Patents

Literature

106 results about "Gamma-methacryloxypropyltrimethoxysilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Curable composition, cured article obtained therefrom, and photochromic optical material and process for producing the same

InactiveUS20040220292A1Improve adhesionEnhance aggregation abilityCoatingsOptical elementsMethacrylateSilylene

A curable composition which provides a coating layer having high adhesion to a substrate and a hard coat layer and extremely excellent photochromic properties such as high color development intensity, high fading speed and excellent durability. This composition comprises (1) 100 parts by weight of radically polymerizable monomers including a silyl monomer such as gamma-methacryloyloxypropyl trimethoxysilane and / or an isocyanate monomer such as 2-isocyanatoethoxy methacrylate, (2) 0.01 to 20 parts by weight of an amine compound and (3) 0.01 to 20 parts by weight of a photochromic compound. A photochromic optical material having excellent adhesion between a photochromic coating layer and a resin substrate and obtained by using this composition as a coating material and a process for producing the photochromic optical material.

Owner:TOKUYAMA CORP

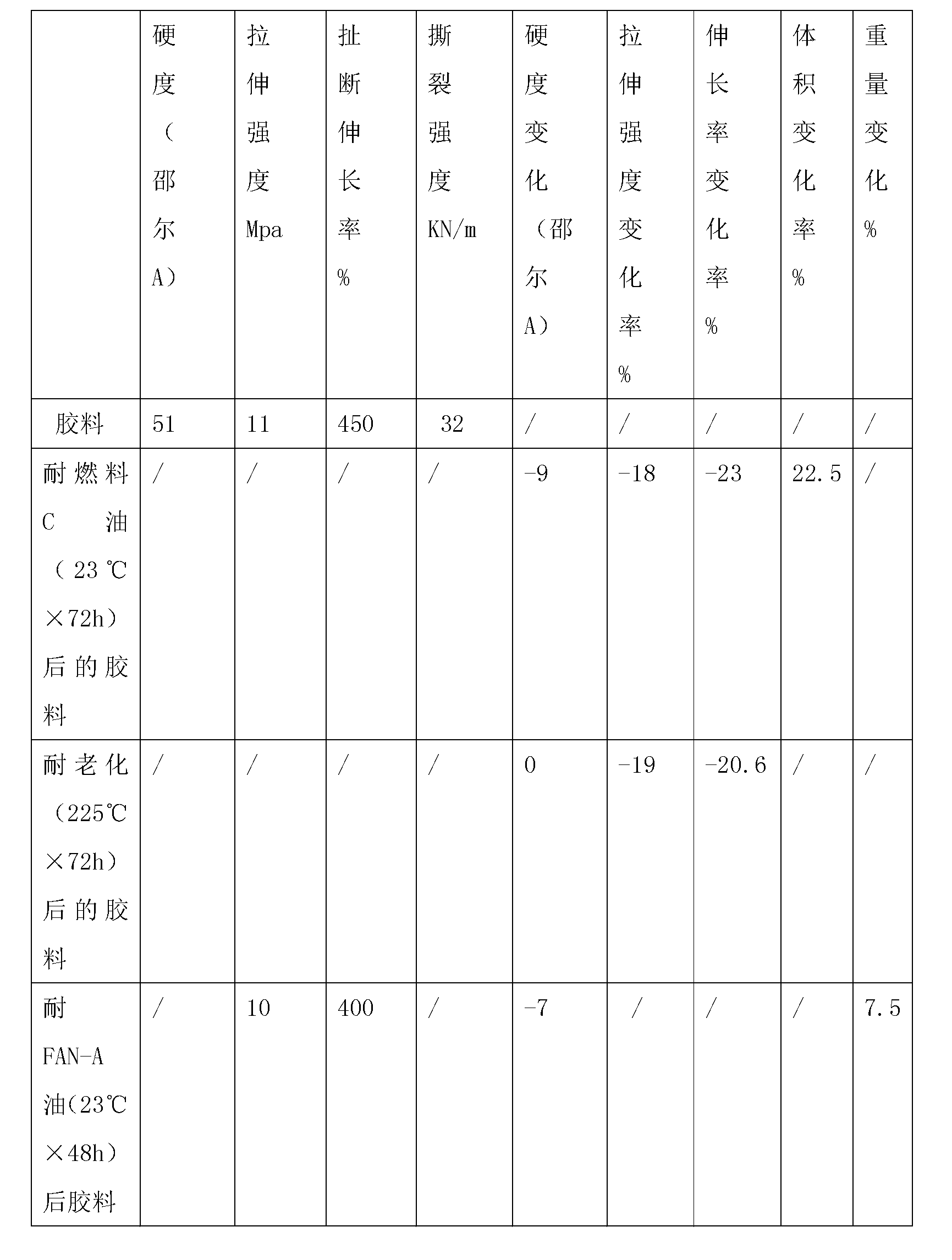

Valve sealing gasket sizing material and preparation method thereof

ActiveCN103012891AImprove performanceGood high and low temperature resistanceDiphenylsilanediolSolvent

The invention discloses a valve sealing gasket sizing material, which is prepared from the following raw materials in parts by weight: 20-30 parts of fluorosilicone rubber, 50-60 parts of hydrogenated nitrile-butadiene rubber, 15-25 parts of chlorosulfonated polyethylene rubber TS-320 (TOSOH, Japan), 2-3 parts of gamma-methacryloxypropyltrimethoxysilane, 1-2 parts of diphenyl silandiol, 14-16 parts of modified tree ash, 2-3 parts of ferrocene, 0.2-0.6 part of dicumyl peroxide (DCP), 20-30 parts of high-abrasion resistant carbon black N330, 20-25 parts of precipitated white carbon black, 5-7 parts of light calcium carbonate, 2-4 parts of zinc oxide, 1-3 parts of calcium stearate, 1-3 parts of aluminium oxide, 5-8 parts of dolomite, 13-15 parts of modified iron tailing powder, 0.1-0.3 part of accelerating agent MBTS, 1-2 parts of sulphur, 1-2 parts of anti-aging agent RD, 1-2 parts of anti-aging agent MB, 1-2 parts of benzimidazole-2-thiol, 1-3 parts of methyltrimethoxy silane, and 2-3 parts of paraffin. The sizing material of the rubber has excellent high and low temperature-resistant, oil-proof, solvent-resistant and chemical-resistant performance, and at the same time is good in mechanical property and low in cost.

Owner:平湖市博宏塑料制品厂

Method for modifying nano titanium dioxide sol by utilizing silane coupling agent

InactiveCN102031022ASimple processMild reaction conditionsPigment treatment with organosilicon compoundsSilanesPollution

The invention discloses a method for modifying nano titanium dioxide sol by utilizing a silane coupling agent. The method comprises: mixing 20-70 parts by weight of absolute ethyl alcohol, 10-25 parts by weight of deionized water and 5-25 parts by weight of hydrochloric acid at room temperature; adding the mixture to the mixed liquor of 100 parts by weight of butyl titanate and 20-70 parts by weight of absolute ethyl alcohol at the addition speed controlled at 0.4-0.6g / min; stirring the mixture for 0.5-1.5 hours, then adding 1-20 parts by weight of silane coupling agent, and stirring the mixture for 0-24 hours; and heating the mixture to 70-85 DEG C and stirring the mixture to react for 0.5-2.0 hour, thus preparing the nano titanium dioxide sol modified by the silane coupling agent, wherein the silane coupling agent is gamma-methacryloxy propyl trimethoxy silane, ethenyl trimethoxy silane or ethenyl triethoxy silane. The method has the characteristics of simple process, mild reaction conditions, no pollution, wider application prospect and the like.

Owner:SOUTH CHINA UNIV OF TECH

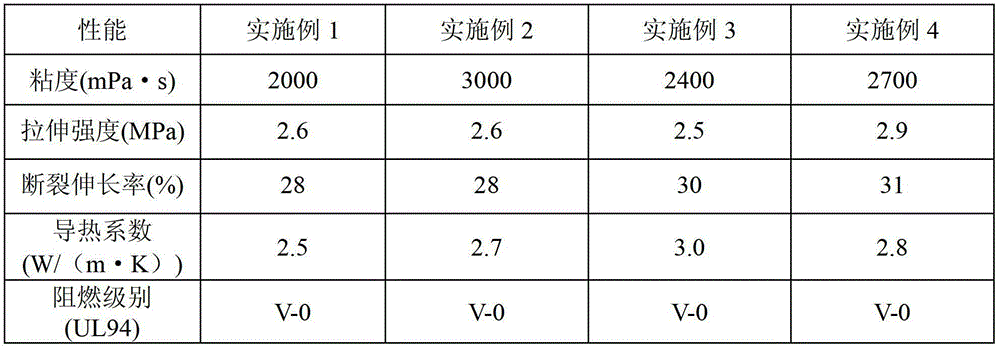

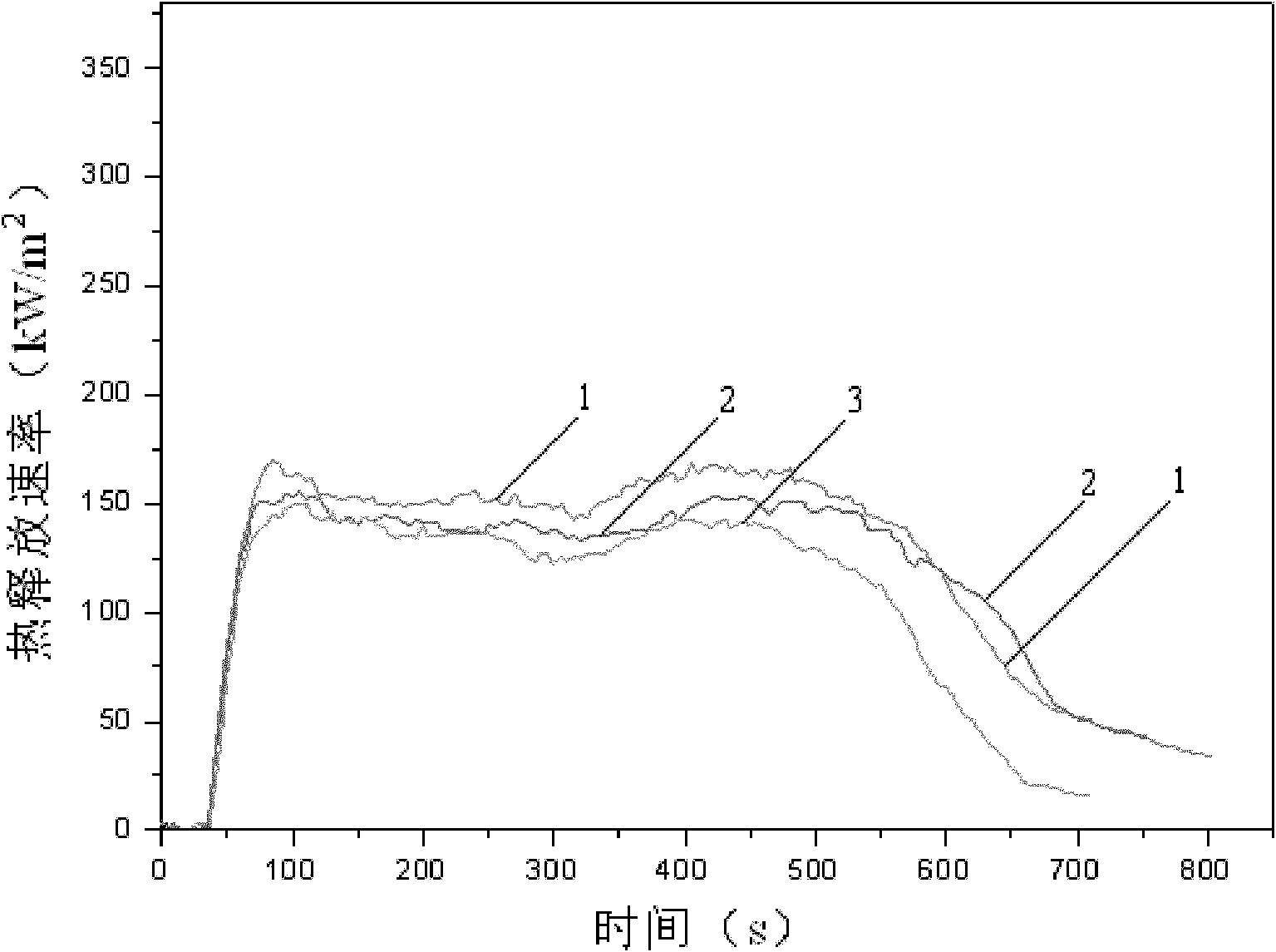

Low-viscosity high-heat-conductivity organic silicon electronic pouring sealant and preparation method thereof

ActiveCN103146340AGood compatibilityLower surface energyNon-macromolecular adhesive additivesOther chemical processesSealantDimethyl siloxane

The invention provides low-viscosity high-heat-conductivity organic silicon electronic pouring sealant and a preparation method thereof. The method comprises the following steps of: mixing high viscosity and low viscosity of vinyl polydimethylsiloxane; adding aluminum oxide with particle size of 1-5 microns as heat conduction filler; further adding a compound coupling agent formed by combining aluminic acid ester, KH570 (gamma-methylacryloyloxypropyl trimethoxysilane) and KH550 (gamma-aminopropyl triethoxysilane) and a compound flame retardant formed by combining melamine cyanurate and aluminum hydroxide into a base material system; and preparing the electronic pouring sealant according to a proper proportion. The prepared pouring sealant has high heat conductivity up to 2.5-3.0W.m<-1>.K<-1>, low viscosity of 2000-3000mPa.s, perfect fluidity and good flame retardance effect; and the production cost is low.

