Patents

Literature

48results about How to "Avoid sliding teeth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

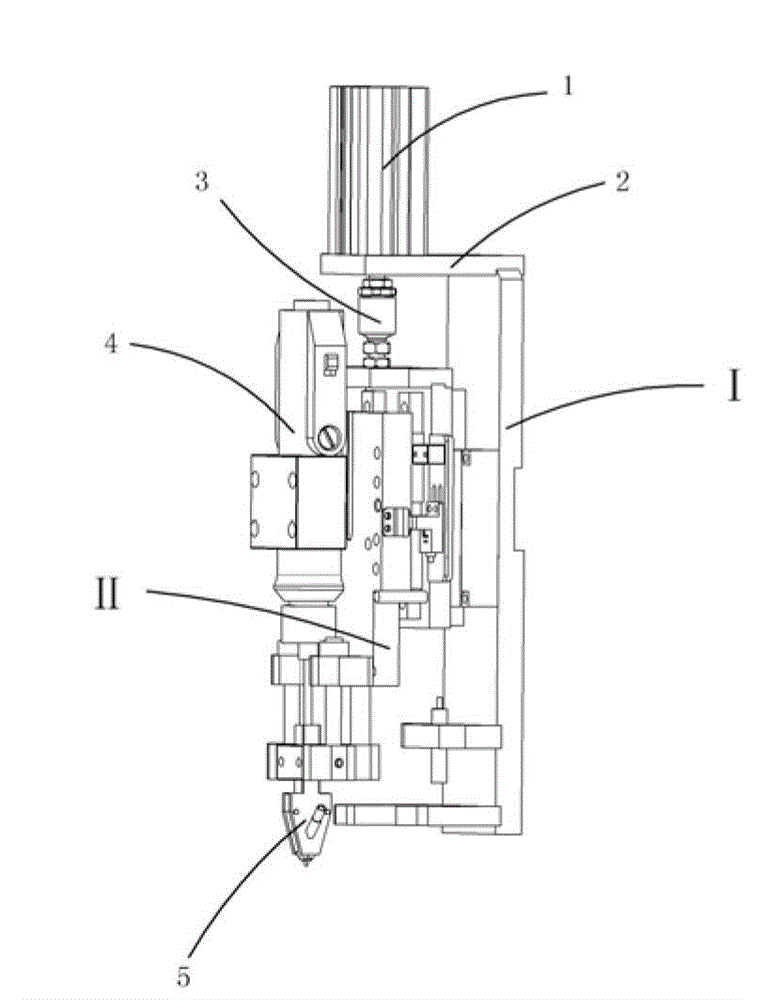

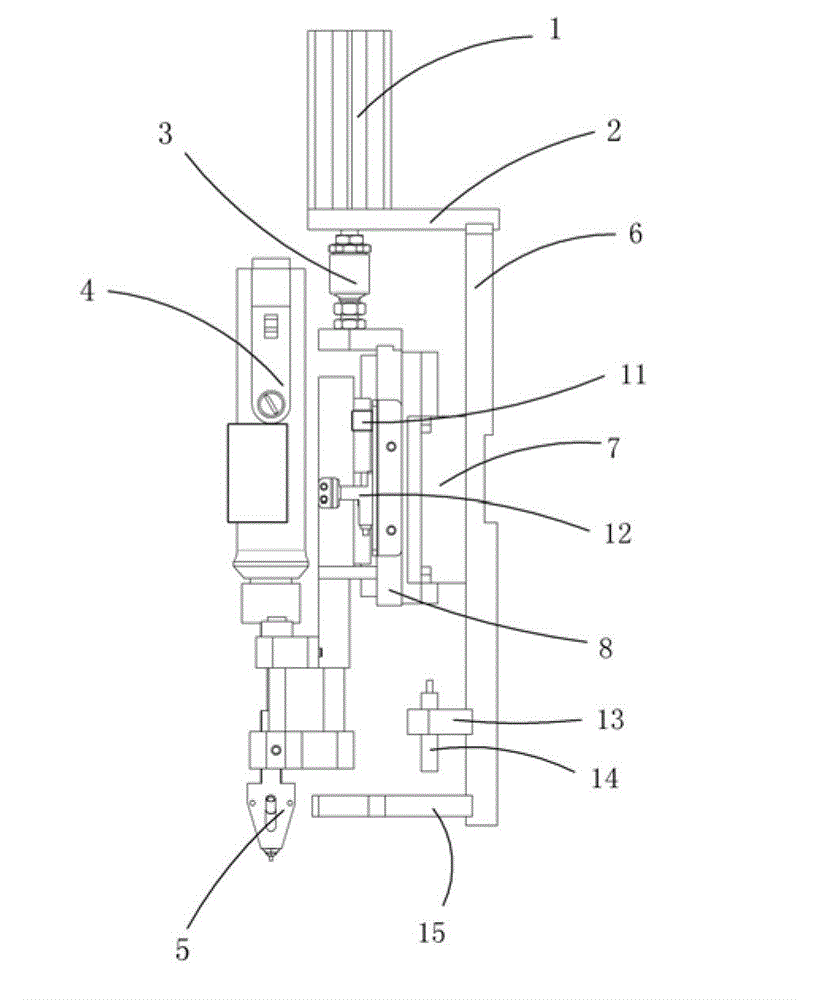

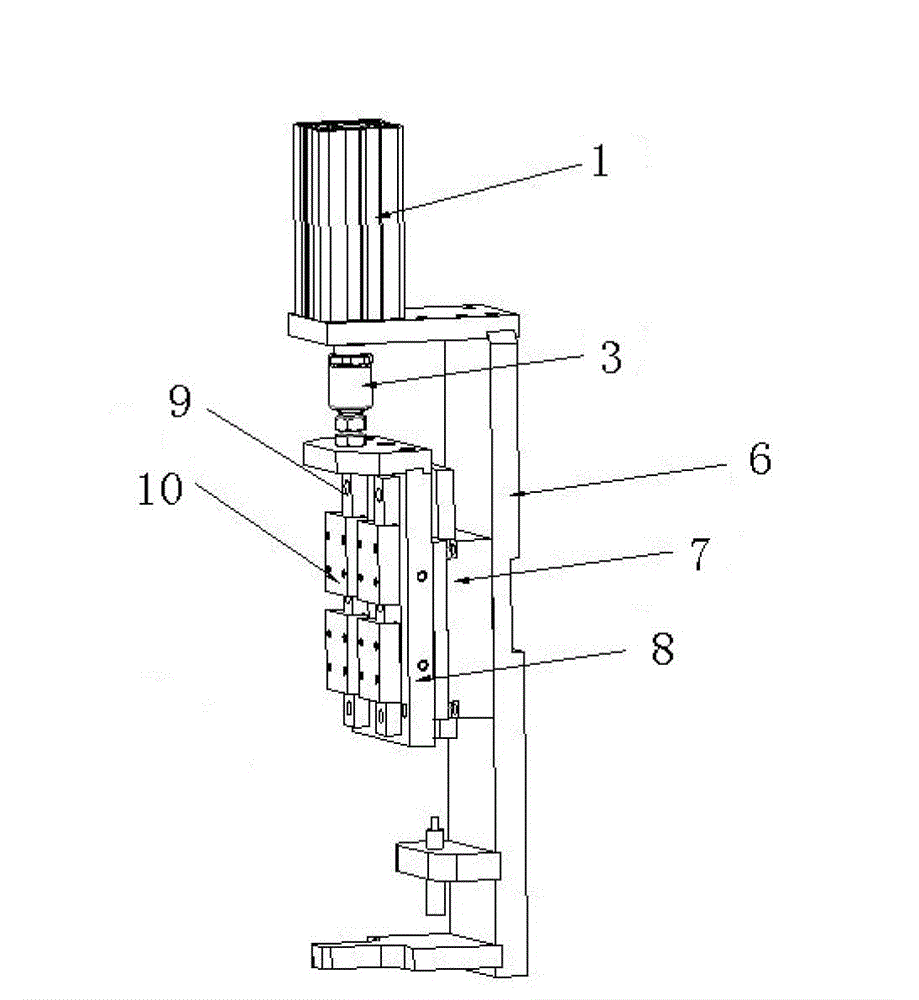

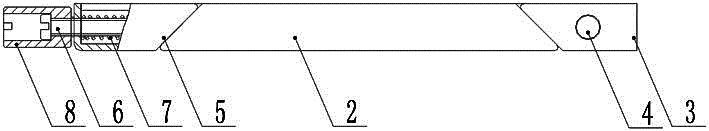

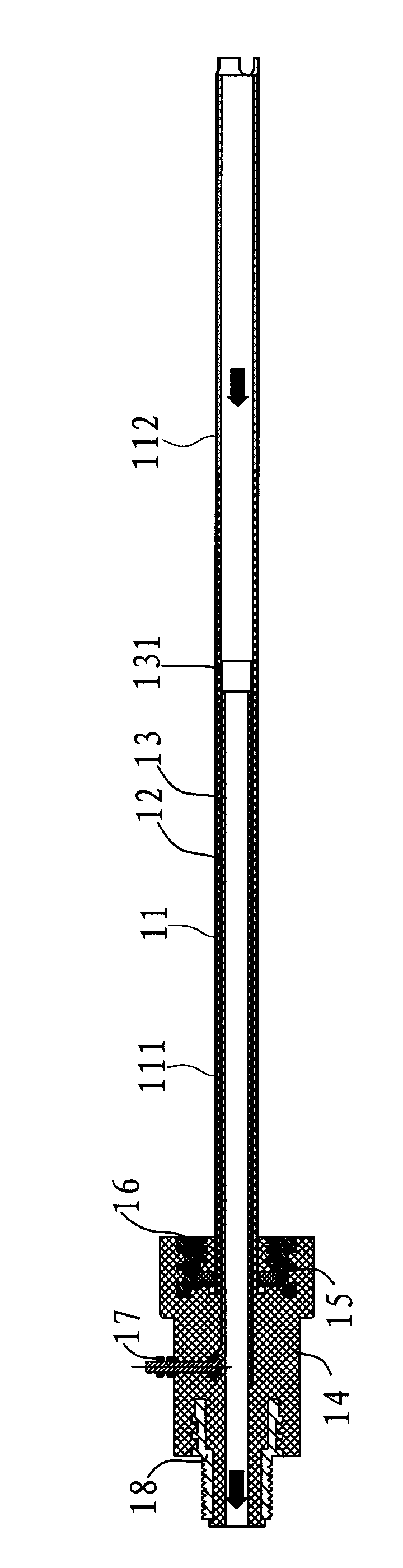

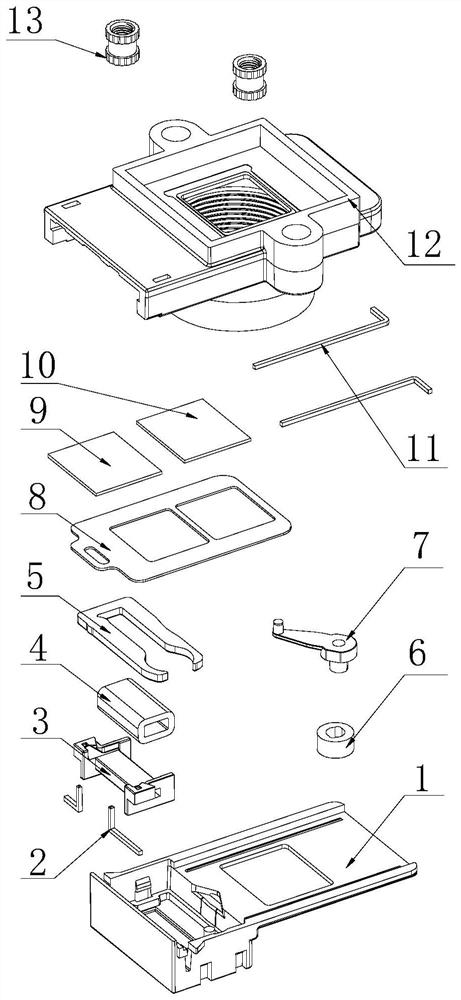

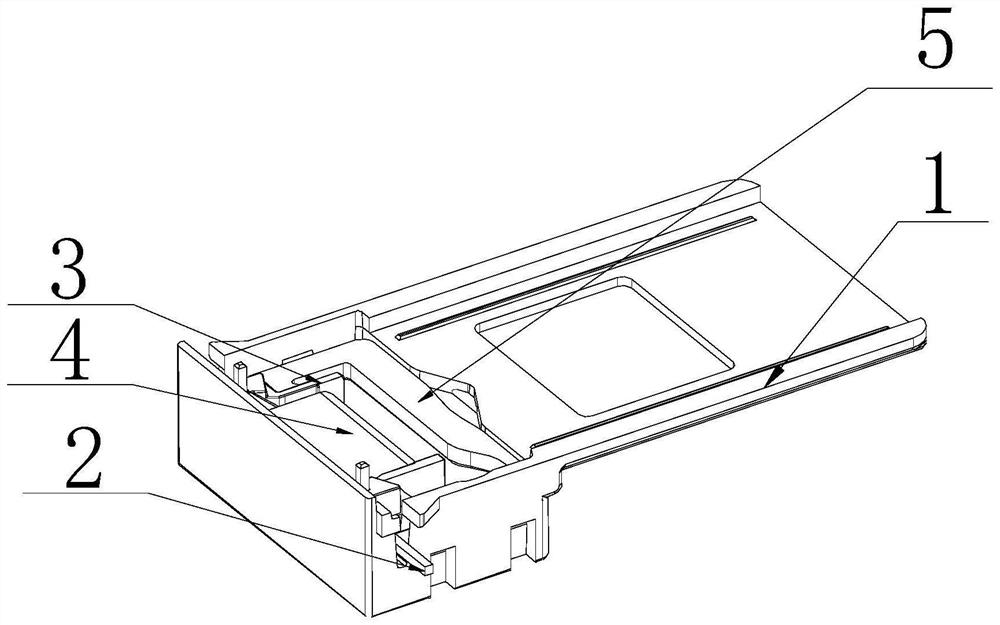

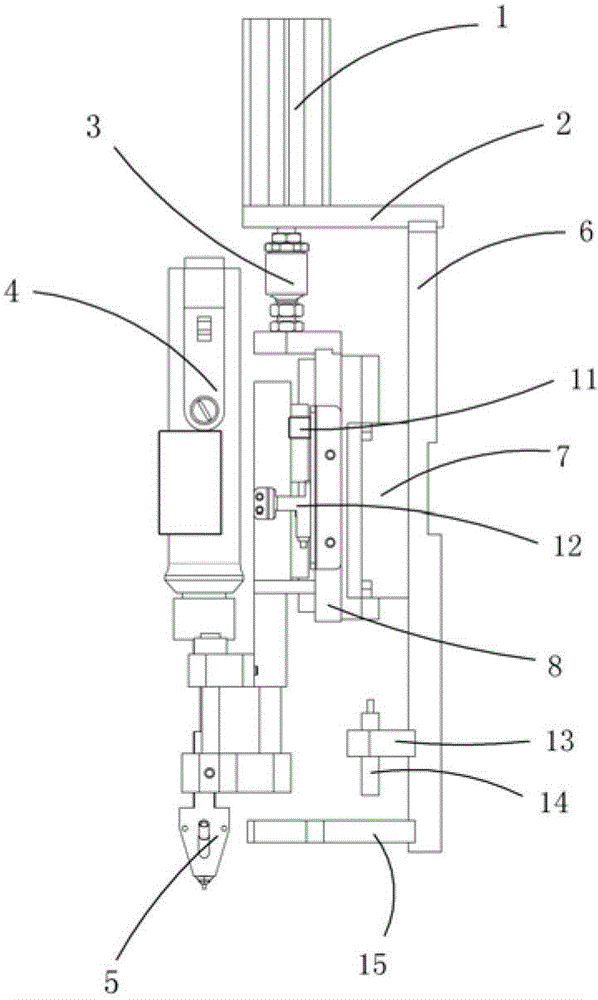

Automatic screw locking elastic mechanism

The invention relates to an automatic screw locking elastic mechanism, of which a downward pushing cylinder is connected with a Z-axis moving mechanism; a spring mechanism is arranged on the Z-axis moving mechanism; an electronic screwdriver bit is arranged on the spring mechanism, the lower end of the electric screwdriver bit is connected with a screw chuck; the upper end of a support plate of the Z-axis moving mechanism is connected with a cylinder installation plate, and the lower end of the support plate is connected with a limit plate; a guide plate is arranged on the support plate; a guide sliding plate is arranged on the guide plate, a slide rail is arranged on the guide sliding plate, and a side block is arranged on the slide rail in a matched manner, a moving plate is fixedly connected with the slide block; the upper part of the moving plate is connected with a fixing plate through springs a and b, and the lower part of the moving plate is connected with a buffer plate; a blind hole is arranged in the moving plate, and a spring c is arranged in the blind hole; and a buffer limit pillar penetrates through the buffer plate, is inserted in the blind hole and is in contact with the spring c. Through the driving of the downward pushing cylinder, the electric screwdriver bit is driven to move downwards, meanwhile, a screw is driven to move downwards and to be rotatably attached on a product in a locked manner, the spring mechanism has a protective effect on the screw and the product, and the whole mechanism stably operates.

Owner:上海莘翔自动化科技有限公司

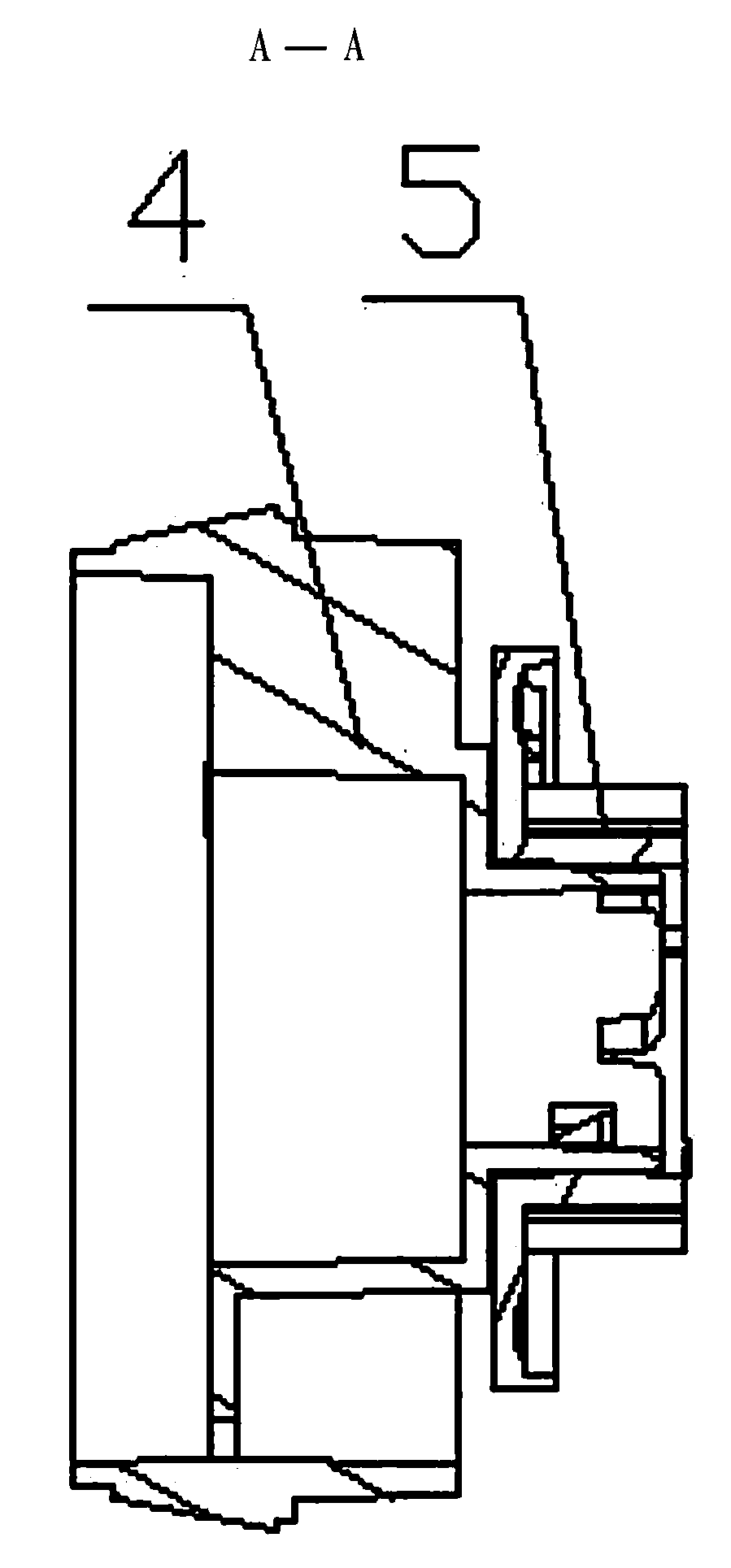

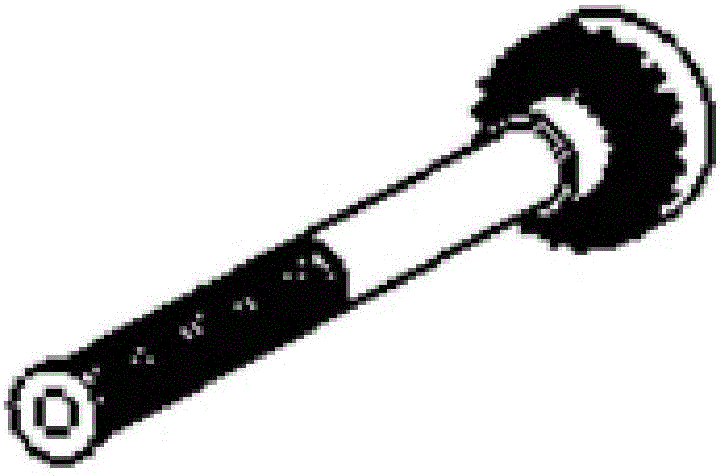

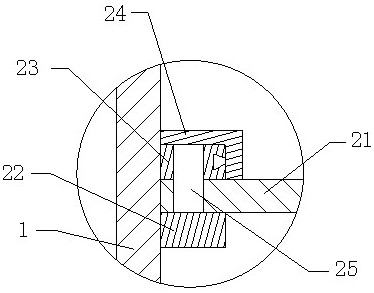

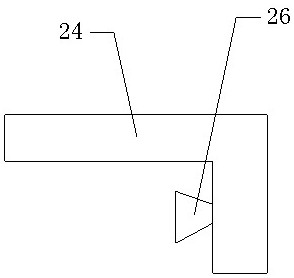

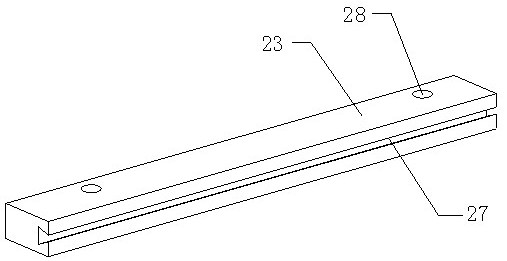

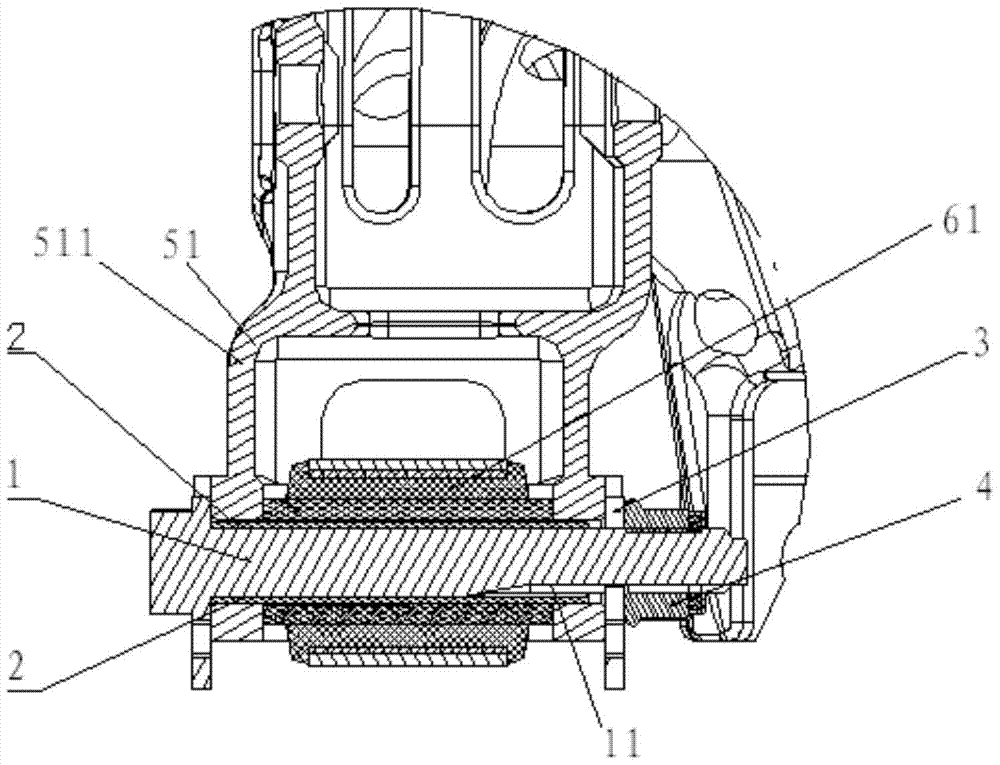

A printed board wedge locking device

ActiveCN104895878AAvoid sliding teethImprove reliabilityFriction grip releasable fasteningsEngineeringRivet

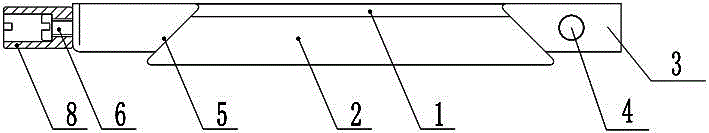

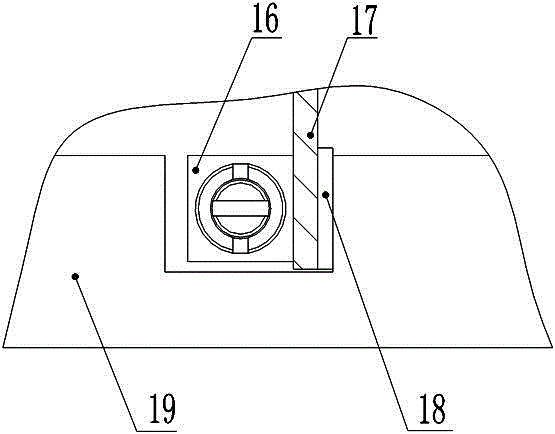

The invention provides a printed board wedge locking device comprising a guide rail (1), a slider (2), a fixing block (3), a countersunk head hollow rivet (4), an extrusion block (5), a bolt (6), a spring (7) and a knob (8). One end of the guide rail (1) is fixed on the fixing block (3) through the countersunk head hollow rivet (4); the slider (2) and the extrusion block (5) are located in a guide groove the guide rail (1) and can move along the guide rail (1). The bolt (6) is fixed in a threaded hole (9) in one end of the guide rail (1) after penetrating through the knob (8), the extrusion block (5) and the spring (7) in turns. The knob (8) is matched with the bolt (6) through threads. When being rotated, the knob (8) can move axially along the bolt (6), extrude the extrusion block (5) and make the slider (2) protrude. The printed board wedge locking device is simple in structure, low in cost, light in weight, good in heat conduction and electric conduction effects and high in reliability.

