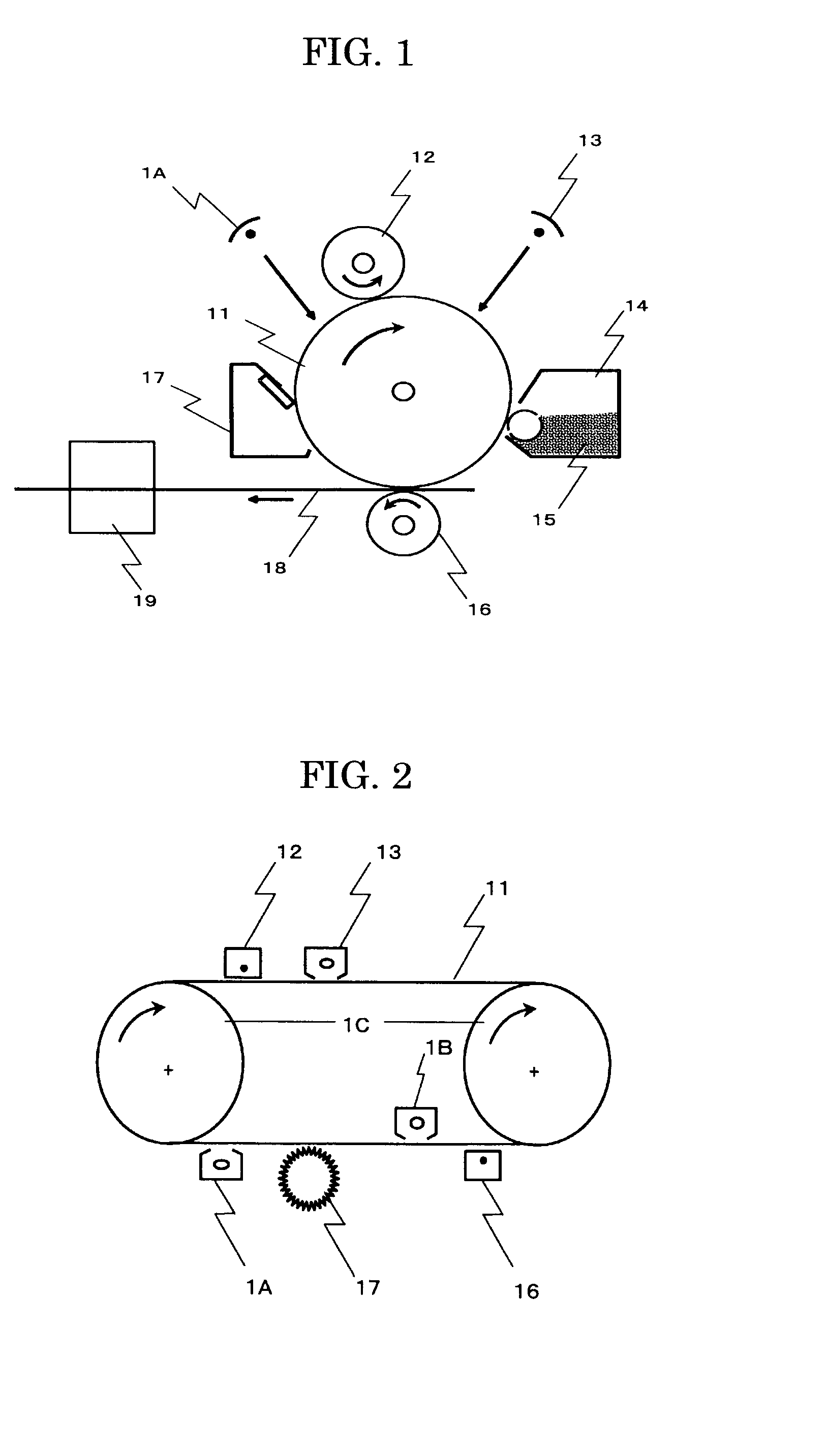

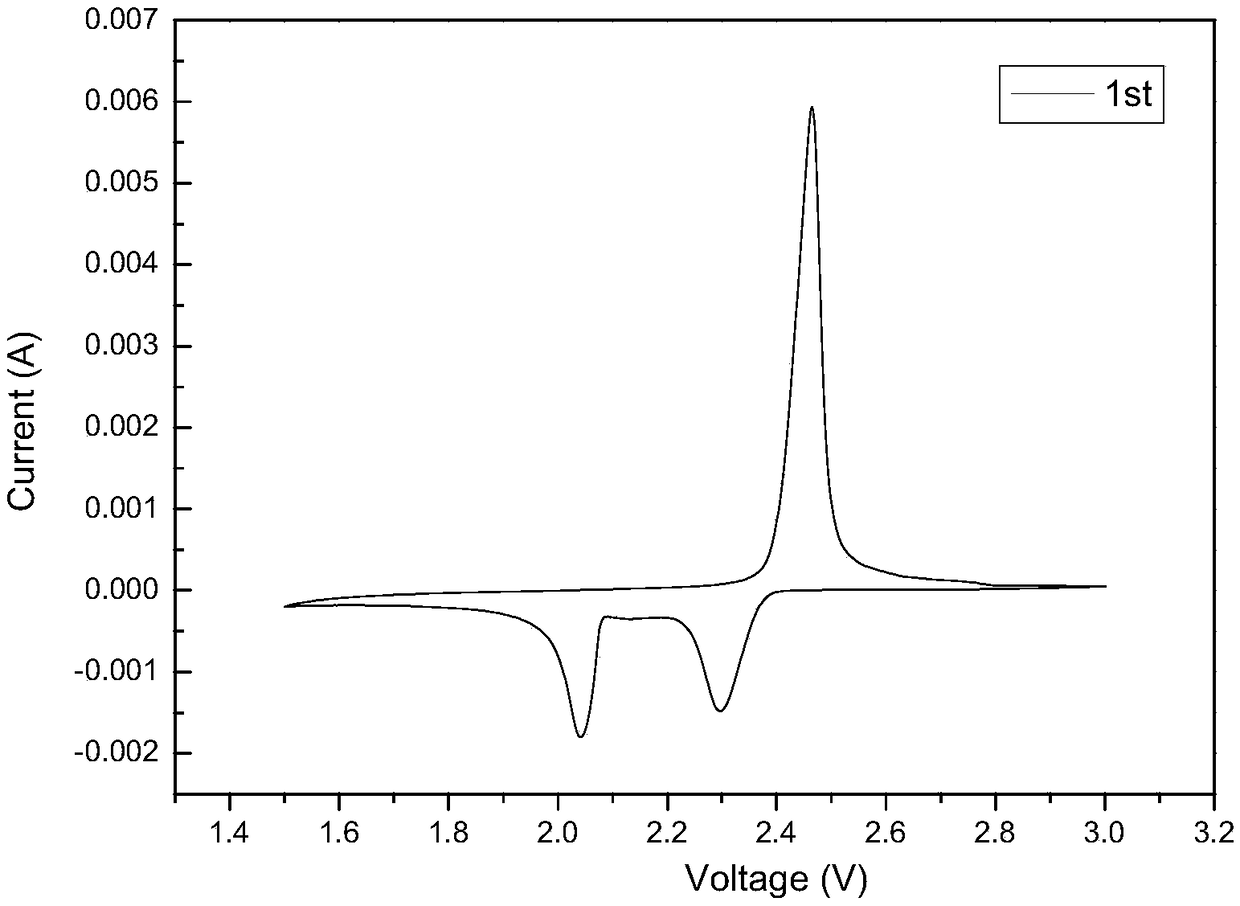

Lithium Anode-Protecting Polymer Layer for a Lithium Metal Secondary Battery and Manufacturing Method

ActiveUS20180301707A1Improve lithium ion conductivityIncrease elasticityFuel and secondary cellsCell electrodesCross-linkLithium metal

Provided is lithium secondary battery comprising a cathode, an anode, and an electrolyte or separator-electrolyte assembly disposed between the cathode and the anode, wherein the anode comprises: (a) a foil or coating of lithium or lithium alloy; and (b) a thin layer of a high-elasticity polymer disposed between the foil / coating and the electrolyte (or separator-electrolyte assembly), having a recoverable tensile strain no less than 2%, a lithium ion conductivity no less than 10−6 S / cm at room temperature, and a thickness from 1 nm to 10 μm, wherein the high-elasticity polymer contains a cross-linked network of polymer chains having an ether linkage, nitrile-derived linkage, benzo peroxide-derived linkage, ethylene oxide linkage, propylene oxide linkage, vinyl alcohol linkage, cyano-resin linkage, triacrylate monomer-derived linkage, tetraacrylate monomer-derived linkage, or a combination thereof in the cross-linked network of polymer chains.