Owner:GUANGZHOU GLORYSTAR CHEM

Wood flour/polypropylene wood-plastic composite material using silane modified ammonium polyphosphate as fire retardant and preparation method thereof

InactiveCN102093735AImprove flame retardant performanceImprove mechanical propertiesHeat resistancePolypropylene

The invention relates to a wood flour / polypropylene wood-plastic composite material and a preparation method thereof, in particular to a wood flour / polypropylene wood-plastic composite material using silane modified ammonium polyphosphate as a fire retardant and a preparation method thereof. The invention solves the problems of poor compatibility, low mechanical properties, poor fire retardance and poor heat resistance of the existing wood flour / polypropylene wood-plastic composite material using ammonium polyphosphate as a fire retardant. The wood-plastic composite material is prepared from wood flour, polypropylene, silane modified ammonium polyphosphate, m-TMI-g-PP coupling agent and antioxidant, wherein the silane modified ammonium polyphosphate is prepared from ammonium polyphosphate and gamma-methacryloxypropyltrimethoxysilane. The preparation method comprises the following steps: preparing the silane modified ammonium polyphosphate; then, mixing the wood flour, polypropylene, silane modified ammonium polyphosphate, m-TMI-g-PP coupling agent and antioxidant; and finally, extruding by using a double screw extruder. The wood-plastic composite material provided by the invention has fine fire retardance, high mechanical properties and good heat resistance; and the process is simple.

Owner:NORTHEAST FORESTRY UNIVERSITY

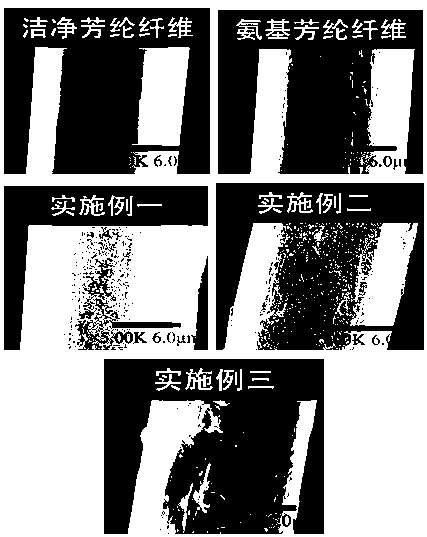

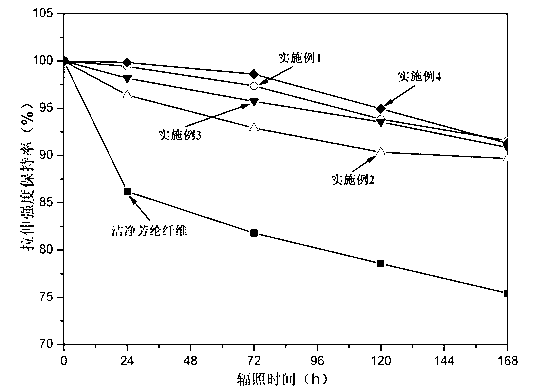

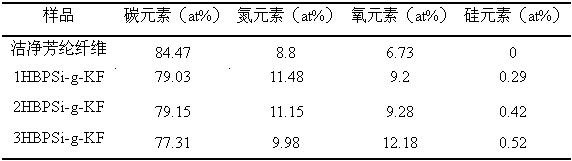

Surface grafting modified aramid fiber and preparation method thereof

The invention relates to a surface grafting modified aramid fiber and a preparation method of the fiber. The method comprises the following steps of: mixing gamma-glycidoxypropyltrimethoxysilane with the aramid fiber with amino on the surface, placing the above mixture into a mixed solution of gamma-methacryloxypropyltrimethoxylsilane and another alkoxy silane, adding deionized water and an organic solvent into the resulting product, and carrying out cleaning and drying after the reaction ends to obtain hyperbranched polysiloxane modified aramid fiber, wherein the surface of the obtained fiber is connected with methacryloxy and another active functional group through chemical bonds. The surface of the fiber provided by the invention not only has the group capable of resisting strong ultraviolet irradiation, but also has the active functional group with high reactivity, as well as is improved in interface bond performance with a resin matrix; the types of the active functional groups can also be changed by regulating process conditions to adapt to reactions with a plurality of different resin matrixes to obtain a plurality of composite materials with outstanding comprehensive performance; and the fiber provided by the invention has the characteristics of high flexibility, strong controllability and wide application field range.

Owner:SUZHOU UNIV +1

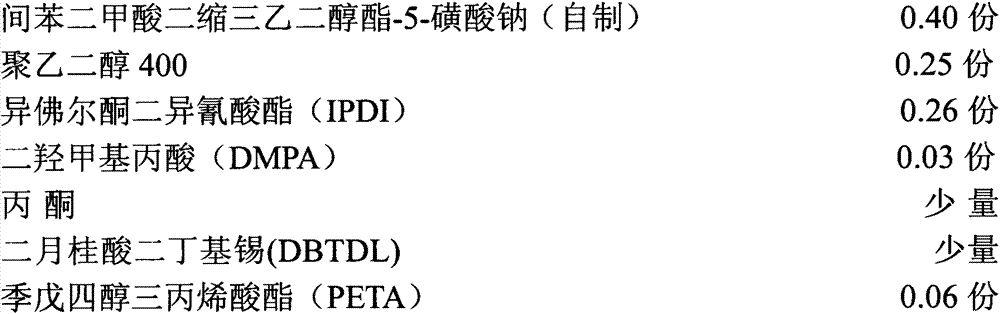

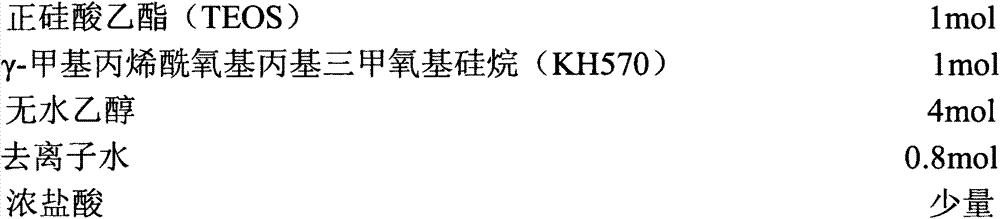

Preparation method for antifogging thin film coating with high light transmission

ActiveCN103709927APolyurea/polyurethane coatingsPigment treatment with organosilicon compoundsSolventDibutyltin dilaurate

Provided is a preparation method for an antifogging thin film coating with high light transmission. M-phthalic acid triethylene glycol ester-5-sodium sulfonate (self made), polyethylene glycol 400, isophorone diisocyanate and pentaerythritol triacrylate are employed as main raw materials, dibutyltin dilaurate is employed as a catalyst, dimethylolpropionic acid is employed as a chain extender, acetone is employed as a solvent, and hydrophilic UV prepolymers are prepared; ethyl orthosilicate is employed as a precursor, gamma-methacryloxy propyl trimethoxysilane is employed as a modifier, a sol-gel method is employed, and uniform and stable modified SiO2 sol is prepared; the hydrophilic UV prepolymers and the modified SiO2 sol are subjected to hybridization through a UV curing way, and a thin film coating is obtained. The prepared thin film coating has good hardness and adhesive force, water resistance and high light transmission and good antifogging effects, and can be used for antifog of surfaces of glass and eyeglass. The preparation technology of the thin film coating accords with green environmental protection concepts, curing and film forming are fast, and comprehensive performances are good. The antifogging thin film coating has good market prospect and is suitable for popularization and application.

Owner:JIANGNAN UNIV

Transparent addable curable LED filament packaging silicone

ActiveCN104164209AIncrease elasticityImprove reinforcementNon-macromolecular adhesive additivesSemiconductor devicesPolymer scienceSilica gel

The invention discloses transparent addable curable LED filament packaging silicone which is characterized by comprising the following components in parts by weight: 50-100 parts of methyl phenyl vinyl silicone resin, 4-30 parts of phenyl hydrogen-containing silicon resin, 5-15 parts of HDK.H2O fumed silica, 0.5-2 parts of gamma-glycidyloxypropyltrimethoxysilane or gamma-methacryloxypropyltrimethoxysilane, 0.02 part of addition reaction catalyst (1,3-platinum divinyltetramethyldisiloxane complex) and 0.02 part of inhibitor (1-ethynylcyclohexanol). The phenyl silicone rubber has the light transmittance of more than 95%, has a remarkable reinforcing effect, is good in rebound resilience and high in tear resistance, tensile strength and break elongation rate and has a remarkable, stable and consistent thixotropic effect.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Curable composition comprising a photochromic compound

InactiveUS20030036579A1Good release effectHigh color densityOrganic chemistryDiffusing elementsCompound aSilylene

A photochromic cured product which has excellent photochromism such as high color density and high fading speed, excellent adhesion to a hard coat and high striping work efficiency. This cured product is obtained by polymerizing and curing a curable composition which comprises (A) a polyfunctional polymerizable monomer such as trimethylolpropane trimethacrylate, (B) a silyl monomer such as gamma-methacryloyloxypropyl trimethoxysilane, (C) another radically polymerizable monomer and (D) a photochromic compound. As for the contents of the polymerizable monomers, the content of the component (A) is 1 to 50 wt %, the content of the component (B) is 0.5 to 20 wt % and the balance consists of the component (C) based on the total of the components (A), (B) and (C). The photochromic compound (D) is contained in an amount of 0.0001 to 10 parts by weight based on 100 parts by weight of the total of the components (A), (B) and (C).

Owner:TOKUYAMA CORP

Chromium-free waterborne corrosion resistant coating used for surface of metal and preparation method thereof

ActiveCN101693811AImprove compactnessLower electrode potentialAnti-corrosive paintsChromium freeSolvent

The invention relates to a chromium-free waterborne corrosion resistant coating for the surface of metal and a preparation method thereof. The chromium-free waterborne corrosion resistant coating comprises the following components in percentage by mass: 15-33 flaked zinc powder, 2.5-8 flaked aluminium powder, 13.5-24 solvent, 0.2-2.5 assistant, 14-22 first silane coupling agent, 2-6 second silane coupling agent, 0.05-1.5 nano SiO2,0.03-1.2 nano TiO2, 0.02-1.5 nano ZrO2, 0.3-1 silver salt, 0.1-0.3 polyaniline, 0-0.6 tackifier and the balance of H2O, wherein the first silane coupling agent is a bi-[Gamma-(triethoxysilane) propyl] tetrasulfide; and the second silane coupling agent is a Gamma-aminopropyltriethoxysilane or Gamma-methacryloxypropyl trimethoxysilane. The coating contains no chromium and has corrosion resistance according with an international newest metal surface corrosion prevention technology.

