Cement porous polymer composite heat insulation plate

A porous polymer and composite thermal insulation technology, which is applied in the field of cement porous polymer composite thermal insulation board, can solve the problems of reducing the service life of the building, easy cracking and falling off of the exterior surface, and affecting residential use, so as to reduce the surface density, reduce the weight, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

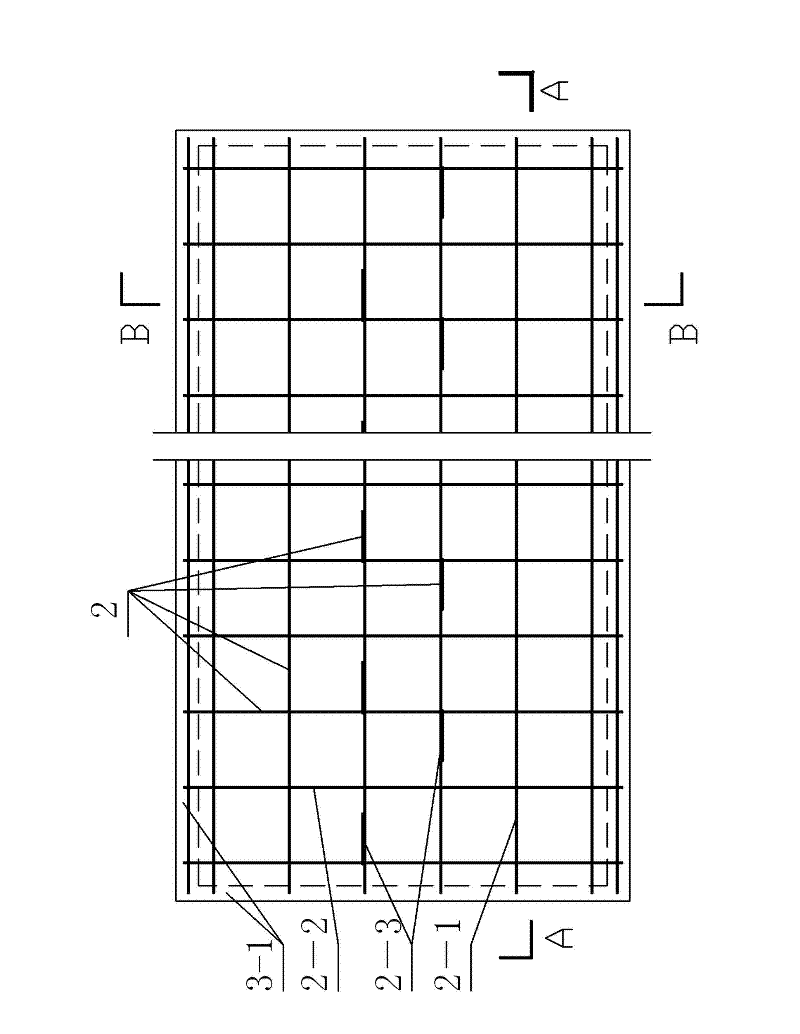

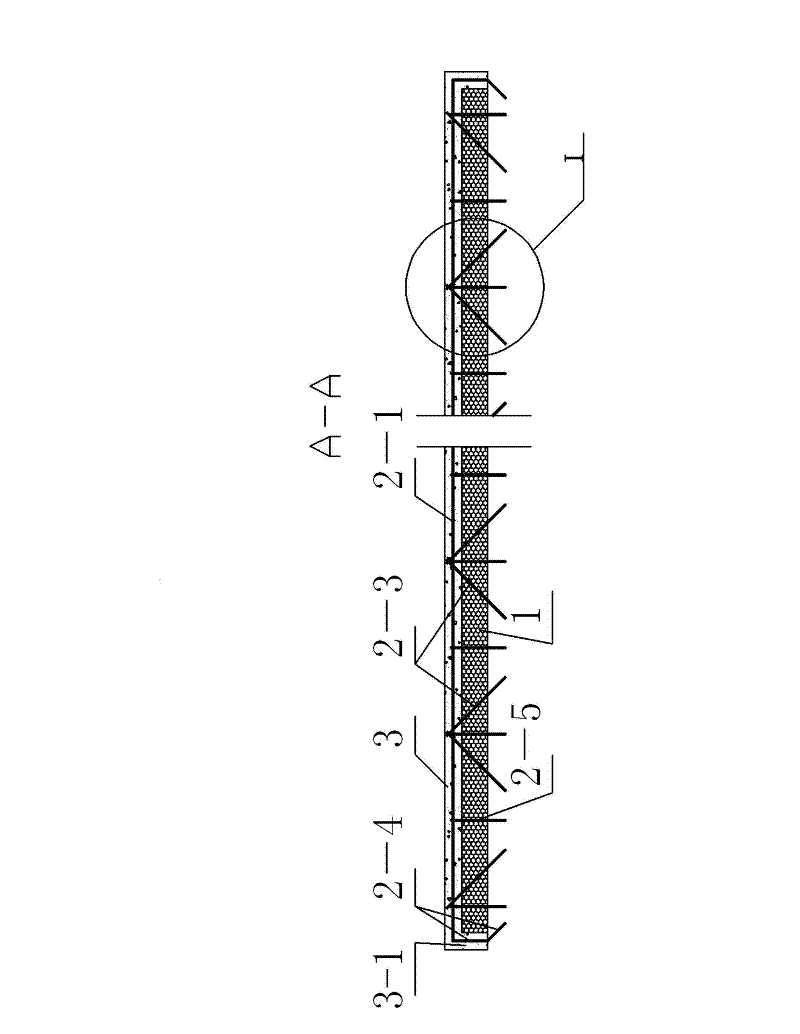

[0022] The content of the present invention will be described in detail below in conjunction with the accompanying drawings, specific implementation methods, and examples:

(1) Specific implementation methods

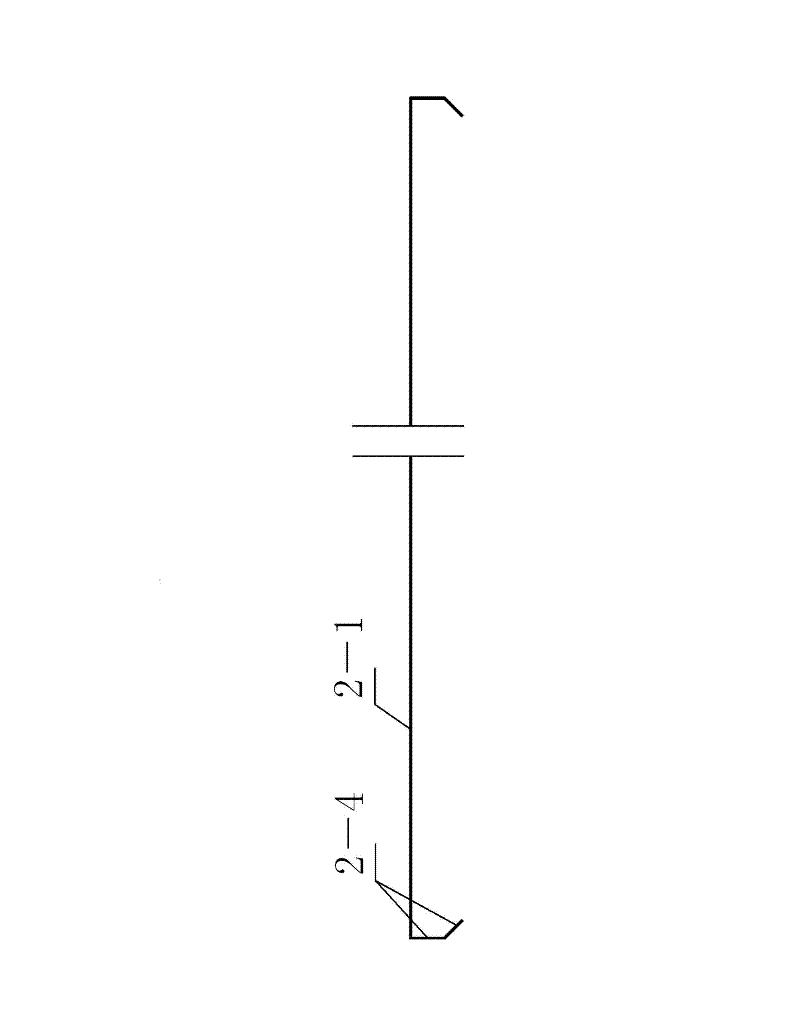

[0023] The specific embodiment of the present invention provides a cement porous polymer composite thermal insulation board, which is characterized in that it includes a high-efficiency thermal insulation layer 1, a three-dimensional rigid skeleton 2 and a cement concrete layer 3 with porous polymer as a lightweight aggregate. The rigid skeleton 2 is connected between the cement concrete layer 3 and the high-efficiency thermal insulation layer 1 and is respectively embedded in the cement concrete layer 3 and the high-efficiency thermal insulation layer 1 so that the three form an integral plate member.

[0024] The cement concrete layer 3 with porous polymer as lightweight aggregate is mainly prepared from porous polymer, cement, stone powder or fly ash, water and water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com