Owner:GLOBAL GRAPHENE GRP INC

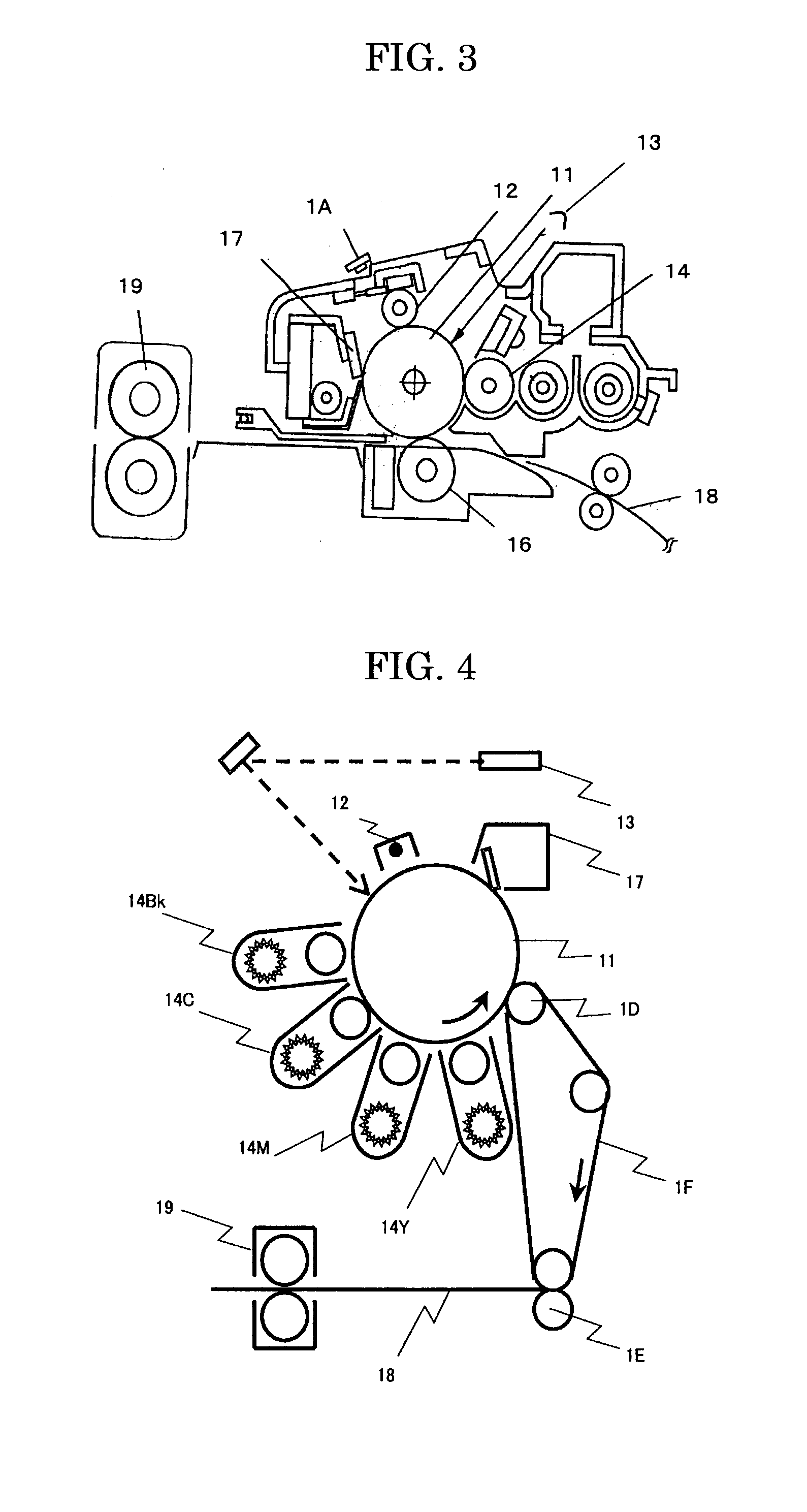

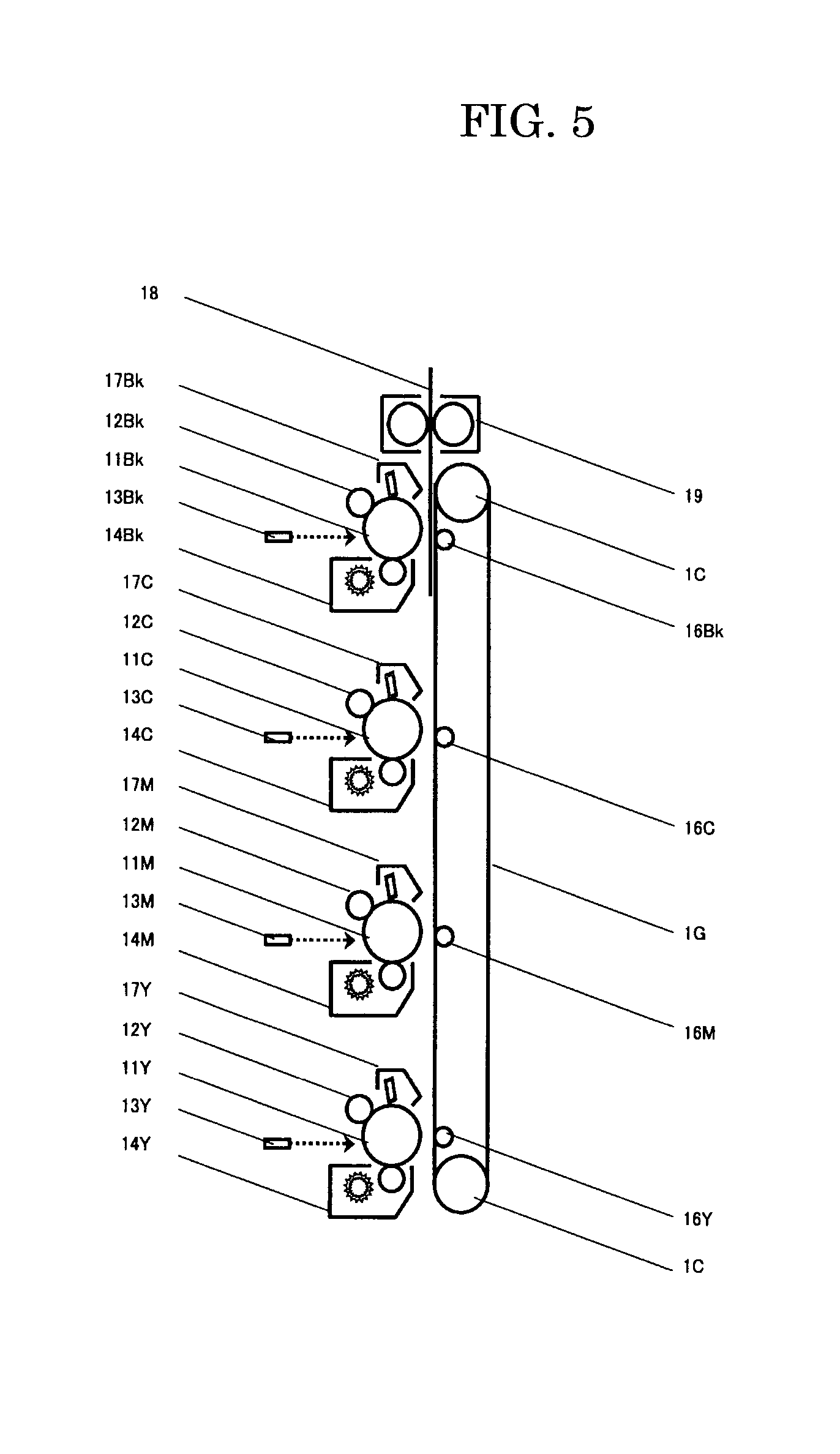

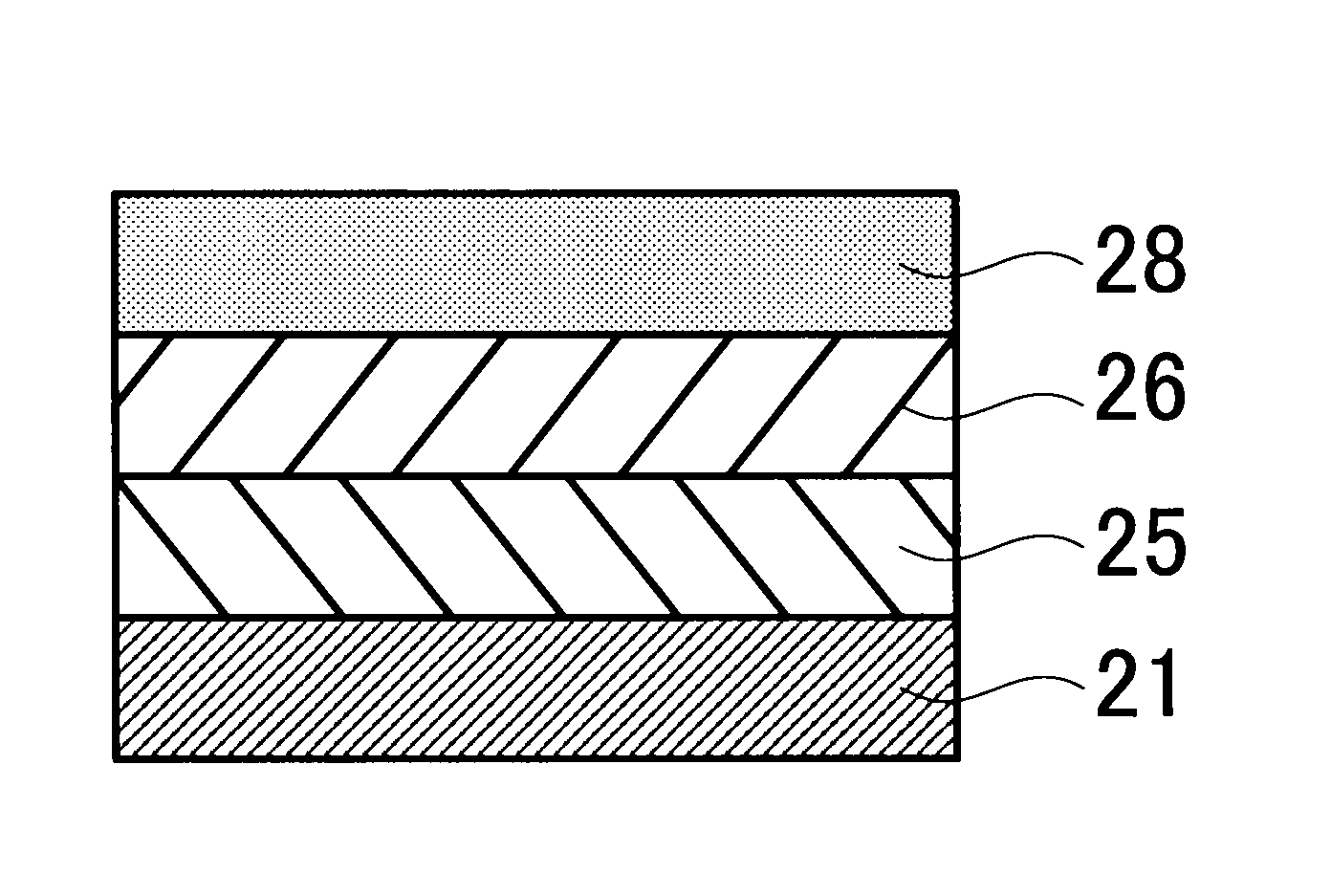

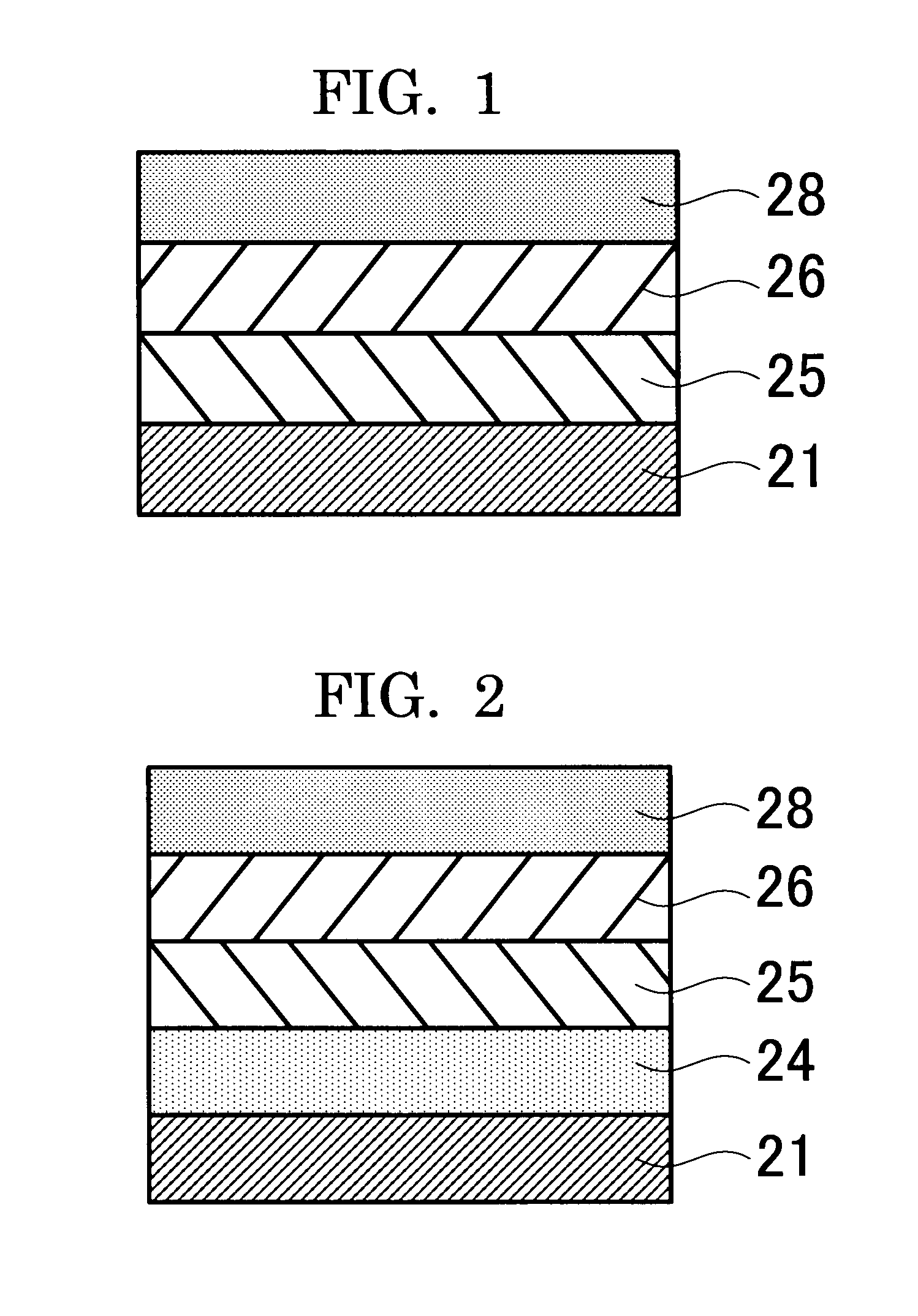

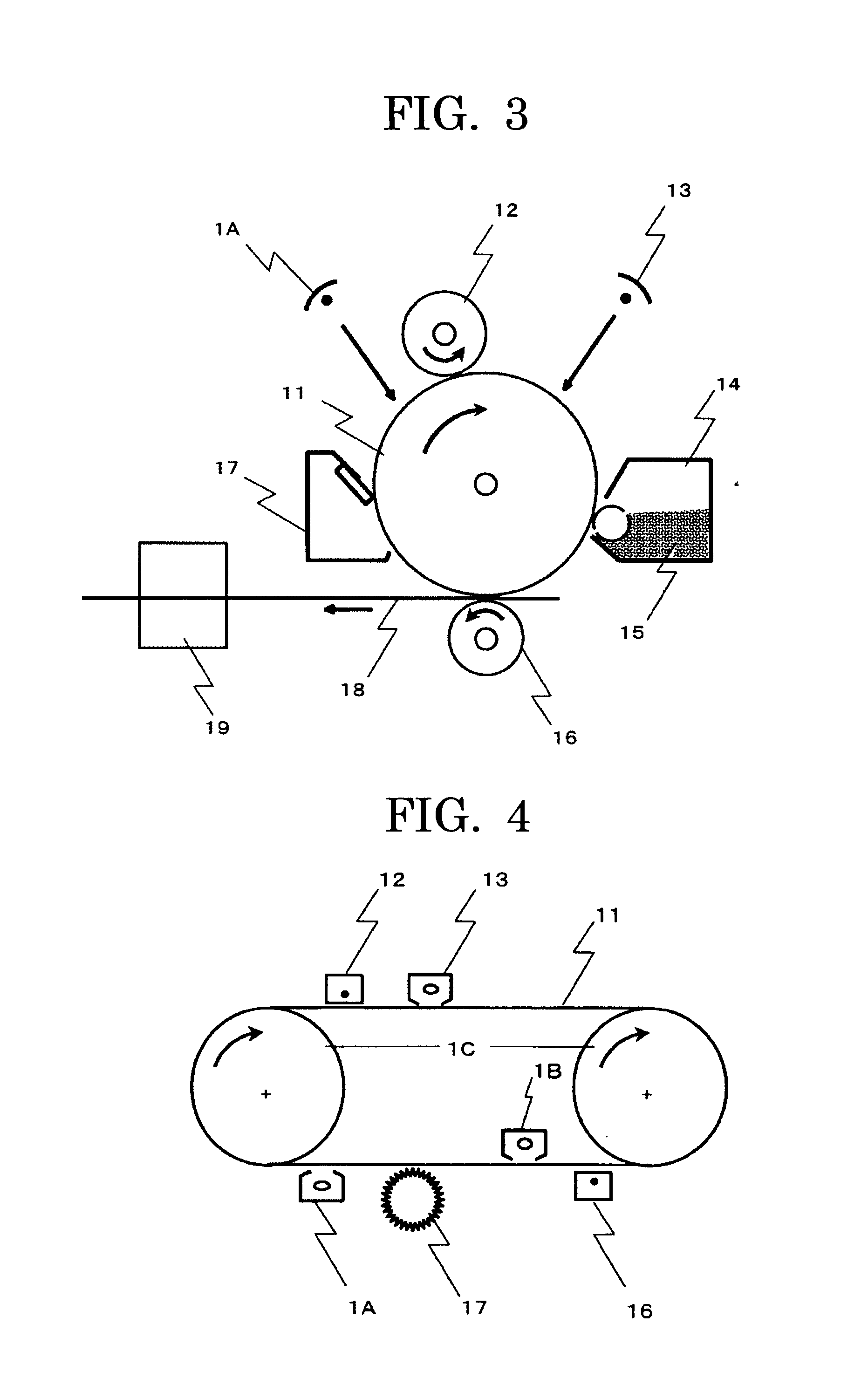

Electrophotographic photoconductor, and electrophotographic apparatus

InactiveUS20080085459A1Improve surface smoothnessImprove wear resistanceElectrographic process apparatusCross-linkElectrical conductor

There is provided an electrophotographic photoconductor which contains at least a conductive substrate, a photoconductive layer comprising a charge generating material and charge transport material, and a surface layer disposed on the photoconductive layer, disposed in this order, wherein the surface layer is a cross-linked resin which contains at least trimethylolpropane triacrylate, a charge transport material having a heat-curable or radical-polymerizable functional group, a silicone compound having a radical-polymerizable functional group, a fluorinated surfactant having a radical-polymerizable functional group, and a silicone compound removing material having a radical-polymerizable functional group having a wettability of 55 mN / m or more to less than 65 mN / m with the silicone compound.