Owner:CHANGZHOU JMT SURFACE ENG TECH

Curable composition comprising a photochromic compound

InactiveUS6802993B2Good release effectHigh color densityOrganic chemistryDiffusing elementsCompound aSilylene

A photochromic cured product which has excellent photochromism such as high color density and high fading speed, excellent adhesion to a hard coat and high striping work efficiency. This cured product is obtained by polymerizing and curing a curable composition which comprises (A) a polyfunctional polymerizable monomer such as trimethylolpropane trimethacrylate, (B) a silyl monomer such as gamma-methacryloyloxypropyl trimethoxysilane, (C) another radically polymerizable monomer and (D) a photochromic compound. As for the contents of the polymerizable monomers, the content of the component (A) is 1 to 50 wt %, the content of the component (B) is 0.5 to 20 wt % and the balance consists of the component (C) based on the total of the components (A), (B) and (C). The photochromic compound (D) is contained in an amount of 0.0001 to 10 parts by weight based on 100 parts by weight of the total of the components (A), (B) and (C).

Owner:TOKUYAMA CORP

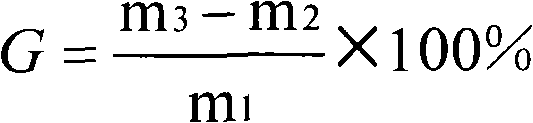

Preparation method for surface-modified quartz sand

The invention relates to a method for modifying the surface of quartz sand by using a gamma-methacryloxy propyl trimethoxy silane coupling agent. The technical scheme for the invention is as follows: quartz sand is used as a raw material, a silane coupling agent is used as a surface modifier, and a high speed heating mixer is employed to modify the surface of the quartz sand through the silane coupling agent. The silane coupling agent and the quartz sand are subjected to reactions of condensation, dehydration and solidification, and therefore a solid covalent bond combination is formed between the silane coupling agent and the quartz sand. The surface-modified quartz sand has substantially improved compatibility with organic polymer resin materials, processing fluidity and dispersibility. When more surface-modified quartz sand and less resin are used in the production of artificial quartz stone slabs, the production cost of the slabs can be reduced, and physical and chemical properties and functions of the prepared slabs can be improved.

Owner:INNER MONGOLIA GOLD MIGHT BUILDING MATERIAL

Modified phosphorous slag used as plastic filler and preparation method thereof

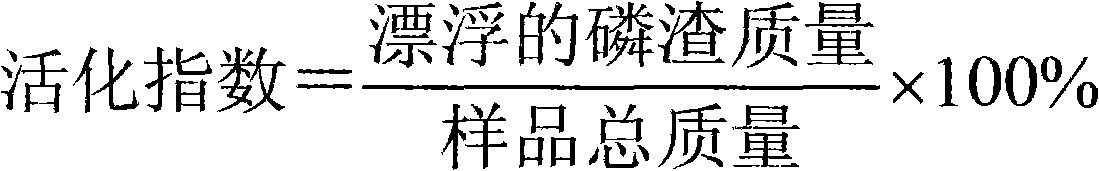

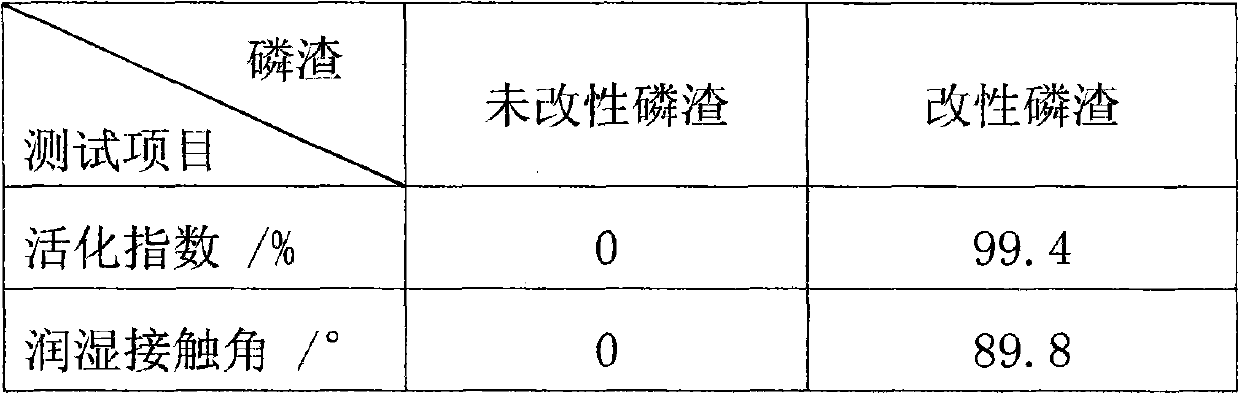

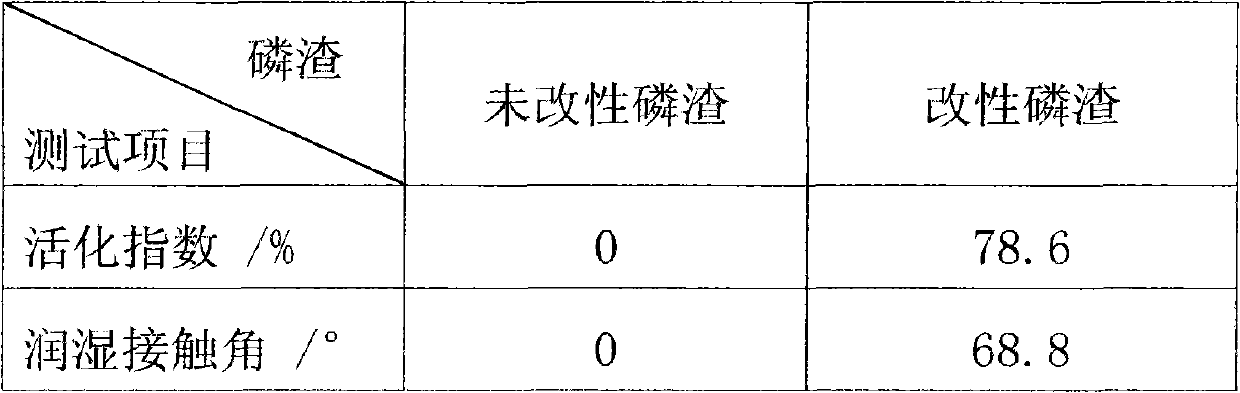

The invention relates to a modified phosphorous slag used as a plastic filler; which is characterized in that: the modified phosphorous slag is mainly composed of 0.1-10wt percent of surface modifier and 90-99.9wt percent of phosphorous slag; the surface modifier is stearic acid or Gamma-aminopropyl triethoxy silane or gamma-methacryloxypropyl trimethoxy silane; the phosphorous slag is crushed, ground and sieved to obtain phosphorous slag fine powder which is modified by the surface modifier through dry process or wet process to obtain the modified phosphorous slag; the modified phosphorous slag is used as thermoplastic or thermosetting plastic fillers, organic lipophilic group led in from the surface of the modified phosphorous slag and polymer macromolecule are reacted or physically entangled, so as to improve the dispersibility of the phosphorous slag in the plastics, improve the combinability and compatibility of the phosphorous slag and the plastics, improve the tensile strength and bending strength and other mechanical properties of plastic composite materials and reduce the cost of plastic products; by adopting the invention, waste is turned into wealth, harm is turned into god, raw material source is wide, the process is simple and the practical applicability is strong.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Nano TiO2 modified styrene-acrylic emulsion and preparation method thereof

The invention discloses a nano TiO2 modified styrene-acrylic emulsion and a preparation method thereof. The emulsion comprises the following components in percentage by weight: 15-24 percent of methyl methacrylate, 12-20 percent of styrene, 15-22 percent of butyl acrylate, 35-45 percent of water, 2-5 percent of methacrylic acid, 1.5-3 percent of octylphenol polyvinyl chloride (PVC) ether, 0.5-1 percent of sodium dodecyl benzene sulfonate (SDBS), 0.2-0.6 percent of sodium bicarbonate, 0.2-0.7 percent of potassium peroxydisulfate, 0.3-0.5 percent of ammonia water, 0.25-0.4 percent of nano TiO2 and 0.05-0.1 percent of gamma-methacryloyl trimethoxypropylsilane. The preparation method comprises the following steps of: firstly, modifying the nano TiO2; secondly, preparing a monomer mixed liquor; and finally, modifying the styrene-acrylic emulsion and the monomer mixed liquor by adopting nano TiO2 to prepare the nano TiO2 modified styrene-acrylic emulsion. The nano TiO2 modified styrene-acrylic emulsion has the characteristics of uniformity in dispersion and calcium ion stability and the advantages of water resistance, anti-aging property, scrubbing resistance, simple process, low price and no environmental pollution.

Owner:JIANGSU UNIV OF SCI & TECH

Wear-resistant, high-temperature resistant and anti-corrosion coating for sand-containing heavy oil gathering pipelines and preparation method thereof

ActiveCN101691473AGood high temperature corrosion resistanceImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsCyclohexanoneDiacetone alcohol

The invention relates to a wear-resistant, high-temperature resistant and anti-corrosion coating for sand-containing heavy oil gathering pipelines and a preparation method thereof. Methylphenyl silicone resin and bisphenol A epoxy resin E-44 are added into mixed solution of dimethylbenzene, diacetone alcohol, cyclohexanone and dimethyl dicarboxylic acid; the mixture is added with gamma-methacryloxypropyltrimethoxysilane and polyether modified methyl alkyl polyorganosiloxane, and then is mixed evenly; the mixture is added with 1,250-mesh titanium dioxide, 800-mesh precipitated barium sulfate, 800-mesh grey ferro titanium powder, 1,250-mesh gas-phase silicon dioxide, 1,250-mesh wollastonite in powder, 2,500-mesh nano-alumina powder and 2,500-mesh molybdenum disulfide, and is stirred and ground into the wear-resistant, high-temperature resistant and anti-corrosion coating for the sand-containing heavy oil gathering pipelines; and after curing, the wear-resistant, high-temperature resistant and anti-corrosion coating forms a wear-resistant, high-temperature resistant and anti-corrosion coat for the sand-containing heavy oil gathering pipelines. The wear-resistant, high-temperature resistant and anti-corrosion coating can be used for corrosion resistance of inner walls of high temperature sand-containing oil gathering pipelines in the development of sand-containing heavy oil fileds.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

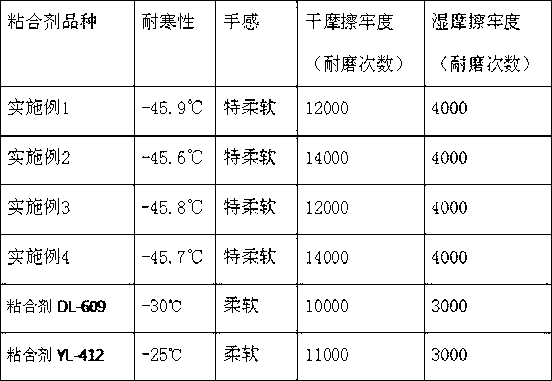

Acrylic ester electrostatic flocking binding agent and preparation method thereof

ActiveCN103214993AGood flexibilityImprove cold resistanceNon-macromolecular adhesive additivesEster polymer adhesivesIsooctyl acrylateSodium acetate

The invention relates to an acrylic ester electrostatic flocking binding agent and a preparation method thereof. The acrylic ester electrostatic flocking binding agent is a polymer emulsion which is prepared from the raw materials: polyoxyethylene dodecyl alcohol (50), sodium dodecyl sulfate, itaconic acid, N-hydroxymethyl acrylamide, acyclic acid, butyl acrylate, 2-ethylhexyl acrylate, styrene, gamma-methacryloxy propyl trimethoxyl silan, epoxy resin E-44, adipic acid dihydrazide, sodium acetate, ammonium persulfate and deionized water through seeded emulsion polymerization. The acrylic ester electrostatic flocking binding agent is an epoxy resin and organic silicon resin jointly-modified acrylic ester electrostatic flocking binding agent. The product has the advantages of flexibility, cold endurance, weather resistance and thermosetting stability and particularly has prominent water resistance and adhesive force.