Owner:CHENGDU LATEST ELECTRONICS TECH

Screw fastening jig

ActiveCN105750898AAvoid sliding teethImprove screw locking efficiencyMetal working apparatusBiochemical engineering

Owner:昆山铭世特精密机械有限公司

Locking member, locking structure and air conditioner

ActiveCN107606759AAchieve lockingImprove fixation efficiencyLighting and heating apparatusSpace heating and ventilation detailsEngineeringMechanical engineering

The invention discloses a locking member, a locking structure and an air conditioner. The locking member comprises a plate body part; a rotary shaft is arranged at one end of the plate body part; a clamping-connection part is arranged at the other end of the plate body part, thus, locking of the two parts can be achieved, and compared with the traditional mode that the two parts are fixed throughscrews, the fixing efficiency between the two parts is improved; and meanwhile, the screw loosening phenomenon caused by repeated screw turning can be avoided, and thus damage of a fixed structure canbe effectively avoided.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

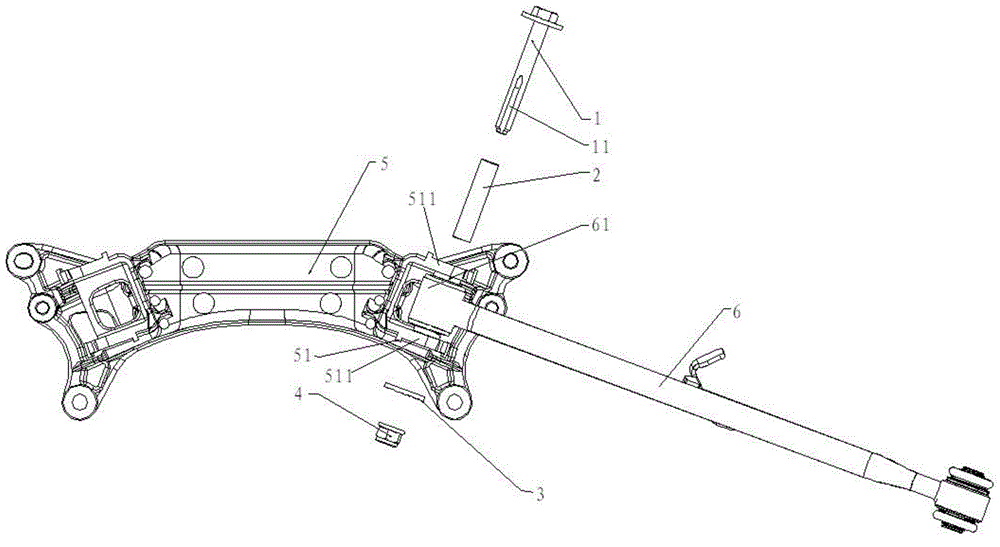

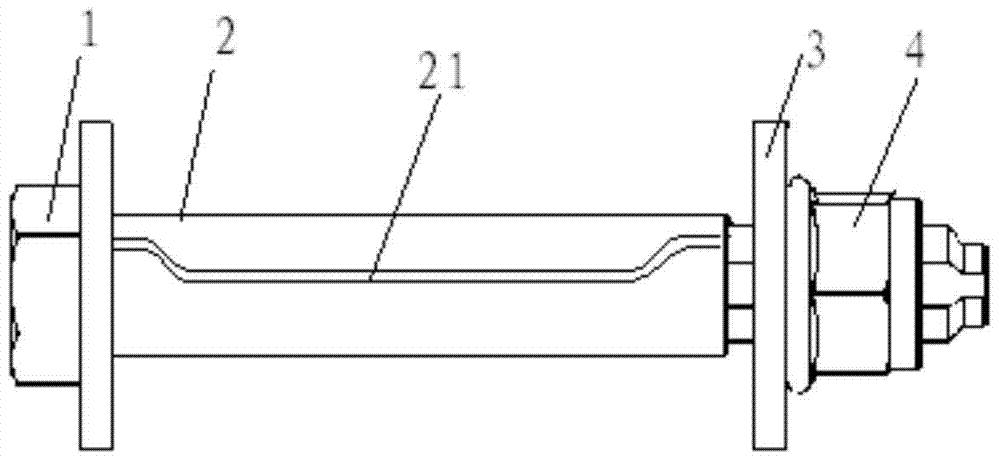

Rear wheel camber angle adjusting device of automobile

The invention discloses a rear wheel camber angle adjusting device of an automobile. The rear wheel camber angle adjusting device includes an eccentric bolt, an elastic sleeve, an eccentric spacer and a locknut. The eccentric bolt is sleeved with the elastic sleeve which is positioned among the eccentric bolt, a lower swing arm installing head and a lower swing arm mounting rack, an axial through groove is arranged on the elastic sleeve, the locknut is screwed up to compel the two ends of the elastic sleeve to shrink to the middle, and the axial through hole extends outwards along the radial direction due to the axial pressing force, namely the elastic sleeve expands in radial direction so as to compensate assembling clearances among the eccentric bolt, the lower swing arm installing head and the lower swing arm mounting rack, the eccentric bolt is prevented from shaking in a lower swing arm and a rear subframe, and the locknut is prevented from being deflected on the eccentric bolt by the shake, the screw loose of the eccentric bolt is reduced, and the service life of the eccentric bolt is improved, and meanwhile the rear wheel camber angle is accurately positioned b the eccentric bolt, and the safety performance of the automobile is improved.