Owner:RICOH KK

Electrophotographic photoconductor, electrophotographic process cartridge containing the same and electrophotographic apparatus containing the same

InactiveUS20080227008A1Low increase in friction coefficient and wearEasy to cleanElectrographic process apparatusCorona dischargeElectrical conductorSurface layer

An object of the present invention is to provide an electrophotographic photoconductor having an extremely low increase in friction coefficient and wear, while also having superior cleanability even after long-term or large-volume printing, and to provide an electrophotographic apparatus for forming an image using a polymerization toner without providing a unit for externally supplying a lubricant to a photoconductor. Namely, the present invention provides an electrophotographic photoconductor having a photosensitive layer and a crosslinked resin surface layer over a conductive substrate, wherein the crosslinked resin surface layer at least contains trimethylolpropane triacrylate, a dimethylpolysiloxane having a radically polymerizable functional group, and lubricating fine particles.

Owner:RICOH KK

Preparation method of in-situ polymerization solid-state battery

ActiveCN108493486AImprove securityCurb churnFinal product manufactureElectrolyte accumulators manufacturePolymer scienceOrganic solvent

The invention relates to a preparation method of an in-situ polymerization solid-state battery. The preparation method comprises the following steps: step S1, mixing electrolyte salt, an organic solvent, 1-10 percent of acrylic ester and 0.1-1 percent of an initiating agent AIBN to prepare a mixture I, wherein the acrylic ester is one of or more of isopentyl tetraacrylate, pentaerythritol triacrylate and allyl hydroxyethyl ether; step 2, weighing an active substance, acetylene black and positive pole piece made by PVDF according to the mass ratio of 6:3:1, taking a lithium sheet as a negativeelectrode, taking the mixture I as an electrolyte and taking a polypropylene thin film as a diaphragm assembly battery; step S3, putting the battery in a drying box and maintaining for 1-30 minutes after the battery is heated to 40-80 DEG C. The preparation method provided by the invention has the benefit that by adopting an in-situ heat curing technology, the interface problem between the electrolyte and a battery anode and cathode can be better solved.

Owner:武汉新能源研究院有限公司

Nanometer SiO2 modifying process of ultraviolet ray cured adhesive

InactiveCN1887972AGood compatibilityGood dispersionNon-macromolecular adhesive additivesPigment treatment with organosilicon compounds(Hydroxyethyl)methacrylateAdhesive

The present invention discloses nanometer SiO2 modifying process of UV ray cured adhesive. The long chain polyether silane coupler in the general expression of (R1O)3SiCH2CH2CH2O(CH2CH2O)a(CH2CH(CH3)O)bC=OC(R2)=CH2 is first used in surface modifying SiO2 of grain size of 5-50 nm inside isopropyl alcohol dispersing medium; the obtained composite pre-polymer is then mixed with epoxy acrylate, hydroxyethyl methacrylate or hydroxypropyl methacrylate, trimethylopropane-3ethoxyl -triacrylic ester, acrylic cid or acrylate with acid functional radical, photoiniitator, KH570, triethanolamine and maleic acid through stirring to obtain the UV adhesive product. The present invention has improved SiO2 dispersivity and stability, and the UV adhesive product has greatly raised adhesion performance.