Owner:LIAONING FIXED STAR FINE CHEM

Nano titanium dioxide-modified composite water-based ink and preparation method thereof

ActiveCN104629532AImprove hydrophilicityReduce usageInksPigment treatment with organosilicon compoundsWater basedAlkane

The invention belongs to the field of water-based ink design and discloses nano titanium dioxide-modified composite water-based ink which comprises nano titanium dioxide-modified water-based acrylic resin, water-based polyester resin, water, ethanol, pigment, an antifoaming agent, a dispersing agent, a leveling agent and a buffer agent. The preparation process of the nano titanium dioxide-modified composite water-based ink comprises the following steps: preparing silane coupling agent modified inorganic nanoparticles from nano titanium dioxide, ethanol, water and gamma-methacryloxy propyl trimethoxyl silane; preparing nano titanium dioxide modified water-based acrylic resin from an alkane-based acrylate monomer, a hydroxyalkyl acrylate monomer, the silane coupling agent modified inorganic nanoparticles, polyethylene glycol, a water-soluble initiator, an emulsifier and water; and finally, preparing the nano titanium dioxide-modified composite water-based ink from the nano titanium dioxide modified water-based acrylic resin, water-based polyester resin, water, ethanol, pigment, an anti-foaming agent, a dispersing agent, a leveling agent and a buffer agent. The water-based ink is resistant to photoaging and antibacterial and mould-proof.

Owner:长兴艾飞特科技股份有限公司

Antibacterial anti-mildew plastic and wood composite material plate and preparation method thereof

The invention discloses an antibacterial anti-mildew plastic and wood composite material plate and a preparation method thereof. The plate is prepared from modified wood flour, plastic, maleic anhydride grafted plastic, graft modified nanometer zinc oxide, activated calcium carbonate, calcium stearate, terpene resin and an antioxidant. The preparation method comprises the steps that the wood flour is modified by using dimethyl dodecyl ammonium chloride; nanometer zinc oxide is treated by using gamma-methacryloxypropyl trimethoxy silane and subsequently subjected to graft modification by using styrene; calcium carbonate is activated by using polyethylene glycol; the plastic, the maleic anhydride grafted plastic, calcium stearate, graft modified nanometer zinc oxide and the terpene resin are stirred and extruded to obtain modified plastic; the modified plastic, the modified wood flour, activated calcium carbonate and the antioxidant are stirred, melted, co-mixed and extruded to form the plate. The antibacterial anti-mildew plastic and wood composite material plate disclosed by the invention is convenient to produce and manufacture, low in production cost, friendly to environment, high in modulus, large in rigidity, resistant to creep deformation and excellent in antibacterial and anti-mildew performances.

Owner:宣城福美达新材料有限公司

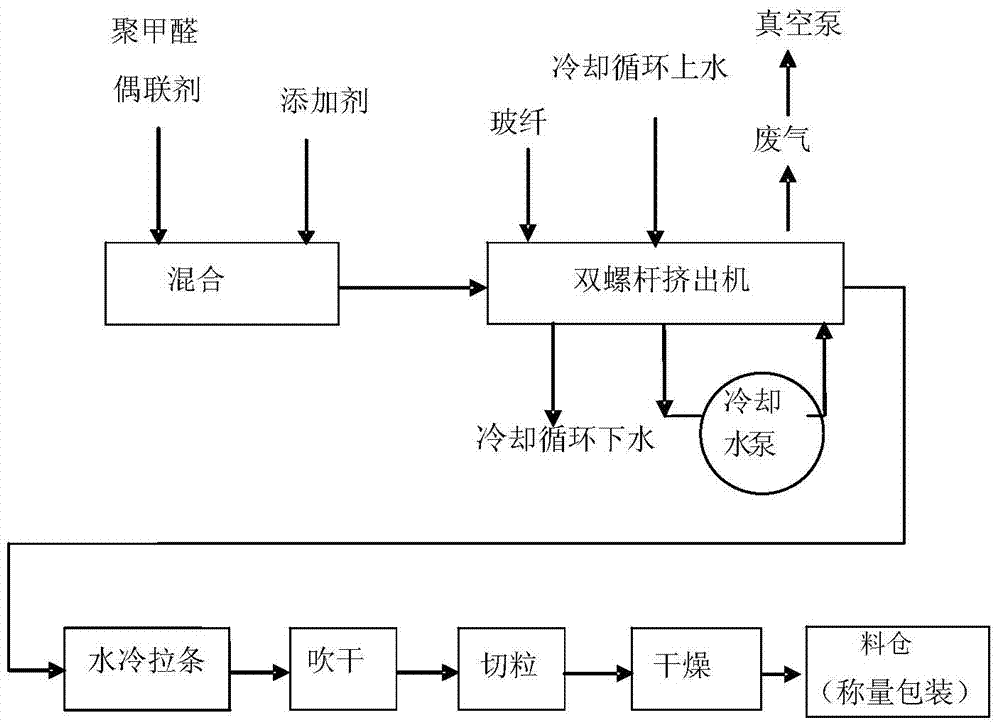

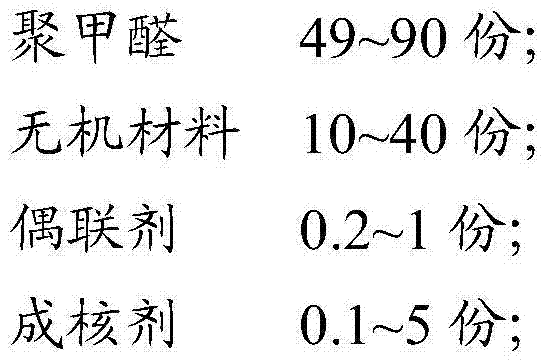

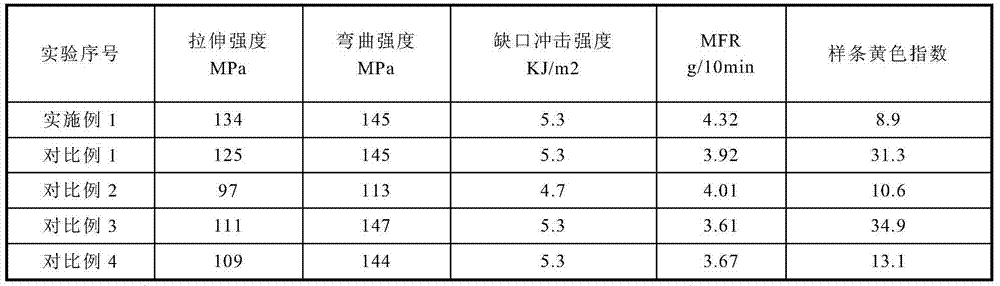

Polyformaldehyde resin composition and preparation method thereof

The invention provides a polyformaldehyde resin composition which comprises polyformaldehyde, an inorganic material, coupling agents, an antioxidant, a formaldehyde absorbing agent and a nucleating agent, wherein the coupling agents are two or more of 2-(3,4-epoxy-cyclohexyl)ethyl trimethoxysilane, 3-glycidyloxypropyltriethoxysilane, gamma-glycidyloxypropyltrimethoxysilane, gamma-methacryloxypropyltrimethoxysilane and gamma-aminopropyltriethoxysilane. The coupling agents can be used for not only effectively improving interfacial properties of the inorganic material and strengthening the bonding of the formaldehyde resin and the inorganic material, but also further improving the strength, modulus and heat resistance of the poly formaldehyde resin composition, and meanwhile effectively solving the problem of the yellow color of the composition, and thus the prepared composition tends to be in a natural color.

