Preparation method of optical anti-reflection polyester films

A polyester film, optical technology, applied in the direction of optics, optical components, coatings, etc., can solve the problems of increasing light transmittance, and the light transmittance of polyester film cannot meet relevant technical requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

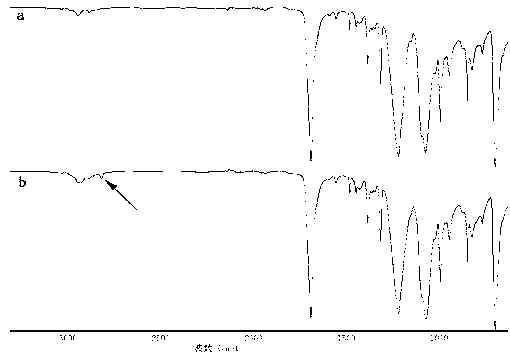

Image

Examples

Embodiment 1

[0020] (1) Preparation of polyester film: Wash about 100 pieces of polyester film with a size of (4×4cm) that have been cut with detergent, distilled water, and acetone several times in sequence, and then put the polyester film into Vacuum-dry in a vacuum oven at 70°C for 12 hours, take it out, and keep it sealed.

[0021] (2) Synthesis of KH570-(meth)acrylate monomer copolymer: add 9.5ml KH570, 1.1ml methyl methacrylate, 4.3ml ethyl acetate, 4.3ml 2-butanone and 0.164g Azobisisobutyronitrile, the solid content in this reaction is 60%, the initiator content is 2% of the amount of KH570 and (meth)acrylic ester monomer substances, the volume ratio of ethyl acetate and 2-butanone solvent The ratio is 1:1; the three-necked flask was evacuated and nitrogen-gassed, and this operation was repeated three times, and then the three-necked flask was placed in a constant temperature oil bath at 76°C and stirred for 3 hours. After the reaction, the product was poured into a dry container a...

Embodiment 2

[0024] (1) Preparation of polyester film: Wash about 100 pieces of polyester film with a size of (4×4cm) that have been cut with detergent, distilled water, and acetone several times in sequence, and then put the polyester film into Vacuum-dry in a vacuum oven at 70°C for 12 hours, take it out, and keep it sealed.

[0025](2) Synthesis of KH570-(meth)acrylate monomer copolymer: add 3.6ml KH570, 3.8ml methyl methacrylate, 0.7ml ethyl acetate, 1.6ml 2-butanone and 0.041g Azobisisobutyronitrile, the solid content in this reaction is 80%, the initiator content is 0.5% of the amount of KH570 and (meth)acrylic ester monomer substances, the volume ratio of ethyl acetate and 2-butanone solvent The ratio is 3:7; the three-necked flask was evacuated and nitrogen-gassed, and this operation was repeated three times, and then the three-necked flask was placed in a constant temperature oil bath at 80°C and stirred for 1 hour. After the reaction, the product was poured into a dry container a...

Embodiment 3

[0028] (1) Preparation of polyester film: Wash about 100 pieces of polyester film with a size of (4×4cm) that have been cut with detergent, distilled water, and acetone several times in sequence, and then put the polyester film into Vacuum-dry in a vacuum oven at 70°C for 12 hours, take it out, and keep it sealed.

[0029] (2) Synthesis of KH570-(meth)acrylate monomer copolymer: add 3.6ml KH570, 5.6ml butyl methacrylate, 16.3ml ethyl acetate, 7.0ml 2-butanone and 0.041g Azobisisobutyronitrile, the solid content in this reaction is 30%, the initiator content is 0.5% of the amount of KH570 and (meth)acrylic ester monomer substances, the volume ratio of ethyl acetate and 2-butanone solvent The ratio is 7:3; the three-necked flask was evacuated and nitrogen-gassed, and this operation was repeated three times, then the three-necked flask was placed in a constant temperature oil bath at 70°C and stirred for 5 hours. After the reaction, the product was poured into a dry container and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com