Owner:ZHEJIANG UNIV +1

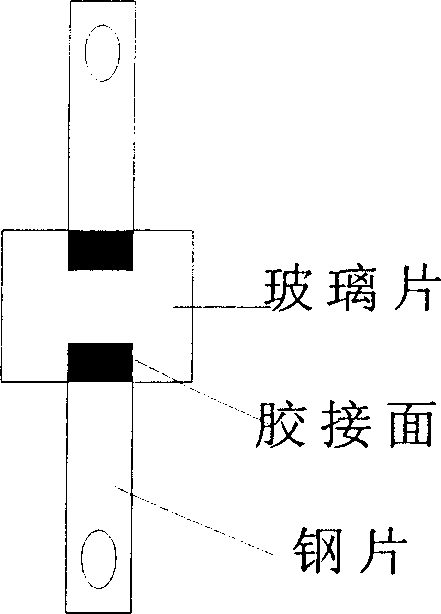

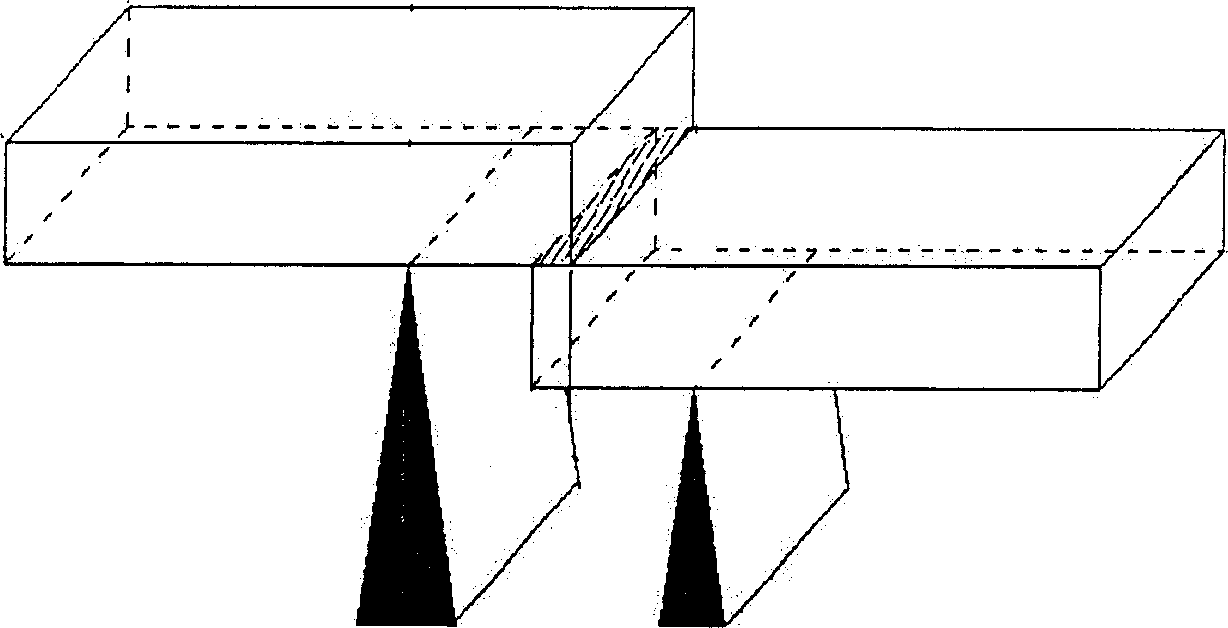

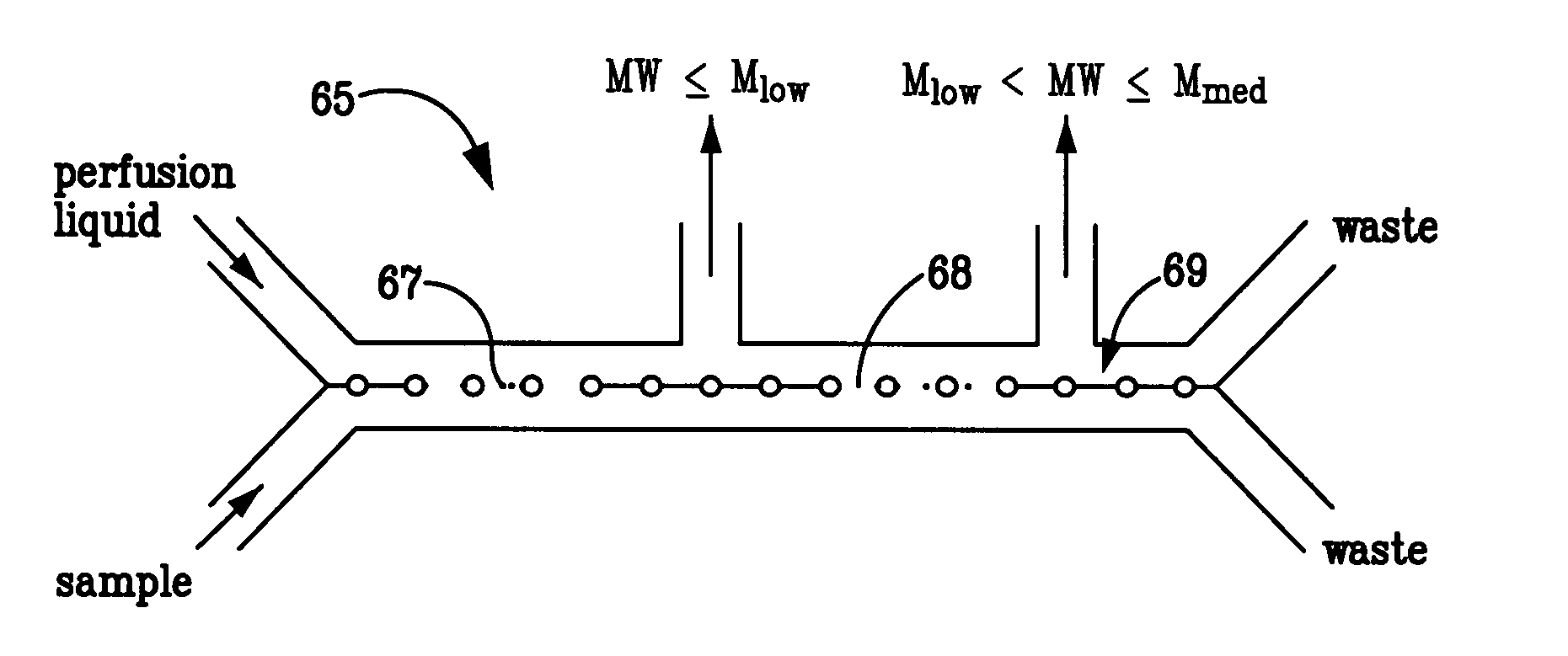

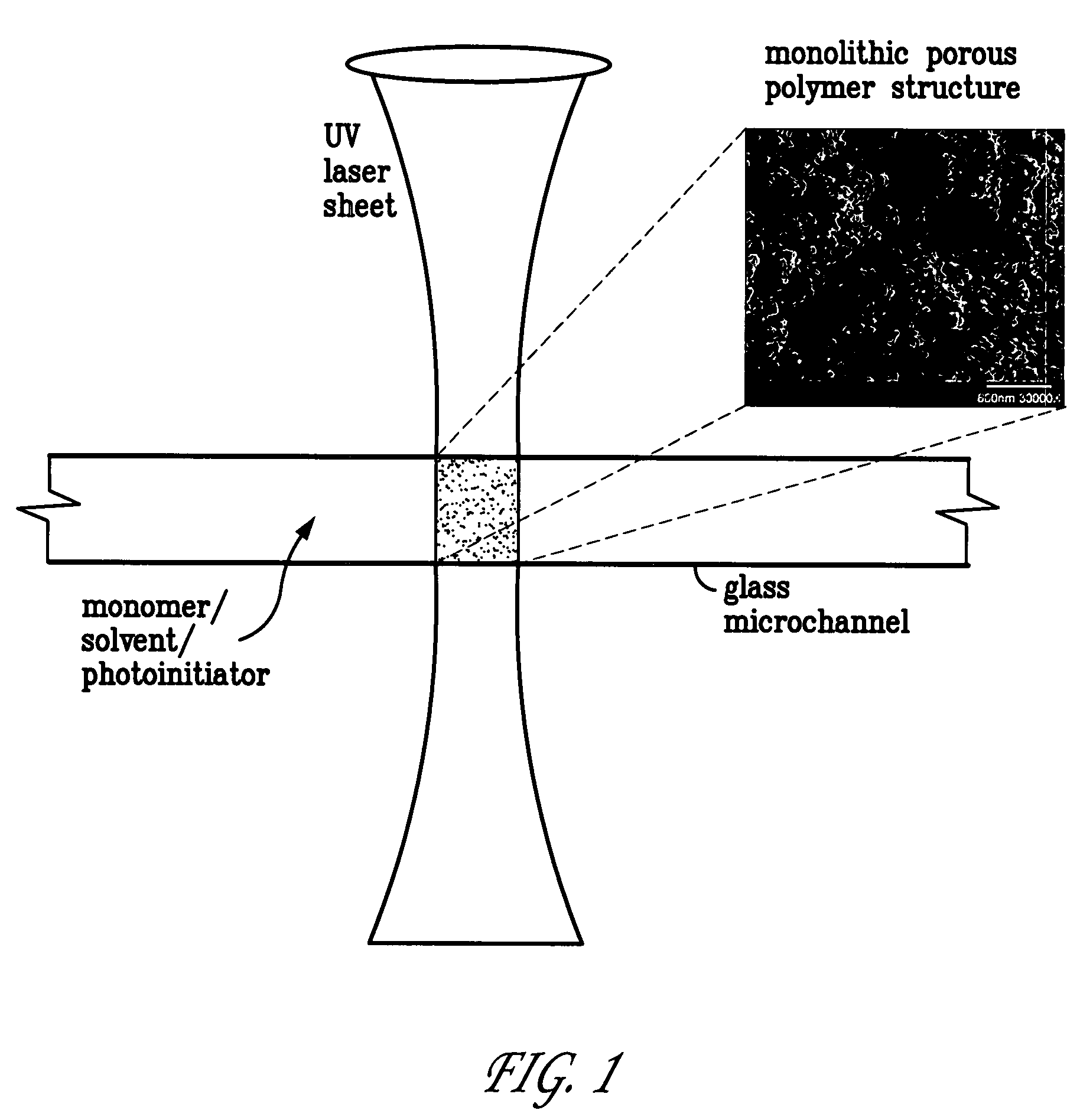

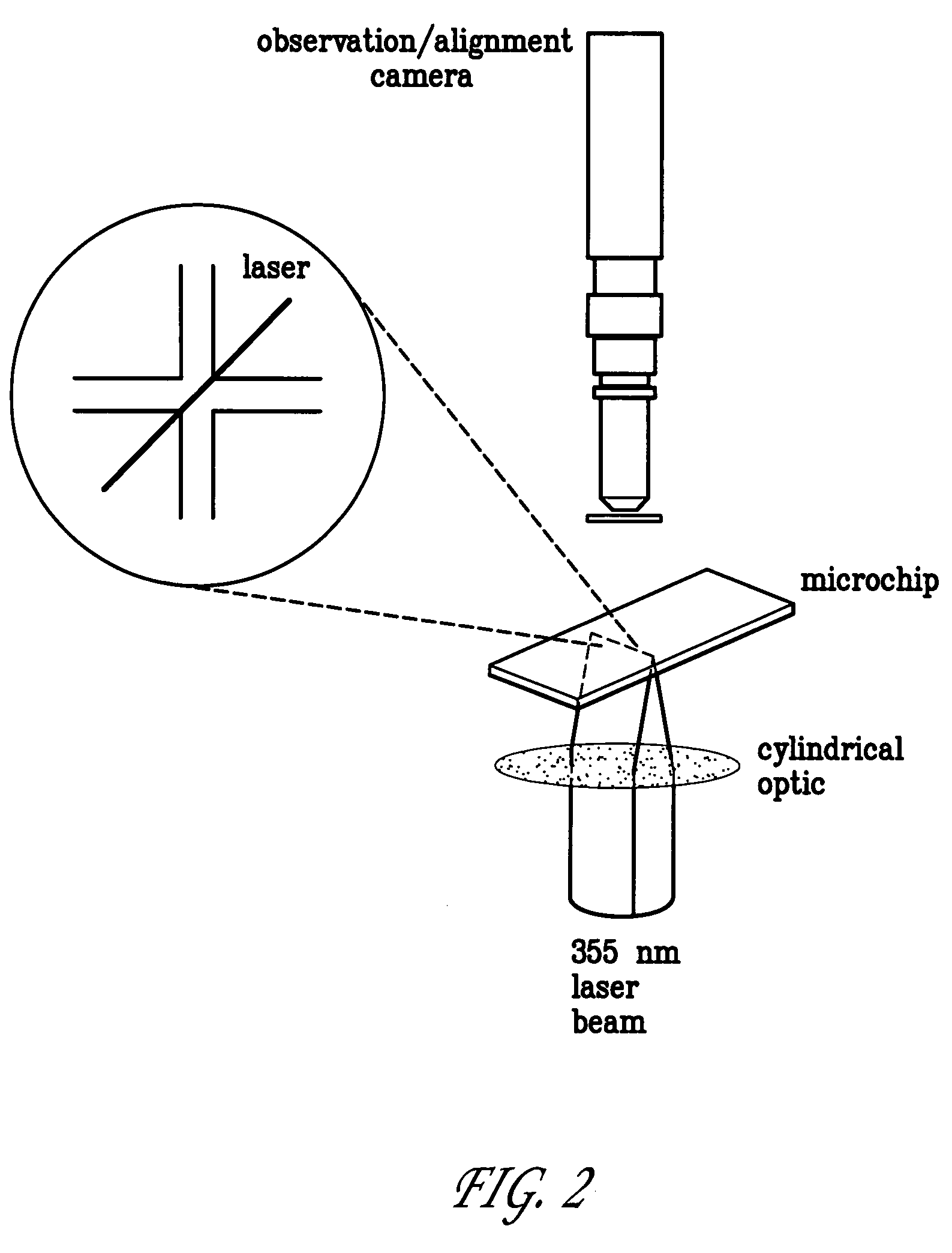

Method for dialysis on microchips using thin porous polymer membrane

InactiveUS7534315B1Minimize handlingComplicated operationGlovesPretreated surfacesDialysis membranesMicrosphere

Laser-induced phase-separation polymerization of a porous acrylate polymer is used for in-situ fabrication of dialysis membranes inside glass microchannels. A shaped 355 nm laser beam is used to produce a porous polymer membrane with a thickness of about 15 μm, which bonds to the glass microchannel and forms a semi-permeable membrane. Differential permeation through a membrane formed with pentaerythritol triacrylate was observed and quantified by comparing the response of the membrane to fluorescein and fluorescently tagging 200 nm latex microspheres. Differential permeation was observed and quantified by comparing the response to rhodamine 560 and lactalbumin protein in a membrane formed with SPE-methylene bisacrylamide. The porous membranes illustrate the capability for the present technique to integrate sample cleanup into chip-based analysis systems.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

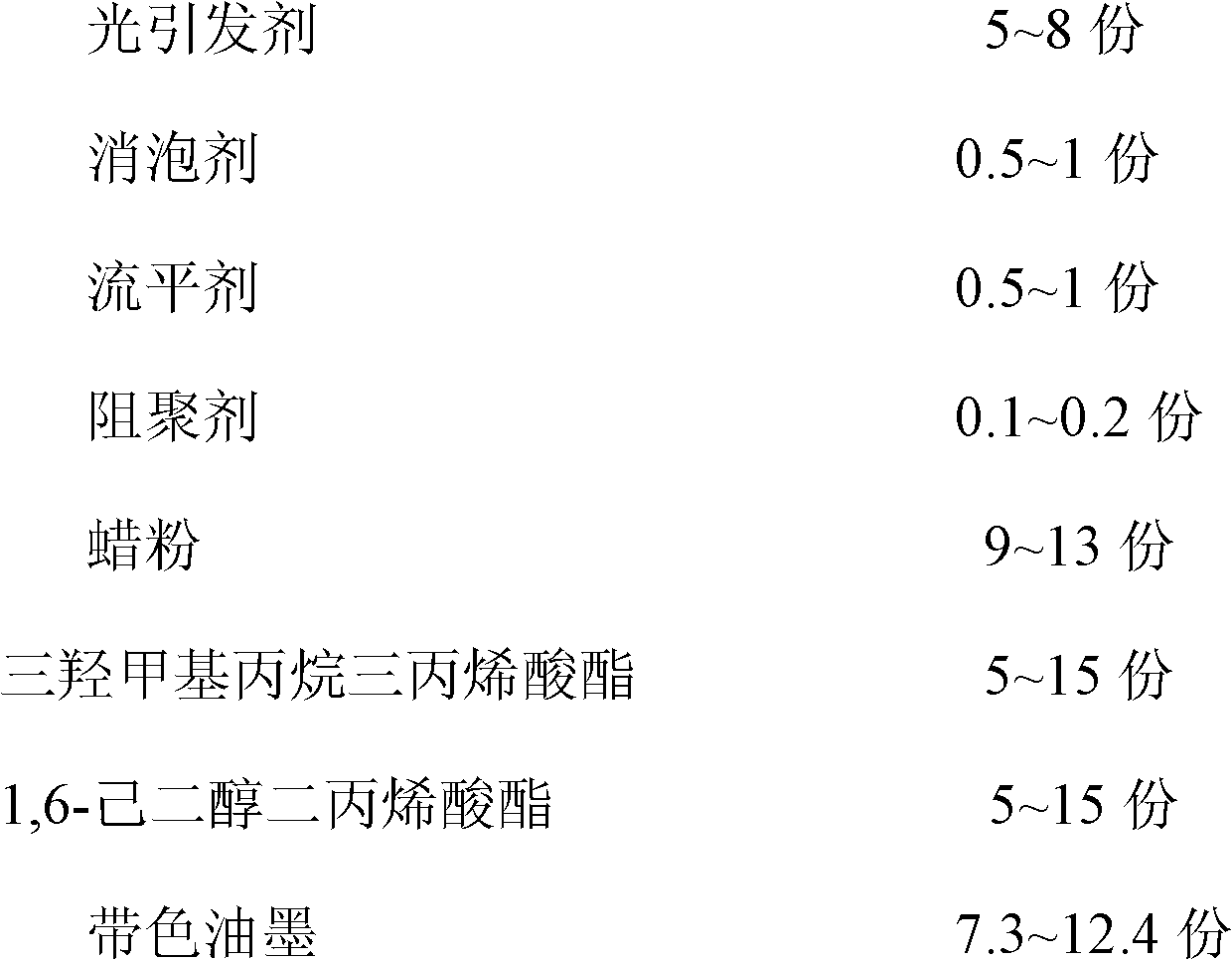

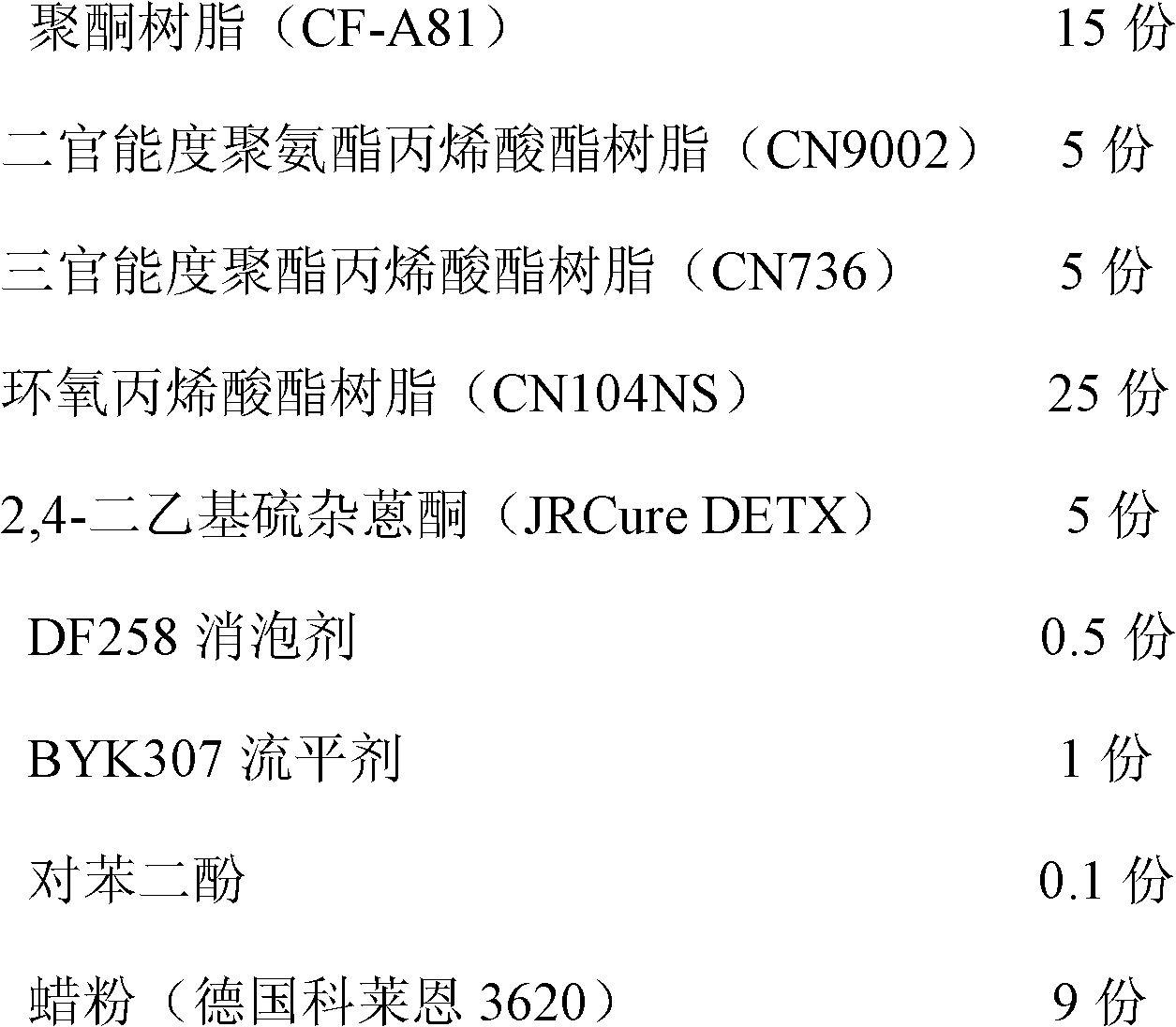

Ultraviolet light cured silk screen snowflake printing ink and preparation method thereof

The invention provides an ultraviolet light cured silk screen snowflake printing ink and a preparation method thereof. The ultraviolet light cured silk screen snowflake printing ink which has a viscosity of 1500-3000cps at the temperature of 25 DEG C is prepared by materials of 50-60 parts of ultraviolet light curable resins, 5-8 parts of photoinitiators, 0.5-1 part of defoamers, 0.5-1 part of flatting agents, 0.1-0.2 part of polymerization inhibitors, 9-13 parts of wax powders, 5-15 parts of trimethylolpropane triacrylate, 5-15 parts of 1, 6-hexanediol diacrylate and 7.3-12.4 parts of colored printing ink which are firstly subjected to a predispersion at a medium speed of 200rpm to 500rpm for 30 minutes in a disc mixer, and then subjected to a dispersion at a high speed of 3000rpm to 3500rpm for one hour. The ultraviolet light cured silk screen snowflake printing ink has the advantages that the appearance is unique, the decorative pattern is delicate, the weather resistance is good, the smell is mild, the printing ink is environment-friendly, printed products touch smooth, and the like.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

UV (Ultraviolet) curing white primer for laser roller painting of woodware and preparation and application methods thereof

InactiveCN103694862AReduce lossReduce usagePretreated surfacesPolyurea/polyurethane coatingsPolyesterUltraviolet

The invention discloses a UV (ultraviolet) curing white primer for laser roller painting of woodware, which has high coating quantity and flat and bright coated surface. The UV curing white primer comprises 15-25 percent of bisphenol A epoxy acrylate, 15-25 percent of polyester acrylate, 1-10 percent of polyurethane acrylate, 8-15 percent of tripropylene glycol diacrylate, 3-8 percent of reagent type hydroxyethyl acrylate, 10-25 percent of trimethylolpropane triacrylate, 5-8 percent of photoinitiator, 0.2-0.4 percent of wetting dispersant, 0.2-0.4 percent of anti-settling agent, 8-15 percent of talcum powder and 10-20 percent of titanium dioxide. The UV curing white primer has the characteristics that after laser roller painting construction is ended, the coating amount is capable of reaching 35-45g / m<2>, the coated surface is flat and bright, the covering power is stronger than that of a common roller painting UV white primer, and the semi-curing repainting between paint films is not required to be ground, and the like. When being used for performing coating, the UV curing white primer has the advantages of time and labor saving, high fullness of products, and less loss of a machine.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