Owner:重庆云天化天聚新材料有限公司 +1

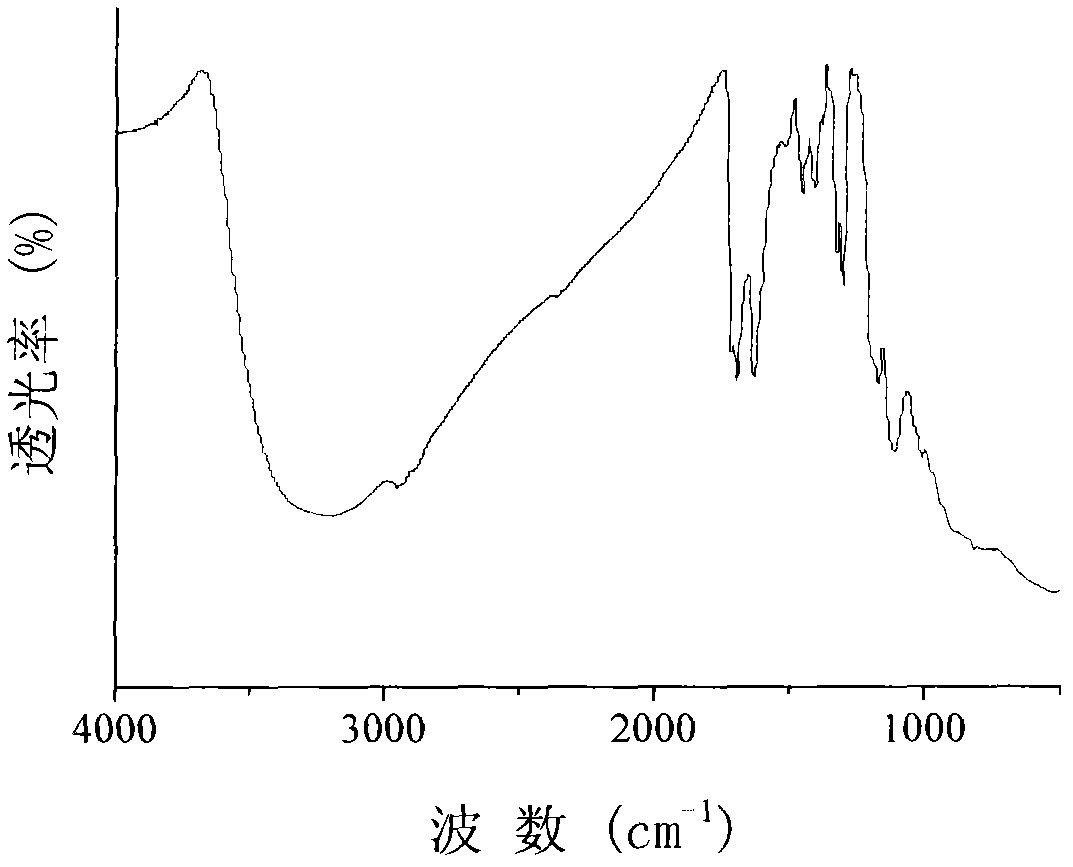

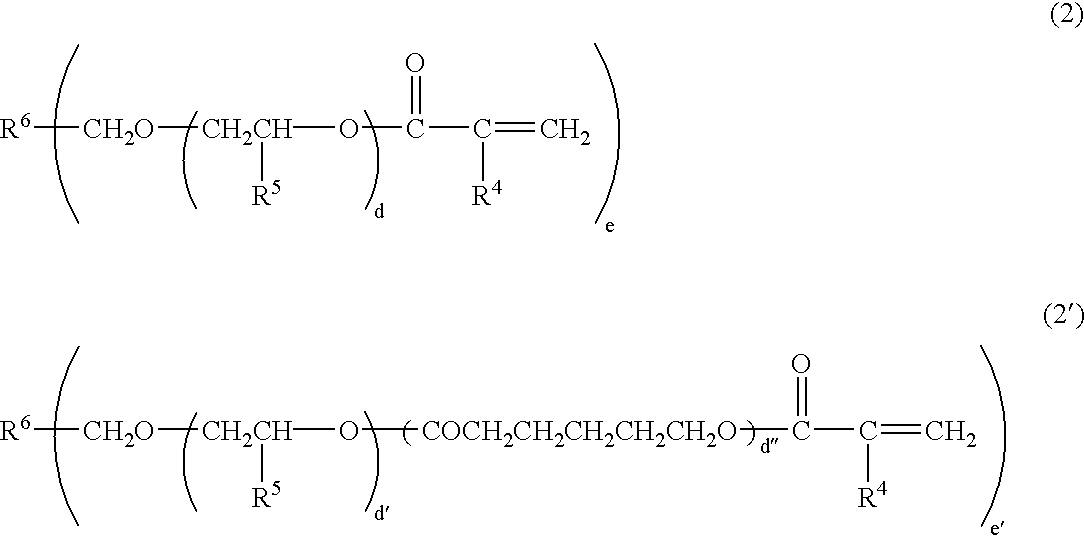

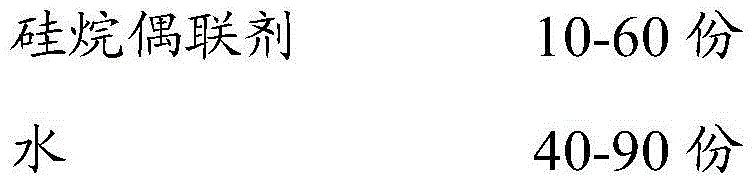

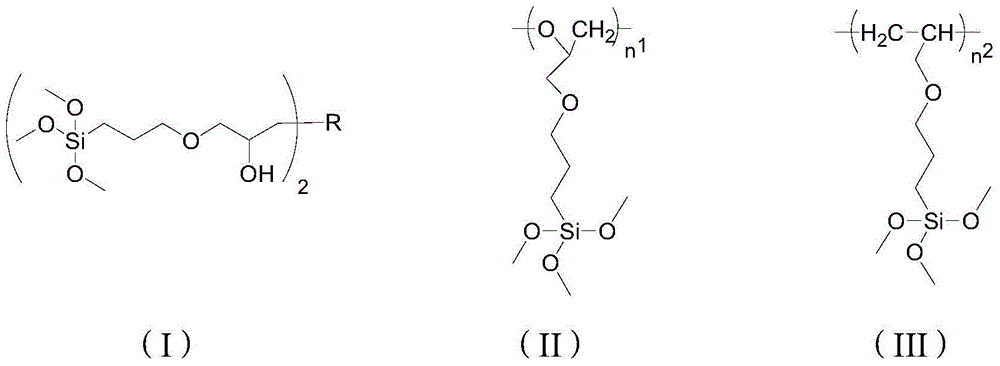

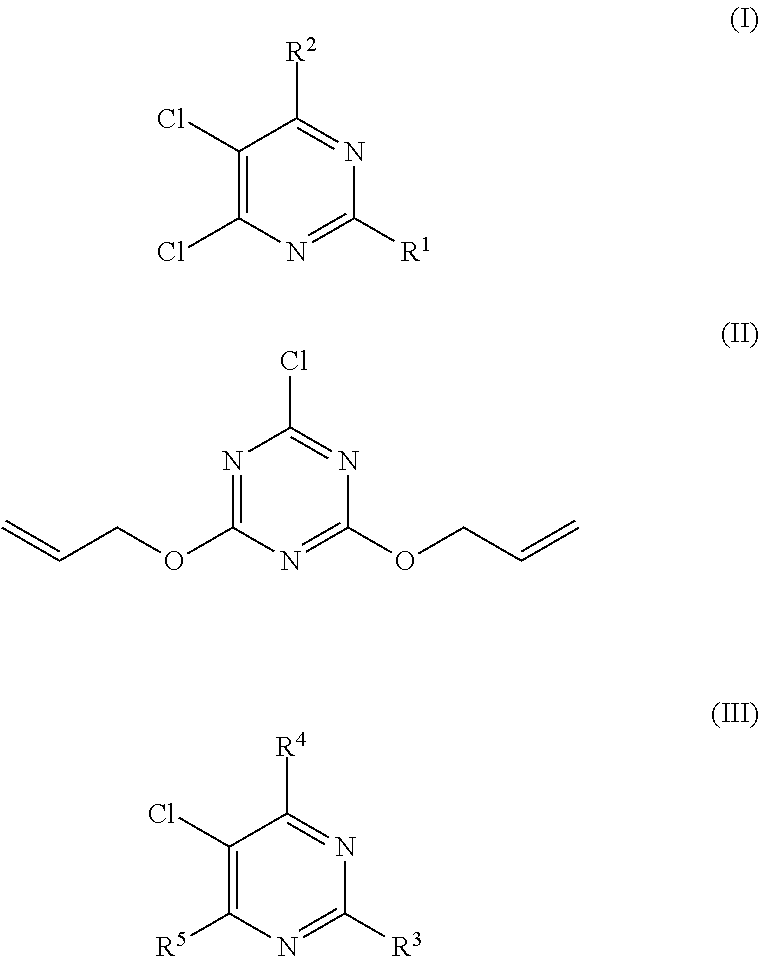

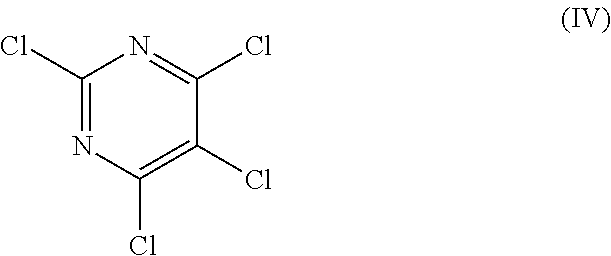

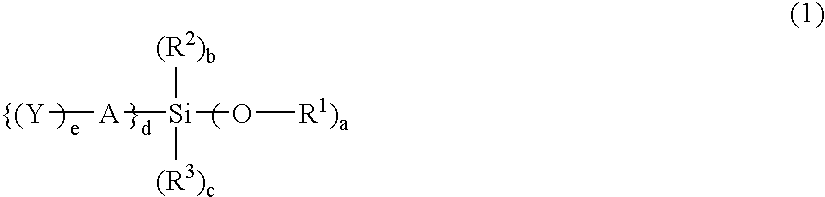

Silane coupling agent hydrolysate, as well as preparation method and application thereof

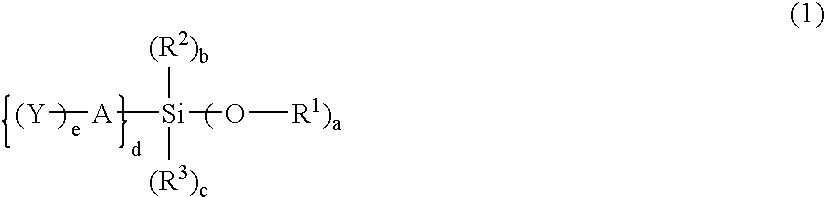

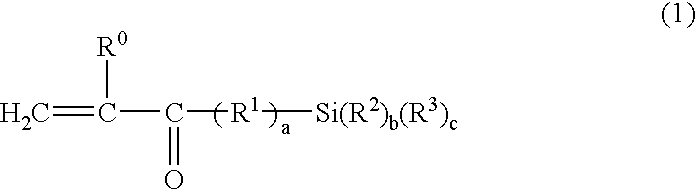

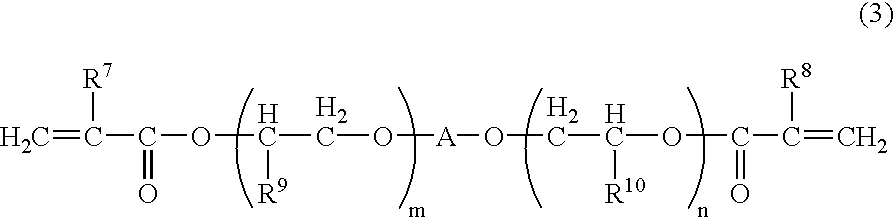

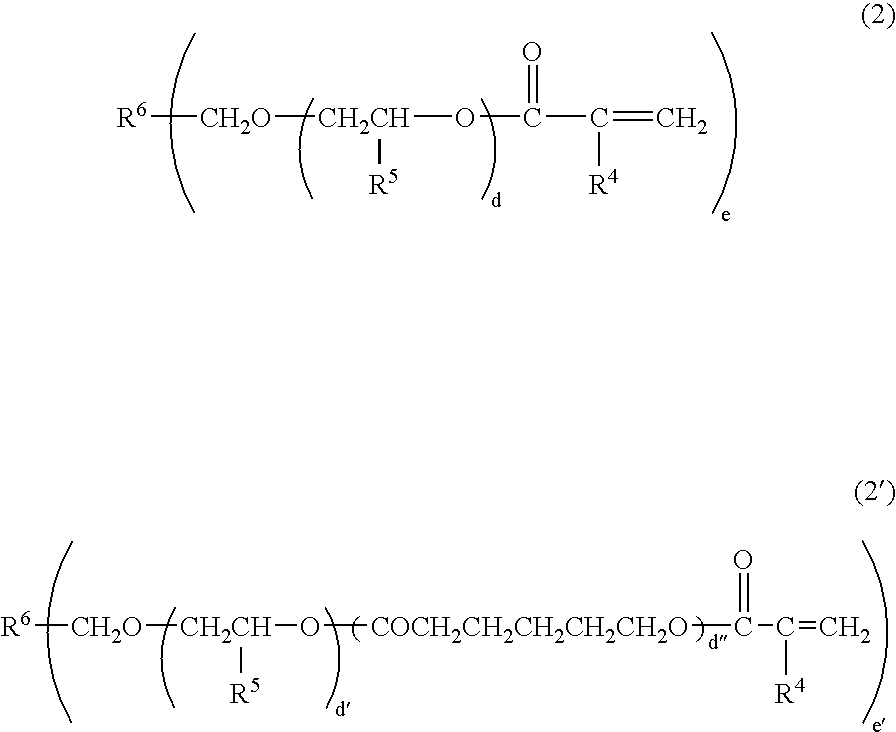

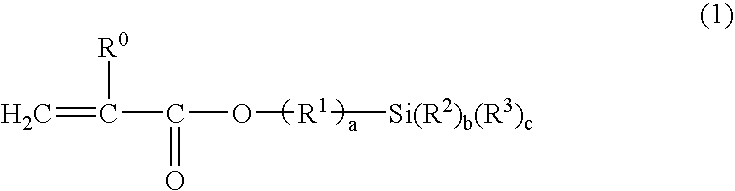

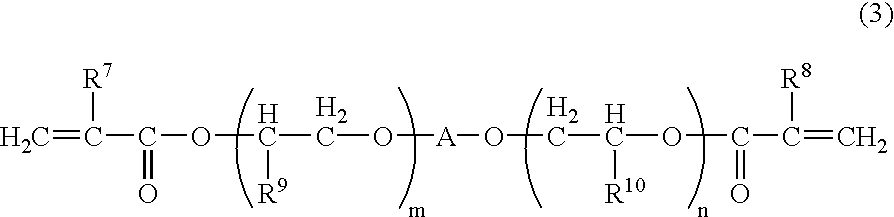

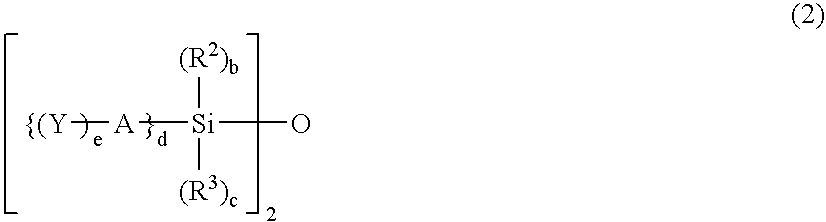

The invention discloses a silane coupling agent hydrolysate, as well as a preparation method and an application thereof. The hydrolysate is prepared from the following raw materials in parts by weight: 10-60 parts of a silane coupling agent, 40-90 parts of water, 0-2 parts of polyol and 0-20 parts of alcohol; the pH value of the hydrolysate is regulated to be 3.5-6.5; and the silane coupling agent is selected from gamma-(2,3-epoxypropoxy)propyl]trimethoxysilane, 3-aminopropyltriethoxysilane, gamma-methacryloxypropyltrimethoxysilane,1,2-bis(triethoxysilyl)ethane and N-(amino-ethyl)-amino-propyl trimethoxy silane, or has the structural characteristics of formulae (I), (II) and (III) as shown in the specification. Metal, especially iron, has excellent anti-corrosive effect when the silane coupling agent hydrolysate is directly applied to the surface of the metal.

