Preparation method for antifogging thin film coating with high light transmission

A thin-film, anti-fog technology, applied in the field of UV light curing, can solve the problems that cannot meet the requirements of material and device miniaturization, multi-function and integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

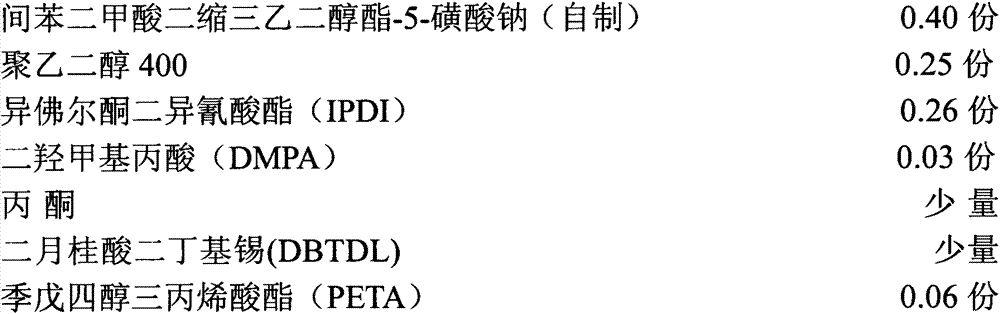

[0014] (1) Synthesis of high light-transmitting hydrophilic UV prepolymer, the quality of each component is as follows:

[0015]

[0016] Weigh 15.6g of IPDI, place it in a three-necked flask, and add dropwise a mixture of 24g of triethylene glycol diisophthalate-5-sodium sulfonate and 15g of polyethylene glycol 400 while stirring, for about 30min, during which Drop 3-4d of dibutyltin dilaurate (DBTDL), and control the temperature at 50°C. After the dropwise addition, continue to react for 1 hour, and monitor the change of NCO value in the system by the di-n-butylamine method. When the theoretical value is reached, add 1.8g of DMPA and raise the temperature to 70°C; Amine method was used to monitor the change of NCO value in the system. When the theoretical value was reached, 3.6g of pentaerythritol triacrylate (PETA) was added to continue the reaction. Acetone was used to control the viscosity of the system throughout the reaction process. When the NCO reaches the theoret...

Embodiment 2

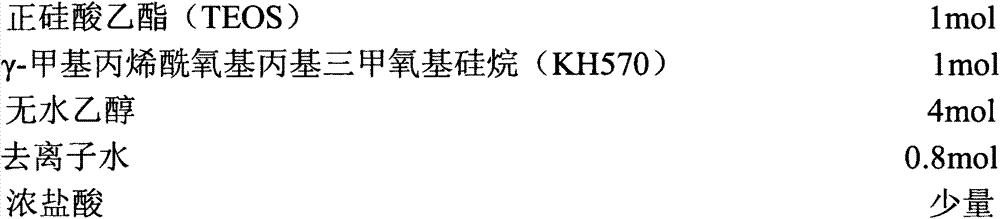

[0024] (1) Synthesis of high light-transmitting hydrophilic UV prepolymer, the quality of each component is as follows:

[0025]

[0026] Weigh 15.6g of IPDI, place it in a three-necked flask, and add dropwise a mixture of 24g of triethylene glycol diisophthalate-5-sodium sulfonate and 15g of polyethylene glycol 400 while stirring, for about 30min, during which Drop 3-4d of dibutyltin dilaurate (DBTDL), and control the temperature at 50°C. After the dropwise addition, continue to react for 1 hour, monitor the change of NCO value in the system by the di-n-butylamine method, when the theoretical value is reached, add 1.8g DMPA, and raise the temperature to 70°C; Amine method was used to monitor the change of NCO value in the system. When the theoretical value was reached, 3.6g of pentaerythritol triacrylate (PETA) was added to continue the reaction. Acetone was used to control the viscosity of the system throughout the reaction process. When the NCO reaches the theoretical v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com