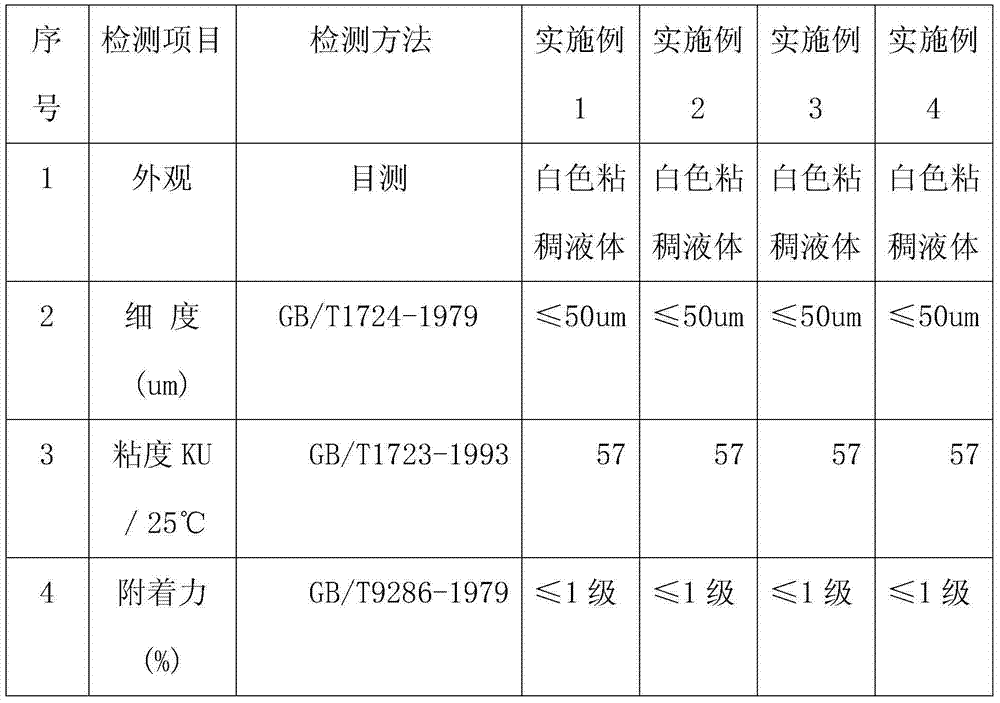

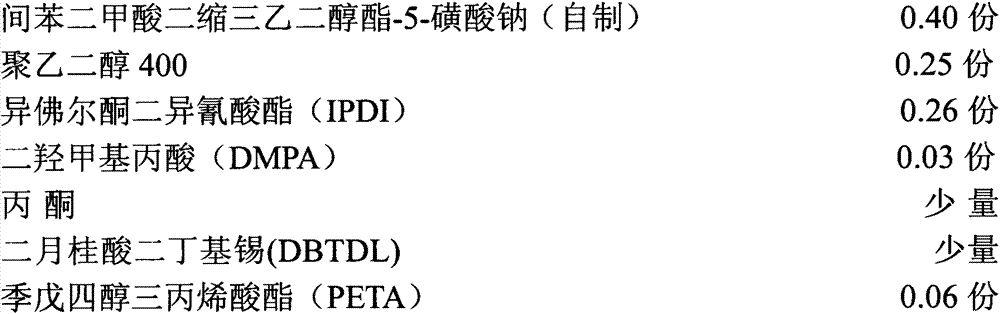

Preparation method for antifogging thin film coating with high light transmission

ActiveCN103709927APolyurea/polyurethane coatingsPigment treatment with organosilicon compoundsSolventDibutyltin dilaurate

Provided is a preparation method for an antifogging thin film coating with high light transmission. M-phthalic acid triethylene glycol ester-5-sodium sulfonate (self made), polyethylene glycol 400, isophorone diisocyanate and pentaerythritol triacrylate are employed as main raw materials, dibutyltin dilaurate is employed as a catalyst, dimethylolpropionic acid is employed as a chain extender, acetone is employed as a solvent, and hydrophilic UV prepolymers are prepared; ethyl orthosilicate is employed as a precursor, gamma-methacryloxy propyl trimethoxysilane is employed as a modifier, a sol-gel method is employed, and uniform and stable modified SiO2 sol is prepared; the hydrophilic UV prepolymers and the modified SiO2 sol are subjected to hybridization through a UV curing way, and a thin film coating is obtained. The prepared thin film coating has good hardness and adhesive force, water resistance and high light transmission and good antifogging effects, and can be used for antifog of surfaces of glass and eyeglass. The preparation technology of the thin film coating accords with green environmental protection concepts, curing and film forming are fast, and comprehensive performances are good. The antifogging thin film coating has good market prospect and is suitable for popularization and application.

Owner:JIANGNAN UNIV

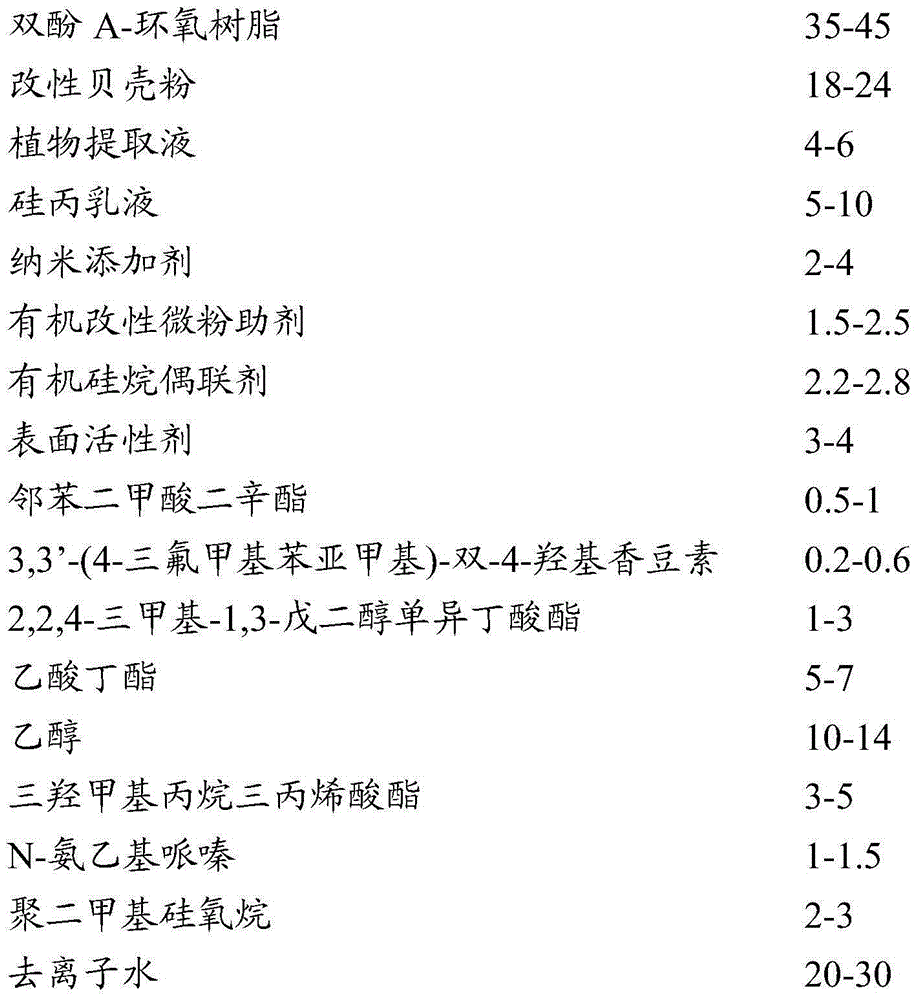

Large-scale colloidal crystals and macroporous polymers and method for producing

Single domain wafer-scale colloidal crystals and macroporous polymers are formed by dispersing concentrated solutions of colloids, desirably mondisperse silica colloids, in a viscous monomer, desirably ethoxylated trimethylolpropane triacrylate, and spin-coating them onto a substrate. Subsequent photopolymerization produces three-dimensionally ordered colloidal crystals trapped inside a polymer matrix. Selective removal of the polymer matrix, such as by oxygen plasma treatment, or removal of the silica spheres, such as by wet etching, produces large-area colloidal crystals and macroporous polymers, respectively.

Owner:CORNING INC

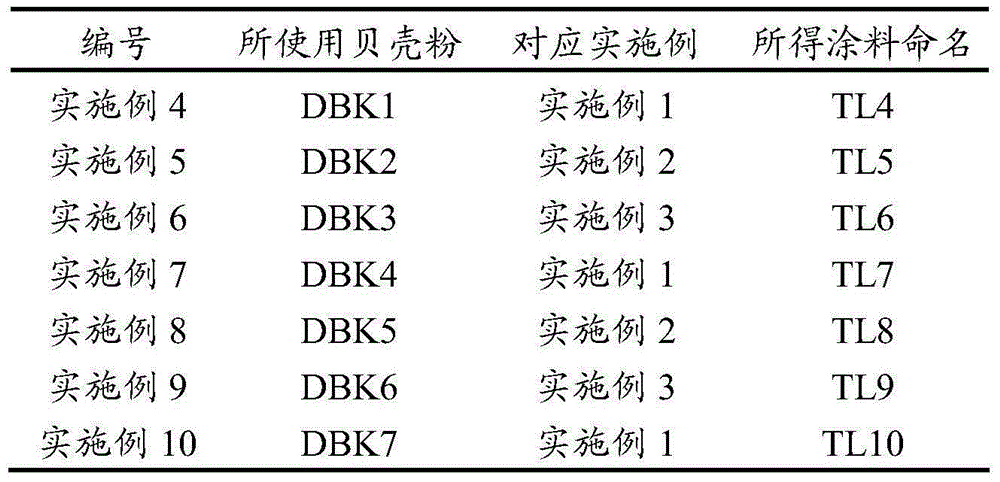

Environmentally friendly shell powder functional coating and preparation method therefor and uses thereof

ActiveCN104987808AImprove performancePractical application value is greatEpoxy resin coatingsDimethyl siloxaneIsoprene

The present invention relates to an environmentally friendly shell powder functional coating, a preparation method therefor and uses thereof. The coating comprises: bisphenol A-epon, modified shell powder, vegetable extract, propyl silicone emulsion, a nano additive, a modified organic micro powder agent, a surfactant, dioctylphthalate, 3, 3'-(4-trifluoromethyl methyl)-bi-4-hydroxy coumarin, 2,2,4-amino trimethyl-1,3-isoprene glycol mono iso-butyl methacrylate, butyl acetate, ethanol, trimethylol propane triacrylate, N-ammonia amino ethyl piperazine, polydimethylsiloxane and deionized water. In the present invention, by modification of a variety of components and materials, selection and collocation of specific components and a specific preparation method, the variety of components exert a synergistic effect, so as to make the prepared coating have significant antimicrobial, environmental-cleaning and wear-resisting properties. The coating has a huge application potential and extensive value in industrial production.

Owner:广西世家丽环保投资有限公司

Acrylic ester rubber and preparation method thereof

InactiveCN101633768AImprove the defect of sticky rollerReasonable ratioSodium stearatePolymer science

The invention provides acrylic ester rubber and a preparation method thereof. The acrylic ester rubber is characterized by comprising the following components by weight: 70-90 portions of tri-acrylate rubber AR840, 10-30 portions of butyronitrile rubber NBR, 55-75 portions of fast extruding carbon black N550, 1-2 portions of anti-aging agent RD, 1-2 portions of anti-aging agent MB, 0.5-1 portion of anti-scorching agent CTP, 3-5 portions of dioctyl phthalate DOP, 1-2 portions of dispersant rhine powder-42, 0.3-0.5 portion of common sulphur, 0.2-0.4 portion of tetramethyl thiuram disulfide TMTD, 3.5-4.0 portions of sodium stearate and 0.3-0.5 portion of potassium stearate. The sticking phenomenon is reduced and the elasticity, extensile intensity and low temperature resistance of the acrylic ester rubber are improved.

Owner:QINGDAO HILYWILL ADVANCED MATERIALS TECH

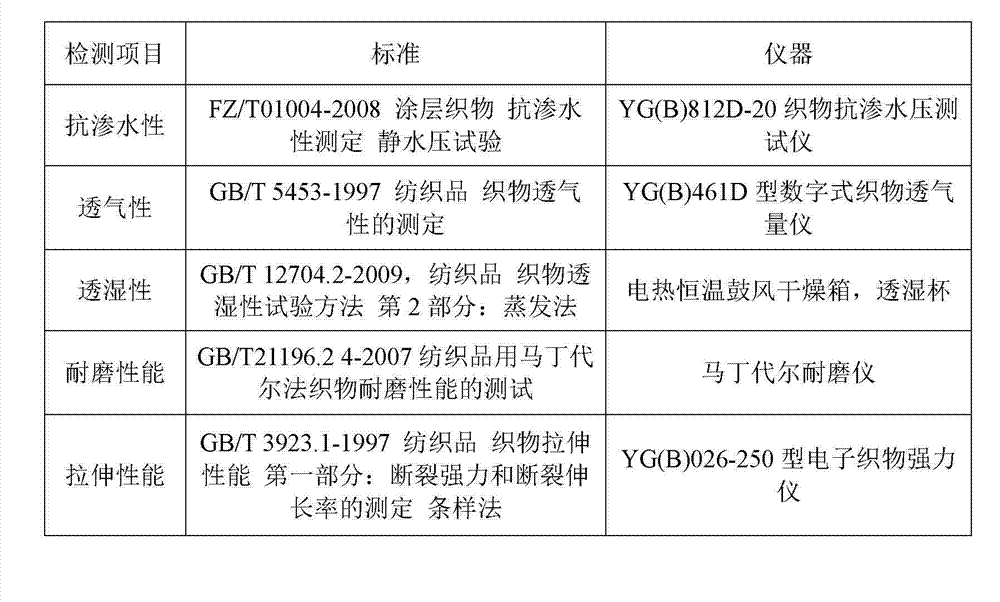

Method for radiation curing of pure organic silicone coated fabric by using electron beams

InactiveCN102965908AImprove thermal stabilityGood chemical stabilityPhysical treatmentSurface-active agentsSolvent

The invention relates to a method for radiation curing of a pure organic silicone coated fabric by using electron beams. The method comprises the following steps of: dispersing vinyl silicone oil, dimethyl silicone oil, hydrogen-containing silicone oil, a silane coupling agent, trimethylolpropane triacrylate, nanoscale silica, a flatting agent and a surface active agent in a vacuum kneading machine, mixing evenly to obtain a coating, finishing a fabric with certain humidity by a rubber blanket preshrinking machine, hot pressing the fabric through a hot pressing roller of a mirror glazing calendar to obtain base cloth, evenly coating the coating on the base cloth, and placing the base cloth on a transmission beam rack of a low-energy electron accelerator through a transmission roller for radiation curing to obtain the fabric. The fabric produced by the method is silky and soft in hand feel, waterproof, anti-seepage, and good in breathability and moisture permeability, and can be widely used in clothing, outdoor, fashionable fabrics and the like; the clothing does not have wrinkles, is easy to iron, and has stretching and recovering properties, and outdoor textiles can withstand the invasion of sun, wind and water; and the coating provided by the invention does not contain any solvent, and is environment-friendly, safe, non-toxic, pollution-free, simple in preparation technology, convenient in operation and construction, and low in energy consumption.

