Modified phosphorous slag used as plastic filler and preparation method thereof

A phosphorous slag and modification technology, applied in the field of modified phosphorous slag and its preparation, can solve the problems of polluting the environment, waste of resources, etc., and achieve the effects of improving binding, improving dispersibility, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

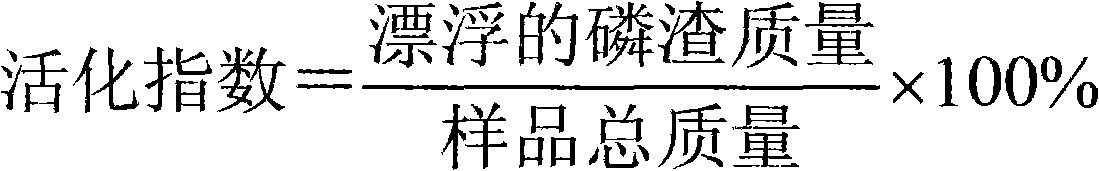

[0034] A modified phosphorus slag used as a plastic filler and a (dry method) preparation method thereof, the specific production process of the modified phosphorus slag is as follows: at 100 ° C, 1 g of stearic acid is dispersed in 100 g of stearic acid at a speed of 800 rpm Phosphorus slag, stirred and dispersed, slowly lowered to room temperature, and finally prepared into dry modified phosphorus slag. The modification effect on phosphorus slag was evaluated by the activation index and wetting contact angle (the larger the activation index value and the wetting contact angle value, the stronger the lipophilicity after the introduction of organic lipophilic groups on the surface of phosphorus slag). The performance indicators are as follows in Table 1:

[0035] Comparison of physical properties before and after modification of phosphorous slag in Table 1 Example 1

[0036]

Embodiment 2

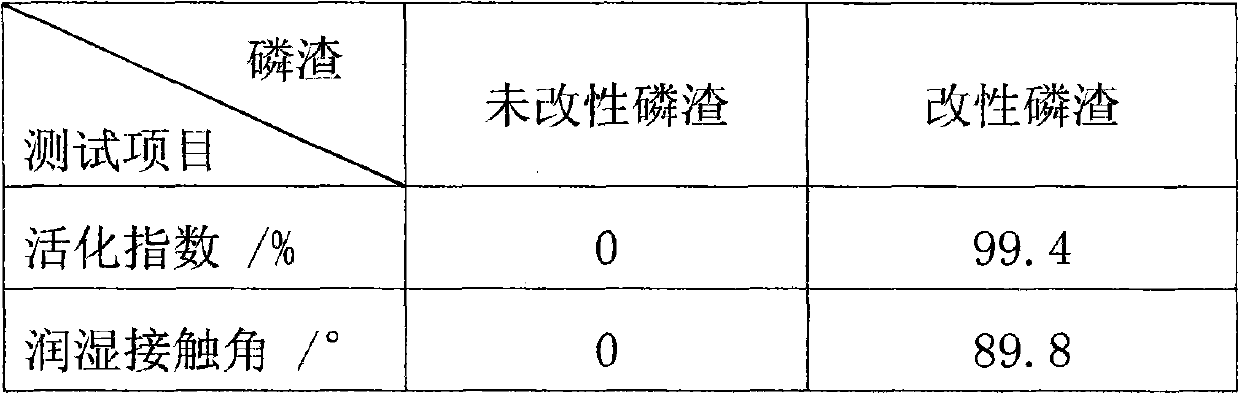

[0038]A modified phosphorus slag used as a plastic filler and a (wet method) preparation method thereof. The specific production process of the modified phosphorus slag is: at room temperature, 1 g of silane KH-570 is dispersed in the Add 50g of distilled water to 100g of phosphorus slag at room temperature, stir and disperse, place the phosphorus slag slurry in an oven at 80°C to remove most of the water, then raise the temperature to 120°C for drying, and finally prepare wet-process modified phosphorus slag. The modification effect on phosphorus slag is evaluated by activation index and wetting contact angle. The performance indicators are as follows in Table 2:

[0039] Table 2 Comparison of physical properties before and after modification of phosphorus slag in Example 2

[0040]

Embodiment 3

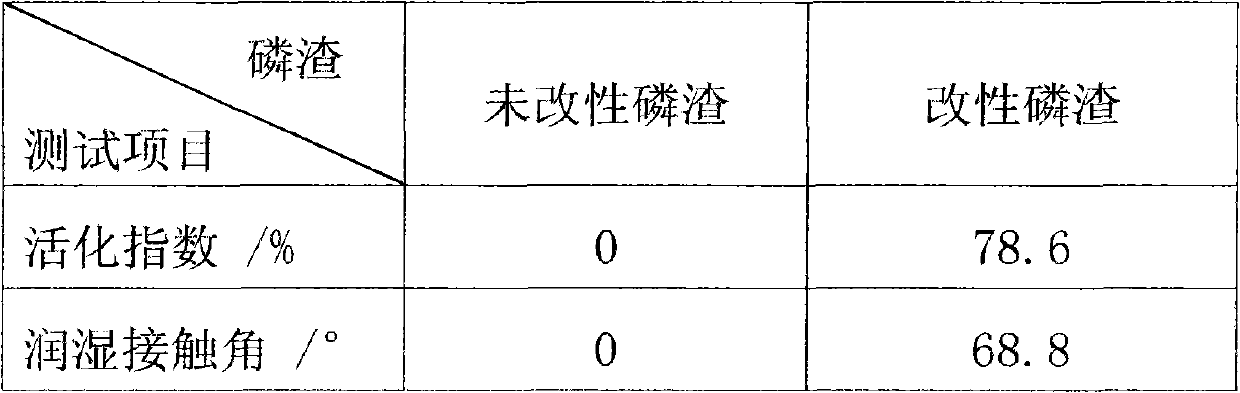

[0042] A modified phosphorus slag and thermoplastic composite material product. The specific production process of the phosphorus slag composite material is: at room temperature, 10g of modified phosphorus slag is dispersed in 100g of polyethylene resin with a stirrer at a speed of 600rpm, stirred and dispersed , and finally prepare a composite material in which phosphorus slag is used as a plastic filler. The tensile strength and elongation at break of the composite material are tested according to GB / T 1040-2006, as shown in Table 3 below:

[0043] The composite material of table 3 embodiment 3 and the physical performance contrast of pure polyethylene

[0044]

[0045] The result of comparing the physical properties of the composite material of Example 3 and pure polyethylene in Table 3 shows that the modified phosphorus slag can be used as a reinforcing filler to fill polyethylene resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com