Owner:CHERY AUTOMOBILE CO LTD

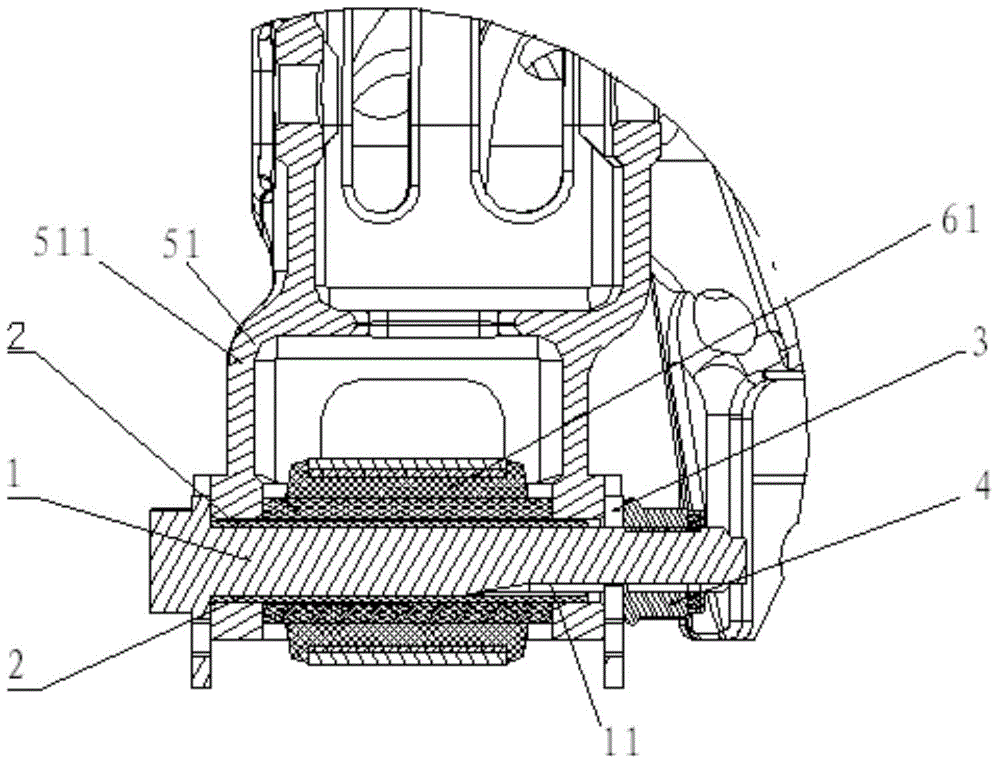

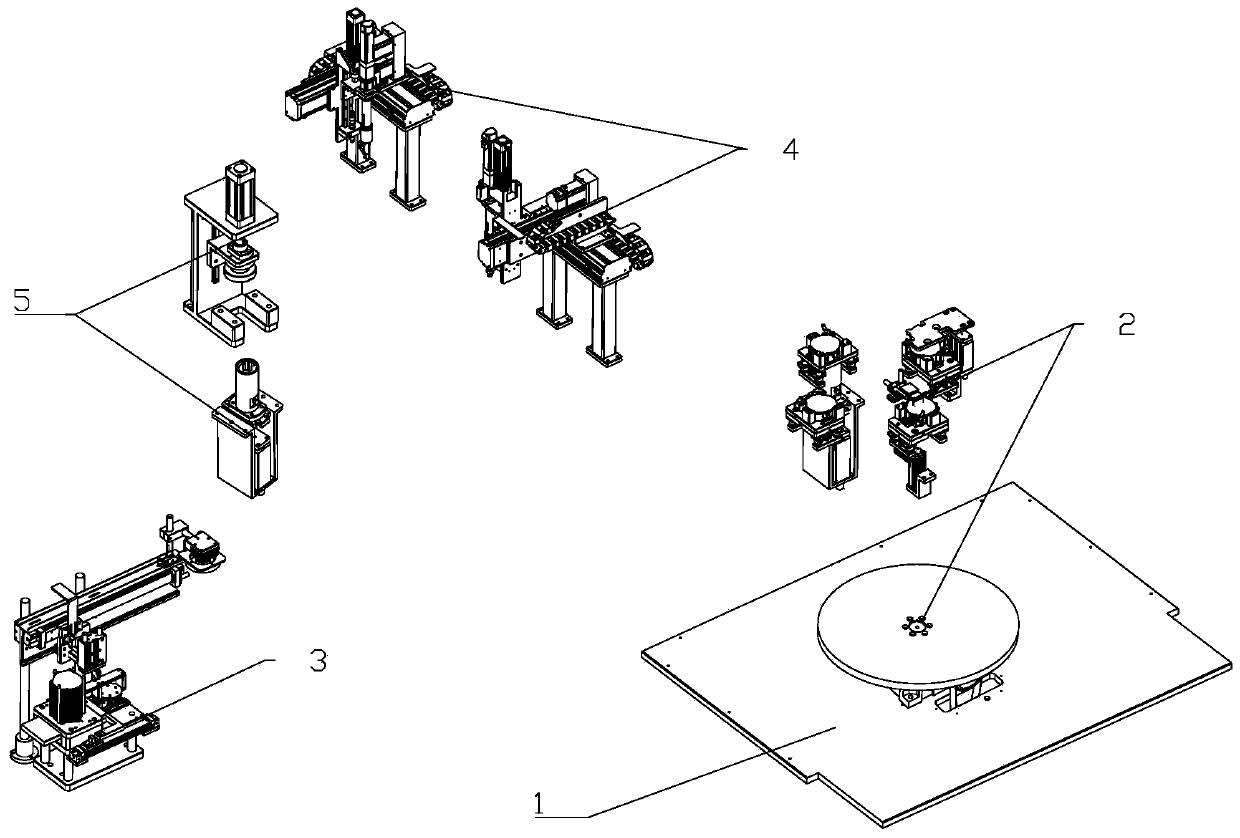

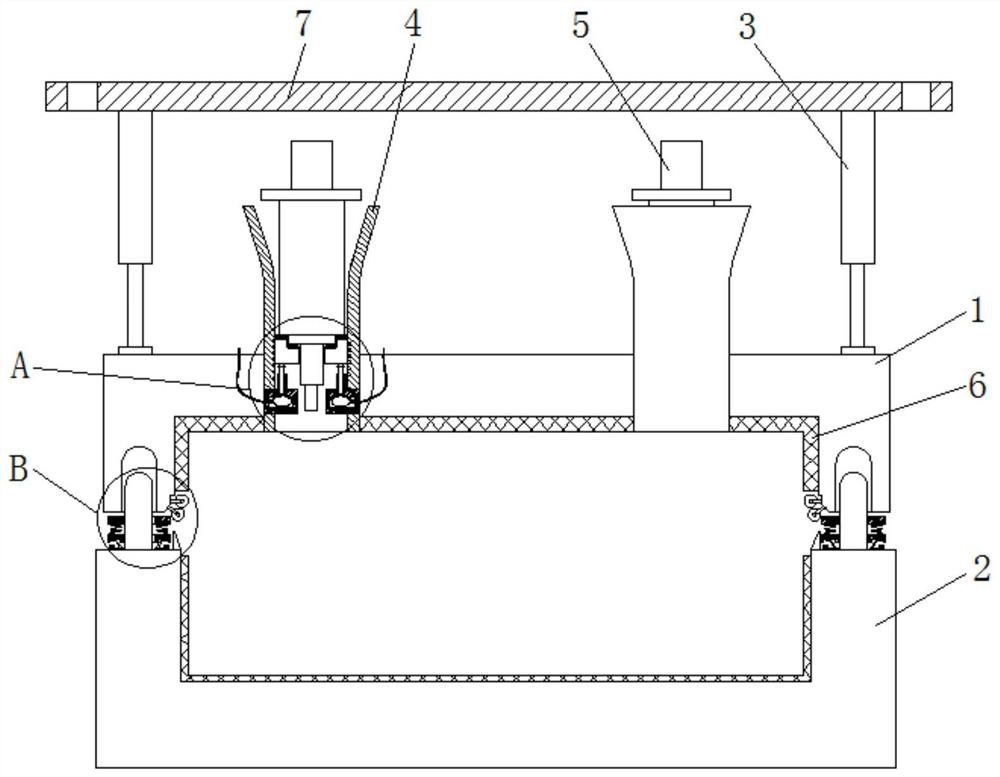

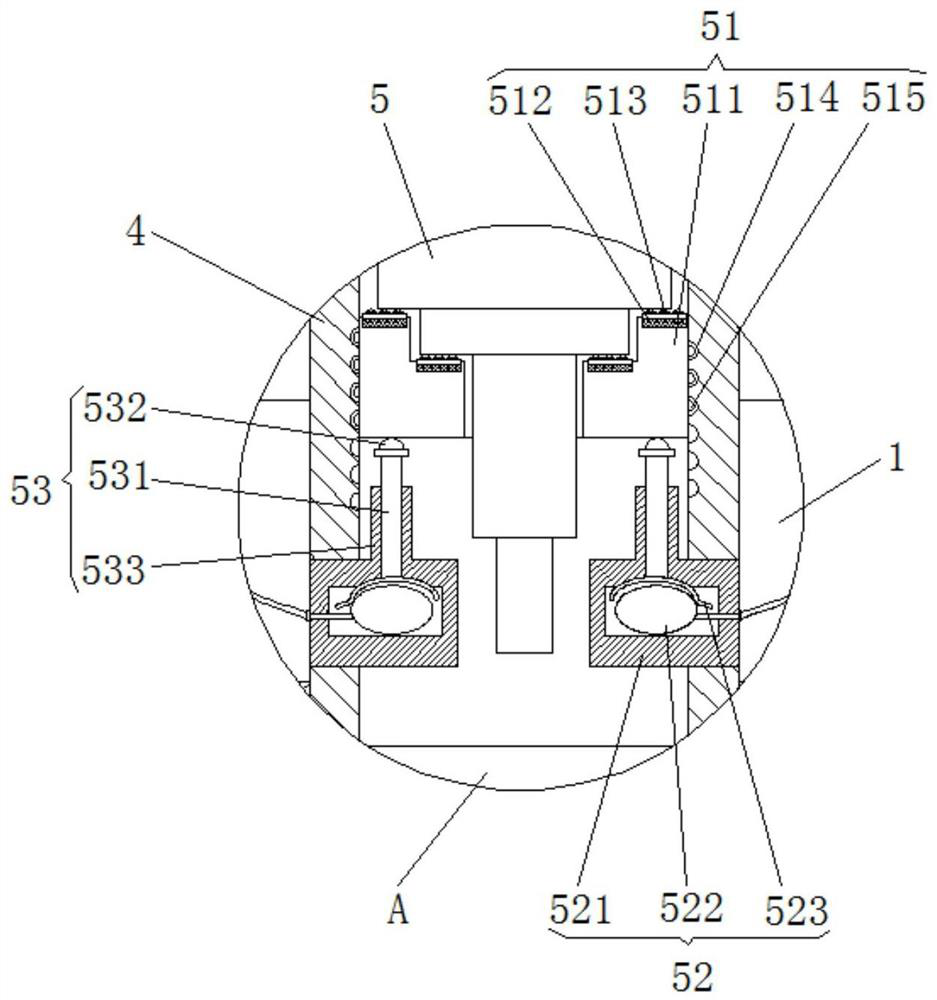

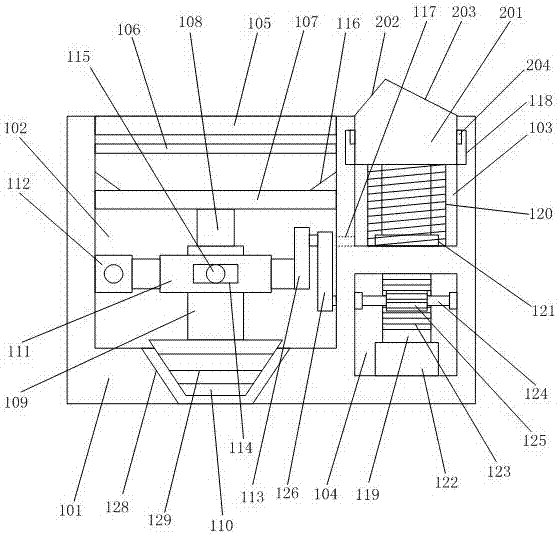

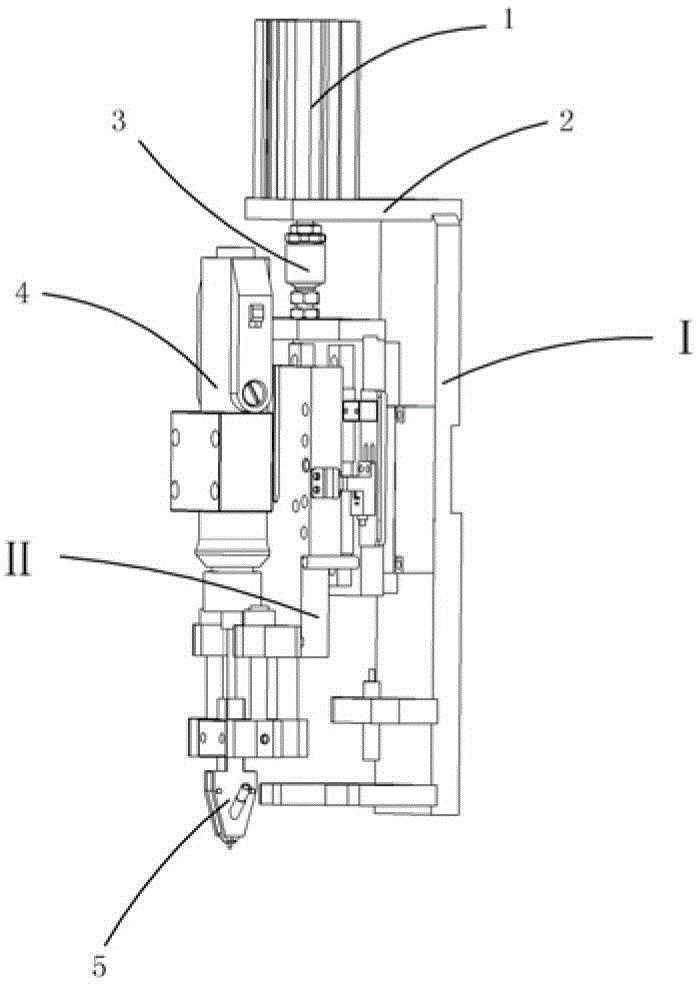

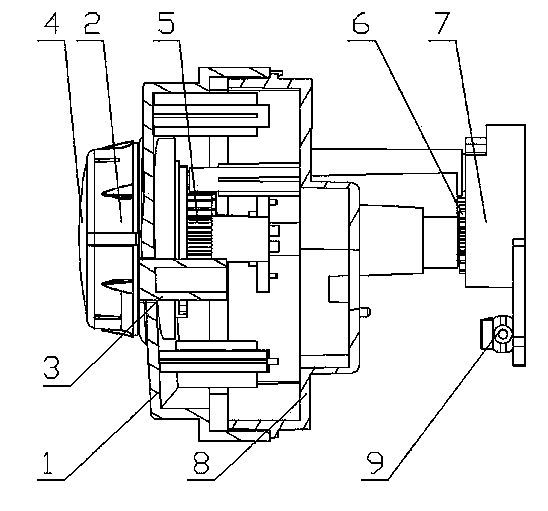

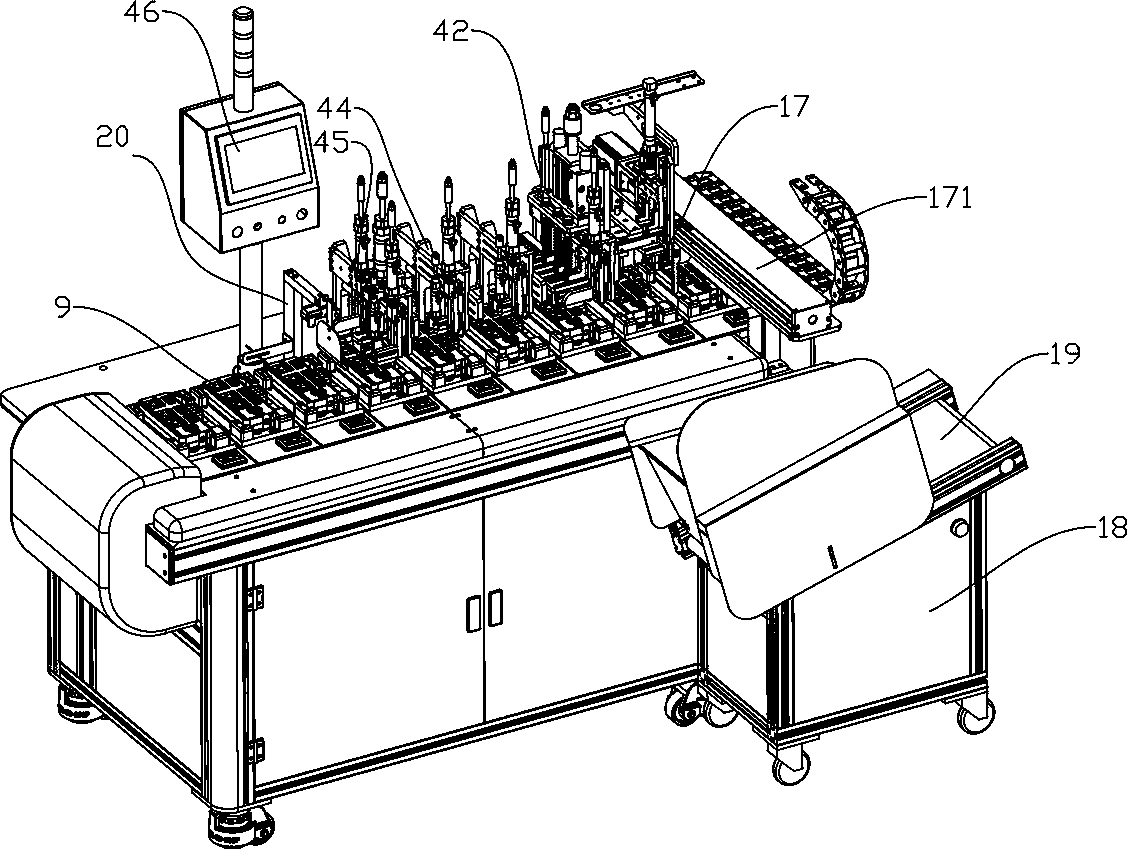

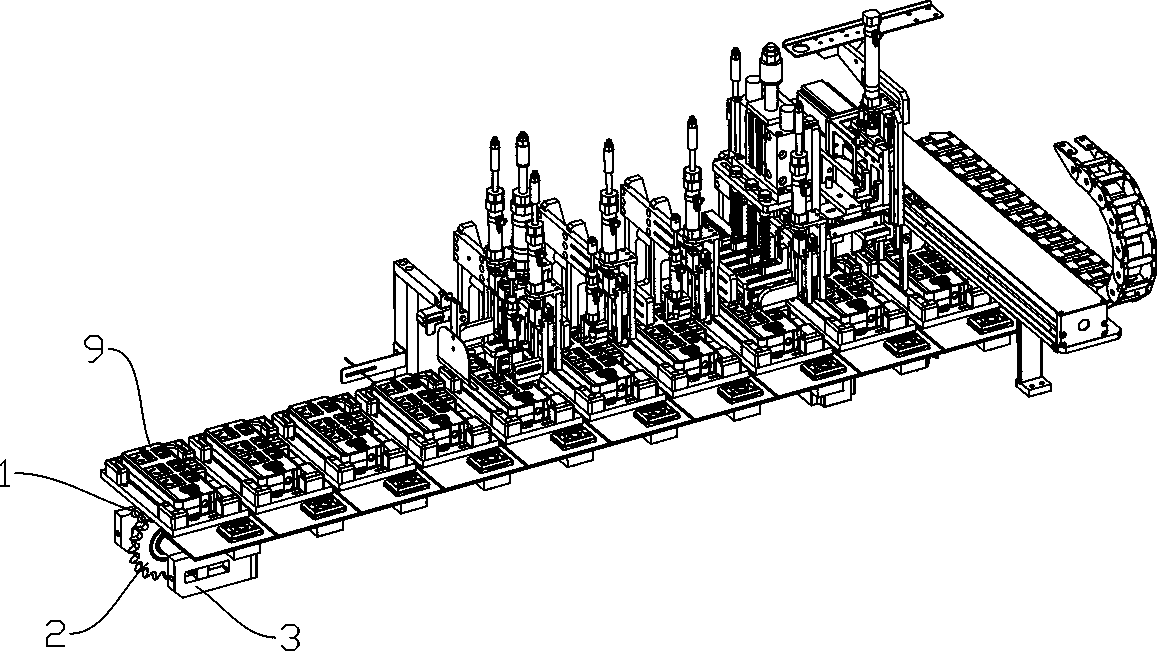

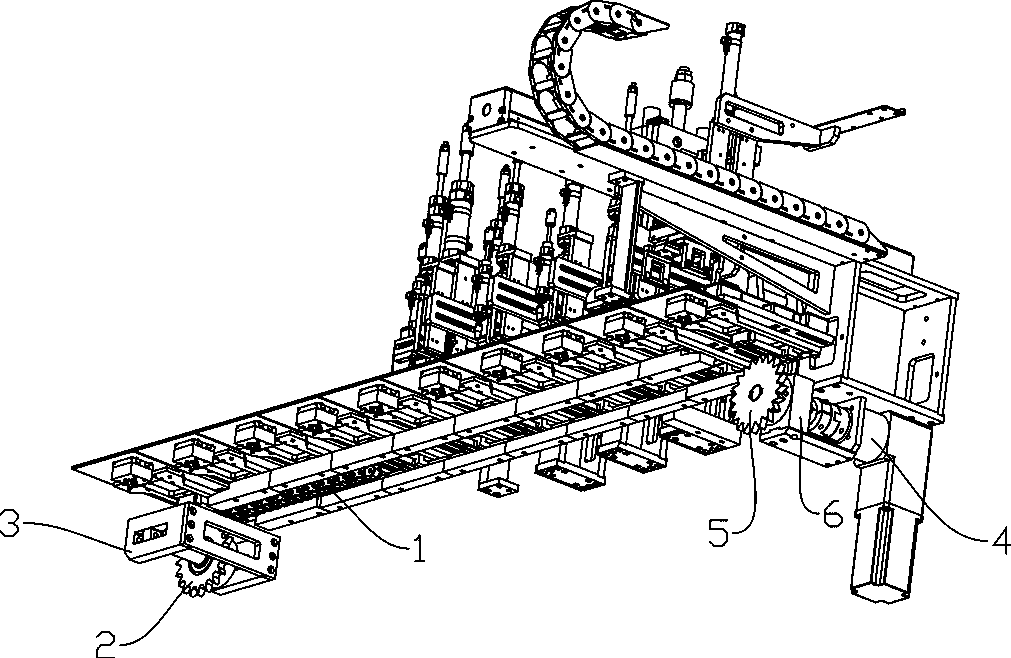

Hydraulic pump and assembly machine thereof

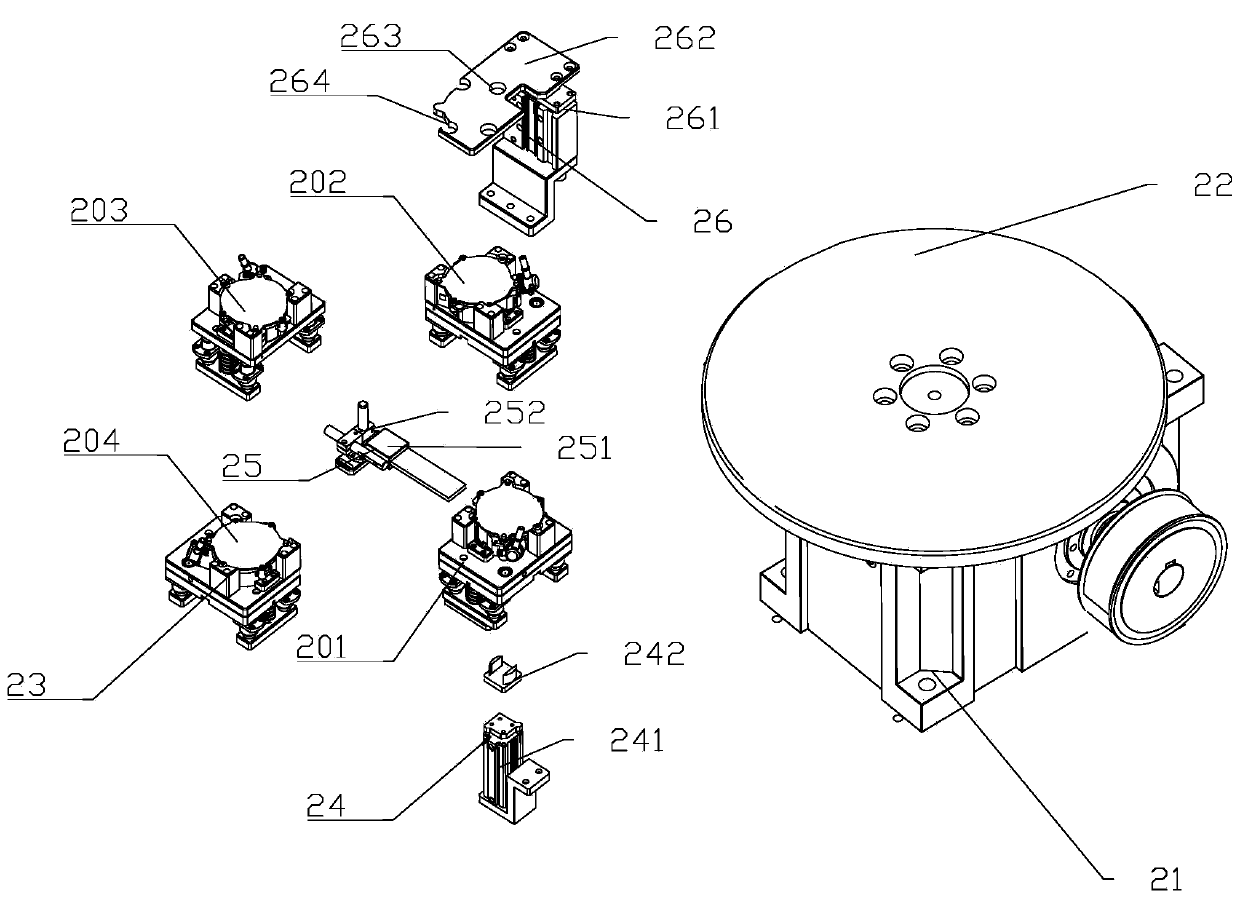

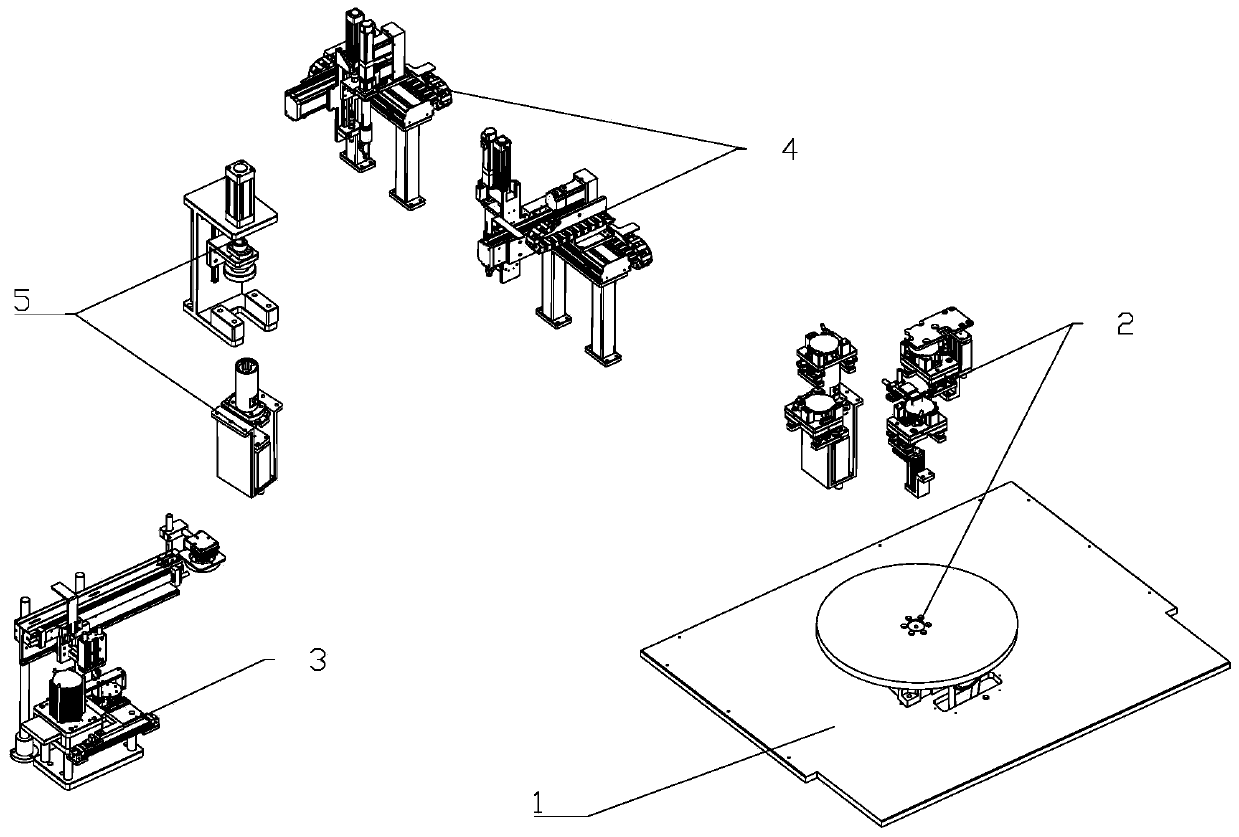

InactiveCN111283422AIncrease success rateMaintain Preload ConsistencyAssembly machinesHydraulic pumpEngineering

The invention relates to the field of hydraulic pumps. An assembly machine of a hydraulic pump comprises a rack, a rotary jig device, a pump cover feeding device, a screw locking device and a sealingdetection device, wherein the rotary jig device, the pump cover feeding device, the screw locking device and the sealing detection device are arranged on the rack, the rotary jig device is arranged atthe center of the rack, the pump cover feeding device, the screw locking device and the sealing detection device respectively correspond to one station of the rotary jig device, four stations are arranged on the jig device, and a loading and unloading conveying device is arranged at the remaining station. The assembly machine of the hydraulic pump has the advantages of high hydraulic pump assembly precision and high jig circulation efficiency, high pump cover assembly precision, accurate separation and transportation of pump covers and accurate sealing detection.