Owner:JIHUA 3509 TEXTILE

Radiant energy curable polyester resin composition

InactiveUS6037385APolyurea/polyurethane coatingsGlass/slag layered productsPolymer chemistryPhysical property

An acrylic urethane prepolymer composition and an unsaturated polyester resin composition to which the prepolymer has been added. The prepolymer composition includes an acrylic urethane prepolymer prepared by the reaction of diisocyanate, such as MDI, with an hydroxyl-containing acrylate monomer, such as a pentaerythritol triacrylate. The prepolymer composition contains a styrene monomer and an inhibitor, such as benzoquinone, to retard the reaction of the prepolymer and styrene monomer prior to the addition of the prepolymer composition into the polyester resin composition and a photoinitiator to promote the polymerization of the resin by exposure to radiant energy. The employment of the urethane prepolymer composition provides for the reduction in the amount of styrene monomer used in the unsaturated resin composition and also provides for improved chemical and physical properties of the photocured, unsaturated resin composition.

Owner:HEHR INT

Method for producing textile coated with coating adhesive

InactiveCN102965907AImprove thermal stabilityGood weather resistancePhysical treatmentAdhesiveWater resistant

The invention relates to a method for producing textile coated with coating adhesive, comprising the following steps of: sheering double-stop end vinyl silicone oil, hydrogen-containing silicone oil, oily polyurethane resin, silane coupling agent, pentaerythritol triacrylate and nano-stage white carbon black by a high-shear homomixer at high efficiency under room temperature to prepare coating adhesive; and hot pressing a base cloth by a hot-press roller of a planishing mill, coating the coating adhesive onto the base cloth, putting the base cloth provided with the coating adhesive on a bundle transferring frame of a 200 KeV low-energy electron accelcrator through a driving roller to be cured in a radiation way to obtain the textile coated with the coating adhesive. The water permeability resistance of the textile is 17084-36483 Pa, the mean air permeability of the textile is 10.97-25.1L / M<2>.s, the moisture permeability rate of the textile is 5799-7832 g / m<2>.24h, the coating layer starts to be broken after being ground at 116-140 circles, the radial breaking strength of the textile reaches 802.7N, and the latitudinal breaking strength of the textile reaches 456.7N. The textile produced by the method can increase the humidity management, is free from wrinkle, easy to iron and press, good in tensile property and recovery property, elastic, flexible, smooth, comfortable in hand feel, nontoxic, sunshine-resistant, wind-resistant, water-resistant, and suitable for the clothes, the outdoors, the fashion fabric and the like.

Owner:JIHUA 3509 TEXTILE

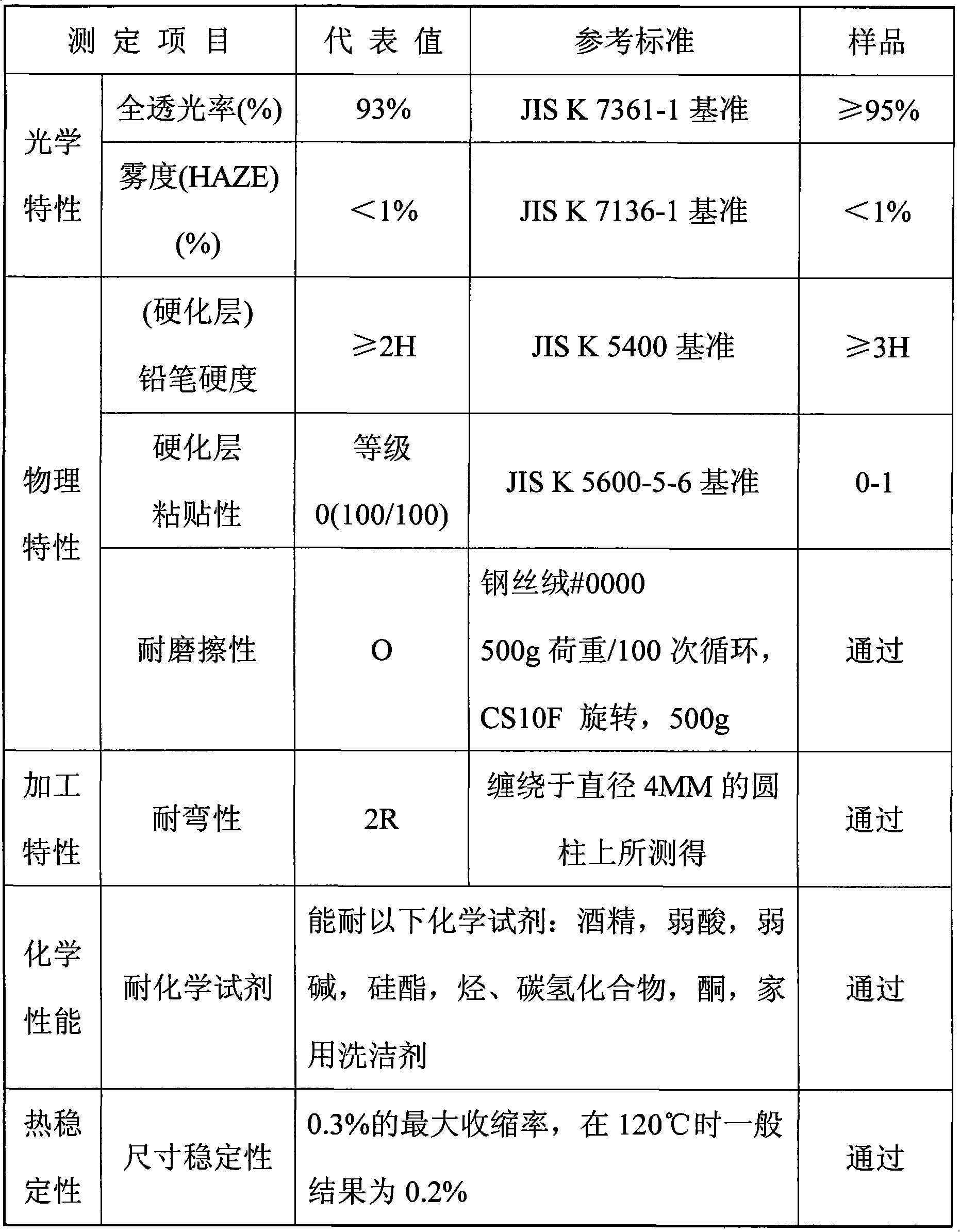

Preparation method of biaxially oriented polyester film surface wear-resistant scratch-resistant coating

InactiveCN101564720AImprove uniformitySolve pollutionPretreated surfacesPolyurea/polyurethane coatingsEpoxyWear resistant

A preparation method of biaxially oriented polyester (BOPET) film surface wear-resistant scratch-resistant coating relates to a preparation method of a BOPET film surface coating and solves the problems of high cost and poor wear resistance and scratch resistance of the coating when preparing the BOPET film surface wear-resistant scratch-resistant coating in the prior art. The preparation method of the invention includes the following steps of: uniformly mixing polyurethane hexa-acrylate, epoxy modified acrylate, dipentaerythritol monohydroxy hexa-acrylate, trimethylolpropane tri-acrylate, tripropylene glycol diacrylate, butyl titanate and compound cracking light trigger to obtain coating material; then coating the coating material on the BOPET film surface done with corona treatment, and finally obtaining the (BOPET) film surface wear-resistant scratch-resistant coating after ultraviolet curing. The BOPET film surface wear-resistant scratch-resistant coating has low cost and good wear resistance and scratch resistance, and the coating performance pencil hardness is over 3H.

Owner:HARBIN INST OF TECH

High gloss high abrasion resistance ultra-violet curing overprinting varnish of mobile phone and preparation method thereof

InactiveCN101967338AImprove wear resistanceHigh gloss and high wear resistancePolyurea/polyurethane coatingsPolyester coatingsIsooctyl acrylatePolyester

The invention discloses a high gloss high abrasion resistance ultra-violet (UV) curing overprinting varnish of mobile phone and a preparation method thereof. The method of the invention uses low-viscosity polyester acrylate and aliphatic polyurethane acrylate as base resin which combines with ethoxylated pentaerythritol tetraacrylate, Trimethylolpropane triacrylate, Tri(propylene glycol) diacrylate, 1,6-hexanediol diacrylate and 2-ethylhexyl acrylate which are used as active diluent, alcohol and ethyl acetate which are used as diluent, benzophenone and 1-hydroxycyclohexyl phenyl ketone which are used as photoinitiator, reactive amine coinitiator, defoaming agent, flatting agent, slip agent and other agents to mix evenly and prepare the UV overprinting varnish. The overprinting varnish of the invention adopts the special raw material formula and has good lustrousness, adhesive force and mechanical stability; as some polyfunctional resins and resins with special functional groups are added, the crosslink density of the UV varnish is increased in the curing process and the hardness of the product is up to 5-7H; and as solid wax powder used as the slip agent is added, the coefficients of friction can be reduced and the product can have extremely high wear resistance.

Owner:苏州凯康化工科技有限公司

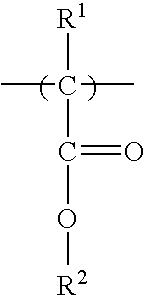

Hydrolytically stable viscosity index improves

InactiveUS20060252660A1Improve propertiesReduce impactLiquid carbonaceous fuelsLubricant compositionViscosity indexAcrylate polymer

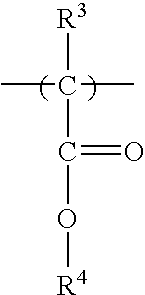

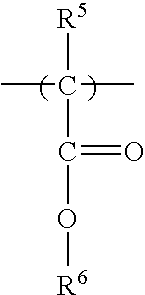

An acrylic acid ester polymer having improved characteristics and oleaginous compositions containing the acrylic acid ester polymer. The acrylic acid ester polymer includes a copolymer derived from a first acrylic acid ester monomer having from about 1 to about 4 carbon atoms, a second acrylic acid ester monomer having from about 12 to about 14 carbon atoms, and a third acrylic acid ester monomer having from about 16 to about 20 carbon atoms. The copolymer has a weight average molecular weight ranging from about 20,000 to about 100,000 daltons and contains no more than about 1 weight percent unreacted monomer.

Owner:DUGGAL AKHILESH +3

Pressure sensitive adhesive, preparation method thereof and protective films using same

ActiveCN101962525AImprove overlay performanceReduce polarityLiquid surface applicatorsFilm/foil adhesivesTectorial membraneAcrylic resin

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

Method for preparing pentaerythritol triacrylate

InactiveCN101462953AReduce pollutionReduce by-productsOrganic compound preparationCarboxylic acid esters preparationPentaerythritolColor intensity

The invention belongs to a method for preparing pentaerythritol trimethylacrylate, comprising the steps as follows: (1) pentaerythritol, acrylic acid, catalyst, solvent and polymerization inhibitor are put into a reaction kettle to be fully mixed and stirred so as to form a miscible liquid; (2) a steam valve of the reaction kettle is opened to slowly heat the miscible liquid, and the temperature is controlled and maintained at 70-90 DEG C for a 20-40min reaction; (3) the mixture is continued to be heated, when the temperature is increased to 80-115 DEG C, reflow is carried out for 3-5h and then the reaction is finished; (4) soda water solution and sodium chloride water solution are added into the mixture and after washing the upper organic phase is extracted; (5) the upper organic phase is separated from the solvent; (6) and filter pressing is carried out to obtain the end product. The method has simple process, good quality, activity and flexibility, low shrinking percentage and color intensity and high yield coefficient, and produces few by-products or little waste water.

Owner:TIANJIN CHEM REAGENT RES INST

Optical diffusion barrier

ActiveCN102778712AHigh hardnessThin coatingDiffusing elementsSynthetic resin layered productsDisplay deviceFlat panel display

The invention relates to an optical diffusion barrier which comprises a substrate, a diffusion layer and a back layer, wherein the diffusion layer is ultraviolet-cured on any one of the surfaces of the substrate by coating solution comprising optical diffusion particles A, resin A and photo-initiator, wherein the resin A consists of epoxy acrylate resin and urethane acrylate with 8 degrees of functionality in the weight ratio of 1:9-9:1; the back layer is ultraviolet-cured on the other surface of the substrate by coating solution comprising optical diffusion particles B, resin B, photo-initiator and antistatic agent, wherein the resin B consists of pentaerythritol triacrylate and caprolactone modified dipentaerythritol penta / hexa-acrylate in the weight ratio of 1:9-9:1; the optical diffusion particles A consist of high polymer micro-spheres in particle sizes of 10-25 microns and inorganic particles in the particle sizes of 1-4 microns, in the weight ratio of 2:1-4:1; the optical diffusion particles B are inorganic particles in the particle sizes of 2-4 microns; and the diffusion barrier has high hardness, thin coating layer and high transmittance, full diffusion performance and good antistatic property and can meet the development direction of a flat panel display in large size, thinning, light weight and low cost.