Owner:GUANGZHOU GEMBOND CHEM

Preparation method of optical anti-reflection polyester films

The invention relates to a preparation method of optical anti-reflection polyester films, and belongs to the field of surface modification of organic film materials. According to the invention, gamma-methacryloxy propyl trimethoxyl silane (KH570) and (meth)acrylate monomers are copolymerized through radical polymerization so as to obtain copolymers with different KH570 contents, and then the polymer is uniformly coated on the surface of a polyester film by using a spin coater. The preparation method disclosed by the invention is simple in operation; and the modified polyester film has light transmittance, and is applicable to the fields of display, optics and decoration and the like such as LED (light-emitting diodes), CRT (cathode ray tubes), PDP (plasma display panels), EL (electroluminescence) and the like.

Owner:CHANGZHOU UNIV

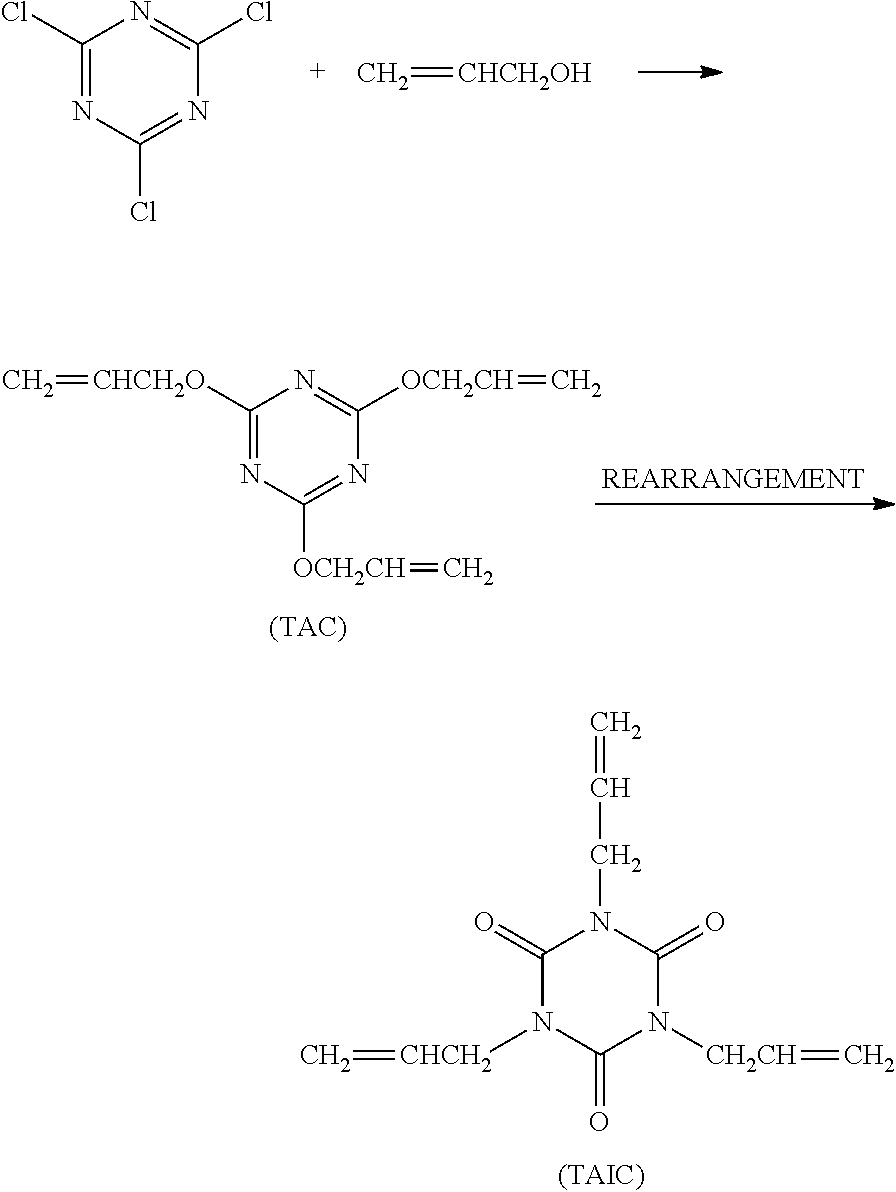

Method of storing triallyl isocyanurate

ActiveUS8691984B2Easy to operateLow viscosityOrganic chemistryHeat-exchange elementsTriallyl isocyanurateWinter season

The present invention provides a method of storing TAIC in which TAIC is prevented from suffering from freezing and solidification during storage thereof in the winter season. In the method of the present invention, the triallyl isocyanurate is mixed with a silane coupling agent to prepare a composition comprising both thereof, and the resulting composition is stored. In the preferred embodiment of the present invention, the silane coupling agent is used in an amount of 5 to 30% by weight based on the weight of the triallyl isocyanurate, and γ-methacryloxypropyl trimethoxysilane is used as the silane coupling agent.

Owner:NIPPON KASEI CHEM CO LTD +1

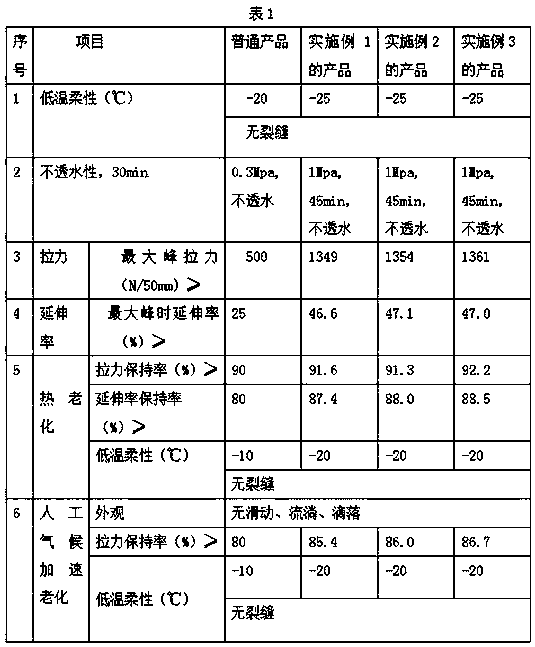

Polymer modified asphalt waterproof roll and production method thereof

InactiveCN108047731AImprove the interface binding forceImprove adhesionLamination ancillary operationsSynthetic resin layered productsPolymer sciencePolymer modified

The invention relates to a polymer modified asphalt waterproof roll and a production method thereof. The waterproof roll is a five-layer structure, and specifically includes, from top to bottom successively, an upper surface isolation layer, an upper polymer modified asphalt layer, a matrix layer, a lower polymer modified asphalt layer and a lower surface isolation layer. The upper polymer modified asphalt layer and the lower polymer modified asphalt layer are prepared from modified asphalt. According to the invention, through modification of asphalt with a polymer modifier, gamma-methacryloxypropyltrimethoxysilane, phenolated lignin, a tackifier and other substances, the obtained modified asphalt has stable properties, and the added modified nano calcium carbonate has high dispersibility,thus effectively improving the storage stability of the modified asphalt system. The waterproof roll prepared from the modified asphalt has improved tearing strength, cohesiveness, water resistance,aging resistance and the like, has high elongation at break, and has improved service life.

