Reinforcement lightweight aggregate concrete flat beam structure

A lightweight aggregate concrete and lightweight aggregate technology, applied in building components, building structures, earthquake resistance, etc., can solve problems such as non-flat beam structures, achieve spacious and comfortable building space, reduce building energy consumption, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

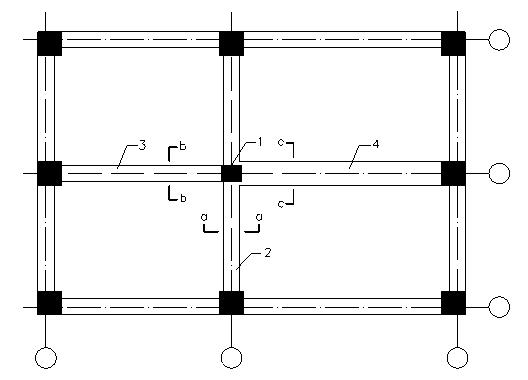

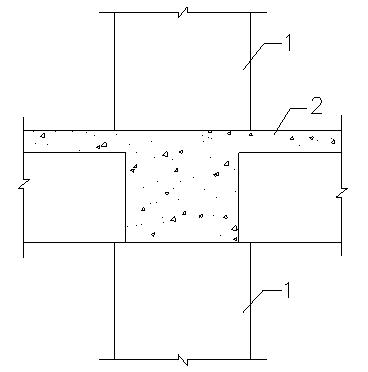

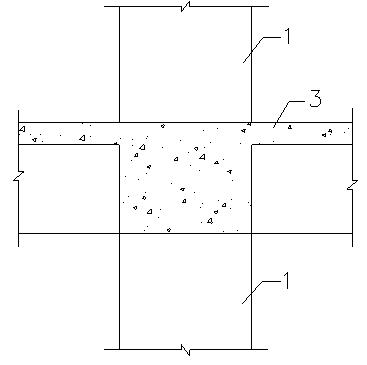

[0025] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail together with the accompanying drawings.

[0026] The reinforced lightweight aggregate concrete flat beam structure of the present invention includes columns, beams and plates, and is characterized in that: the beam is a flat beam made of steel bars and lightweight aggregate concrete, and the beam width of the flat beam is greater than or equal to the beam height; the column is a reinforced lightweight aggregate concrete column.

[0027] In this embodiment, the dry apparent density of the lightweight aggregate concrete is lower than 1950kg / m 3 ; The amount of each component of the lightweight aggregate concrete per cubic meter of material is: cement: sand: lightweight aggregate: fly ash: silica fume: water: superplasticizer = 425kg: 650kg: 550kg: 80kg: 35kg: 160kg: 7kg. The lightweight aggregate is shale ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com