Owner:昆山乐凯锦富光电科技有限公司

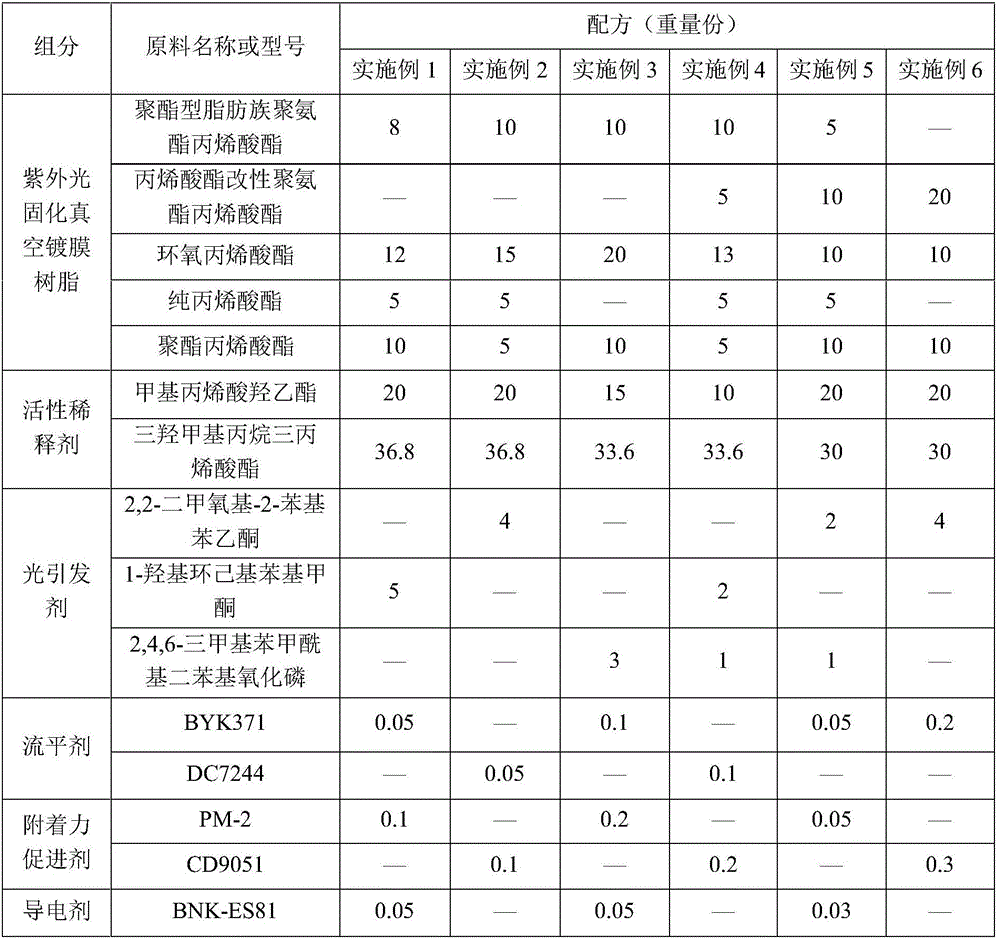

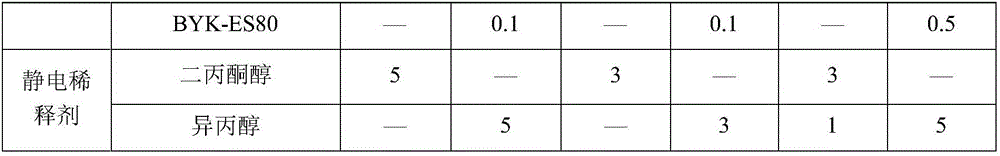

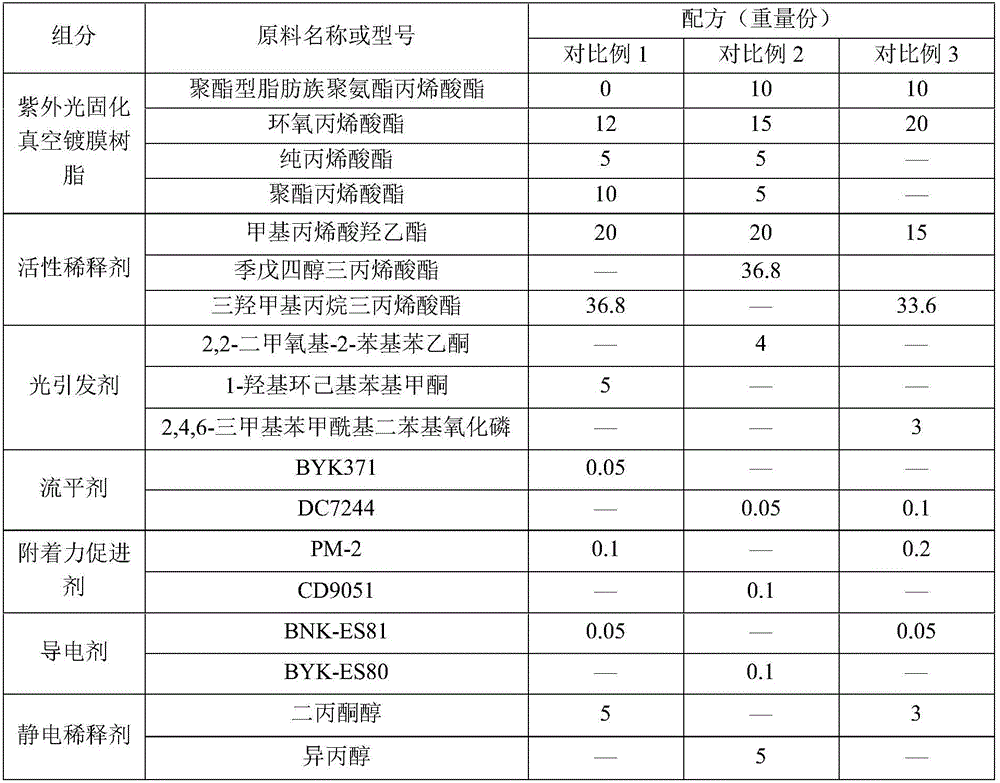

Ultraviolet curing vacuum coating metal primer capable of achieving electrostatic spraying

ActiveCN105670463ALow priceHigh viscosityPolyurea/polyurethane coatingsPowdery paintsUltravioletUrethane acrylate

The invention discloses ultraviolet curing vacuum coating metal primer capable of achieving electrostatic spraying and a preparation method thereof.The ultraviolet curing vacuum coating metal primer capable of achieving electrostatic spraying is prepared from, by weight, 5-20 parts of urethane acrylate, 10-20 parts of epoxy acrylate, 0-5 parts of pure acrylate, 5-10 parts of polyesteracrylate, 30-40 parts of trimethylolpropane triacrylate, 10-20 parts of low-functionality active diluted monomers, 2-5 parts of photoinitiator, 0.05-0.1 part of a flatting agent, 0.05-0.5 part of adhesion promoter, 0.01-0.5 part of a conductive agent and 3-5 parts of electrostatic thinner.The ultraviolet curing vacuum coating metal primer prepared through the method can be used for electrostatic spraying, has the advantages of being good in coating performance, good in adhesion, high in salt fog resistance, high in production efficiency, high in paint utilization rate and the like, and has wide market prospects.

Owner:GUANGDONG SHEN ZHAN IND CO LTD

Flame-retardant UV curing coating and preparation method thereof

InactiveCN103525272AGood chemical resistanceImprove low temperature resistanceFireproof paintsPolyester coatingsPolyesterSodium thiocyanate

A flame-retardant UV curing coating is prepared from the following raw materials in part by weight: 10-12 parts of trimethylol propane triacrylate, 50-55 parts of polyester acrylate, 3-5 parts of isopropanol, 5-8 parts of ethoxylated trimethylolpropane triacrylate, 1-2 parts of tetrabutylphosphonium chloride, 2-3 parts of sodium thiocyanate, 2-6 parts of hexabromocyclododecane, 3-4 parts of diethylene glycol butyl ether, -5 parts of benzil dimethyl ketal, 2-3 parts of 2-hydroxy-2-methyl-1-phenyl-1-acetone, 3-4 parts of dispersing auxiliary agent and 4-5 parts of dispersing auxiliary agent. The flame-retardant UV curing coating has excellent chemical resistance and low temperature resistance, and has strong adhesion to difficultly-adhered substrates, such as plastic; after addition of the dispersing auxiliary agents, the flame-retardant UV curing coating is good in leveling property, can form a uniform and thin coating layer, and is high in curing speed; and by adding tetrabutylphosphonium chloride and the hexabromocyclododecane, the flame-retardant UV curing coating has excellent flame retardance.

Owner:安徽蓝柯复合材料有限公司

Hydrolyzable UV (ultraviolet) protection ink

The invention provides a hydrolyzable UV (ultraviolet) protection ink, which is prepared by mixing the following components in parts by weight: 30-48 parts of modified organosilicon acrylic resin, 6-15 parts of modified epoxy acrylic resin, 5-12 parts of isobornyl acrylate, 10-15 parts of trimethylolpropane triacrylate, 5-12 parts of chlorinated rubber, 7-15 parts of grass green pigment, 2-5 parts of silane coupling agent, 0.1-0.5 part of defoaming agent, 0.5-1.0 part of leveling agent, 0.02-0.04 part of polymerization inhibitor, 5-15 parts of calcium carbonate and 2-8 parts of 369 photoinitiator. The UV protection ink provided by the invention is a hydrolyzable UV curing protection ink of which the curing time can be obviously shortened. In addition, after finishing processing touch screen cover plate glass or ITO glass, the protective film can be removed by soaking in alkaline water. The UV protection ink has the advantage of no residue, can be peeled easily, and thus, has wide application prospects.

Owner:XIAMEN HOWER MATERIAL

UV curing luminous plate and its preparing process

ActiveCN101397495ANo emissionsNo pollutionSynthetic resin layered productsLuminescent compositionsNon toxicityAcrylic resin

An UV curing luminescent panel consists of a luminescent layer and a reflective layer. The luminescent layer with the thickness of 0.02-5.0mm consists of light-cured resin (10-40 percent of resins such as epoxy acrylic resin, polyurethane acrylic resin, polyester acrylic resin and the like), photosensitive diluent (photosensitive diluent is 10-20 percent of resins of ethoxylated acrylic ester, propoxylated neopentyl glycol diacrylate, TMPTA and the like), photoinitiator (2-10 percent of beans development kit BDK and the like), luminescent materials (10-65 percent) and additive (0-5 percent). The UV curing luminescent panel has the advantages of no solvent emission, saving energy due to instant drying of UV curing, high production efficiency due to on-line processing, and being applicable to base materials sensitive to heat; furthermore, the prepared luminescent panel is characterized by high brightness, long luminescent time, excellent acid and alkali resistance and weatherability, good printing performance, non-toxicity, no radiation and stable physicochemical performance.

Owner:DALIAN LUMINGLIGHT SCIENCE & TECHNOLOGY CO LTD

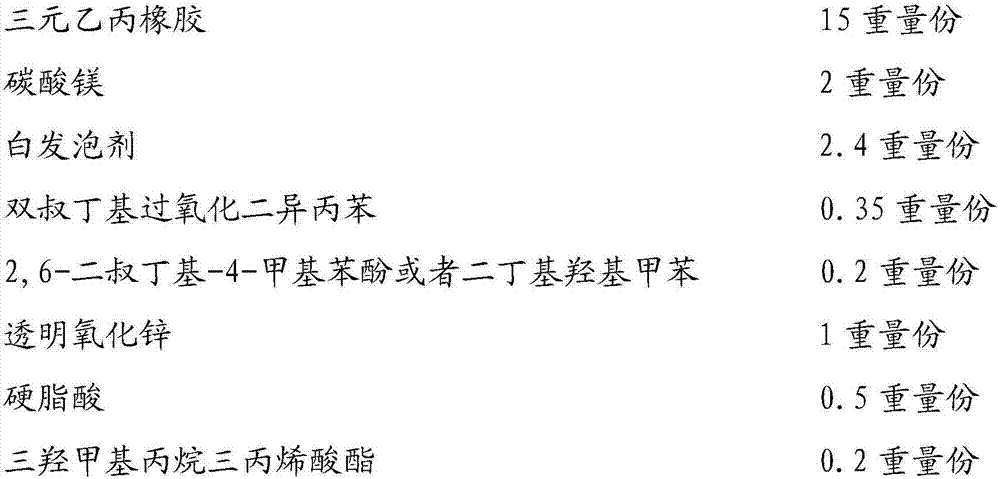

Transparent foam sole formulation and method of using formulation to make sole

ActiveCN107501713AGood flexibilityImprove blending effectSolesPolymer scienceButylated hydroxytoluene

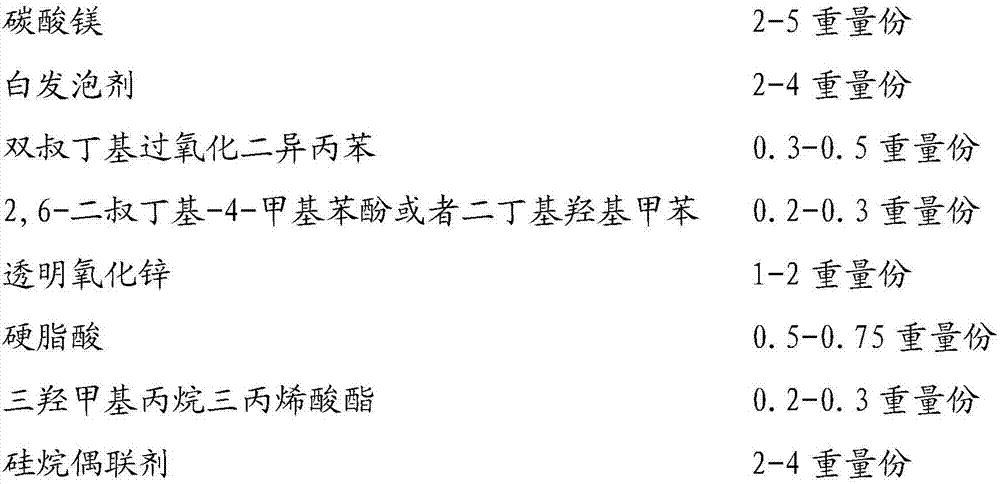

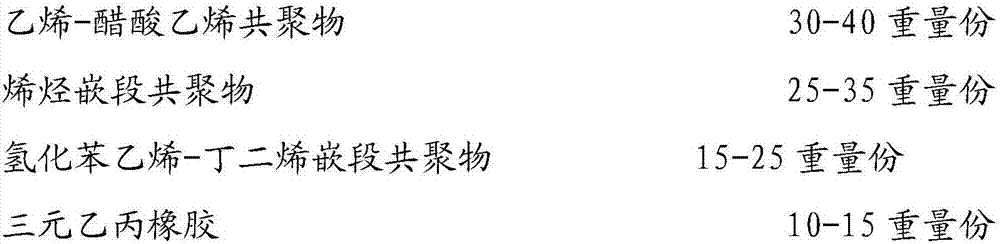

The invention relates to a transparent foam sole formulation, made from magnesium carbonate, a white foaming agent, bis(tert-butylperoxy) diisopropyl benzene, 2,6-di-tert-butyl-4-methylphenol or butylated hydroxytoluene, transparent zinc oxide, stearic acid, trimethylolpropane triacrylate, silane coupling agent, ethylene-vinyl acetate copolymer, olefin block copolymer, styrene-butadiene-styrene triblock copolymer, and ethylene-propylene-diene monomer rubber, wherein the magnesium carbonate is powdery and has particle size of 40-80 mesh. A sole made by comprehensively selecting formulations and processes is pervious to light, and can meet the requirements of soles in terms of physical parameters such as elasticity, yellowing resistance, and compression set deformation.

