High-performance hollow floor plate and column joint

A technology of slab-column joints and hollow floors, which is applied to floors, building components, buildings, etc., can solve the problems of weakening the punching shear performance and bearing capacity of slab-column joints, and achieve the effect of improving ductility and seismic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

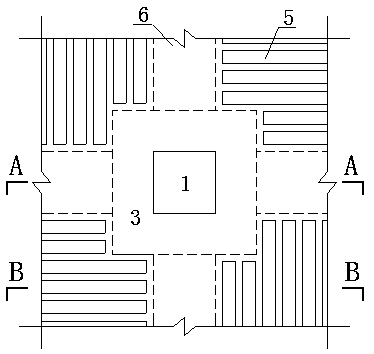

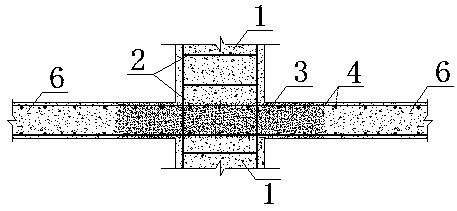

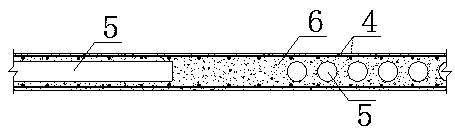

[0025] The high-performance hollow floor slab column node of the present invention includes concrete column 1, column longitudinal reinforcement and stirrup 2, solid ECC part 3, cylinder core 4, cylinder core area concrete 5, and slab longitudinal reinforcement 6.

[0026] The solid ECC part 3 of the present invention is only used for local floor slabs around the column, and other parts and columns are made of ordinary concrete, and the thickness of the slab is h Should not be less than 180mm. The width of the solid ECC part 3 should not be less than (0.5 h 0 +100) mm, h 0 is the effective height of the board.

[0027] The core 4 of the present invention adopts a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com