Hydrolytically stable viscosity index improves

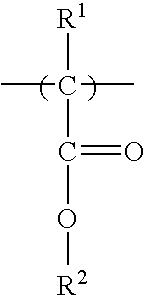

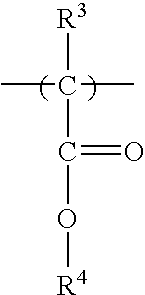

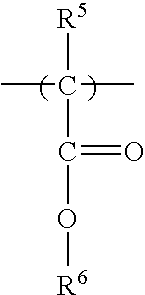

a technology of oleaginous fluid and viscosity index, which is applied in the direction of liquid carbonaceous fuels, lubricant compositions, fuels, etc., can solve the problems of imposing severe demands on hydraulic fluids, water or moisture ingress to the system can have a serious effect on the performance of hydraulic fluids, and hydraulic fluids containing acrylic acid ester copolymers have a tendency to form acids, so as to improve hydrolytic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0074] In the following example, an acrylic acid ester copolymer was made in a 10 liter reaction vessel. Hydraulic oils containing the reaction products from Runs 1-4 were tested for hydrolytic stability as described above. The hydraulic oils contained 6.7 weight percent of the reaction product, 0.85 weight percent of HiTEC® 521 antiwear hydraulic package 86.45 weight percent AMERICAS CORE 15ON base oil and 6 weight percent AMERICAS CORE 600N base oil from Exxon Mobil Corporation of Irving, Tex.

TABLE 3Run 1Run 2Run 3Run 4Copolymer PropertiesKinematic viscosity11351162806812at 62.63 wt. %,(cSt at 100° C.)Weight average58,20057,00068,80057,700molecular weight(Mw)Number average33,90032,80040,10032,300molecular weight(Mn)GPC conversion (%)99.0099.9094.6096.10Residual monomer0.420.814.842.32(wt. %)PerformanceCharacteristicsD2619 HydrolyticStabilityCopper weight loss−0.07−0.071.26−0.17(mg / cm2)Acidity of water001.390(mg KOH)Copper appearance1A1A2B1A

[0075] Runs 1 and 2 exhibited lower res...

example 2

[0076] In the next series of runs, copolymers were made in a full scale reaction vessel. As in Example 1, the copolymers were tested in hydraulic oils to determine the hydrolytic stability of the oils containing the copolymers. The copolymers made in Runs 5 and 6 were made with nitrogen sparging. The copolymer of Run 7 was made without nitrogen sparging.

TABLE 4Run 5Run 6Run 7Copolymer PropertiesKinematic viscosity at 62.63 wt.101510831139%, (cSt at 100° C.)Weight average molecular weight54,10055,80063,800(Mw)Number average molecular weight31,00031,00033,500(Mn)GPC conversion (%)98.9098.9097.35Residual monomer (wt. %)0.300.371.33Performance CharacteristicsD2619 Hydrolytic StabilityCopper weight loss (mg / cm2)−0.05−0.06−0.14Acidity of water (mg KOH)000Copper appearance1A1A1A

[0077] As shown by the foregoing examples, runs 1-2, 5-6 provide superior hydrolytic stability to fluids containing the copolymers, provided the monomer content of the copolymers added to the hydraulic oils did no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com