Owner:XTEPCHINA

Ceramic pulp for photo-curable 3D printing and preparation method and application of ceramic pulp

ActiveCN110627501AHigh viscosityAdditive manufacturing apparatusCeramic shaping apparatusTripropylene glycolMeth-

The invention discloses ceramic pulp for photo-curable 3D printing and a preparation method and application of the ceramic pulp. The ceramic pulp includes ceramic powder, photo-curable resin, a photoinitiator and a dispersant, wherein the photo-curable resin comprises the components: in percent by mass, 10-60% of bisphenol A epoxy acrylate, 10-60% of trimethylolpropane triacrylate, 10-60% of tripropylene glycol diacrylate and 10-60% of isobornyl methacrylate. The rheological performance of the slurry can be adjusted through selection of reactive diluents with different functionalities and adjustment of the ratio of the diluents, needs of light curing molding can be met by the slurry, and degreasing and sintering are performed on a molded sample so as to obtain a high-density zirconia ceramic product with a relative density of up to 98.8%.

Owner:SHENZHEN RES INST CENT SOUTH UNIV +1

Conducting photosensitive resin for 3D printing and preparation method thereof

In order to solve the problem of no conductivity and poor mechanical properties in the photosensitive resin for 3D printing in the prior art, the invention provides a conducting photosensitive resin for 3D printing, which comprises a photosensitive prepolymer, a monomer, a crosslinking agent, a photoinitiator, a surfactant conducting particles. On the basis of the total weight of the conducting photosensitive resin, the content of the photosensitive prepolymer is 30-60 wt%, the content of the monomer is 10-40 wt%, the content of the crosslinking agent is 10-30 wt%, the content of the photoinitiator is 1-5 wt%, the content of the organosilicon surfactant is 1-5 wt%, and the content of the conducting particles is 15-40 wt%. The monomer is phenoxyethyl acrylate, the crosslinking agent is trihydroxymethyl tripropane triacrylate, and the viscosity of the conducting photosensitive resin is 80-400 mPa.s. The invention also provides a preparation method of the conducting photosensitive resin. The conducting photosensitive resin provided by the invention is suitable for 3D printing equipment, and has excellent conductivity and mechanical properties after being cured.

Owner:BYD CO LTD

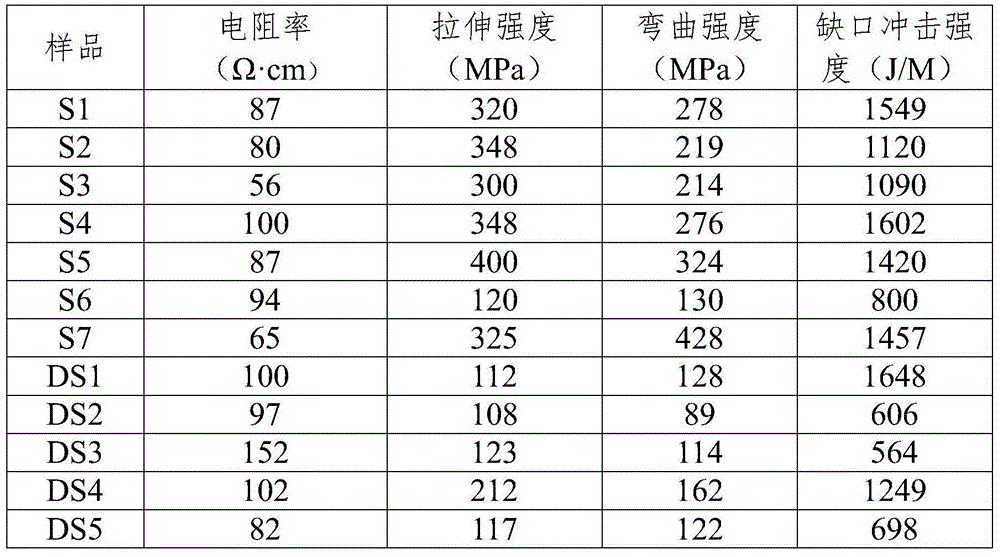

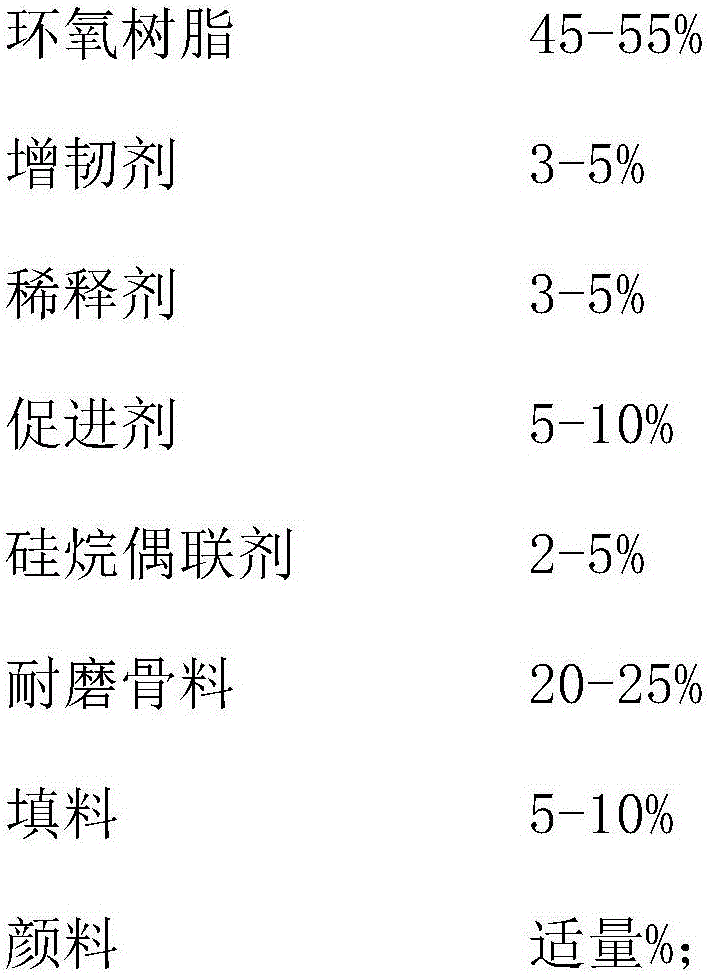

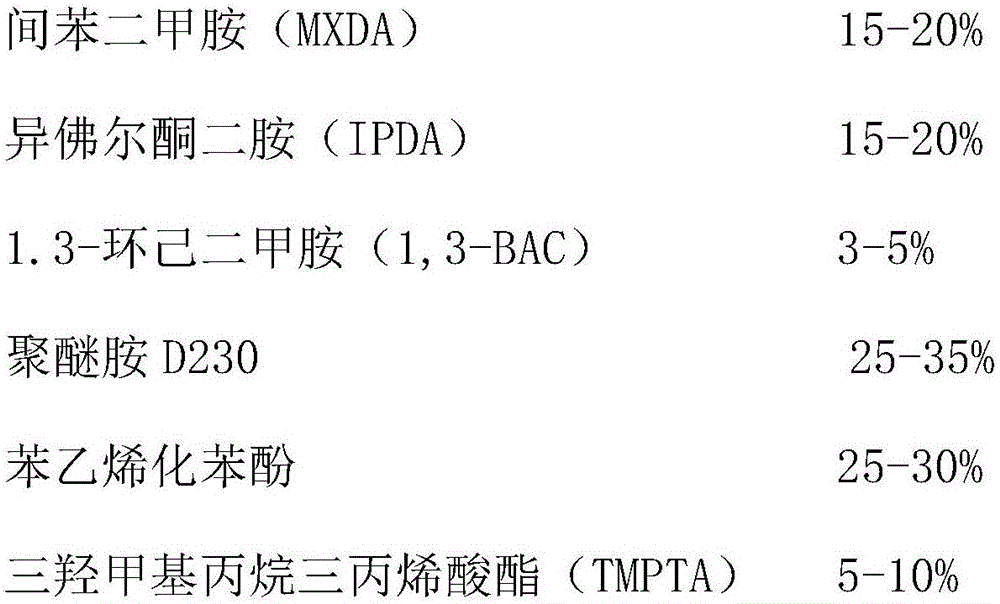

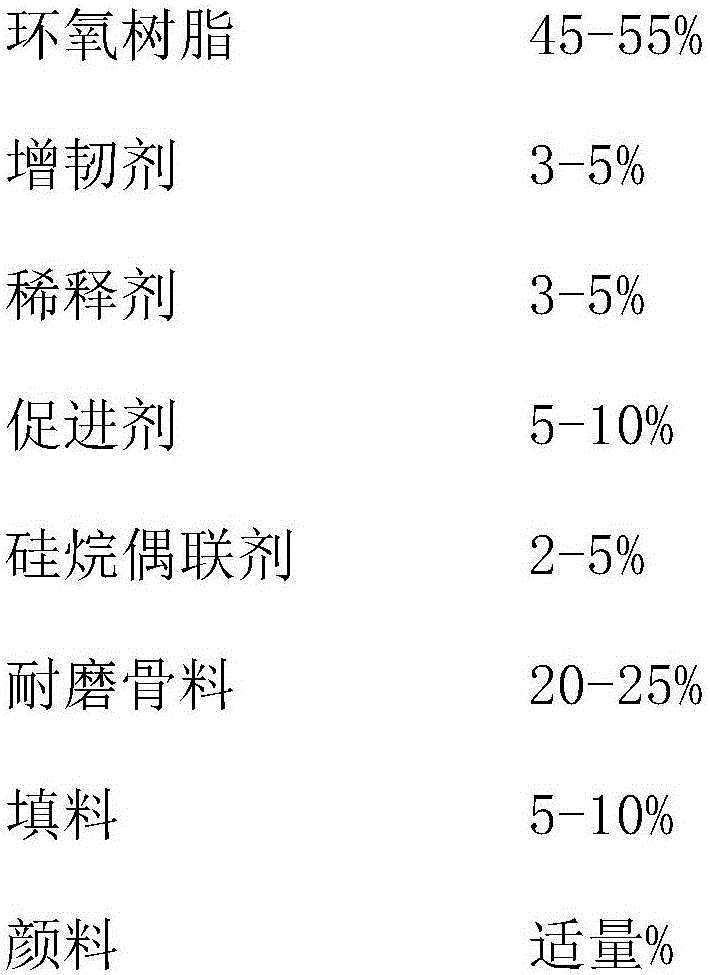

High wear-resistant epoxy coating, preparation method thereof and coating layer

The invention relates to high wear-resistant epoxy coating, a preparation method of high wear-resistant epoxy coating and a high wear-resistant epoxy coating layer. The high wear-resistant epoxy coating provided by the invention is characterized by being prepared from an A component and a B component, wherein (1) the A component is prepared from the following raw materials in percentage by mass: 45 to 55 percent of epoxy resin, 3 to 5 percent of toughening agent, 3 to 5 percent of diluting agent, 5 to 10 percent of accelerator, 2 to 5 percent of silane coupling agent, 20 to 25 percent of abrasive aggregates, 5 to 10 percent of filler and appropriate percent of pigment; (2) the B component is prepared from the following raw materials in percentage by mass: 15 to 20 percent of MXDA (M-Xylylenediamine), 15 to 20 percent of IPDA (Isophorone Diamine), 3 to 5 percent of 1,3-BAC (1,3-bis(aminomethyl)-cyclohexan), 25 to 35 percent of polyether amine D230, 25 to 30 percent of styrenated phenol and 5 to 10 percent of TMPTA (Trimethylolpropane triacrylate); the A component and the B component are mixed according to a proportion of 1:5. The high wear-resistant epoxy coating disclosed by the invention has excellent wear resistance, high hardness, good heat resistance and water resistance, good chemical reagent corrosion resistance, high fullness, high construction efficiency, convenience in construction and a wide application range.

Owner:SHANGHAI ZHENGOU IND

Ultraviolet cured wood paint and preparation method thereof

The invention discloses ultraviolet cured wood paint and a preparation method thereof. The raw material formula of the ultraviolet cured wood paint comprises the following components in percentage by weight: 30 to 35 percent of modified unsaturated polyester resin, 10 to 20 percent of polyester acrylate, 10 to 15 percent of 1,6-hexanediol diacrylate, 5 to 10 percent oftrimethylolpropane propoxylate triacrylate, 3 to 5 percent of polyhydroxyethyl methacrylate, 0.2 to 0.6 percent of settling agent, 10 to 20 percent of transparent powder, 3 to 6 percent of talcpowder, 0.5 to 1.5 percent of photoinitiator 1, 3 to 5 percent of photoinitiator 2 and 0.2 to 0.6 percent of flatting agent. The ultraviolet cured wood paint can be used as a transparent base coat, is low in cost, simple in preparationmethod and environmentally-friendly, has high transparency, high film performance, high rubbing property and high leveling property, and can create huge economic and social benefit.

Owner:HUIZHOU CHANGRUNFA PAINT

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com