Owner:王加县

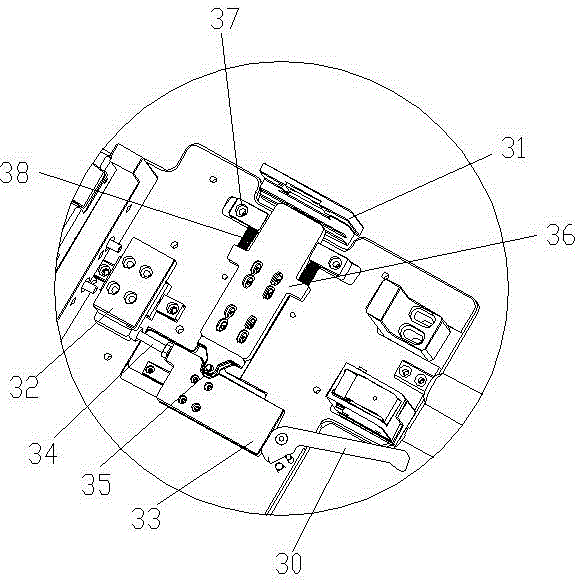

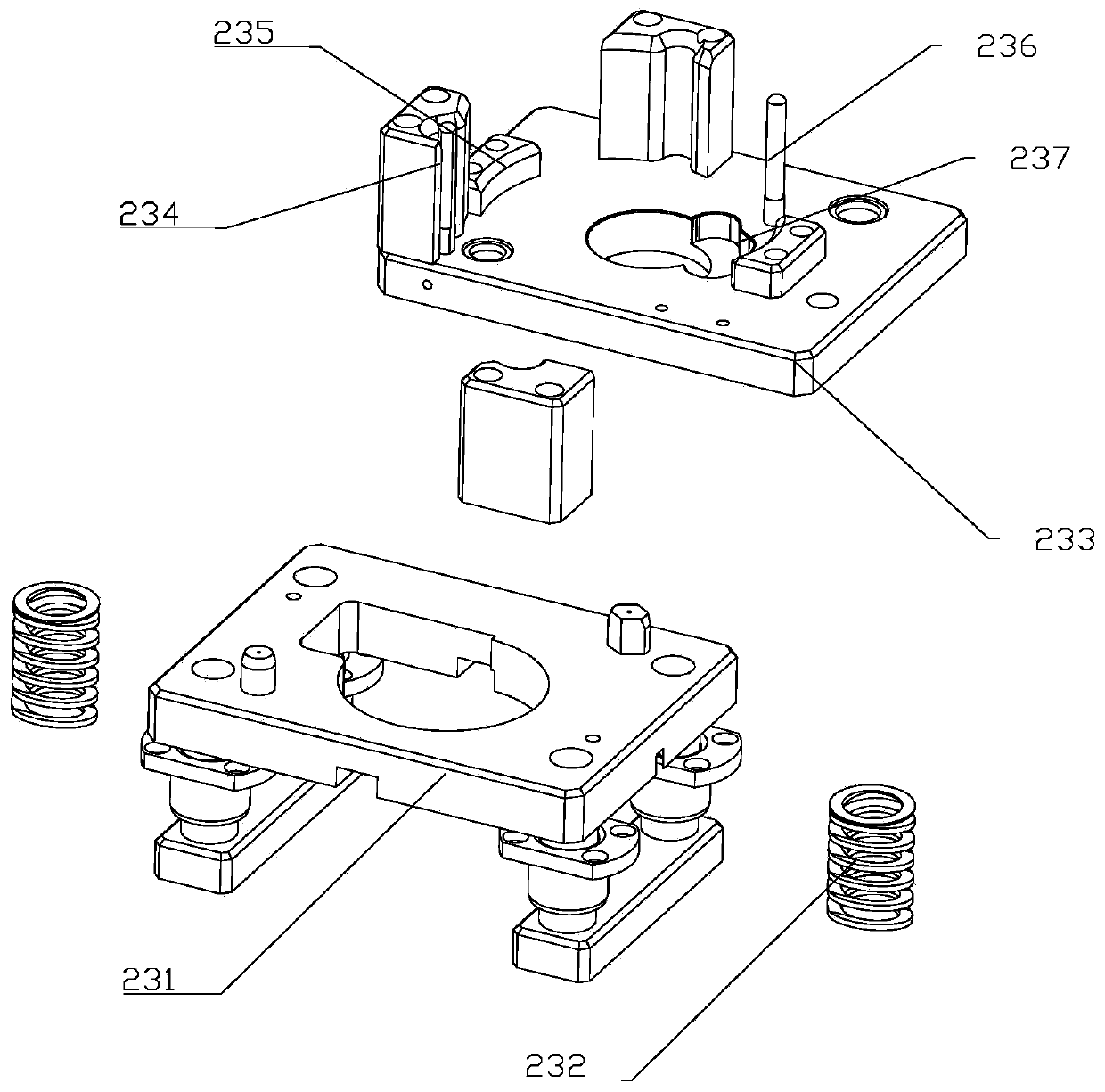

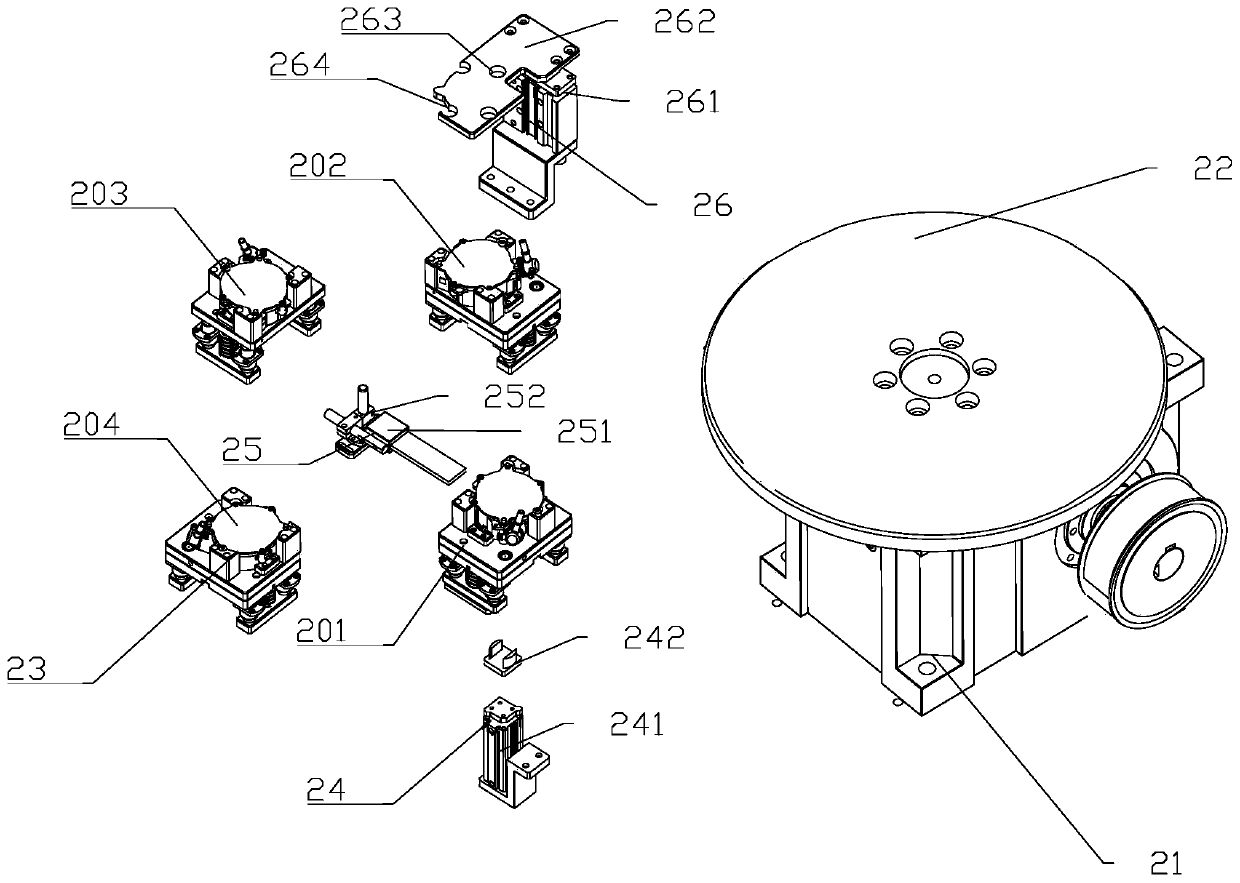

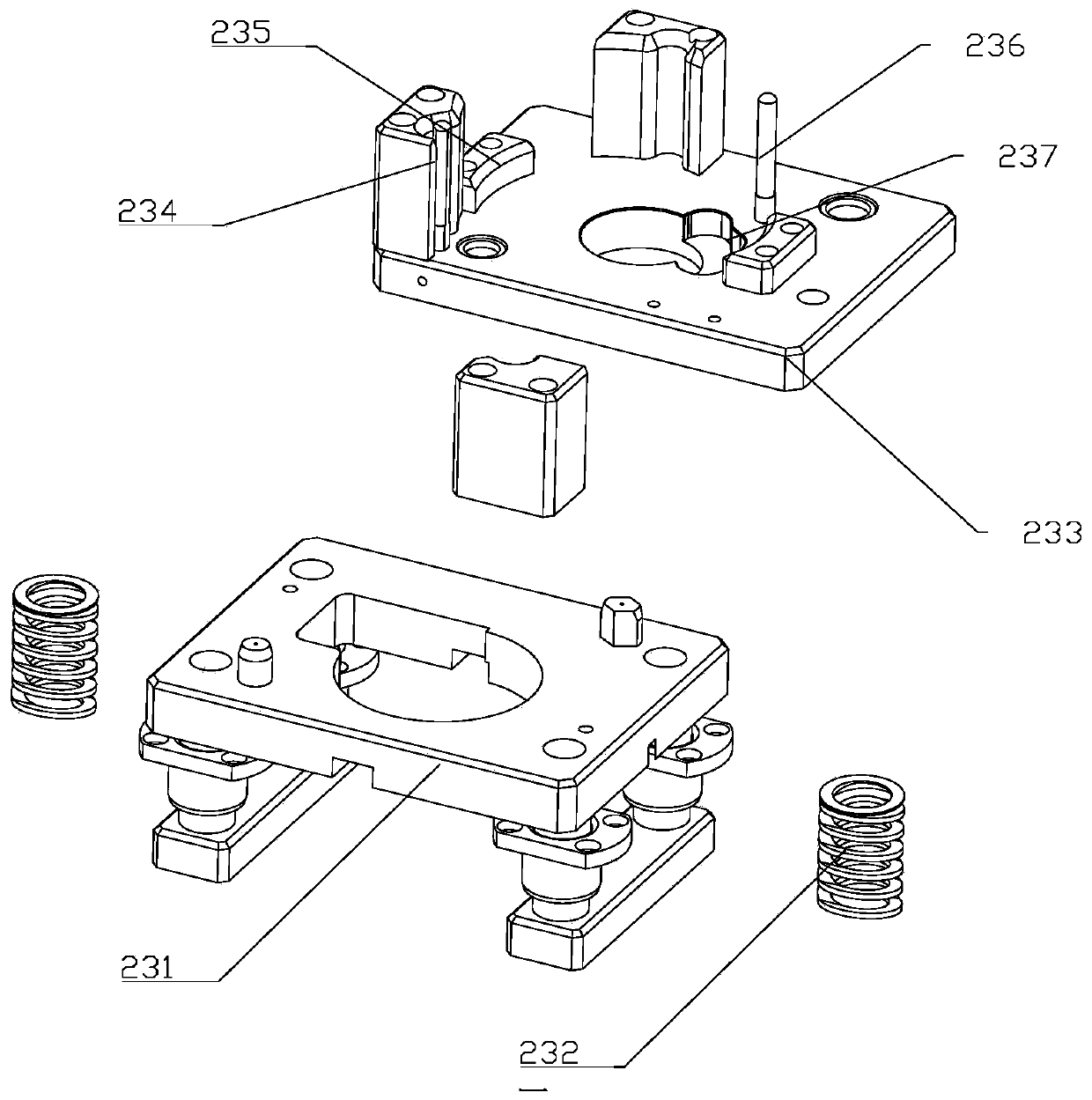

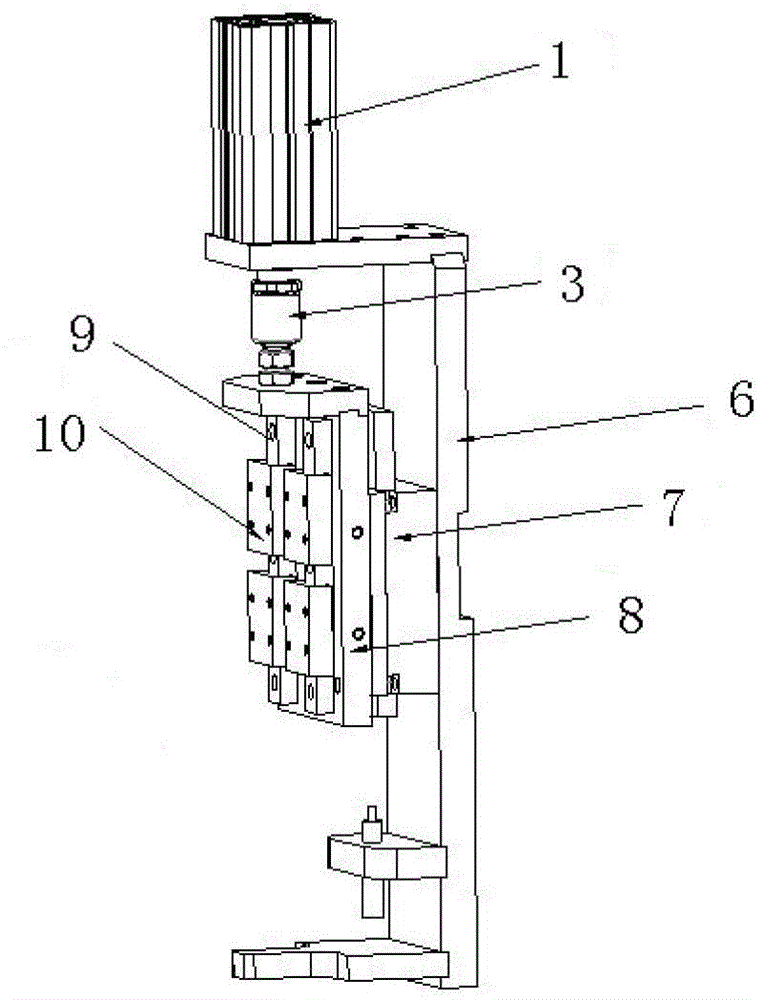

Rotary jig device of hydraulic pump assembly machine and jig rotating method

The invention relates to the field of hydraulic pumps. A rotary jig device of a hydraulic pump assembly machine comprises a divider, a turntable, jig assemblies, a correction assembly, a laser assembly and a pressing assembly; the divider is mounted on a rack, the center of the turntable is mounted on an output shaft of the divider, and the jig assemblies are mounted on the turntable and correspond to four stations, namely a pump cover feeding station, a pump cover locking station, a detection station and a feeding and discharging station respectively; and the correction assembly and the laserassembly correspond to the feeding station, and the pressing assembly corresponds to the pump cover locking station. The rotary jig device of the hydraulic pump assembly machine has the advantages ofhigh hydraulic pump assembly precision, good stability and high jig circulation efficiency.

Owner:王加县

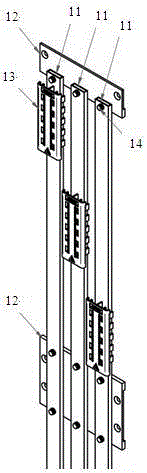

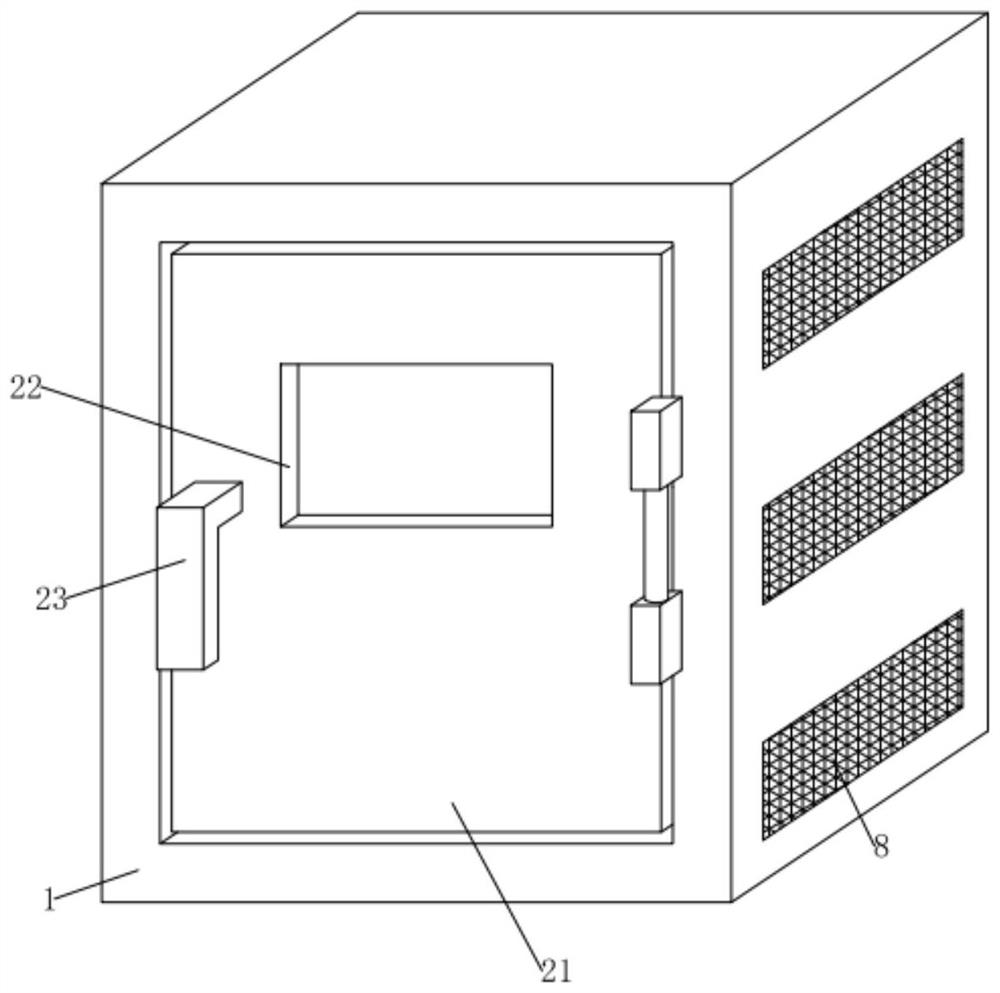

Collection and diversion device for power supply cabinet

PendingCN106848782AGood anti-corrosion functionGuaranteed reliabilityCouplings bases/casesPotential differenceEngineering

Provided is a collection and diversion device for a power supply cabinet. The collection and diversion device is installed on a power supply cabinet body, and comprises multiple omnibus bars, multiple insulating lining plates and multiple omnibus bar shield plates; wherein different omnibus bars are connected to a positive pole supple line, a negative pole supple line and a ground lead respectively; the multiple insulating lining plates are connected to the power supply cabinet body and the omnibus bars; the multiple omnibus bar shield plates are arranged on the omnibus bars, and cover wiring positions of the omnibus bars. The collection and diversion device for the power supply cabinet facilitates cabinet wiring arrangement, reduces the potential difference among equipment, improves equipment operation reliability, reduces the unintended touch probability of the omnibus bars and the cabinet body and the equipment, and improves the wiring reliability.

Owner:SHANGHAI RAILWAY COMM

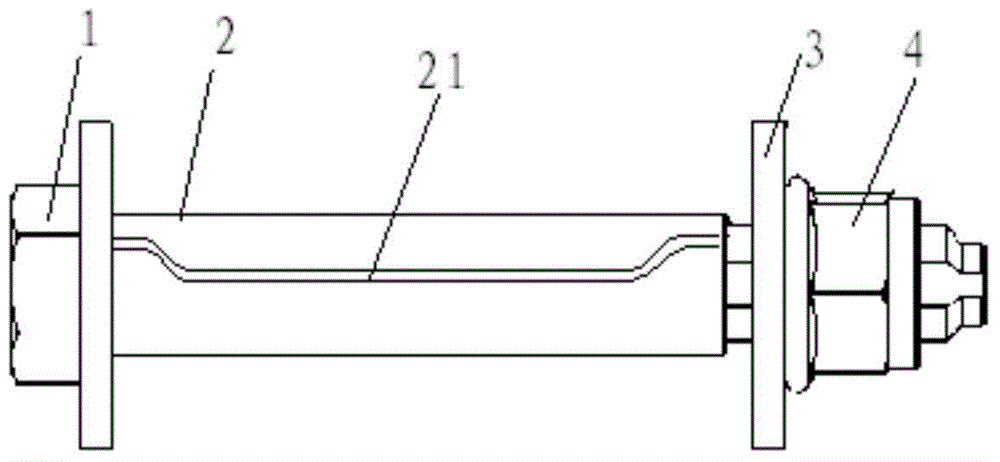

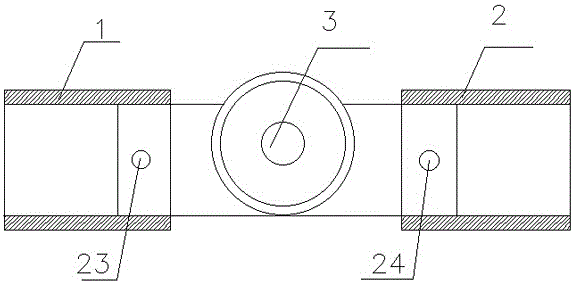

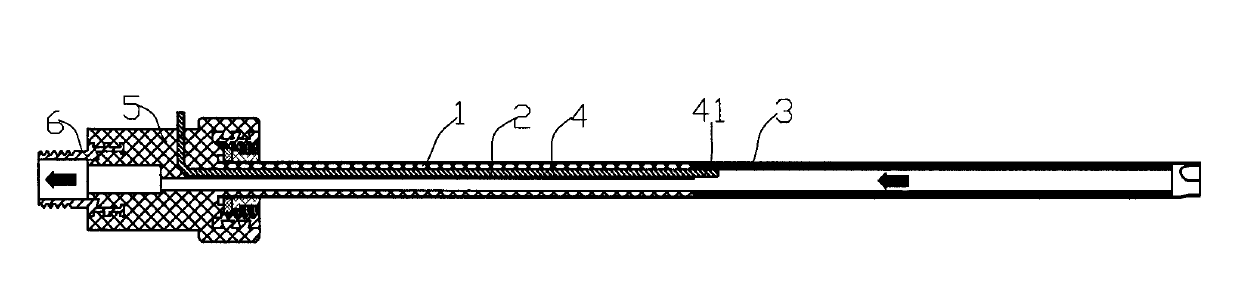

Connecting structure for aluminum alloy pipes and self-locking bend device

ActiveCN105020225AImprove connection strengthSimple structureRod connectionsSelf lockingUltimate tensile strength

The invention discloses a connecting structure for aluminum alloy pipes and a self-locking bend device. The connecting structure comprises the first aluminum alloy pipe, the second aluminum alloy pipe and the self-locking bend device. The self-locking bend device comprises a first bend and a second bend. The first bend comprises a first body and a first pipe joint. The second bend comprises a second body and a second pipe joint arranged on one side of the second body. The first body and the second body are in butt connection. The first pipe joint is sleeved with the first aluminum alloy pipe. A first cylindrical pin is inserted into the overlapped position of the first aluminum alloy pipe and the first pipe joint. The two ends of the first cylindrical pin are welded to the first aluminum alloy pipe. The second pipe joint is sleeved with the second aluminum alloy pipe. A second cylindrical pin is inserted into the overlapped position of the second aluminum alloy pipe and the second pipe joint. The two ends of the second cylindrical pin are welded to the second aluminum alloy pipe. The connection strength between the aluminum alloy pipe and the pipe joints is greatly improved.