Owner:GUANGXI WUXUAN JINPAI WATERPROOF MATERIAL SCI & TECH CO LTD

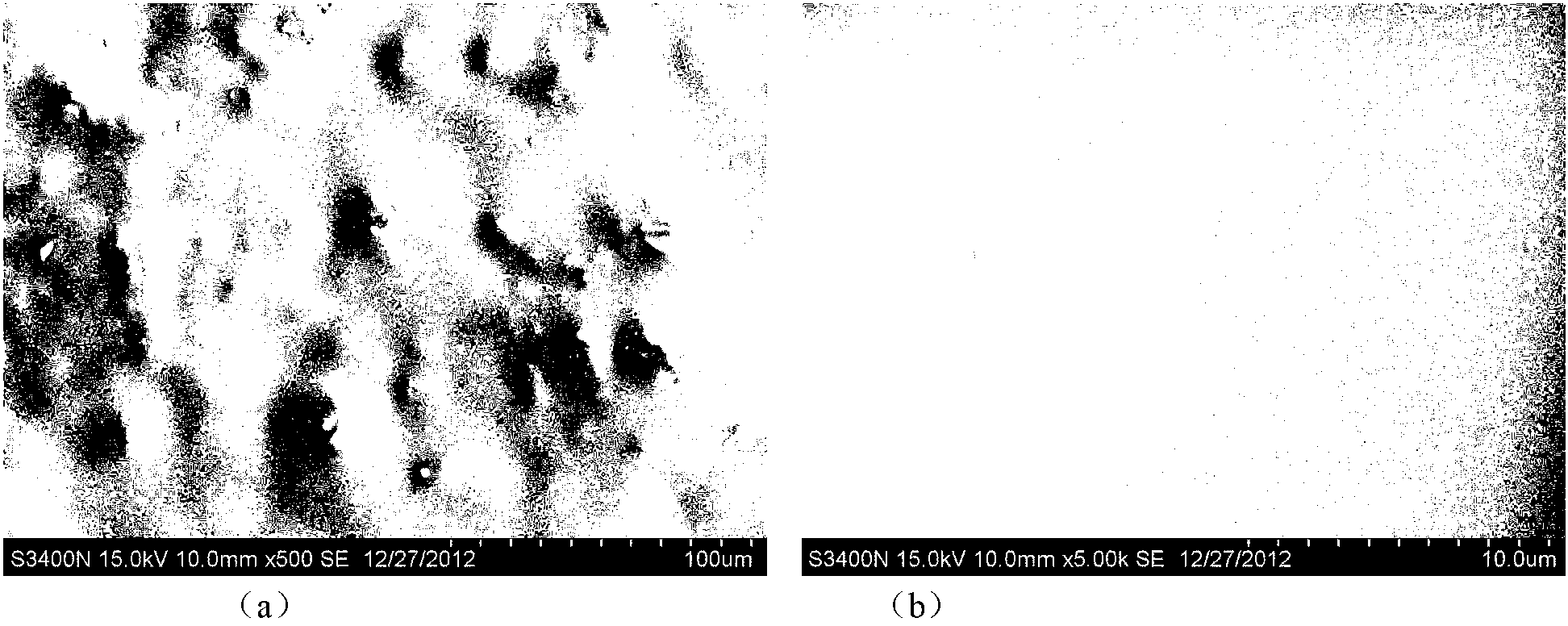

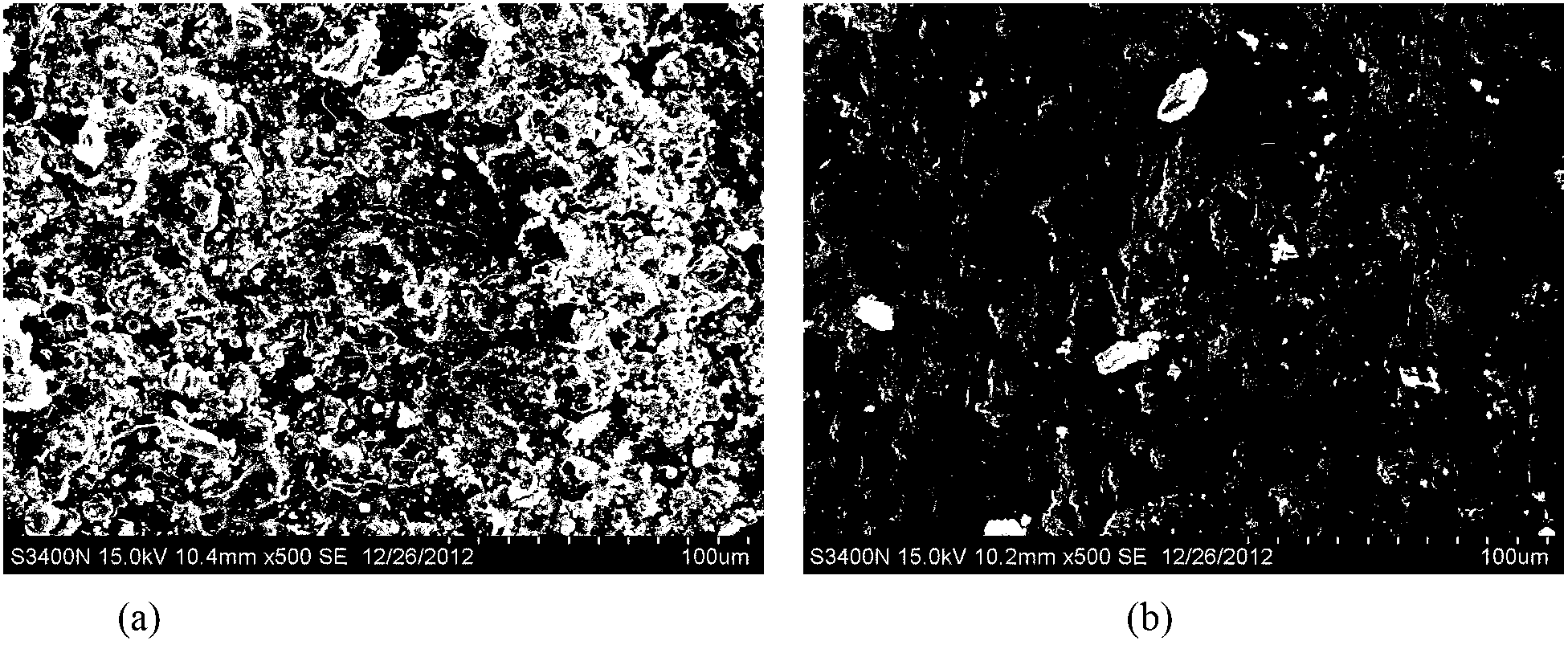

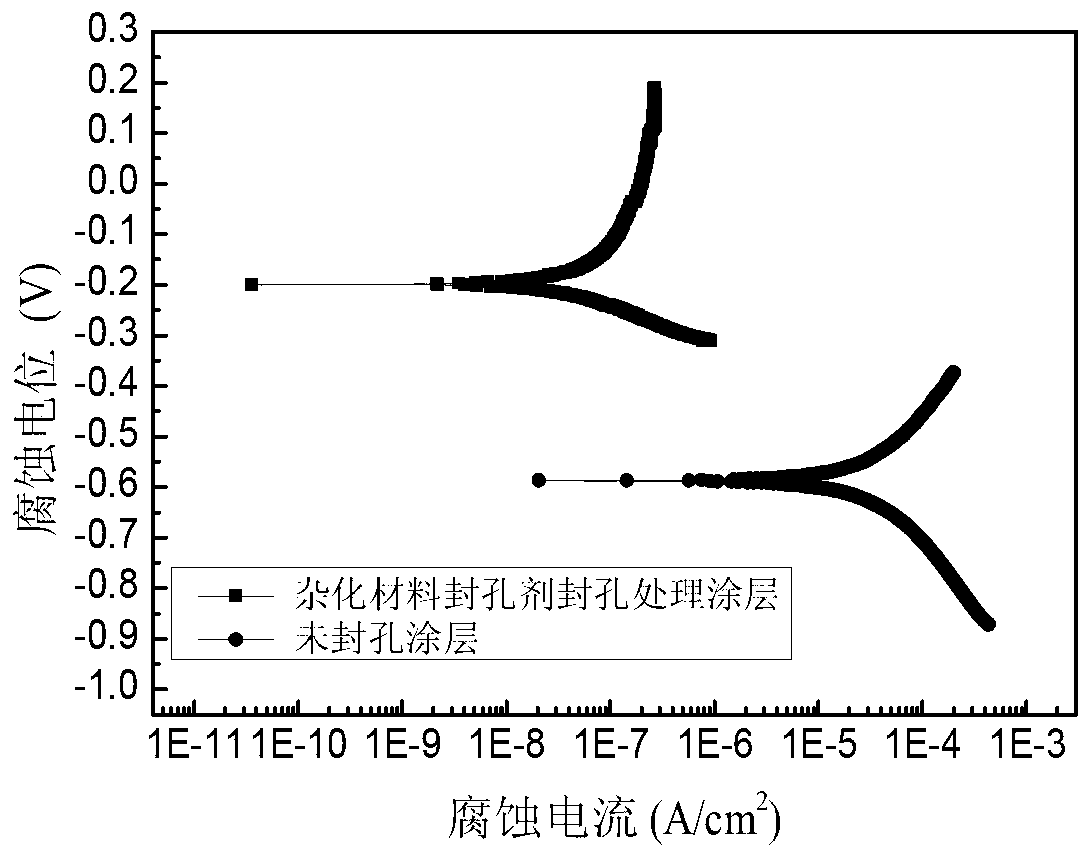

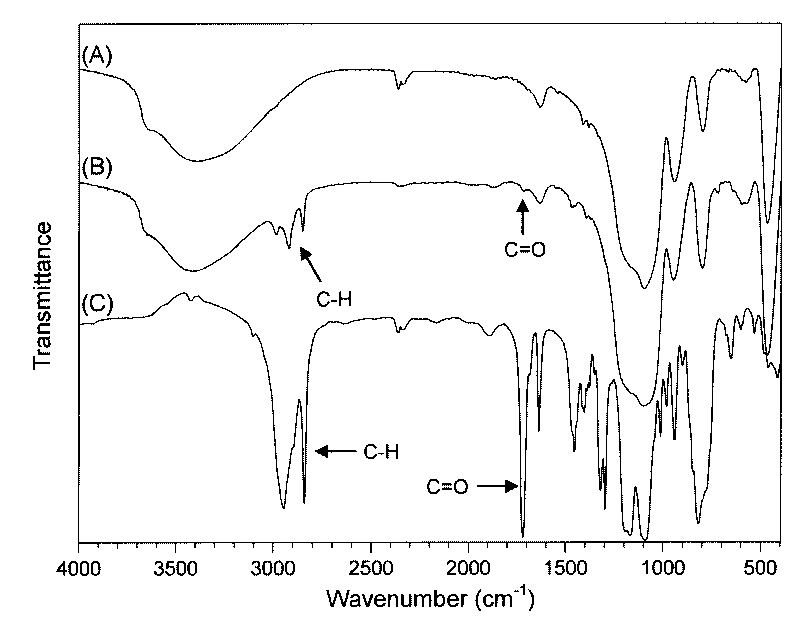

Hybrid material hole sealing agent for improving corrosion resistance of plasma spraying coating in acid environment

InactiveCN103184406AGood sealing effectStrong acid corrosion resistanceMolten spray coatingPorosityN dimethylformamide

A hybrid material hole sealing agent for improving corrosion resistance of a plasma spraying coating in acid environment is composed of the following components: ethyl orthosilicate, anhydrous ethanol, N,N-Dimethylformamide, Gama-methacryloxy propyl trimethoxyl silane, 25vol.% nitric acid, 25vol.% ammonia water and distilled water, wherein the proportion according to volume ration of ethyl orthosilicate to anhydrous ethanol to N,N-Dimethylformamide to distilled water to Gama-methacryloxy propyl trimethoxyl silane is equal to 4:3:1:(4-6), and the volume of N,N-Dimethylformamide is 20% to 30% of the total volume of ethyl orthosilicate, anhydrous ethanol, distilled water and Gama-methacryloxy propyl trimethoxyl silane; and the hybrid material hole sealing agent is prepared with a sol-gel method, wherein the 25vol.% nitric acid and 25vol.% ammonia water are used as pH regulators. The porosity factor of the plasma spraying coating processed by using the hybrid material hole sealing agent is reduced to 1 / 40 to 9 / 250 of that of a coating with unsealed holes, the electrochemical corrosion potential is increased by 65.2% to 65.8% of that of the coating with unsealed holes, and the corrosion current density is reduced to 1 / 370 to 1 / 500 of that of the coating with unsealed holes.

Owner:HOHAI UNIV

Coating composition and optical article

ActiveUS7442734B2Good Photochromic PropertiesImprove adhesionCosmetic preparationsNon-fibrous pulp additionOxygenHydrolysis

There is provided a coating composition which can be applied to a substrate such as a plastic lens so as to form a photochromic coating layer having good photochromic properties and excellent adhesion to the substrate on the surface of the substrate.This composition comprises, for example, as monomer components, 0.1 to 20 wt % of monomer having a group which produces a silanol group through hydrolysis such as γ-methacryloyloxypropyltrimethoxysilane and 0.1 to 50 wt % of monomer having at least one oxycarbonyl group in a molecule. The composition can further contain a maleimide compound as a monomer component and further desirably contains an amine compound.

Owner:TOKUYAMA CORP

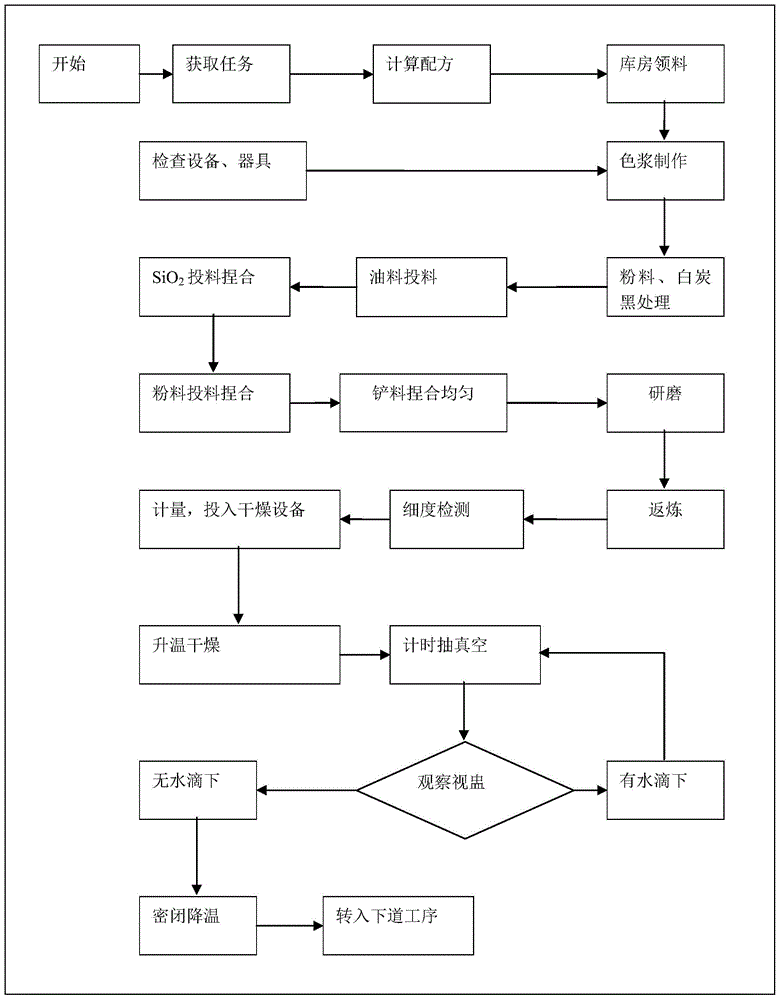

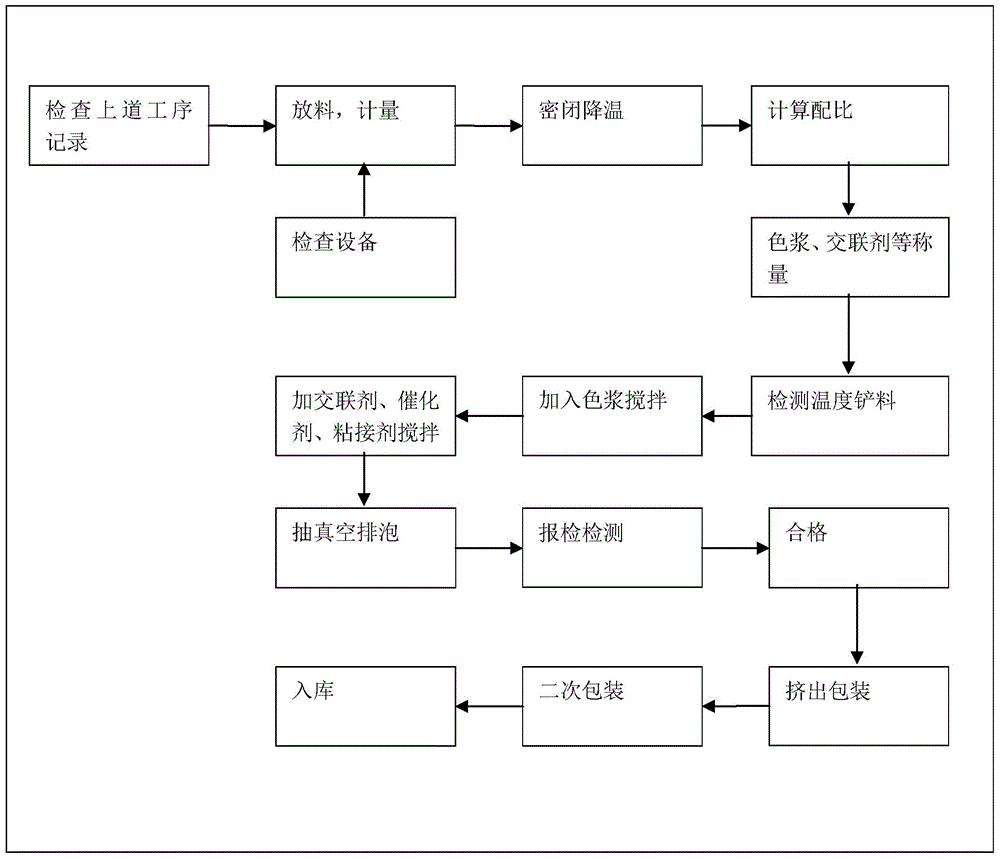

Special single-component jointing and gap filling silicon rubber for curing EMAS at room temperature and preparation method of special single-component jointing and gap filling silicon rubber

