A shock-resistant anti-theft bottle cap

An anti-theft bottle cap and impact-resistant technology, which is applied in the field of bottle caps, can solve problems such as deformation and loosening of the safety ring, liquid leakage in the bottle, and detachment of the safety ring, so as to avoid tooth slipping or chipping, not easily deformed or loose, even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

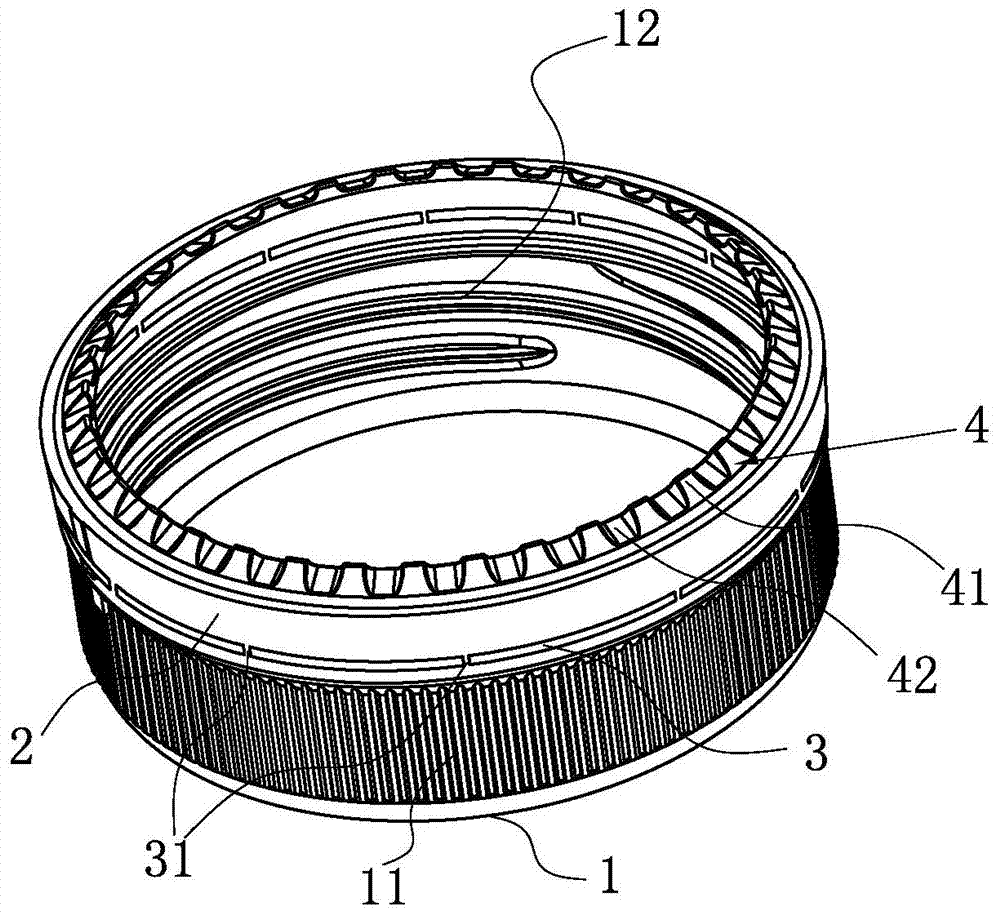

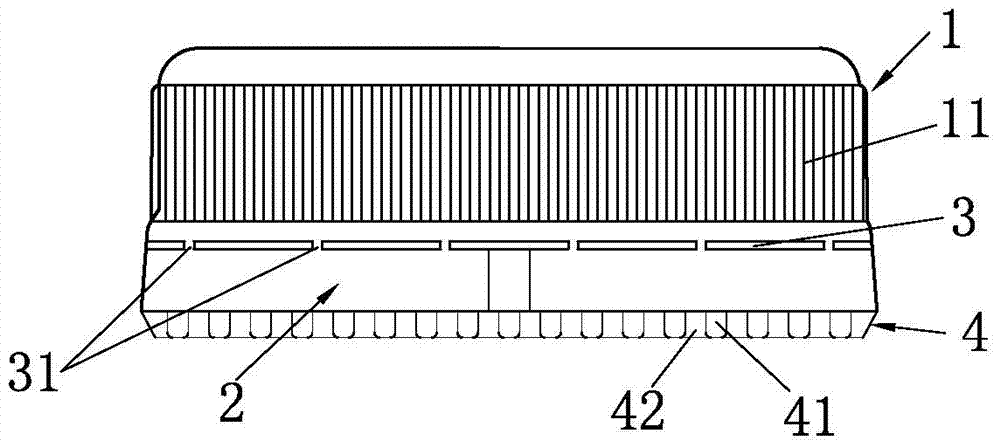

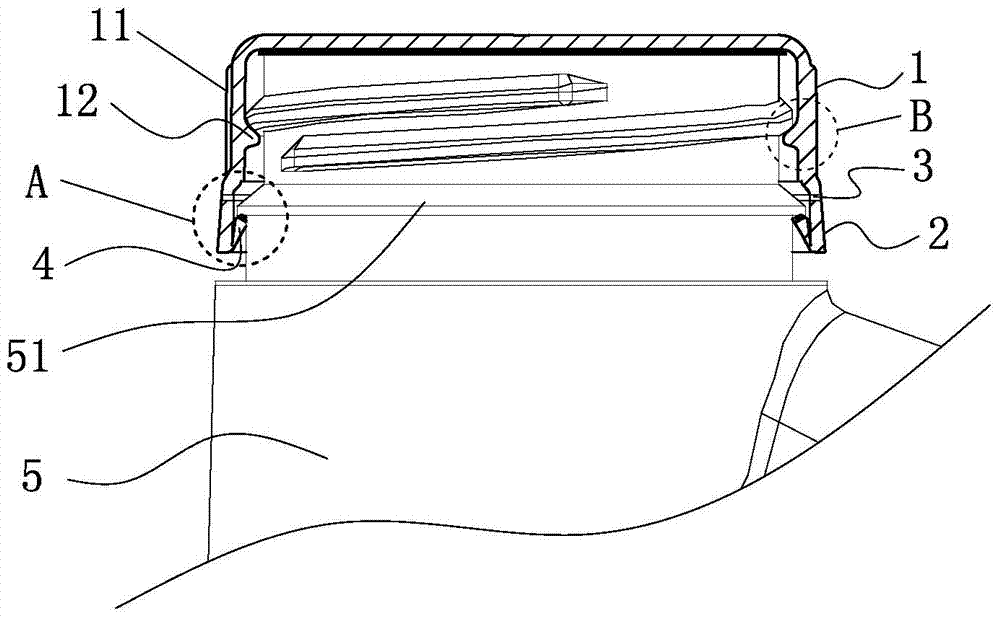

[0018] Such as Figure 1 to Figure 5 As shown, an impact-resistant and anti-theft bottle cap includes an integrally injection-molded bottle cap body 1, a safety ring 2 and an annular anti-theft skirt 4. The side wall of the bottle cap body 1 is formed with an internal thread 12. After injection molding, the The cutting knife with equidistant gaps cuts and processes between the bottle cap body 1 and the safety ring 2 to form a ring slit 3. On the ring slit 3, there are several holes connecting the bottle cap body 1 and the safety ring 2 at equal intervals. The connecting bridge 31, when unscrewing the bottle cap, the connecting bridge 31 is easy to break under the action of the rotating torque; the annular anti-theft skirt 4 is reversibly connected to the edge of the safety ring 2, and the annular anti-theft skirt 4 4 Form a ring of flanges o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com