Owner:苏州市智永亿精密五金有限公司

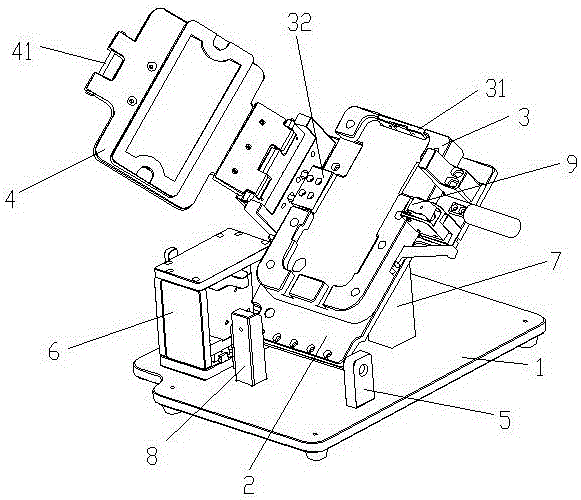

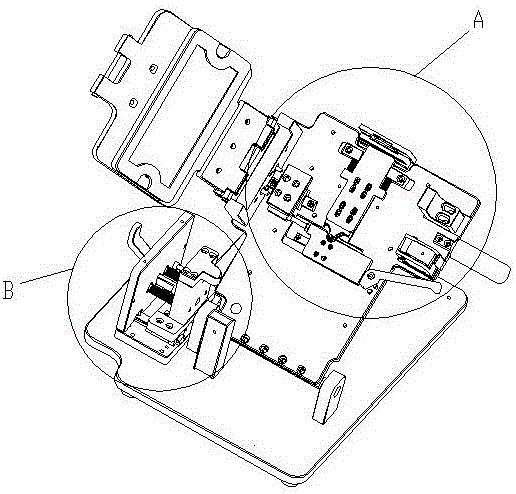

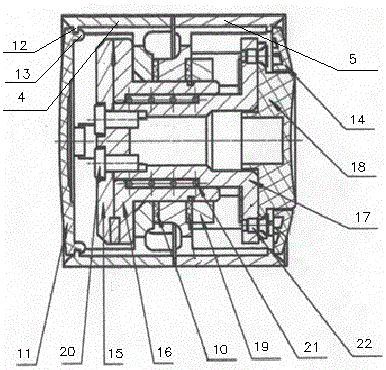

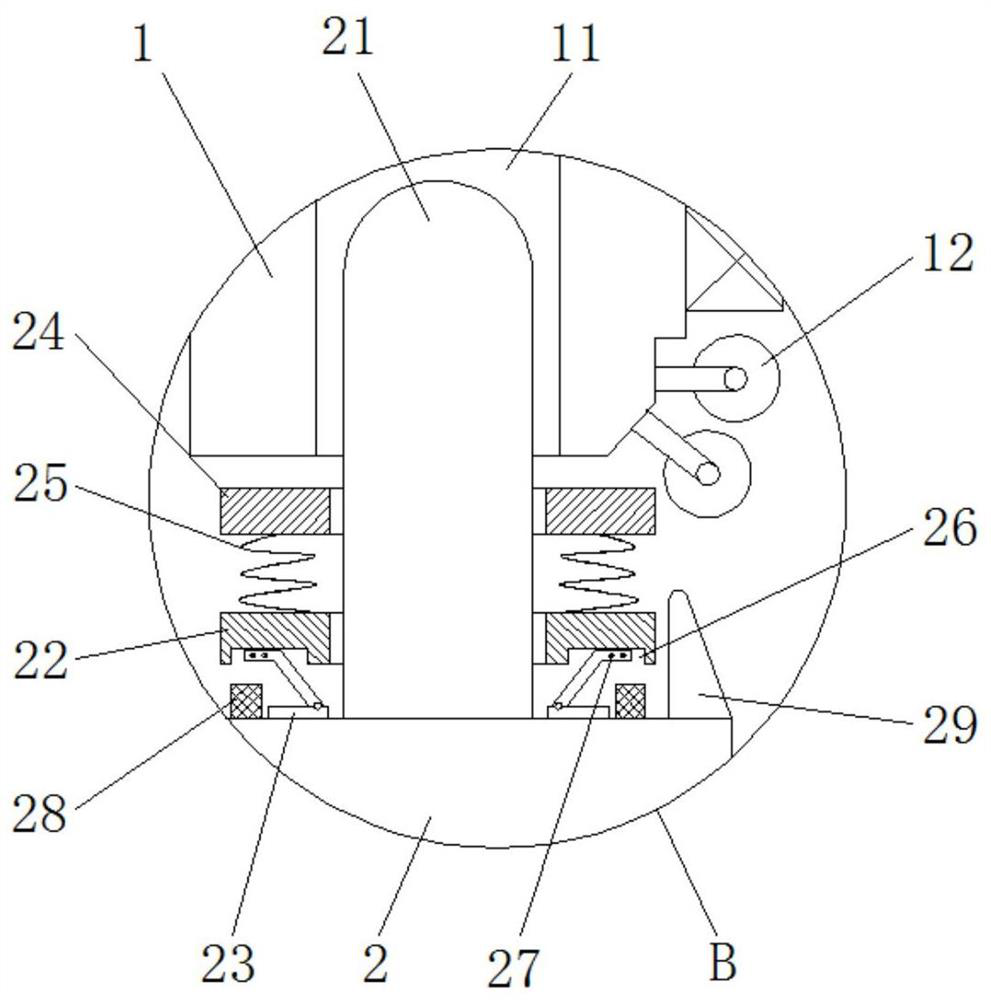

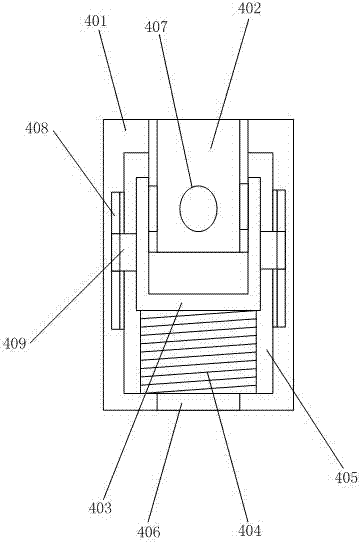

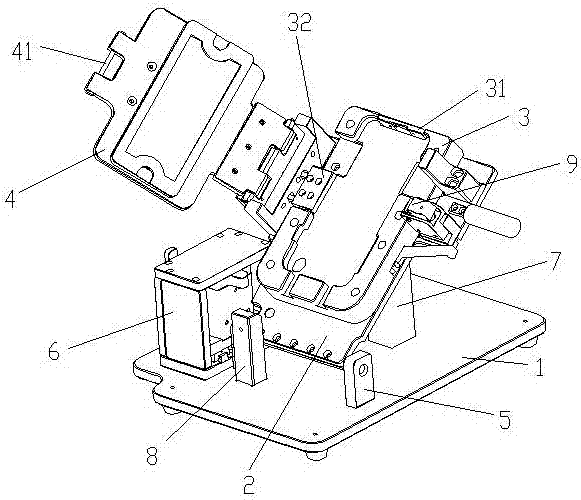

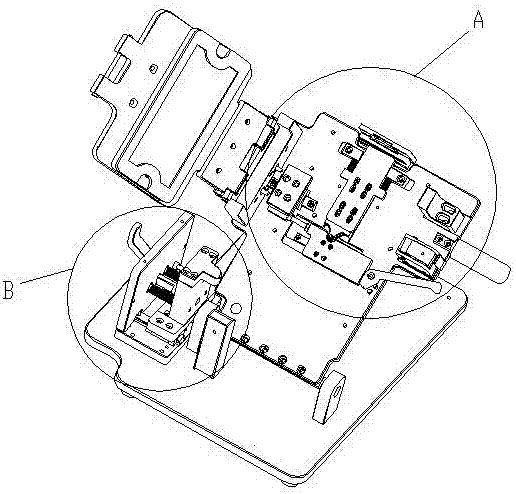

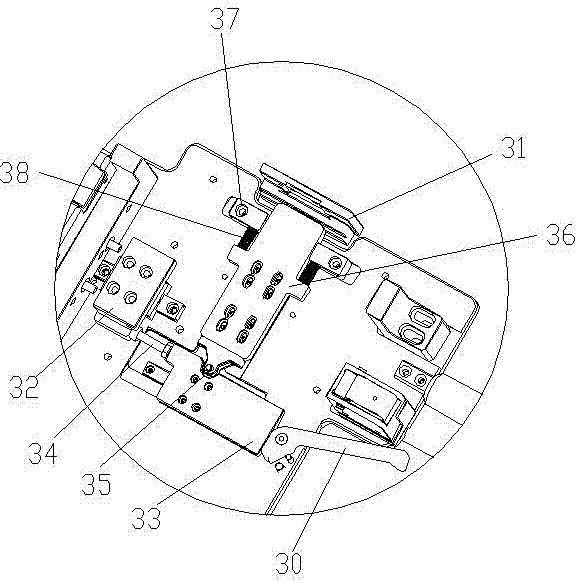

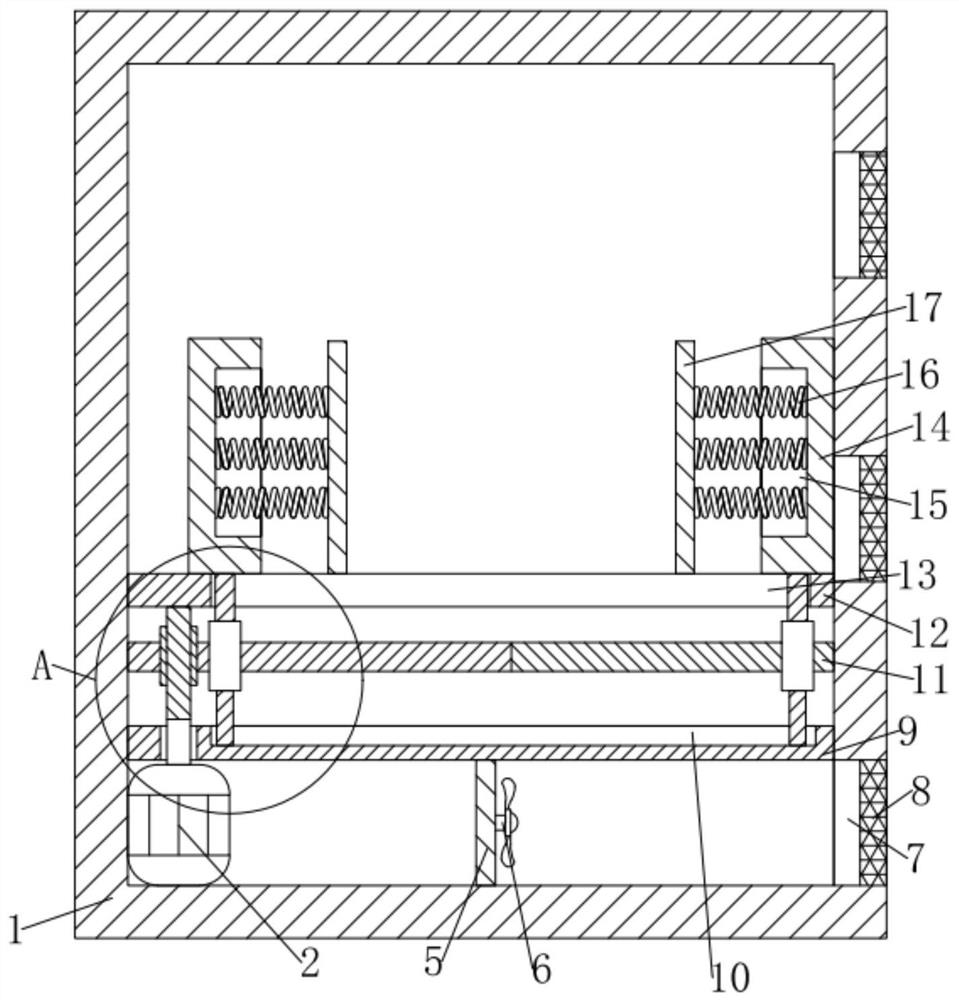

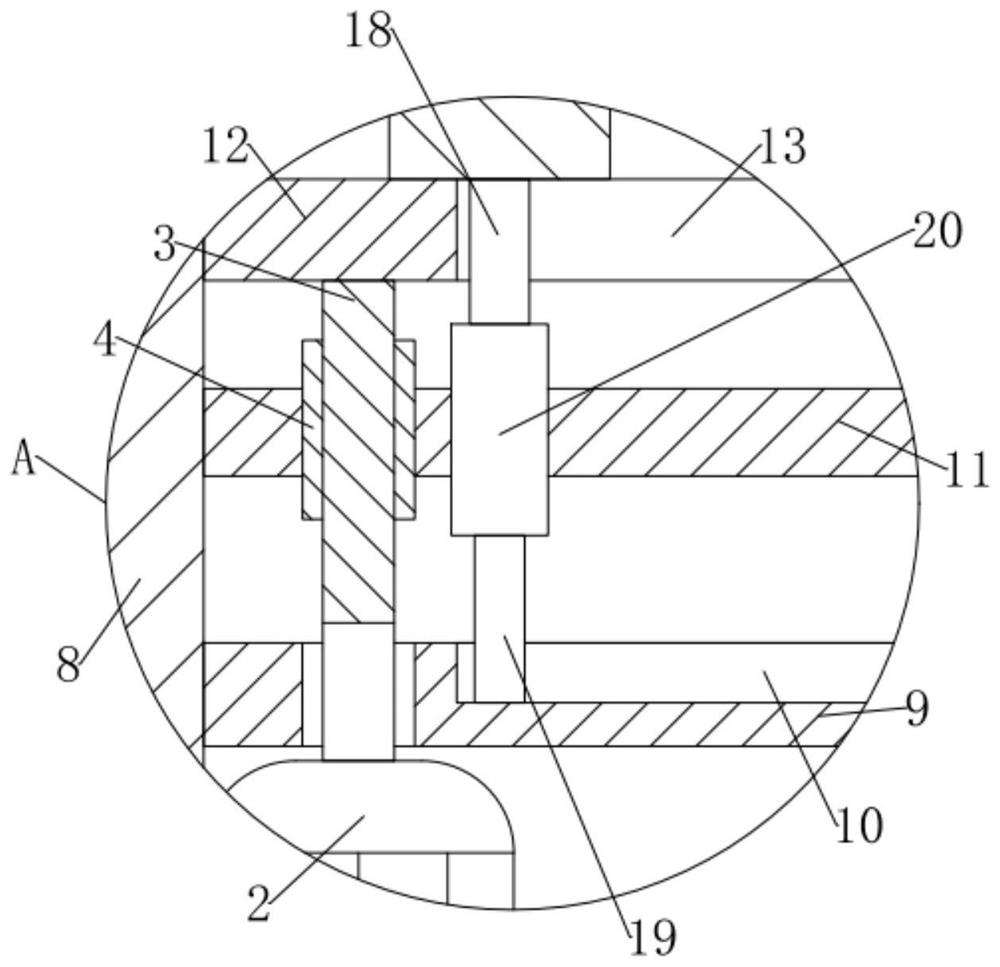

A molded case circuit breaker installation equipment

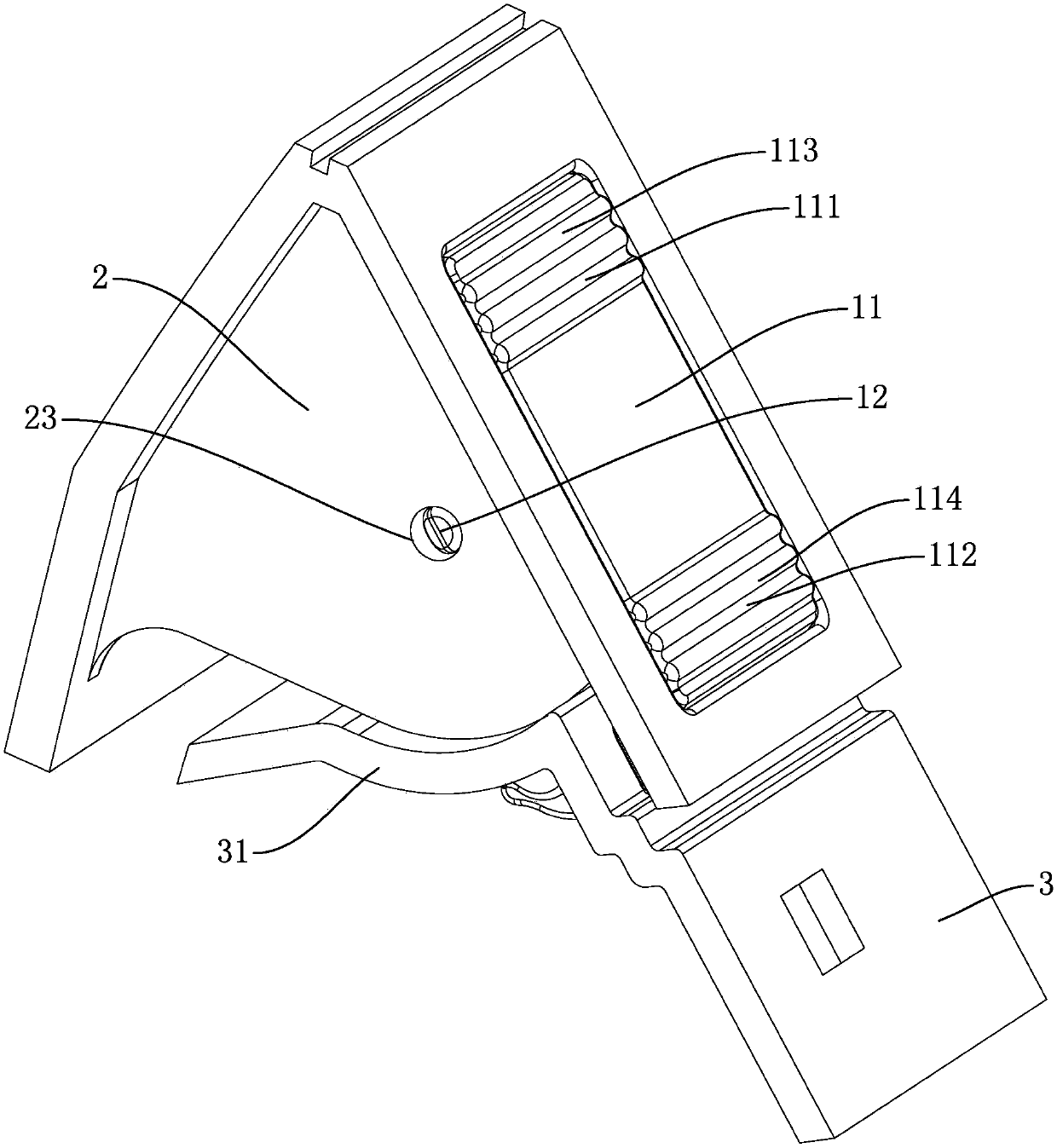

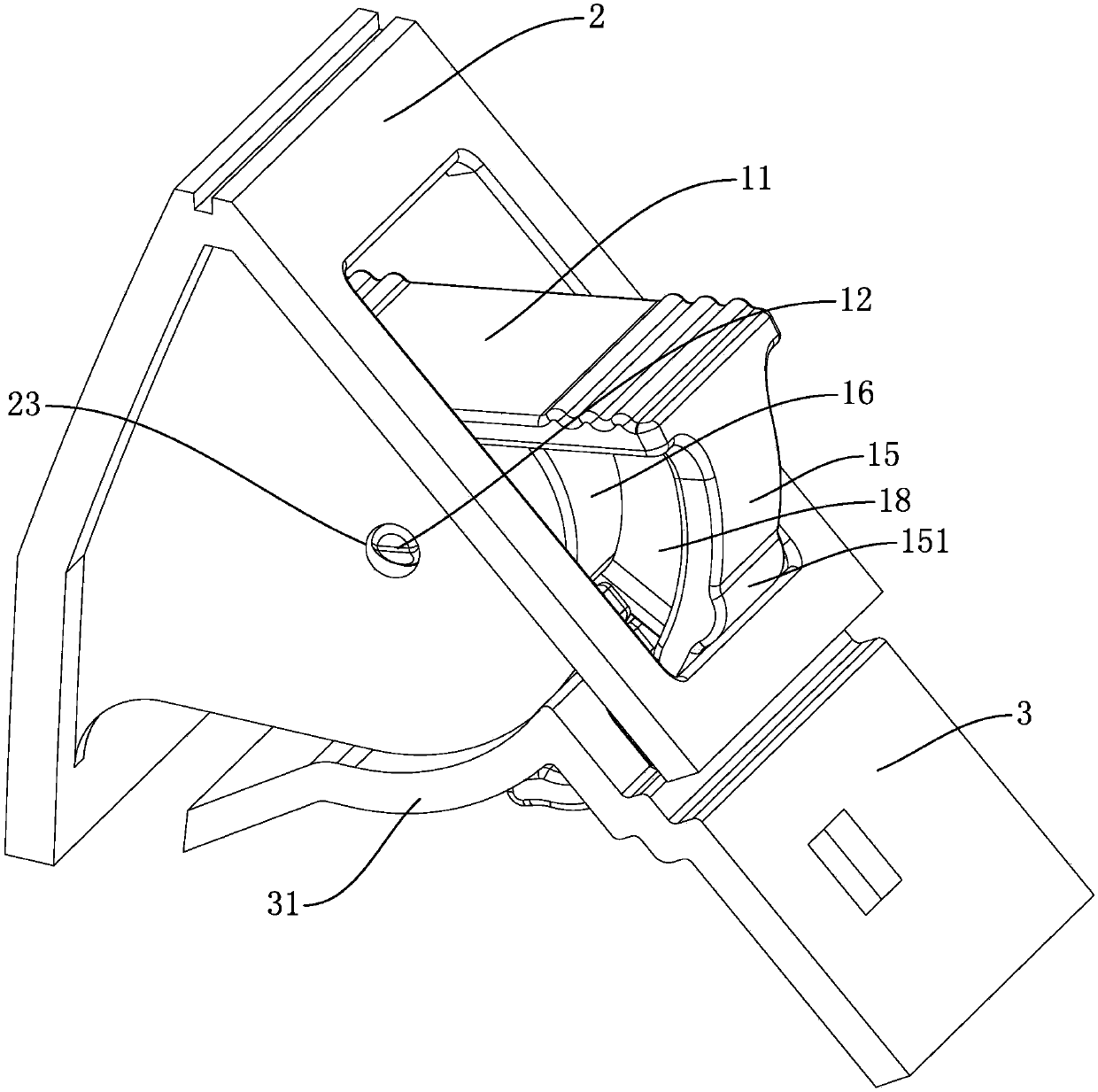

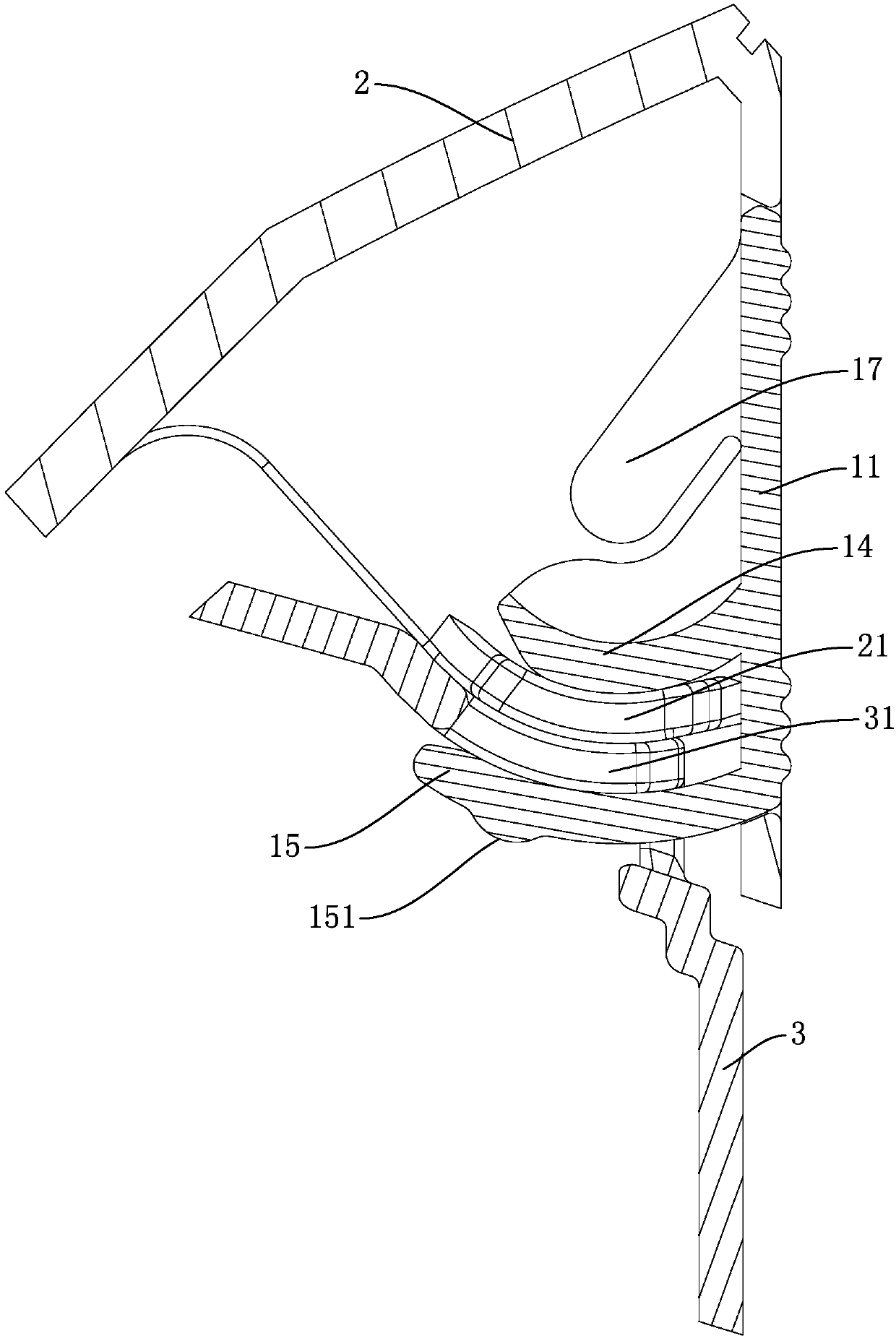

ActiveCN110277283BProtective shellPlay a buffer roleProtective switch detailsScrew threadCircuit breaker

The invention relates to a molded case circuit breaker installation device. The device comprises a clamping seat and a supporting seat, wherein clamping grooves are formed in the bottom surface of the clamping seat and the top surface of the supporting seat; the clamping groove are used for clamping a circuit breaker, and a pushing cylinder is arranged on the top surface of the clamping seat; the pushing cylinder is fixed on a transverse plate; a positioning buffer mechanism is arranged between the clamping seat and the supporting seat; a guide sleeve is arranged on the top surface of the clamping seat, the top end of the guide sleeve adopts a conical structure, the bottom end of the conical structure adopts circular arc transition, and the guide sleeve is used for guiding an electric screwdriver; a rotary supporting mechanism is arranged in the guide sleeve, and a protection mechanism and a supporting mechanism are arranged at the bottom in the guide sleeve. The device avoids the screw driving deflection, protects the shell of the circuit breaker, and eliminates the safety risk; the device achieves the buffering of an electric screw driver, and also has a limiting function; the device avoids the screw thread slipping when the electric screw driver is pressed too much, thereby protecting the shell of the circuit breaker, and reducing the production cost.