InactiveCN104672912AApplicable Liquidity RequirementsImprove flame retardant performanceSilanesAdhesive

The invention discloses special single-component jointing and gap filling silicon rubber for curing EMAS at room temperature and a preparation method of the special single-component jointing and gap filling silicon rubber. Low-viscosity alpha, omega-dihydroxy-polydimethylsiloxane is used as base rubber, linear polydimethylsiloxane is used as an additive, the hydroxyl content is increased, a fumed silica is adopted for reinforcing, a mixture of aluminum hydroxide and melamine cyanurate is used as flame-resistant filler, methyltris(methylethylketoxime)silane and tri(2-butaneneoxime)cinylsilane are used as crosslinking agents, aminopropyltriethoxysilane and gamma-methacryloxypropyltrimethoxysilane are used as adhesives, a production process is controlled, and then, the special single-component jointing and gap filling silicon rubber for curing EMAS at room temperature, which is good in flowability, capable of rapidly curing, good in flame retardance, moderate in strength and good in adhesive strength, is obtained, so that the application requirement of an EMAS system is met.

Owner:CHENGDU TALY TECH CO LTD +1

Soilless cultivation matrix of paeonia lactiflora and manufacturing method thereof

InactiveCN103503750AStrong water absorptionImprove the bactericidal effectAgriculture gas emission reductionCultivating equipmentsSodium BentonitePeat

The invention relates a soilless cultivation matrix of paeonia lactiflora. The soilless cultivation matrix comprises, by volume, 20-30 parts of peat, 10-15 parts of feculae bombycis, 10-12 parts of weathered coal, 15-20 parts of vinasse and 5-10 parts of modified plant ash. By weight, 3%-4% of bentonite, 1%-2% of gamma-methacryloxy propyl trimethoxyl silane, 1%-2% of canola oil, 0.8%-1.5% of sodium laurate, 3%-4% of tea saponin, 0.2%-0.5% of moringa oleifera seeds, 3%-4% of chitosan liquid, of the plant ash and moderate water are added into the plant ash. The solution is fully stirred for 1-2 hours at the revolving speed of 600-800rpm, granulated and dried. The cultivation matrix of the formula is used for soilless cultivation of the paeonia lactiflora, flower seedlings grow fast, branches and leaves are flourishing, the overall integration rate is high and can reach 78%, and the diameter of a flower is large and can reach more than 75mm.

Owner:合肥市天丰菌业科技有限公司

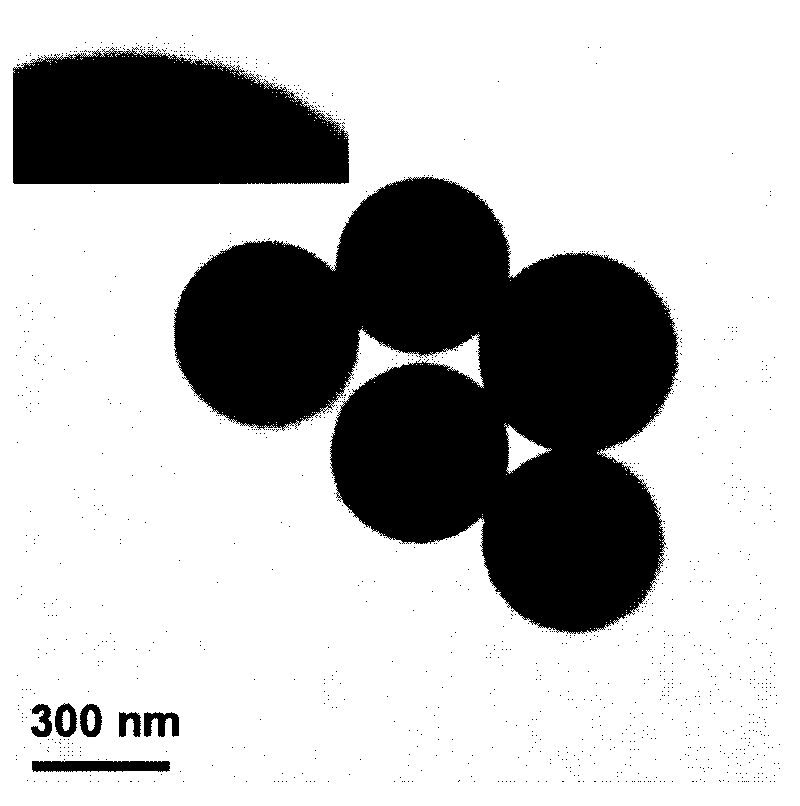

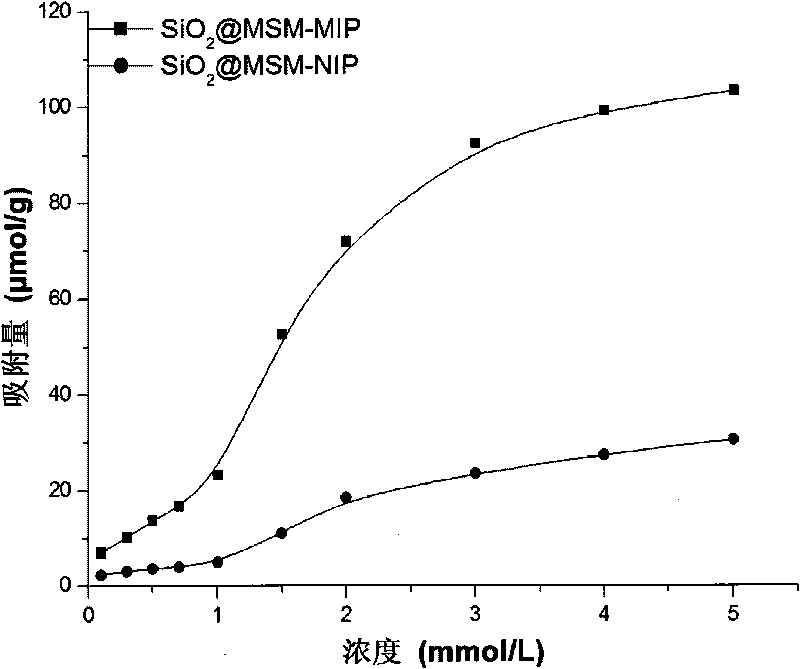

Preparation method of molecularly imprinted polymer on nano-silica gel surfaces of sulfonylurea herbicides

InactiveCN101757896AHighly selective adsorptionEfficient and fast separationOther chemical processesFunctional monomerSilanes

The invention relates to a preparation method of a molecularly imprinted polymer on nano-silica gel surfaces of sulfonylurea herbicides, which comprises the following steps: preparing SiO2 pellets; ultrasonically dispersing the prepared SiO2 pellets into a toluene solution of gamma-methacryloxypropyl trimethoxy silane, and carrying out backflow reaction to obtain modified SiO2 pellets; adding template molecules and functional monomers into a polymerization solvent and fully shaking up to obtain a pre-assembled solution; ultrasonically dispersing the modified SiO2 pellets into the polymerization solvent, and adding cross-linking agent, initiating agent and the pre-assembled solution; mixing, carrying out ice bath ultrasonic treatment, stirring, introducing N2 for removing oxygen, carrying out temperature programming thermal-initiated polymerization under the N2 atmosphere, centrifuging and removing supernatant liquid; and ultrasonically washing precipitates sequentially with a methanol-acetic acid solution and methanol to obtain polymer pellets the template molecules of which are removed. The molecularly imprinted polymer pellets prepared by the invention not only have specific recognition capability for the template molecules and analogs thereof but also have excellent characteristics of enrichment and recovery, thus the molecularly imprinted polymer pellets can be used as dispersed solid phase extraction materials for separating and enriching the sulfonylurea herbicides in environment, food and other complex samples.

Owner:NANJING MEDICAL UNIV

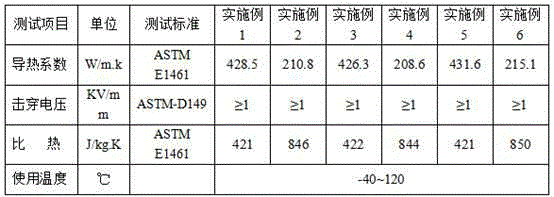

High-performance nano carbon cooling composite material

ActiveCN104559819AImprove fitImprove cooling effectFilm/foil adhesivesCoatingsTrimethylsilanePolyethylene glycol

The invention discloses a high-performance nano carbon cooling composite material, which is composed of two parts, namely a carrier and a coating, wherein the carrier is a copper tape or an aluminum tape; the coating is prepared from the following raw materials in parts by weight: 20-55 parts of organic resin, 20-60 parts of nano carbon, 1-5 parts of propyl trimethoxysilane or propyl trimethylsilane, 1-10 parts of gamma-methacryloxypropyltrimethoxysilane and 0.5-3 parts of polyethylene glycol. The nano carbon and the organic resin are compounded and coated on the copper tape or the aluminum tape, so that the fitting property of the coating material and a base material is improved; the heat dissipation performance can also be improved; the machinability, the flexibility and the heat dissipation performance of the product can be improved by the copper tape or the aluminum tape as the carrier of the nano carbon or the resin; and the compatibility with the resin material can be improved by nano carbon pretreatment by the gamma-methacryloxypropyltrimethoxysilane, so that the overall mechanical property of the composite material is improved.

Owner:HUIZHOU KINGBALI TECH

Nano-silica-modified composite water-based ink and preparation method thereof

The invention relates to the field of water-based ink and discloses nano-silica-modified composite water-based ink. The ink comprises components as follows: nano-silica-modified water-based acrylic resin, water-based polyester resin, water, ethanol, a pigment, an antifoaming agent, a dispersing agent, a leveling agent and a buffering agent. A preparation method of the ink comprises steps as follows: firstly, preparing silane coupling agent modified inorganic nanoparticles from nano-silica, the ethanol, the water and gamma-methacryloxy propyl trimethoxyl silane; then preparing nano-silica-modified water-based acrylic resin from an alkyl acrylate monomer, a hydroxyalkyl acrylate monomer, the silane coupling agent modified inorganic nanoparticles, polyethylene glycol, a water-soluble initiator, an emulsifier and the water; finally, preparing the nano-silica-modified composite water-based ink from the nano-silica-modified water-based acrylic resin, the water-based polyester resin, the water, the ethanol, the pigment, the antifoaming agent, the dispersing agent, the leveling agent and the buffering agent. The water-based ink has excellent wear resistance and chemical resistance.

Owner:长兴艾飞特科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com