Preparation method of biaxially oriented polyester film surface wear-resistant scratch-resistant coating

A technology of biaxially stretched polyester and scratch resistance, which is applied in the field of preparation of biaxially stretched polyester film surface coatings, can solve the problems of poor wear and scratch resistance and high cost of coatings, and achieve coating resistance Good wear and scratch resistance, lower production costs, and lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

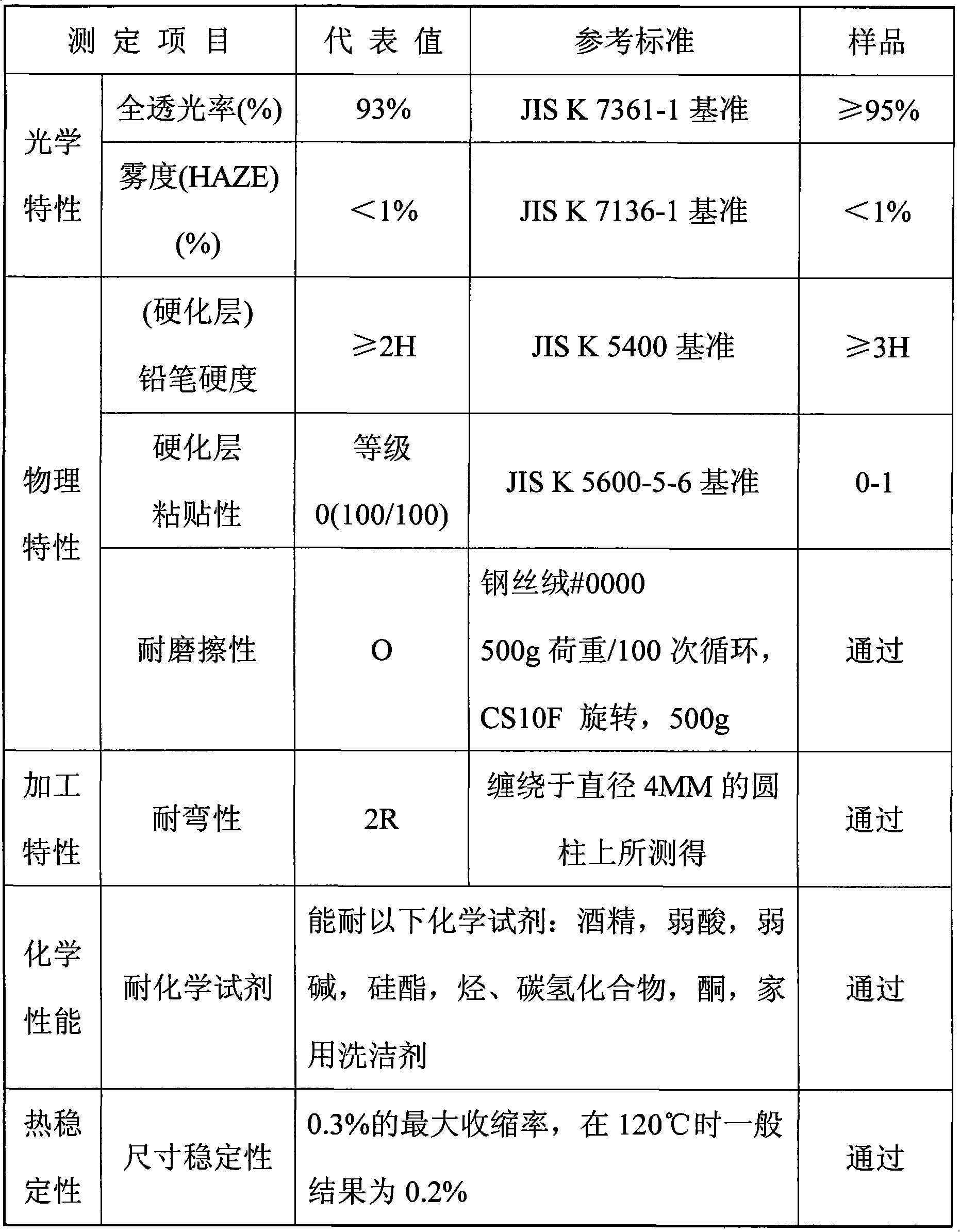

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment one: the preparation method of the wear-resistant and scratch-resistant coating on the surface of the biaxially stretched polyester film in this embodiment is realized through the following steps: 1. 20 to 80 parts of polyurethane hexaacrylate, 5 parts by mass ~15 parts of epoxy modified acrylate, 5~20 parts of dipentaerythritol monohydroxy hexaacrylate, 5~50 parts of trimethylolpropane triacrylate, 2~50 parts of tripropylene glycol diacrylate, 0.5~2 1 part of butyl titanate and 3 to 10 parts of composite cracking type photoinitiator are mixed in a mixer at a speed of 50 to 1000 r / min for 10 to 60 minutes to obtain a coating, wherein the composite cracking type photoinitiator is composed of 2 to 5 parts of photoinitiator 184 are mixed with 1 to 5 parts of photoinitiator 1173, photoinitiator 1490 and photoinitiator 1700; 2. The coating obtained in step 1 is uniform Coating on the corona-treated BOPET film surface, and then cured by a 1000W UV curing m...

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the epoxy-modified acrylate used in step 1 is epoxy-modified acrylate with a model number of 6230 produced by Taiwan Changxing Chemical Co., Ltd. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0016] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step one, 30 to 60 parts of polyurethane hexaacrylate, 8 to 12 parts of epoxy-modified acrylate, and 8 to 15 parts of dipentaerythritol monohydroxyl Hexaacrylate, 10-30 parts of trimethylolpropane triacrylate, 10-30 parts of tripropylene glycol diacrylate, 0.8-1.5 parts of butyl titanate and 4-8 parts of composite cracking type photoinitiator are mixed. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com