Owner:泰州亿丰达电器有限公司

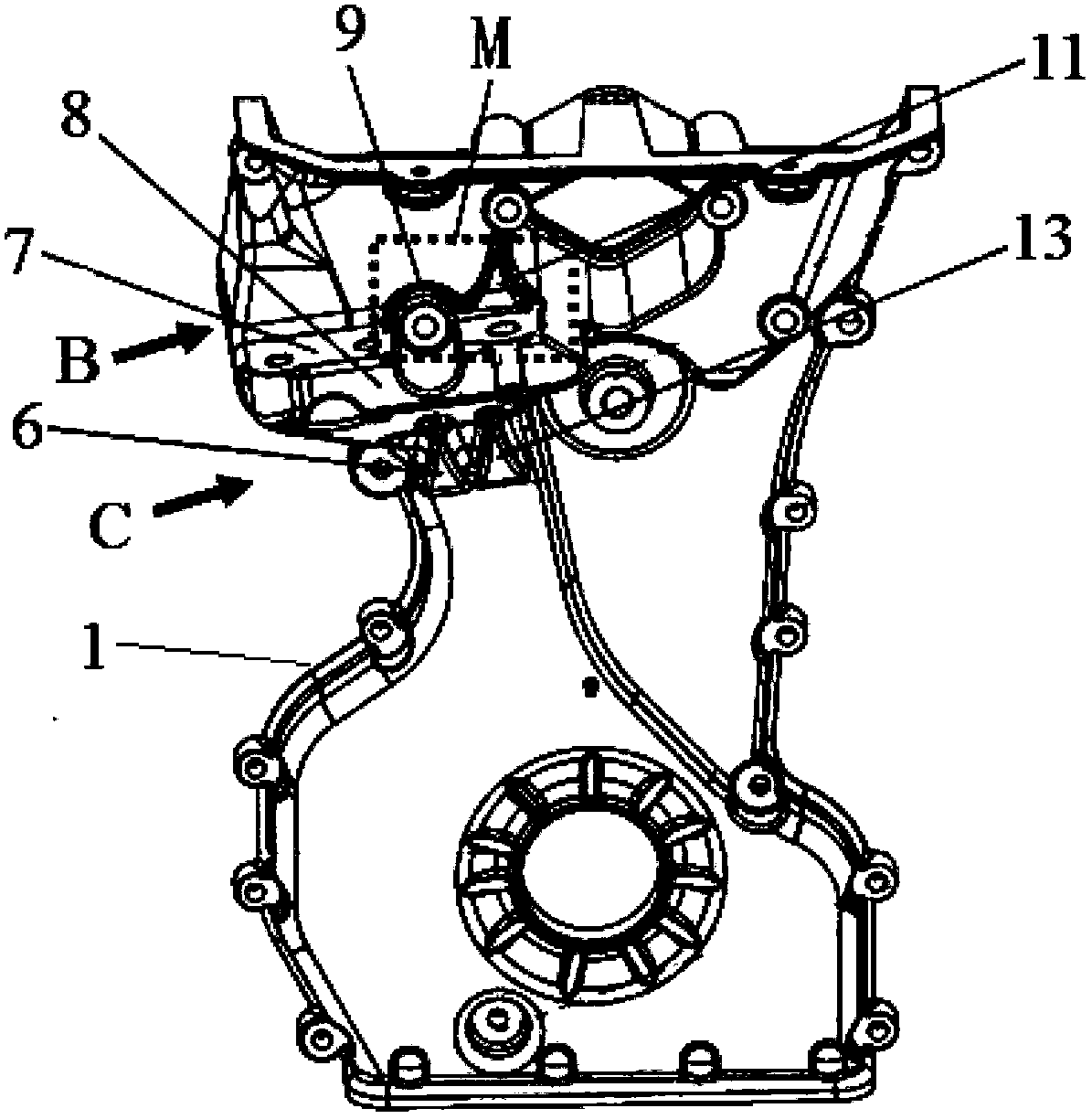

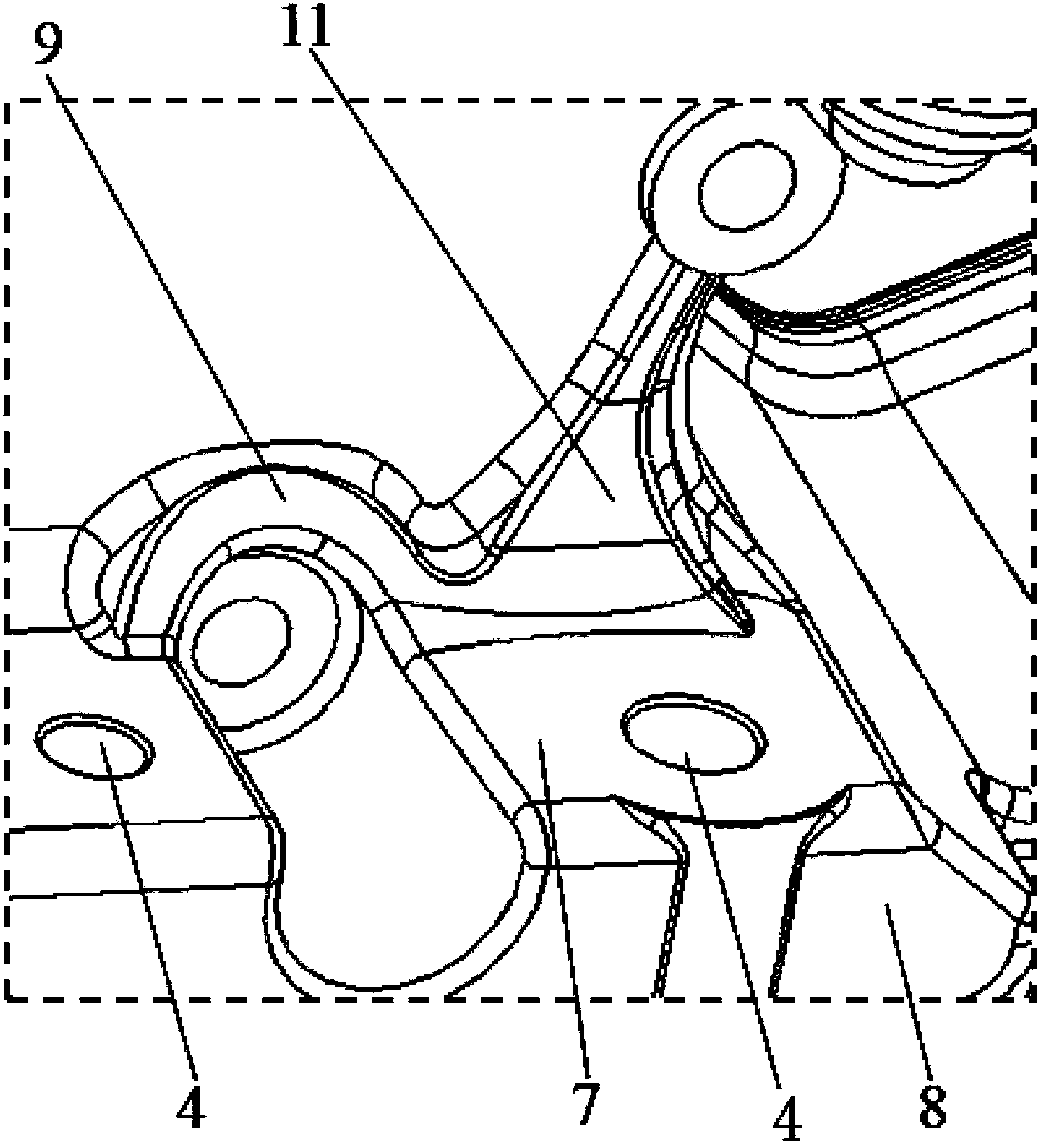

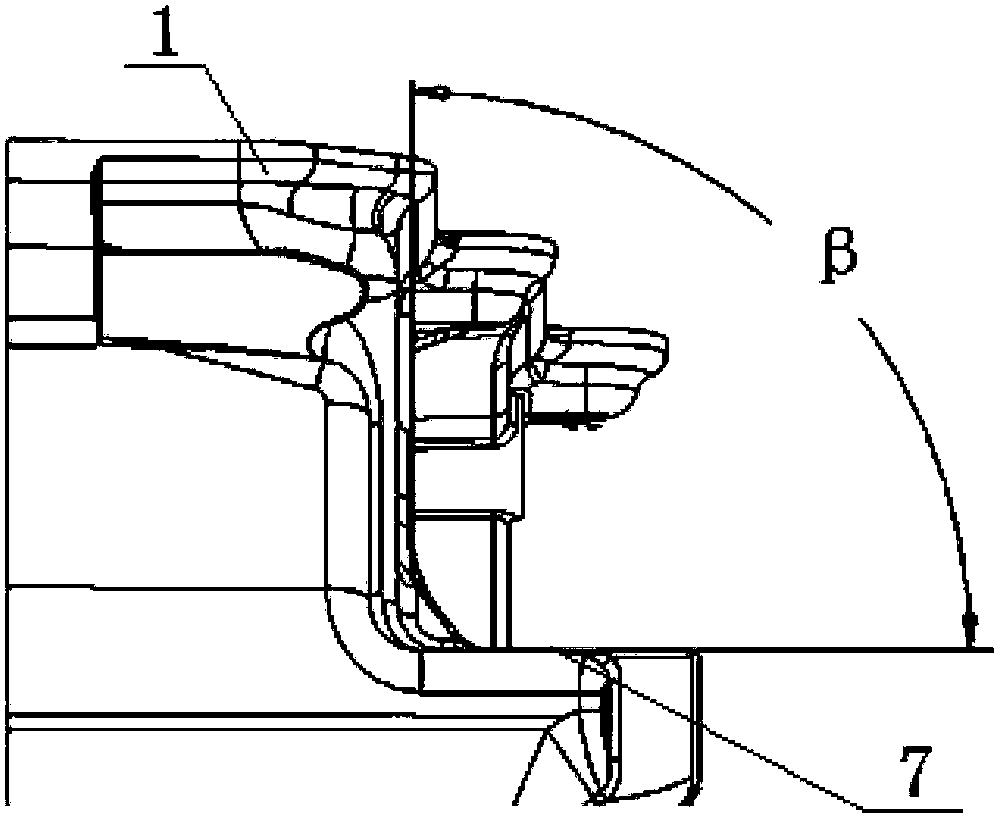

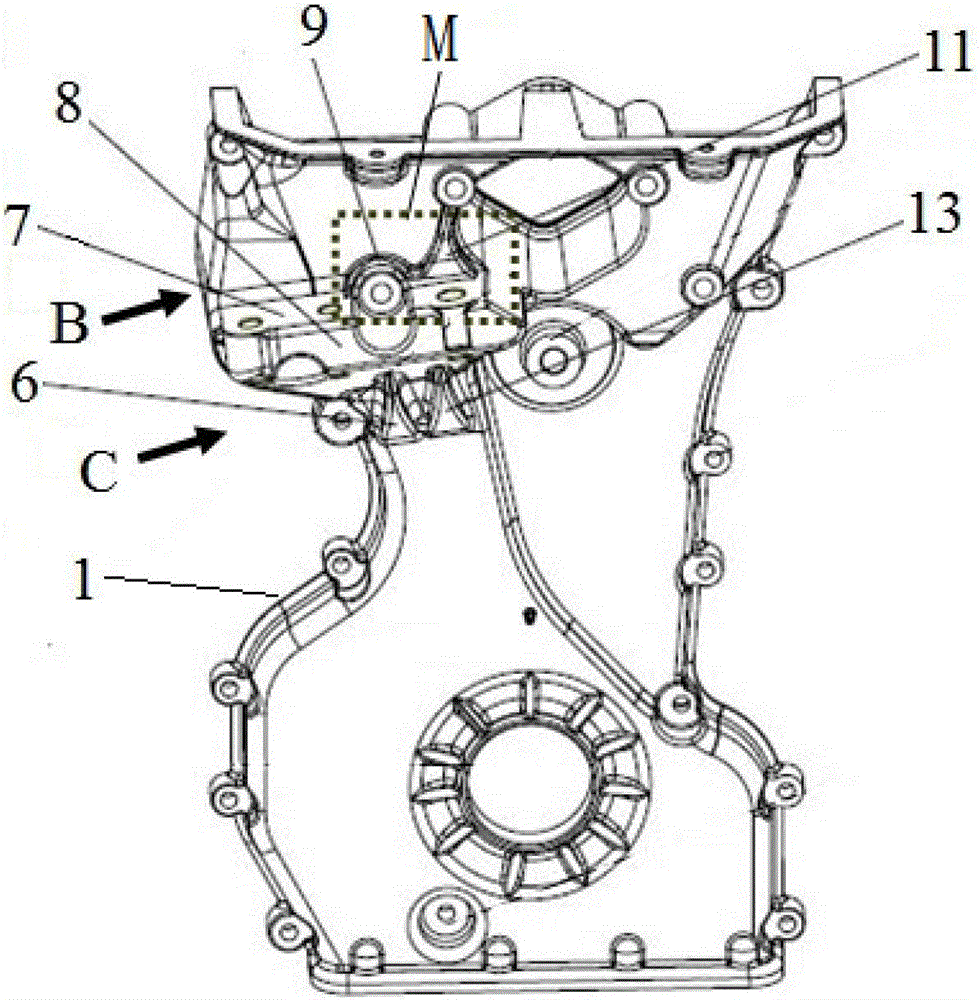

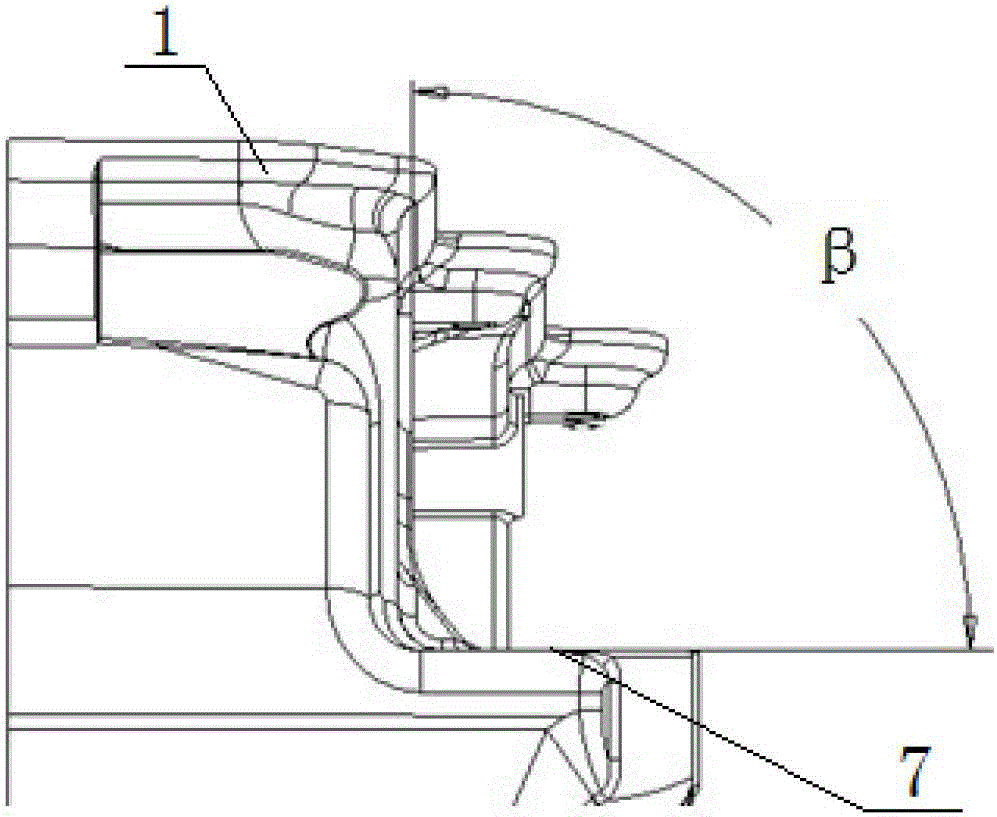

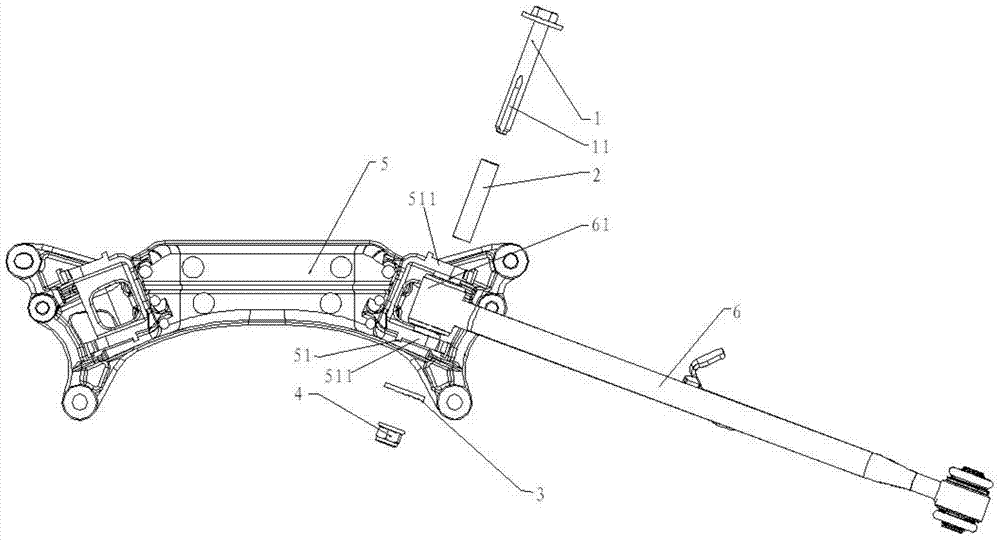

Motor front cover with hanging right support installation structure

ActiveCN103661626AAvoid stress concentrationImprove connection reliabilitySuperstructure subunitsEngineeringPowertrain

The invention discloses a motor front cover with a hanging right support installation structure. The motor front cover with the hanging right support installation structure comprises a motor front cover body and a right support installation platform which is arranged on the exterior side of the motor front cover body; a hanging bolt installation hole is formed in a supporting boss; a first reinforcing rib and a second reinforcing rib are arranged above a root portion which connects the right support installation platform and the motor front cover body; a third reinforcing rib is arranged under the root portion which connects the right support installation platform and the motor front cover body; an included angle beta which is formed between a right support installation surface of the right support installation platform and the motor front cover body is from 90.3 to 90.5 degrees. The motor front cover with the hanging right support installation structure has the advantages of being good in assembling manufacturability and high in intensity, improving reliability of connection between an integral vehicle and a power assembly and prolonging the service life of the motor and the integral vehicle.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Drainage structure of airplane cabin door

PendingCN107235137AAvoid enteringEffective protectionAircraft accessoriesFuselagesJet aeroplaneEngineering

The invention provides a drainage structure of an airplane cabin door. The drainage structure comprises a drainage bottom tank, a water retaining bar, a drainage tube and a check valve, wherein the drainage bottom tank comprises a tank base as well as a water collecting tank, a drive chamber and a water retaining tank which are arranged in the length direction of the tank base; a tapered hole is formed in the bottom of the water collecting tank; the drainage tube is fixedly connected with the bottom of the tapered hole; the check valve is connected in series onto the drainage pipe. According to the drainage structure of the airplane cabin door, complete sealing can be realized when the tapered hole is plugged by a tapered seal head, automatic seal is realized when the cabin door is closed, normal air pressure is ensured,and safe take-off is guaranteed; when the airplane cabin door is opened, drainage is realized automatically, and water droplets at the edge of the cabin door are also blocked under the action of the water retaining bar, and water cannot be accumulated.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

High-strength corrosion-resistant plastic screw

The invention discloses a high-strength corrosion-resistant plastic screw. The screw comprises a screw rod, a screw head integrally connected with one end of the screw rod, and a locking disc head arranged at the other end of the screw rod in a sleeving mode, wherein an external thread structure is integrally machined on the screw rod, and the screw rod, the screw head and the locking disc head are all made of high-strength corrosion-resistant plastic. The high-strength corrosion-resistant plastic comprises the following raw materials of, by weight, 58%-62% of PA6, 25%-28% of glass fiber, 8%-12% of nano silicon dioxide and 4%-8% of nano aluminum oxide. According to the high-strength corrosion-resistant plastic screw, through the above mode, the screw rod, the screw head and the locking disc head are all made of the high-strength corrosion-resistant plastic with an excellent formula, and have excellent strength and corrosion resistance, and the phenomena of screw loose and breaking in the using process of the screw are avoided.

Owner:苏州华丰不锈钢紧固件有限公司

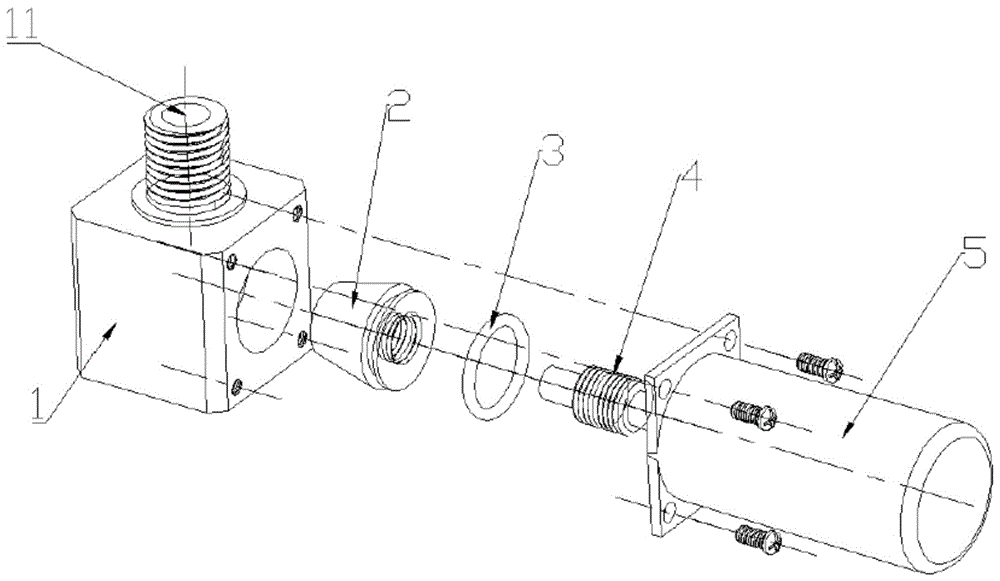

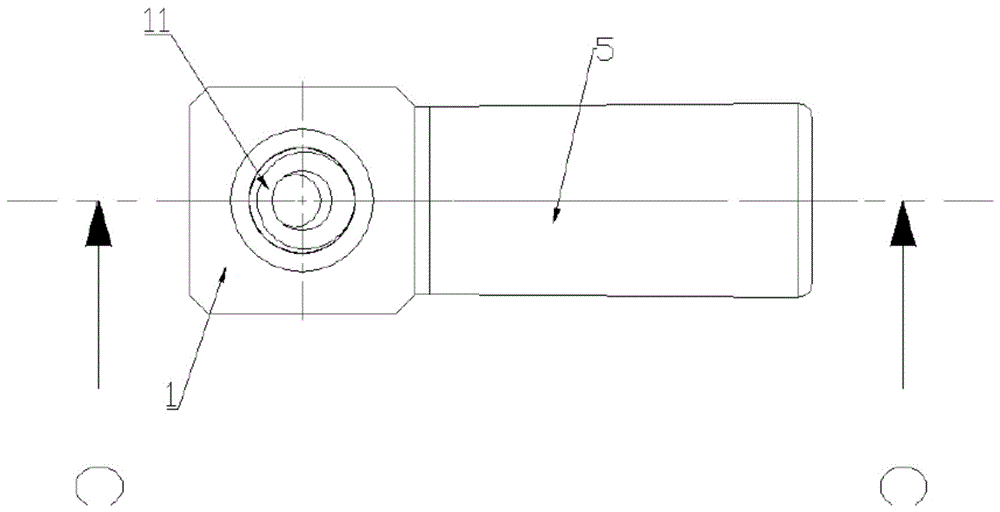

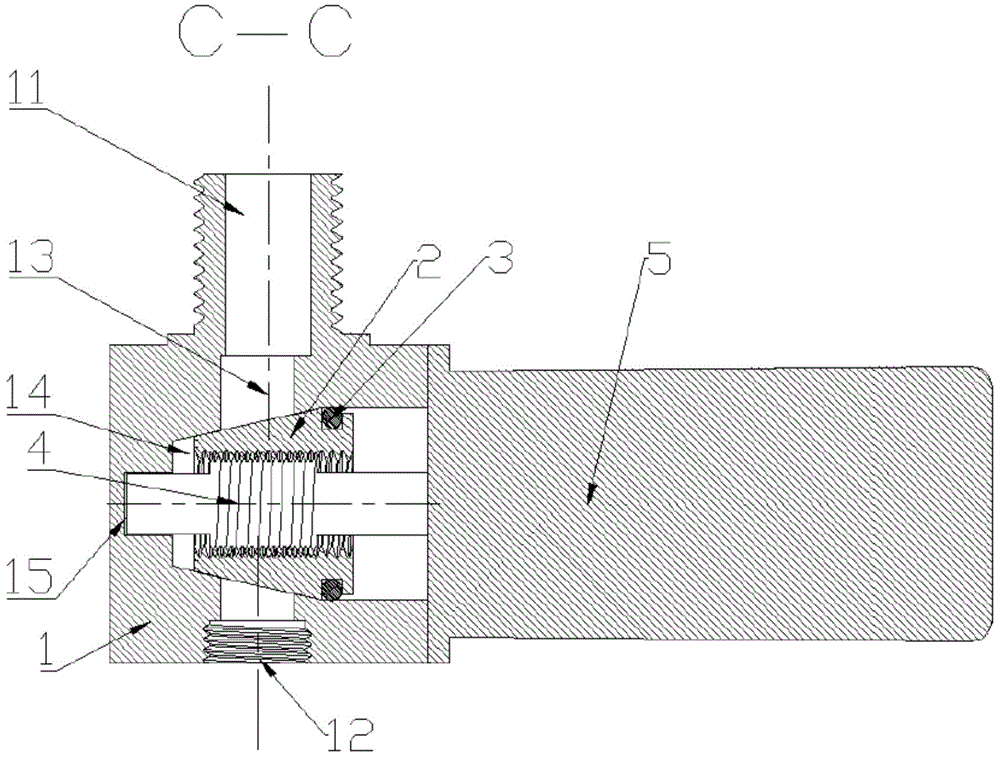

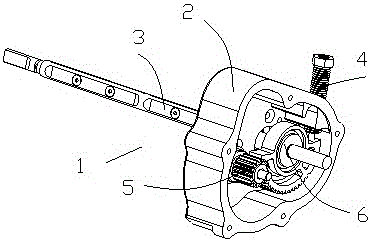

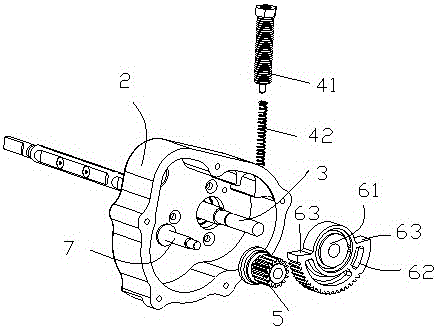

Oil discharge valve of engine sump and control circuit of oil discharge valve

ActiveCN106640266AEasy to drainAvoid sliding teethLubricant filling/drainingMachines/enginesOil canReduction drive

The invention provides an oil discharge valve of an engine sump and a control circuit of the oil discharge valve, and belongs to the technical field of valves and electric control circuits thereof. By the oil discharge valve of the engine sump, oil can be discharged from the engine sump conveniently and controllably. An oil inlet is formed in the outer side of the top of a valve body; an oil channel is formed in the valve body; an oil discharge opening is formed in an outlet of the oil channel; a valve element chamber is formed in a position perpendicular to the axis direction of the oil channel; a valve element is arranged in the valve element cavity; a mounting blind hole is formed in one side, which is close to the end surface of the front of the valve element, of the side wall of the valve body; a motor with a speed reducer is arranged outside the valve body; a lead screw is fixedly arranged on an output shaft of the motor with the speed reducer; an end of the output shaft of the motor with the speed reducer penetrates through the valve element chamber and is inserted in the mounting blind hole; the lead screw is in threaded connection with an inner threaded hole formed in the valve element; and the lead screw drives the valve element to horizontally move in the valve body in a reciprocating manner. The control circuit controls the motor to drive the valve element to move in the valve body, so that oil can be discharged from the engine sump conveniently, quickly and controllably.

Owner:上海轩维汽配制造有限公司

Three-way electricity guard wall structure and manufacturing method thereof

ActiveCN102192598BUniform thicknessGuaranteed absolute water resistanceFluid heatersElectricityWater flow

The invention discloses a three-way electricity guard wall structure for a water heater. The structure comprises a first water pipe and a second water pipe which are integrated respectively, wherein the pipe walls of the water pipes are made of insulating materials; a grounding copper pipe connected with a ground wire is sleeved in the left side of the first water pipe; the second water pipe is sleeved in the grounding copper pipe; the first water pipe is longer than the second water pipe; the grounding copper pipe is provided with an exceeding section exceeding the second water pipe at the right end of the second water pipe, and the exceeding section divides the first water pipe into a first part at the left side of the exceeding section and a second part at the right side of the exceeding section; the exceeding section is contacted with the water flow only at the exceeding section; and because of the lengths of the first water pipe and the second water pipe, the intensity of the current after passing through the second part of the first water pipe and the intensity of the current after passing through the second water pipe are less than 5mA. Moreover, the invention also discloses a manufacturing method of the three-way electricity guard wall. Good insulating performance and grounding performance of the grounding copper pipe are ensured by uniform injection molding, smoothness of the water flow pipes is ensured, and the water flow of the inner pipe is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

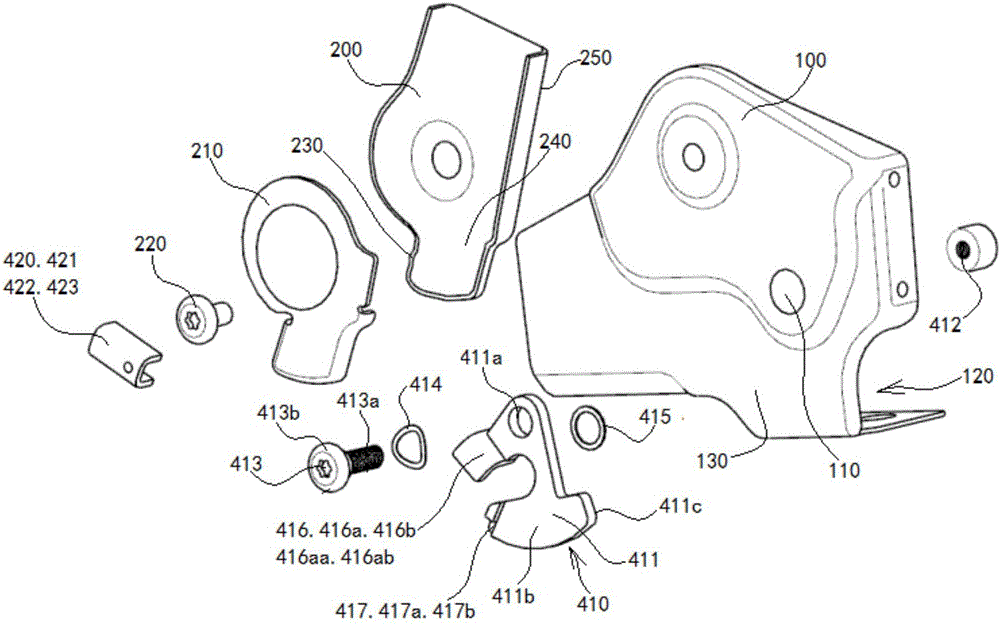

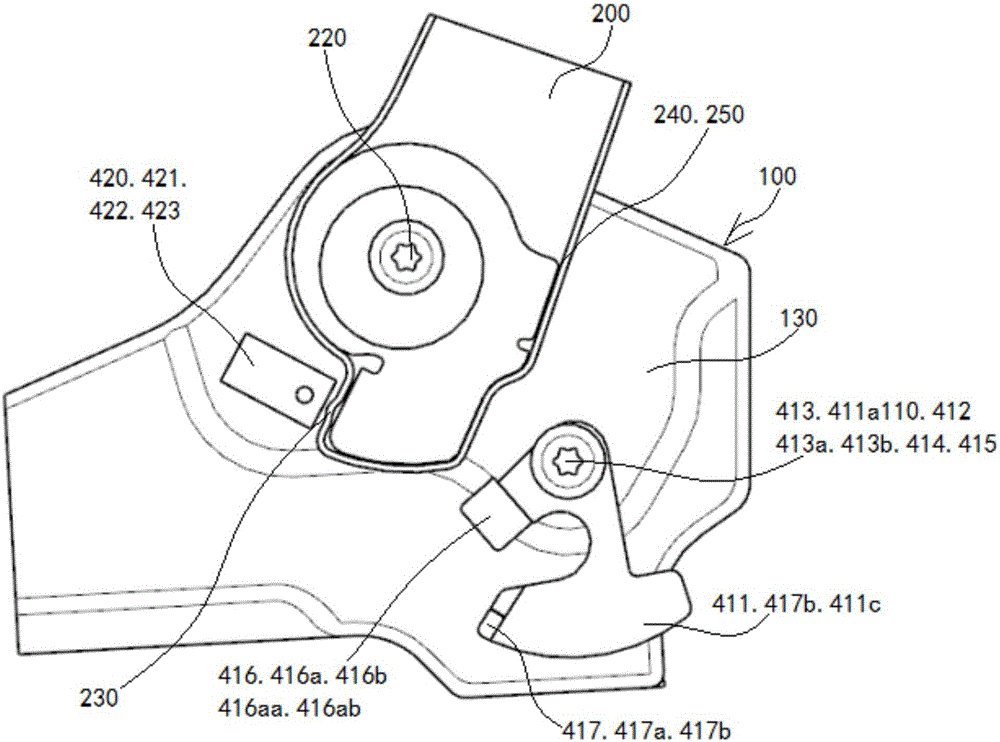

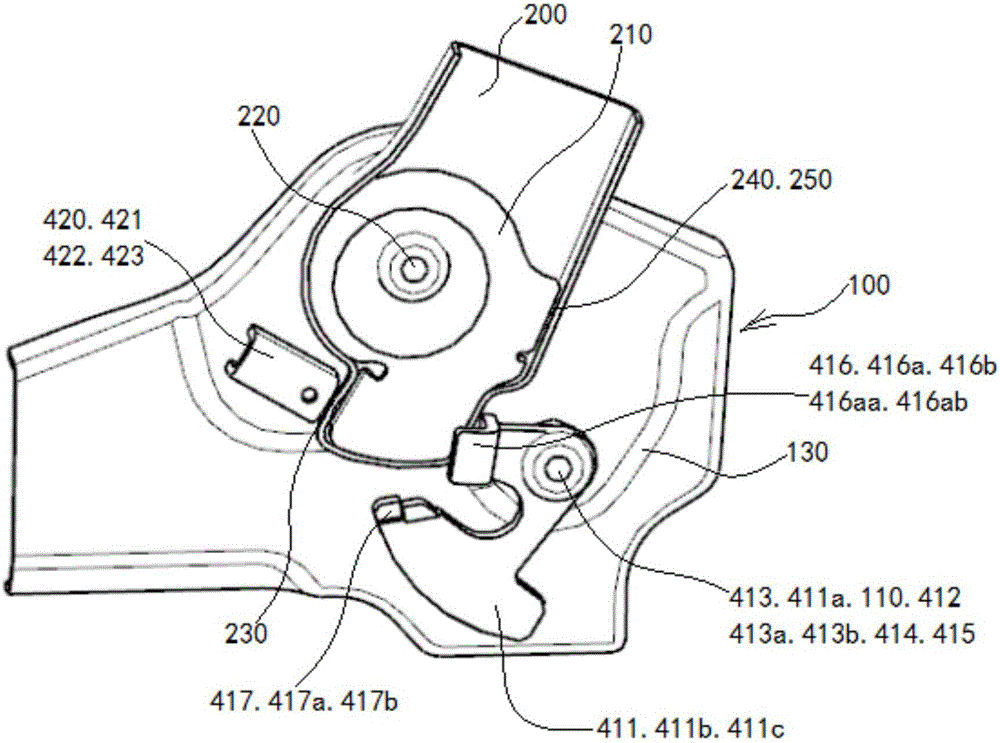

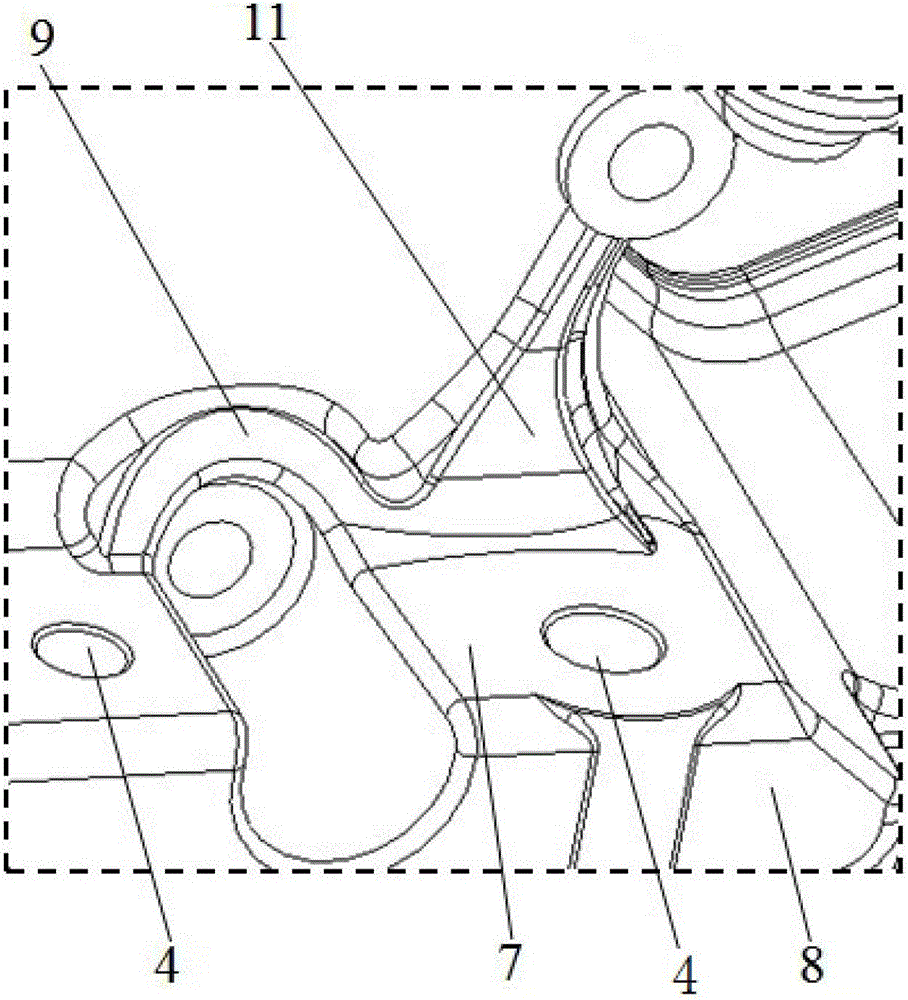

Inertia locking mechanism for seat

The invention discloses an inertia locking mechanism for a seat. The inertia locking mechanism is characterized by comprising an inertia locking mechanism body which is used in a combined structure of a rotating part and a fixed part in the seat, wherein the rotating part is hinged to the fixed part; the inertia locking mechanism body is installed on the fixed part. During collision, the inertia locking mechanism body locks up the rotating part by the aid of inertia, and on normal condition, the inertia locking mechanism body does not lock up the rotating part without affecting rotation of the rotating part. The inertia locking mechanism can solve the problem that the one-sided medium and low strength angle-adjuster seat is insufficient in strength in front-back collision test, a stop piece cannot interfere turnover and use of the seat in the normal use process, and the inertia retaining piece cannot cause shaking and abnormal noise. The cost of the inertia locking mechanism is only 25%-30% of that of the conventional scheme.

Owner:YANFENG ADIENT (SHENYANG) SEATING CO LTD

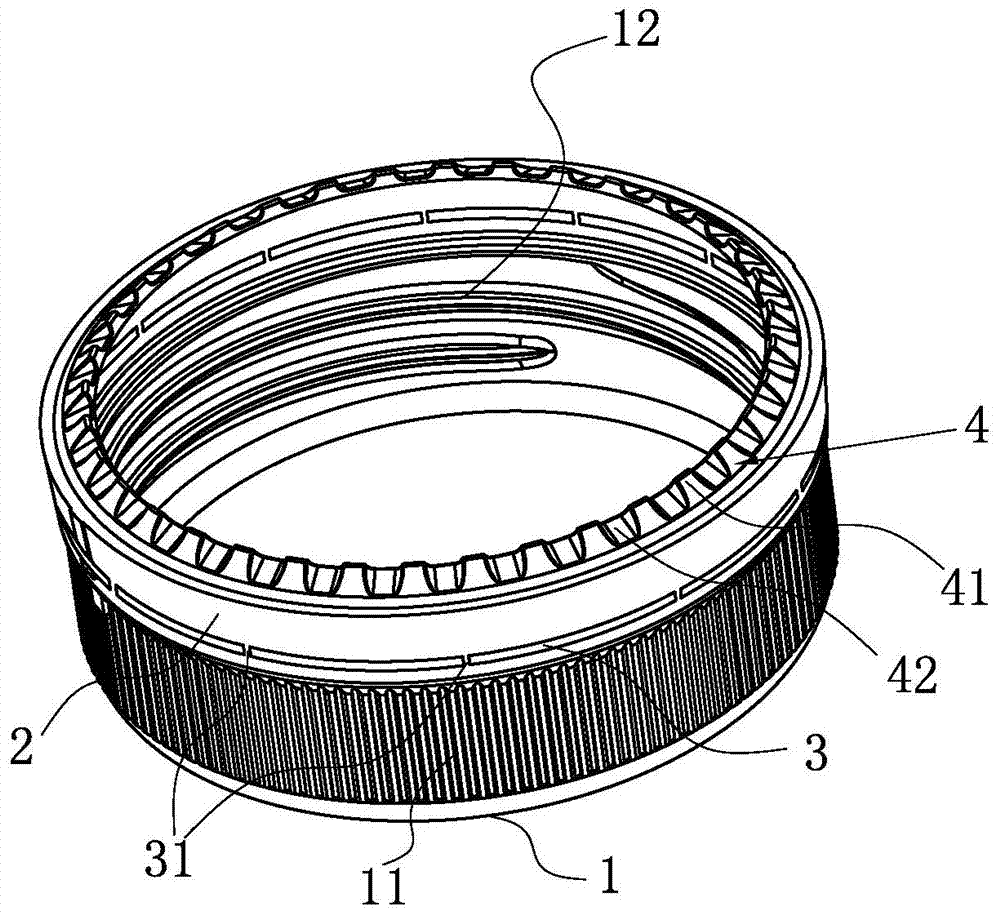

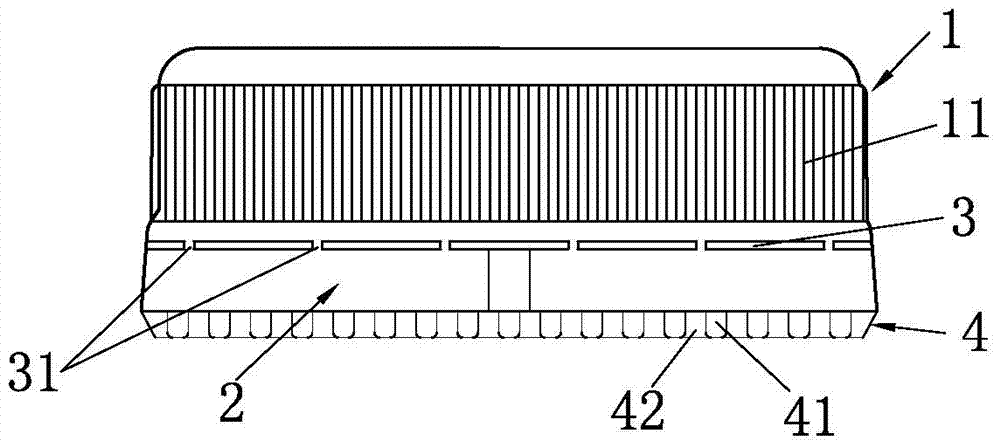

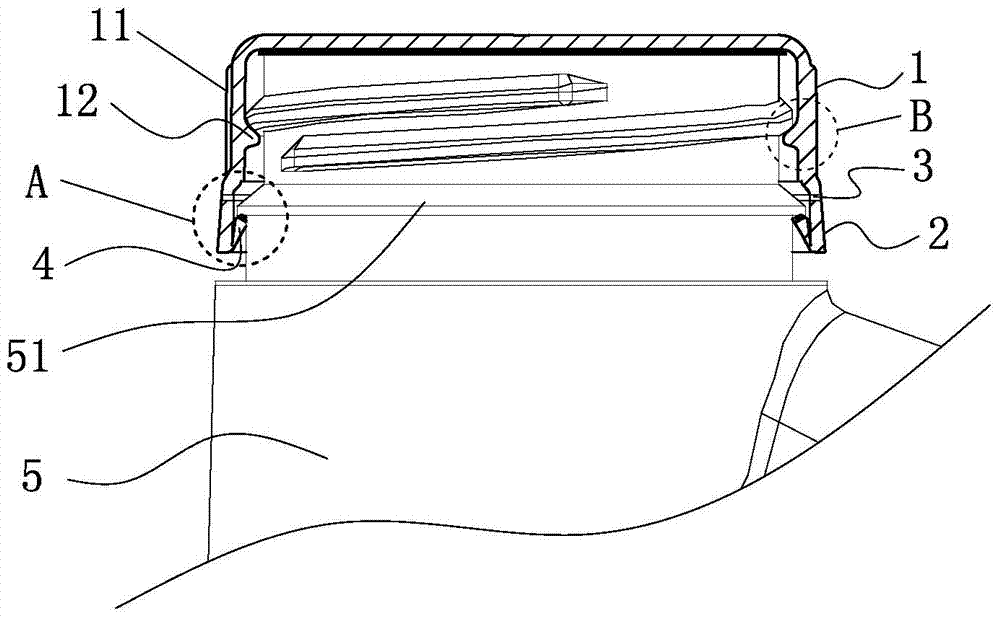

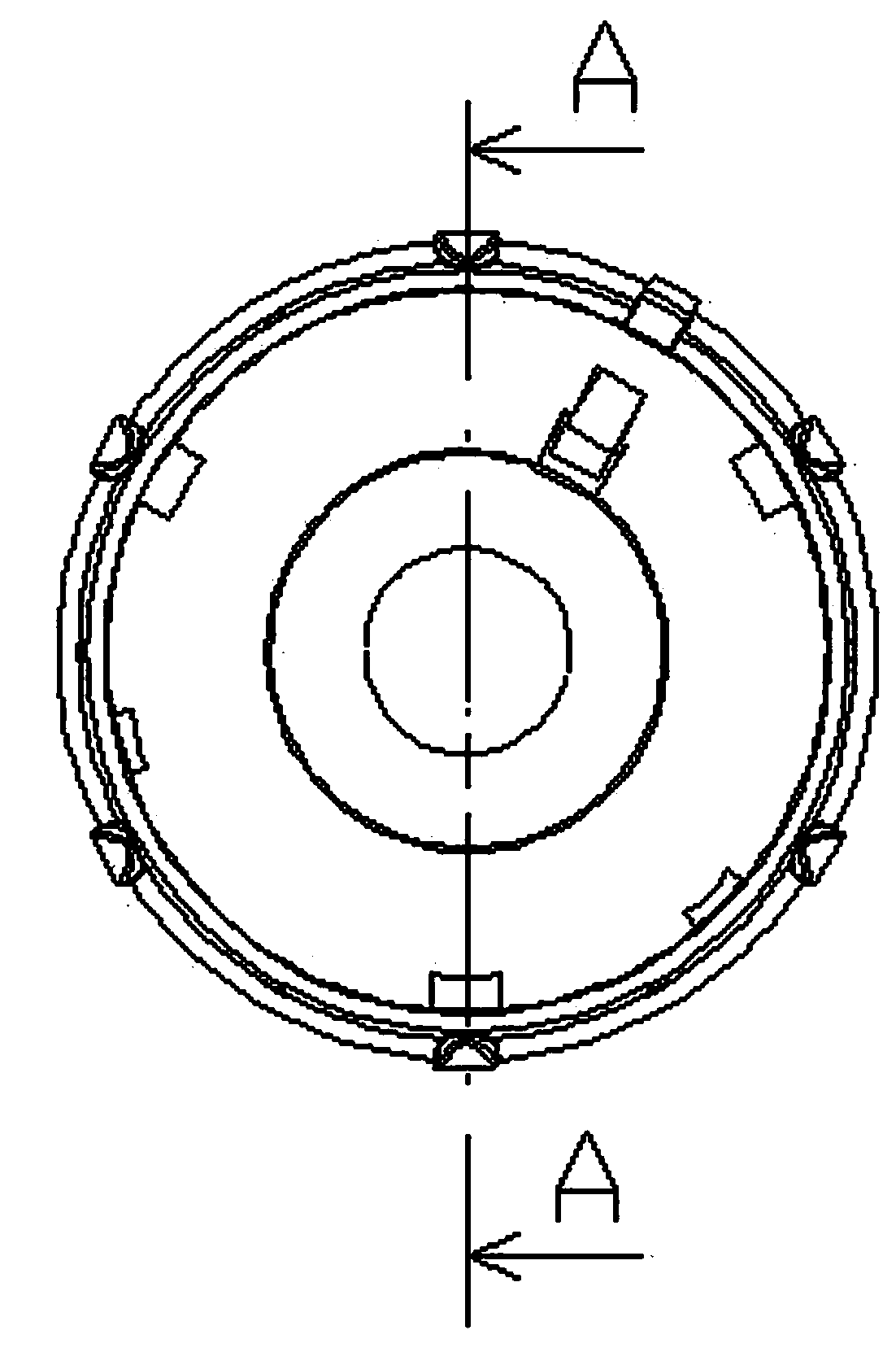

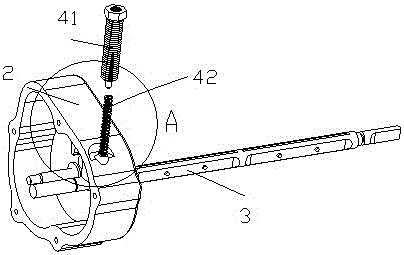

A shock-resistant anti-theft bottle cap

An anti-impact theftproof bottle cap comprises a bottle cap body (1) provided with internal threads, a safety ring belt (2), and an annular theftproof surrounding (4) that are subjected to integral injection molding. A ring kerf (3) is disposed between the bottle cap body (1) and the safety ring belt (2). The ring kerf (3) is provided with a plurality of connecting bridges (31) at equal intervals. The annular theftproof surrounding (4) is reversibly connected to the edge of the safety ring belt (2). The annular theftproof surrounding (4) forms a flange in the inner side of the safety ring belt (2), and the annular theftproof surrounding (4) is connected to the safety ring belt (2) in an obtuse angle manner. An inner ring of the annular theftproof surrounding (4) is close to the center line of the bottle cap, and an outer ring of the annular theftproof surrounding (4) is connected to the safety ring belt (2). Wedge-shaped lugs (41) that are distributed in a spaced manner are formed in the surface of the annular theftproof surrounding (4) away from the inner cavity of the bottle cap. A thin-wall portion (42) is formed between the two adjacent wedge-shaped lugs (41). The wedge-shaped lugs (41) are of a wedge-shaped protrusion structure. The high end of the wedge-shaped lug structure is close to the inner ring, and the low end of the wedge-shaped lug structure is close to the outer ring. The bottle cap can bear the upward stamping force from the interior of a bottle and prevent the bottle cap from being loosened, and has good anti-stamping performance and theftproof performance.

Owner:QUANZHOU HUASHUO IND

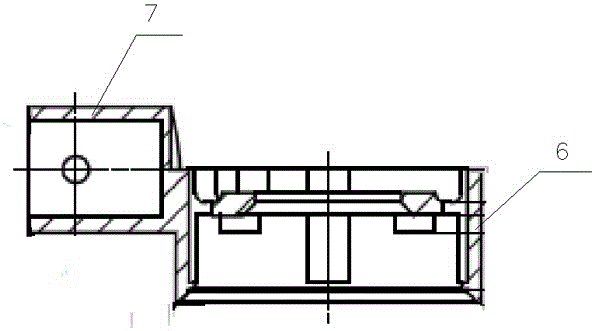

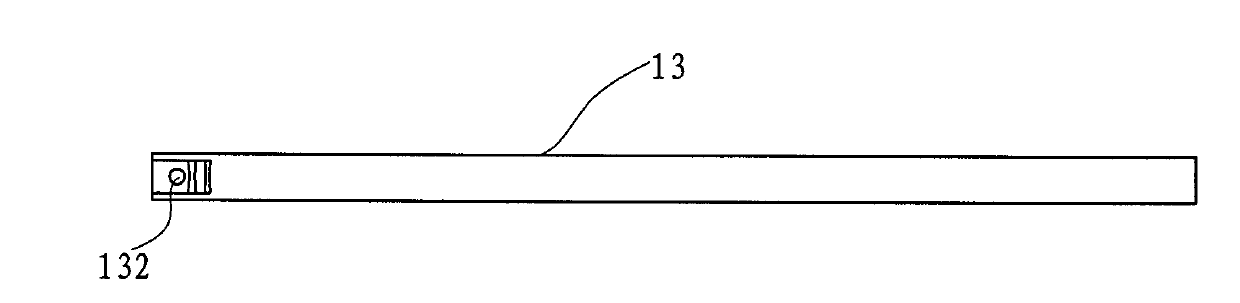

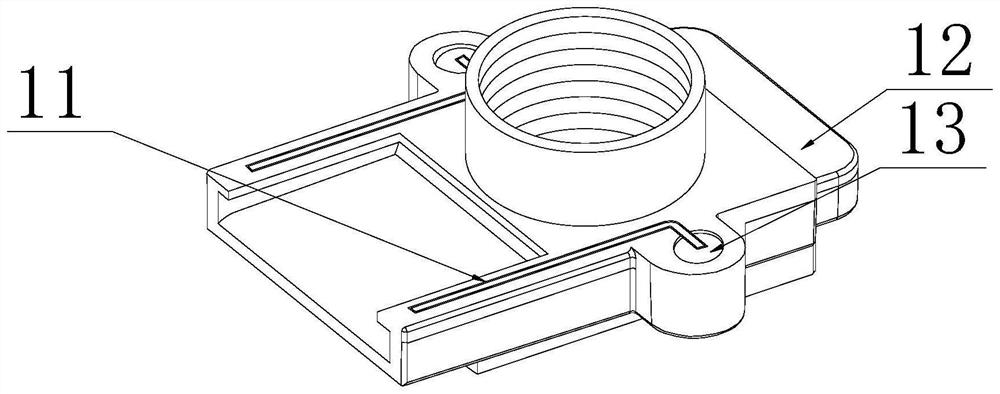

Double optical filter switcher without wire connection

InactiveCN114397789AAvoid sliding teethAvoid crackingMountingsCamera body detailsWire rodAdhesive glue

A double optical filter switcher without wire connection comprises a bottom shell, one end of the bottom shell is rotatably connected with a rocking handle, one end, close to the bottom shell, of the rocking handle is adhered with a magnet through glue, a surface cover is inserted into the top of the bottom shell, copper nuts are integrally injection-molded at the two ends of the surface cover, and the surface cover is divided into a thread part and a base part; the screw thread part and the base part are integrally formed in an injection molding mode, L-shaped grooves are formed in the top of the face cover, the number of the L-shaped grooves is two, the ends, penetrating through the L-shaped grooves, of the guide pins are welded to the copper nuts, and fixing glue adheres to the exposed positions of the guide pins. The circuit of the switcher is sealed in the internal space, so that short circuit caused by contact with the outside is reduced, and the problem of poor open circuit caused by scratching and pulling is effectively avoided; and the thread part of the surface cover and the base are integrated, so that the perpendicularity during product assembly is ensured, and meanwhile, the light leakage phenomenon caused by product assembly gaps can be effectively avoided.

Owner:深圳市臻荣电子有限公司

Automatic screw locking elastic mechanism

ActiveCN102975012BSafe and stable operationAvoid sliding teethMetal working apparatusSlide plateEngineering

The invention relates to an automatic screw locking elastic mechanism, of which a downward pushing cylinder is connected with a Z-axis moving mechanism; a spring mechanism is arranged on the Z-axis moving mechanism; an electronic screwdriver bit is arranged on the spring mechanism, the lower end of the electric screwdriver bit is connected with a screw chuck; the upper end of a support plate of the Z-axis moving mechanism is connected with a cylinder installation plate, and the lower end of the support plate is connected with a limit plate; a guide plate is arranged on the support plate; a guide sliding plate is arranged on the guide plate, a slide rail is arranged on the guide sliding plate, and a side block is arranged on the slide rail in a matched manner, a moving plate is fixedly connected with the slide block; the upper part of the moving plate is connected with a fixing plate through springs a and b, and the lower part of the moving plate is connected with a buffer plate; a blind hole is arranged in the moving plate, and a spring c is arranged in the blind hole; and a buffer limit pillar penetrates through the buffer plate, is inserted in the blind hole and is in contact with the spring c. Through the driving of the downward pushing cylinder, the electric screwdriver bit is driven to move downwards, meanwhile, a screw is driven to move downwards and to be rotatably attached on a product in a locked manner, the spring mechanism has a protective effect on the screw and the product, and the whole mechanism stably operates.

Owner:上海莘翔自动化科技有限公司

Vehicle-mounted hand-operated air conditioner controller

ActiveCN104121665ASmall operating forceEasy to operateSpace heating and ventilation safety systemsLighting and heating apparatusKey pressingControl theory

The invention discloses a vehicle-mounted hand-operated air conditioner controller, and relates to the technical field of vehicle-mounted air conditioners. The vehicle-mounted hand-operated air conditioner controller comprises a panel which is provided with a rotary knob and keys. The rotary knob is sleeved with a rotary knob cap. The rotary knob cap is fixedly connected with a circuit board inside the controller. The rear portion of the rotary knob is connected with a driving cylindrical gear which is meshed with a driven cylindrical gear at one end of a middle rotating shaft. A cylindrical gear at the other end of the middle rotating shaft is meshed with a rear gear. The rear gear is fixed to a rear cover. A boss is arranged on the rear gear. The rear gear is fixedly connected with a control part inside an air conditioner box through the boss and a pull rope. The vehicle-mounted hand-operated air conditioner controller can solve the problems that a rotary knob of an existing hand-operated air conditioner controller is simple and simplex in appearance structure, operating force of the rotary knob is large and not uniform, and the operation hand feeling of the rotary knob is affected.

Owner:DONGFENG LIUZHOU MOTOR

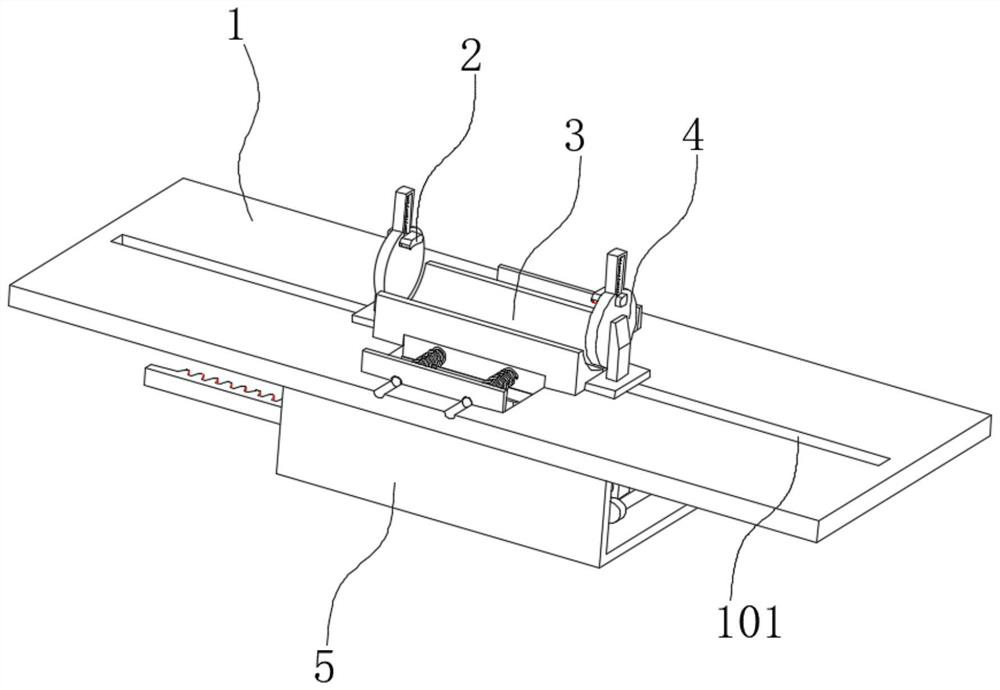

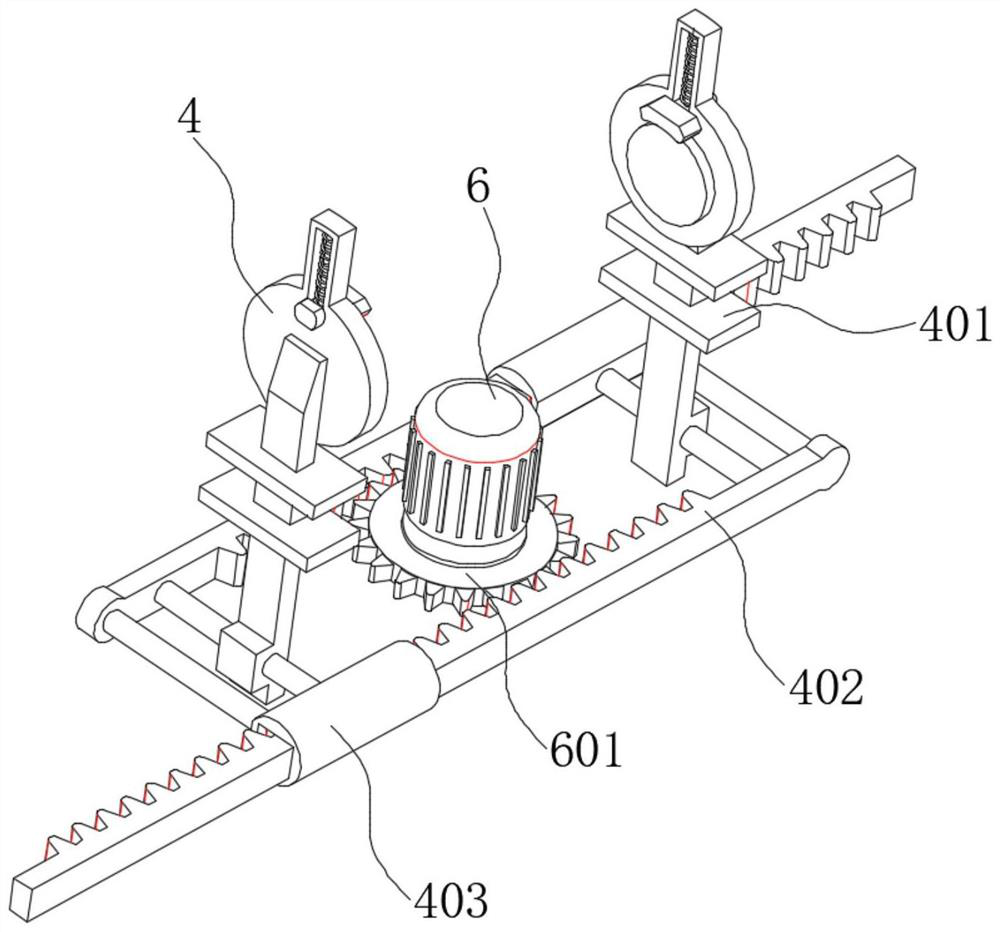

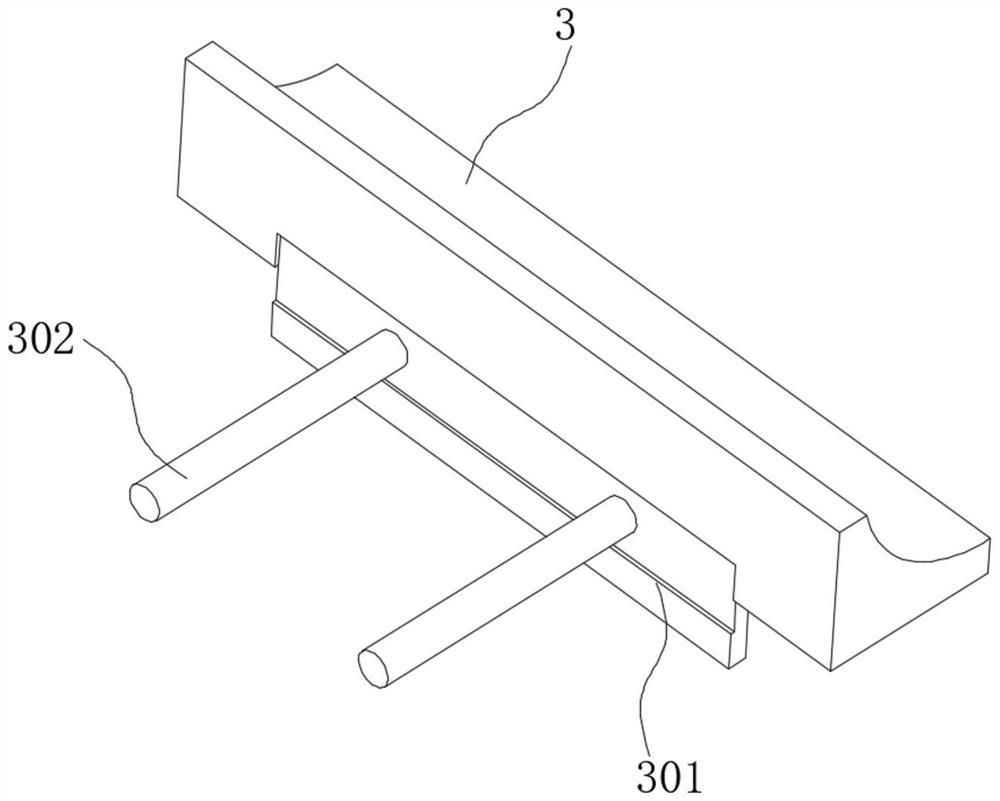

Tool clamp suitable for assembling batteries of various specifications

InactiveCN113664758AQuick clamping workAlways observe the degree of clampingHybrid vehiclesWork holdersGear wheelElectric machinery

The invention discloses a tool clamp suitable for assembling batteries of various specifications, and relates to the technical field of battery related machining auxiliary equipment. The tool clamp comprises a machining plate and two low arc plates, clamping plates are arranged on the left and right portions of the upper end of the machining plate, the low arc plates are located between the two clamping plates, I-shaped frames are fixed to the lower ends of the clamping plates, connecting plates are fixed to the middles of the lower ends of the I-shaped frames, and progressive toothed plates are arranged on one sides of the connecting plates. A motor is fixed into a mounting frame, a main gear is fixed to the rotating shaft end of the motor, moving plates are fixed to the positions, corresponding to movable openings, of the lower side of the low arc plates, and height limiting arc plates are arranged on the side walls, in the opposite directions, of the two clamping plates. According to the tool clamp suitable for assembling the batteries of various specifications, the motor sequentially drives the main gear, the progressive toothed plates and the clamping plates to move, the working efficiency of clamping the batteries is reduced, and meanwhile, the height of the batteries of different specifications is effectively limited through movable adjustment of the low arc plates and a height limiting arc plate.

Owner:江苏戴宏机电科技有限公司

Self-tapping method for machine screw and self-tapping pre-manufactured hole of machine screw

ActiveCN106224909AGuaranteed number of engagementsAvoid sliding teethRoad vehiclesLight fasteningsEngineeringMachine

The invention provides a self-tapping method of a machine screw. The method includes the step that a pre-manufactured hole is pre-formed before tapping of the machine screw, and is characterized in that a four-section structure is formed in the periphery of the hole inner wall of the pre-manufactured hole, thus, the quantity of tooth engagement can be guaranteed while tapping resistance of the machine screw is reduced, and tooth screw looseness is avoided.

Owner:HASCO VISION TECHNOLOGY CO LTD

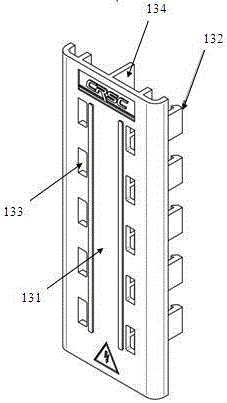

Linear tester for testing plug-in boards

ActiveCN106443312BAvoid bad thingsSmall footprintElectric connection testingSortingPatch panelHigh pressure

The invention discloses a linear testing device used for detecting a patch panel. The linear testing device comprises a main body, which is provided with a circulating conveying system, a detecting device, and a sorting device. The circulating conveying system comprises a ring-shaped chain used for conveying work pieces and a gear assembly, which is engaged with the ring-shaped chain, and is used to drive the rotating of the ring-shaped chain. The detecting device comprises a switching on / off detecting device, a high voltage detecting device, and a polarity detecting device, which are disposed on the circulating conveying system. The sorting device comprises a conveying mechanism used for conveying the work pieces and a rotatable baffle plate mechanism. By adopting the linear testing device, land occupation is less, and the phenomenon of the rotating disc-type testing device of easily flying of the wires of the patch panel during rotation is prevented. The ring-shaped chain is used as the conveying assembly, the chain is made of metal or rigid plastics, and has no telescopic performance, and therefore positioning is more accurate during a conveying process.

Owner:BULL GRP CO LTD

A lock screw fixture

ActiveCN105750898BImprove lock payment efficiencyAvoid scratchesMetal working apparatusBiochemical engineering

Owner:昆山铭世特智能科技有限公司

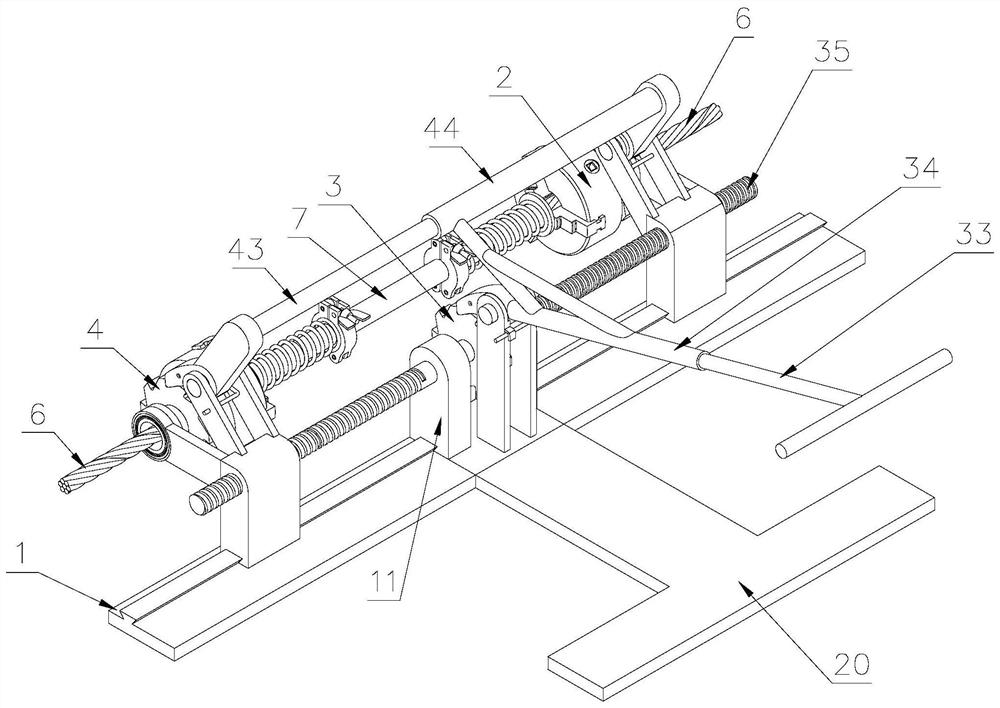

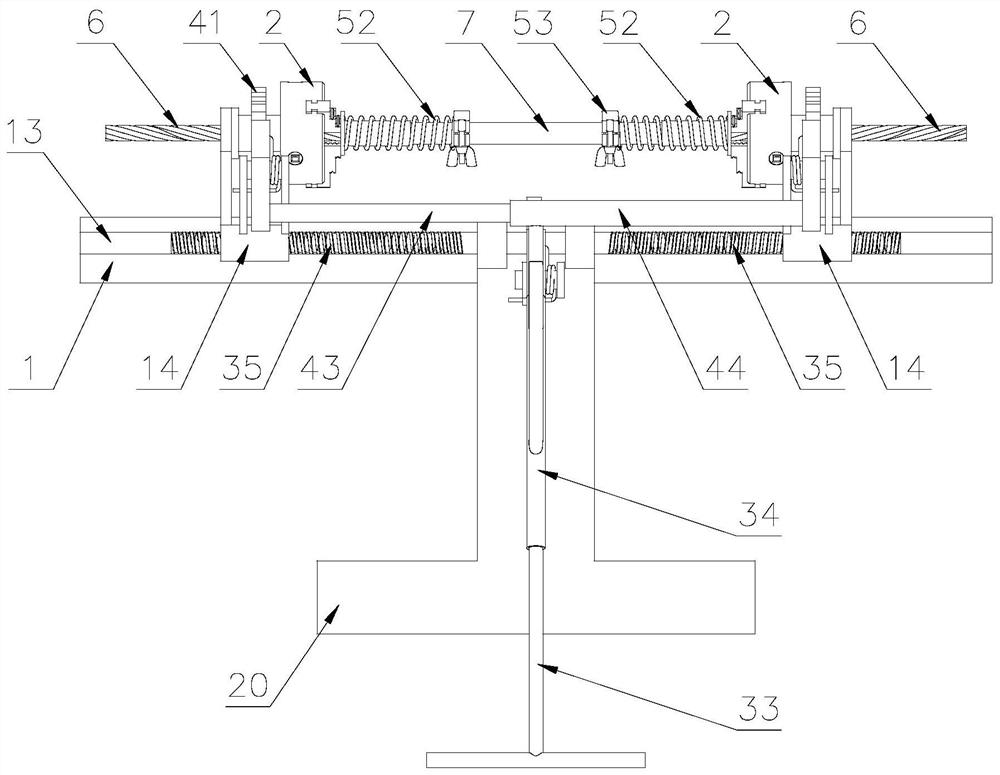

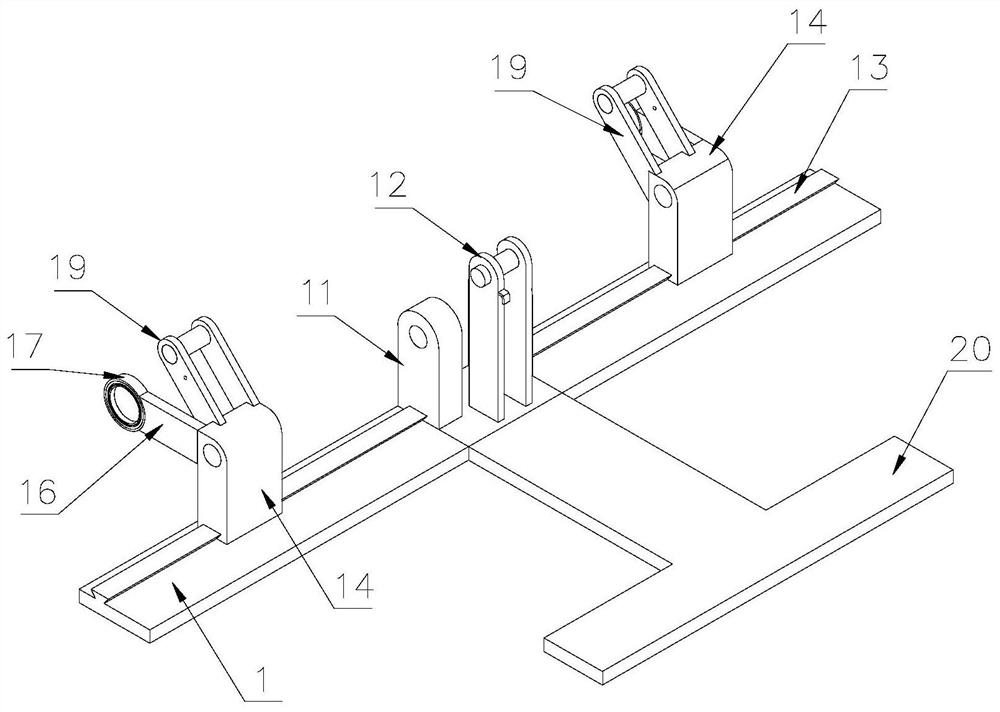

An auxiliary device for crimping and piercing pipes for overhead transmission lines

ActiveCN112582110BImprove crimping efficiencyGuaranteed accuracyCable/conductor manufactureRatchetWrench

Owner:国网山东省电力公司建设公司 +2

Engine front cover with suspension right bracket installation structure

ActiveCN103661626BAvoid stress concentrationImprove connection reliabilitySuperstructure subunitsEngineeringUltimate tensile strength

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

A kind of ventilation valve with limit device

ActiveCN103954028BImprove reliabilityExtended service lifeAir-flow control membersEngineeringMechanical engineering

The invention discloses a ventilation valve with a limiting device. The ventilation valve with the limiting device comprises a housing, wherein a wind guide plate cross shaft for mounting a wind guide plate is arranged in the middle of the housing; a driving pivot is arranged in the housing; a separable driving gear is arranged on the driving pivot; a wind guide plate gear is arranged at the tail end of the wind guide plate cross shaft; the wind guide plate gear is matched with the driving gear. In the ventilation valve with the limiting device, with adoption of a locating shoulder on the wind guide plate gear and an adjusting screw on the housing, a user can adjust a relative position between a locating pin on the adjusting screw and the locating shoulder according to the stroke requirement of the wind guide plate; when the wind guide plate reaches the maximal stroke, the ventilation valve can stop automatically to prevent the ventilation valve from continuously rotating to cause slippage of the gear, so that the reliability and the service life of the ventilation valve are greatly improved and prolonged.

Owner:NANTONG LONGSHUO LIGHT ALLOY TECH CO LTD

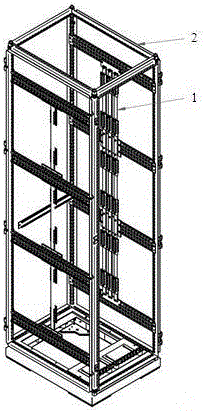

An Energy Saving Embedded Control System

ActiveCN111010837BThe sliding teeth are convenientEasy to handleCasings/cabinets/drawers detailsMounting boards securingControl systemStructural engineering

Owner:山东迪昕达信息技术有限公司

Clamping and fixing device for automobile welding

InactiveCN111992958AImprove welding efficiencyImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesMotor vehicle partElectric machinery

The invention discloses a clamping and fixing device for automobile welding, and belongs to the technical field of automobiles. The clamping and fixing device comprises a protection box, wherein a first support plate is fixedly connected between the left and right inner walls of the protection box, a forward and reverse rotation motor is fixedly connected to the lower interior of the protection box, a first mounting hole is formed in the lower end of the first support plate, the output end of the forward and reverse rotation motor movably penetrates through the first mounting hole, the outputend of the forward and reverse rotation motor is fixedly connected with a worm, a threaded rod is rotatably connected between the left and right inner walls of the protection box, a worm gear is fixedly connected to the surface of the threaded rod, and the worm is meshed with the worm gear; and the threaded rod is located at the upper part of the first support plate, the surface of the threaded rod is in threaded connection with two nuts, and the upper ends of the two nuts are fixedly connected with connecting rods. Finally an automobile part to be welded can be clamped by two clamping platesthrough a simple transmission structure, so that the welding efficiency of workers is improved, and the working efficiency is further improved.

Owner:HEFEI CHANGQING MACHINERY

Device for adjusting camber angle of rear wheel of automobile

The invention discloses an automobile rear wheel camber adjustment device, which comprises: an eccentric bolt, an elastic sleeve, an eccentric washer and a locking nut. In the present invention, an elastic sleeve is placed outside the eccentric bolt. The elastic sleeve is located between the eccentric bolt, the mounting head of the lower swing arm and the mounting bracket of the lower swing arm. The two ends of the sleeve shrink toward the middle, and the axial through groove will expand radially outward due to the axial compression force, that is, the elastic sleeve expands in the radial direction, thereby compensating for the eccentric bolt and the mounting head of the lower swing arm. , The assembly gap between the mounting brackets of the lower swing arm avoids the sway of the eccentric bolt in the lower swing arm and the rear sub-frame, and the deflection of the lock nut on the eccentric bolt caused by the sway, reducing the sliding of the eccentric bolt. The service life of the eccentric bolt is improved, and at the same time, the eccentric bolt maintains accurate positioning of the camber angle of the rear wheel, thereby improving the safety performance of the vehicle.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com